Single-crystal furnace crystal bar positioning device and single-crystal furnace using same

A positioning device and furnace crystal technology, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of small crystal ingot placement space and easy damage of ingot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

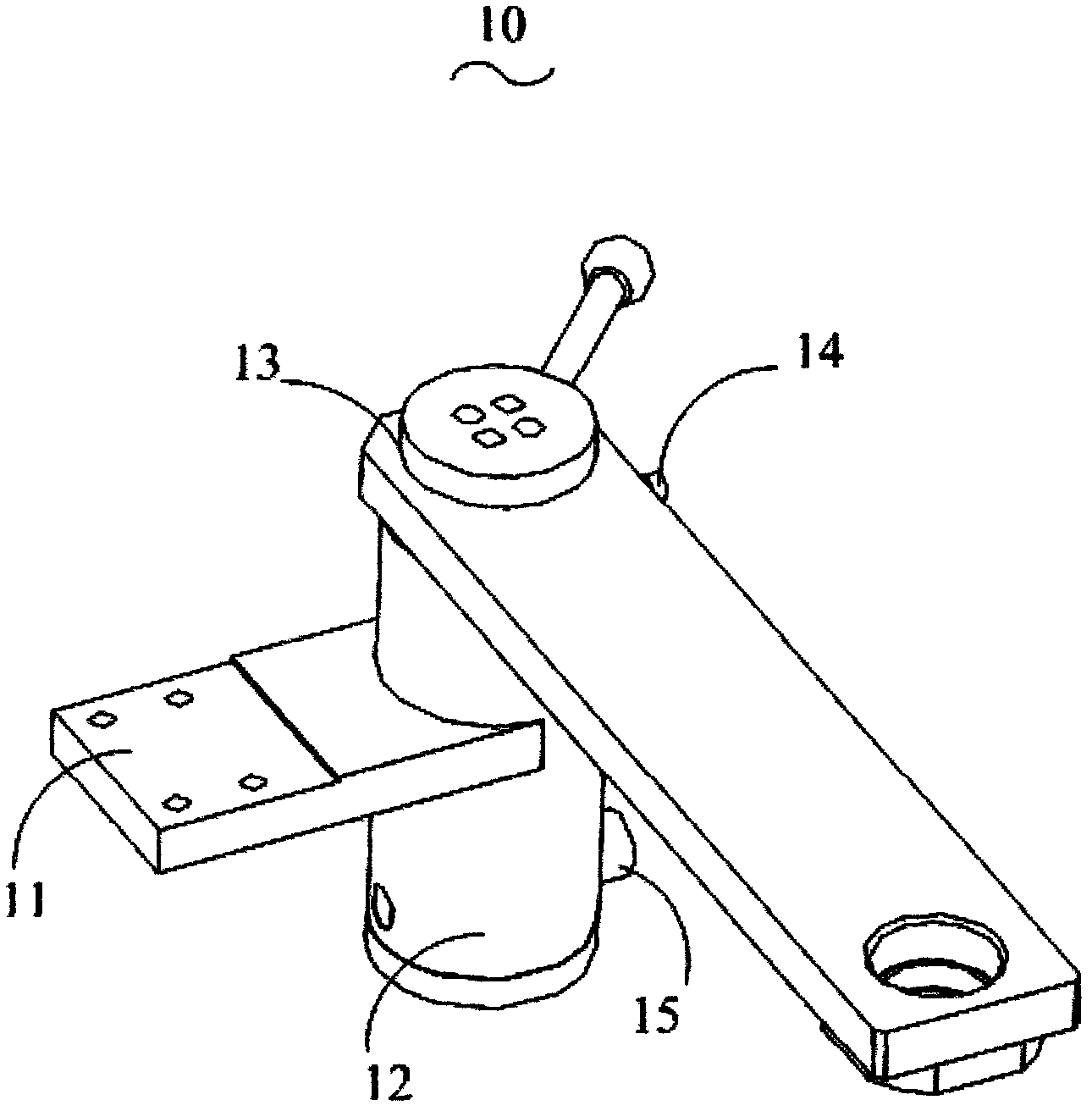

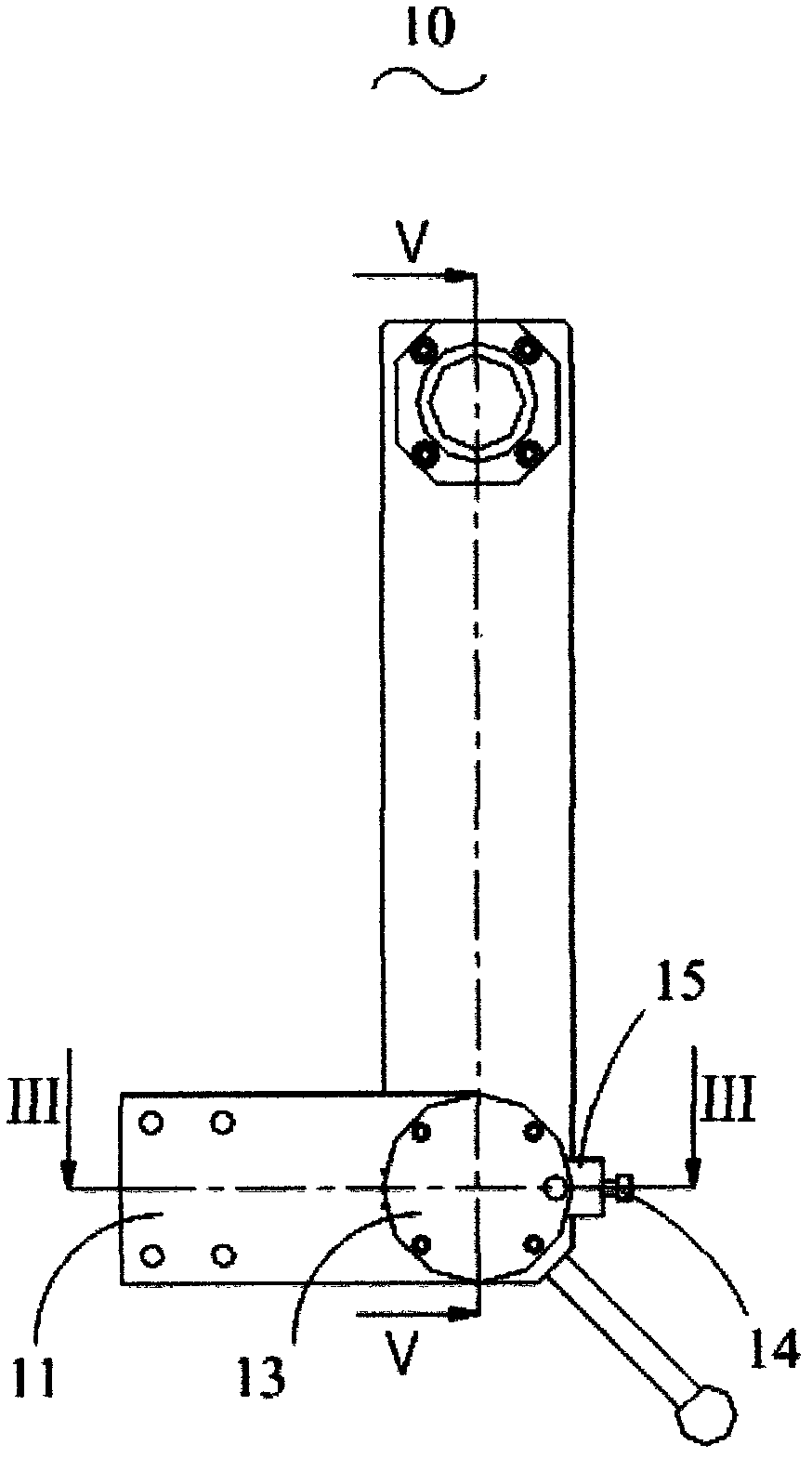

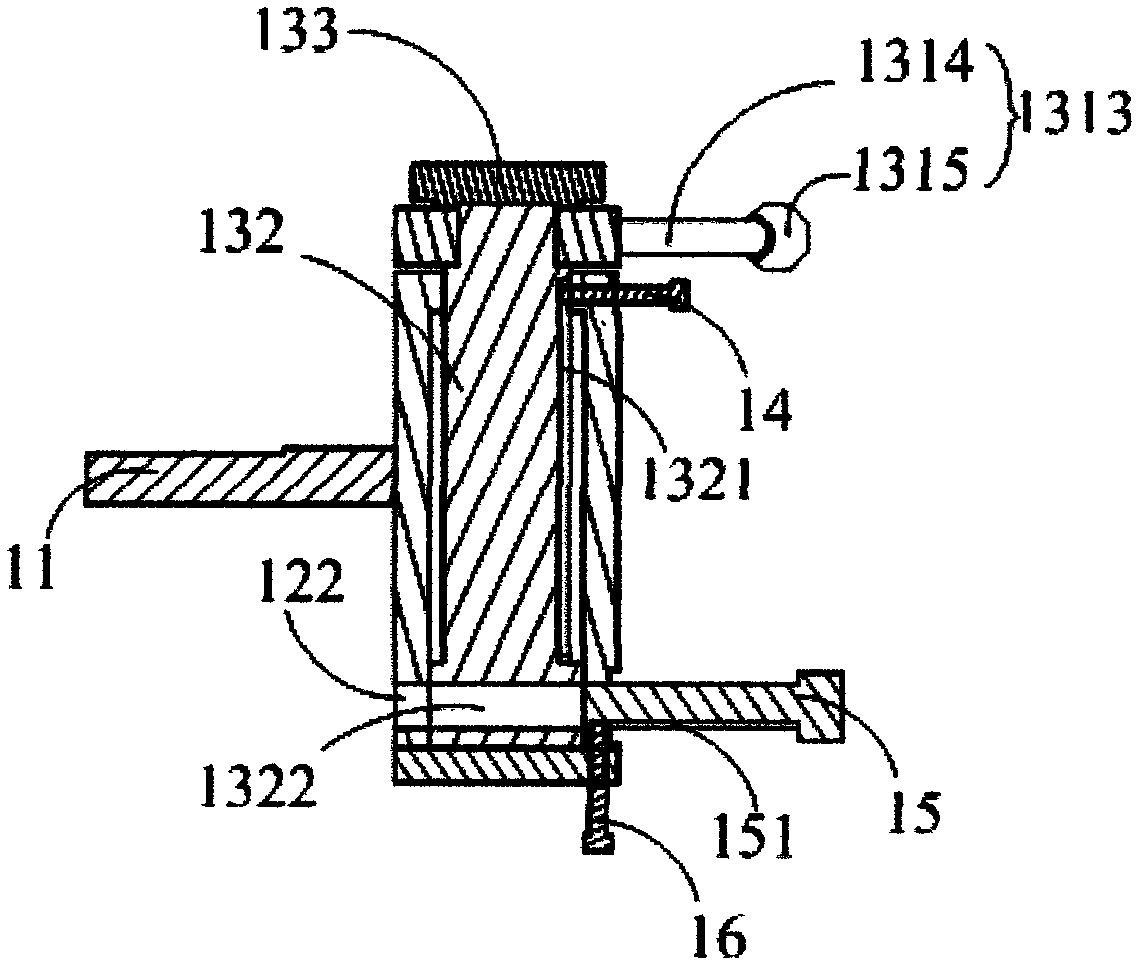

[0016] Please also see figure 1 , figure 2 , the single crystal furnace ingot positioning device 10 includes a connecting portion 11 , a cylindrical housing portion 12 , a telescopic portion 13 , a longitudinal guide 14 and a fixing member 15 .

[0017] Please also see Figure 3 to Figure 5 One end of the connecting part 11 is connected to the middle part of the cylinder housing part 12, and the other end of the connecting part 11 is provided with a positioning hole 111, and the connecting part 11 is connected to the lower flange of the upper furnace body of the polycrystalline furnace through the positioning hole 111. The connecting portion 11 is perpendicular to the side wall of the cylinder receiving portion 12 . The telescopic part 13 is arranged in the cylindrical housing part 12 and one end of the telescopic part 13 protrudes from the cylindrical housing part 12, and the end of the telescopic part 13 protruding from the cylindrical housing part 12 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com