Method for welding low-grade non-oriented silicon steel through laser welding machine

A technology of laser welding machine and oriented silicon steel, which is applied in the field of metallurgy, can solve the problems of increased difficulty in stable operation of the production line, decreased welding performance of steel plates, and increased magnetic properties, etc., to improve the cross-sectional size of the welding toe, improve the welding quality, and reduce the fracture of the weld seam. Band rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

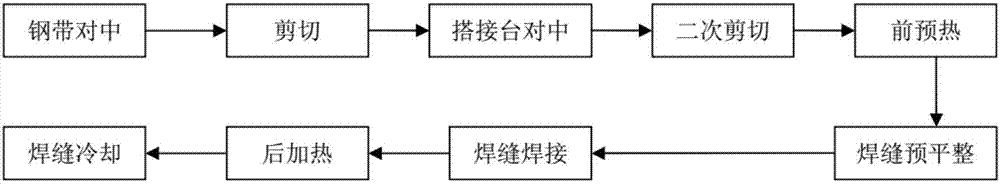

Method used

Image

Examples

specific Embodiment approach

[0035] Below in conjunction with example the present invention will be further described.

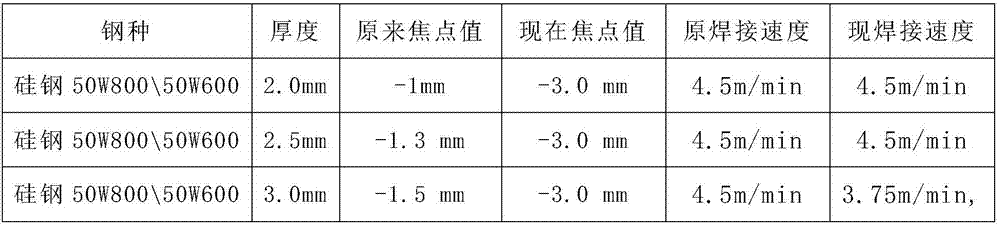

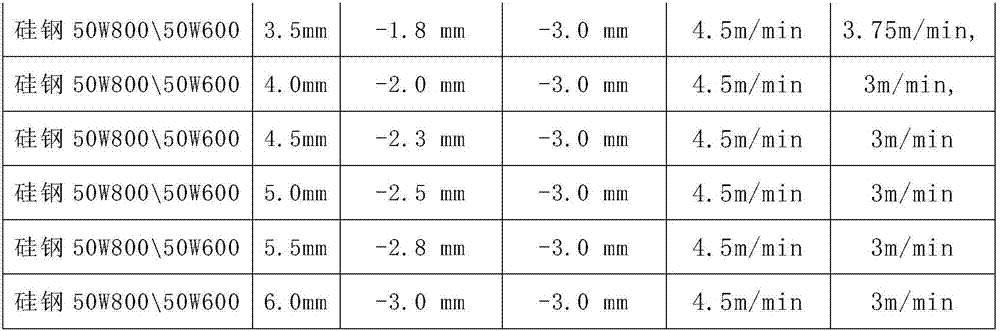

[0036] 1. When welding 50W800 / 50W600, the thickness of the steel strip is below 2.5mm (including 2.5mm), the welding machine speed is 4.5m / min, the laser focus of the welding machine is selected at -3mm, and the secondary shear value is selected as 0.5mm. The cupping test was carried out after welding, and the results showed that the quality of the weld seam was excellent and met the requirements.

[0037] 2. When welding 50W800 / 50W600, the thickness of the steel strip is 2.5mm to 3.5mm (including 3.5mm), the welding speed is 3.75m / min, the laser focus of the welding machine is selected at -3mm, and the secondary shear value is selected as 0.5 mm. The cupping test was carried out after welding, and the results showed that the quality of the weld seam was excellent and met the requirements.

[0038] 3. When welding 50W800 / 50W600, the thickness of the steel strip is 3.5mm to 6.0mm (incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com