Patents

Literature

70results about How to "Guaranteed bending effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold-rolled martensite steel plate with yield strength of 750 MPa grade and manufacturing method thereof

ActiveCN107619993ALightweight effect is goodImproved Chemical Composition DesignUltimate tensile strengthMartensite

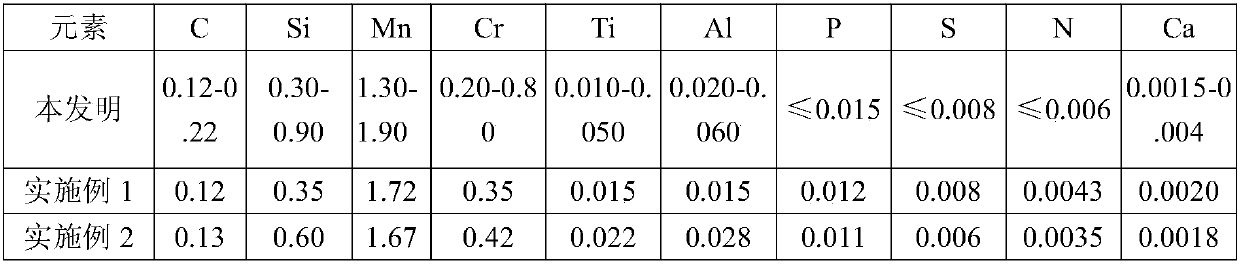

The invention relates to a cold-rolled martensite steel plate with yield strength of 750 MPa grade and a manufacturing method thereof, and mainly aims to solve the technical problem that the existingcold-rolled martensite steel plate with yield strength of 750 MPa grade is high in manufacturing cost. The cold-rolled martensite steel plate provided by the invention consists of the following chemical components in percentage by weight: 0.12-0.22% of C, 0.30-0.90% of Si, 1.30-1.90% of Mn, 0.20-0.80% of Cr, 0.010-0.050% of Ti, 0.020-0.060% of Al, less than or equal to 0.015% of P, less than or equal to 0.008% of S, less than or equal to 0.006% of N, 0.0015-0.004% of Ca and the balance of iron and inevitable impurities. The steel plate has yield strength of 790-830 MPa, tensile strength greater than 980 MPa, and percentage elongation after fracture A80 greater than or equal to 6%. The cold-rolled martensite steel plate is mainly used for manufacturing a truck boundary beam, a square tube stand column and the like.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Bending copper substrate PCB manufacture method

ActiveCN107072080AGuaranteed bending effectAvoid hiding waterMultilayer circuit manufactureEngineeringCopper foil

The invention provides a bending copper substrate PCB manufacture method. The bending copper substrate PCB manufacture method comprises steps of manufacturing a copper substrate, a manufacturing an optical plate, manufacturing a ruler, successively placing a PP, the optical plate, the copper substrate, a PP and a copper foil on copper foil to perform lamination and bending. The bending copper substrate PCB manufacture method uses laminating glue hole filling to replace resin hole filling, avoids water accumulating behind the resin-filled hole after browning, simplifies a working process and provides product stability. The bending copper substrate PCB manufacture method realizes the copper substrate PCB selective laminating through the optical plate and the ruler, and guarantees the bending effect of the copper substrate PCB.

Owner:SHENZHEN SUN & LYNN CIRCUITS

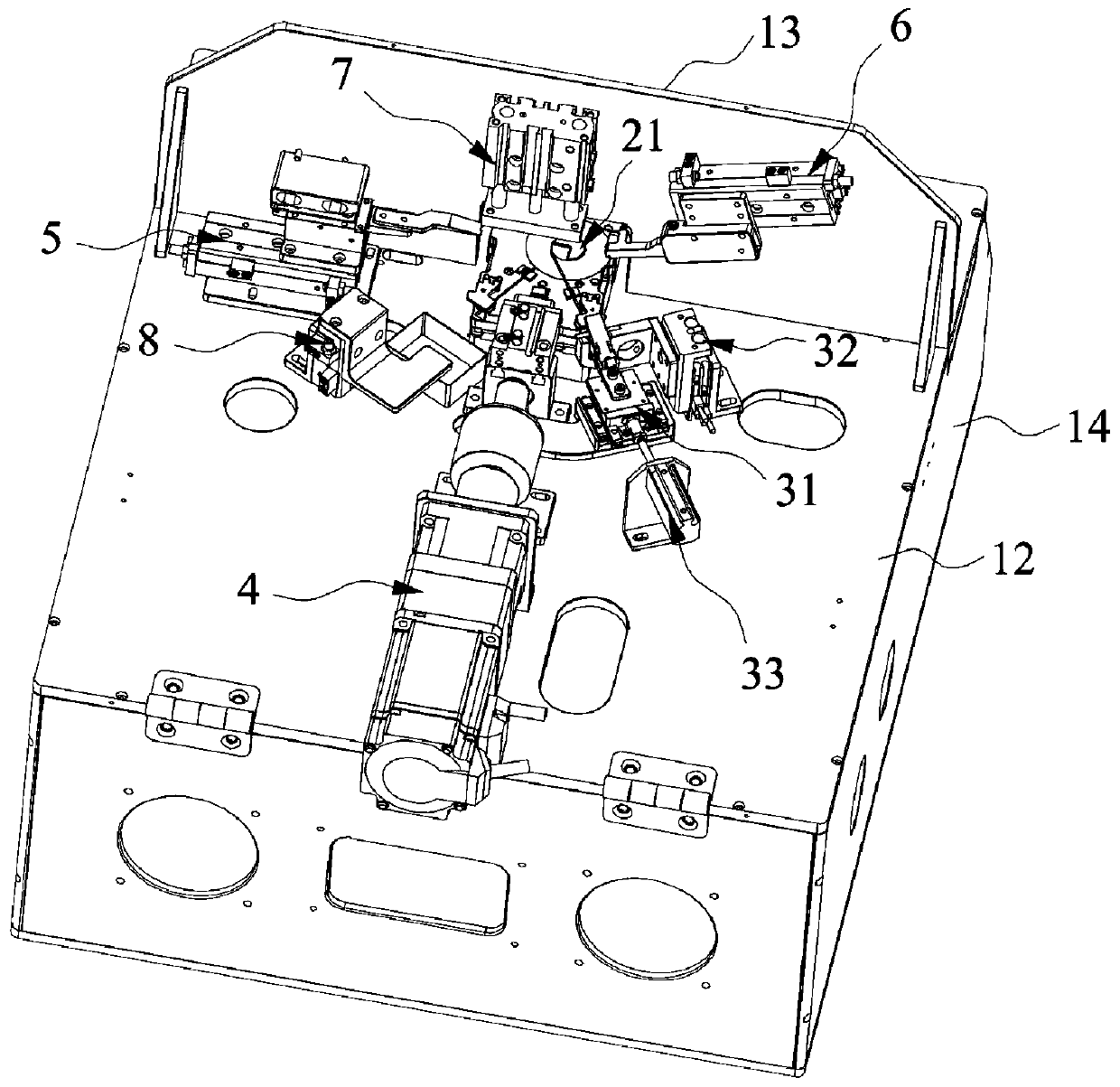

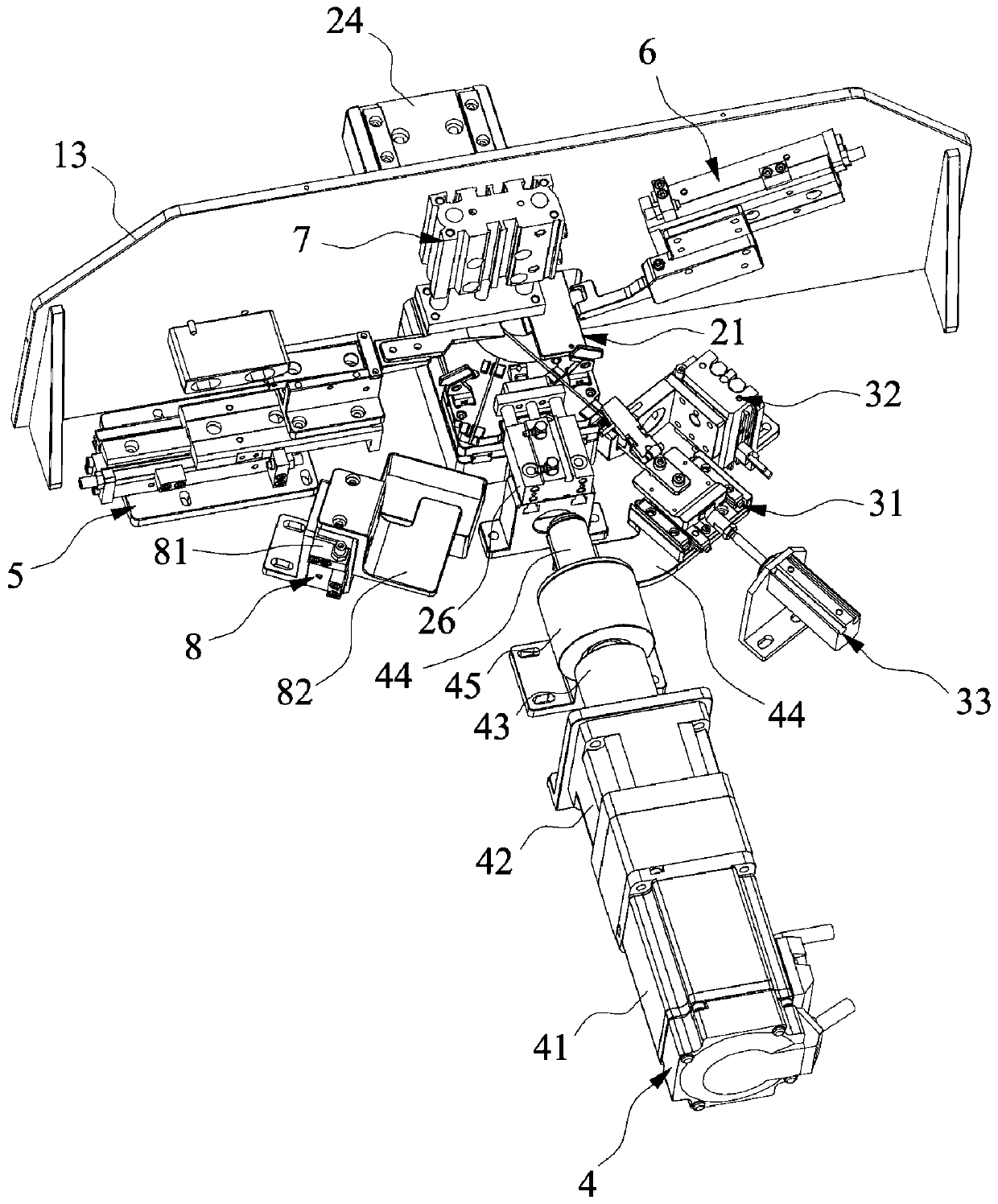

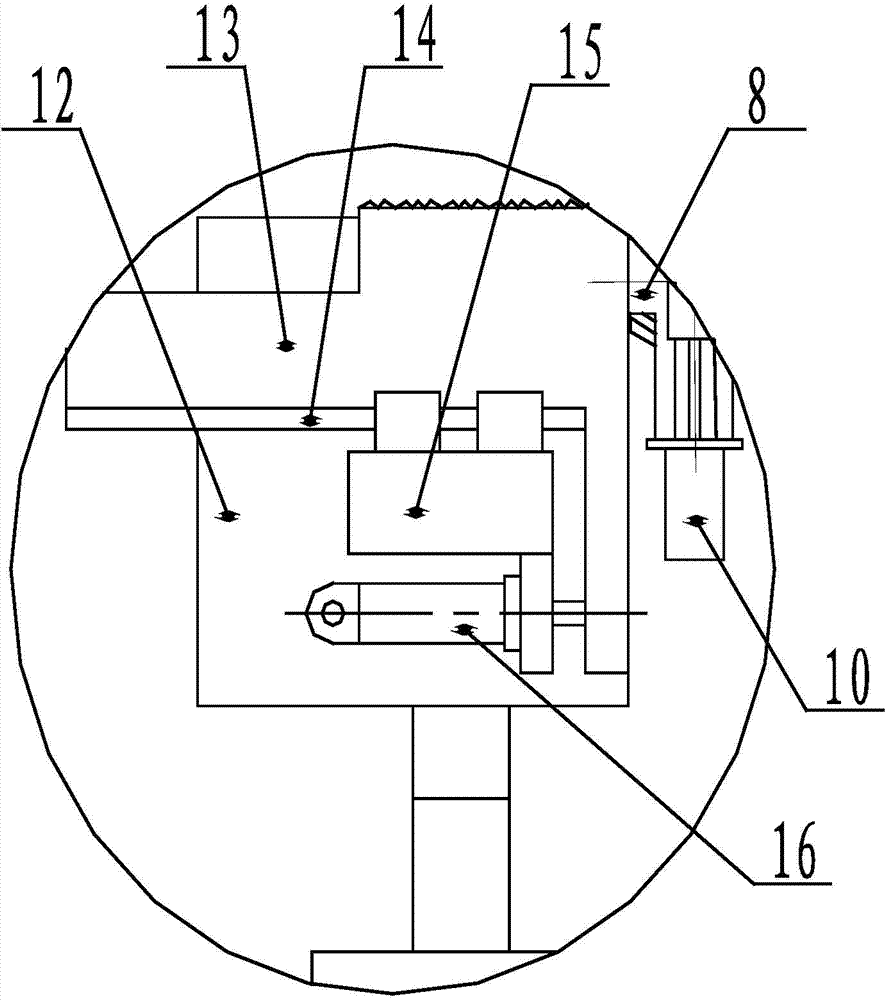

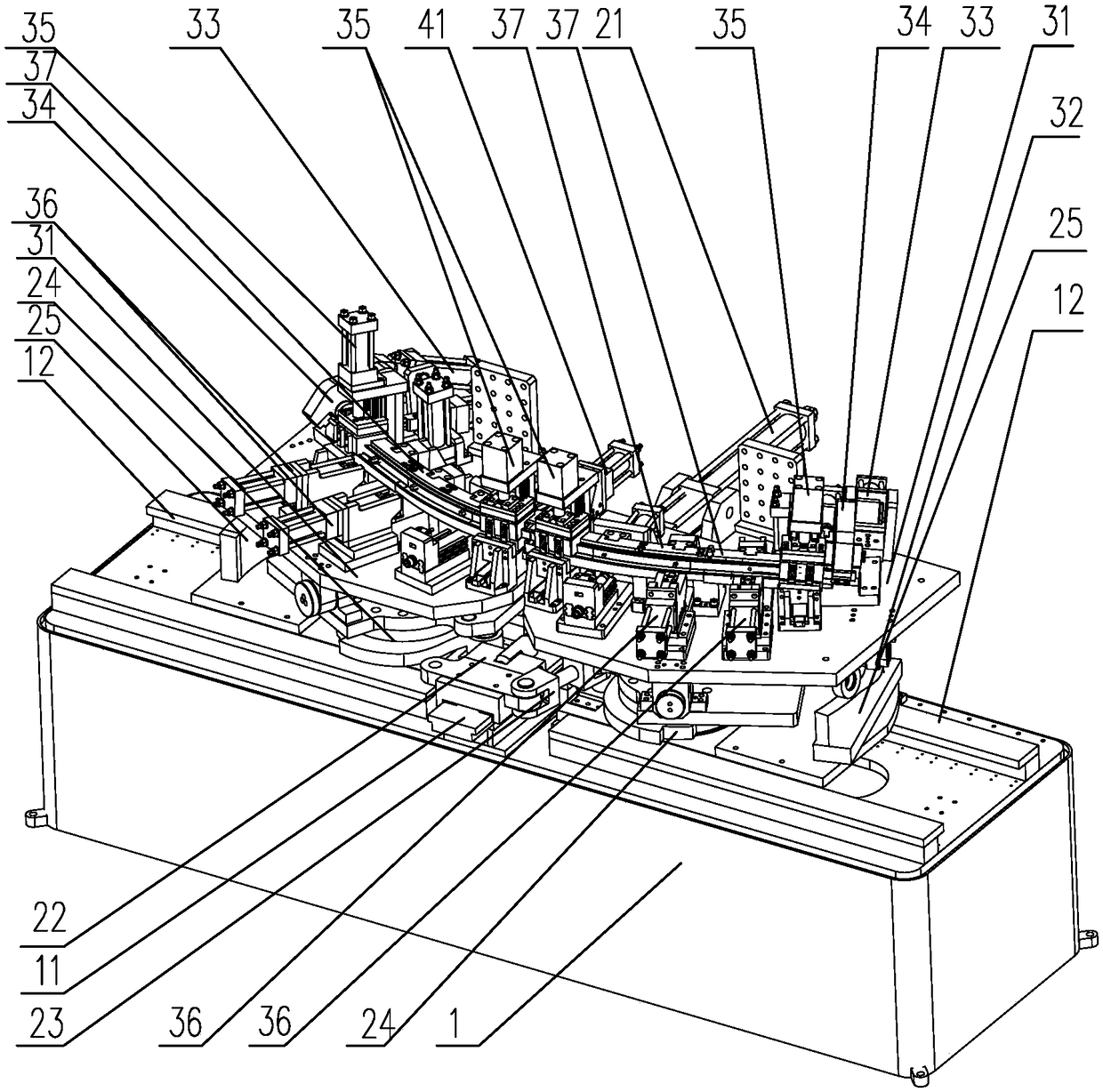

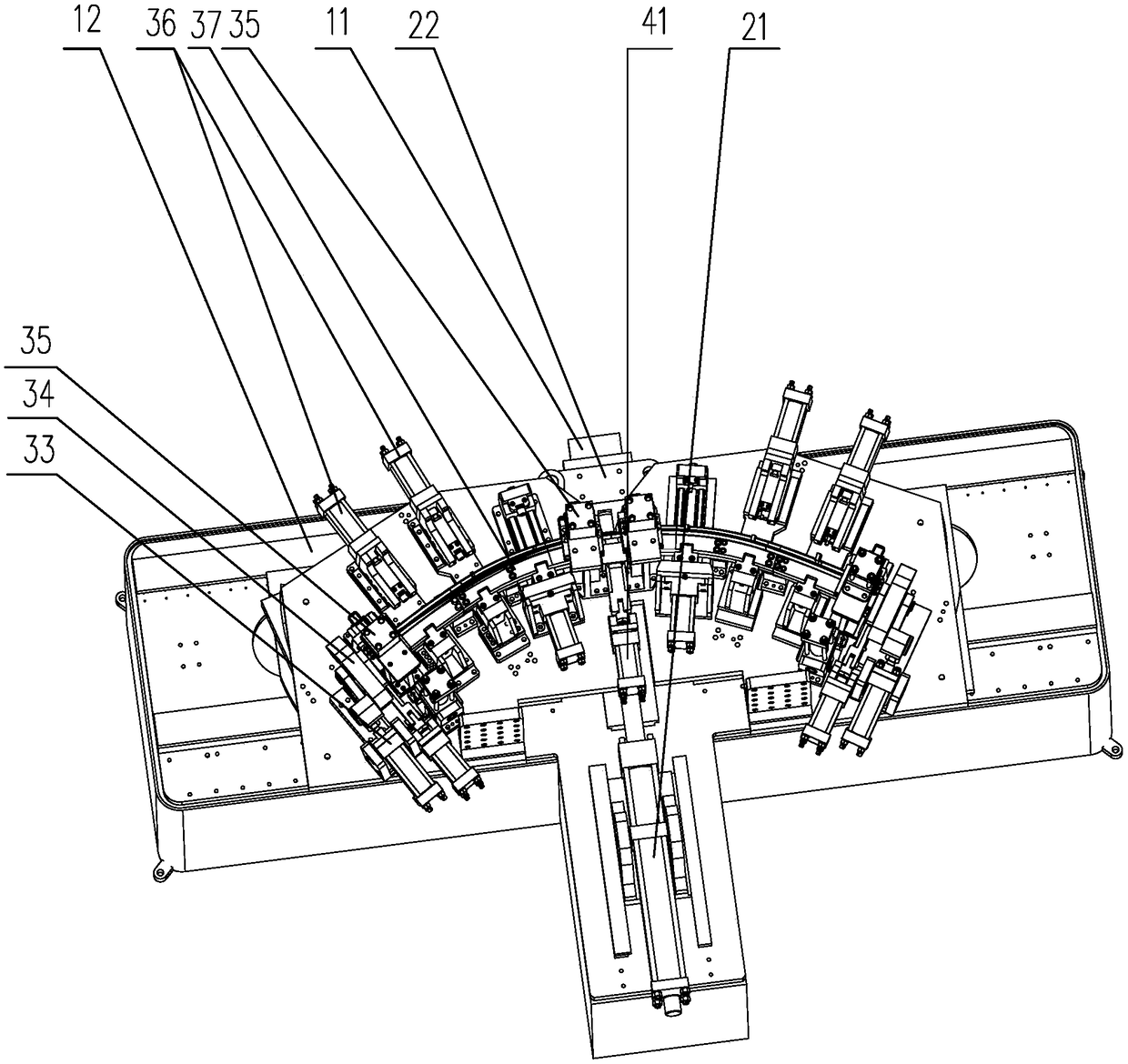

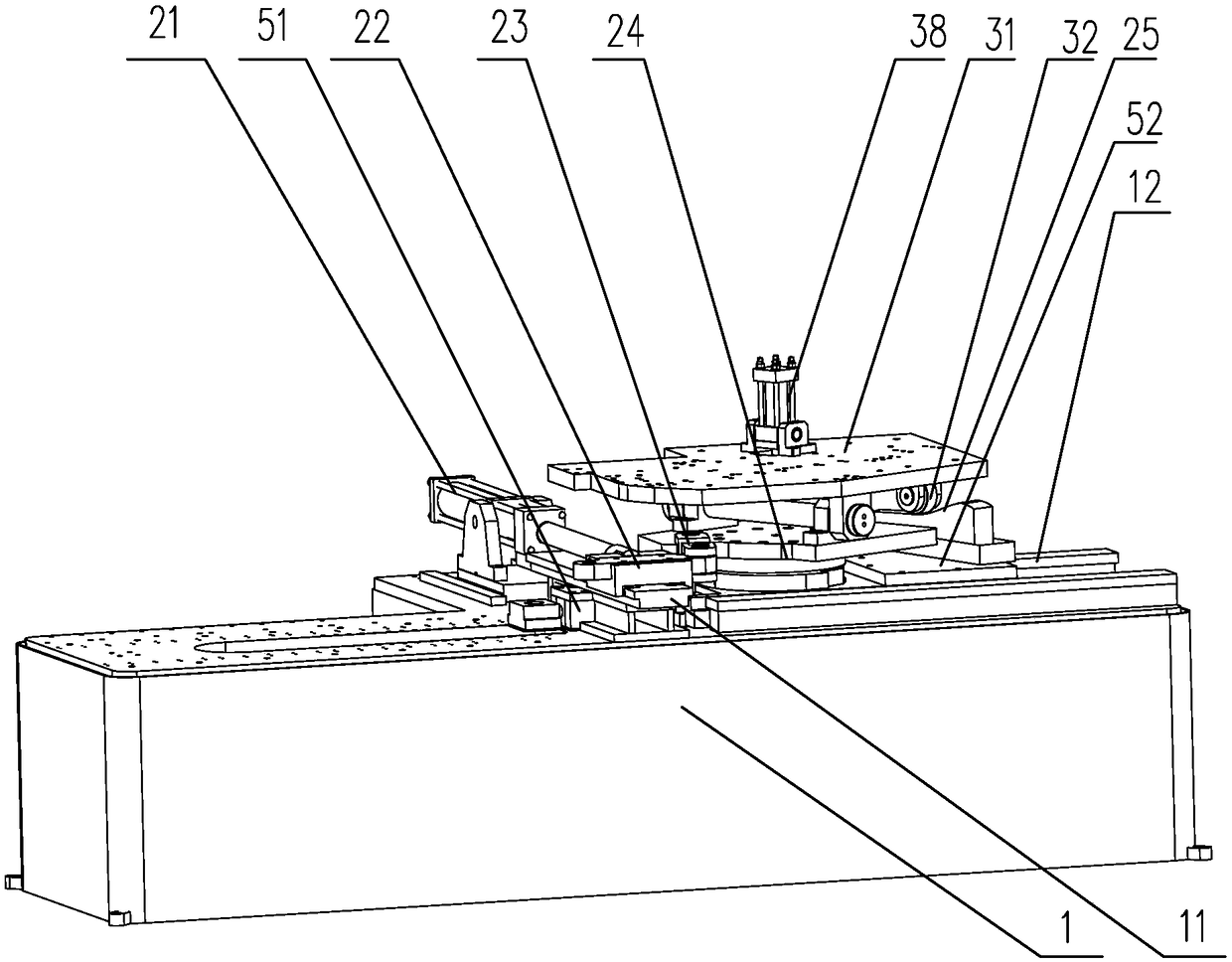

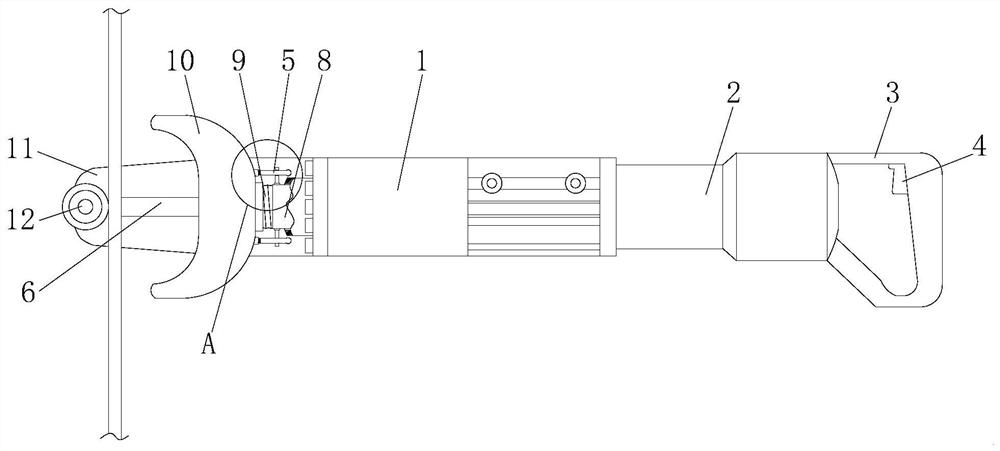

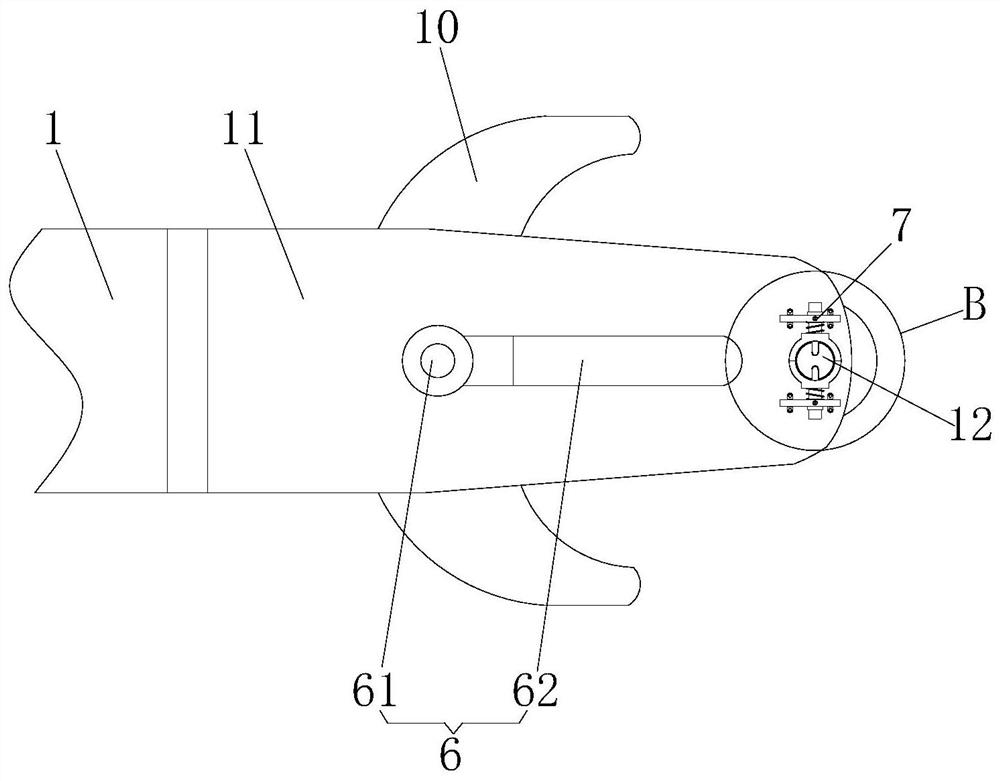

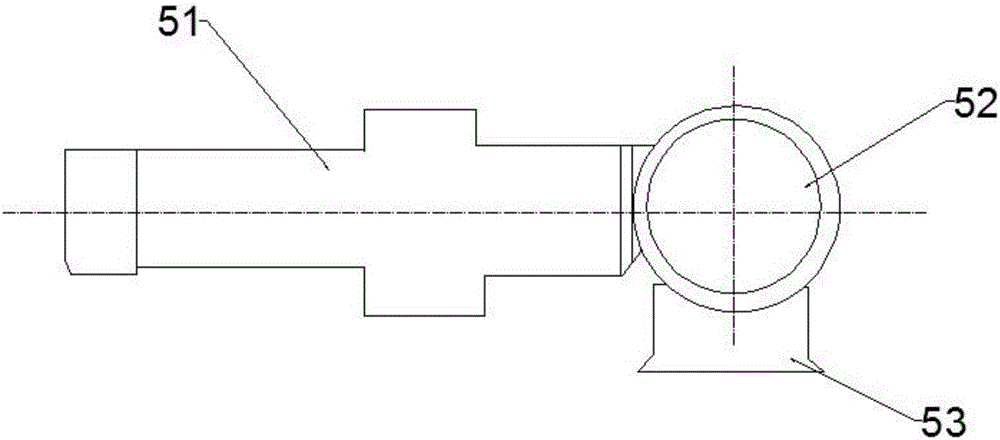

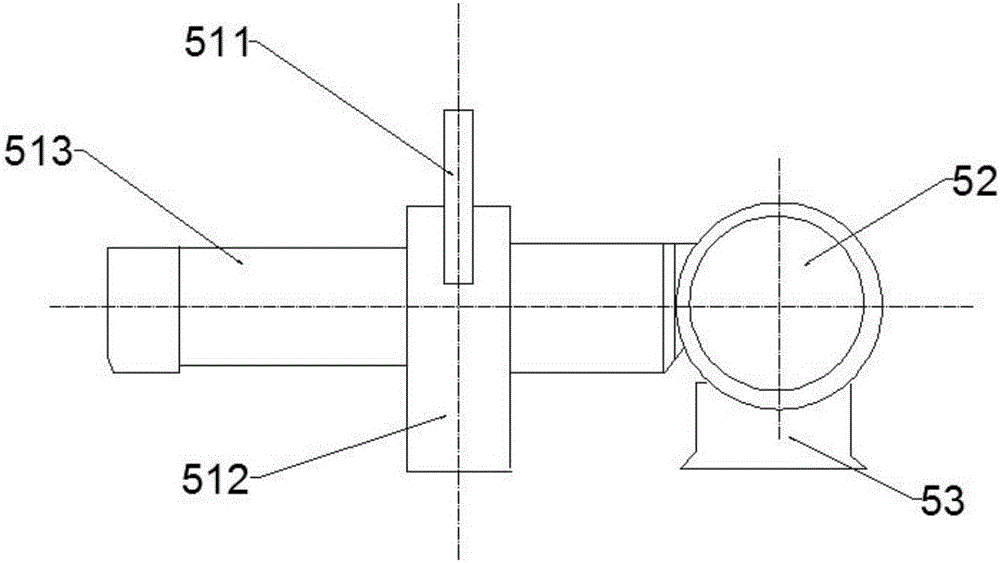

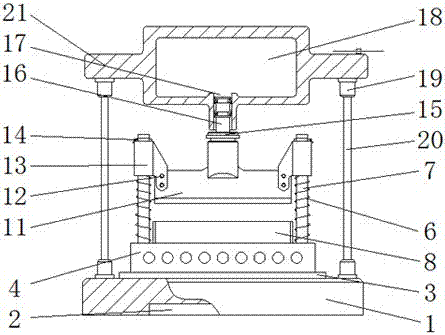

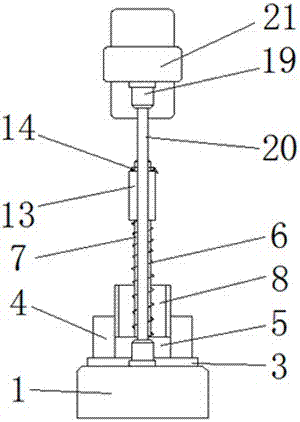

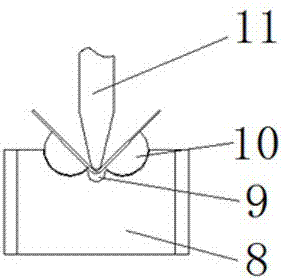

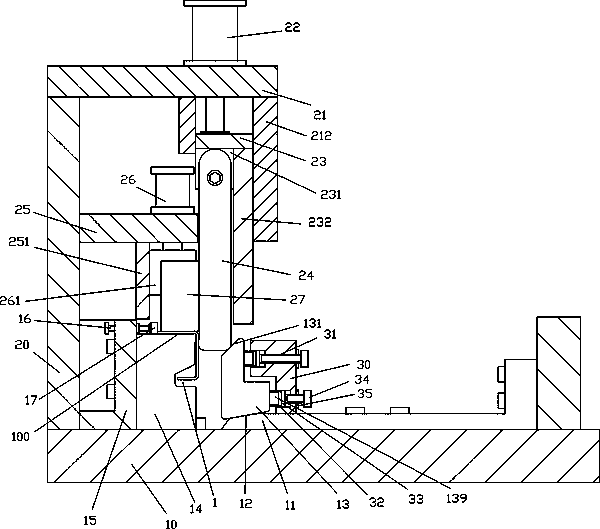

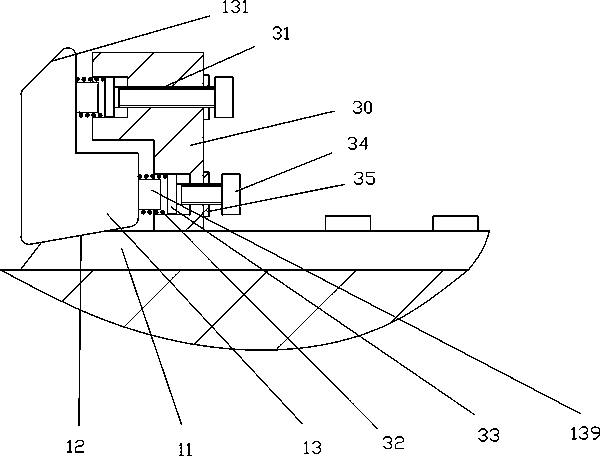

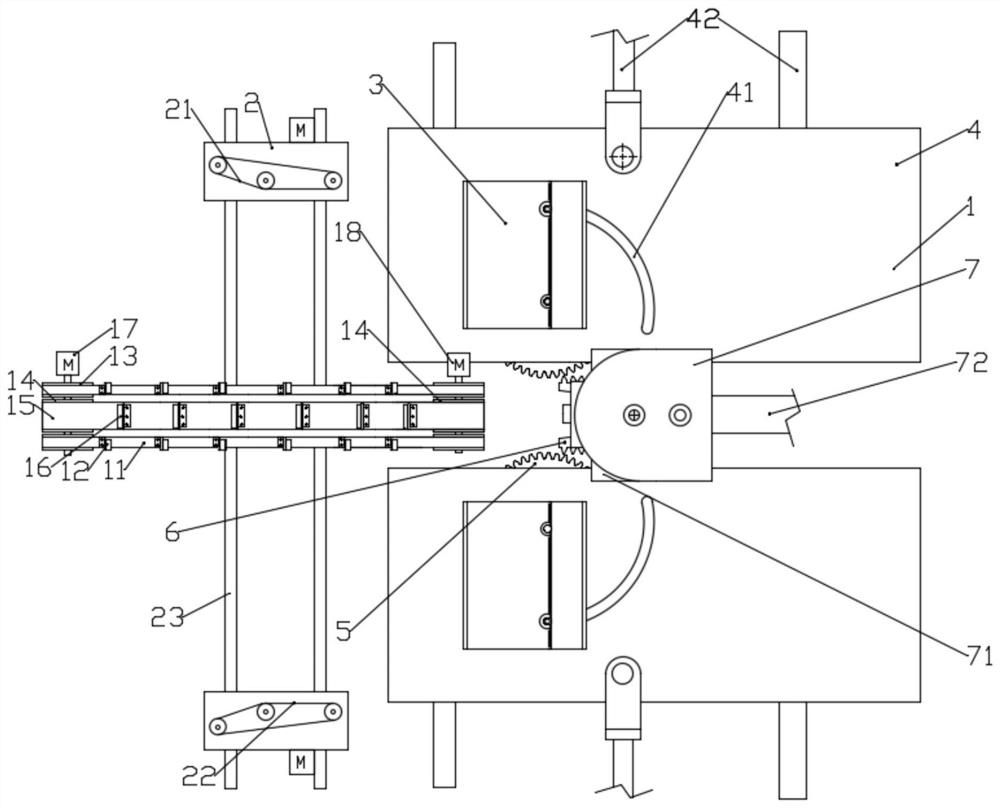

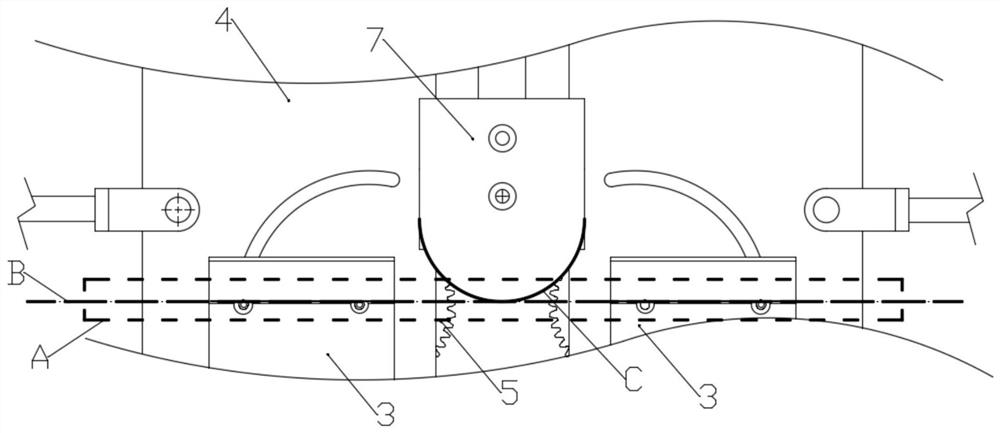

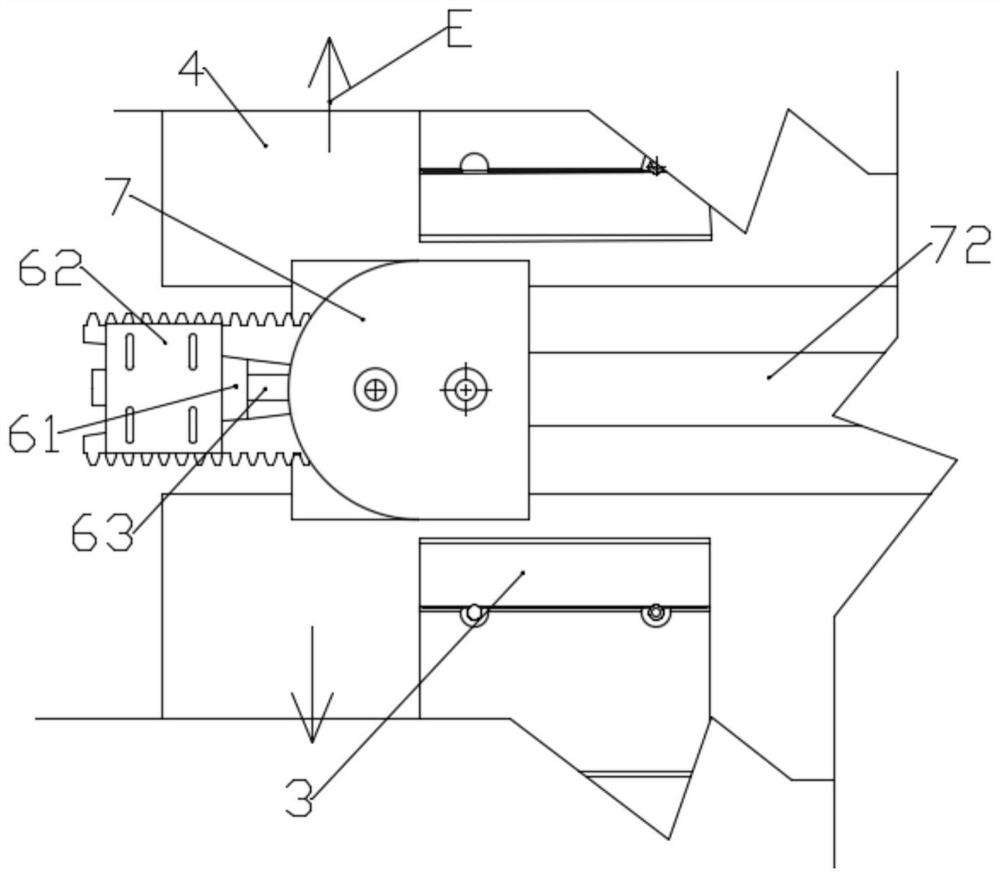

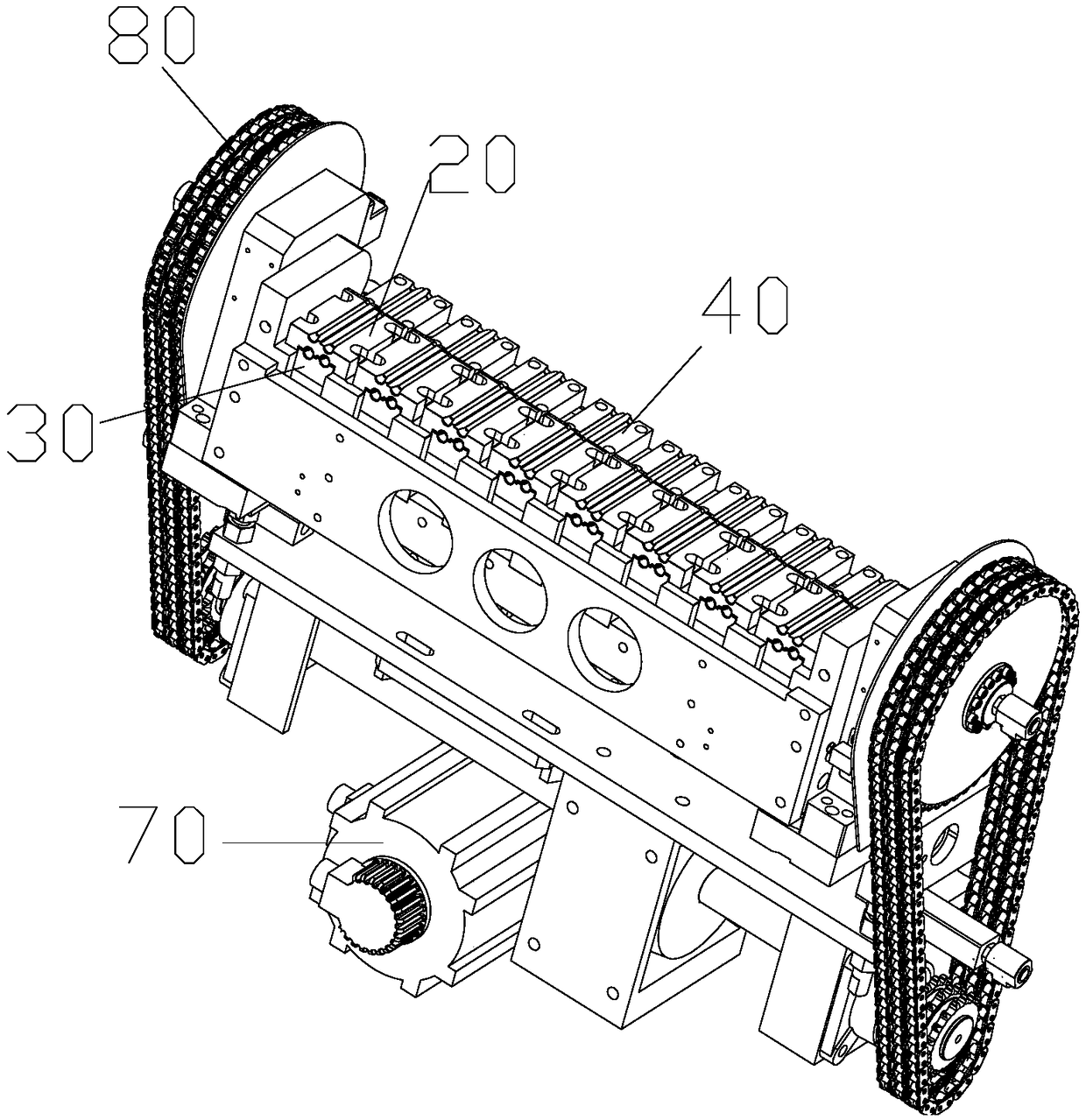

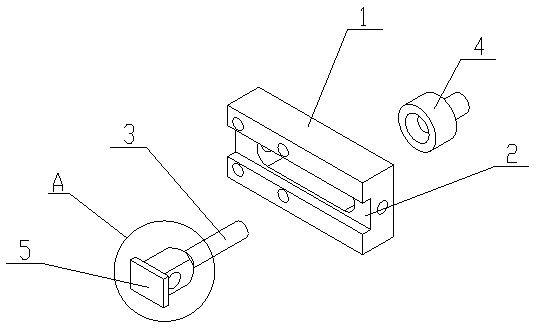

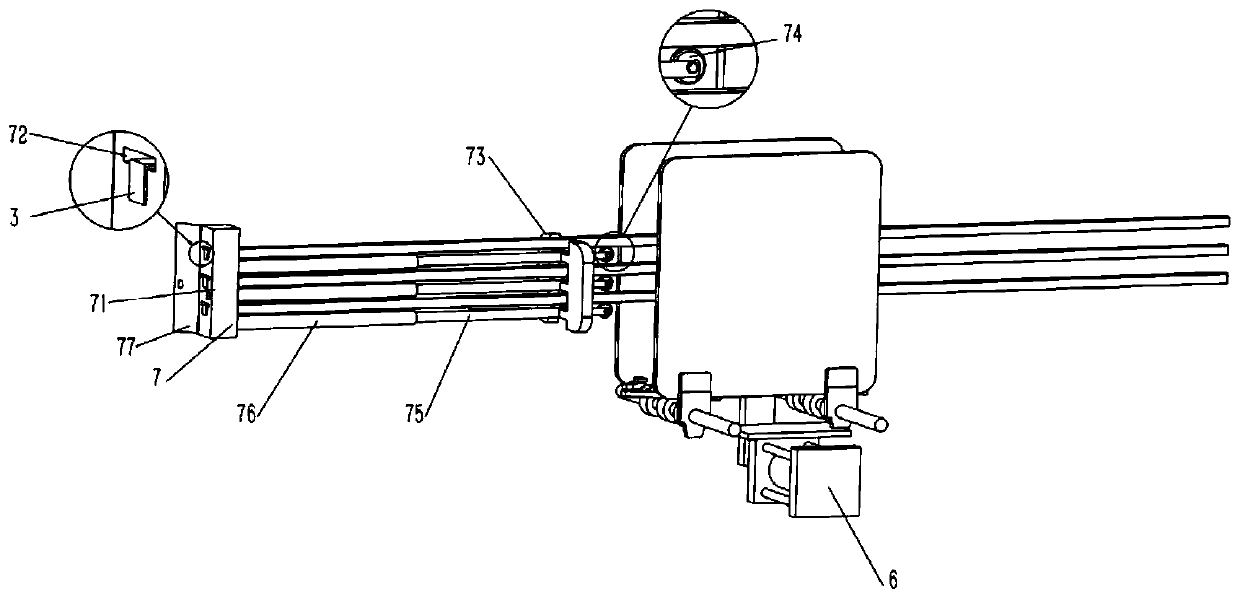

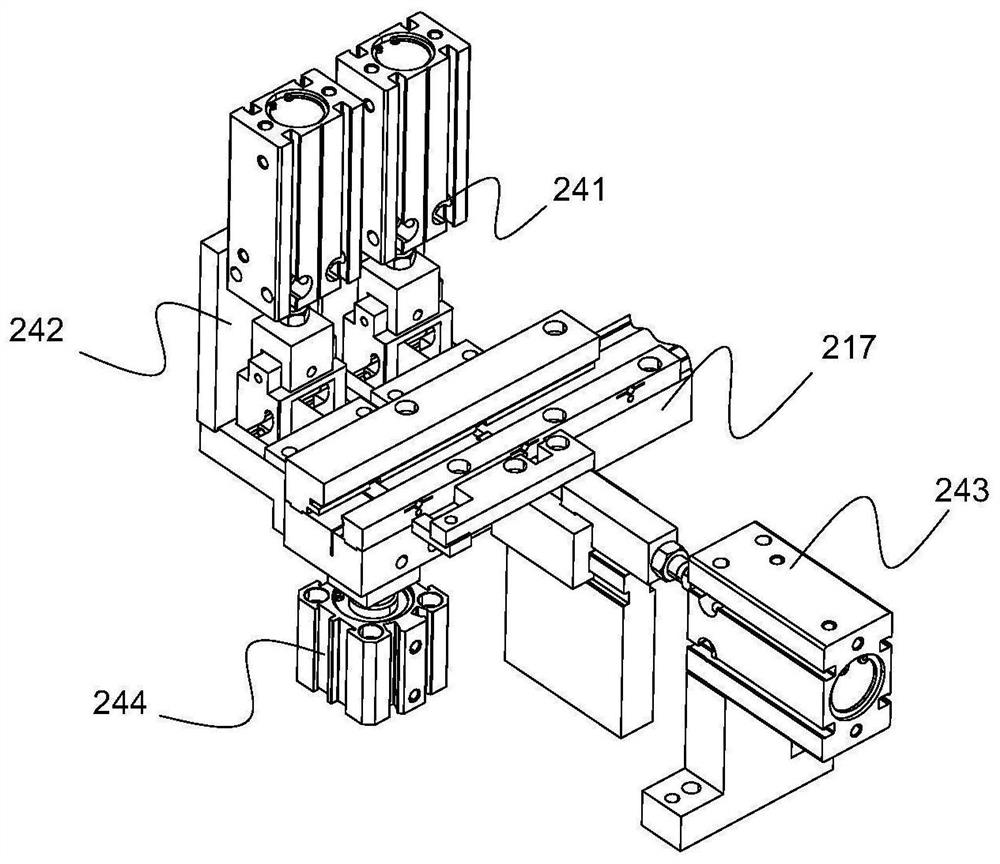

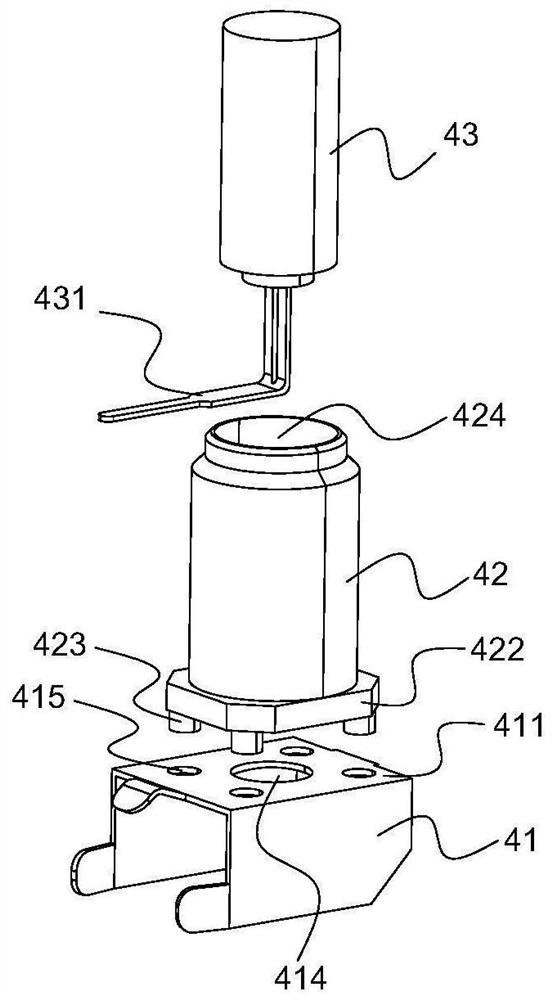

Automatic bending machine for coil conductor

ActiveCN110773667AImprove bending efficiencyReduce labor costsCoils manufactureElectrical conductorEngineering

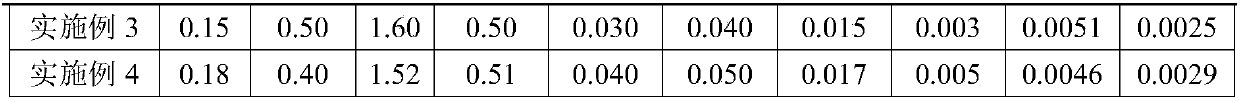

The invention relates to the technical field of bending machines, and particularly discloses an automatic bending machine for a coil conductor. The automatic bending machine for the coil conductor comprises a workbench, a carrier, a clamping jaw mechanism, a rotating mechanism and a tongue piece mechanism, wherein the carrier, the clamping jaw mechanism, the rotating mechanism and the tongue piecemechanism are arranged on the workbench; the carrier is used for fixing a coil body, the clamping jaw mechanism and the rotating mechanism are arranged at intervals, and the clamping jaw mechanism has a first position and a second position; when the clamping jaw mechanism is positioned at the first position, the tongue piece mechanism is used for abutting against the joint of the coil body and afirst conductor, and the clamping jaw mechanism is used for clamping the first conductor; and the rotating mechanism is used for driving the clamping jaw mechanism to rotate from the first position tothe second position so as to bend the joint. When the clamping jaw mechanism is positioned at the first position, the tongue piece mechanism abuts against the joint of the first conductor and the coil body, then the first conductor is clamped through the clamping jaw mechanism, and then the rotating mechanism is used for rotating, so that the joint of the first conductor and the coil body can beautomatically bent, the bending efficiency can be improved, and the labor cost can be reduced.

Owner:KUNSHAN LIANTAO ELECTRONICS CO LTD

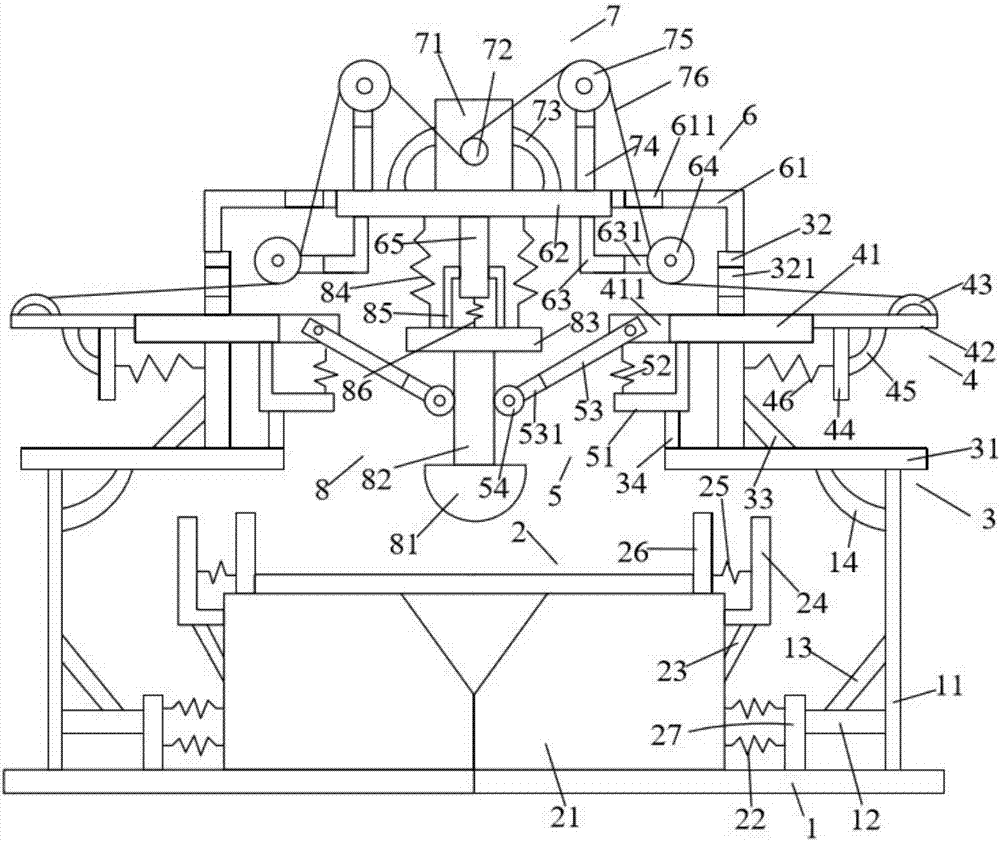

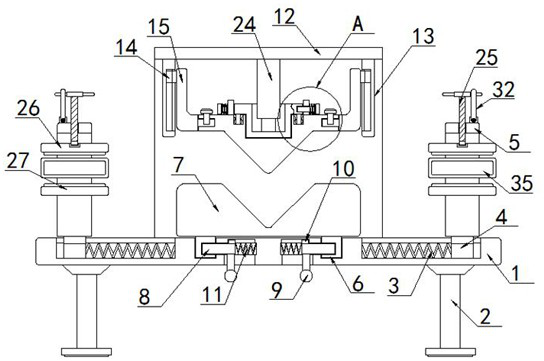

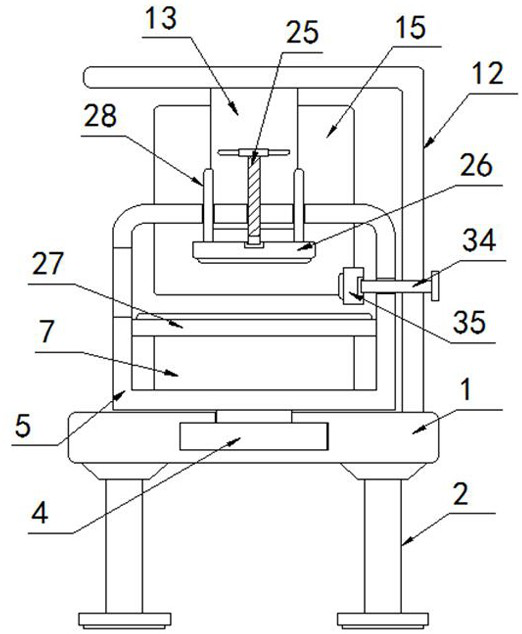

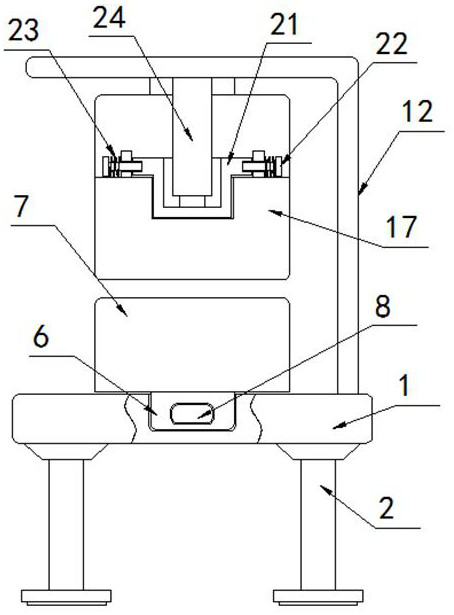

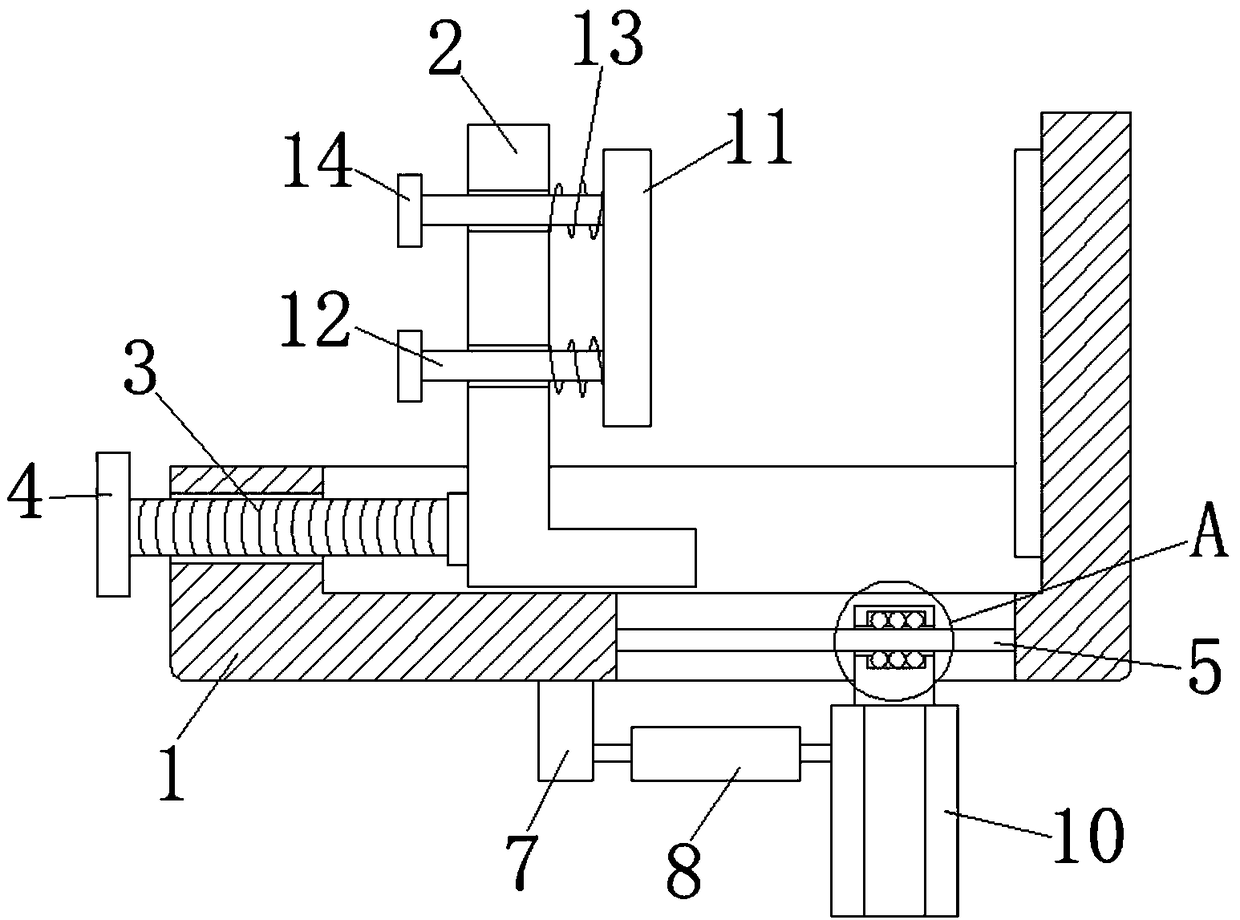

Rapid and efficient hardware plate bending system

ActiveCN106853468AImprove bending efficiencyEfficient and fast bendingMetal-working feeding devicesPositioning devicesEngineering

A rapid and efficient hardware plate bending system comprises a base plate, a supporting and fixing device, a support device, an abutting device, a roller device, a transverse plate device, a motor device and a pressing device, wherein a first supporting rod, a first cross rod, a first oblique rod and a first bent rod are arranged on the base plate, the supporting and fixing device comprises a supporting block, a first spring, a second oblique rod, a first support, a second spring, an abutting plate and a first fixing rod, the support device comprises a first transverse plate, a second supporting rod, a second fixing rod and a first vertical rod, the abutting device comprises a first abutting rod, a second cross rod, a first connecting ring, a second vertical rod, a second bent rod and a third spring, the roller device comprises a second abutting rod, a fourth spring, a second support and a first roller, and the transverse plate device comprises a second transverse plate, a third support, a fourth support, a second roller and a third vertical rod. The rapid and efficient hardware plate bending system can conduct effective bending treatment on hardware plates and is high in bending efficiency and rapid, and the bending time can be greatly saved.

Owner:重庆市雷驰金属结构制造有限公司

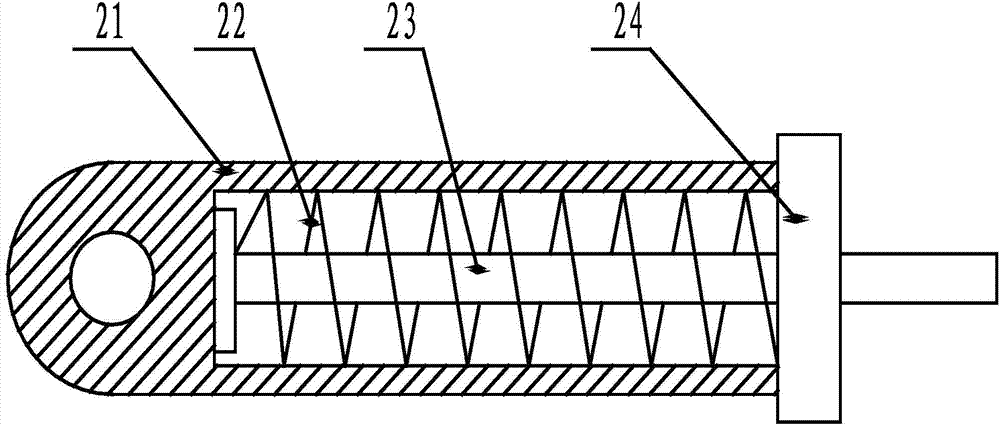

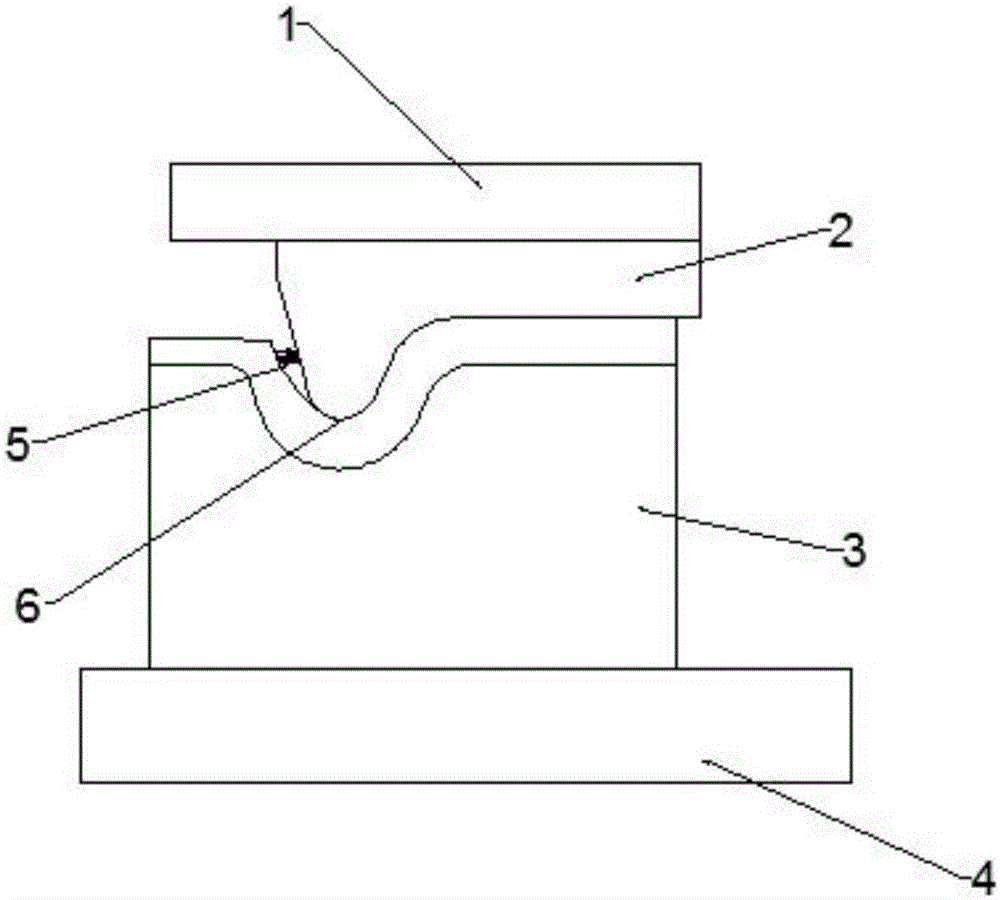

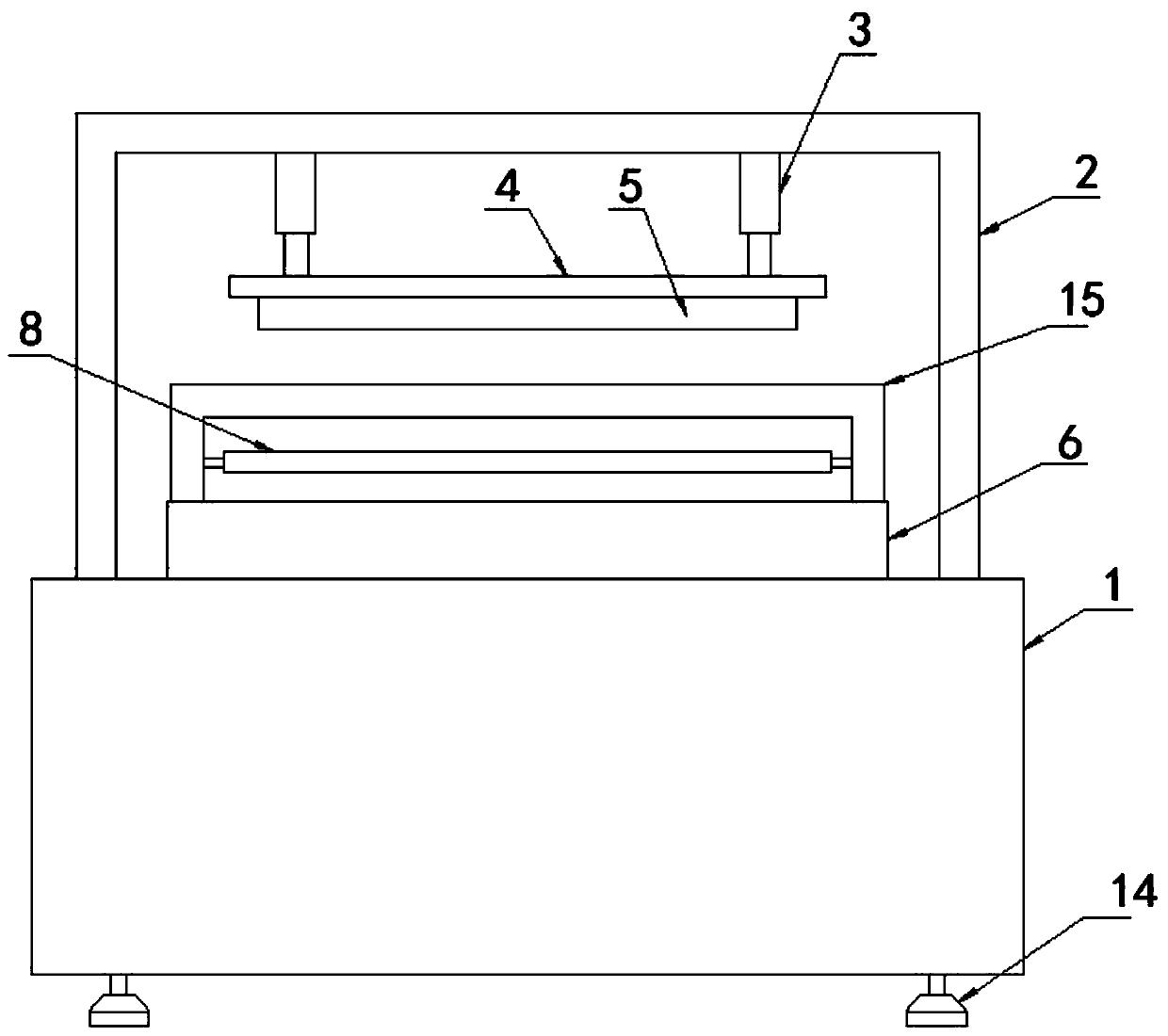

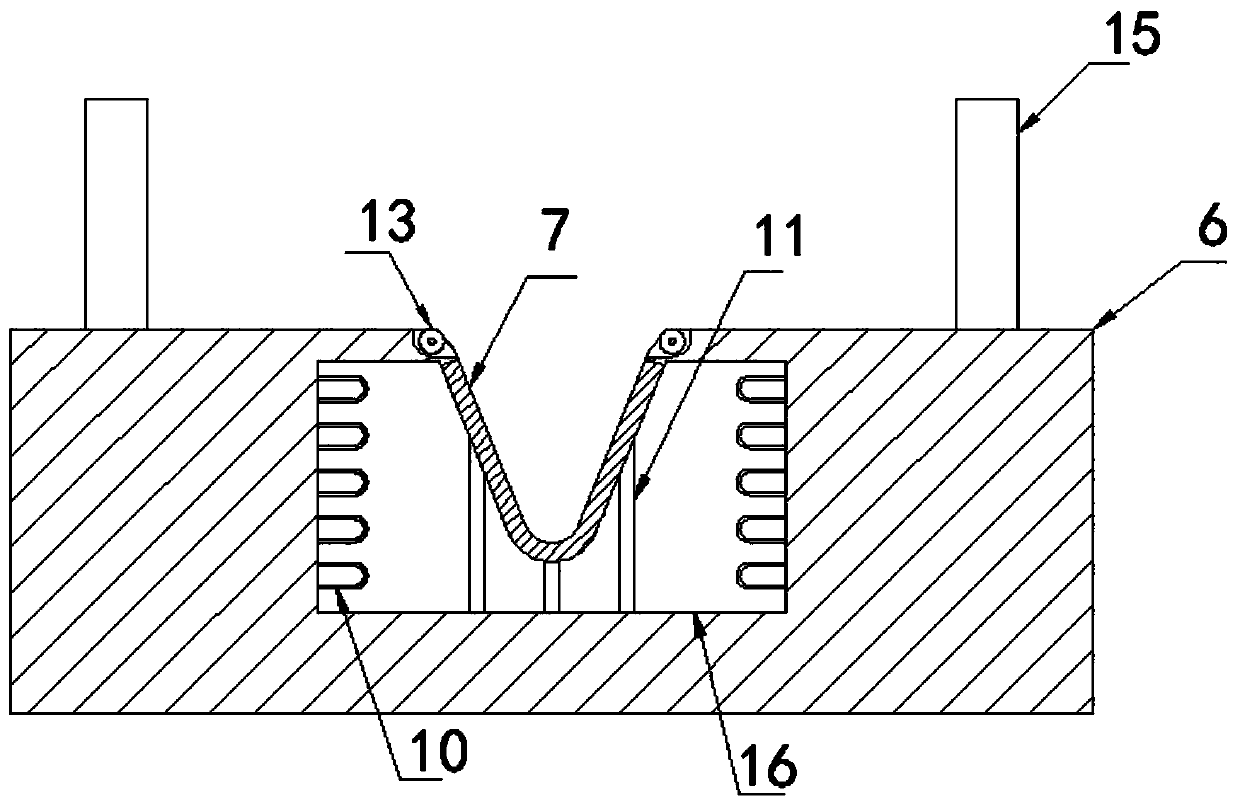

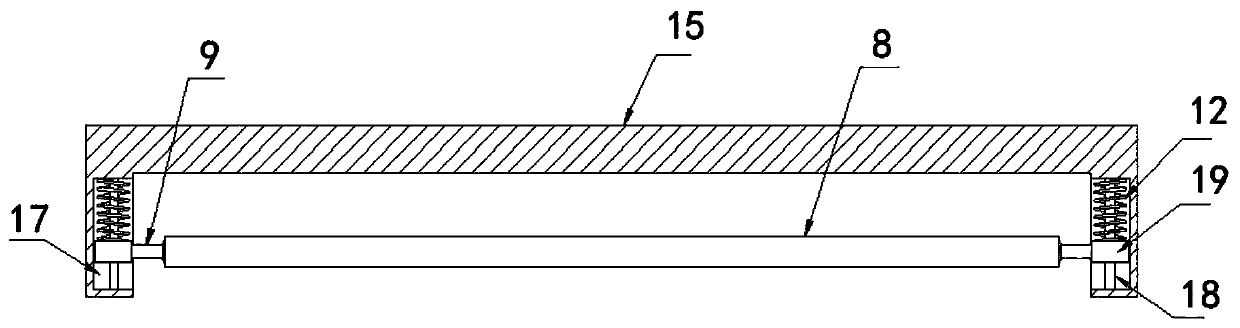

Automobile oil pipe pressing machine

InactiveCN104722617AGuaranteed bending effectAvoid breakingMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention relates to an automobile oil pipe pressing machine which comprises a base. Parallel guide rails are arranged above the base, a moving trolley is arranged on the parallel guide rails, a rotary stepping motor is fixed to the trolley, a rotary shaft of the rotary stepping motor is fixedly connected with a clamping head, and a fixing column, a clamping mechanism and a bending mechanism are installed on the right side of the base. The automobile oil pipe pressing machine is simple in structure, enables oil pipes to be attractive in appearance, enables pass percent and production efficiency to be improved, can conduct continuous multiple-angle bending on the oil pipes and is very high in oil pipe machining efficiency.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

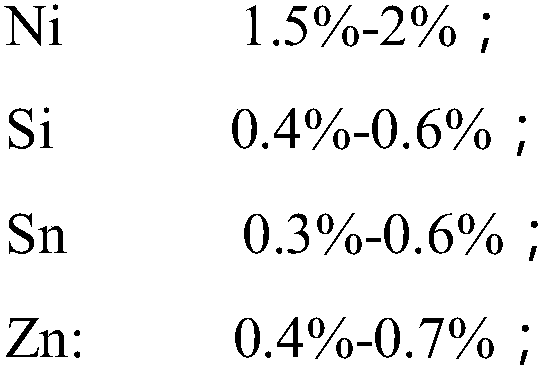

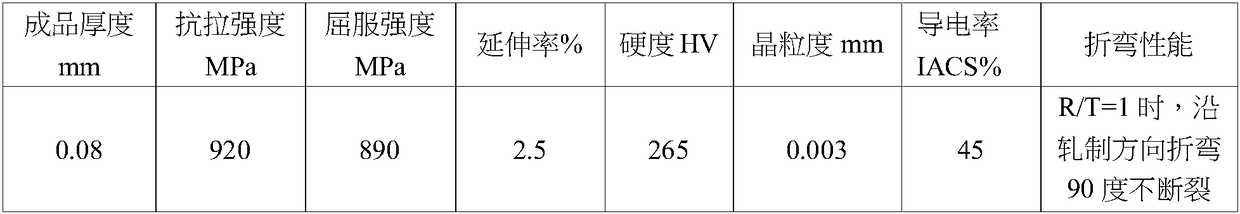

Copper alloy strip with high intensity, high conductivity and high bending performance and preparation method thereof

InactiveCN108998695ASufficient tensile strengthLow conductivityMetal rolling arrangementsGrain structureImpurity

The invention provides a copper alloy strip with high intensity, high conductivity and high bending performance and a preparation method thereof. The copper alloy strip is prepared from the followingraw material components in percentage by weight: 1.5 to 2 percent of Ni, 0.4 to 0.6 percent of Si, 0.3 to 0.6 percent of Sn, 0.4 to 0.7 percent of Zn, less than or equal to 0.02 percent of Fe, less than or equal to 0.01 percent of Mg and the balance of Cu and unavoidable impurities. The preparation method comprises the following steps: adding the raw materials during semi-continuous casting for casting to form a cast blank, performing high-temperature annealing, hot-rolling cogging, all-side milling, rough rolling, intermediate rolling, softening annealing in an elevator furnace, cleaning, secondary intermediate rolling, solution treatment in an air-cushion furnace, aging in the elevator furnace, rolling of a twenty-roller finished product, cleaning, low-temperature annealing in the elevator furnace, secondary cleaning, bending and straightening and shearing of the finished product, and packaging the product in a warehouse. The copper alloy strip can solve the problem that an existingelectronic copper strip cracks during bending and is low in anti-softening temperature due to low strength, poor conductivity and thick grain structures.

Owner:FUJIAN ZIJIN COPPER

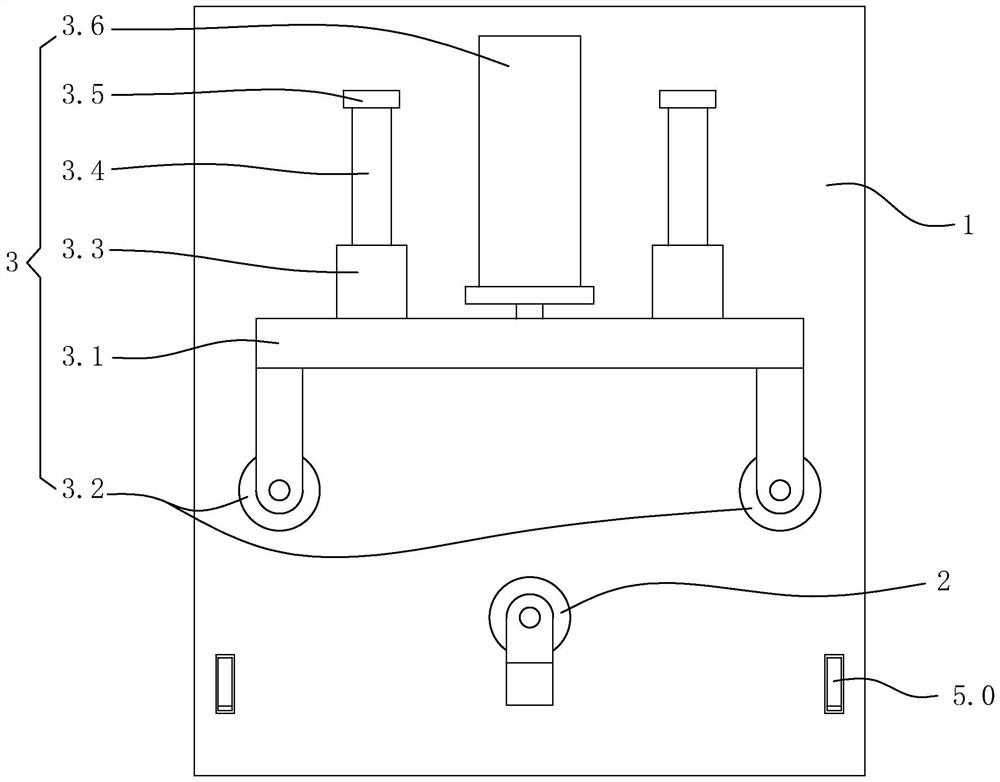

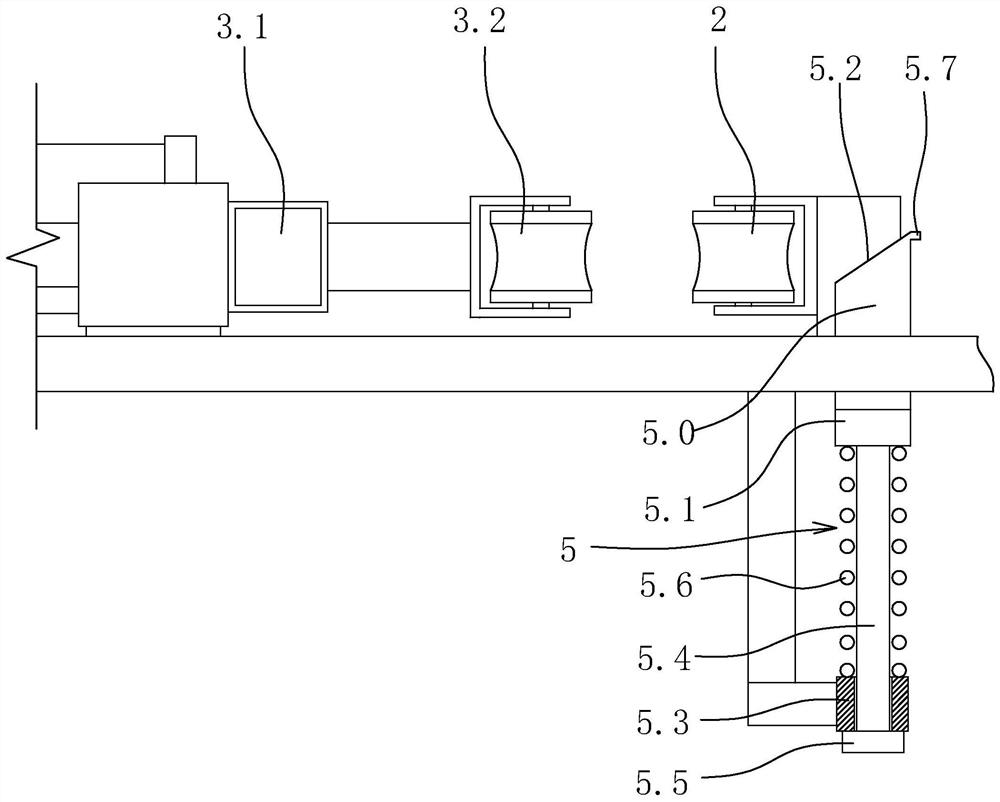

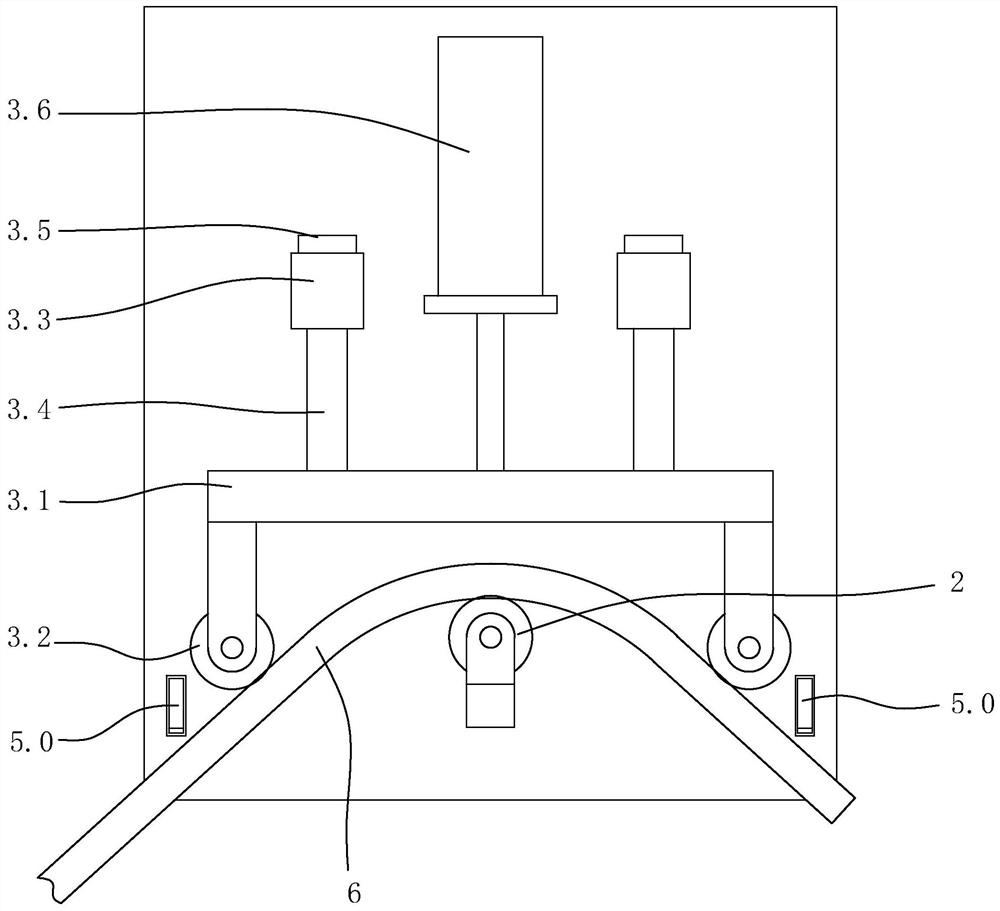

Car door sliding rail stretch bending machine

The invention discloses a car door sliding rail stretch bending machine. The car door sliding rail stretch bending machine comprises a support. Two stretch bending devices are arranged on the supportin a mirror image manner. Each stretch bending device comprises a movable platform and a drive mechanism, wherein the movable platform is arranged on the support and provided with an arc carrying track, and the movable platform is provided with a positioning device; and the drive mechanism comprises a steering disc, a lifting track and a steering drive piece, the position, corresponding to the movable platform, of the steering disc is rotationally arranged on the support, the steering disc is hinged to the movable platform, the lifting track is arranged on one side of the steering disc, the movable platform is provided with wheels, and the wheels and the lifting track are in sliding fit. A cropping device is arranged between the two stretch bending devices, and the support is further provided with an adjusting device for adjusting the distance between the two stretch bending devices. The improved structure of the car door sliding rail stretch bending machine is simple and reasonable, the whole machine structure is simple, stretch bending of a car door sliding rail in the vertical direction and the horizontal direction is effectively achieved, forming is fast, and the production efficiency is higher.

Owner:浙江创大汽车部件有限公司

Narrow aluminum plate for bending and shaping method of narrow aluminum plate for bending

The invention relates to an aluminum section material, in particular to a narrow aluminum plate for bending. The narrow aluminum plate for bending contains the following substances in percentage by mass of 0.32-0.34% of Si, less than or equal to 0.12% of Fe, less than or equal to 0.01% of Cu, less than or equal to 0.01% of Mn, 0.45-0.48% of Mg, less than or equal to 0.01% of Zn, less than or equalto 0.01% of Cr, 0.01-0.025% of Ti, less than or equal to 0.01% of single impurities, less than or equal to 0.1% of total impurities, and the balance Al. The narrow aluminum plate for bending providedby the invention is good in stretching properties, is difficult to break when being used for bending after groove cutting, and is high in connecting strength after being bent.

Owner:江苏中福铝镁科技有限公司

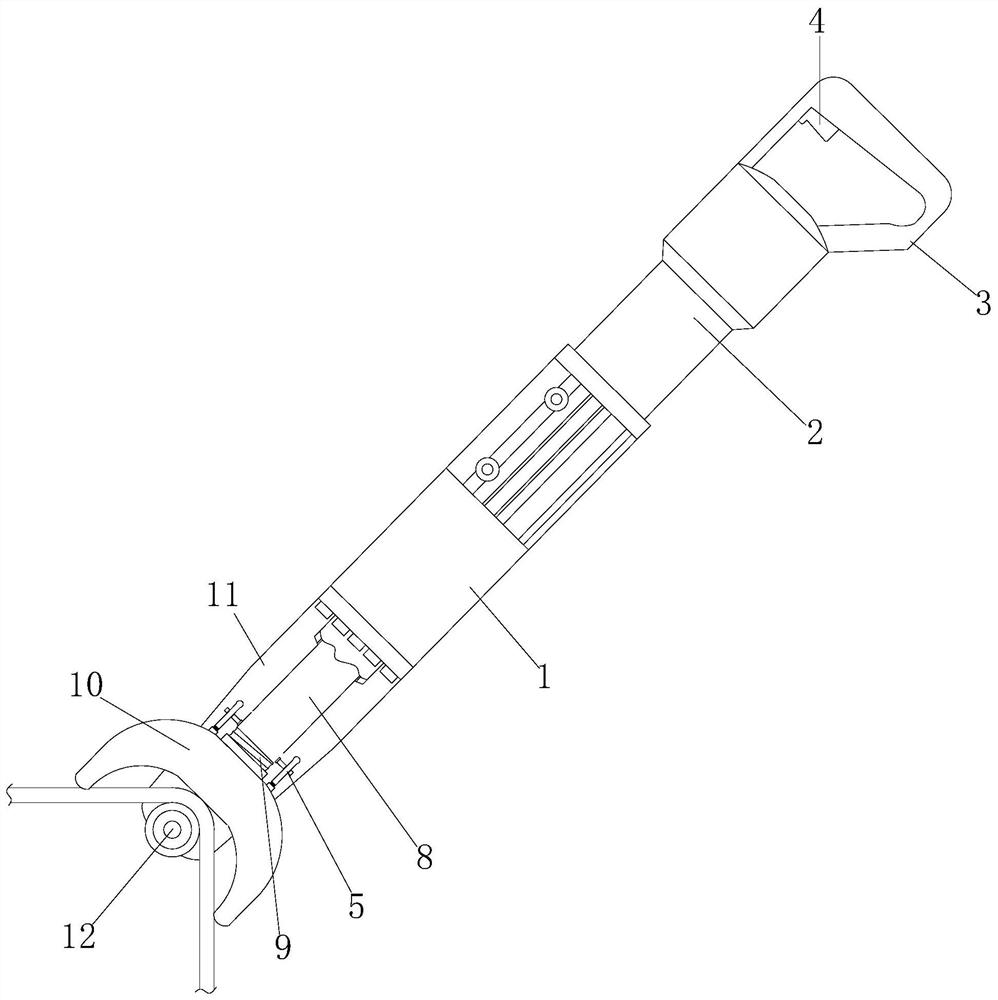

Reinforcement bending machine

The invention discloses a reinforcement bending machine. The reinforcement bending machine comprises a hydraulic rod and a connecting block, wherein a handle is connected to one end of the hydraulic rod through a connecting block, a switch is assembled at the inner side end of the handle, the switch, a power supply and the hydraulic rod are correspondingly and electrically connected, a piston rodis assembled at the other end of the hydraulic rod, a threaded sleeve is fixedly assembled at the end head of the outer side end of the piston rod, an ejecting block is connected to the outer wall ofthe threaded sleeve in a threaded mode, a connecting plate is fixedly assembled on the rear side of the end head of the hydraulic rod, the connecting plate is connected with the ejecting block througha limiting structure, a clamping block is connected to the end head of the connecting plate through a fixing structure, the clamping block is matched with the ejecting block, and the upper and lowersides of the ejecting block are correspondingly connected with the piston rod through the limiting structure. According to the reinforcement bending machine, the bending effect and the bending efficiency of reinforcement are ensured, meanwhile carrying is convenient, the limitation is small, the degree of freedom of use is ensured, and the practicability is high.

Owner:中铁九局集团第一建设有限公司

Anti-slip stable bending machine for metal plate processing

The invention discloses an anti-slip stable bending machine for metal plate processing, which comprises a workbench, a supporting base is mounted at the lower end of the workbench, a first pushing spring is mounted in a groove formed in the workbench, and the first pushing spring is connected with a bearing sliding block; the bearing sliding block is in sliding connection with the workbench through a groove formed in the workbench, a movable plate is installed at the upper end of the bearing sliding block, and a supporting back plate is installed at the upper end of the workbench. According to the anti-slip stable bending machine for metal plate processing, a first bending plate and a second bending plate are arranged to be of a detachable structure, namely, the first bending plate and the second bending plate are detached and replaced, so that the bending effect of a plate-shaped structure can be effectively guaranteed, the position of an upper pressing plate is moved up and down, and the bending effect of the plate-shaped structure is effectively guaranteed. And at the moment, it can be effectively avoided that in the follow-up bending process, the bending effect is affected due to the fact that the plate deviates.

Owner:南京黄石机床制造有限公司

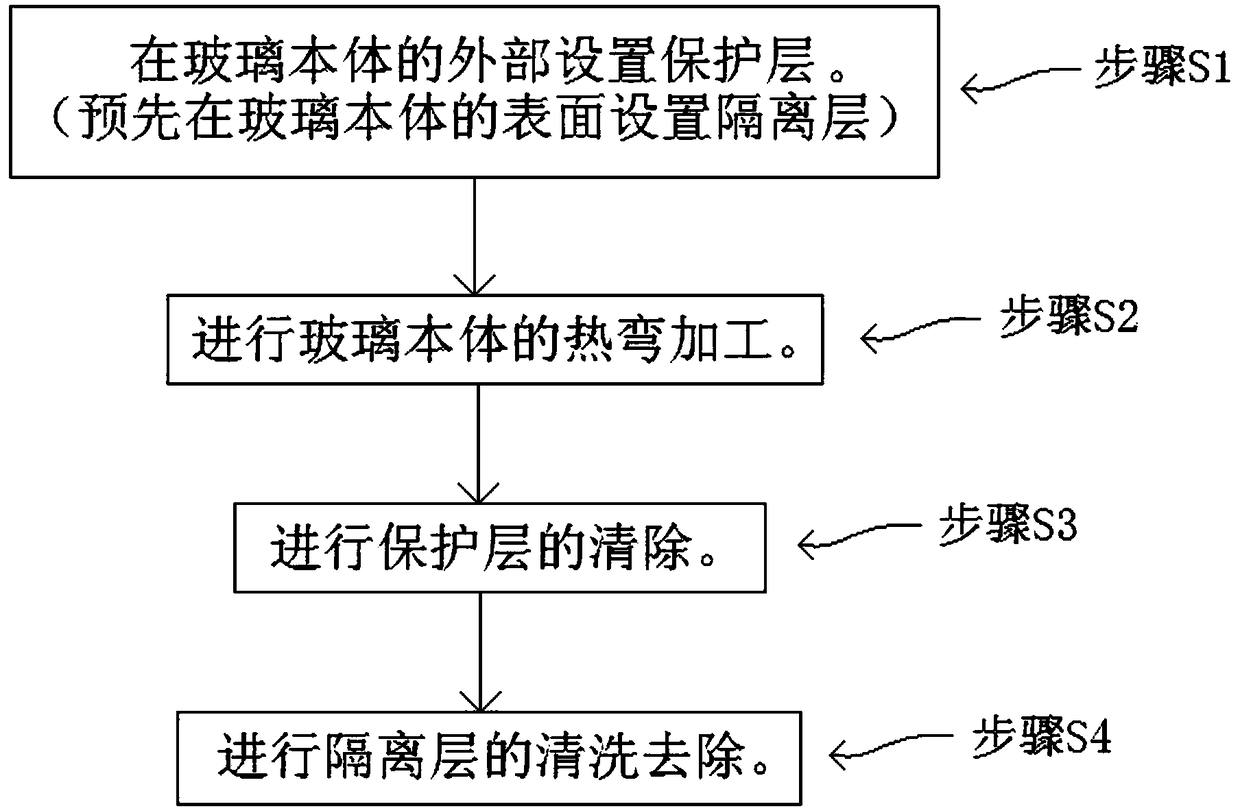

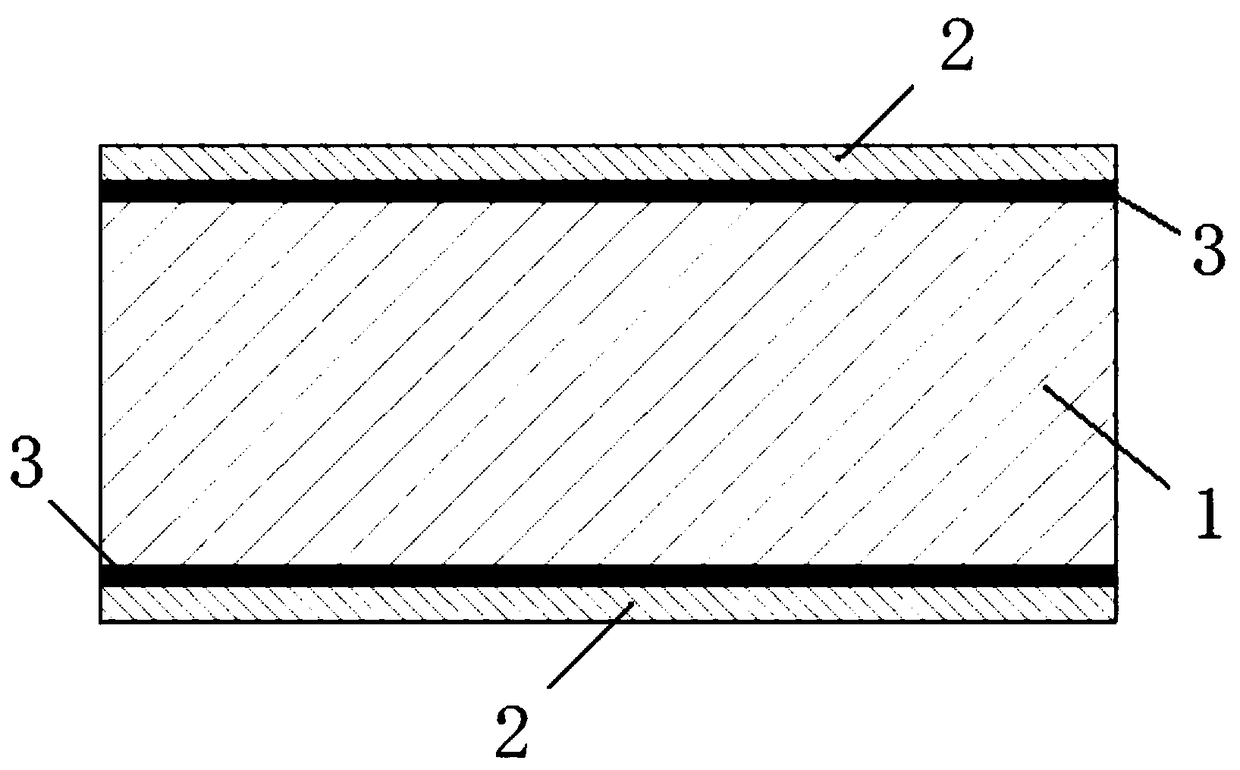

Preparation method of curved glass

ActiveCN109160718AAvoid Hot Bending ResistanceGuaranteed accuracyGlass reforming apparatusProtection layerPoor quality

The invention belongs to the technical field of preparation of curved glass and specifically relates to a preparation method of the curved glass. In order to solve the problems of low preparation efficiency and poor quality caused by the defects of a glass body in a preparation process when the curved glass is prepared by adopting a hot bending process, the invention discloses the preparation method of the curved glass. The preparation method comprises the following steps: step S1, arranging a protection layer at the outer part of the glass body; step S2, performing hot bending on the glass body; step S3, eliminating the protection layer, so as to obtain the curved glass finally. The curved glass is processed and prepared by adopting the preparation method, so that the preparation efficiency of the curved glass is improved, and the quality of the finally obtained curved glass is also enhanced.

Owner:杨玉金

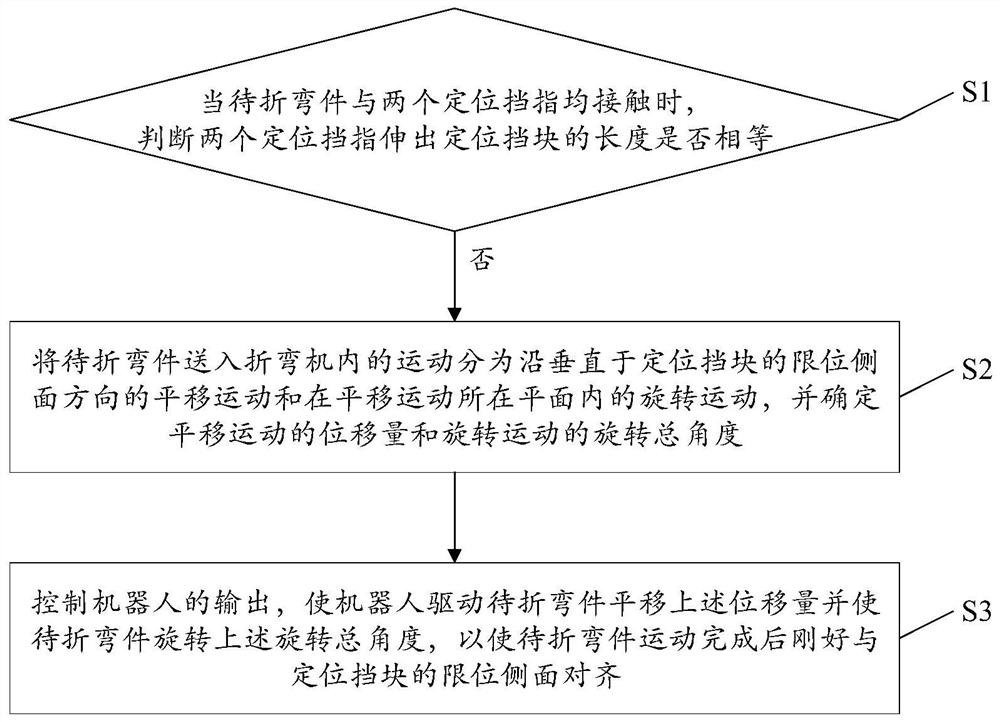

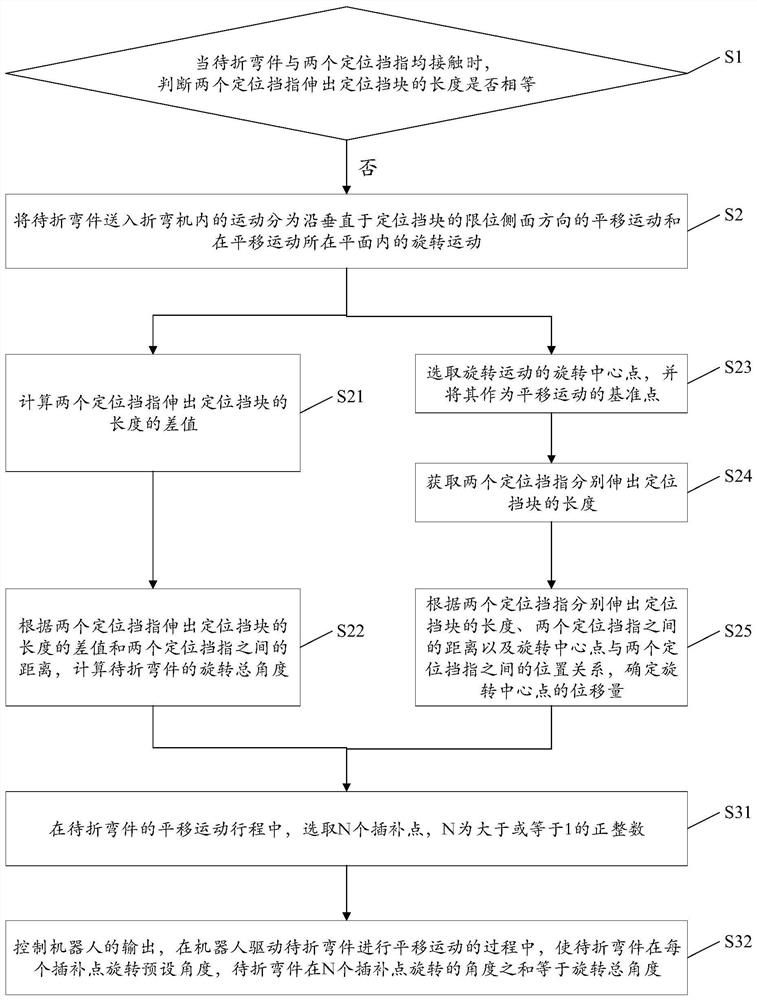

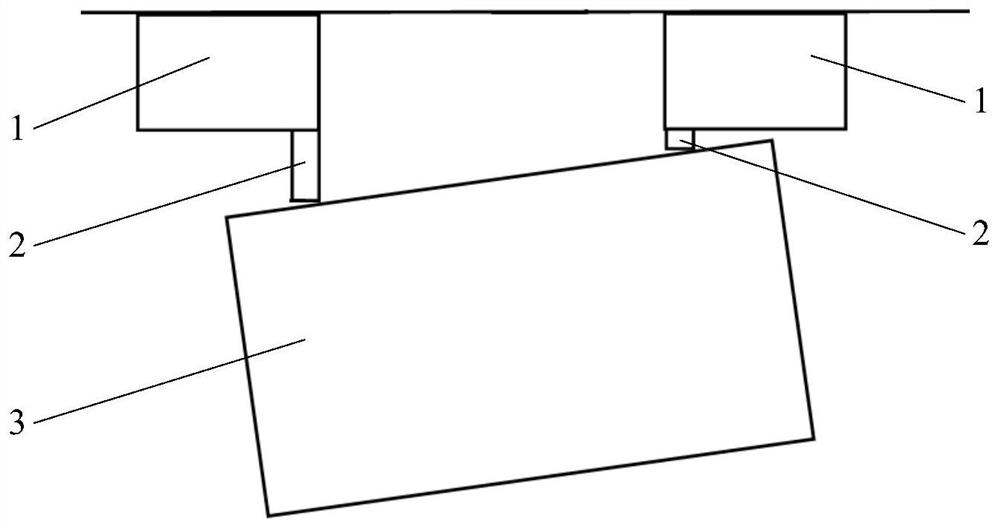

Positioning method, device and equipment for to-be-bent part of bending machine and storage medium

The invention discloses a positioning method, device and equipment for a to-be-bent part of a bending machine and a storage medium. The positioning method, device and equipment are applied to processcontrol over feeding of the to-be-bent part into the bending machine by a robot. The bending machine comprises a positioning stop block, wherein two telescopic positioning stop fingers are arranged onthe side, used for limiting the to-be-bent part, of the positioning stop block. The positioning method comprises the steps that when the to-be-bent part makes contact with the two positioning stop fingers, whether the lengths, stretching out of the positioning stop block, of the two positioning stop fingers are equal or not is judged; if not, the motion of feeding the to-be-bent part into the bending machine is divided into translation motion in the direction perpendicular to the limiting side face of the positioning stop block and rotation motion in the plane where the translation motion islocated, and the displacement of the translation motion and the total rotation angle of the rotation motion are determined; and the output of the robot is controlled, so that the robot drives the to-be-part part to horizontally move by the displacement and rotate by the total rotation angle, the to-be-bent part is just aligned with the limiting side face after moving is completed, and extrusion force generated between the to-be-bent part and the stop block is avoided.

Owner:BEIJING A&E TECH

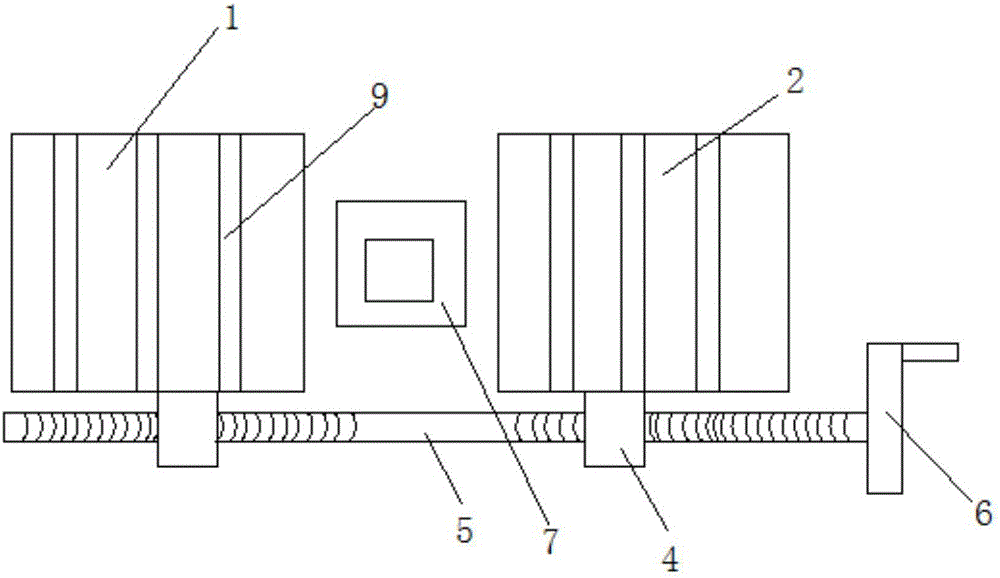

Pneumatic bending machine

The invention discloses a pneumatic bending machine. The pneumatic bending machine comprises a rack, a locating device, a pneumatic prepressing device, a pneumatic bending device and an electronic control device, wherein the locating device is arranged on the rack and is used for bearing a product to be bent, the pneumatic prepressing device is used for tightly pressing the product to be bent on the locating device through vertical movement, the pneumatic bending device is used for bending the product to be bent through stretching and contraction movement, the electronic control device is electrically connected with the pneumatic prepressing device and the pneumatic bending device, and is used for having control over movement of the pneumatic prepressing device and movement of the pneumatic bending device, the pneumatic bending device comprises bending plunger chips, a plunger chip base, elastic component locating pins, elastic components, stroke control pins and bending air cylinders fixedly connected with the stroke control pins, guide grooves are formed in the plunger chip base, one end of each bending plunger chip penetrates through the corresponding guide groove to be opposite to the product to be bent, the other end of each bending plunger chip is close to the corresponding stroke control pin, the elastic component locating pins are fixed to the plunger chip base, each elastic component locating pin is sleeved with one end of the corresponding elastic component, and the other end of each elastic component abuts against the other end of the corresponding bending plunger chip.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

Hydraulic bending machine

ActiveCN106334736AEffective controlEffective adjustmentMetal-working feeding devicesPositioning devicesEngineeringFixed position

The invention provides a hydraulic bending machine. The hydraulic bending machine comprises a bending machine body. The bending machine body comprises an upper die base, an upper die, a lower die base, a lower die and a throat. The upper die is fixed below the upper die base, and the lower die is fixed above the lower die base. The upper die and the lower die are correspondingly arranged. The throat is vertically arranged on the front face of the lower die, so that parts to be machined are bent. The throat is of a groove structure, and the bottom of the groove structure is arranged to be in a smooth arc shape. The up-down radial length of a groove is 25-30cm, and the throat depth is 10-20cm. A workpiece positioning device is arranged at one end of the throat. The workpiece positioning device is fixed to the position 3-8cm away from the surface of the throat. According to the hydraulic bending machine, the fixed positions can be adjusted in the axial direction and the radial direction at the same time on the whole; and moreover, the adjusting structure is simple in arrangement, adjusting is flexible and the adjusting position is accurate. In addition, the workpiece position adjusting device is arranged, fixation is further performed, the steps and time used for positioning from the beginning are omitted, the bending efficiency can be effectively improved, and the positioning effect and bending effect are guaranteed.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

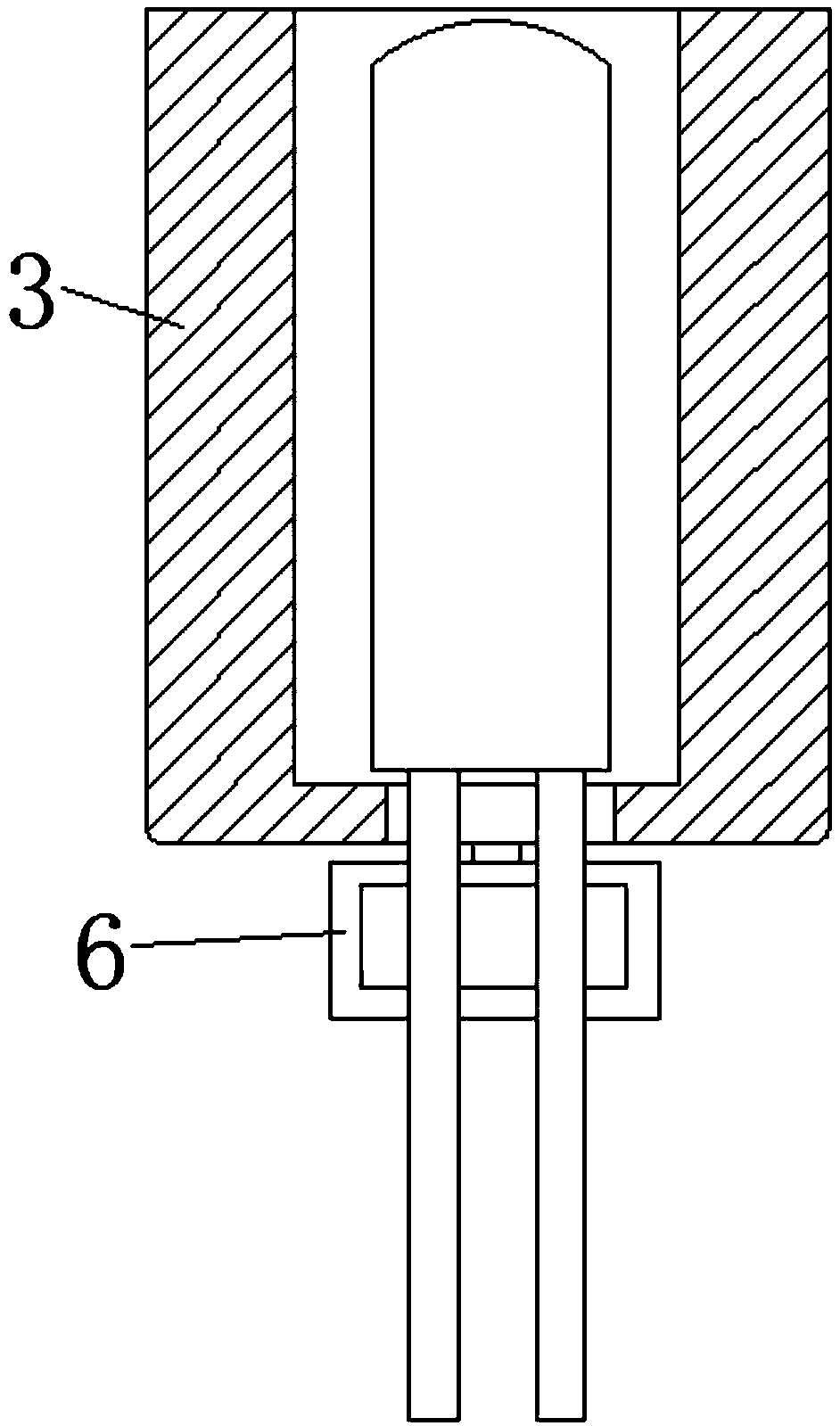

LED element automatic bending machine

The invention discloses an LED element automatic bending machine. The LED element automatic bending machine comprises a base and a supporting column, the base is fixedly connected with the top of thesupporting column, a fixing sleeve is fixedly connected to the top of the supporting column, and a through hole is formed in the bottom of the fixing sleeve; two supporting blocks symmetrically arranged are fixedly connected to the bottom of the fixing sleeve, L-shaped clamping rods are arranged on the supporting blocks in a sliding mode, one ends, opposite to each other, of the two L-shaped clamping rods are fixedly connected with extrusion blocks, and one ends, far away from the extrusion blocks, of the L-shaped clamping rods are connected with the fixing sleeve through turnbuckles; and thebottom of one side, close to the fixing sleeve, of the supporting column is fixedly connected with a telescopic air cylinder, the output end of the telescopic air cylinder is fixedly connected with apushing plate, and a sliding groove corresponding to the pushing plate is formed in the top of the base. According to the LED element automatic bending machine, through the arrangement of the extrusion blocks, pins can be well fixed, so that an LED element can be effectively prevented from shaking, and the bending effect of the pins can be guaranteed.

Owner:肇庆高新区黑阳科技有限公司

Auxiliary righted-angle bending device for metal plate

The invention discloses an auxiliary righted-angle bending device for a metal plate. The auxiliary righted-angle bending device comprises a base, a support spring, movable guide blocks, a connecting seat, an oil pressure opening and connecting valves. A weight reduction hole is formed in the lower end of the base. Side stress baffles are mounted on the upper portion of a bending bottom plate. A shaft rod is arranged in the support spring. A bending seat is arranged on the upper portion of a bearing block. A bending knife is arranged on the upper portions of the movable guide blocks. A bolt ismounted on the upper portion of the left end of the bending knife. A positioning pin is mounted on the upper portion of a connecting block. A hydraulic piston is connected to the upper portion of theconnecting seat. A hydraulic bin is arranged above the oil pressure opening. Compared with an existing common bending device, by the adoption of the auxiliary righted-angle bending device for the metal plate, the applicability of the device is improved greatly while the structure is increased, the auxiliary righted-angle bending device is suitable for more different sizes of righted-angle fillet radii, the quakeproof capacity of the whole device is improved, the service life of the device is prolonged effectively, and the use cost is lowered in a disguised form.

Owner:昆山天卓贸易有限公司

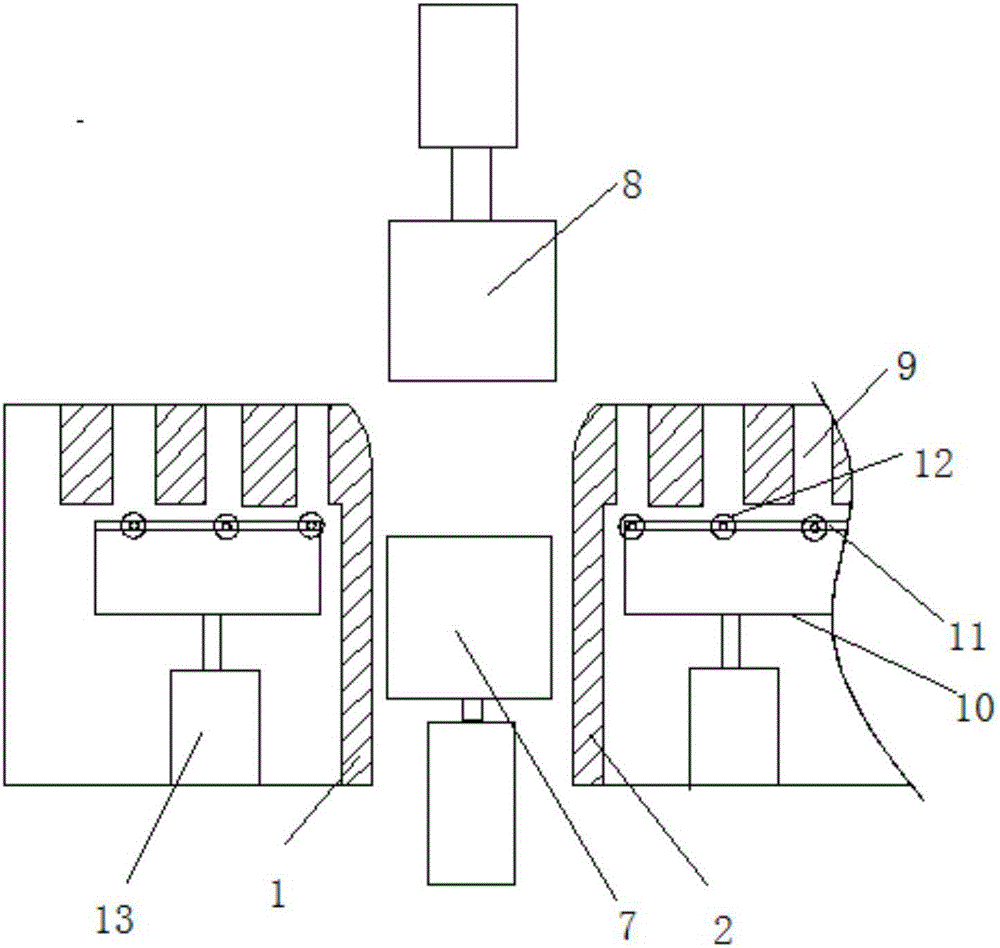

Automatic adjusted 90-degree angle bending forming mechanism

The invention disposed an automobile adjusted 90-degree angle bending forming mechanism. The automobile adjusted 90-degree angle bending forming mechanism comprises a fixed base plate. A right lower die fixed block is fixed to the right portion of the top surface of the fixed base plate. A slant wall face is formed on the top surface of the left end of the right lower die fixed block. A lower dieadjusting block is located on the left end of the right lower die fixed block. The bottom surface of the lower die adjusting block is a bevel, and the bevel is pressed on the slant wall face. The topsurface of the lower die adjusting block is an upper slant wall face. A left vertical plate is fixed to the top surface of the left portion of the fixed base plate. An upper supporting plate is fixedto the top surface of the left vertical plate. A hold-down cylinder is fixed to the top surface of the upper supporting plate. The right side of the bottom end of a punch pin is provided with an arc-shaped chamfered part. The arc-shaped chamfered part is pressed on the upper slant wall face. The punch pin is movably connected so that the automobile adjusted 90-degree angle bending forming mechanism can be used for machining plates to be bent with different similar thicknesses and can ensure the bending effect.

Owner:DONGGUAN DINGTONG PRECISION METAL CO LTD

Automatic bending mechanism

The invention discloses an automatic bending mechanism. The automatic bending mechanism comprises a fixing seat; the top of the fixing seat is provided with a mounting groove; an L-shaped push plate is slidably connected inside the mounting groove; one side of the L-shaped push plate is rotationally connected with a screw rod; one end of the screw rod penetrates through the inner wall of the mounting groove and is fixedly connected with a knob; the inner wall of the mounting groove is provided with a threaded hole corresponding to the screw rod; the internal bottom of the mounting groove is provided with a through opening; a sliding rod is fixedly connected inside the through opening; the sliding rod is slidably sleeved with a slider; the bottom of the fixing seat is fixedly connected witha fixed block corresponding to the slider; the fixed block is connected with the slider through a turnbuckle; a servo motor is arranged at one side of the slider; and an output shaft of the servo motor penetrates through the slider and extends outwards. By arranging the screw rod and the L-shaped push plate, the automatic bending mechanism disclosed by the invention can be freely adjusted according to the dimension of an LED element so as to guarantee the bending effect of lead pins of the LED element.

Owner:肇庆高新区黑阳科技有限公司

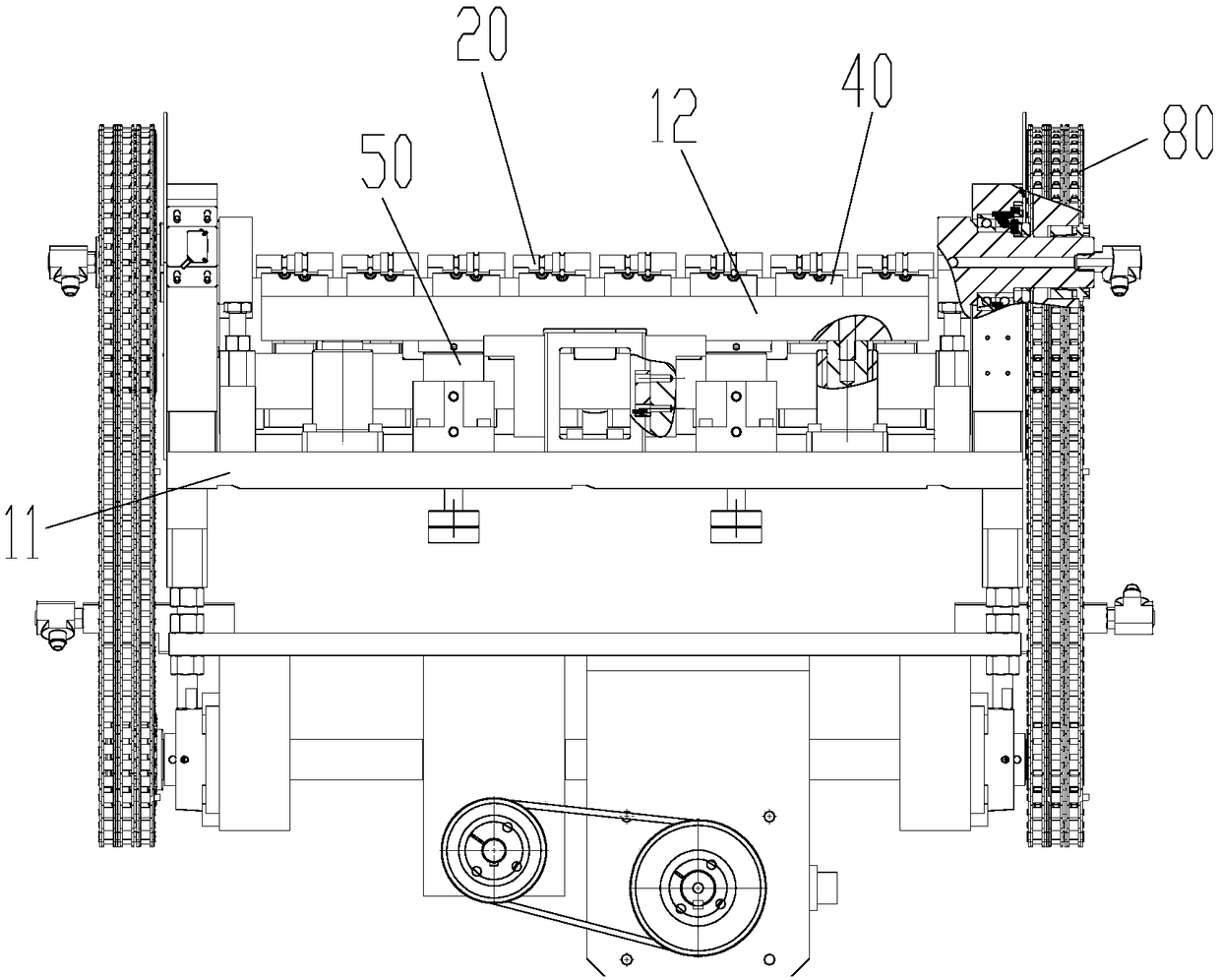

Stainless steel pipe machining process

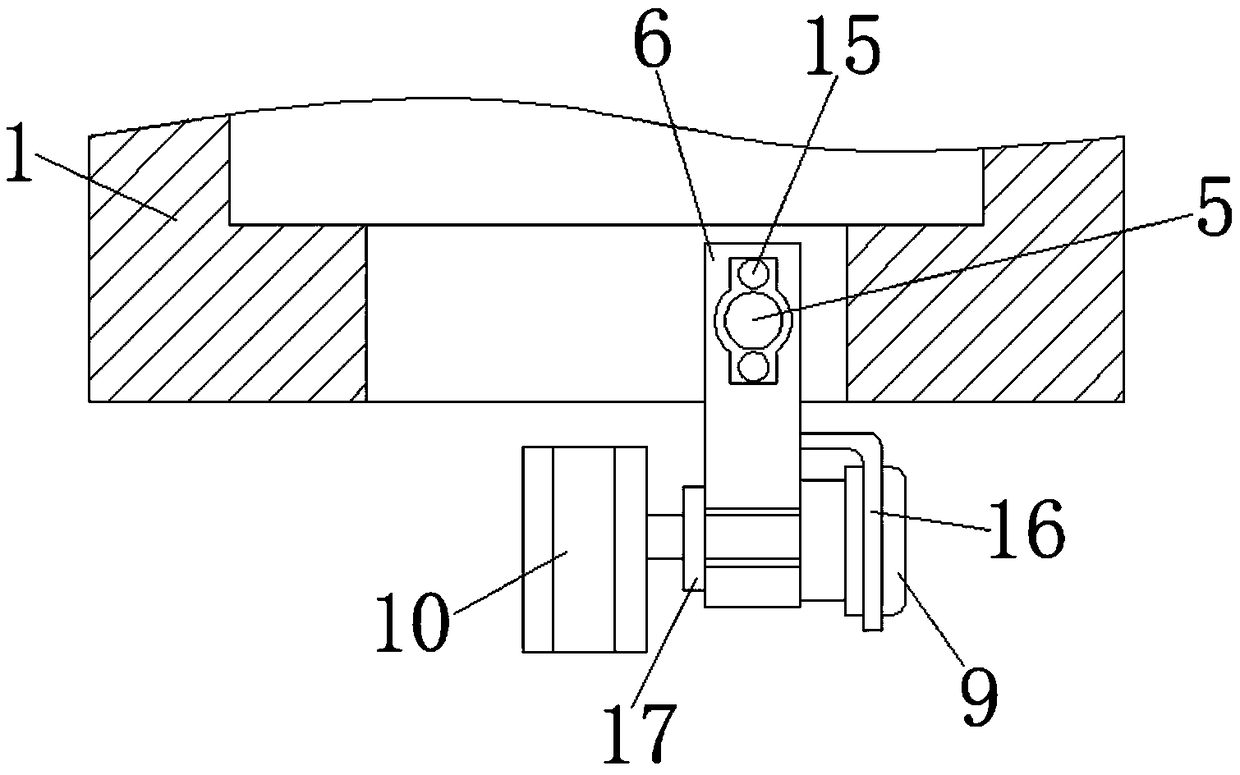

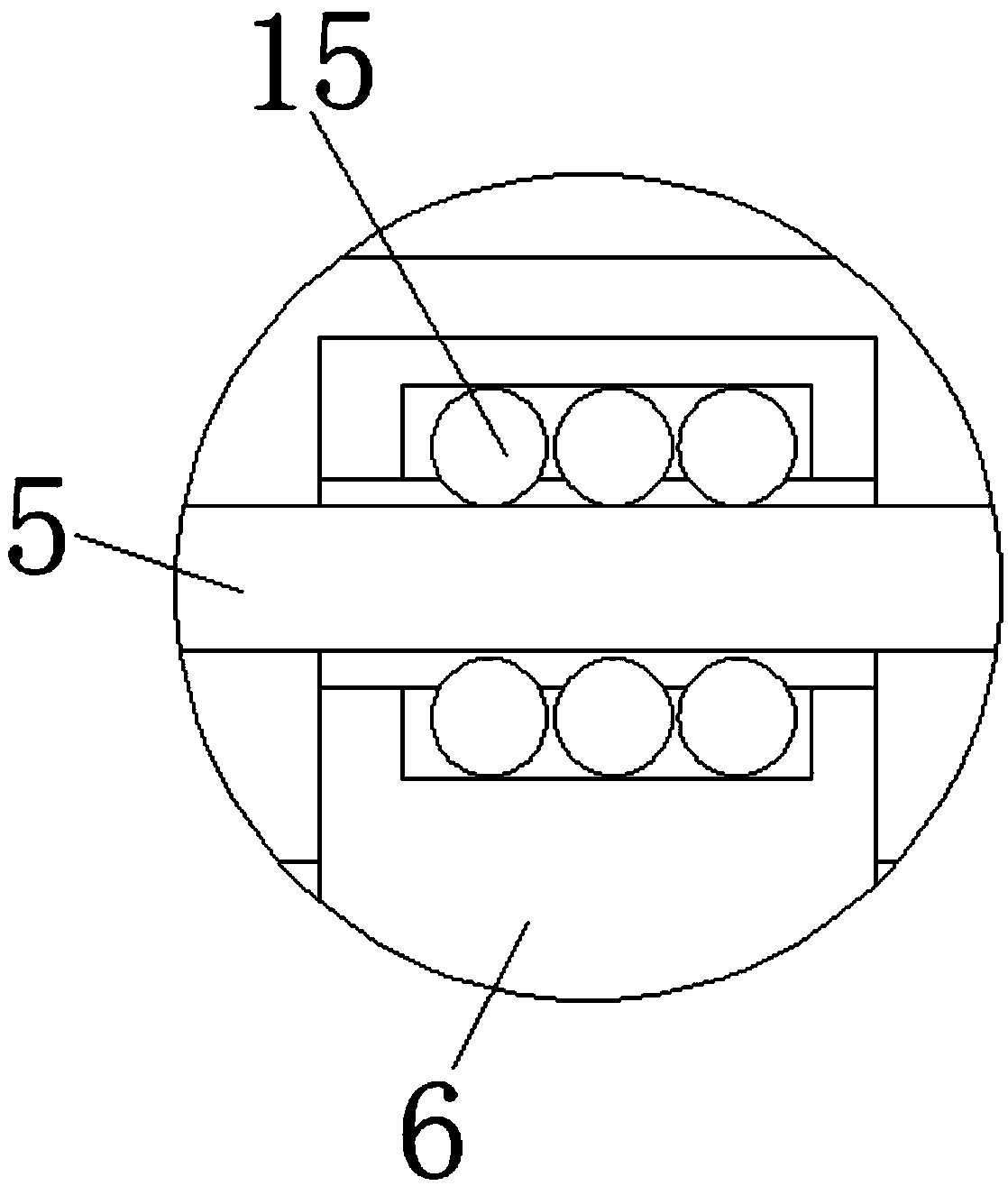

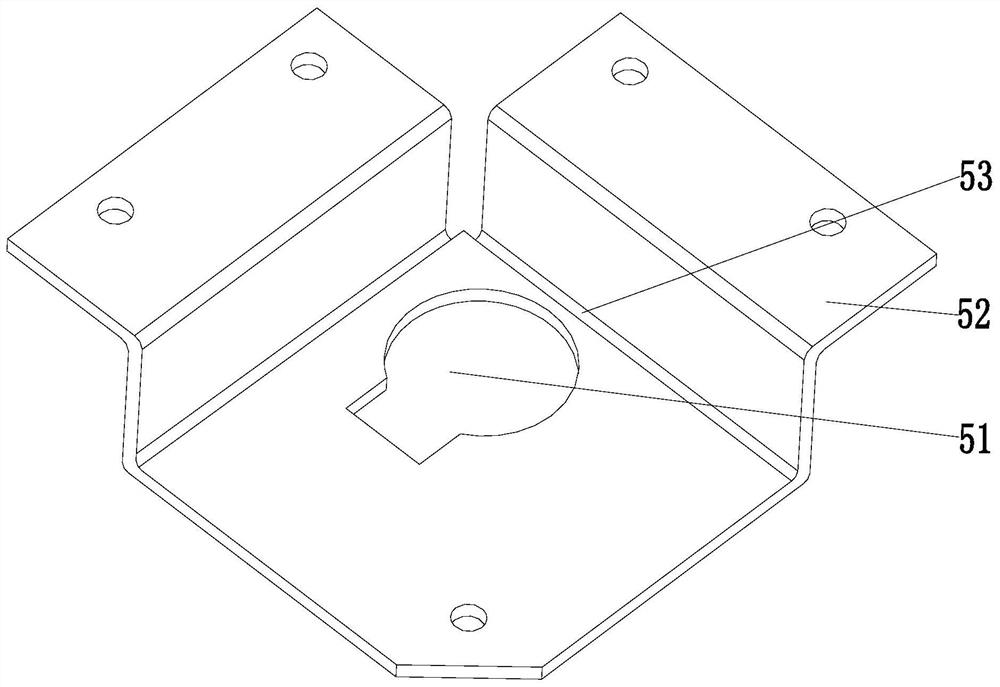

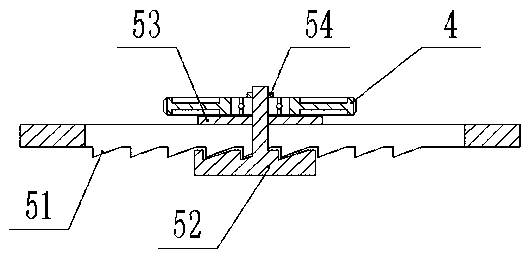

ActiveCN112676402AAchieve separationGuaranteed bending effectMetal-working feeding devicesMetal working apparatusMetallurgyGear wheel

The invention discloses a stainless steel pipe machining process. The stainless steel pipe machining process operates according to the following steps that firstly, the outer diameter of a stainless steel pipe is measured, outer bending pieces, a bending head and gears with corresponding specifications are selected and installed according to the outer diameter of the stainless steel pipe, and the width of a wedge-shaped rack is adjusted till the wedge-shaped rack normally meshes with the two gears; then the stainless steel pipe is conveyed to the interiors of the outer bending pieces at the corresponding axial positions; and when the outer bending pieces and the bending head are in a reset state, the stainless steel pipe located in the outer bending pieces is synchronously bent to a preset angle through the bending head and locked, and in the bending process, when the bending head moves to any position, the axis of a bending groove penetrates through a center of a bending annular groove of the bending head, and preferably, the two outer bending pieces slide in the direction away from the bending head at an angle perpendicular to the current stainless steel pipe. By means of the stainless steel pipe machining process, automatic feeding, bending and discharging of the stainless steel pipe can be achieved, and the stainless steel pipe bending efficiency and the automation degree are improved.

Owner:扬中市旭禾管业制造有限公司

Movable bending mechanism capable of facilitating discharging of large-bent-degree plates

InactiveCN106270031AGuarantee product qualityImprove discharge efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a movable bending mechanism capable of facilitating discharging of large-bent-degree plates. The movable bending mechanism comprises a left movable workbench and a right movable workbench which are matched symmetrically at an interval, the left workbench and the right workbench are driven to move by nut-screw mechanisms on two sides, the nut-screw mechanisms comprise nuts arranged on the outer sides of the left workbench and the right workbench respectively, screws are screwed into the nuts on the same sides, a movable die holder is arranged between the left workbench and the right bench, a punch holder is arranged above the left workbench and the right workbench, guide grooves are formed in the upper end faces of the left workbench and the right workbench along the plate conveying direction, movable U-shaped fixing frames are arranged in the left workbench and the right workbench below the guide grooves, two parallel fixing rods are mounted on U-shaped end ports of the U-shaped fixing frames, and guide rollers corresponding to the guide grooves are mounted on the fixing rods rotationally sequentially. The movable bending mechanism capable of facilitating discharging of the large-bent-degree plates is capable of machining the large-size plates, guaranteeing product quality and completing bending requirements automatically so as to meet the requirement on large-batch machining production.

Owner:讯龙型材折弯(合肥)有限公司

Bending mechanism and pipe bending equipment provided with same

InactiveCN108927429AEasy to bendAchieve bendingMetal-working feeding devicesPositioning devicesArchitectural engineering

The invention provides a bending mechanism and pipe bending equipment provided with the same. The bending mechanism comprises a bending plate, a plurality of second clamping plates and a plurality ofthird clamping plates. The bending plate is rotatably arranged on a main body rack for bending a tubular product and the bending plate has an initial position and a bending position; the second clamping plates are adjustably arranged on the bending plate, and a second positioning slot is formed in each second clamping plate; the third clamping plates are adjustably arranged on the main body rack,the second clamping plates and the third clamping plates are arranged correspondingly one by one, and a third positioning slot is formed in each third clamping plate; when the bending plate is locatedin the initial position, the slot wall face of the second positioning slot of each second clamping plate and the slot wall face of the third positioning slot of the corresponding third clamping plateare located in a same arc-shaped face; and the second clamping plates and the third clamping plates are adjustably arranged along the vertical direction, so that the slot wall faces of the second positioning slots and the slot wall faces of the third positioning slots are attached to the outer wall of the tubular product.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

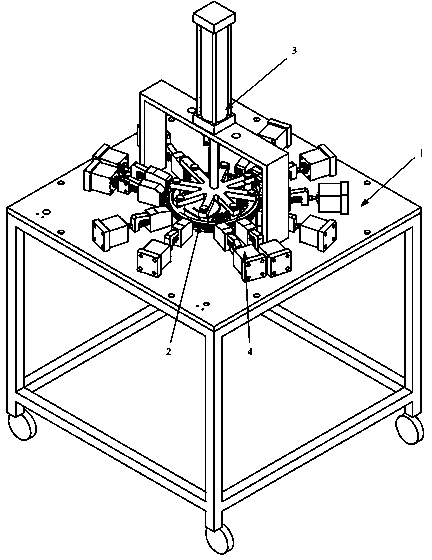

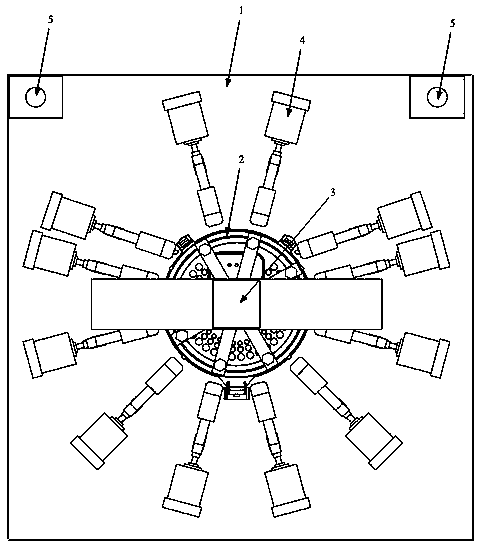

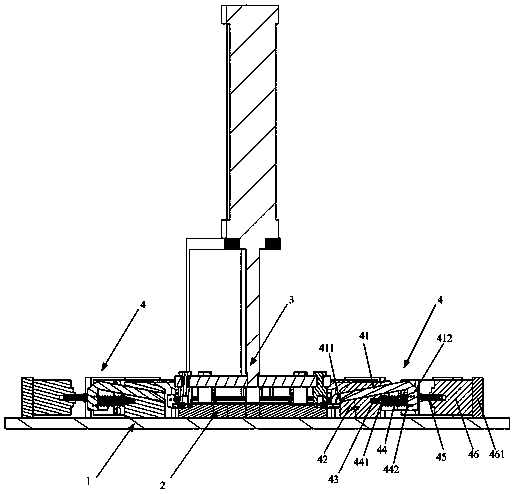

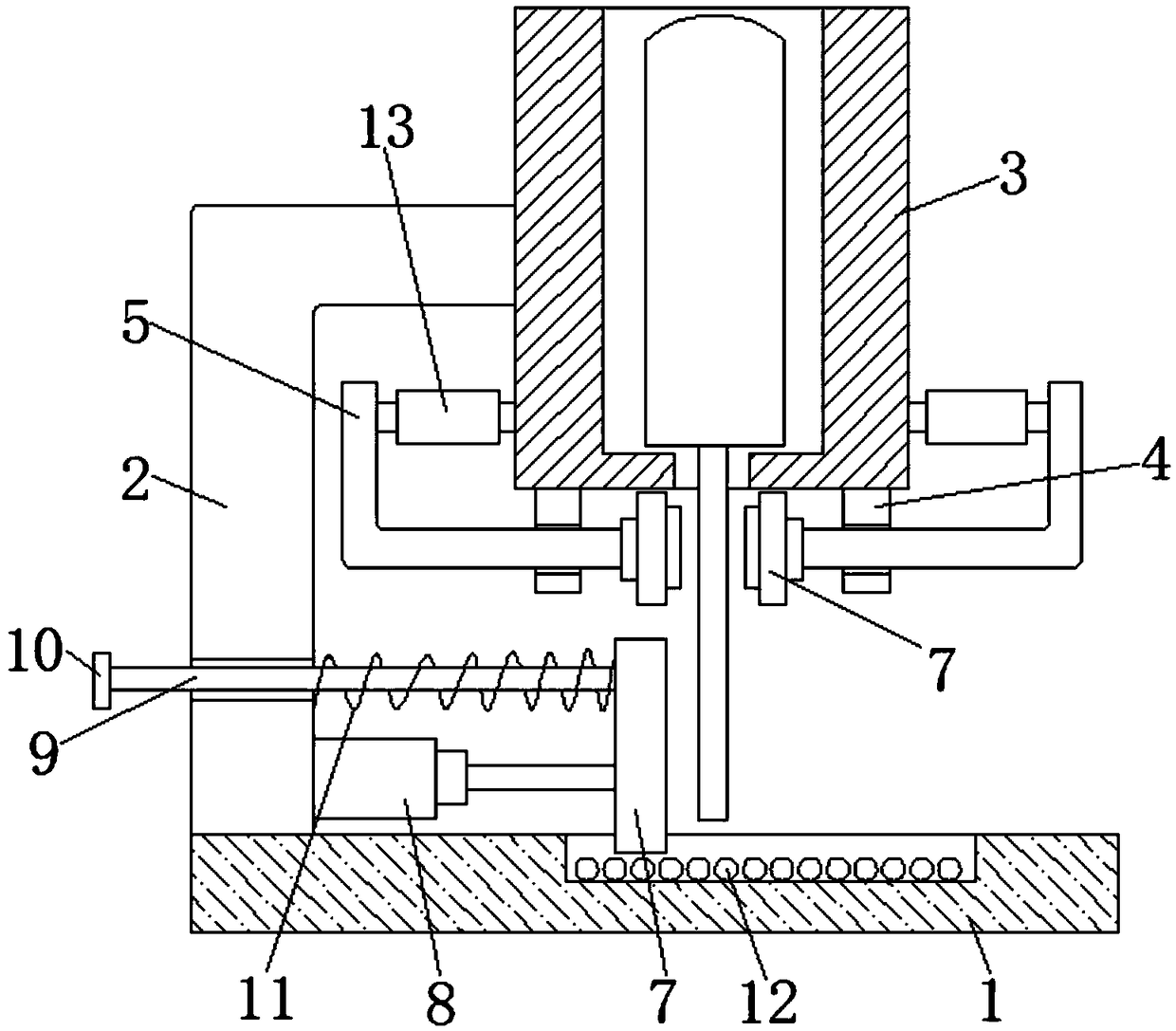

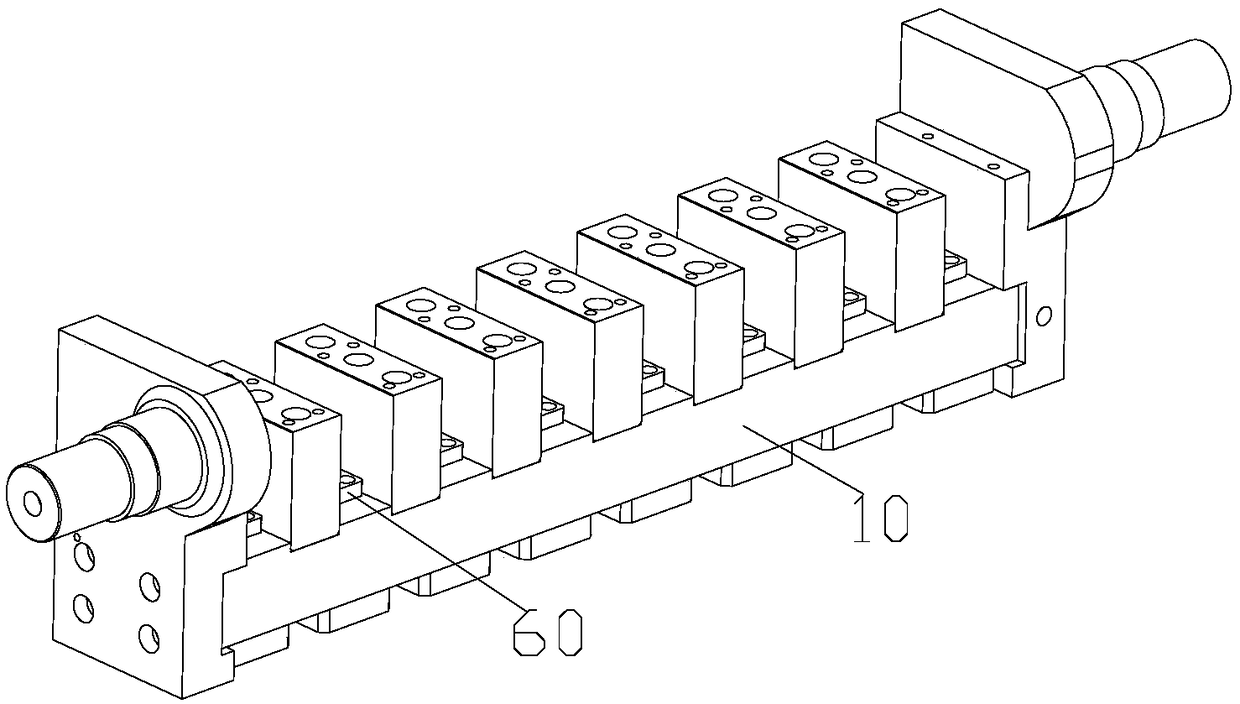

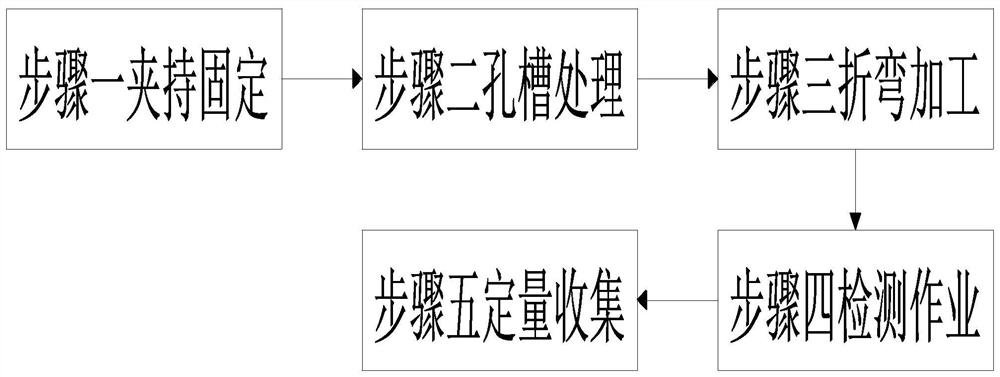

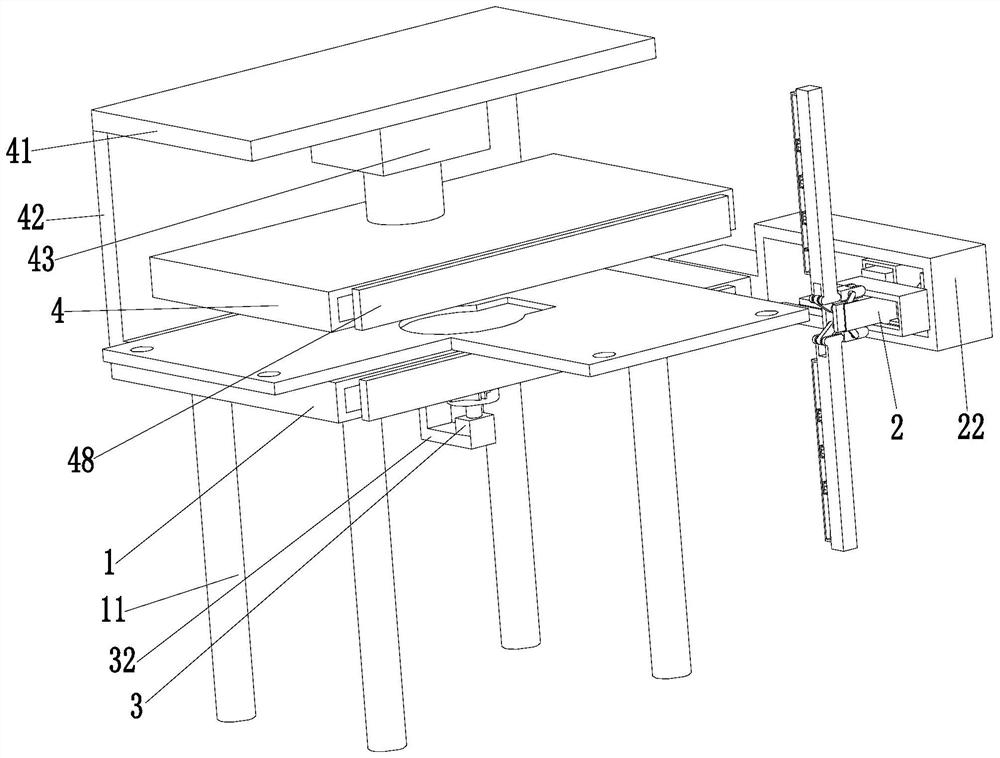

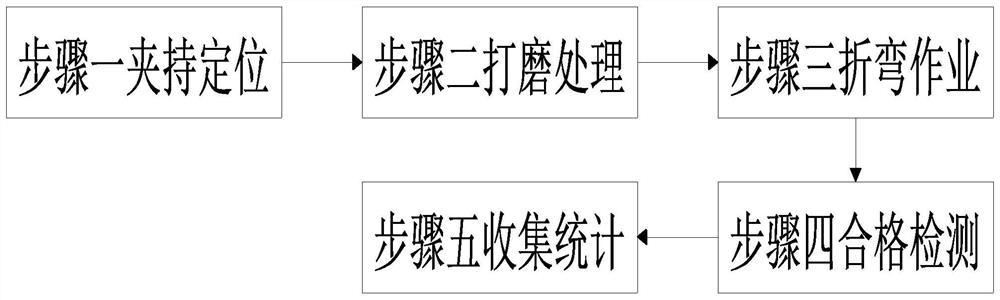

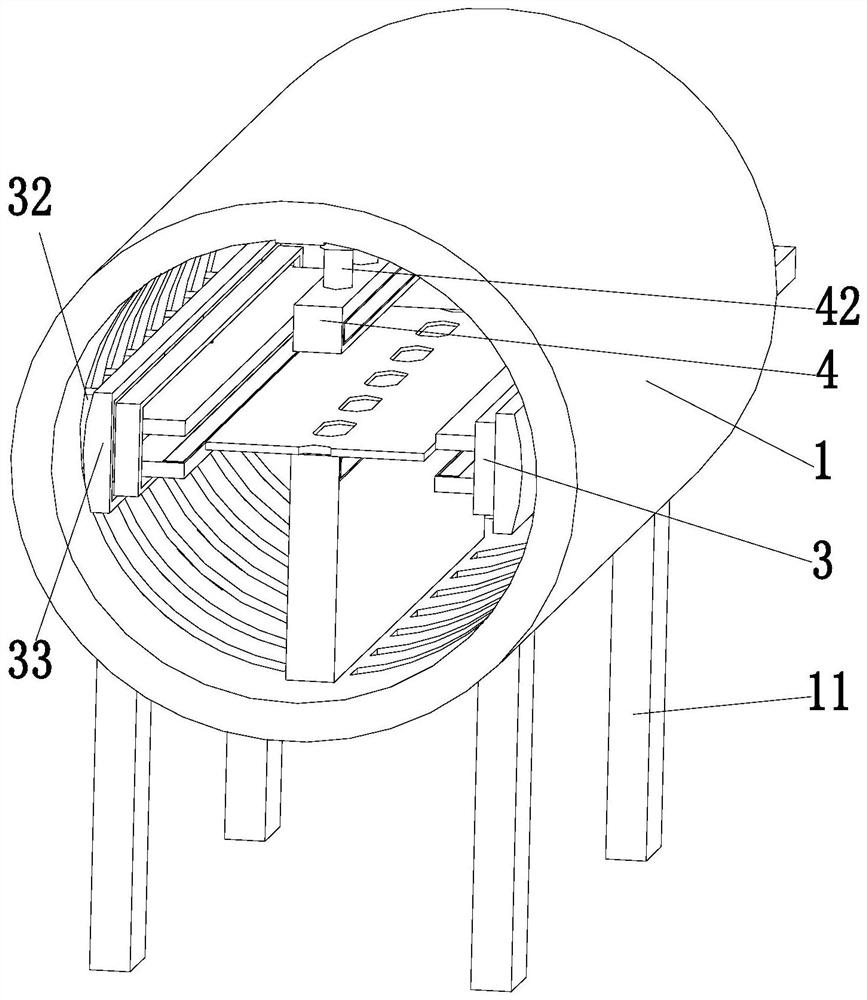

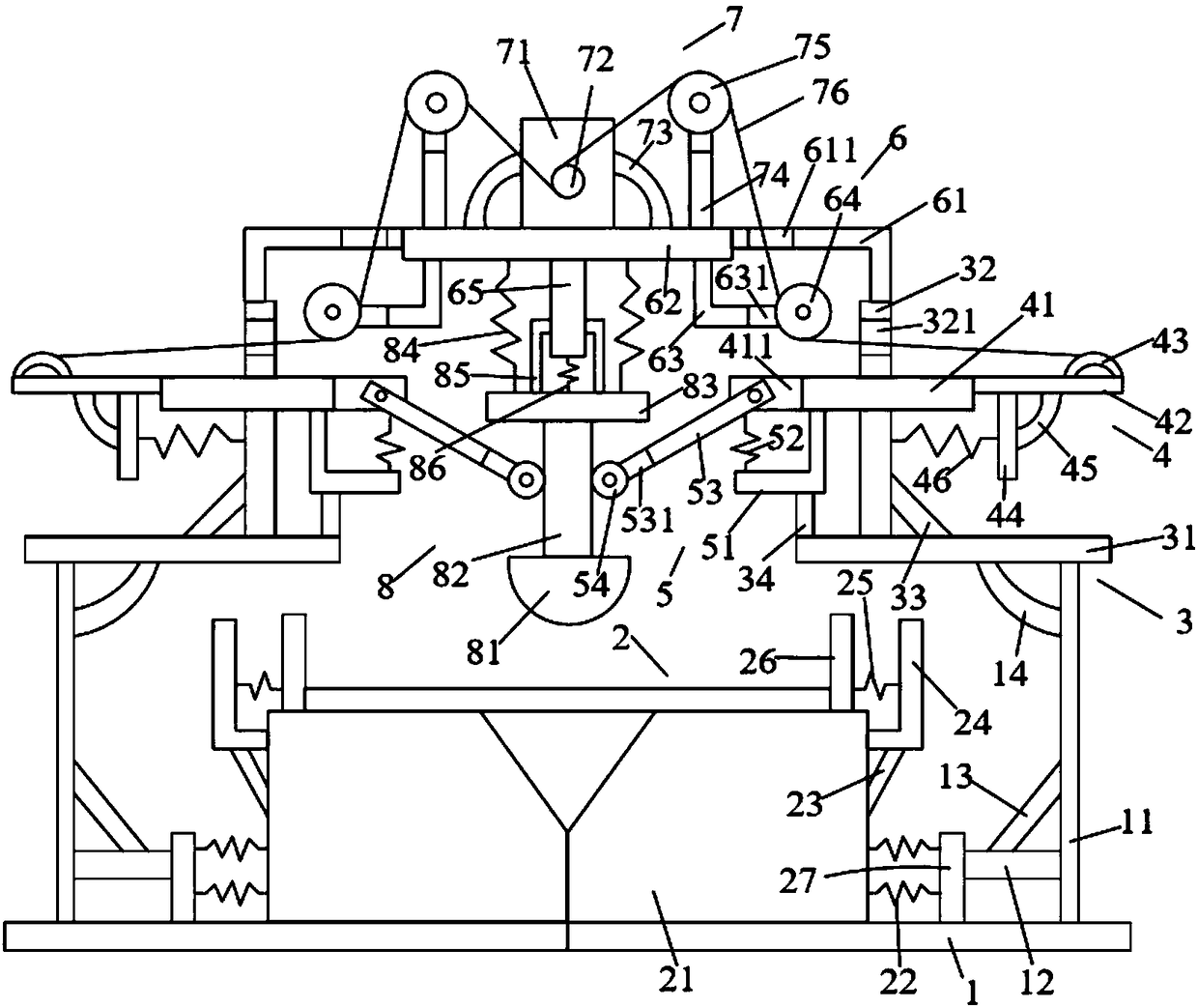

A method of bending and forming a sheet metal part after stamping

ActiveCN111036740BReduce production efficiencyHigh defective rateMetal-working feeding devicesOther manufacturing equipments/toolsStructural engineeringSheet metal stamping

The invention relates to a bending forming method of a sheet metal part after stamping, which mainly includes the following steps, including clamping and fixing, hole groove processing, bending processing, detection operation, quantitative collection and other processes, and the sheet metal parts used after stamping The bending and forming equipment includes a bottom plate, a clamping and rotating device, an intermittent rotating device and a clamping device. The present invention can solve the following problems in the bending and forming of existing sheet metal parts. a. At present, the sheet metal parts are processed into angled It is necessary to bend sheet metal parts. In mass production, bending machines are often used, but the bending machine is not easy to adjust the bending angle of sheet metal parts. It often needs to be stopped. Bending operations waste a lot of time, reduce production efficiency, and waste the time for manual machine adjustment; b. When the bending machine bends sheet metal parts, the bending effect is not stable due to the unstable bending process. Poor, the product defective rate is high.

Owner:佛山市广浩科技有限公司

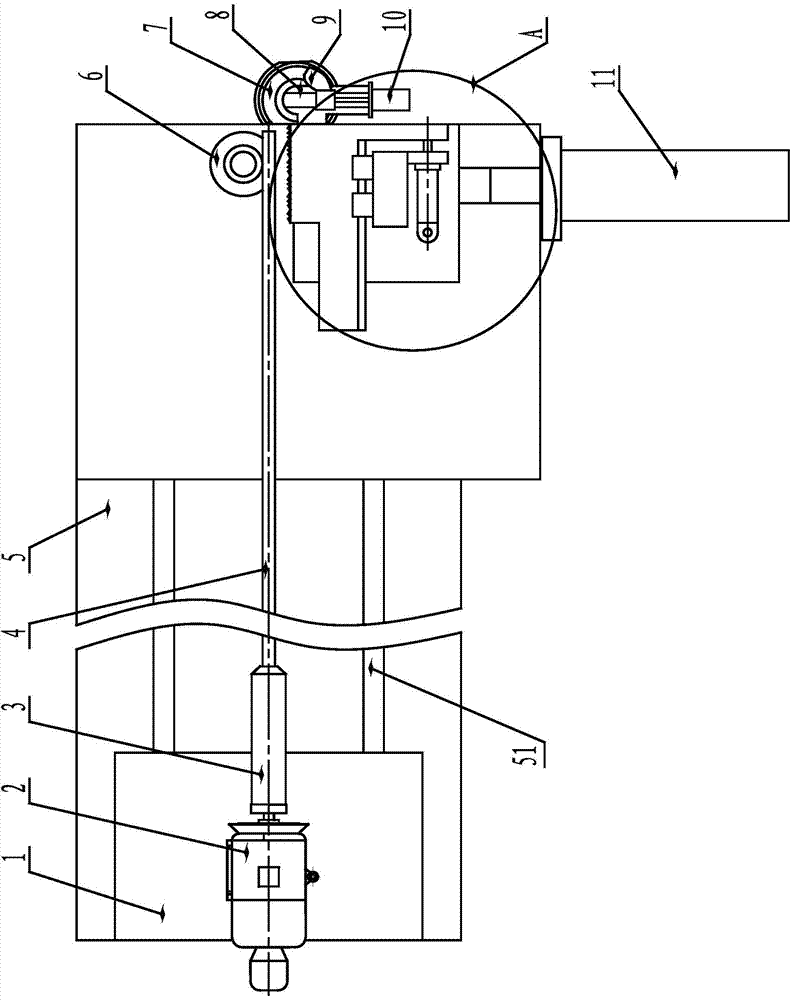

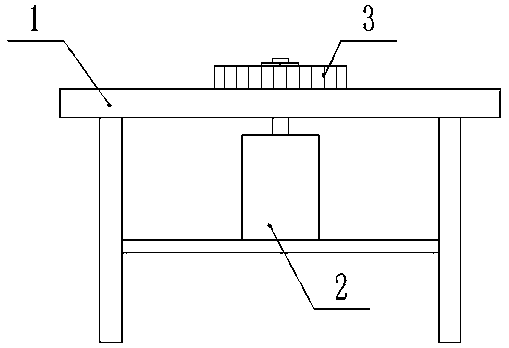

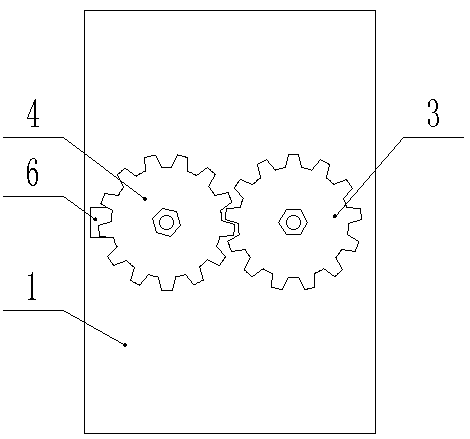

Gear bearing machine

The invention discloses a gear bending machine, and belongs to the field of bending machines. A bending machine special for bending of resistance wires of an electric heating boiler is provided, and the bending machine can adjust the bending magnitude according to the machined resistance wires. According to the technical scheme, the gear bending machine comprises a platform, a motor, a driving gear, a driven gear and a driven control assembly; the motor is arranged below the platform, an output shaft of the motor is vertically arranged, the output shaft of the motor penetrates through the platform and can rotate relative to the platform, the driving gear is fixed to the output shaft of the motor, a sliding groove is formed in the platform, the driving gear and the driven gear are engaged,the driven gear can slide along the sliding groove, a driven control assembly fastening the driven gear is arranged between the driven gear and the sliding groove, and the maximum distance between engaged teeth of the driving gear and the driven gear is 3 mm.

Owner:穆崇虎

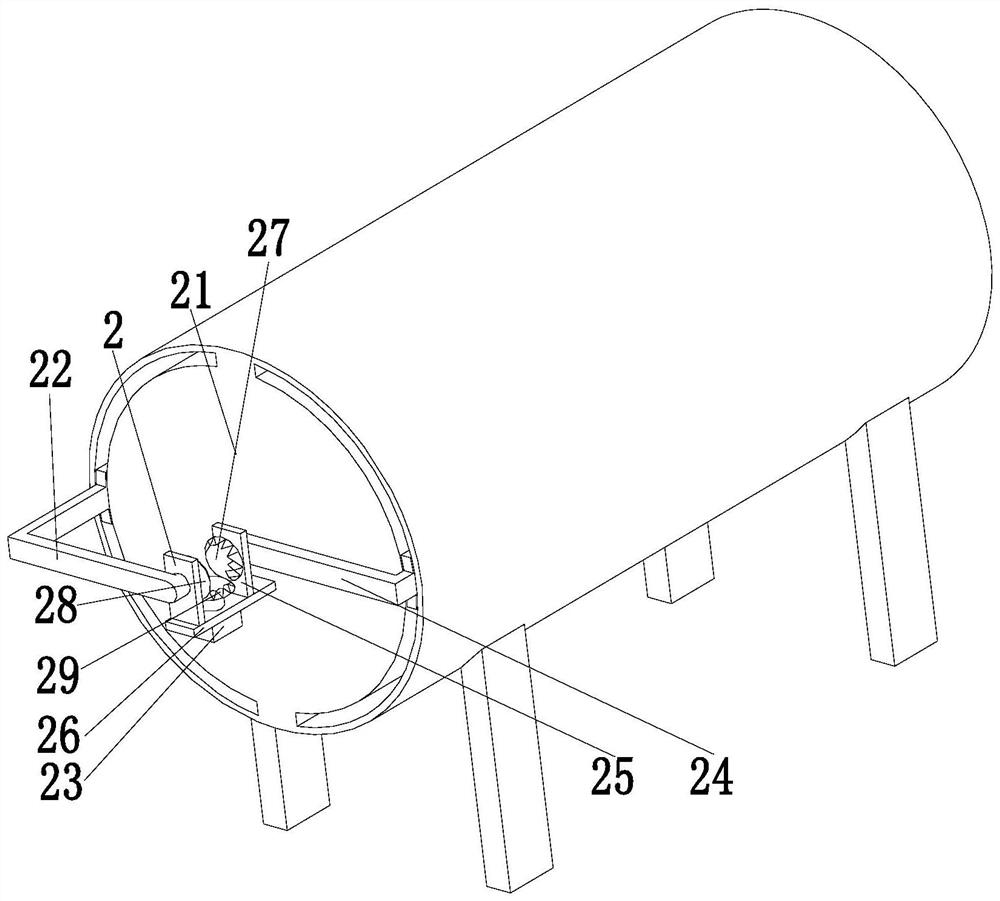

Bending method for manufacturing and processing electric power cabinet

ActiveCN110883148BImprove yieldImprove work efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachine

The invention relates to a bending method for manufacturing and processing electric power cabinets, which mainly includes the following steps, including clamping and positioning, grinding, bending operations, qualified inspection, and collecting statistics, etc., and the bending equipment used includes hollow round tubes , power rotating device, clamping device and clamping pre-bending device, the present invention can solve the following difficult problems existing in the bending and forming of the existing power and electrical cabinet profiles, a, currently the power and electrical cabinet profiles are processed into pieces with angles, It is necessary to bend the profile of the power electrical cabinet. The bending process often uses a bending machine, but the bending angle of the profile is not easy to adjust, and it is often necessary to stop the machine. After complex angle adjustments, the bending is performed The operation wastes a lot of time and reduces the production efficiency; b, when the bending machine bends the profile of the electric cabinet, the bending effect is poor due to the unstable bending process.

Owner:东莞市世欣五金制品有限公司

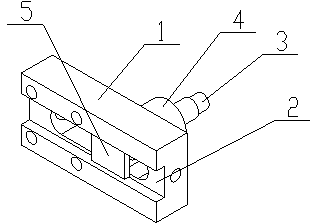

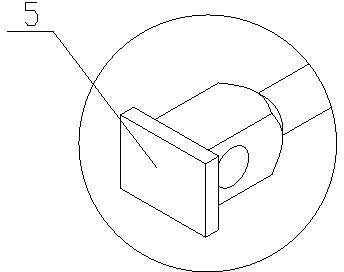

Fixing device for bending machine blade

The invention relates to the technical field of fixing devices, in particular to a fixing device for a bending machine blade. The fixing device comprises a pressing block used for tightly pressing the bending machine blade, a straight groove is formed in the upper surface of the pressing block, and the upper and lower surfaces of the pressing block are provided with wedge blocks, wherein the wedge blocks are used for adjusting the levelness of the blade and are perpendicular to the straight groove. According to the fixing device for the bending machine blade, the levelness of the blade is ensured through adjustment of the wedge blocks.

Owner:朱德仲

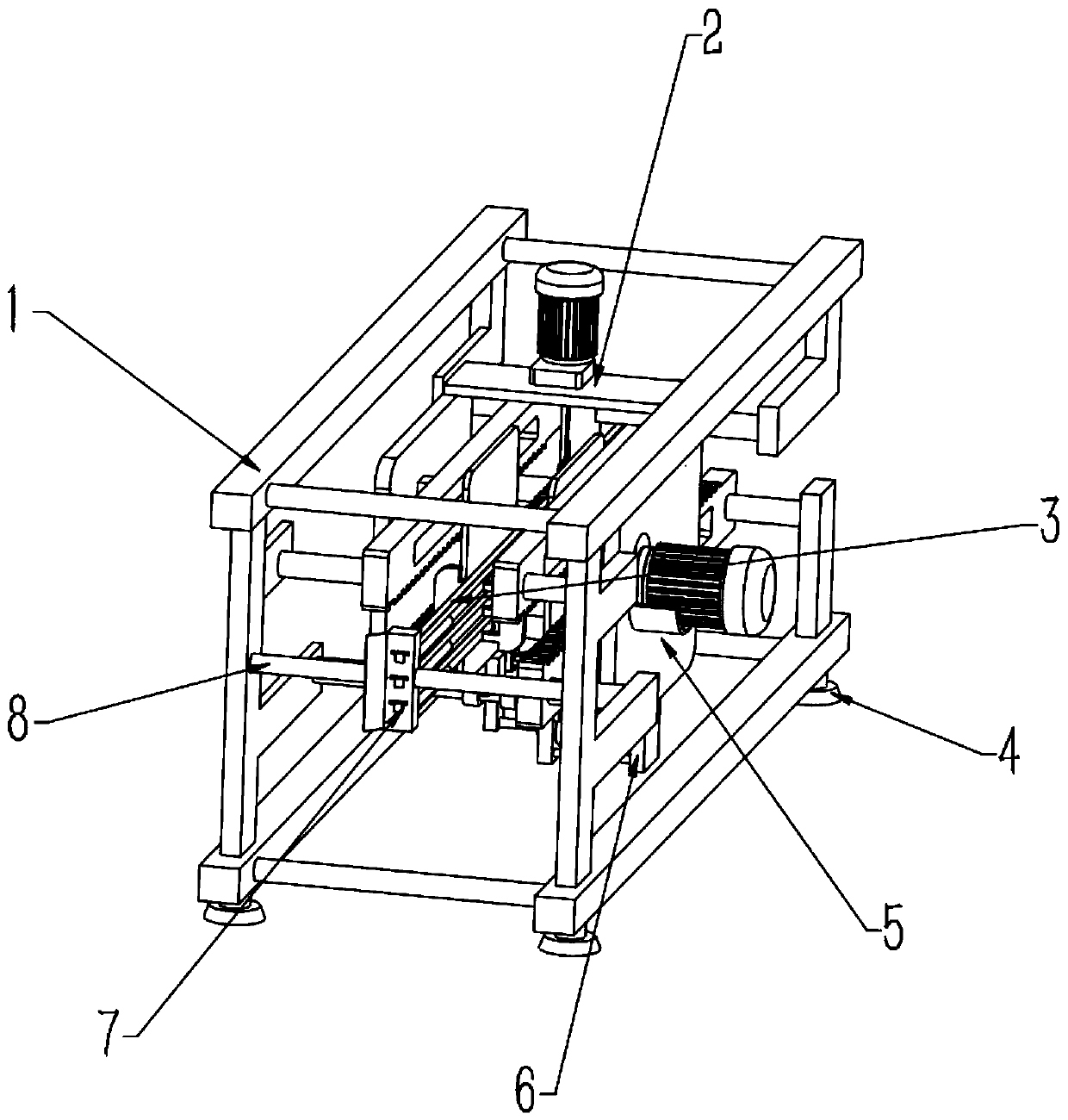

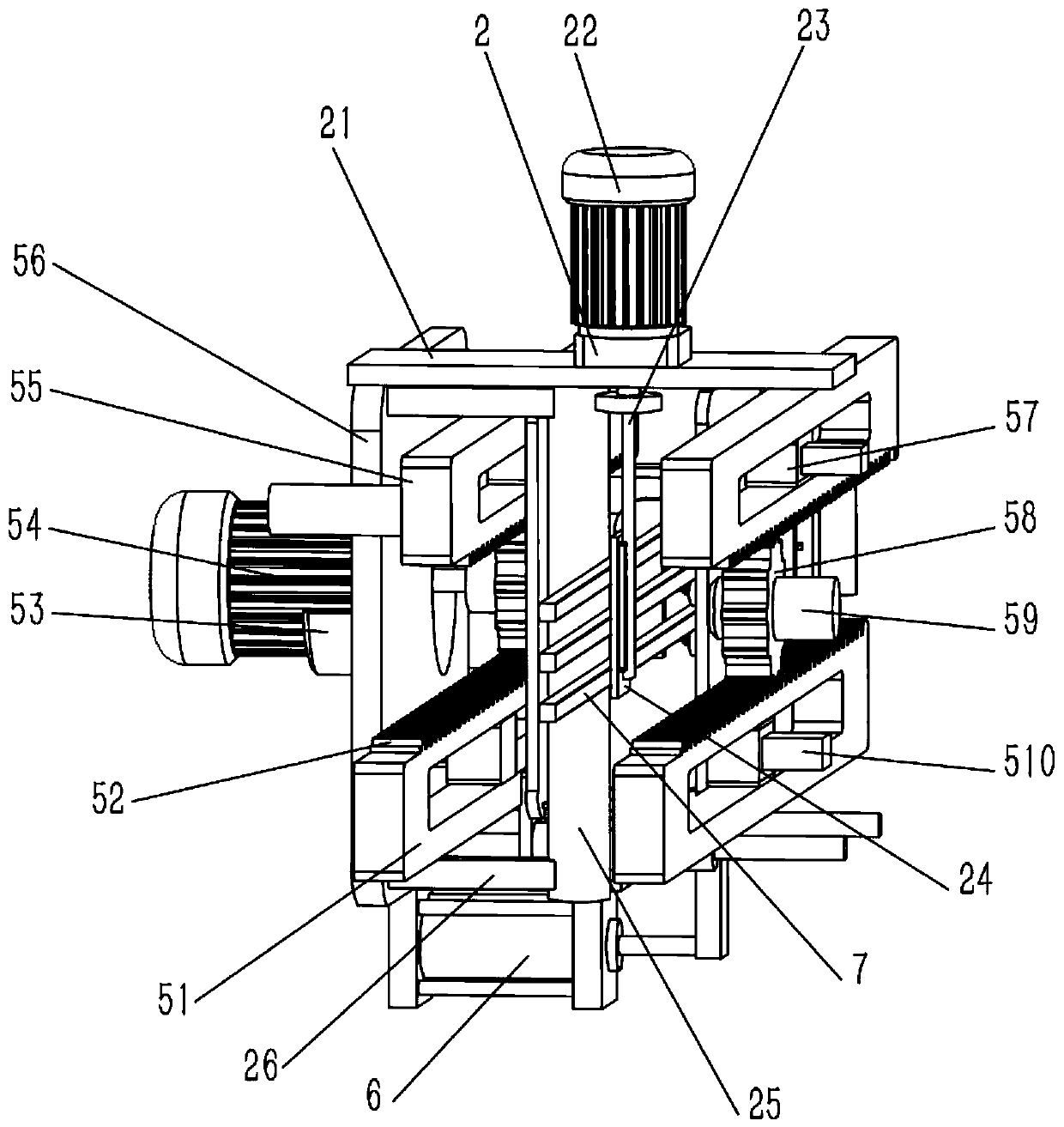

Bus bending machine

The invention discloses a bus bending machine. The bus bending machine comprises a rack, supporting legs are fixedly connected to the corners of the periphery of the bottom of the rack, a driving assembly is arranged in the rack, a placing device is arranged in the driving assembly, multiple buses are arranged in the placing device in a penetrating manner, the placing device and the two sides in the rack are fixedly connected with reinforcing rods, a clamping device is arranged on the bottom of the driving assembly, a bending device is arranged on the top of the driving assembly, the driving assembly comprises two first fixed bases and two second fixed bases fixedly connected to the left side and the right side in the rack, the two second fixed bases are located over the two first fixed bases, sliding blocks are in sliding connection into the first fixed bases and the second fixed bases, third connecting rods are fixedly connected to the sliding blocks, and first fixed plates are connected between two third connecting rods on the left side in the rack and between two third connecting rods on the right side in the rack. The bus bending machine has the advantages of accurately determining the bending position and being good in bending effect.

Owner:安徽方舟电气设备有限公司

Ultra-wide hydraulic bending machine tool with transverse stabilizer bar

PendingCN110860585AGuaranteed bending effectReach limit effectShaping toolsMetal-working feeding devicesHydraulic cylinderEngineering

The invention relates to the technical field of bending machine tools and discloses an ultra-wide hydraulic bending machine tool with a transverse stabilizer bar. The ultra-wide hydraulic bending machine tool comprises a base. A fixed rack is arranged above the base, the bottom of the fixed rack is fixedly arranged on the upper surface of the base, two hydraulic cylinders are fixedly arranged on the top of the fixed rack, the two hydraulic cylinders are symmetrically arranged, a fixed plate is horizontally arranged below the two hydraulic cylinders, the tail ends of piston rods of the two hydraulic cylinders are fixedly connected to the upper surface of the fixed plate, a transversely arranged bending head is fixedly arranged on the lower surface of the fixed plate, a fixed seat is transversely arranged below the bending head, the lower surface of the fixed seat is fixedly connected to the upper surface of the base, a bending slot is formed in the upper surface of the fixed seat, and the bending slot is matched with the bending head. The ultra-wide hydraulic bending machine tool with the transverse stabilizer bar can heat a panel in the bending slot, so that the bending effect of the panel is guaranteed. Meanwhile, the ultra-wide hydraulic bending machine tool can limit the panel in the bending process, so that the bending effect of the panel is improved.

Owner:马鞍山市中亚机床制造有限公司

Rolling type insulated wire bending device

ActiveCN113369409AGuaranteed bending effectEasy to operateStructural engineeringMechanical engineering

The invention discloses a rolling type insulated wire bending device, and aims to provide the rolling type insulated wire bending device which is convenient and rapid to operate, can ensure the bending effect of a large-diameter insulated wire and can bend the large-diameter insulated wire into a specific angle. The rolling type insulated wire bending device comprises a rack, a fixed roller and a wire bending mechanism, wherein the rack comprises a workbench; the fixed roller is arranged on the workbench, and a rotating shaft of the fixed roller is vertically distributed; the wire bending mechanism comprises a horizontal moving bracket, horizontal guide sleeves fixed on the workbench, horizontal guide rods which are arranged on the horizontal moving bracket and are in sliding fit with the horizontal guide sleeves, a jack which is arranged on the workbench and used for pushing the horizontal moving bracket and two movable rollers which are arranged on the horizontal moving bracket side by side; and rotating shafts of the movable rollers are parallel to the rotating shaft of the fixed roller, and the fixed roller is located between moving tracks of the two movable rollers.

Owner:国网浙江省电力有限公司江山市供电公司

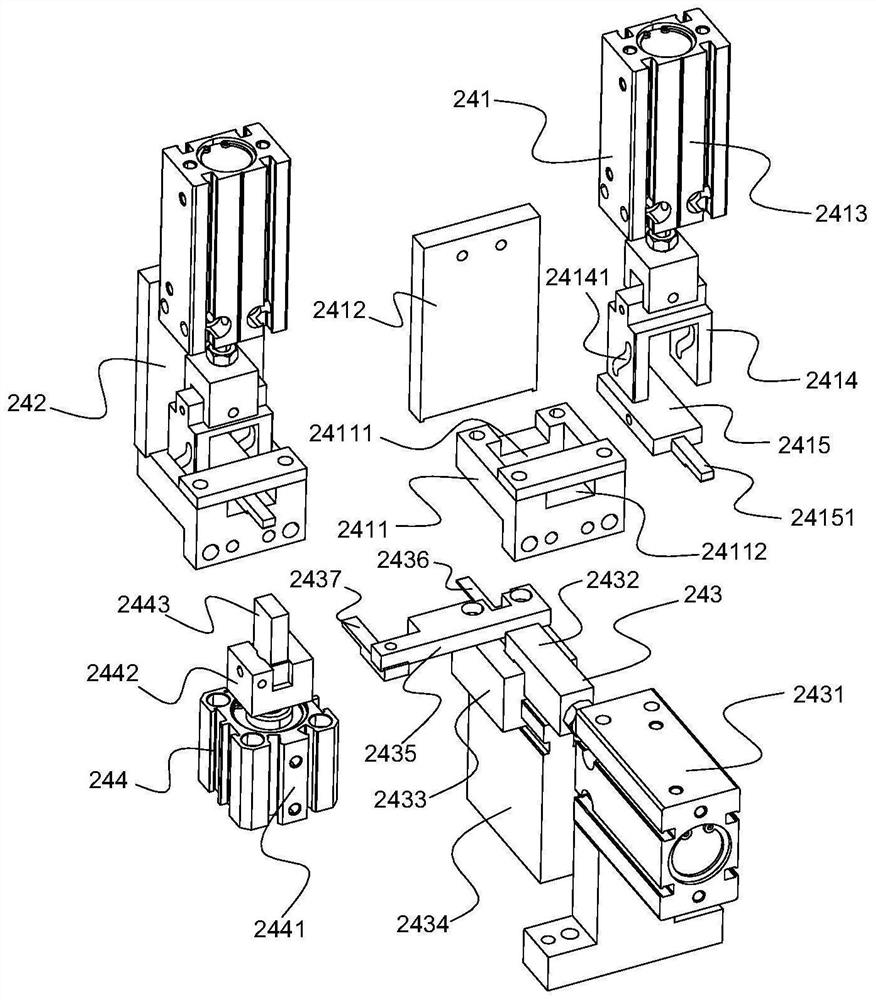

Bending mechanism and bending method for wiring terminal of radio frequency coaxial connector

InactiveCN112382912AGuaranteed accuracyGuaranteed bending effectContact member manufacturingStructural engineeringRadio frequency

The invention relates to the field of assembly equipment, in particular to a wiring terminal bending mechanism of a radio frequency coaxial connector. The bending mechanism comprises a rack, and a material frame, a first pre-pressing assembly, a second pre-pressing assembly, a side surface bending assembly and a bottom bending assembly which are arranged on the rack; a feeding channel is arrangedin the material frame; a first bending station and a second bending station are arranged on the material frame; the position of the first pre-pressing assembly is matched with that of the first bending station; the position of the second pre-pressing assembly is matched with that of the second bending station; the first pre-pressing assembly and the second pre-pressing assembly are located on thesame side of the material frame. The side face bending assembly is installed on the other side of the material frame and matched with the first pre-pressing assembly and the second pre-pressing assembly at the same time. The bottom bending assembly is installed below the material frame, and the position of the bottom bending assembly corresponds to the position of the second pre-pressing assembly.According to the pin bending device, the pin is transversely pressed firstly, then the pin is pressed again from bottom to top, and the bending effect is guaranteed by bending in different directionstwice in sequence.

Owner:朱伟雅

A fast and efficient bending system for metal sheets

ActiveCN106853468BFast and efficient bending handlingQuick fixMetal-working feeding devicesPositioning devicesPetroleum engineering

A rapid and efficient hardware plate bending system comprises a base plate, a supporting and fixing device, a support device, an abutting device, a roller device, a transverse plate device, a motor device and a pressing device, wherein a first supporting rod, a first cross rod, a first oblique rod and a first bent rod are arranged on the base plate, the supporting and fixing device comprises a supporting block, a first spring, a second oblique rod, a first support, a second spring, an abutting plate and a first fixing rod, the support device comprises a first transverse plate, a second supporting rod, a second fixing rod and a first vertical rod, the abutting device comprises a first abutting rod, a second cross rod, a first connecting ring, a second vertical rod, a second bent rod and a third spring, the roller device comprises a second abutting rod, a fourth spring, a second support and a first roller, and the transverse plate device comprises a second transverse plate, a third support, a fourth support, a second roller and a third vertical rod. The rapid and efficient hardware plate bending system can conduct effective bending treatment on hardware plates and is high in bending efficiency and rapid, and the bending time can be greatly saved.

Owner:重庆市雷驰金属结构制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com