Longitudinal flat overlapping joint die of cable Al-plastic composite tape

A technology of aluminum-plastic composite belt and mold, which is applied in the direction of fiber mechanical structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

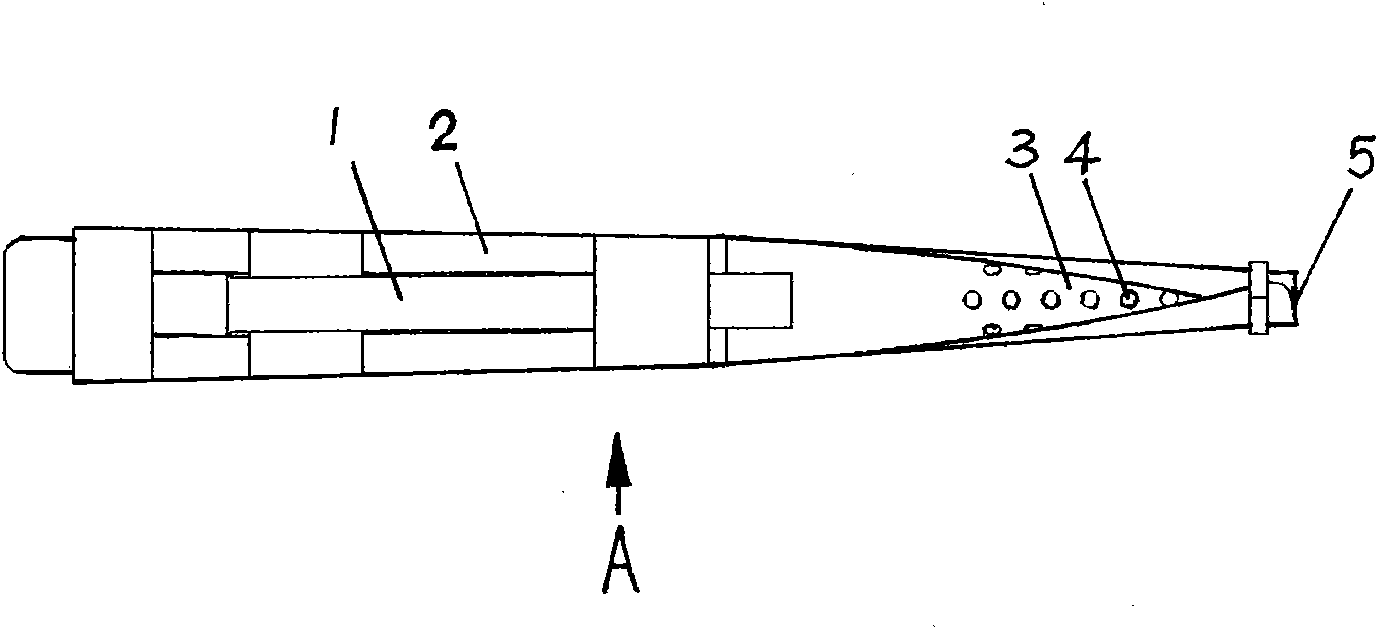

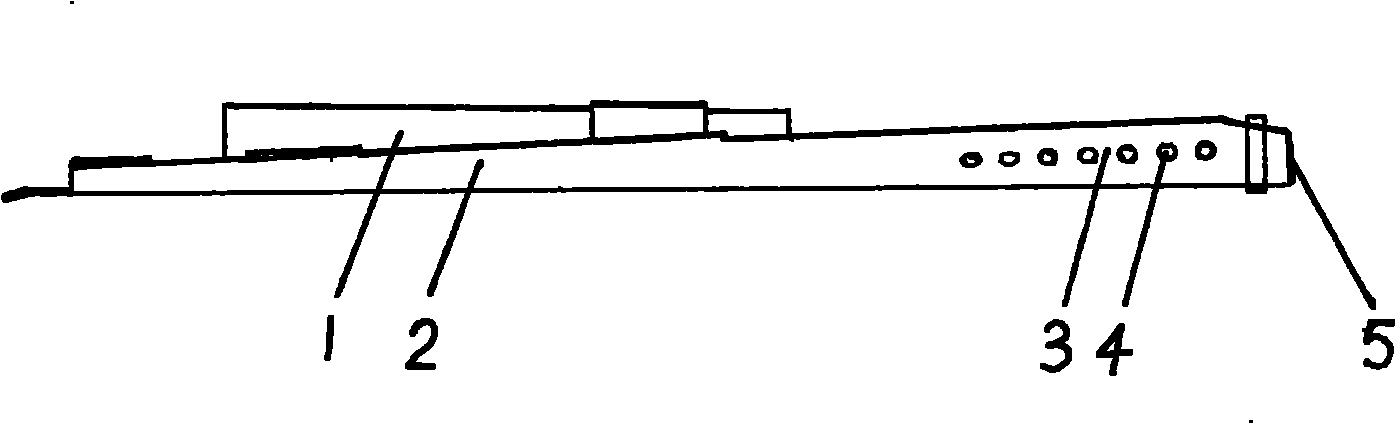

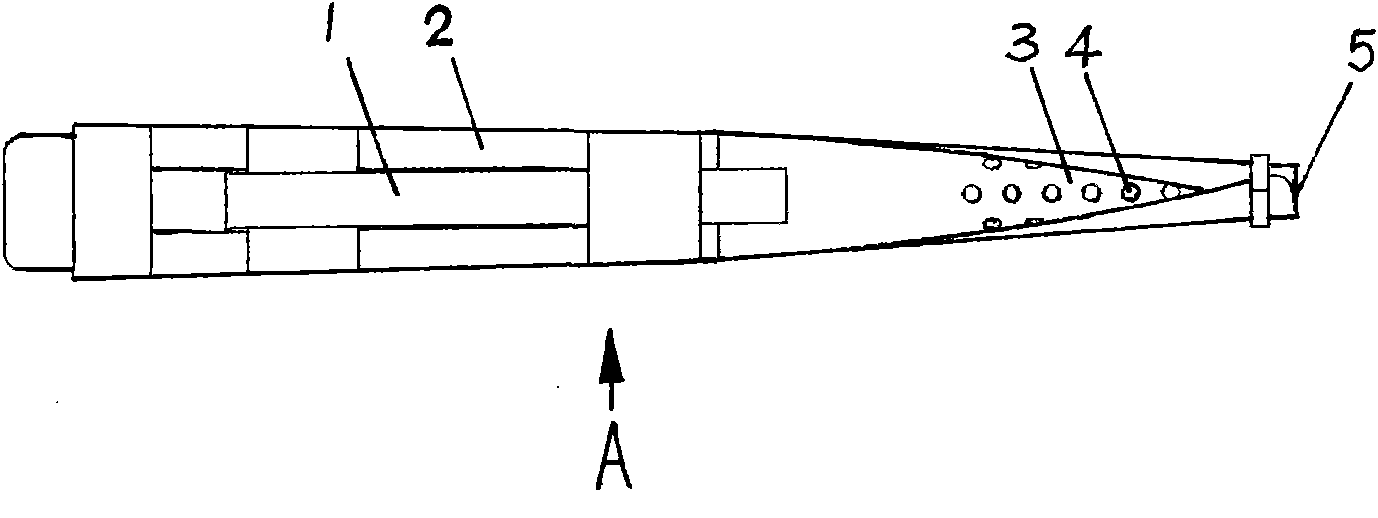

[0010] refer to figure 1 , figure 2 , using a metal plate rolled aluminum-plastic composite belt guide groove 2 and a tapered lap cavity 3, a plurality of small holes 4 are set on the wall of the tapered lap cavity 3, and the exit 5 of the tapered lap cavity is rolled into Circular, tapered lap cavity 3 is integrated with the aluminum-plastic composite tape guide groove 2, and then the optical cable core guide tube 1 is set in the aluminum-plastic composite tape guide groove 2, so that the present invention is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com