Patents

Literature

45 results about "Electromagnetic casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-strong strength, high-toughness and anticorrosive aluminum alloy and preparation method for same

ActiveCN103667825AImprove corrosion resistanceImprove solid solubilityRare-earth elementElectromagnetic casting

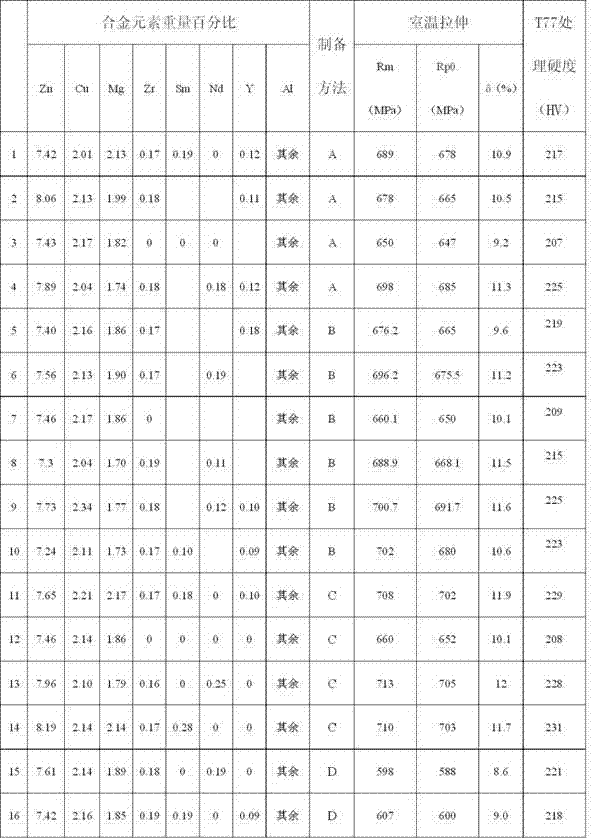

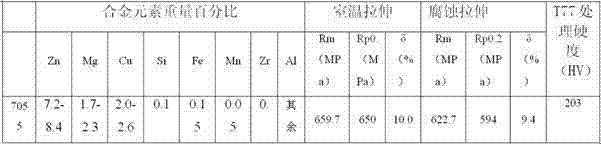

The invention relates to an ultra-strong strength, high-toughness and anticorrosive aluminum alloy and a preparation method for the same. A trace amount of specially-reinforced rare earth elements Sm, Nd and Y are added on the basis of an Al-Zn-Mg-Cu-Zr alloy, an electromagnetic casting mode is adopted for improving the solid solubility of the alloy, homogenizing the structure and reducing segregation, and the proportion of main alloy elements is optimized to make a breakthrough in the strength of the alloy. The aluminum alloy has ultra-strong strength, higher plasticity and high anticorrosive performance; in addition, the high-abundance rare earth element such as Sm and Y serving as one of raw materials is excessively overstocked in the market, and is low in cost, so that not only can be the cost of the alloy remarkably lowered, but also the problem of application unbalance of the rare earth elements can be relieved; the strength of a material prepared from the alloy is stronger than 700MPa after the material is subjected to T77 treatment, and is remarkably stronger than that of a material prepared from a 7055 alloy, and the comprehensive performance of the material is remarkably higher than that of a material prepared from an Al-Zn-Cu-Mg aluminum alloy currently with the highest comprehensive performance.

Owner:华峰铝业有限公司

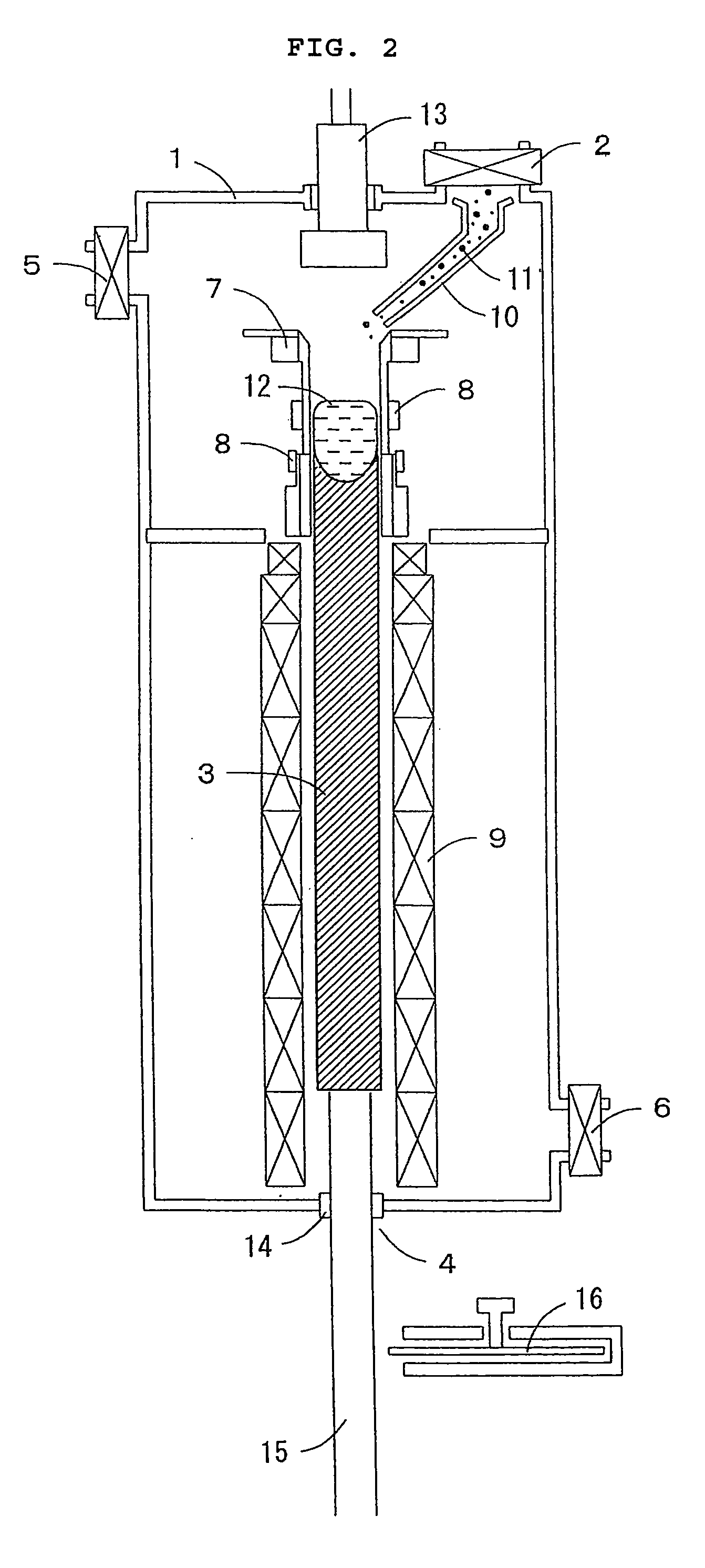

Silicon casting apparatus

InactiveUS20090044926A1Prevent effectively generationReduce facility costsPolycrystalline material growthFrom frozen solutionsElectromagnetic castingElectric discharge

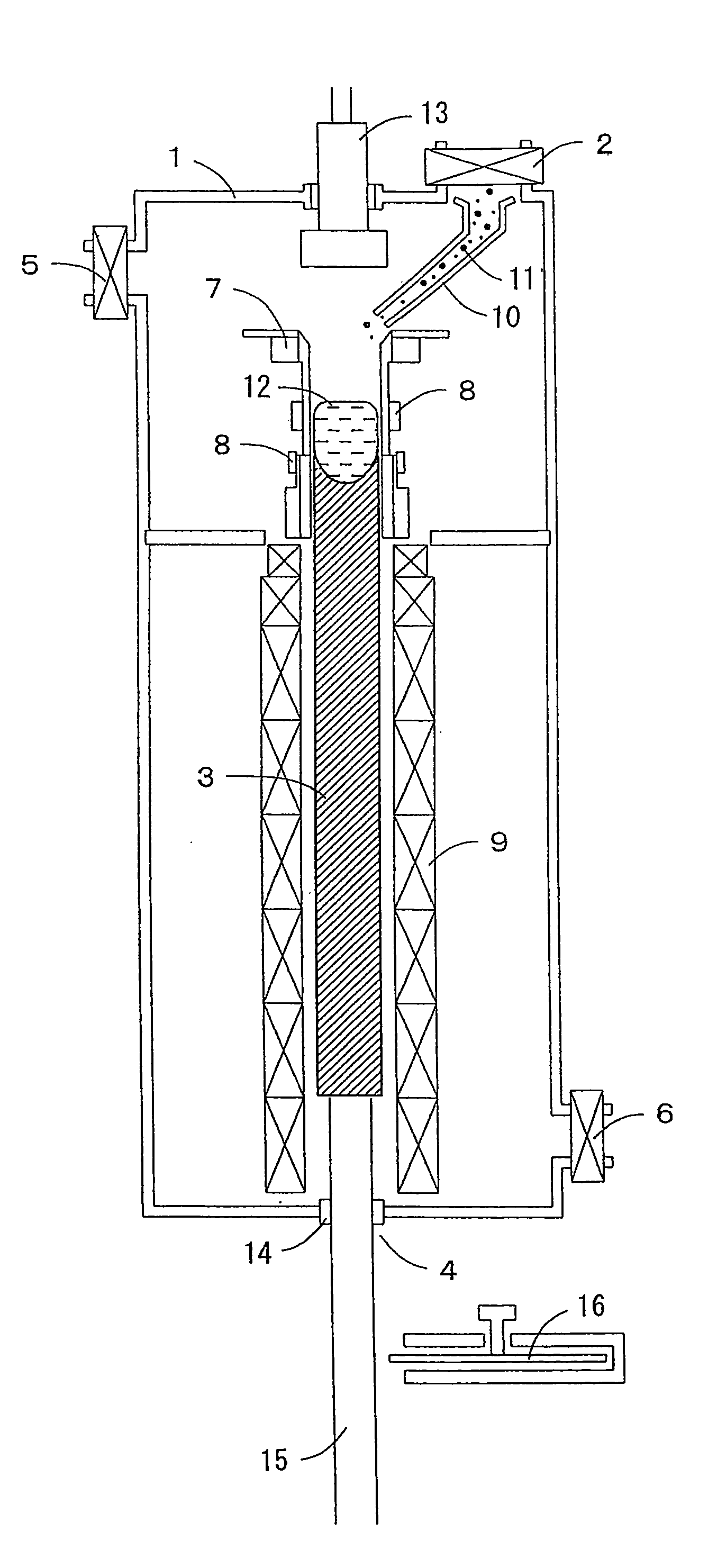

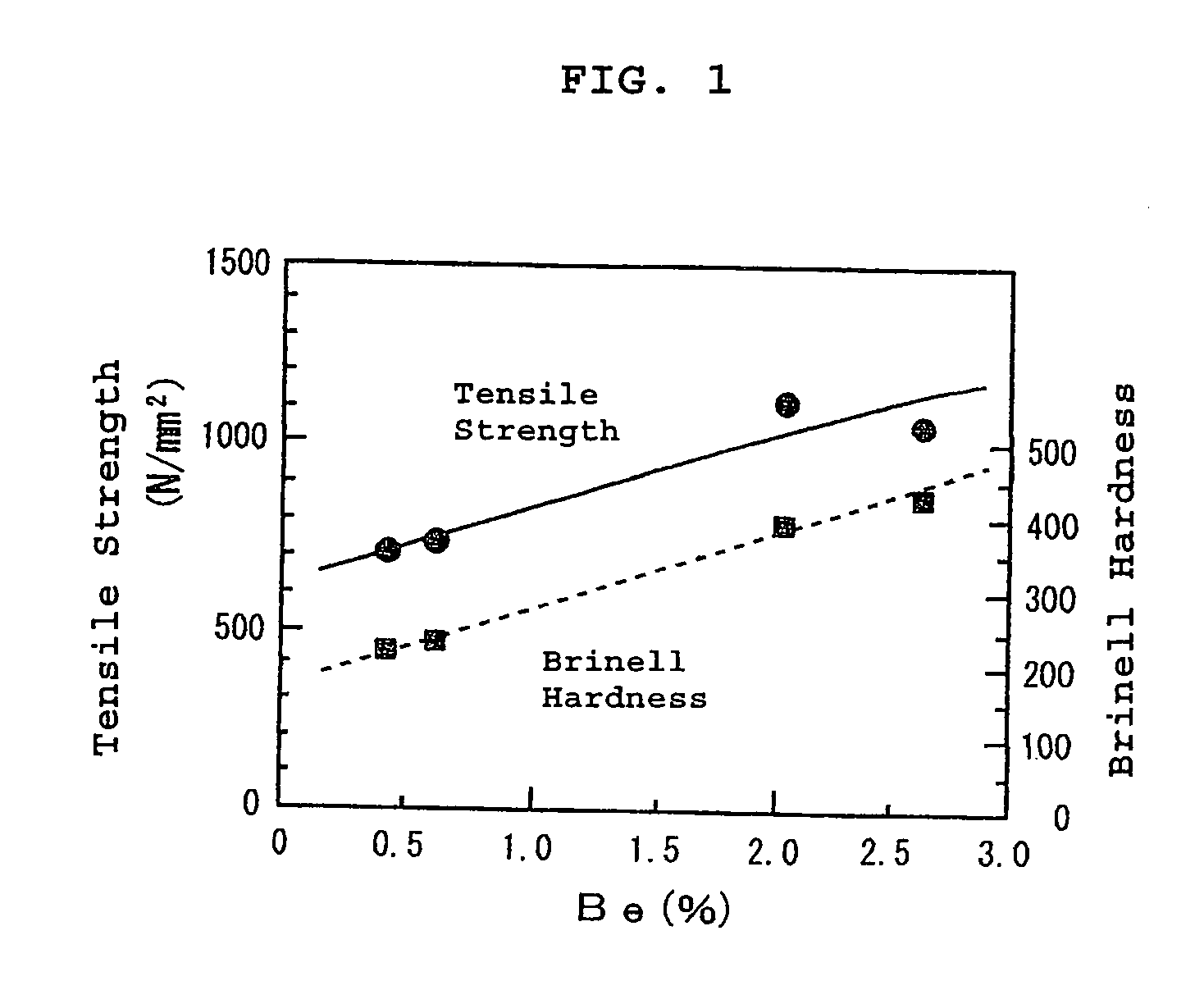

In a silicon casting apparatus according to the present invention, silicon melted by electromagnetic induction heating is continuously solidified using an electrically-conductive bottomless cold crucible and an induction coil surrounding the cold crucible. The cold crucible is made of copper alloy containing beryllium (desirably containing beryllium of 0.1 to 5 mass %), whereby the generation of electric-discharge flaw can be effectively prevented in performing electromagnetic casting. The use of the silicon casting apparatus according to the present invention can greatly extend a crucible life to reduce facility costs. Additionally, a solar-cell silicon ingot can be produced with high quality.

Owner:SUMCO SOLAR CORP

Silicon electromagnetic casting device

ActiveCN101829767AIncrease in sizeLarge synthetic output powerElectromagnetic castingTerminal voltage

The invention discloses a silicon electromagnetic casting device. The device comprises a furnace body container, a crucible with conductivity arranged in the furnace body container and induction coils arranged on the periphery of the crucible, wherein the designated gas with some pressure is filled in the furnace body container; after the induction coils in the silicon electromagnetic casting device are energized, silicon in the crucible is heated through induction, melted and then solidified; and each induction coil comprises more than two coils with different induction frequencies positioned from up to bottom. As the silicon electromagnetic casting device adopts more than two coils with different induction frequencies, large total output power can be generated through the combination ofthe induction coils when the terminal voltage of the induction coils with different induction frequencies are set to be less than the specified voltage according to different settings of the induction frequencies and induction output powers of the induction coils. By adopting the silicon electromagnetic casting device, silicon ingots with high quality and larger volume can be produced through thesimple and feasible method.

Owner:丽达科技有限公司 +1

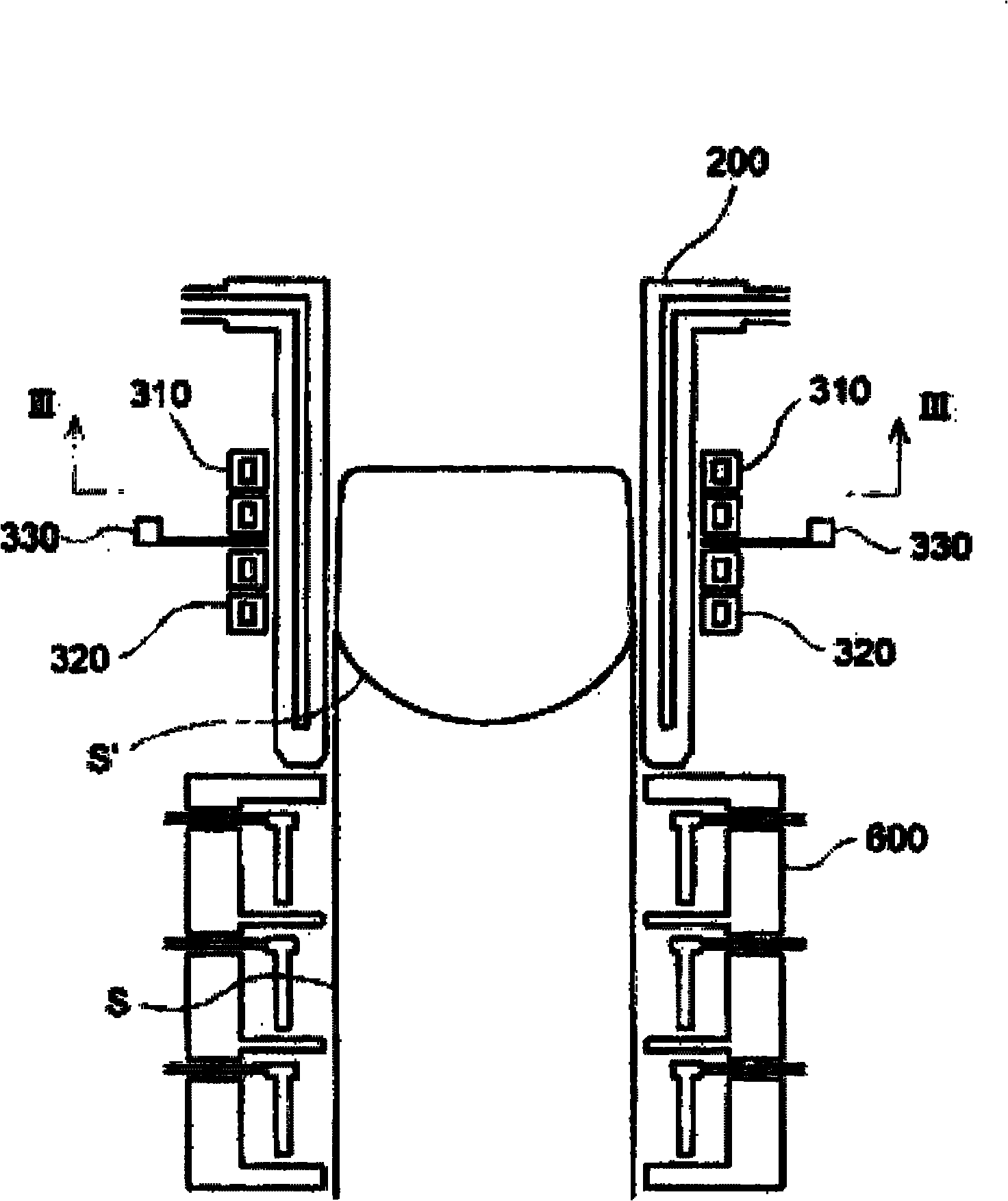

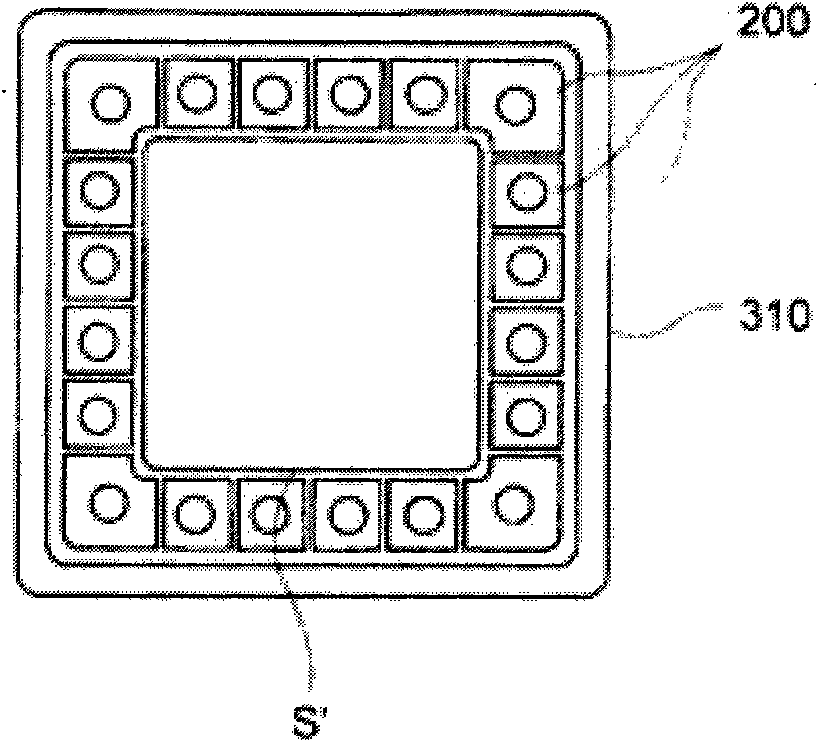

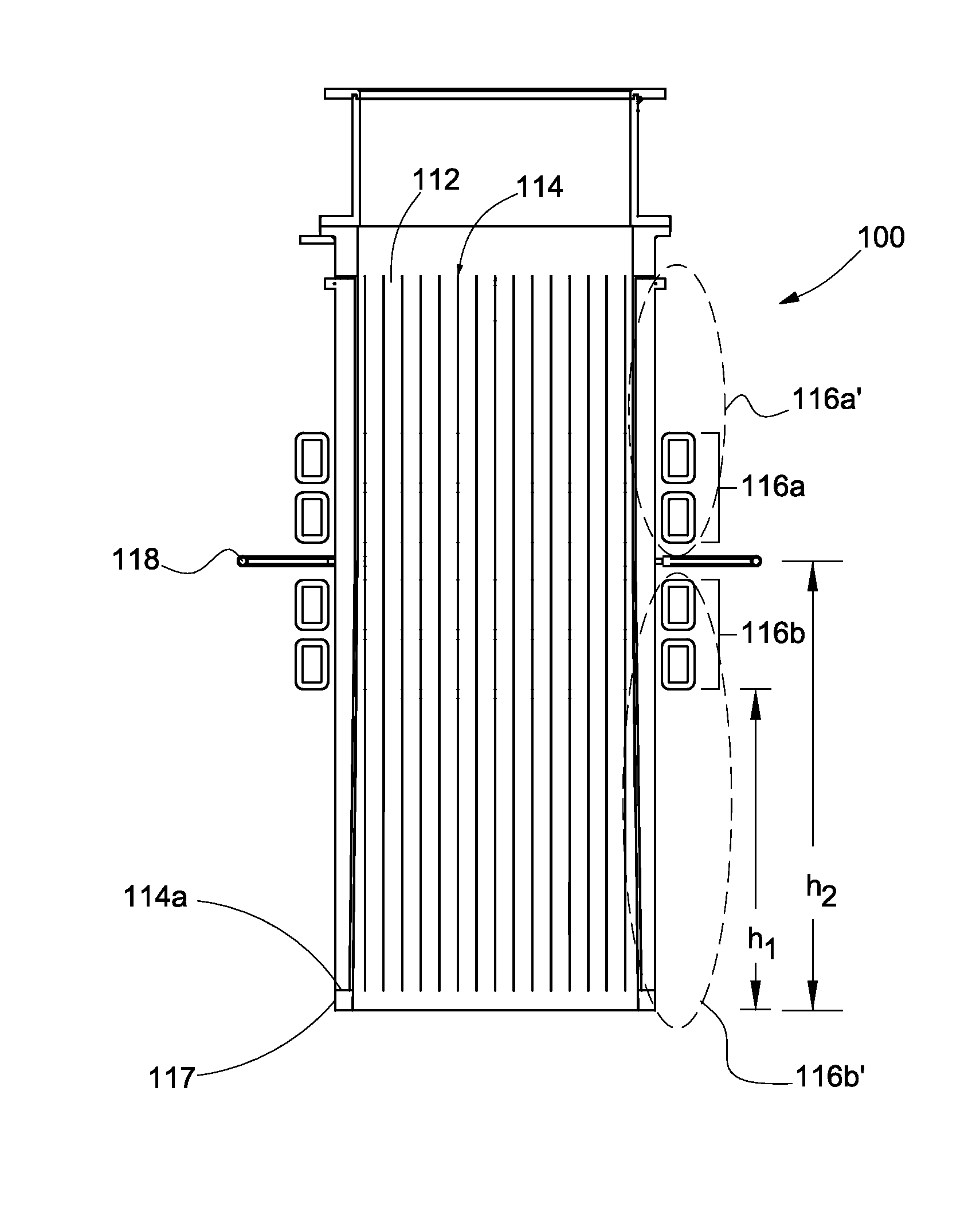

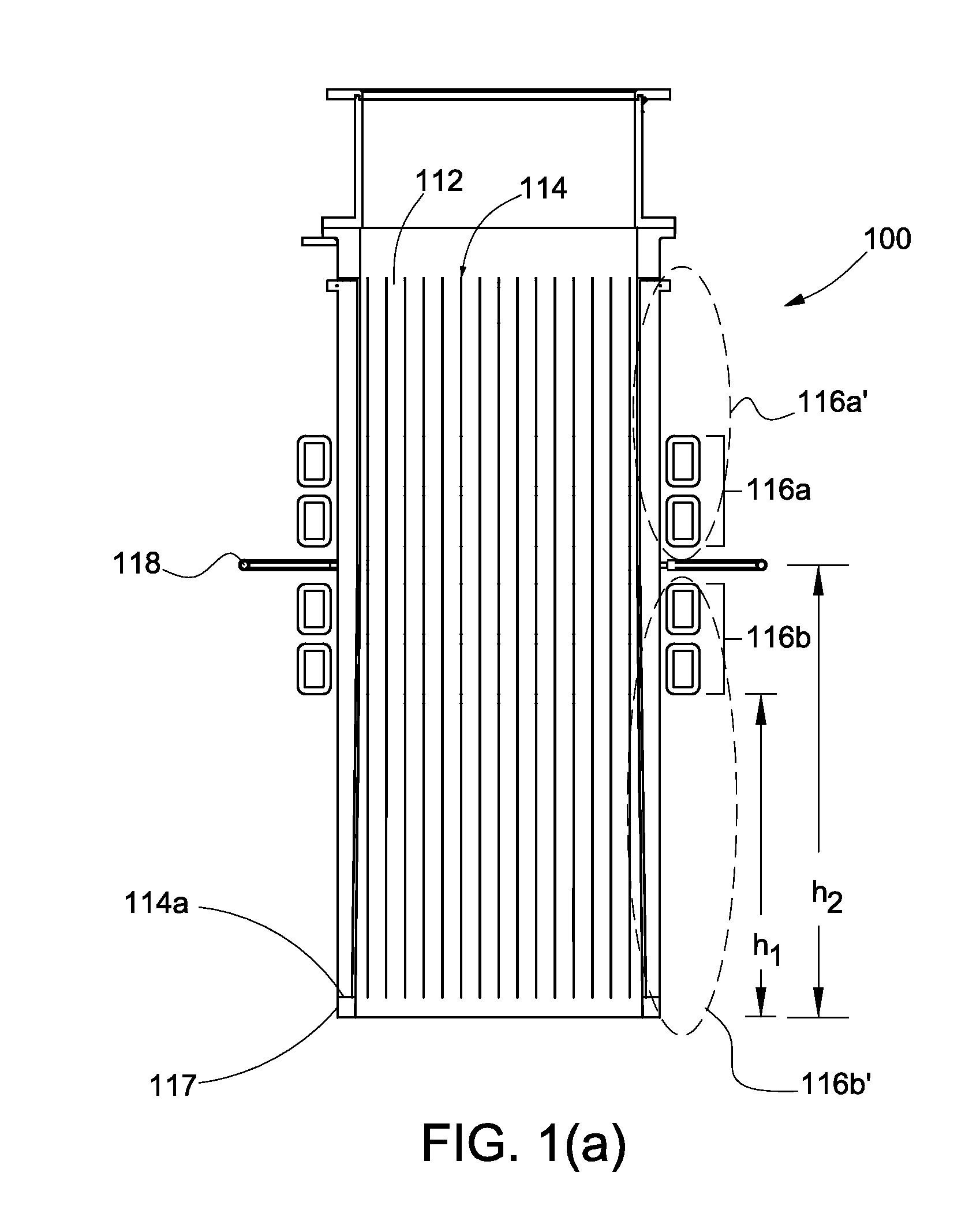

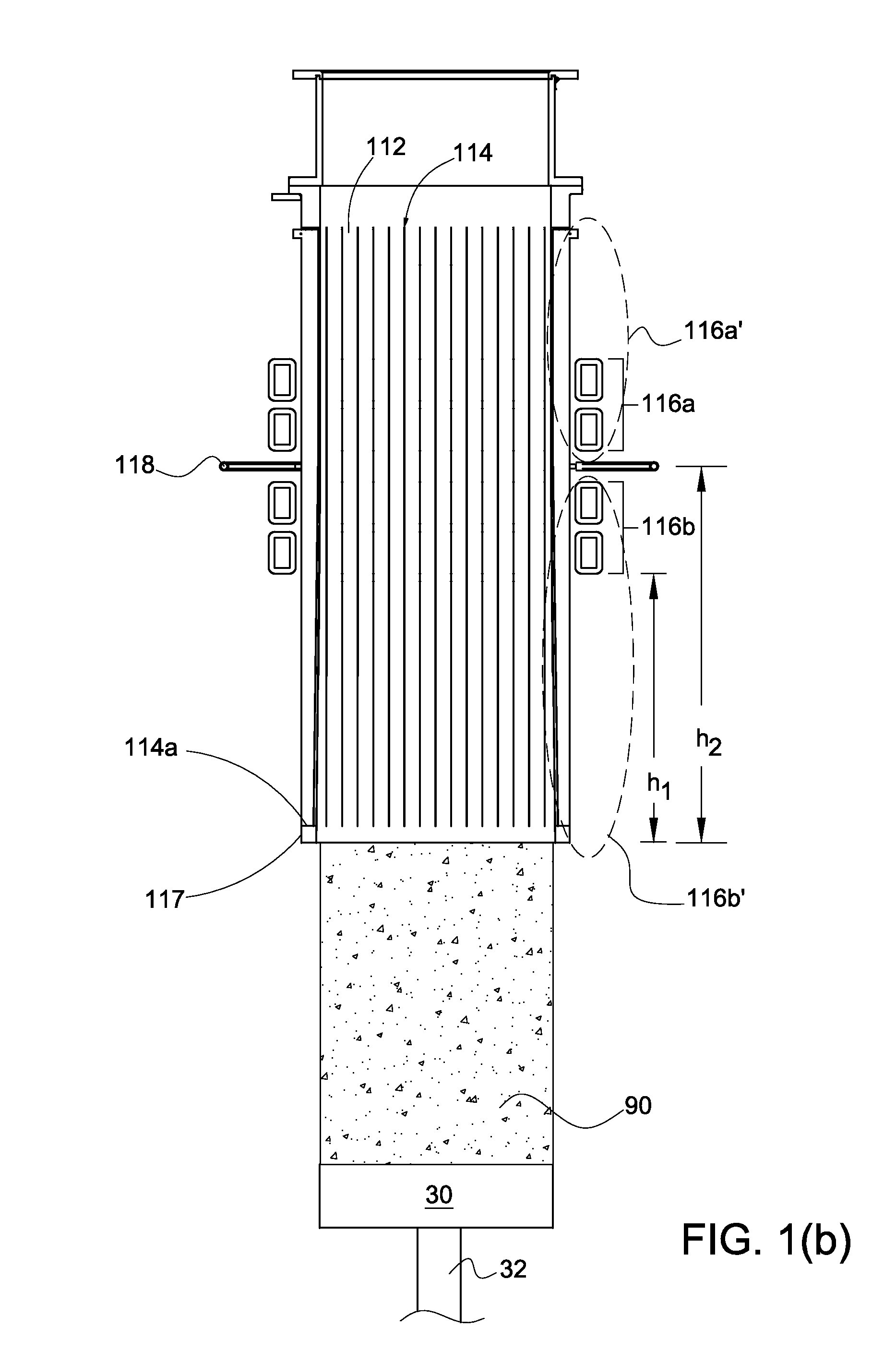

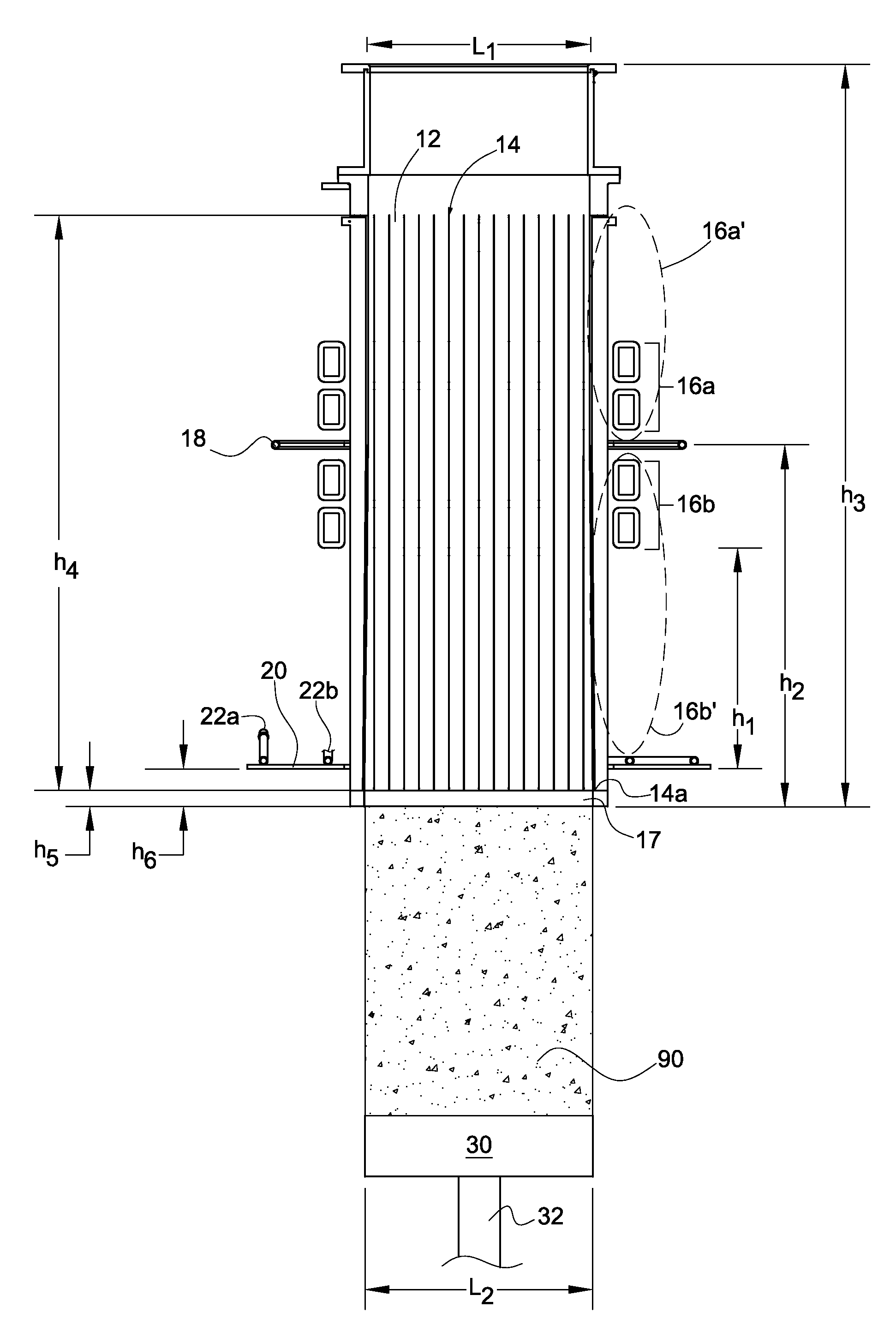

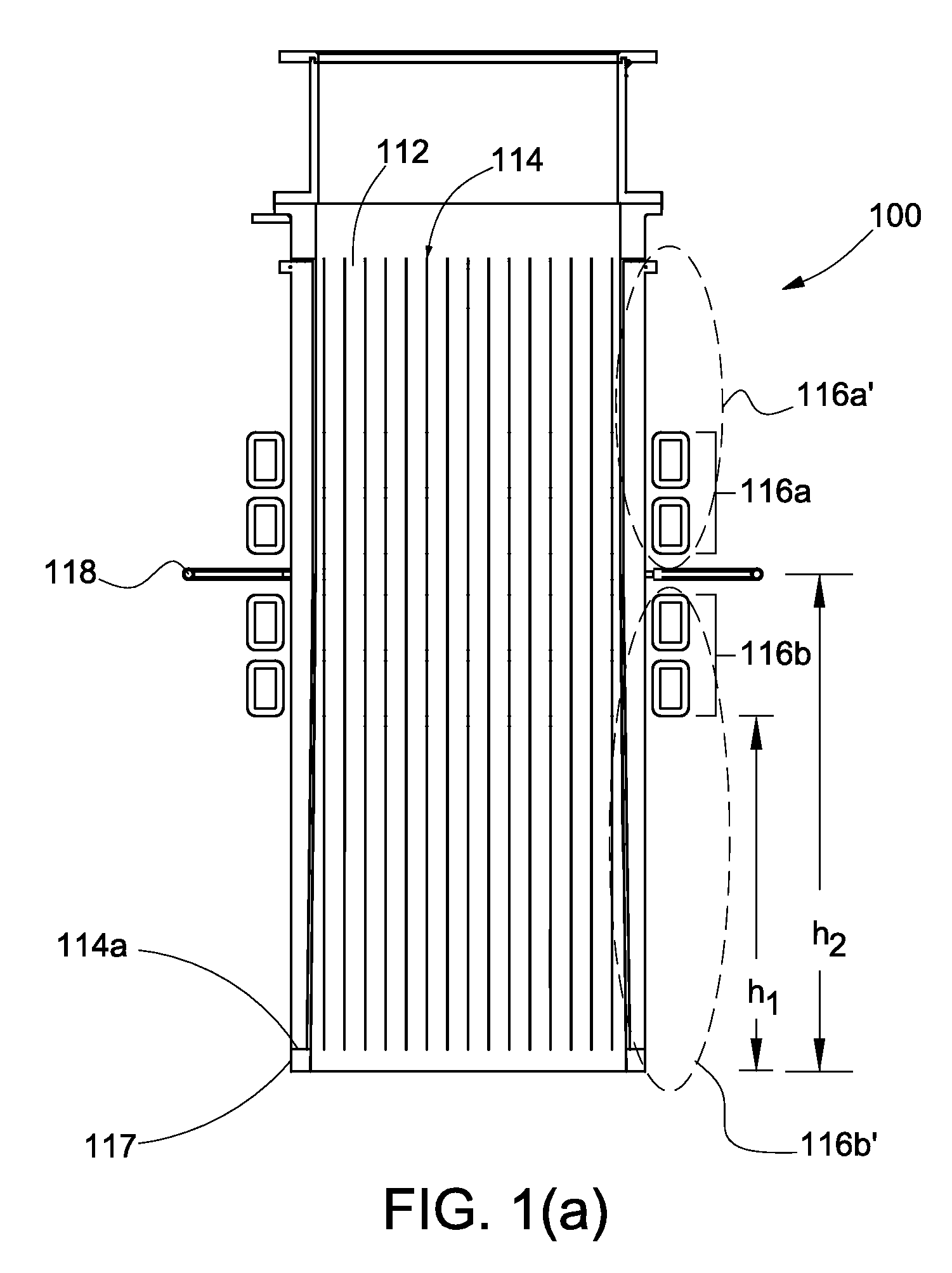

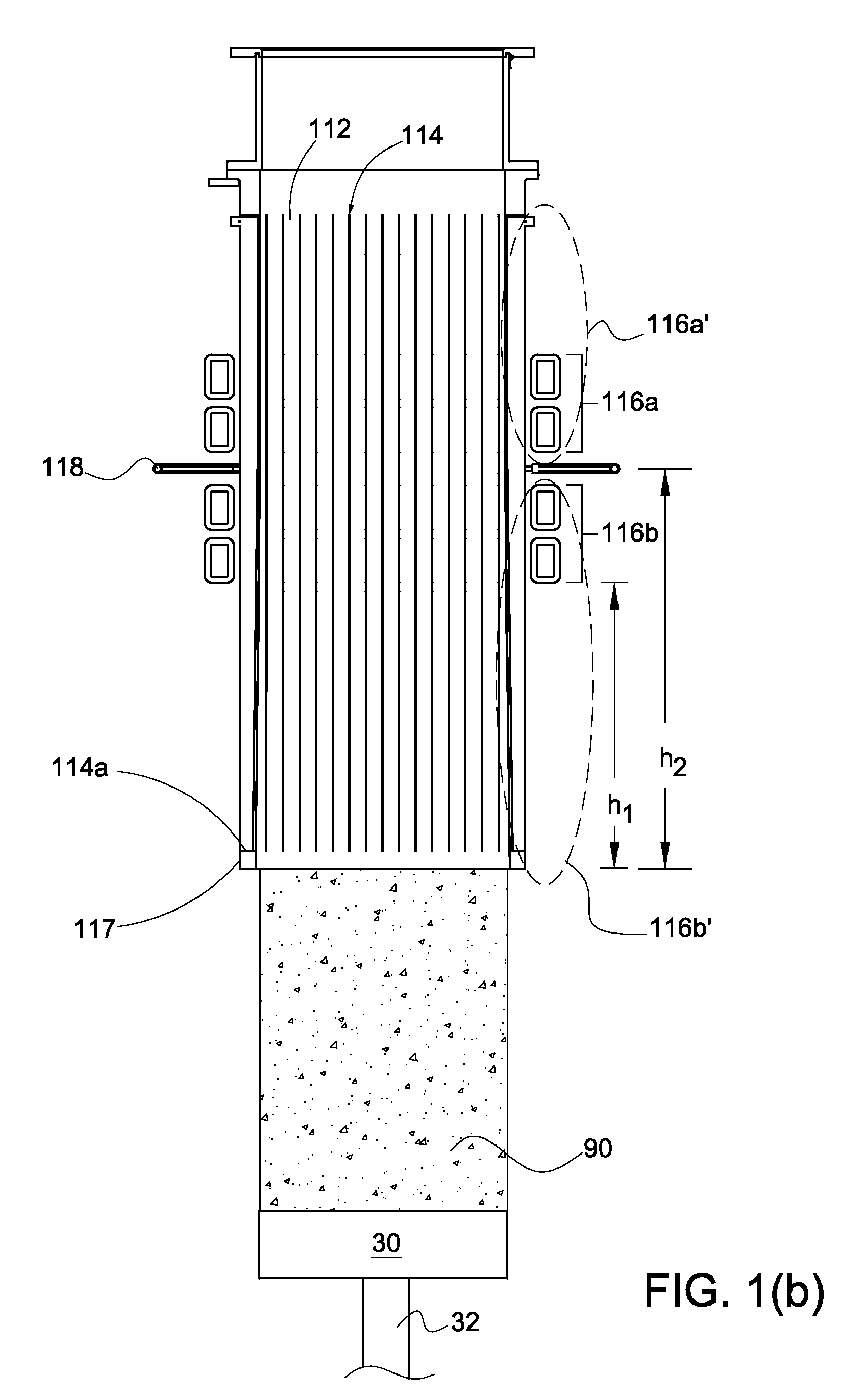

Open Bottom Electric Induction Cold Crucible for Use in Electromagnetic Casting of Ingots

ActiveUS20120236898A1Melt-holding vesselsPolycrystalline material growthElectromagnetic castingCrucible

An open bottom electric induction cold crucible with a slotted wall extending below one or more induction coils surrounding the partial exterior height of the crucible is used in an electromagnetic casting process for the production of ingots. A bottom magnetic shield is provided around the outer perimeter of the crucible's slotted wall in the vicinity of the bottom opening and the bottom termination of the wall slots and the bottom connecting member.

Owner:CONSARC

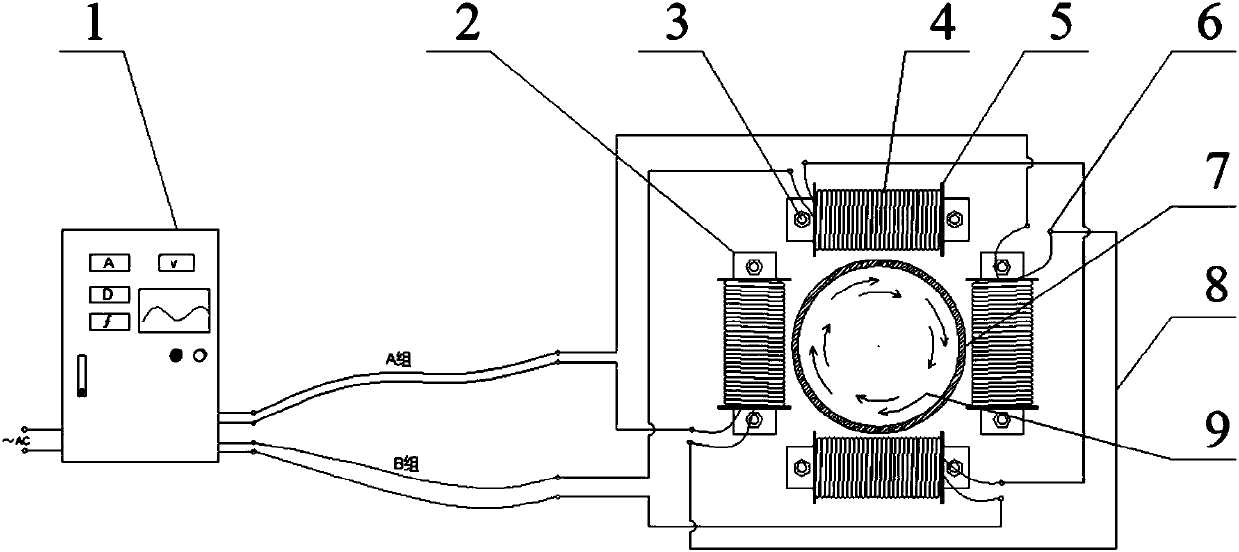

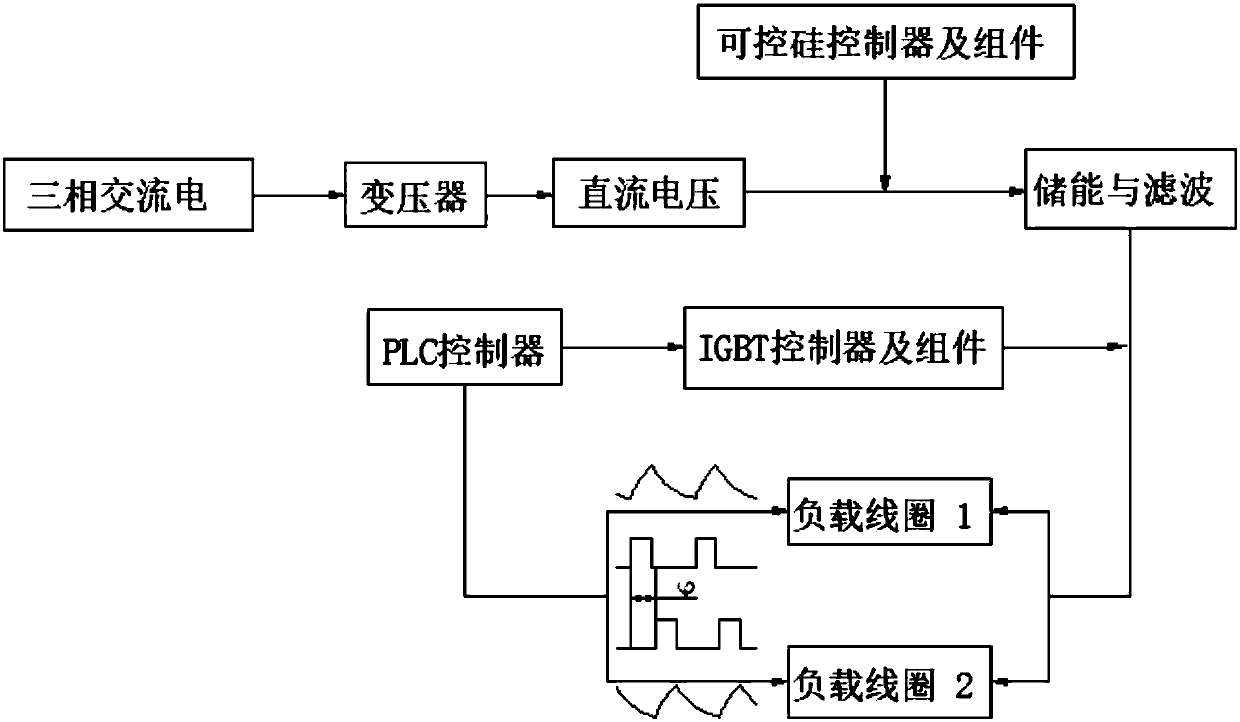

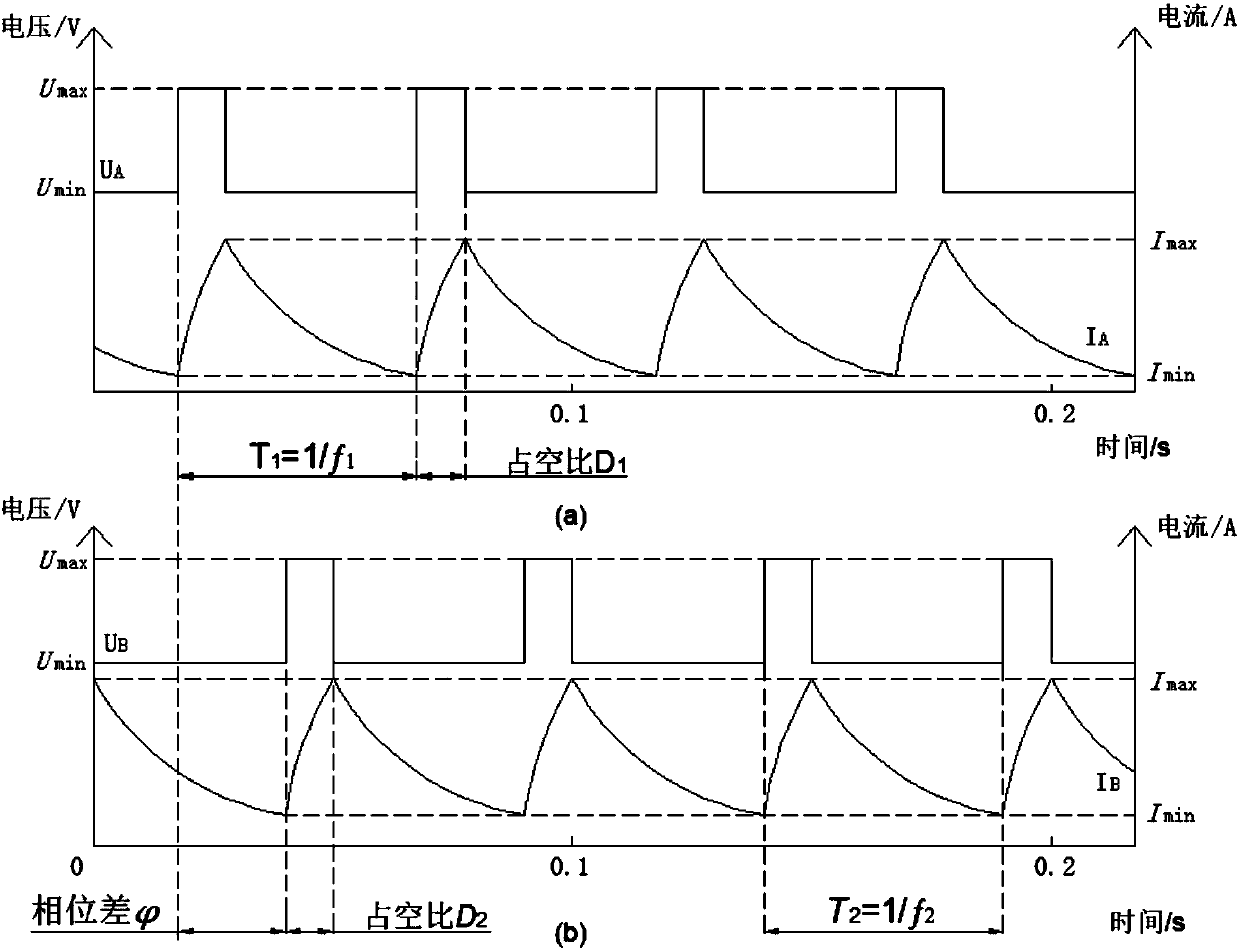

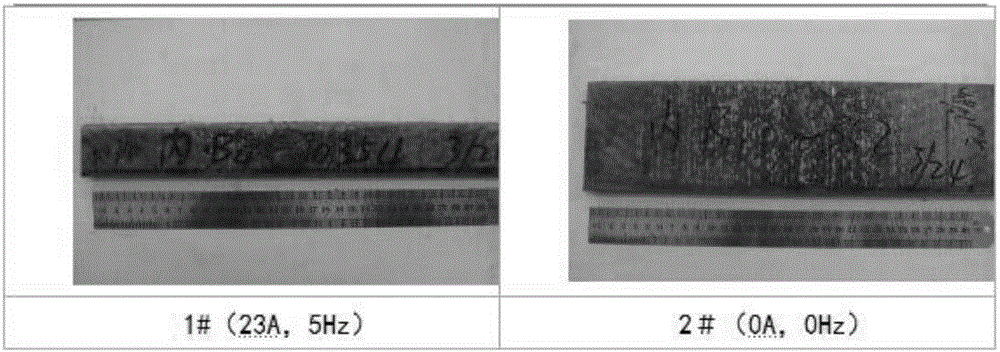

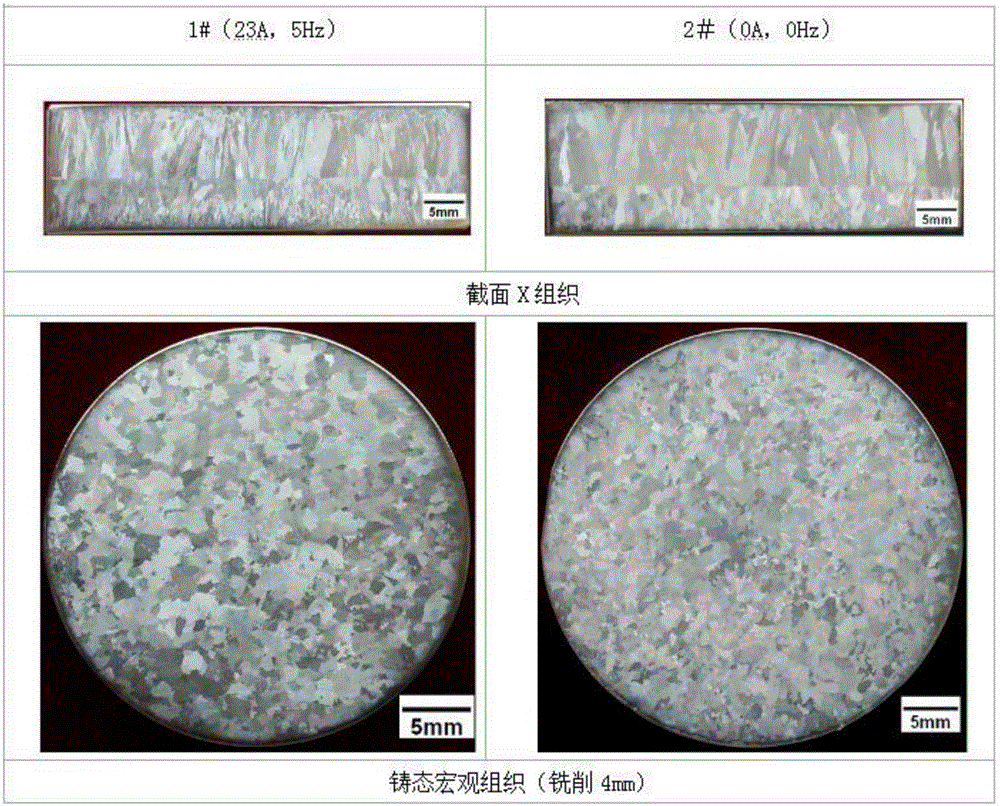

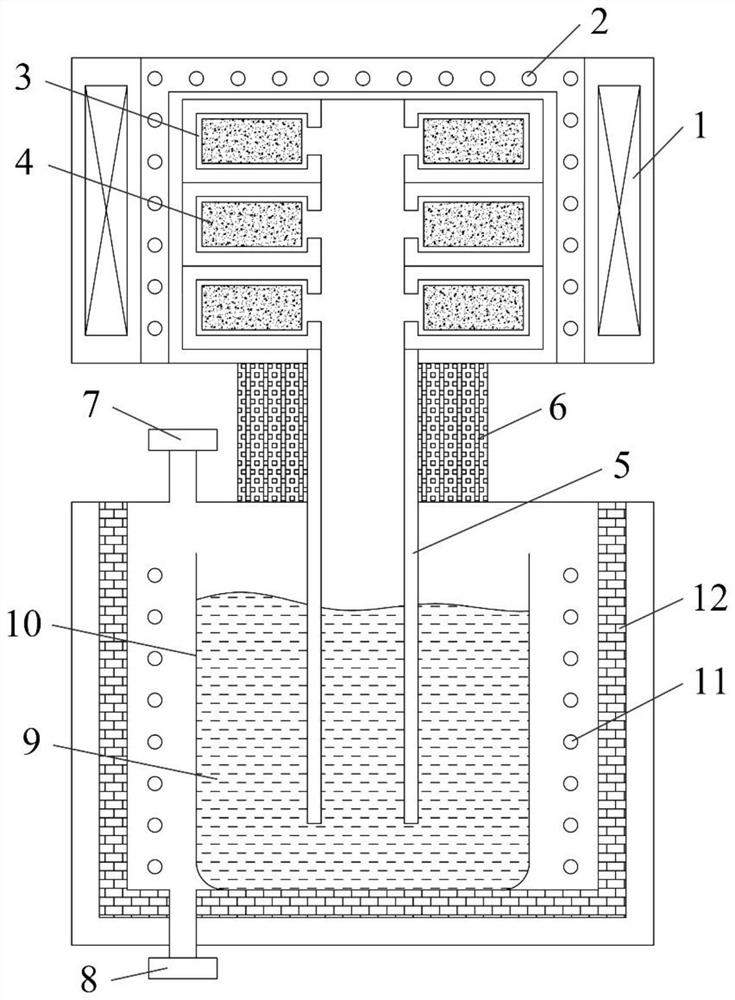

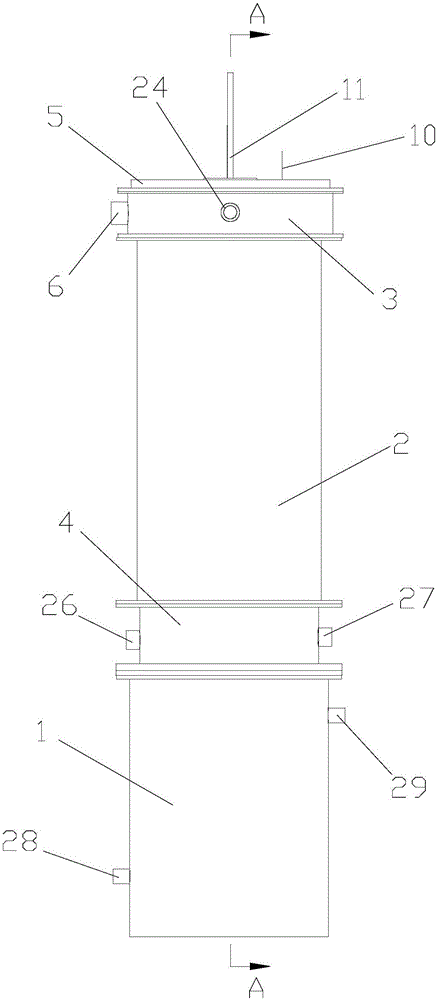

Electromagnetic casting method of difference phase traveling wave magnetic field

The invention relates to an electromagnetic casting method of a difference phase traveling wave magnetic field. The electromagnetic casting method of the difference phase traveling wave magnetic fieldcomprises the following steps of during an electromagnetic casting process, arranging magnetic field applying devices on the periphery of a metal melt, and applying magnetic fields on the metal meltthrough the magnetic field applying devices during a metal melt inner sleeve casting process; forming a group of magnetic field applying devices through 2n magnetic field applying devices, and arranging two groups of magnetic field applying devices, wherein each group of magnetic field applying devices respective produces a group of pulse electromagnetic signals, and a phase angle difference of the two groups of electromagnetic pulse signals is 90 degrees; and forming the difference phase traveling wave magnetic field in the metal melt. According to the method provided by the invention, the function of the electromagnetic fields on an alloy melt is fully realized, the magnetic field control at different parts during a preparation process of blanks with different shapes and specifications is realized, a magnetic field refining effect is improved, temperature and components are uniform, the melt is purified, a structure and components of an alloy casting blank are remarkably improved, and a performance of an ingot casting is improved.

Owner:NORTHEASTERN UNIV

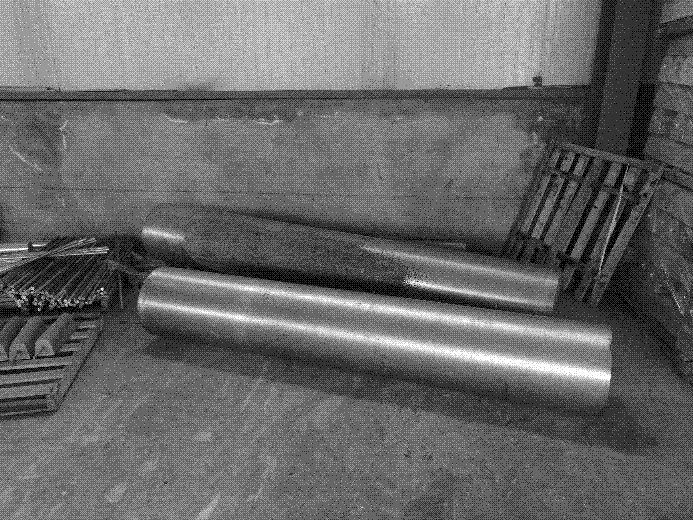

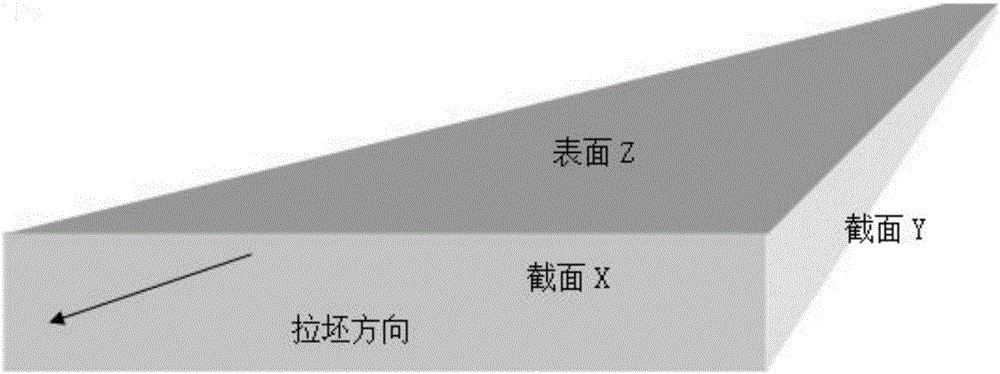

Forging process for preparing isotropic ultrahigh-strength heat-resistant magnesium alloy structural member

The invention discloses a forging process for preparing an isotropic ultrahigh-strength heat-resistant magnesium alloy structural member. Firstly, a cast ingot prepared through semi-continuous electromagnetic casting is subjected to homogenizing annealing, an ingot blank is formed through machining, the height direction of the cylindrical ingot blank and any two mutually perpendicular radial directions are used as the Z direction, the Y direction and the X direction correspondingly, 3-6 passes of heading are performed in the Z direction, the Y direction and the X direction, and the pass deformation amount is 20-40%; then the X direction or the Y direction is used as the axis, 2-6 passes of corner angle rolling compressing are performed, the pass deformation amount is 10-20%, intermediate annealing is performed, and the forging process is performed repeatedly once or twice; a forge piece is subjected to T6 treatment after forging is finished, and a final forge piece with the diameter being 450-650 mm and the height being 300-700 mm is obtained; as for both the height direction and the radial directions of the T6 state at the room temperature, the tensile strength is larger than or equal to 460 MPa, the yield strength is larger than or equal to 400 MPa, the ductility is larger than or equal to 4%, and the strength difference between the height direction and the radial directions is smaller than or equal to 10 MPa, and the ductility difference between the height direction and the radial direction is smaller than or equal to 0.5%; and as for both the height direction and the radial directions at the temperature of 200 DEG C, the tensile strength is larger than or equal to 350 MPa, and the ductility is larger than or equal to 6%.

Owner:CENT SOUTH UNIV

Electromagnetic casting process for 5754 aluminum alloy

InactiveCN102642001ASuppress turbulenceSuppression uniformityMetal rolling arrangementsElectromagnetic castingSlag

The invention discloses an electromagnetic casting process for 5754 aluminum alloy, which belongs to the field of aluminum alloy plate production and comprises the following steps: material preparation, material dosing, material adding, melting, stirring, slag removing, primary refining, sampling, component adjusting, carbon tetrachloride refining, beryllium adding, magnesium ingot adding, secondary refining, slag removing, furnace revolving, argon introducing and refining in a maintaining furnace, gas removing, filtering, cast rolling, reeling, cooling and packaging. The electromagnetic casting process has the advantages of effectively restraining turbulence and flow evenness in a cast rolling area of 5754 aluminum alloy melt in the cast rolling process due to a direct current magnetic filed, improving temperature distribution evenness of the 5754 aluminum alloy melt, disturbing solidified balance organization due to oscillation effect in the solidified process, improving content of alloy element in crystal and greatly improving quality of a cast rolling base.

Owner:江苏鑫皇铝业发展有限公司

Method of preparing aluminum alloy wheel hub with high structural strength

InactiveCN104674032AImprove structural strengthHigh hardnessElectromagnetic castingMetallic materials

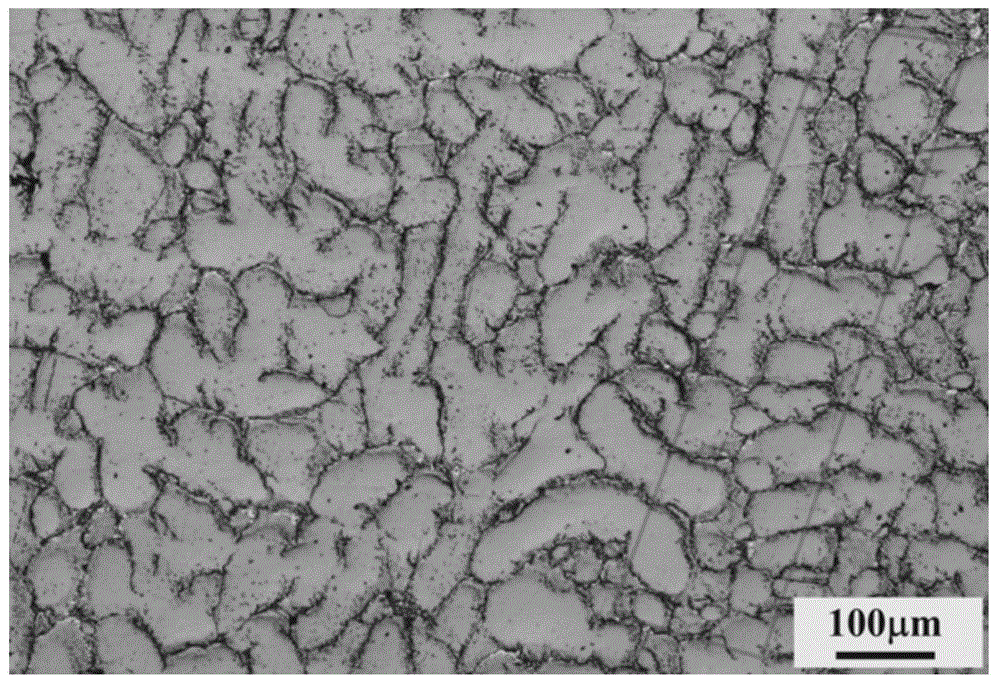

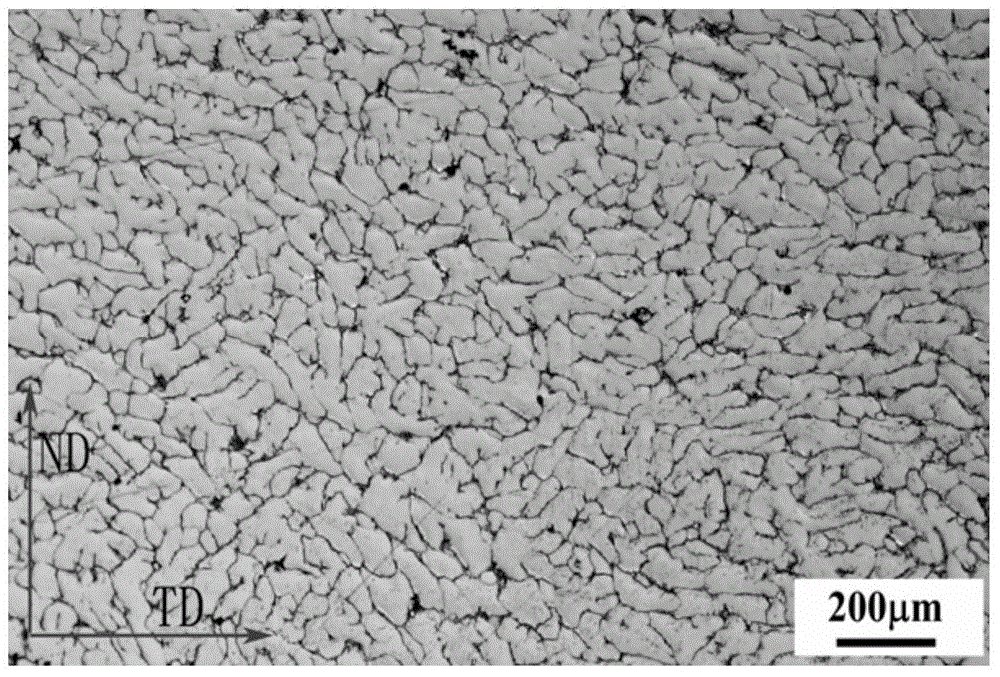

The invention relates to a method of preparing an aluminum alloy wheel hub with high structural strength and belongs to the technical field of metal material processing. The method comprises the steps of smelting a 6061 aluminum alloy, preparing a semisolid 6061 aluminum alloy blank with equiaxed grains by using an electromagnetic casting technique, then carrying out thixotropic die forging on the semisolid 6061 aluminum alloy blank, and carrying out T6 heat treatment on a formed part at last. The whole technical process is simple to implement; small damage is caused to a die; the aluminum alloy wheel hub with the high structural strength can be prepared; and the hardness, tensile strength and elongation of the prepared 15-21in aluminum alloy wheel hub are higher than those of an aluminum alloy wheel hub prepared by the conventional casting method by 50-60Hv, 160-170MPa and 2-3% respectively.

Owner:NORTHEASTERN UNIV

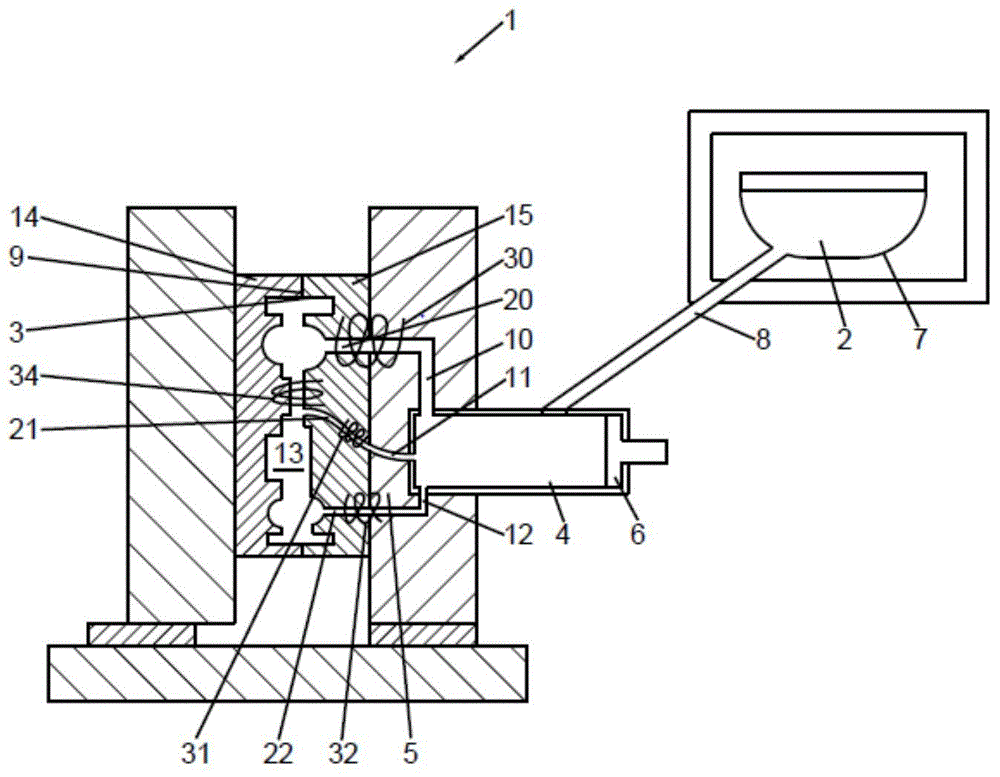

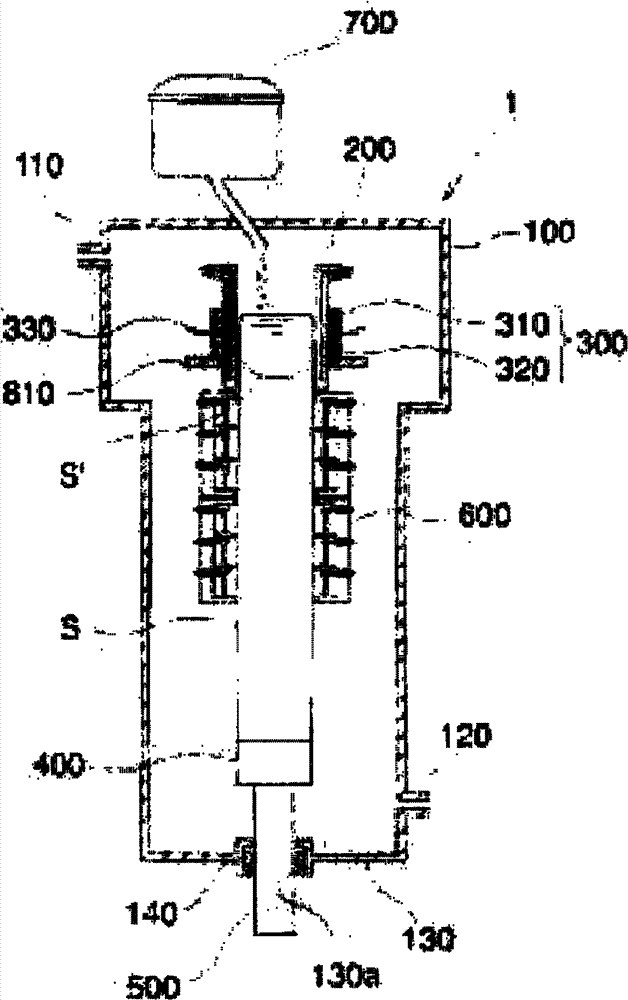

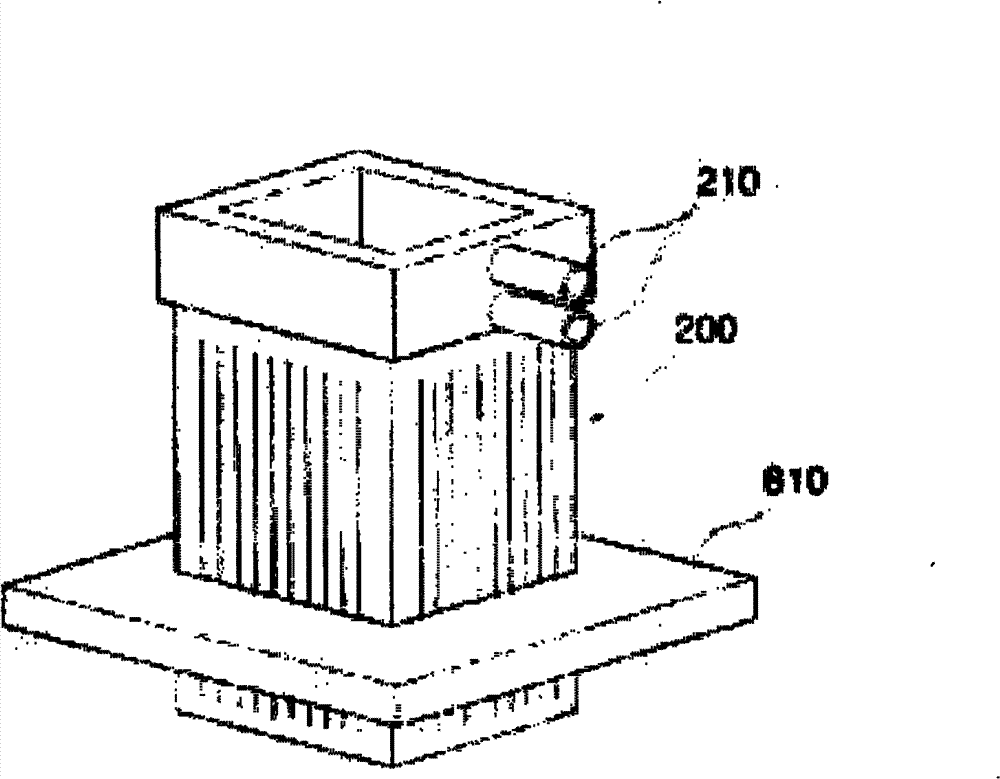

Casting device and casting method

InactiveCN104001860AFlow velocity increases or decreasesDoes not require complex controlsFoundry mouldsFoundry coresElectromagnetic castingElectromagnetic field

The invention relates to a direct electromagnetic casting driving apparatus (1) and a method of manufacturing a cast component through a plurality of casting channels (10, 11, 12). Different solution channels (20, 21, 22) in the casting channels (10, 11, 12) are heated, braked or accelerated in different degrees by means of the electromagnetic fields of electrified coils (30, 31, 32, 33). A non-contact feed is also provided. Required casting driving force is reduced. The invention ensures controllable starting of a second casting step and reverse action on edge layer solification. Meanwhile, the running material is reduced and the injection weight is minimized.

Owner:舒乐绞扭机有限责任公司

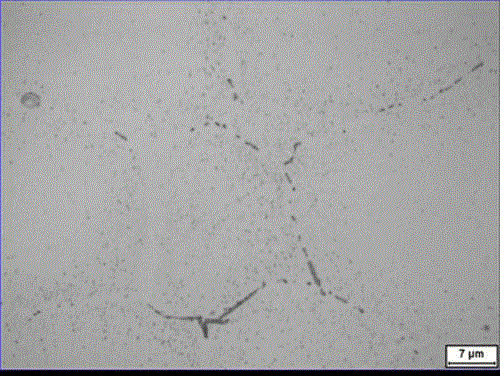

Beryllium-aluminum alloy sheet and manufacturing method thereof

ActiveCN104942271ARefining as-cast structureImprove plastic deformation abilityElectromagnetic castingMechanical property

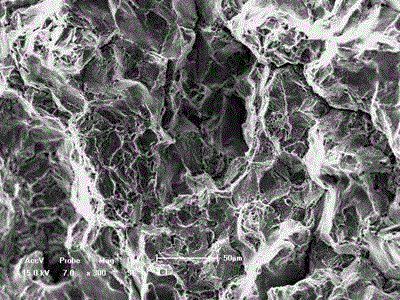

The invention discloses a beryllium-aluminum alloy sheet and a manufacturing method thereof. The manufacturing method comprises the sequential steps of manufacturing beryllium-aluminum alloy cast ingots, performing hot-pressing preforming on the beryllium-aluminum alloy cast ingots and performing hot-rolling forming on beryllium-aluminum alloy ingot blanks so that the beryllium-aluminum alloy sheet can be obtained. In the step of manufacturing the beryllium-aluminum alloy cast ingots, near-liquidus electromagnetic casting is adopted for manufacturing the beryllium-aluminum alloy cast ingots. The manufacturing method is a composite processing method combining near-liquidus electromagnetic casting, solid-state hot-pressing preforming and precision rolling. Near-liquidus electromagnetic casting is adopted in the step of manufacturing the beryllium-aluminum alloy cast ingots, formation of small and uniform non-dendritic structures is facilitated, and refining of alloy as-cast structures of beryllium-aluminum alloy is facilitated. Alloy dendritic structures of the cast ingots are further fragmented through hot-pressing performing, and the plastic deformation capacity of the alloy is improved. Finally, the sheet of the required thickness is obtained through a precision rolling method, and both the mechanical property and the composition of the produced beryllium-aluminum alloy sheet meet the requirements.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

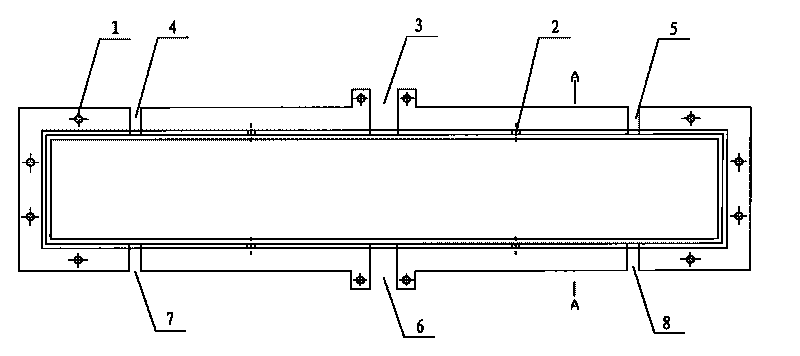

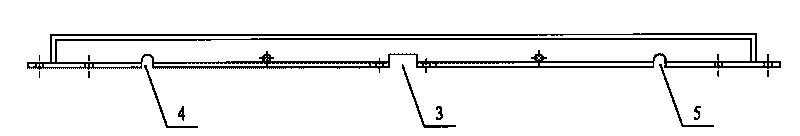

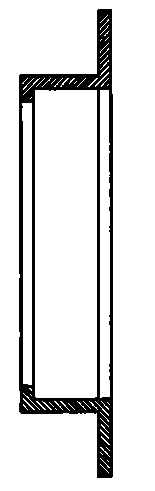

Frame baffle for fixing electromagnetic casting magnetic field-aided generator

The invention relates to a frame baffle for fixing an electromagnetic casting magnetic field-aided generator. Upper and lower sides of the frame baffle are provided with symmetrical fabrication holes or unsymmetrical fabrication holes, wherein the aim that the upper side is provided with the fabrication holes is for an incoming cable, a cooling water pipe and a fixing bolt to pass through; and the aim that the lower side is provided with the fabrication holes is to counteract nonuniform warp and deformation caused by a thermal stress, namely symmetrical sides of a slot and a hole of the frame baffle are provided with the corresponding fabrication holes for counteracting expansion and distortion caused by the thermal stress to eliminate the great-degree warp and deformation caused by opening the fabrication holes only on the single side. The nonuniform thermal stress deformation and warp of the frame baffle caused by heating are avoided by regulating and optimizing the positions and the number of the fabrication holes of the frame baffle so as to prolong the service life of the baffle from a plurality of weeks to more than one year and greatly reduce the consumption of auxiliary materials; and because the serious thermal stress warp is eliminated, the service life of a packing frame of a casting mold is greatly improved.

Owner:苏州有色金属研究院有限公司

Open bottom electric induction cold crucible for use in electromagnetic casting of ingots

An open bottom electric induction cold crucible with a slotted wall extending below one or more induction coils surrounding the partial exterior height of the crucible is used in an electromagnetic casting process for the production of ingots. A bottom magnetic shield is provided around the outer perimeter of the crucible's slotted wall in the vicinity of the bottom opening and the bottom termination of the wall slots and the bottom connecting member.

Owner:CONSARC

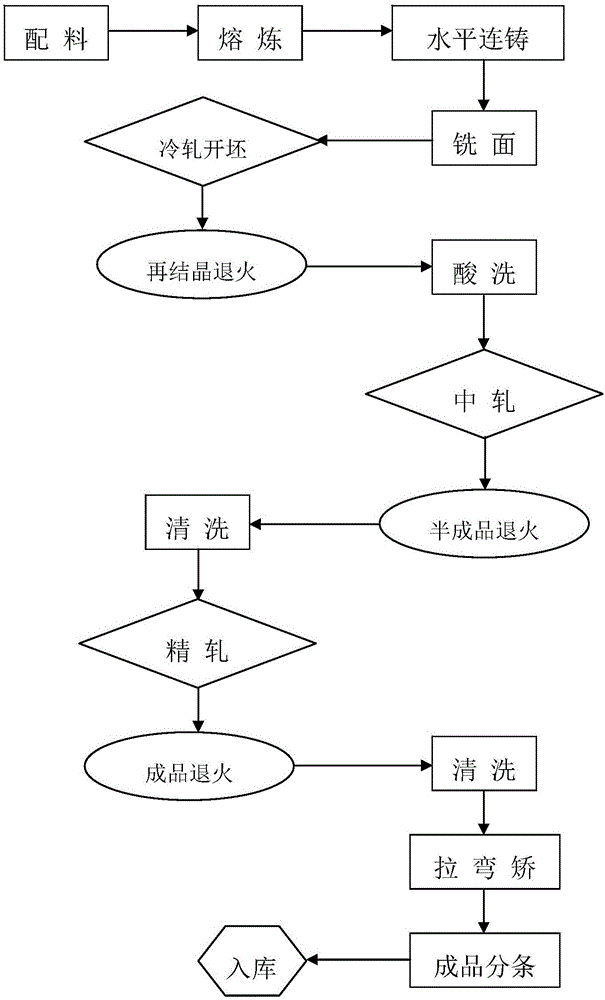

High-precision complicated white copper alloy ternary alloy production technology

InactiveCN106736307AImprove corrosion resistanceImprove surface qualityMetallic material coating processesElectromagnetic castingCupronickel

The invention provides a high-precision complicated white copper alloy ternary alloy production technology which comprises the following steps of white copper blank casting, ingot cold machining and surface defect removing, wherein in the white copper blank casting step, horizontal continuous casting is conducted by adopting an electromagnetic casting technology, wherein the smelting temperature is 1,200-1,350 DEG C, and liquid copper is water-cooled; in the ingot cold machining step, rough rolling, annealing and intermediate rolling, annealing and finish rolling, and annealing are performed; and in the surface defect removing step, passivating, pickling and washing of a copper strip are performed, wherein the used passivator is benzotriazole, the concentration of a passivating liquid is 0.5-2.5 g / L, and the conductivity of pure water for washing is controlled to below 50 microseconds / cm. According to the high-precision complicated white copper alloy ternary alloy production technology, horizontal continuous casting is conducted, hot mills and heating furnaces are omitted, the production efficiency is high, and the energy consumption is low; the produced complicated white copper is high in corrosion resistance, tensile performance and elongation.

Owner:江苏兴成新材料有限公司

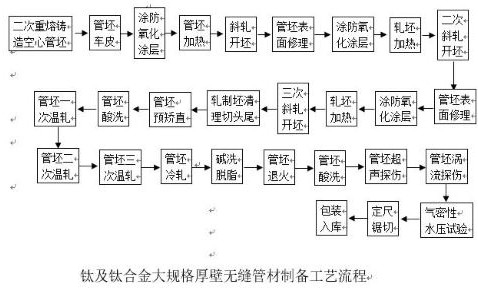

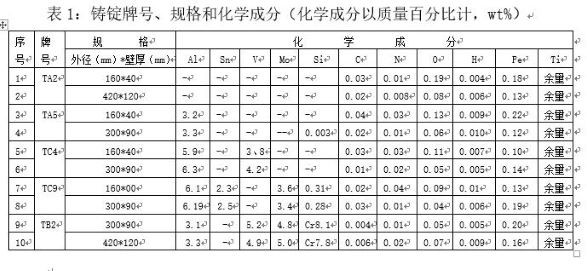

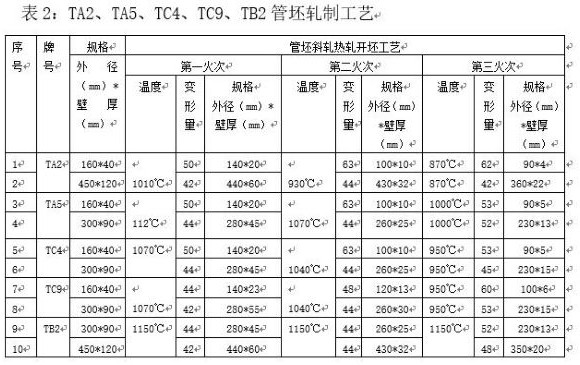

Preparation method of titanium and titanium alloy large-specification seamless pipe

ActiveCN112845654AImprove plasticityReduce lossTemperature control deviceFurnace typesElectromagnetic castingSurface cleaning

The invention provides a preparation method of a titanium and titanium alloy large-specification seamless pipe. According to the preparation method, an electromagnetic casting hollow pipe blank is adopted, a two-roller or three-roller skew rolling process is adopted to conduct cogging on the pipe blank for 2-3 passes, then warm rolling-cold rolling-cold stretching or warm rolling-cold stretching or warm rolling-expanding stretching is conducted, and the stretched pipe is subjected to inspection, fixed-length sawing, surface cleaning and finished product annealing and then is packaged and put in storage. By means of the preparation method, the problems of uneven wall thickness, unstable quality, unsuccessful perforation and the like of a pierced billet in the traditional skew rolling-perforation process are avoided; the process link of repeatedly heating and repeatedly rolling a cast ingot in the traditional process is omitted, so that the heating time is shortened, and oxidation of the pipe blank which sucks air after heating is relieved; annealing and pickling procedures and pickling metal loss are reduced; and large-specification seamless pipes with the diameter ranging from 80mm to 424mm and the wall thickness ranging from 2mm to 30mm can be produced to meet market requirements.

Owner:XINJIANG UNIVERSITY

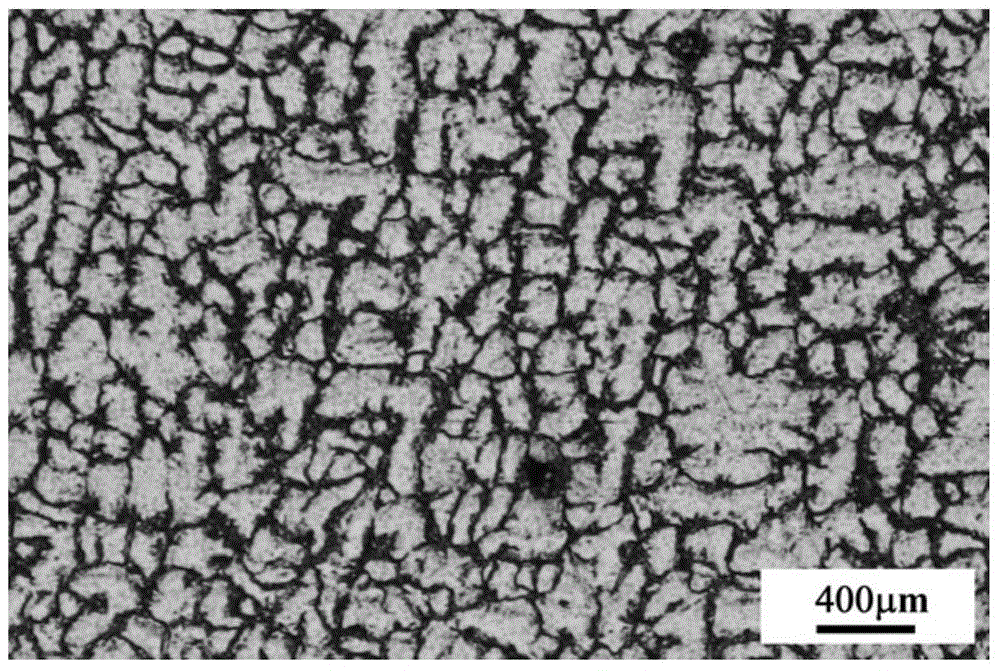

Semi-continuous casting process of VW64M high-strength heat-resistant magnesium alloy big ingot blank

The invention discloses a semi-continuous casting process of a VW64M high-strength heat-resistant magnesium alloy big ingot blank. An alloy contains, by weight, 5.0-7.0% of Gd, 2.5-4.0% of Y, 0.1-0.3% of Ag, 0.15-1.0% of Zn, 0.25-0.65% of Zr, 0.002-0.050% of Ca and the balance Mg. The process mainly includes the following steps that a magnesium ingot is molten at the temperature ranging from 670 DEG C to 720 DEG C; a Mg-Ca intermediate alloy and a fluxing agent are added; alloy elements are added at the temperature of 750 DEG C to 800 DEG C; refining and slagging-off are performed; gas feeding and stirring are performed; the temperature is adjusted to reach 680 DEG C to 700 DEG C and maintained for still standing for 1.5-3.5 hours; and low-temperature low-speed electromagnetic casting is performed. By coordinating the process parameters of all the steps, the magnesium alloy ingot blank being free of cracks, smooth in surface, small in grain size, uniform in structure and free of solute segregation and having the diameter phi of 300-630 mm and the length of at least 1000 mm is obtained.

Owner:CENT SOUTH UNIV

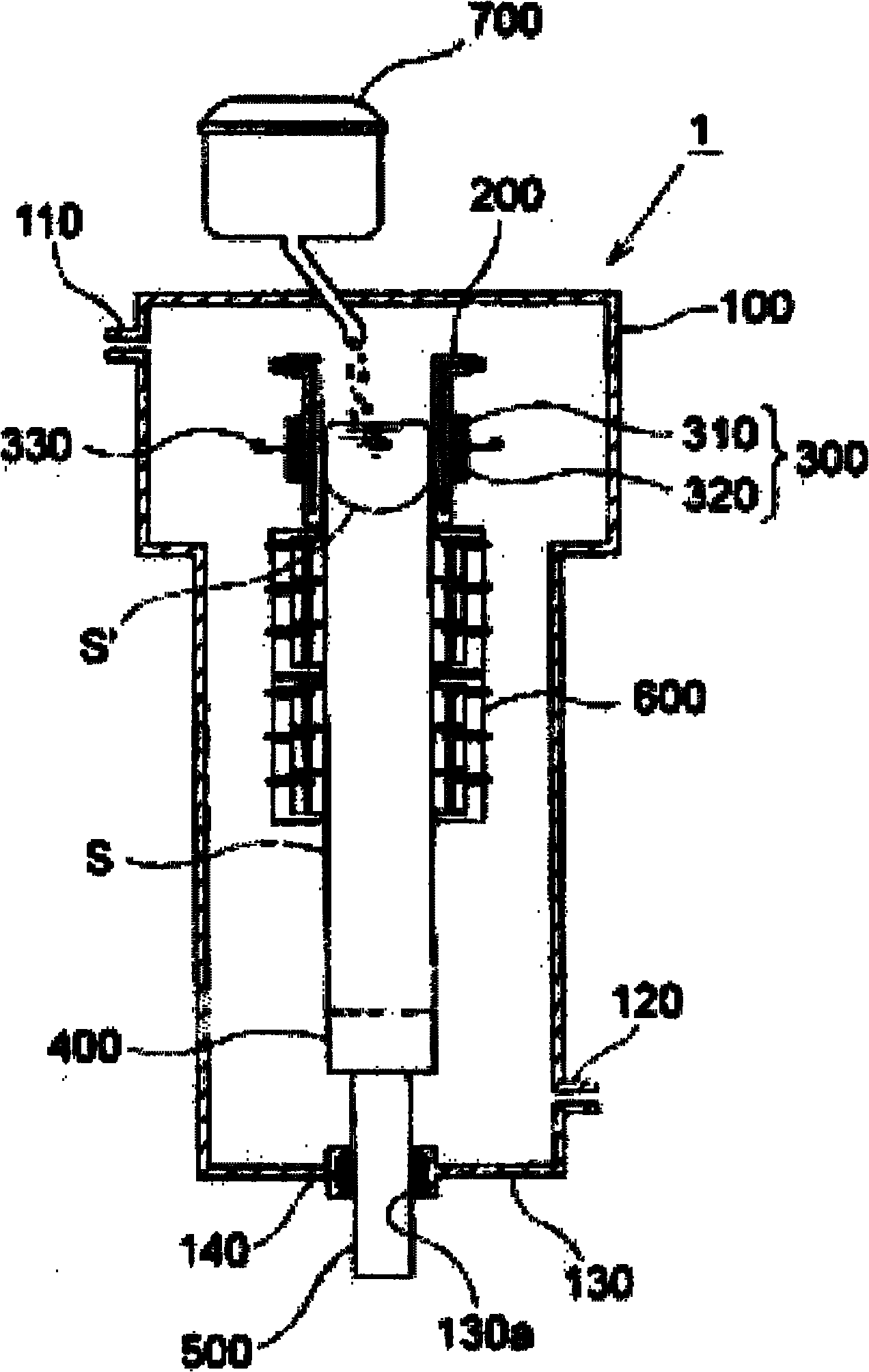

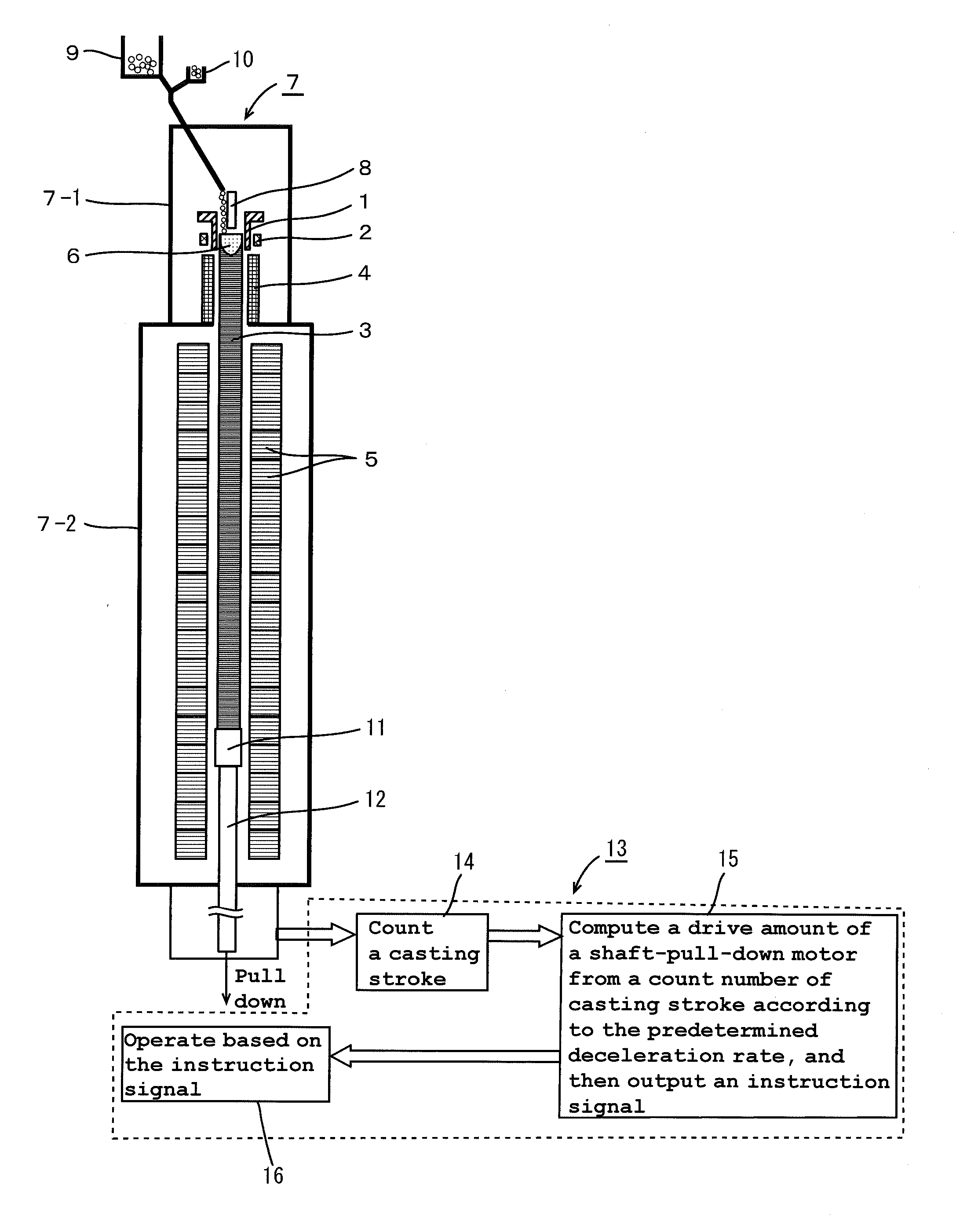

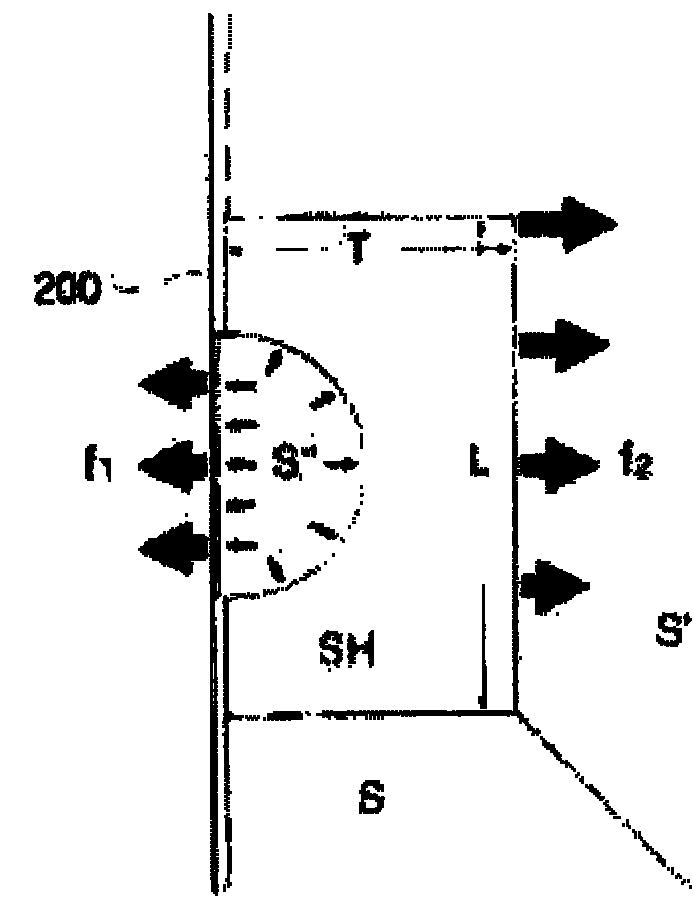

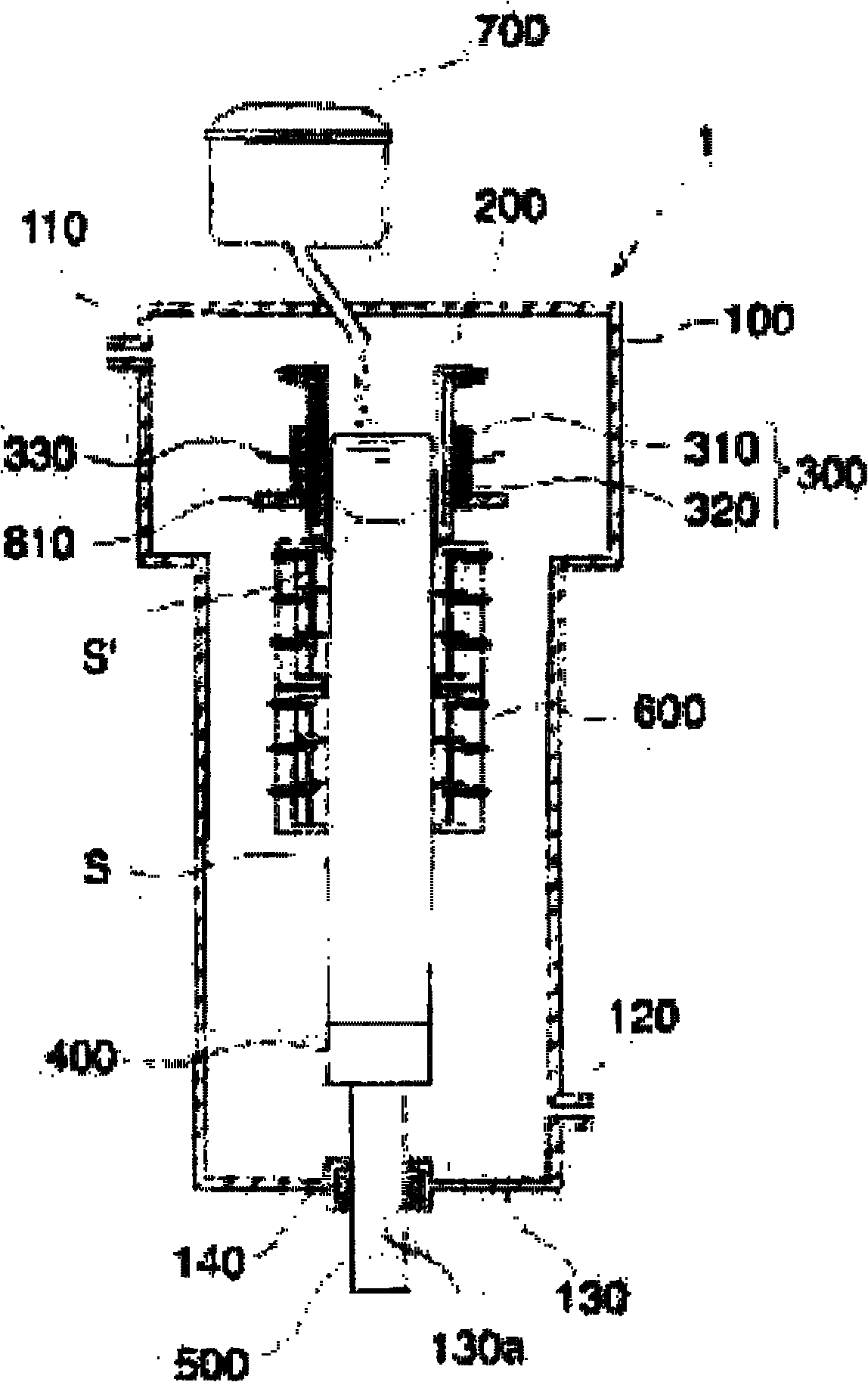

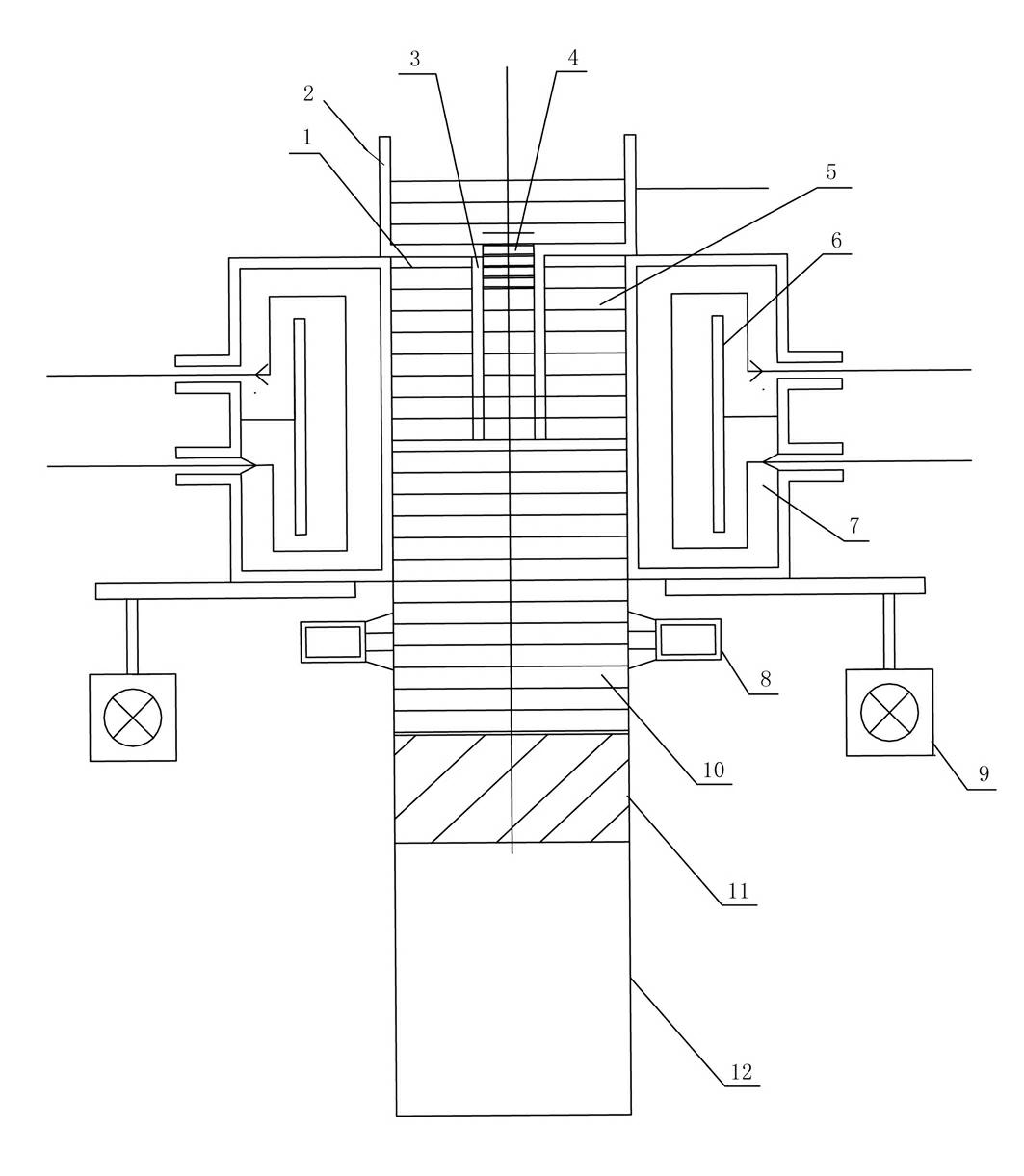

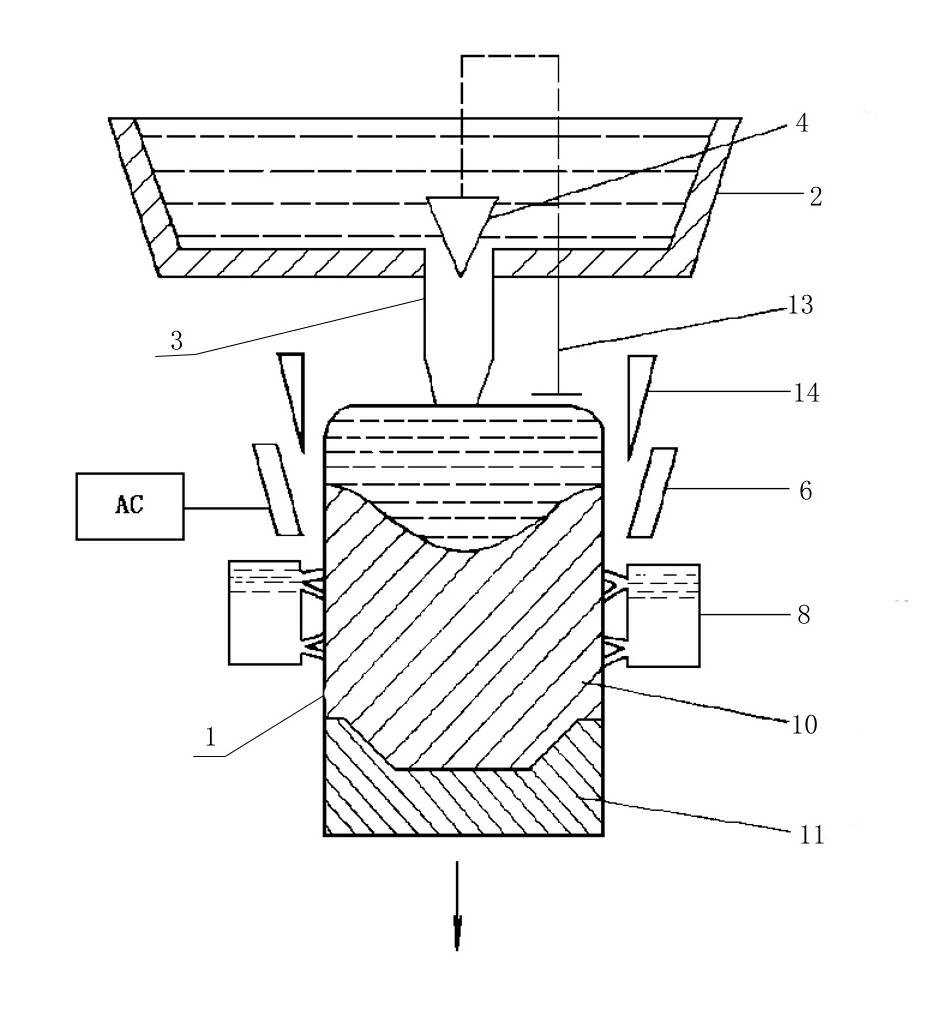

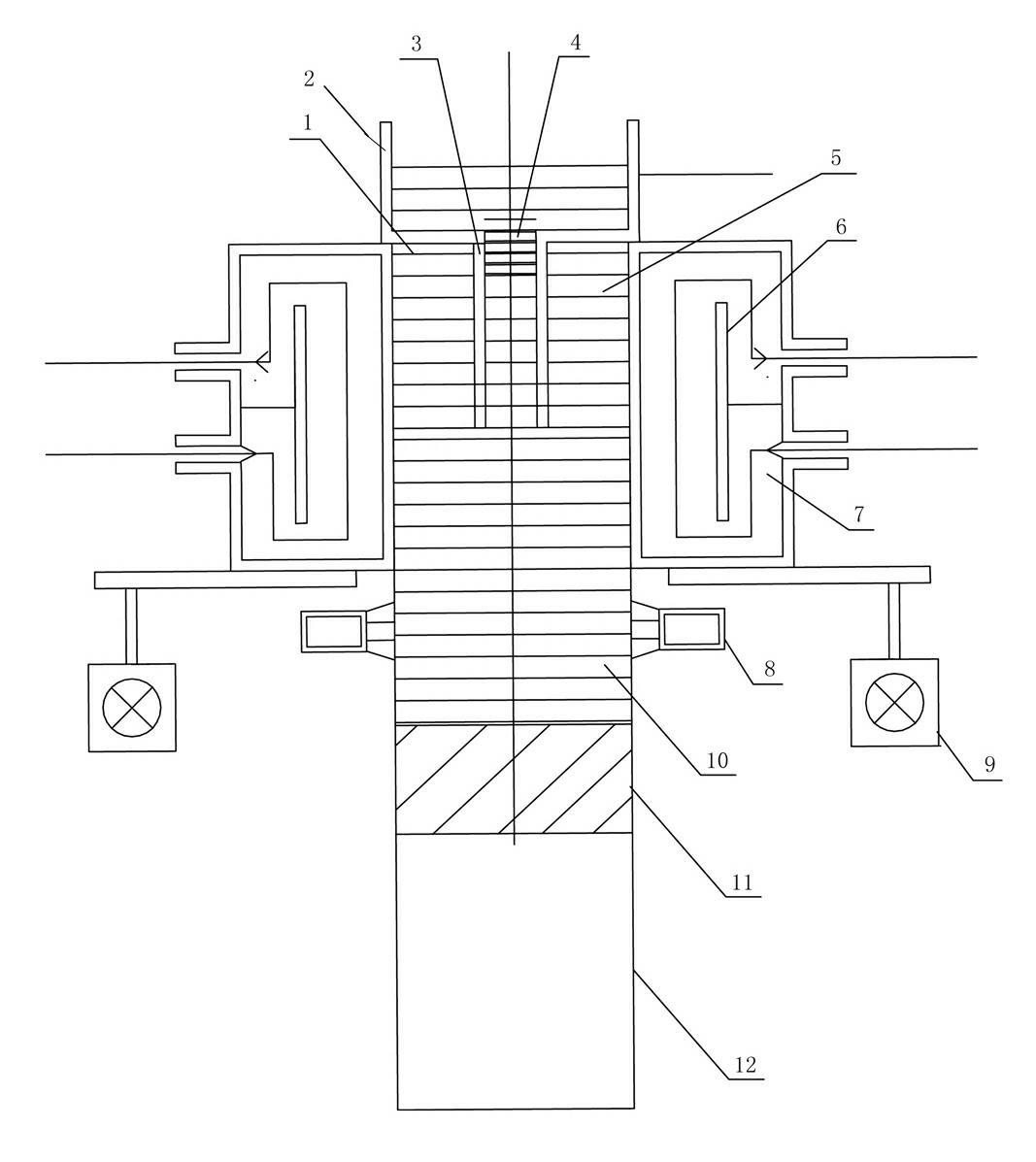

Electromagnetic casting method and apparatus for polycrystalline silicon

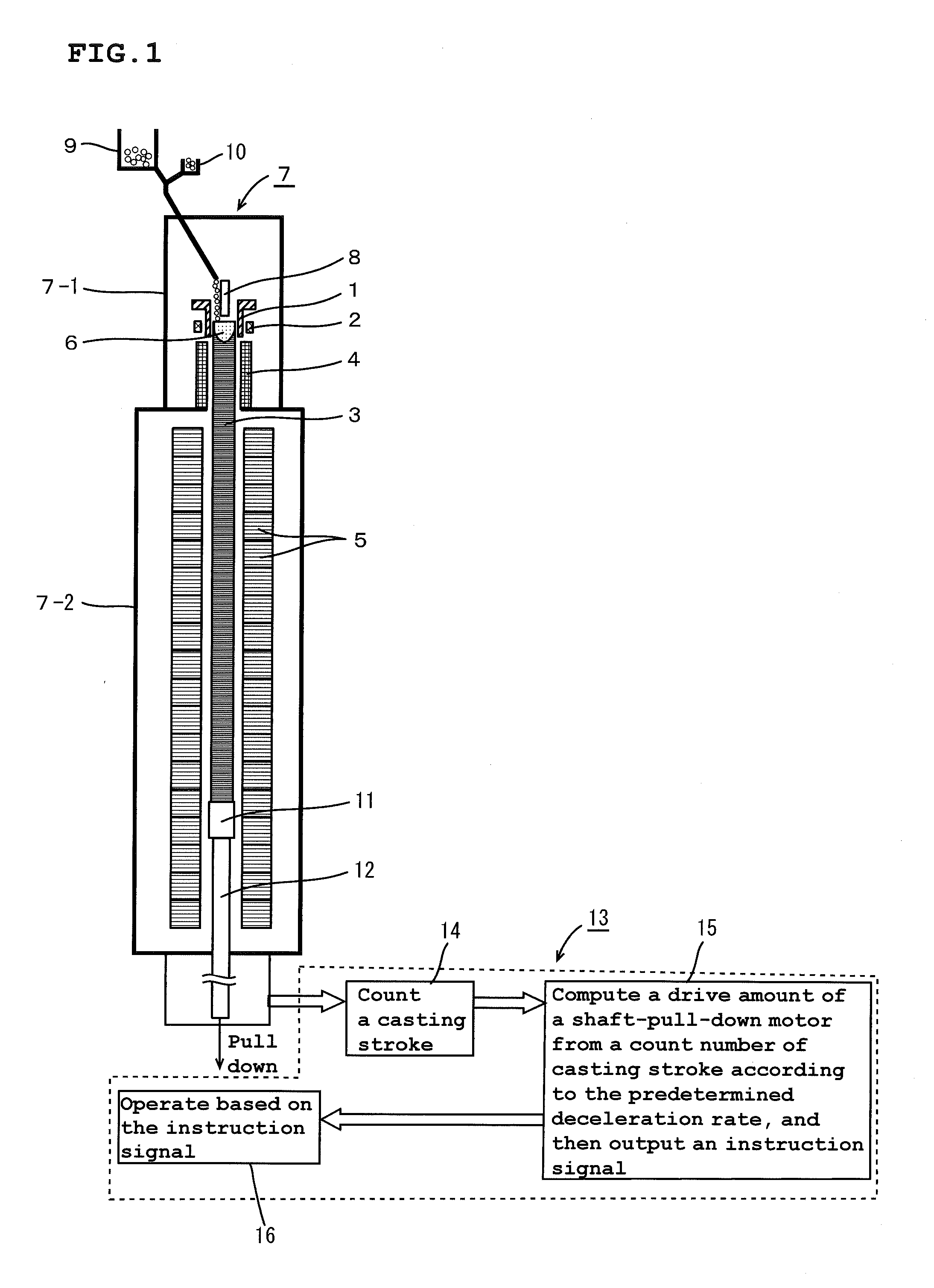

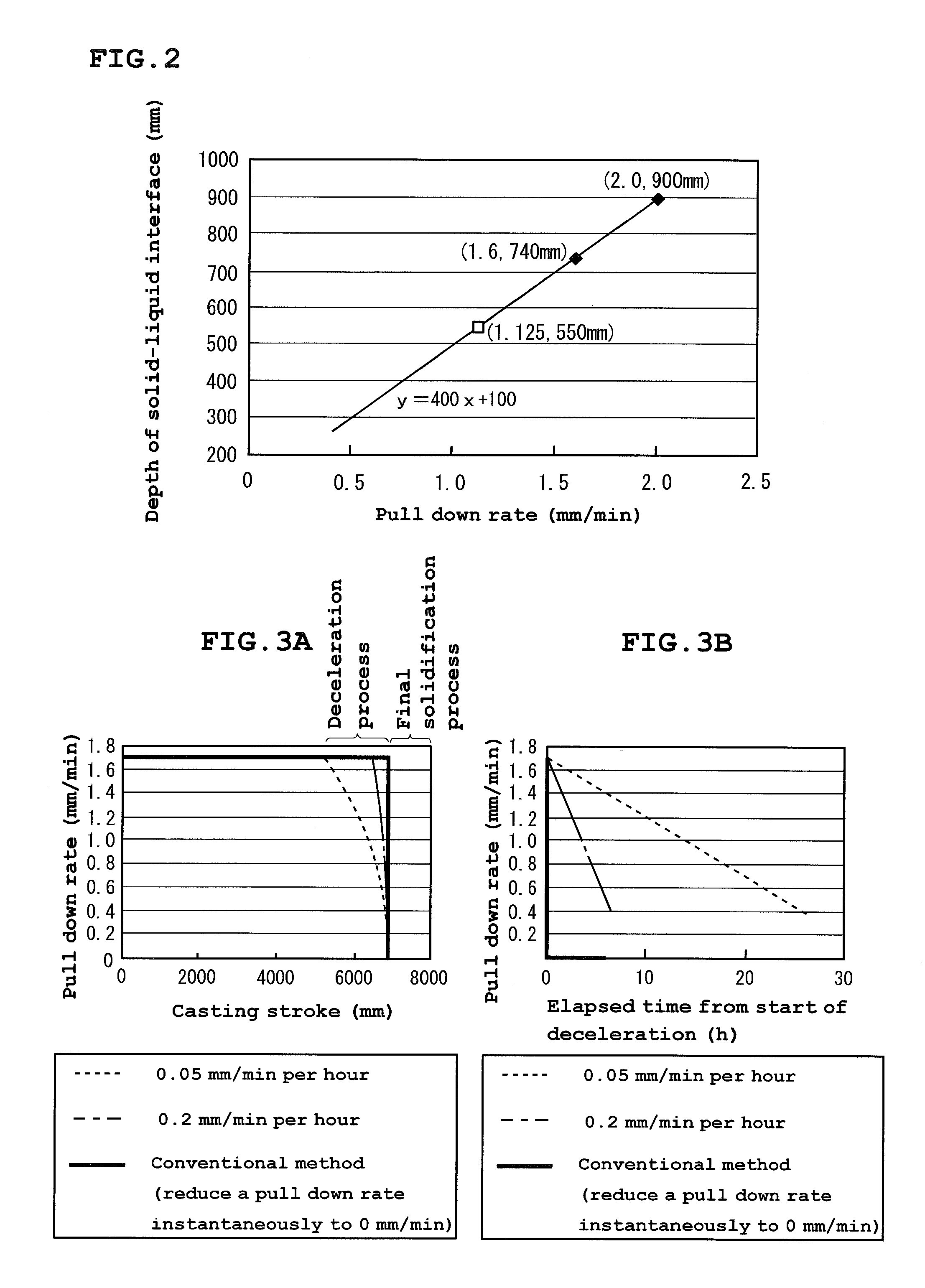

ActiveUS20130255315A1Confinement of molten silicon inside the solidified portion can be preventedImprove production yieldPolycrystalline material growthBlowing machine gearingsElectromagnetic castingSolar cell

Disclosed is an electromagnetic casting method of polycrystalline silicon which is characterized in that polycrystalline silicon is continuously cast by charging silicon raw materials into a bottomless cold mold, melting the silicon raw materials using electromagnetic induction heating, and pulling down the molten silicon to solidify it, wherein the depth of solid-liquid interface before the start of the final solidification process is decreased by reducing a pull down rate of ingot in a final phase of steady-state casting. By adopting the method, the region of precipitation of foreign substances in the finally solidified portion of ingot can be reduced and cracking generation can be prevented upon production of a polycrystalline silicon as a substrate material for a solar cell.

Owner:SUMCO CORP

Electromagnetic casting method for aluminium-1% silicon fine wire masterbatch for integrated circuit linkage

The present invention relates to MF and HF continuous elecromagnetic casting and LF electromagnetic stirring process for preparing aluminum -1% silicon fine wire masterbatch for IC linkage. Into one special 6-120 mm inner diameter induction crystallizer, current of 1000-100000 Hz and current of 5-100 Hz are separately fed to generate electromagnetic field, so that liquid metal is suspended insidethe crystallizer. Under the action of strong electromagnetic stirring and strong water spraying cooling, liquid metal is oriented and solidified fast to realize continuous casting. The features includes excellent surface quality, homogeneous element components without segregation, compact and fine crystal structure, good ventilation, less pinhole and less oxide inclusion.

Owner:黄国兴

Silicon electromagnetic casting device

ActiveCN101830465AResistance to deformation pressureAvoid deformationSilicon compoundsElectromagnetic castingCrucible

The invention discloses a silicon electromagnetic casting device. The device comprises a furnace body container, a crucible with conductivity arranged in the furnace body container and an induction coil arranged on the periphery of the crucible, wherein the designated gas with some pressure is filled in the furnace body container; after the induction coil in the silicon electromagnetic casting device is energized, silicon in the crucible is heated through induction, melted and then solidified; and rigid structures made of insulation material are embedded on the periphery surface of the crucible. By using the invention, when melted silicon infiltrates in small gaps between the solidified silicon ingot and the crucible and performs setting expansion to exert pressure on the internal surfaceof the crucible, the rigid structures embedded on the periphery of the crucible act to resist deformation pressure so that the outward deformation of the crucible can be avoided, the crucible can be protected and the production can continues.

Owner:丽达科技有限公司 +1

Oxygen-free copper strip horizontal electromagnetic casting device

InactiveCN102179490AImprove material performanceReduce broken belt rateElectromagnetic castingMedium frequency

The invention relates to an oxygen-free copper strip horizontal electromagnetic casting device and belongs to oxygen-free copper strip production and processing matched equipment. The oxygen-free copper strip horizontal electromagnetic casting device comprises a crystallizer shell, a medium-frequency power supply, an induction coil, an electromagnetic oscillator, a shielding cover, a cooling water tank, a bottom die and a pouring mechanism; the pouring mechanism consists of a tundish and a pouring gate plug; the tundish is arranged on the upper part of the crystallizer shell; the bottom of the crystallizer shell is provided with a pouring gate; the pouring gate plug is arranged in the pouring gate; the tundish is communicated with the upper part of the crystallizer shell through the pouring gate; the upper part of the crystallizer shell is provided with the induction coil; the electromagnetic oscillator is connected with the induction coil; the induction coil is connected with the medium-frequency power supply; the induction coil is formed by winding pure copper of which the section is rectangular; the circulating cooling water is filled in the hollow part of the induction coil for the primary cooling; a cooling water box and a shower pipe are arranged on the lower part of the crystallizer shell, and spray water to cool the crystallized stripped copper blank for the secondary cooling; and the bottom of the crystallizer shell is provided with the bottom die.

Owner:ZHONGTIAN ALLOY TECH

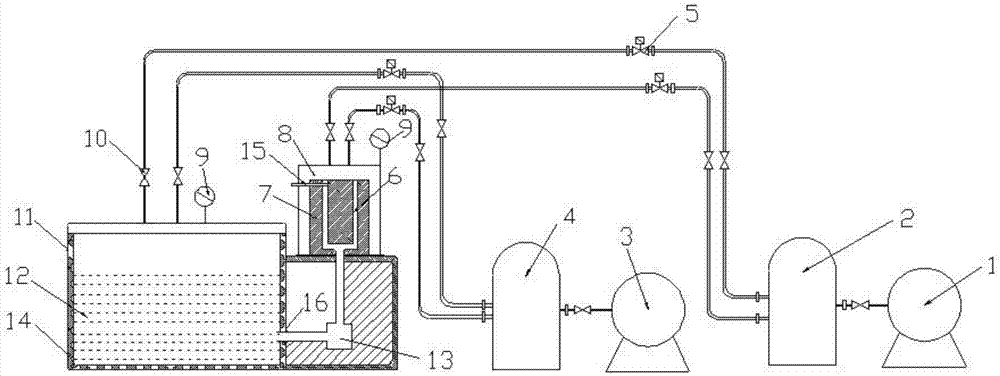

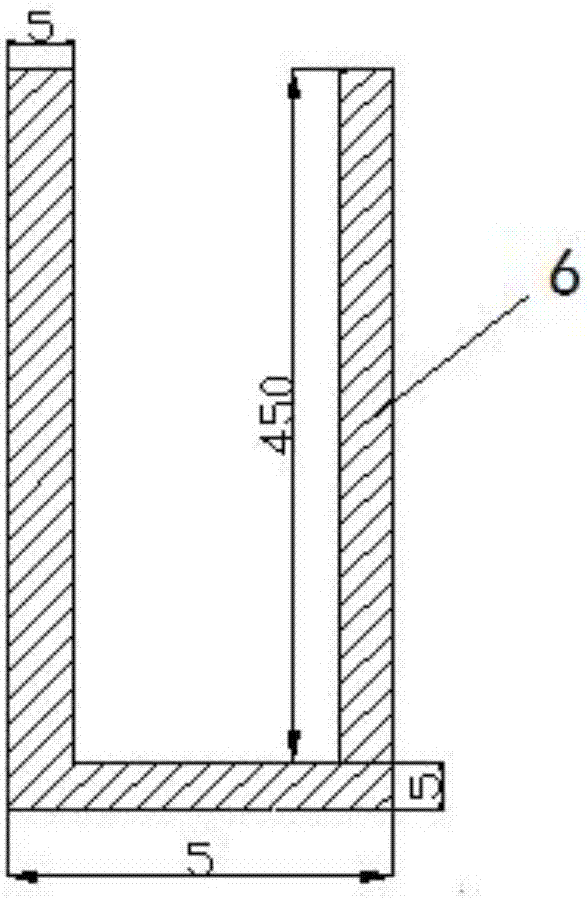

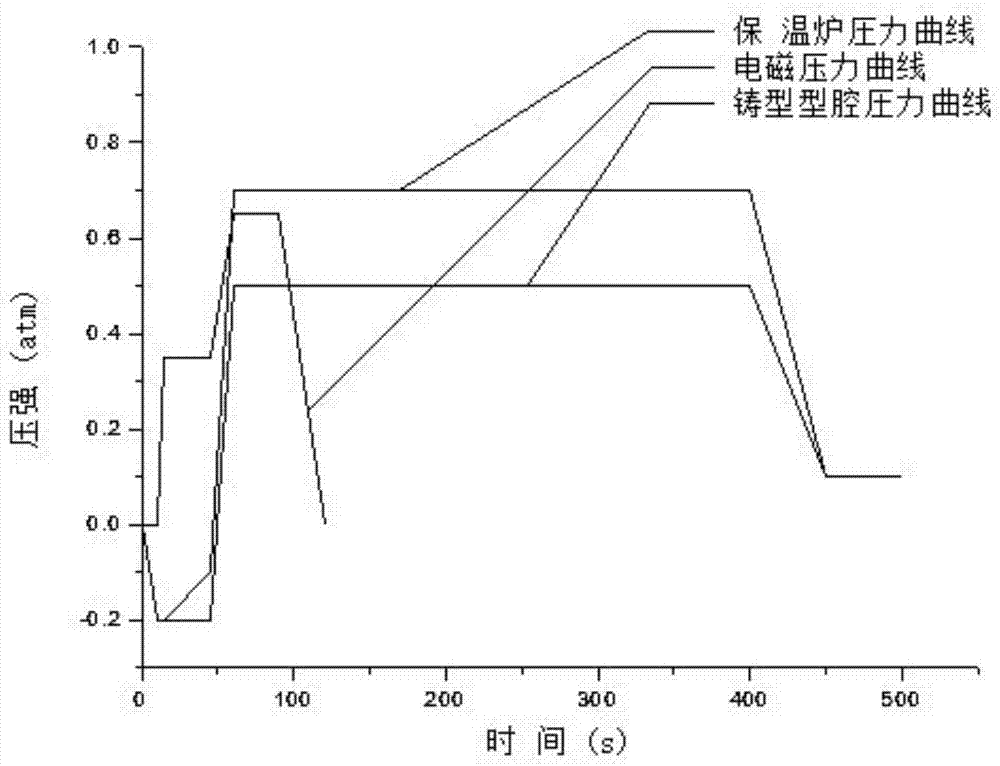

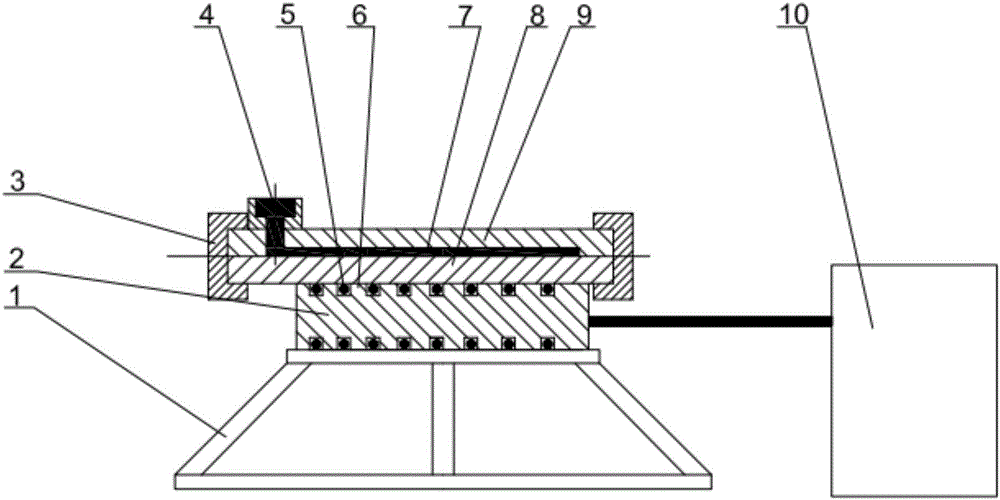

Electromagnetic casting system

InactiveCN107570690AInhibited porosityGuaranteed complete fillingVacuum pumpingElectromagnetic casting

The invention belongs to the technical field of metal forming equipment, and particularly relates to an electromagnetic casting system. The system comprises a heat preservation device, an electromagnetic casting device, a vacuum device and a pressure device, wherein the heat preservation device comprises a heat preservation furnace; the electromagnetic casting device comprises a casting mold cavity; and the vacuum device and the pressure device are correspondingly connected with the heat preservation furnace and the casting mold cavity, and are used for carrying out vacuum pumping treatment and pressurization treatment on the heat preservation furnace and the casting mold cavity correspondingly. According to the electromagnetic casting system, on the basis of electromagnetic casting, the vacuum pumping treatment is carried on metal liquid contained in the heat preservation furnace and pressure is slowly applied to the metal liquid during casting, and the vacuum pumping treatment and pressurization operation are also carried out in a casting mold region, thus the phenomenon of air holes generated during casting of the metal liquid is avoided, the quality of a casting piece is improved, the situations that mold filling of the metal liquid is complete and solidification is achieved according to a preset solidification process are guaranteed, and the service life of an electromagnetic pump is further prolonged.

Owner:北京北方恒利科技发展有限公司

Electromagnetic casting process applied to high-precision complex cupronickel ternary alloy production

InactiveCN106702296AImprove distributionEliminate defects such as segregationElectromagnetic castingCupronickel

The invention belongs to the technical field of ternary alloy production application, and in particular relates to an electromagnetic casting process applied to high-precision complex cupronickel ternary alloy production. The process comprises the following steps: S1) cleaning a copper raw material and ingredients; S2) smelting the cleaned copper raw material and ingredients through a smelting furnace; and S3) firstly pouring a smelted solution in the step 2 into a device provided with an electromagnetic coil to generate an electromagnetic force for electromagnetic treatment. The electromagnetic casting process applied to high-precision complex cupronickel ternary alloy production provided by the invention has the beneficial effects that a liquid metal is solidified in a solid state; in co-melting of a solid and a liquid, the electromagnetic force is generated by the electromagnetic coil, and an electromagnetic field is applied to the metal to improve metal flow and distribution of a solute, so that the defects such as segregation on the surface of an ingot and in the ingot are effectively eliminated and fine and uniform crystal structures are obtained so as to improve the product quality, and therefore, the product yield is improved and the production and economical cost is lowered.

Owner:江苏兴成新材料有限公司

Lug copper material production technology

ActiveCN109304371AGuaranteed thermal conductivityGuaranteed bending effectRollsWork cleaning devicesElectricityElectromagnetic casting

The invention discloses a lug copper material production technology which comprises the following steps: adopting an oxygen-free copper furnace to carry out electromagnetic casting on high-purity cathode copper to prepare ingot blank; carrying out hot rolling first and then online cooling on the ingot blank; carrying out finish-milling on surfaces: carrying out finish-milling on double surfaces twice, and scrubbing with clear water; rough rolling and cogging: carrying out two-rack four-pass rolling; adopting rapid abrasive to clean and remove oil, and carrying out refined scrubbing with the abrasive; cleaning again after annealing; rolling and cleaning with all oil having no chromatic aberration; rapidly annealing and cleaning without scrubbing grains; rolling to obtain a finished productwith all oil having no chromatic aberration; rapidly cleaning and removing oil; annealing and cleaning without scrubbing grains; and carrying out lossless shearing and withdrawing-straightening on thefinished product to obtain a lug copper strip. With adoption of the lug copper material production technology, the electricity and heat conduction performance and the bending performance of the copper strip can be effectively ensured, the surface defect can be effectively removed, the surface pollution caused by emulsion and rolling oil is reduced, the surface is prevented from the scrubbing grains, scratch and other defects, nickel plating of the copper strip during the following machining process is tighter and more uniform, and the service life of a lug processed in the following process can be prolonged to 10 years.

Owner:中铜华中铜业有限公司

Aluminum silicon carbide differential pressure electromagnetic casting equipment

PendingCN114523093AImprove molding efficiencyImprove molding qualityMolten metal conveying equipmentsCarbide siliconElectromagnetic casting

The invention relates to the technical field of electromagnetic casting, in particular to aluminum silicon carbide differential pressure electromagnetic casting equipment which comprises a smelting device and an electromagnetic forming device, the smelting device comprises a smelting cavity, a graphite crucible and an electric heating mechanism, the graphite crucible is arranged in the smelting cavity, and the electric heating mechanism is arranged in the smelting cavity; the electromagnetic forming device comprises a forming cavity provided with an electromagnetic field generator, after the electromagnetic field generator is started, an electromagnetic field can be generated in the forming cavity, forming molds are arranged in the forming cavity, and a silicon carbide prefabricated body is placed in each forming mold. And additional driving force is provided for the infiltrating process of the aluminum alloy melt in the silicon carbide prefabricated body, the compactness of the aluminum silicon carbide composite material is improved, generation of microdefects in the composite material is avoided, and the use safety is high.

Owner:苏州思萃热控材料科技有限公司

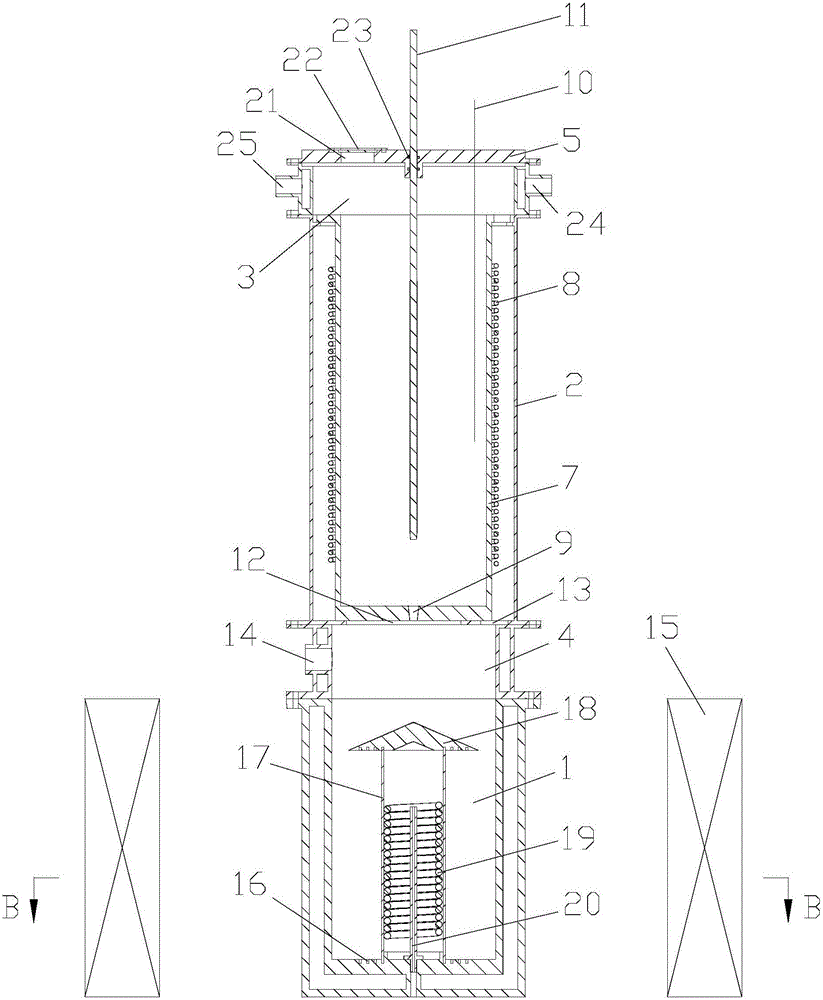

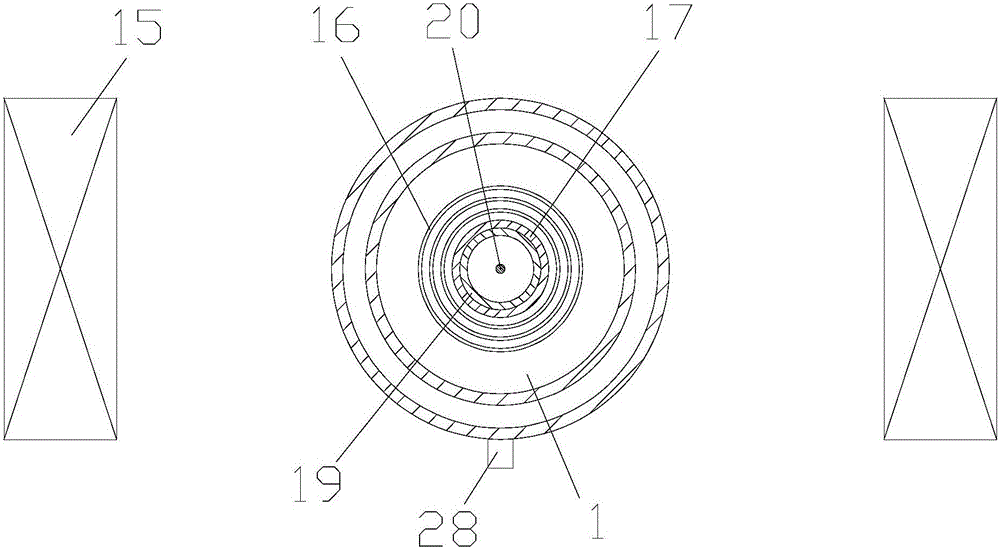

Solidification orientation device under magnetic field

The invention relates to a solidification orientation device under a magnetic field, and belongs to the technical field of electromagnetic casting. The device comprises a cylindrical cooling copper die connected with a shell through a second flange, the shell is connected with a sealing cover through a first flange, an air inflation hole is formed in the first flange, a crucible is fixed in the shell, and a gap is reserved between the crucible and the shell and communicated with the first flange; the outer wall of the crucible is wound with an induction heating coil, a casting opening is formed in the bottom of the crucible, a casting control lever is arranged in the crucible, and the casting opening can be plugged in a casting sealing manner when the casting control lever downwards moves; a through hole and an air through hole are formed in the bottom of the shell, the gap and the second flange are communicated through the air through hole, and an exhaust hole is formed in the second flange; and a steady-state magnetic field generator is arranged outside the cooling copper die, a base plate of the cooling copper die is provided with a ring-shaped groove homocentric with the inner wall of the cooling copper die, a quartz tube is installed in the groove, and a conic diverter is arranged at the top of the quartz tube. The solidification orientation device is simple in structure and convenient to use; and studying of the included angle relationship between multiple different solidification organization growth directions and the magnetic field direction can be achieved in one experiment.

Owner:NORTHEASTERN UNIV

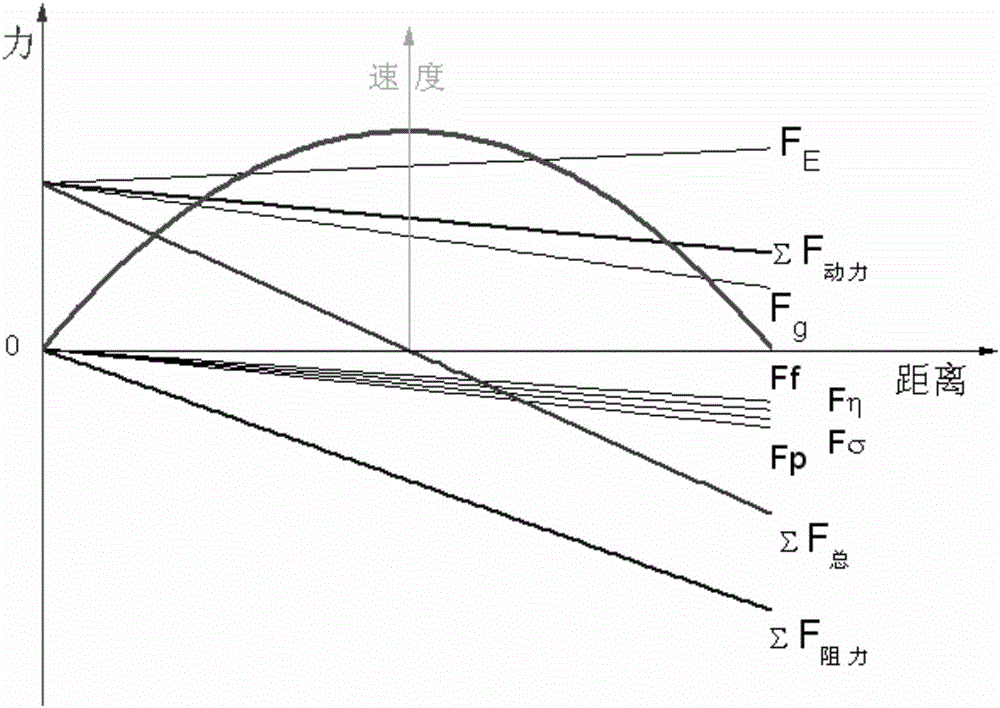

Progressively increased tooth pitch traveling wave magnetic field casting equipment and casting method

The invention relates to progressively increased tooth pitch traveling wave magnetic field casting equipment and a casting method. The casting equipment comprises a horizontally arranged metal melt filling device and a traveling wave magnetic field electromagnetic inductor located at the bottom of the metal melt filling device, wherein the traveling wave magnetic field electromagnetic inductor generates a traveling wave magnetic field by loading current, so that a metal melt in the metal melt filling device moves at constant speed for filling. By the use of the progressively increased tooth pitch traveling wave magnetic field casting equipment and the casting method, the progressively decreased traveling wave magnetic field can be obtained, so that alloy melt filling is steady, and recesses in the surface of a melt solidification process are eliminated; the production efficiency and the surface quality of traveling wave magnetic field casting can be effectively improved; and the technical obstacles are cleared away to comprehensively popularize electromagnetic casting.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Preparation of copper-chromium alloy contact material by aluminothermal reduction-electromagnetic casting process

ActiveCN100344777CLow costReduce energy consumptionContact materialsHigh-tension/heavy-dress switchesAl powderElectromagnetic casting

Owner:NORTHEASTERN UNIV LIAONING

A production process of tab copper material

ActiveCN109304371BGuaranteed thermal conductivityGuaranteed bending effectRollsWork cleaning devicesElectromagnetic castingMachining process

The invention discloses a lug copper material production technology which comprises the following steps: adopting an oxygen-free copper furnace to carry out electromagnetic casting on high-purity cathode copper to prepare ingot blank; carrying out hot rolling first and then online cooling on the ingot blank; carrying out finish-milling on surfaces: carrying out finish-milling on double surfaces twice, and scrubbing with clear water; rough rolling and cogging: carrying out two-rack four-pass rolling; adopting rapid abrasive to clean and remove oil, and carrying out refined scrubbing with the abrasive; cleaning again after annealing; rolling and cleaning with all oil having no chromatic aberration; rapidly annealing and cleaning without scrubbing grains; rolling to obtain a finished productwith all oil having no chromatic aberration; rapidly cleaning and removing oil; annealing and cleaning without scrubbing grains; and carrying out lossless shearing and withdrawing-straightening on thefinished product to obtain a lug copper strip. With adoption of the lug copper material production technology, the electricity and heat conduction performance and the bending performance of the copper strip can be effectively ensured, the surface defect can be effectively removed, the surface pollution caused by emulsion and rolling oil is reduced, the surface is prevented from the scrubbing grains, scratch and other defects, nickel plating of the copper strip during the following machining process is tighter and more uniform, and the service life of a lug processed in the following process can be prolonged to 10 years.

Owner:中铜华中铜业有限公司

Semi-continuous casting process of vw64m high-strength heat-resistant magnesium alloy billet

The invention discloses a semi-continuous casting process of a VW64M high-strength heat-resistant magnesium alloy big ingot blank. An alloy contains, by weight, 5.0-7.0% of Gd, 2.5-4.0% of Y, 0.1-0.3% of Ag, 0.15-1.0% of Zn, 0.25-0.65% of Zr, 0.002-0.050% of Ca and the balance Mg. The process mainly includes the following steps that a magnesium ingot is molten at the temperature ranging from 670 DEG C to 720 DEG C; a Mg-Ca intermediate alloy and a fluxing agent are added; alloy elements are added at the temperature of 750 DEG C to 800 DEG C; refining and slagging-off are performed; gas feeding and stirring are performed; the temperature is adjusted to reach 680 DEG C to 700 DEG C and maintained for still standing for 1.5-3.5 hours; and low-temperature low-speed electromagnetic casting is performed. By coordinating the process parameters of all the steps, the magnesium alloy ingot blank being free of cracks, smooth in surface, small in grain size, uniform in structure and free of solute segregation and having the diameter phi of 300-630 mm and the length of at least 1000 mm is obtained.

Owner:CENT SOUTH UNIV

A kind of preparation method of high-strength wear-resistant alloy cu-15ni-8sn

The invention discloses a preparation method for a high-strength wear-resistant alloy Cu-15Ni-8Sn. The process comprises the following steps: adding electrolytic copper and nickel; pouring the electrolytic copper and nickel in an intermediate-frequency coreless induction furnace; adding charcoal; charging nitrogen gas with one barometric pressure; melting; melting for 30-65 minutes at 1300-1350 DEG C; adding tin and melting at 1250-1300 DEG C; adding a refiner and a deoxidizer; stirring; adding a grain refiner; adding a modifier; slagging off; carrying out inspection before melting; carrying out electromagnetic casting after ingredients are qualified; cutting a head and a tail; scalping; carrying out ingredient inspection after melting; carrying out organization structure analysis; and carrying out performance detection. A Cu-15Ni-8SnC72900 alloy melt and cast by virtue of the intermediate-frequency coreless induction furnace, which is obtained by the preparation method disclosed by the invention, is low in production cost; and the developed products are high in quality. The developed products can be applied to national defense and military industry, ocean engineering and high-end preparation manufacturing industry; and the increasingly urgent needs of the national defense and military industry, ocean engineering and high-end preparation manufacturing industry on high-performance copper alloy materials are met.

Owner:JINCHUAN GROUP LIMITED

Silicon electromagnetic casting device

ActiveCN101830465BResistance to deformation pressureAvoid deformationSilicon compoundsElectromagnetic castingCrucible

The invention discloses a silicon electromagnetic casting device. The device comprises a furnace body container, a crucible with conductivity arranged in the furnace body container and an induction coil arranged on the periphery of the crucible, wherein the designated gas with some pressure is filled in the furnace body container; after the induction coil in the silicon electromagnetic casting device is energized, silicon in the crucible is heated through induction, melted and then solidified; and rigid structures made of insulation material are embedded on the periphery surface of the crucible. By using the invention, when melted silicon infiltrates in small gaps between the solidified silicon ingot and the crucible and performs setting expansion to exert pressure on the internal surfaceof the crucible, the rigid structures embedded on the periphery of the crucible act to resist deformation pressure so that the outward deformation of the crucible can be avoided, the crucible can be protected and the production can continues.

Owner:丽达科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com