Patents

Literature

179results about How to "No significant increase in cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

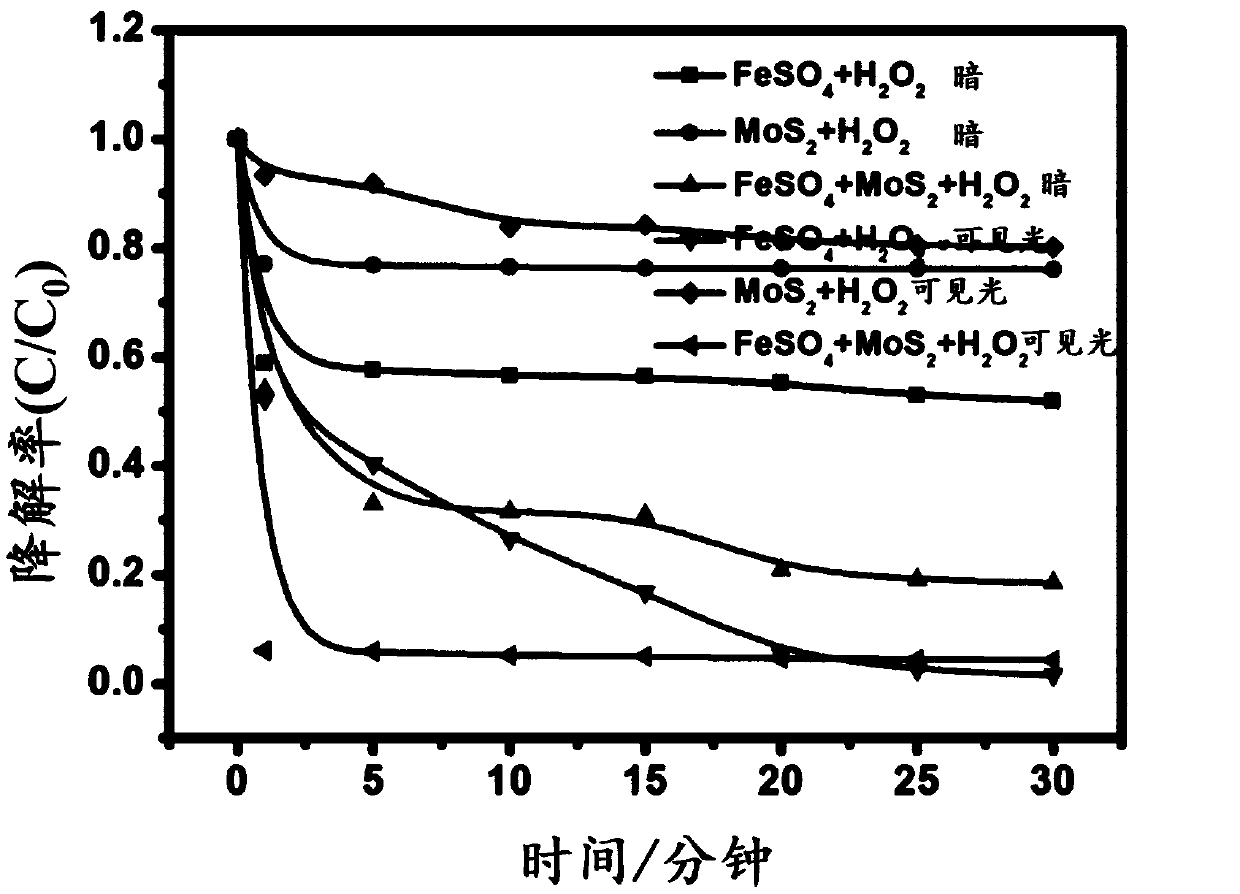

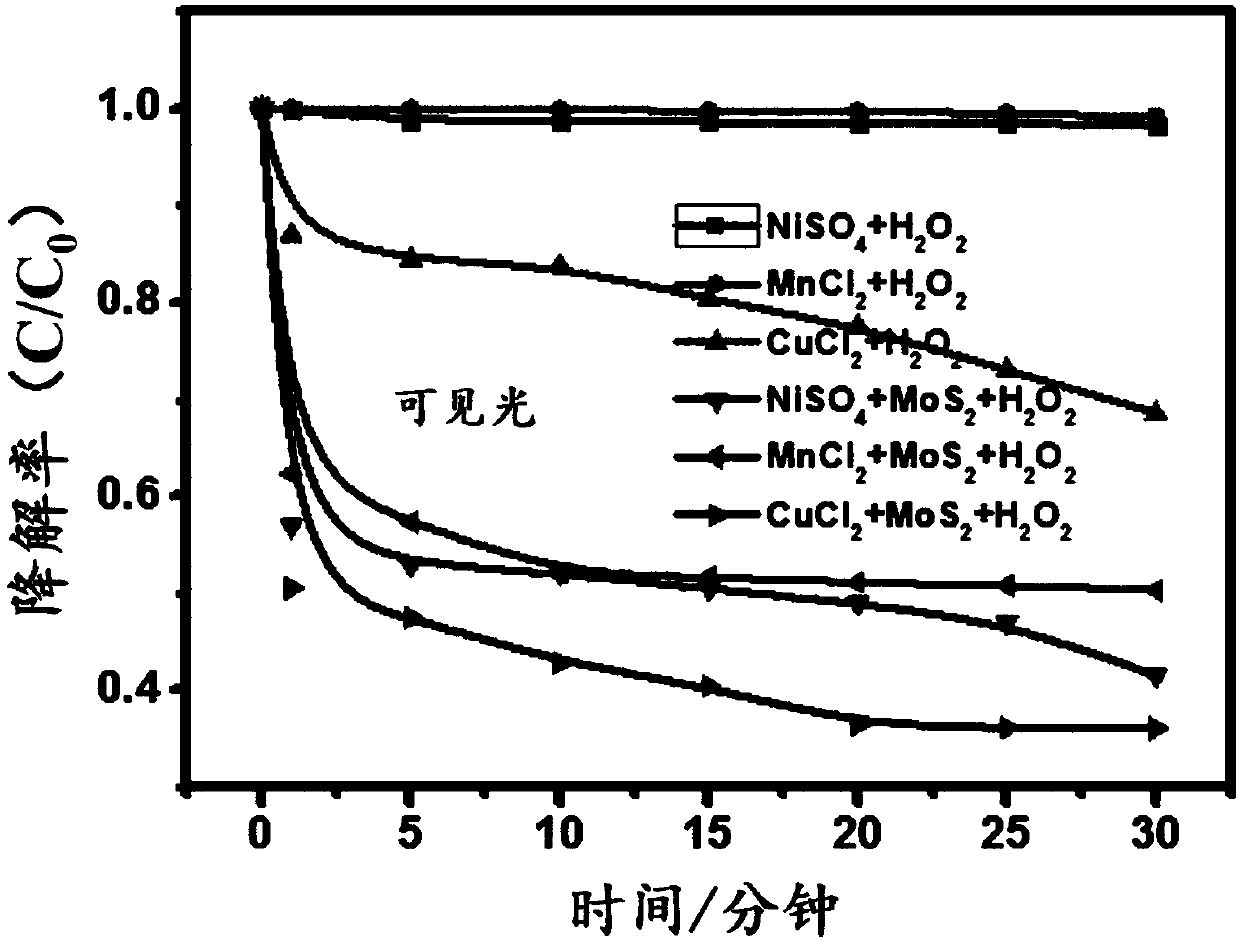

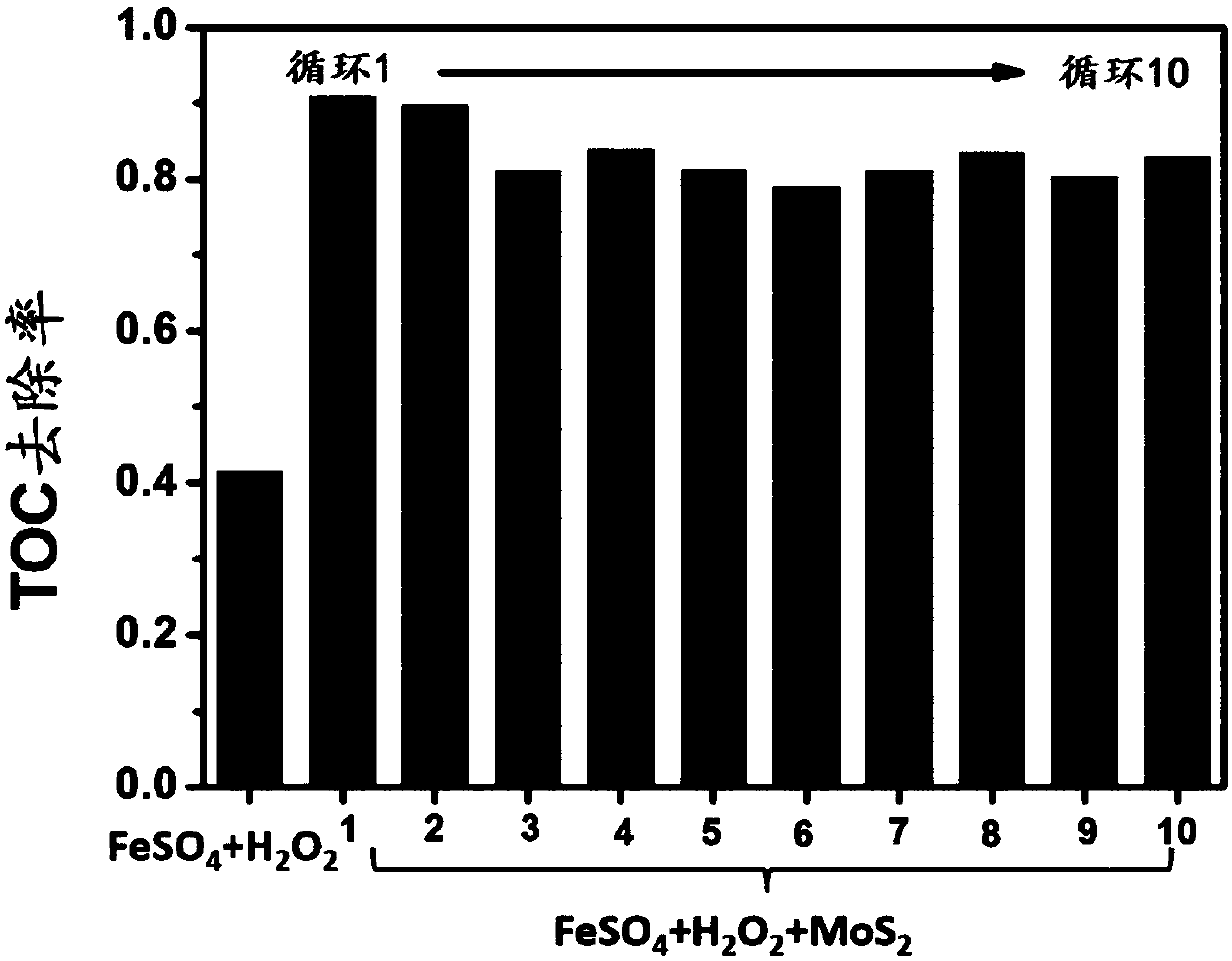

Sulfide-containing industrial wastewater treatment reagent and reaction method thereof

InactiveCN107720930AImprove utilization efficiencyImprove degradation efficiencyWater contaminantsWater/sewage treatment by oxidationHydrogen peroxide breakdownFenton reaction

The invention relates to the field of chemistry, in particular to the treatment of contaminants. A sulfide-containing industrial wastewater treatment reagent comprises a Fenton reagent containing an iron source and hydrogen peroxide, and also comprises sulfide, wherein the sulfide is mixed in the Fenton reagent to be used as a cocatalyst of the Fenton reagent. Compared with the traditional homogeneous Fenton reaction system, the cheap and readily available sulfide is used as the cocatalyst, so that the catalytic reaction is firstly carried out on the surface of the sulfide to improve the efficiency of decomposition of hydrogen peroxide to generate hydroxyl radicals during the Fenton reaction process and improve the degradation efficiency and the utilization efficiency of the hydrogen peroxide, and the sulfide per se can be recycled, and the problem of producing a large amount of iron sludge by homogeneous Fenton can be avoided, thereby reducing the treatment cost.

Owner:EAST CHINA UNIV OF SCI & TECH

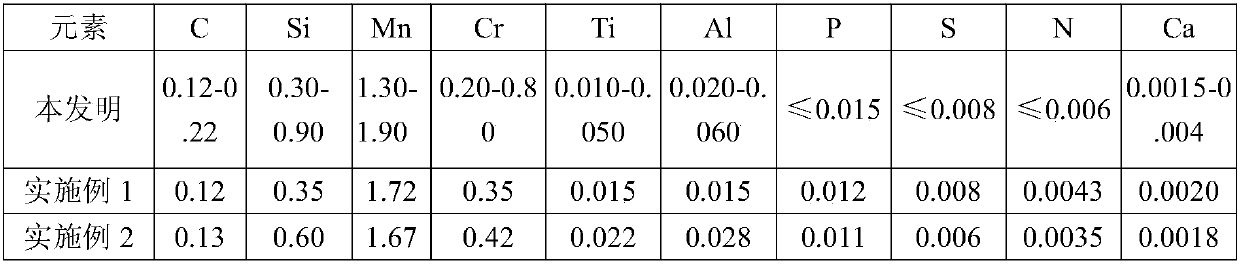

Cold-rolled martensite steel plate with yield strength of 750 MPa grade and manufacturing method thereof

ActiveCN107619993ALightweight effect is goodImproved Chemical Composition DesignUltimate tensile strengthMartensite

The invention relates to a cold-rolled martensite steel plate with yield strength of 750 MPa grade and a manufacturing method thereof, and mainly aims to solve the technical problem that the existingcold-rolled martensite steel plate with yield strength of 750 MPa grade is high in manufacturing cost. The cold-rolled martensite steel plate provided by the invention consists of the following chemical components in percentage by weight: 0.12-0.22% of C, 0.30-0.90% of Si, 1.30-1.90% of Mn, 0.20-0.80% of Cr, 0.010-0.050% of Ti, 0.020-0.060% of Al, less than or equal to 0.015% of P, less than or equal to 0.008% of S, less than or equal to 0.006% of N, 0.0015-0.004% of Ca and the balance of iron and inevitable impurities. The steel plate has yield strength of 790-830 MPa, tensile strength greater than 980 MPa, and percentage elongation after fracture A80 greater than or equal to 6%. The cold-rolled martensite steel plate is mainly used for manufacturing a truck boundary beam, a square tube stand column and the like.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

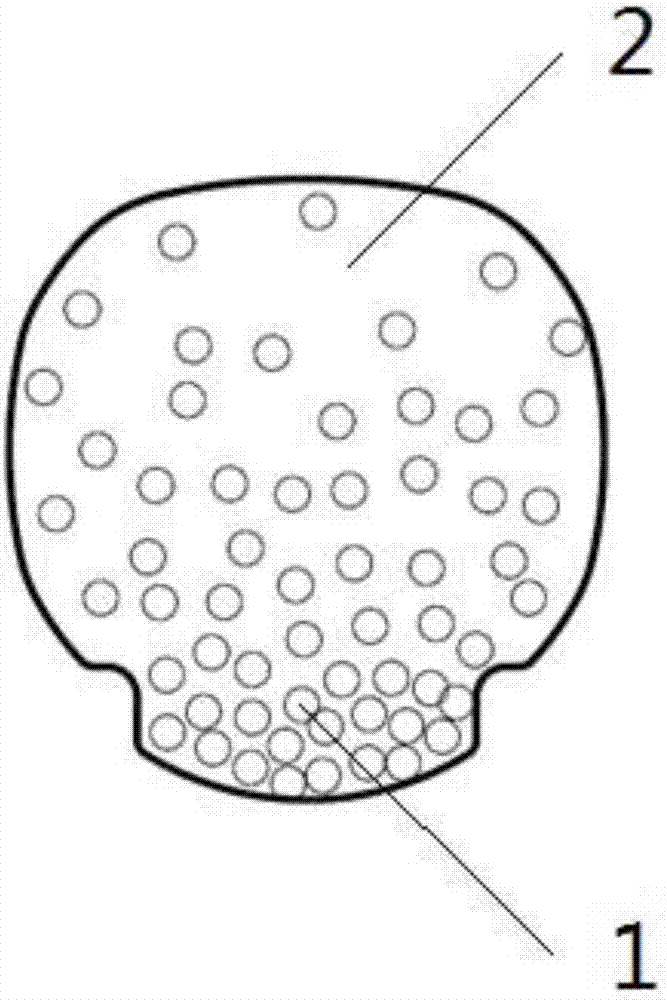

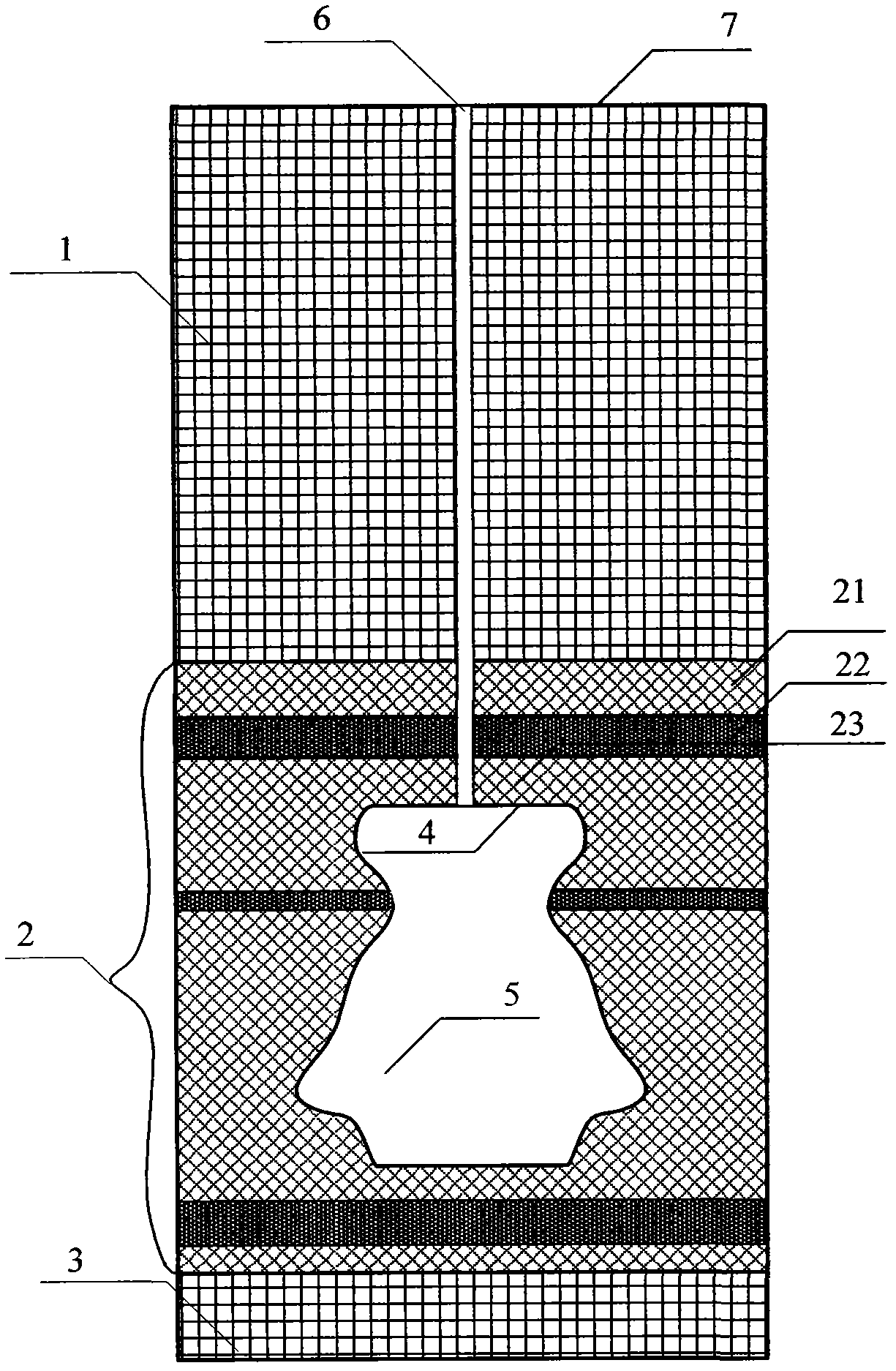

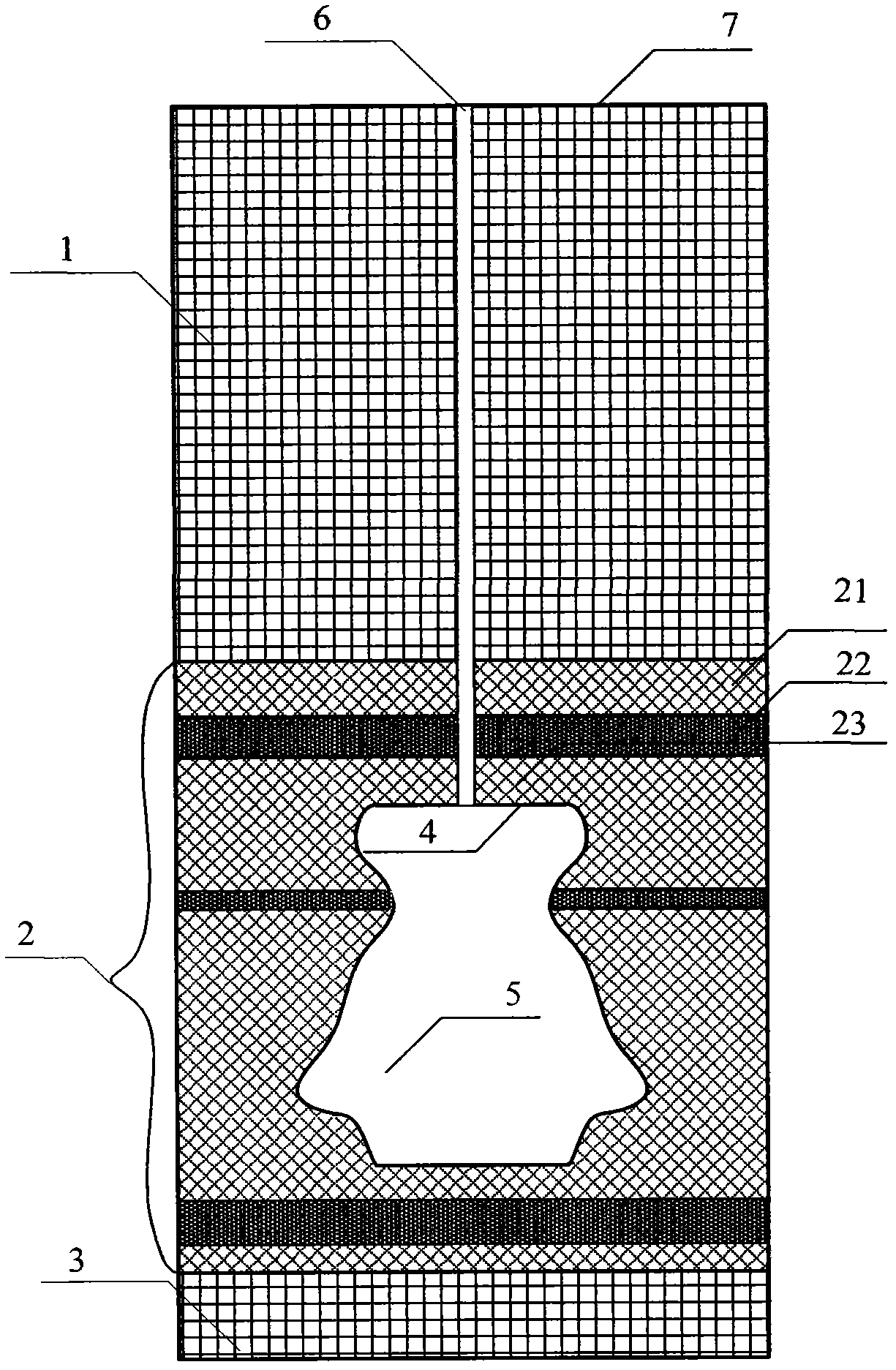

Multiple-interlayer salt cavern gas storage and building method of multiple-interlayer salt cavern gas storage

The invention belongs to the field of oil and gas resource development and particularly relates to a multiple-interlayer salt cavern gas storage and a building method of the multiple-interlayer salt cavern gas storage. The multiple-interlayer salt cavern gas storage comprises a salt cavern and a natural gas injection-production string system, wherein the natural gas injection-production string system is connected with the top of the salt cavern. Top mud rocks, multiple-interlayer salt rocks and bottom mud rocks are sequentially arranged downwards from the ground. The multiple-interlayer salt rocks are composed of salt rocks and interlayers which alternately appear. The multiple-interlayer salt cavern gas storage is characterized in that the salt cavern is positioned in the multiple-interlayer salt rocks; a first salt rock layer, the interlayer and a second salt rock layer are sequentially arranged from the bottom of the top mud rocks to the top of the salt cavern; and the top of the salt cavern is in the shape of circular plane. The building method of the multiple-interlayer salt cavern gas storage comprises the following steps of: selecting top structure, drilling a well, completing the well, installing the injection-production string, carrying out solution mining, and controlling the size of the top structure. According to the building method, the characteristics of the top structure of the multiple-interlayer salt cavern gas storage are mainly considered, the parameters of the size of the top structure are provided, the operability is strong, and the cost is not obviously increased. The building method is good in popularization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

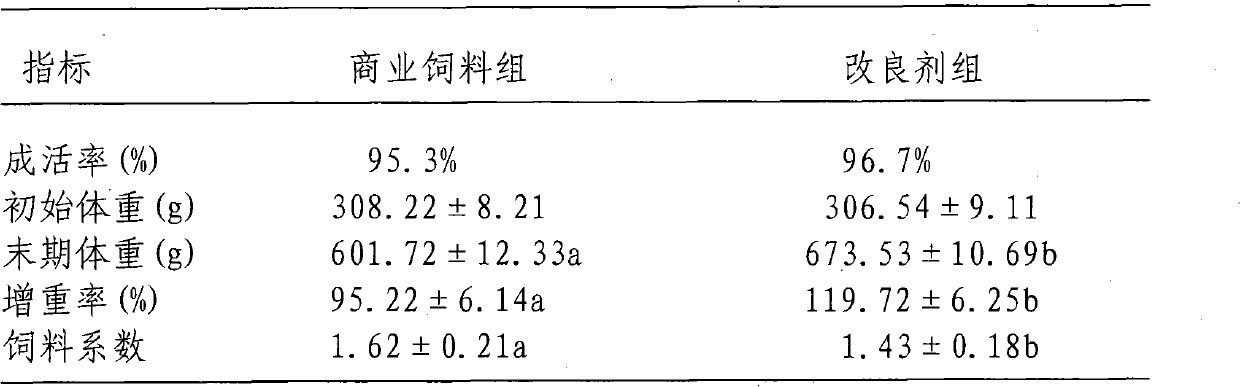

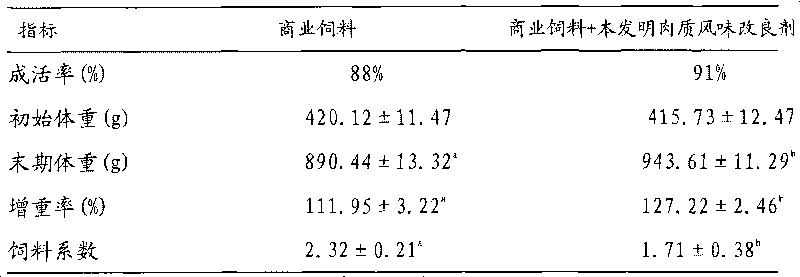

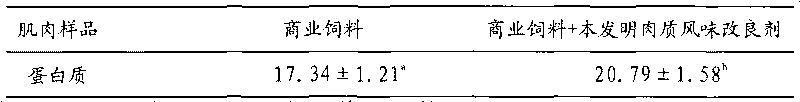

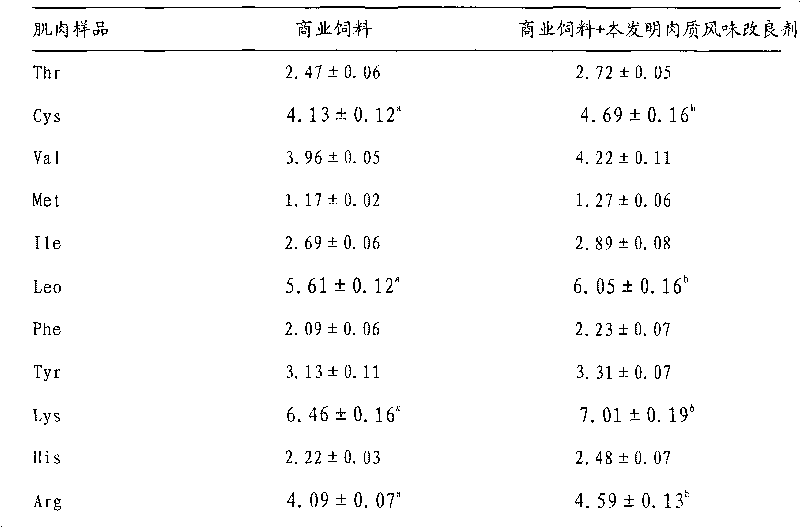

Meat quality flavor modifying agent for grass carp or carp and preparation method thereof

ActiveCN101744145AIncrease attractivenessImprove immunityAnimal feeding stuffBiotechnologyAquaculture industry

The invention relates to a feed additive of aquaculture industry, in particular to a meat quality flavor modifying agent for grass carp or carp and a preparation method thereof. Each kilogram of modifying agent comprises the following components: 30 to 50g of seaweed extract, 10 to 20g of combination of inosinic acid and guanylic acid, 20 to 30g of carnitine, 15 to 30g of glycin, 10 to 20g of alanine and the balance of zeolite powder. The preparation method comprises the following steps: firstly, crushing solid materials in the seaweed extract, the combination of inosinic acid and guanylic acid, the carnitine, the glycin, the alanine and the zeolite powder materials and sieving the crushed solid materials through a sieve with 80 to 100 meshes for later use; and secondly, mixing and stirring the crushed solid materials in the proportion to ensure that the coefficient of variation CV of the uniformity is less than 5 percent to obtain the product. The modifying agent can effectively improve protein content, content of total amino acids, content of essential amino acids and content of delicious amino acid in muscles of the grass carp and the carp.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

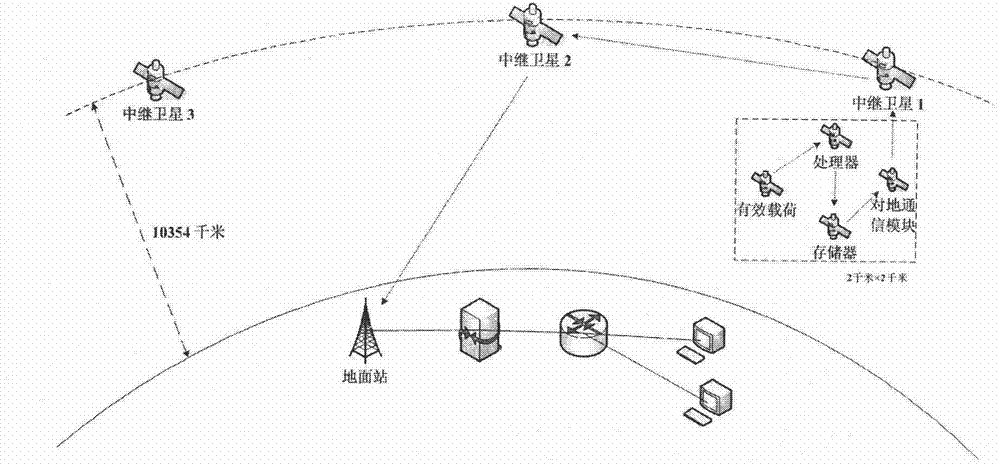

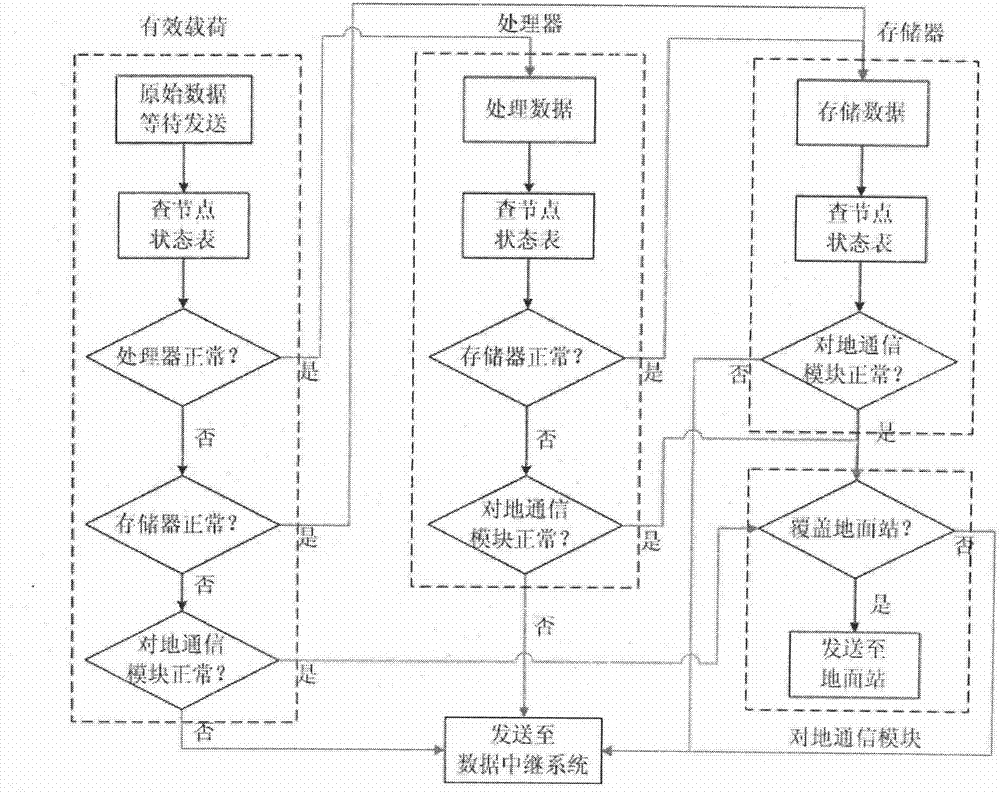

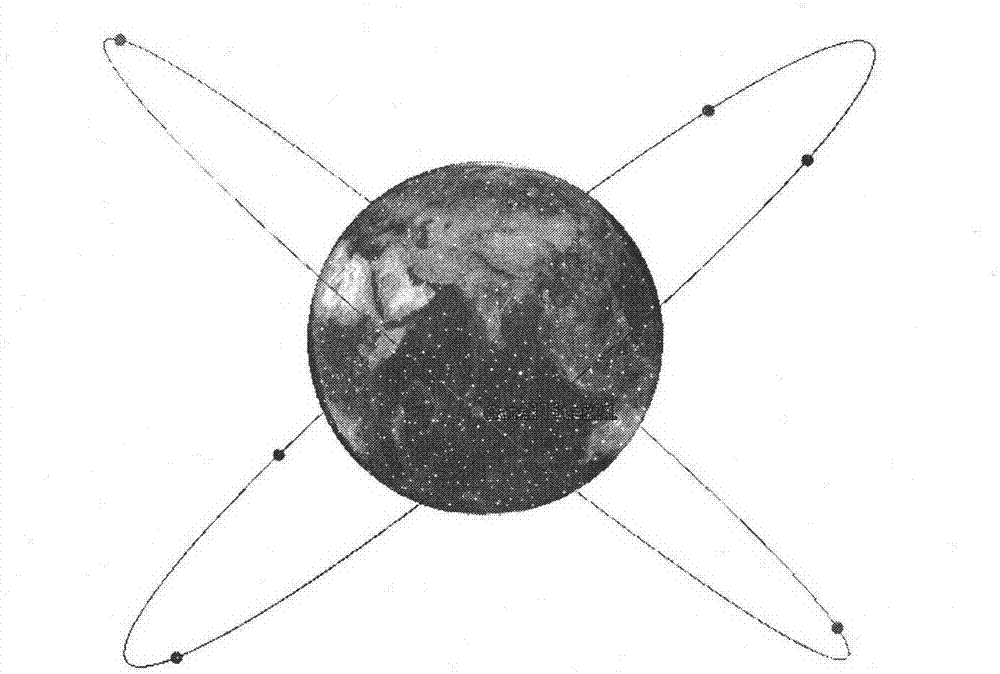

Separation modular satellite system and method based on medium earth obit (MEO) data relay

ActiveCN102932050ARealize real-time data transmissionNo significant increase in costRadio transmissionEnd-to-end delaySatellite

The invention discloses a separation modular satellite system and a method based on MEO data relay. The system comprises a separation modular satellite cluster, an MEO data relay system and an earth station, wherein the separation modular satellite cluster generates data after onboard processing and sends the data to the MEO data relay system; the MEO data relay system performs routing on the data and sends the data to the earth station in a transparent forwarding mode; and the earth station performs further analysis processing on the received data to obtain a final result. According to the system and the method, end-to-end delay of the separation modular satellite system can be effectively reduced, and therefore real-time data transmission of the separation modular satellite system is achieved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

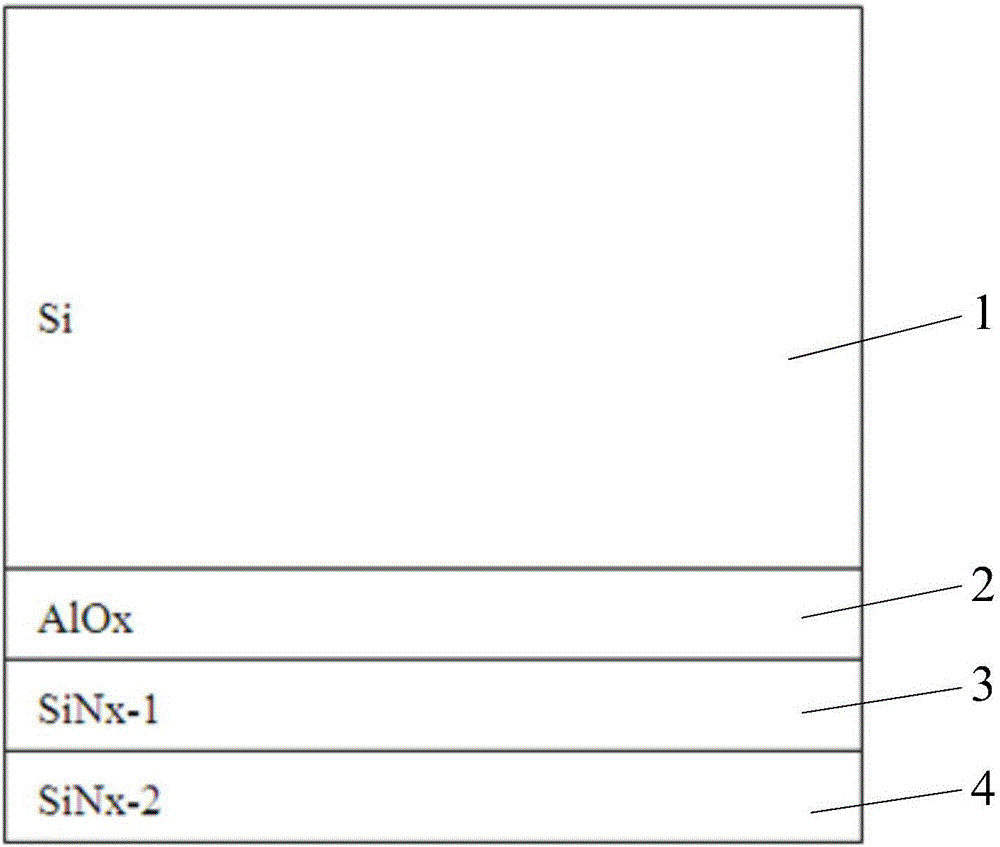

Solar cell back passive film layer structure and preparation method thereof

ActiveCN106169510AImprove conversion efficiencyNo significant increase in costFinal product manufacturePhotovoltaic energy generationRefractive indexSolar cell

The present invention provides a solar cell back passive film layer structure. The main improvement is that: an alumina film, a first silicon nitride film and a second silicon nitride film are formed in order at the solar cell substrate back surface to form a multi-layer back passive film lamination structure; the film thickness of the alumina film is in the range of 10-40nm, and the refractive index of the alumina film is in the range of 1.55-1.70; the film thickness of the first silicon nitride film is in the range of 40-100nm, and the refractive index of the first silicon nitride film is in the range of 1.90-2.20; and the film thickness of the second silicon nitride film is in the range of 40-100nm, and the refractive index of the second silicon nitride film is in the range of 1.90-2.20. Optimally, the film thickness of the alumina film is 20nm, and the refractive index of the alumina film is 1.62nm; the film thickness of the first silicon nitride film is 75nm, and the refractive index of the first silicon nitride film is 2.10; and the film thickness of the second silicon nitride film is 75nm, and the refractive index of the second silicon nitride film is 2.00. The conversion efficiency of the solar cell is improved.

Owner:WUXI SUNTECH POWER CO LTD

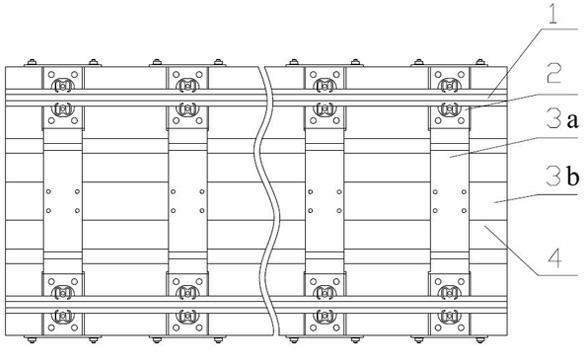

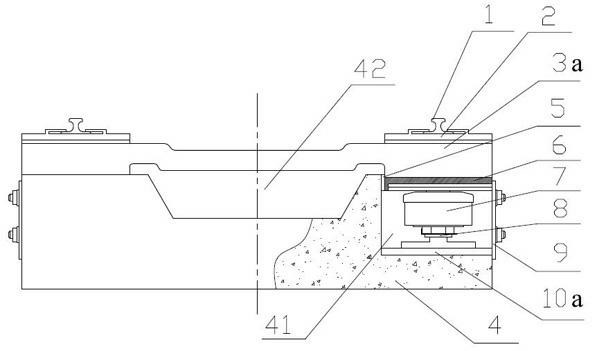

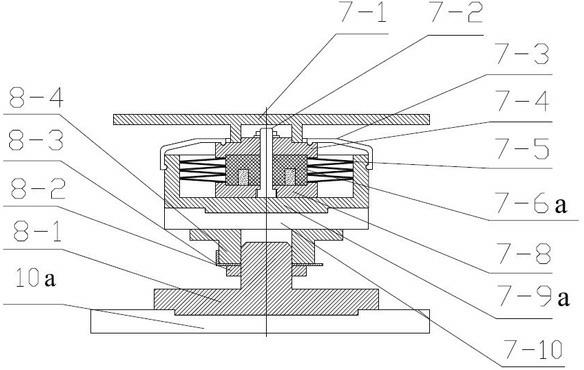

Elastic vibration-reduction ballast bed system

The invention discloses an elastic vibration-reduction ballast bed system, which comprises a concrete ballast bed and a low-frequency vibration isolator installed in the concrete ballast bed. An elastic mechanism in the low-frequency vibration isolator consists of a positive stiffness elastic element made of metal rubber or the positive stiffness elastic element and a negative stiffness elastic element which are connected in parallel. The positive stiffness elastic element is a disc spring, a spiral spring, the metal rubber, a metal rubber-spring armour, a metal rubber-lead core composite spring or any series-parallel combination of the disc spring, the spiral spring, the metal rubber, the metal rubber-spring armour and the metal rubber-lead core composite spring. The negative stiffness elastic element is a disc spring or a diaphragm spring. The elastic vibration-reduction ballast bed system can meet requirements of middle-high-grade vibration reduction and has a simple structure. The site construction process is simple and convenient, and consumed materials of the ballast bed are relatively reduced. Therefore, the elastic vibration-reduction ballast bed system is low in construction cost and suitable for popularization and application in the whole line.

Owner:河北金擘机电科技有限公司 +1

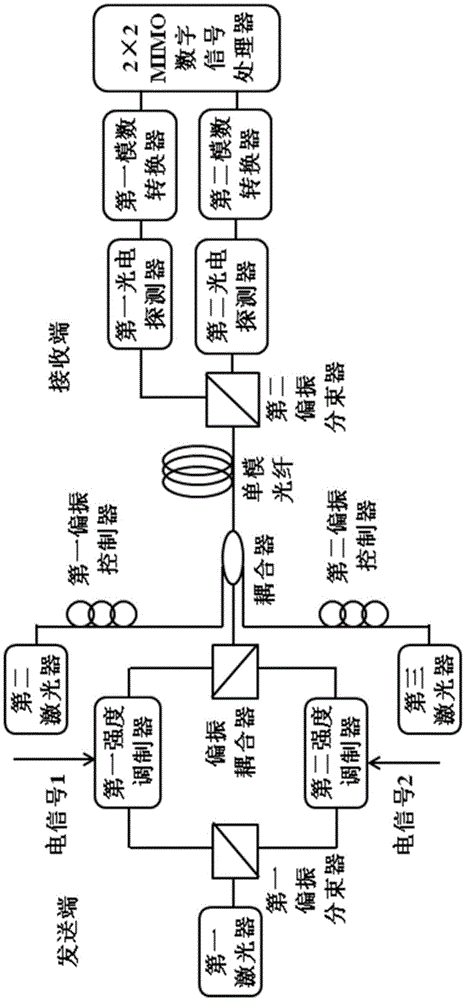

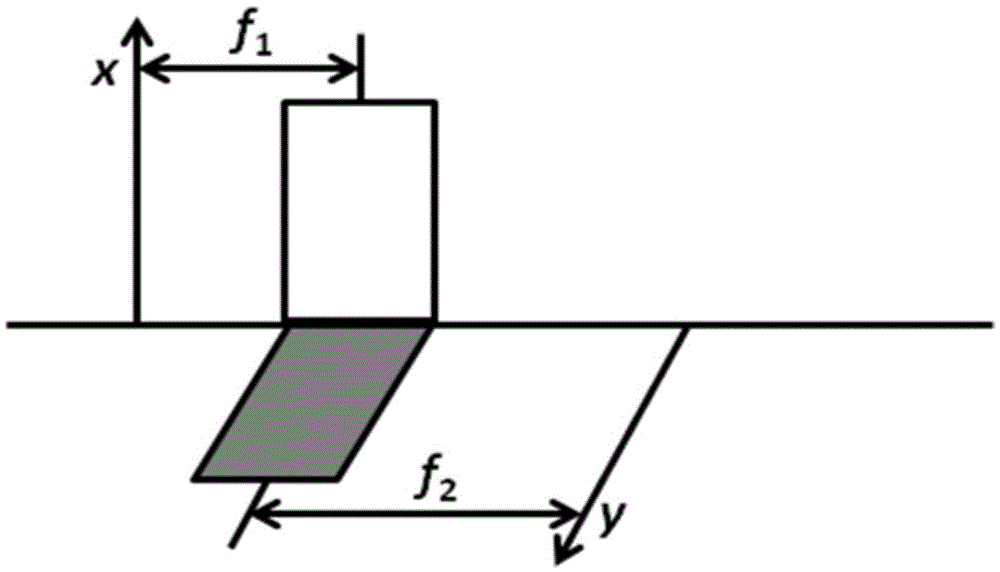

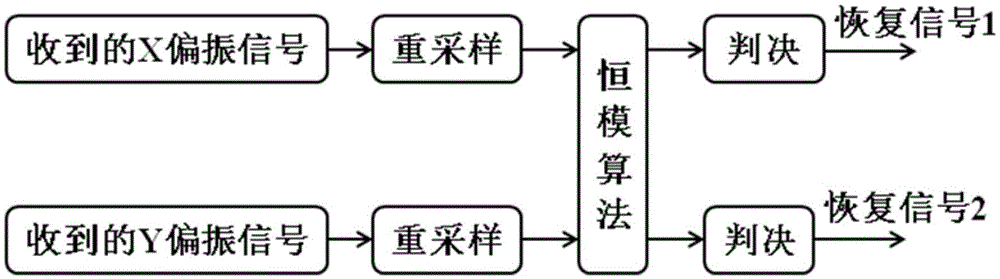

Polarization-independence direct detection system and method based on light intensity modulation signal

ActiveCN105553560ANo significant increase in costImprove transmission capacityPolarisation multiplex systemsElectromagnetic transmittersMultiplexingSignal on

The invention discloses a polarization-independence direct detection system and method based on a light intensity modulation signal, and relates to the field of optical fiber communication. The method comprises the following steps that: a sending send divides light signals into two beams of perpendicular signals in a polarization state, the two signals in the polarization state are respectively modulated in an intensity modulation mode, and polarization multiplexing signals are formed after the two signals pass through a polarization coupler; two beams of lasers perpendicular in polarization direction are used as two pilot signals used for carrying out frequency beating with the polarization multiplexing signals on a receiving end so as to realize polarization-independence light signal receiving; and the receiving end divides the received signals into two beams of perpendicular signals in a polarization state, the two beams of signals respectively are subjected to re-sampling changing into doubled sampling, then a conventional constant modulus algorithm is utilized for processing, and recovered signals are directly judged. According to the invention, the transmission capacity of the system is doubled without increasing the cost of the system.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

Certificate false proof method based on light weight digital signature scheme

InactiveCN101388767AEnsure safetyEasy to useFinanceUser identity/authority verificationSignature CodeDigital Signature Algorithm

The invention relates to a method for proofing false certificates based on a lightweight level digital signature scheme, which belongs to the cryptography and the computer field, the method enables the unforgeability of the certificates to be corresponding to the safety of a public key digital signature scheme and comprises the three parts of a key generating part of certificate forgery, a digital signature part and an identification checking part, wherein the key generating part is used for generating a pair of a private key and a public key of a license-issuing authority, the digital signature part is used for generating signature codes to the Hash abstract of key information of the certificates for the license-issuing authority, the identification checking part is used for identifying authenticity of the certificates for a user end inquiry unit, the method is safe and has low cost, can prevent insiders of the license-issuing authority commit a crime, can replace official seals of companies and can widely used in distributing business of various certificates.

Owner:苏盛辉 +2

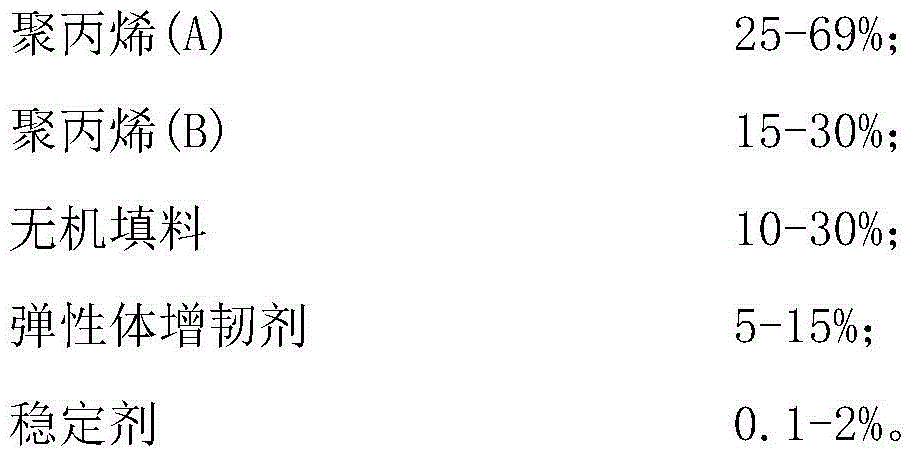

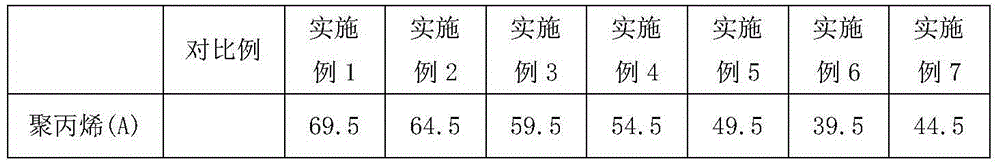

Injection molding-grade high-performance polypropylene composite material with good appearance and preparation method of injection molding-grade high-performance polypropylene composite material

InactiveCN104558834AHigh Molecular Weight DistributionImprove the appearance of injection moldingElastomerPolypropylene composites

The invention discloses an injection molding-grade high-performance polypropylene composite material with a good appearance and a preparation method of the injection molding-grade high-performance polypropylene composite material. The polypropylene composite material comprises the following raw materials in percent by weight: 25-69 percent of polypropylene (A), 15-30 percent of polypropylene (B), 10-30 percent of an inorganic filler, 5-15 percent of an elastomer flexibilizer, 0.1-2 percent of a stabilizer, and 0-5 percent of other additives. The polypropylene composite material and the preparation method have the advantages that 1, the molecular weight distribution of a PP matrix is improved to achieve the effect of improving the appearance of the injection molded polypropylene composite material through synergistic effect of polypropylene resin with high molecular weight and polypropylene resin with low molecular weight; 2, the original optimum proportion of the inorganic filler to the elastomer flexibilizer is not changed, and an excellent mechanical property is still kept while the injection molded polypropylene composite material has a good appearance; 3, the component kinds of an original modified material are not changed, the material performance is not influenced, and at the same time, the cost is not remarkably increased.

Owner:SHANGHAI PRET COMPOSITES +2

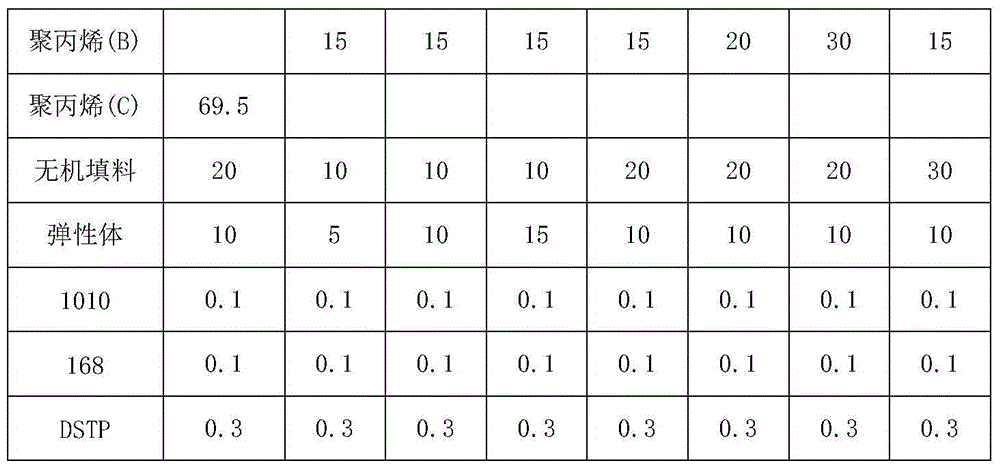

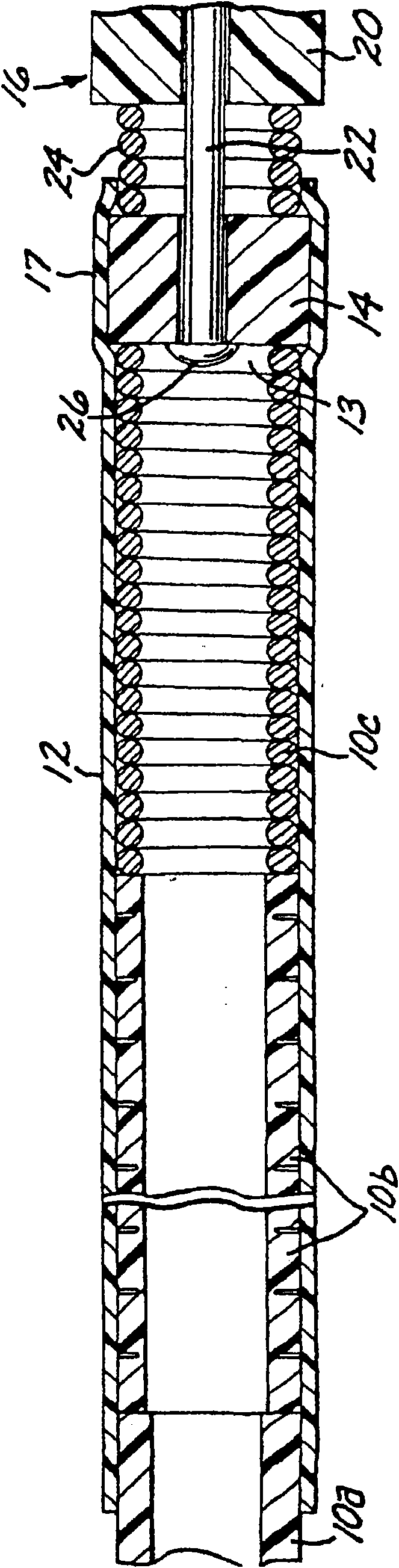

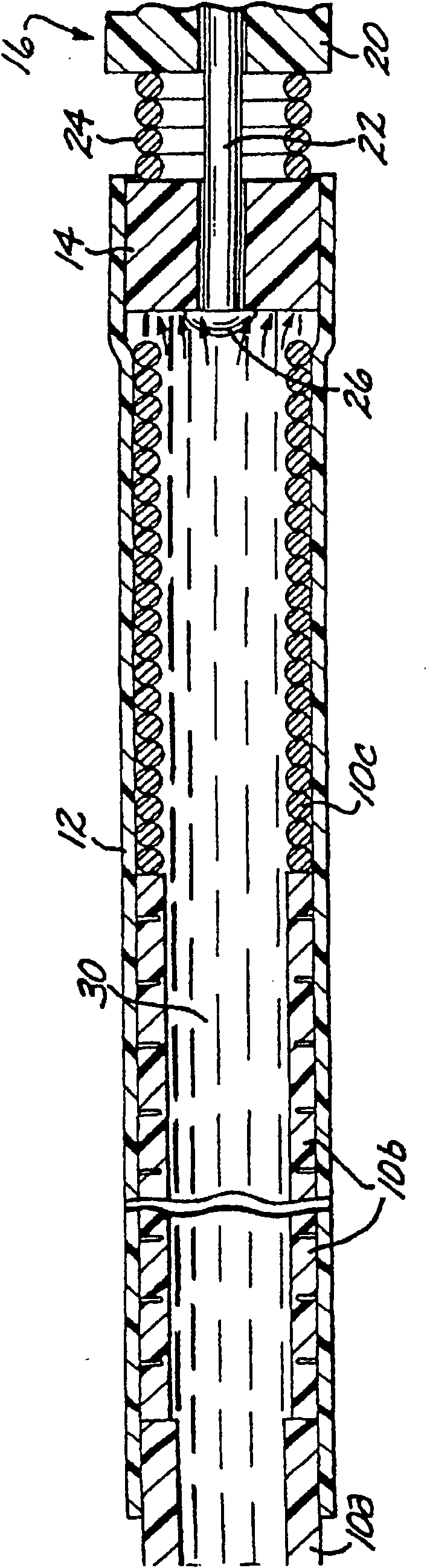

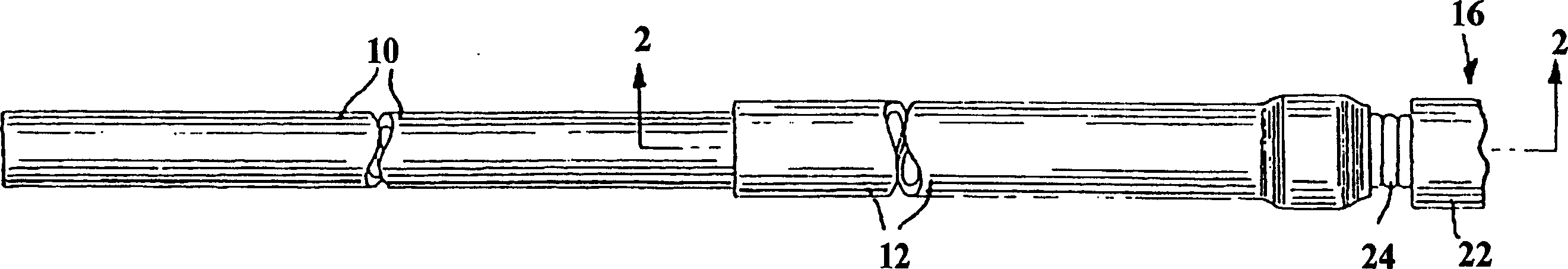

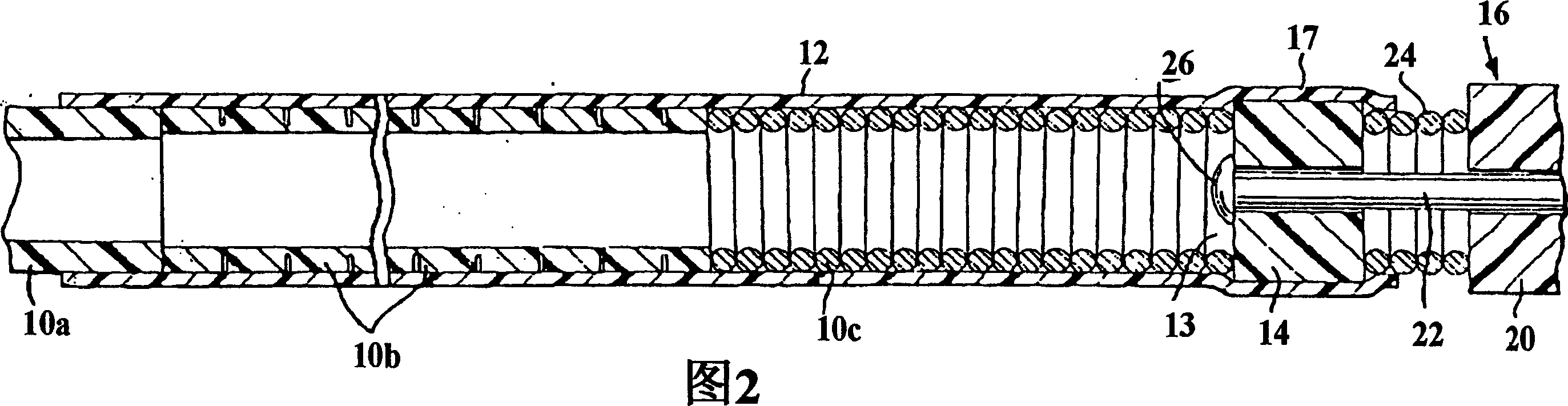

Mechanism for the deployment of endovascular implants

InactiveCN101589972AEasy and reliable disengagementFirmly attachedOcculdersCoatingsShortest distanceCoupling

Owner:MICROVENTION INC

Damage tolerant medium-strength titanium alloy

The invention discloses a damage tolerant medium-strength titanium alloy which is composed of, by mass, 5.5-7% of aluminum, 2.0-3.5% of zirconium, 2.0-3.5% of molybdenum, 2.0-3.5% of niobium and the balance of titanium and unavoidable impurities. Room-temperature tensile strength in an annealing state is 900-1000 MPa, room-temperature fracture toughness KIC is greater than or equal to 70 MPa.m1 / 2, and room-temperature fatigue crack propagation rate is da / dN is less than 3.5x10-5mm / cycle when R=0.1 and delta K=11 MPa.m1 / 2. The damage tolerant medium-strength titanium alloy does not contain element vanadium harmful to human body, element niobium difficult to being oxidized is added, raw material cost is not obviously increased generally while material performance is more stable, and safety and reliability of material application are improved.

Owner:WESTERN METAL MATERIAL

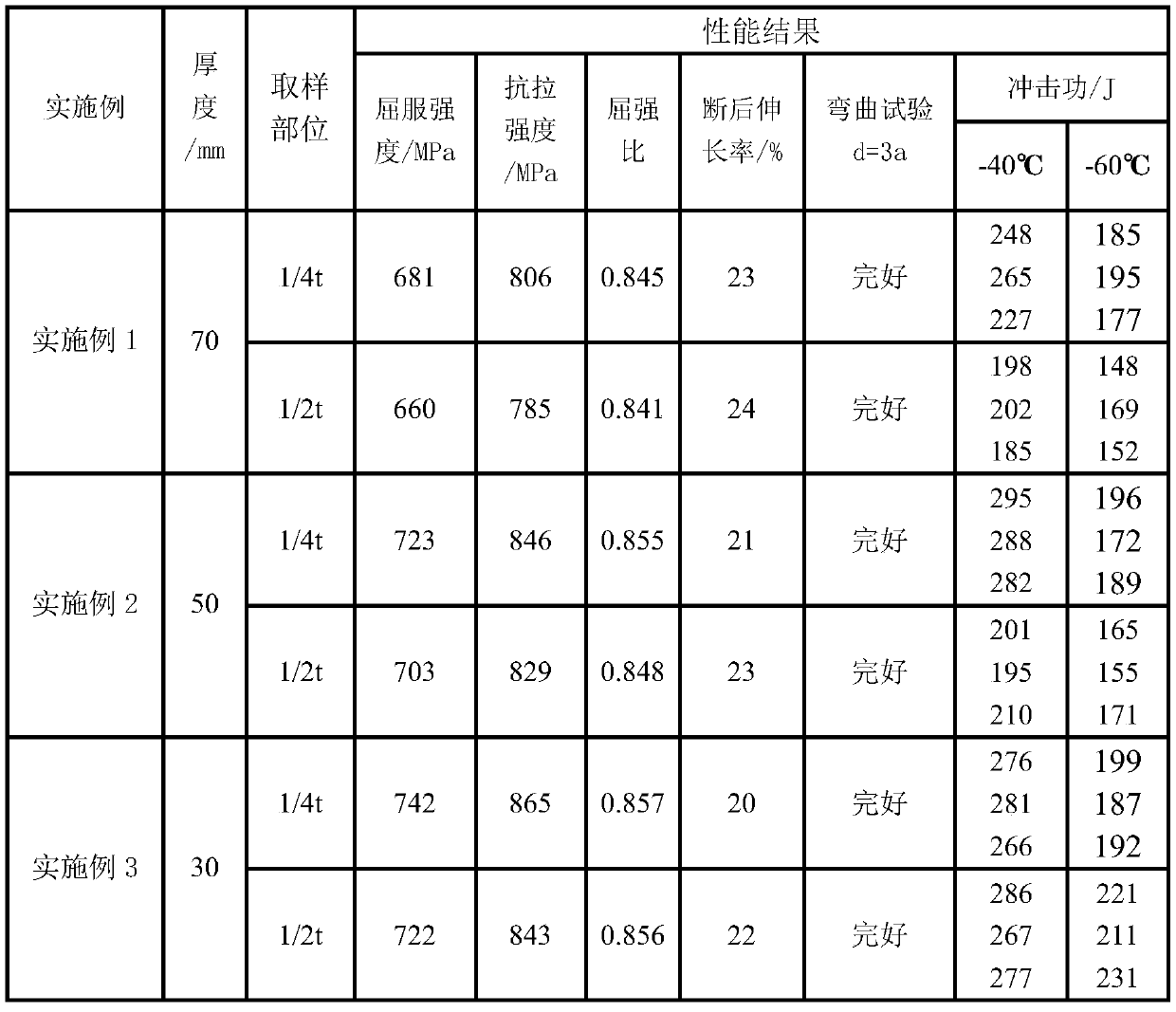

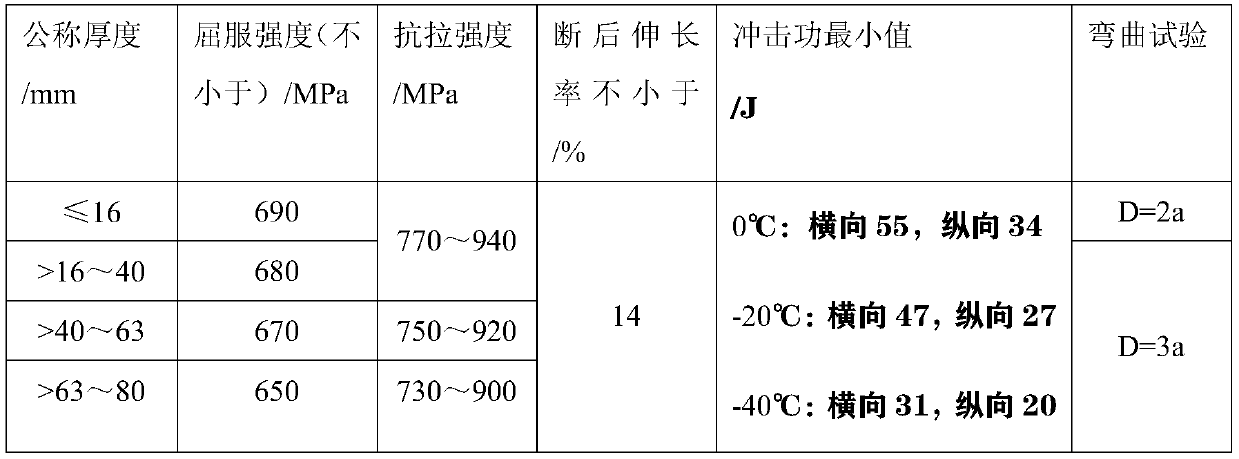

690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and manufacturing method

The invention discloses 690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and a manufacturing method, and relates to the technical field of steel smelting. Thesteel comprises the following chemical components of, in percentage by mass, 0.05%-0.10% of C, 4.1%-4.7% of Mn, 0.15%-0.4% of Si, less than or equal to 0.010% of P, less than or equal to 0.003% of S,0.01%-0.05% of Ti, less than or equal to 0.6% of Ni + Cr + Mo, and the balance Fe and inevitable impurities. The requirements of ultra-high strength steel safety performance and construction cost in acomplex environment in the field of engineering machinery can be met.

Owner:NANJING IRON & STEEL CO LTD

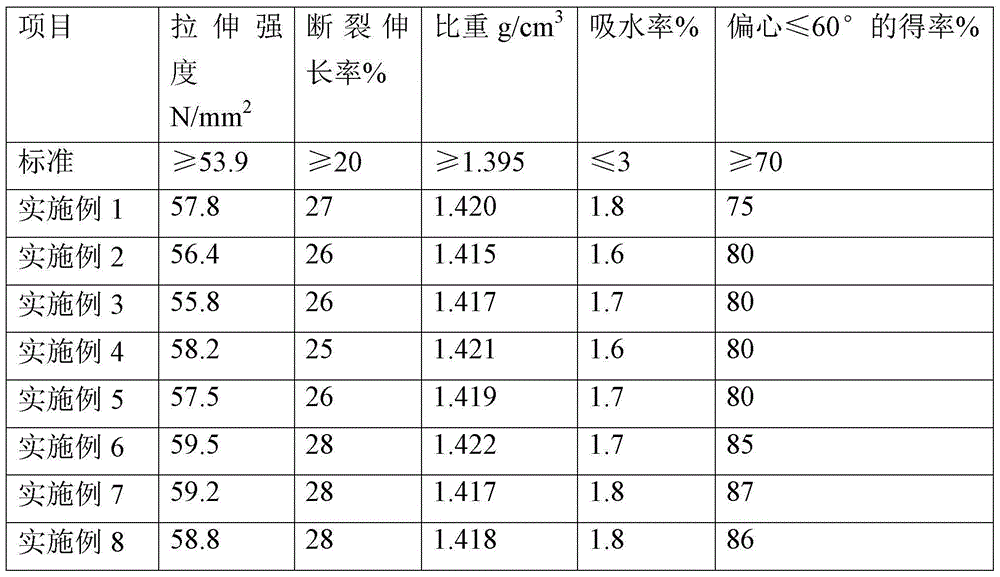

Polyvinyl chloride material for manufacturing ping-pong balls and preparation method thereof

ActiveCN104592686AImprove flatnessThe preparation method is safeSport apparatusPlasticizerPolyvinyl chloride

The invention discloses a polyvinyl chloride material for manufacturing ping-pong balls and a preparation method thereof. The polyvinyl chloride material comprises the following raw materials in parts by weight: 50-150 parts of polyvinyl chloride, 5-20 parts of nano calcium carbonate, 6-22 parts of solid plasticizer, 3-12 parts of Ca-Zn composite stabilizer, 10-30 parts of flexibilizer and 0.01-0.1 part of pigment. The polyvinyl chloride material is substantially approximate to celluloid ping-pong balls in terms of mechanical properties, particularly of leaping ability and strike resistance, and is also substantially approximate to the celluloid ping-pong balls in terms of appearance and ball striking sense.

Owner:JIANGNAN UNIV +1

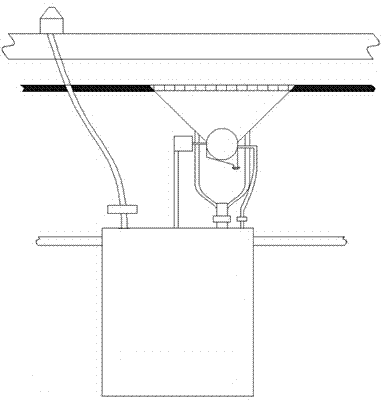

Mechanism for the deployment of endovascular implants

InactiveCN1652726AEasy and reliable disengagementFirmly connectedOcculdersBlood vesselsCouplingThree vessels

The invention discloses a mechanism used for the expansion of the implant (20) in the filamentous blood vessel, comprising a flexible expanding tube (10), an intracavity which extends between the proximal end and the distal end (11, 13) of the opening and a coupling element (14) connected with the proximal end of the implant. The tube is provided with a fixed bushing (12) which extends to the distal end and passes over the distal end. The coupling element is fixed in the bushing and can be released. The expanding tube and the connected implant pass through the blood vessel through the miniature pipe until the implant is positioned into the target blood vessel site. In order to separate the implant with the tube, liquid is injected through the cavity to put pressure on the coupling element so that the implant can be pushed out by the flowing pressure from the fixed bushing. The coupling element can comprise a purifying channel, which is used for air elimination from the miniature pipe before the implant passes through.

Owner:MICROVENTION INC

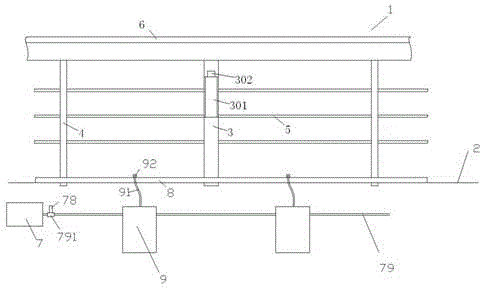

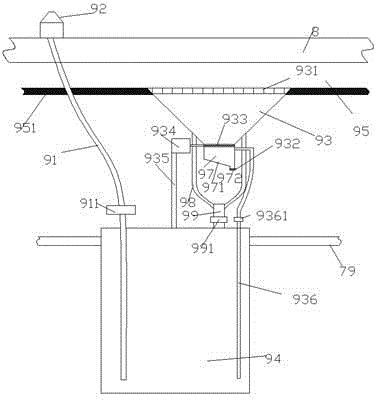

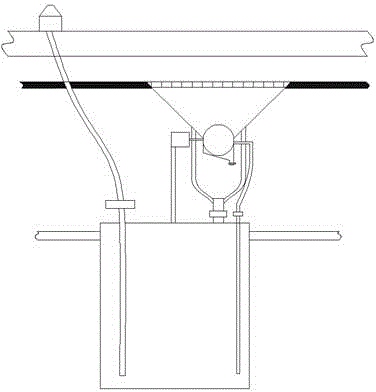

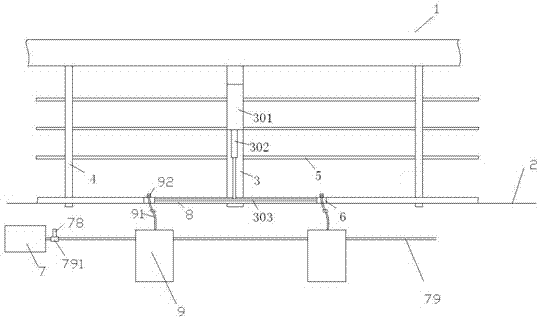

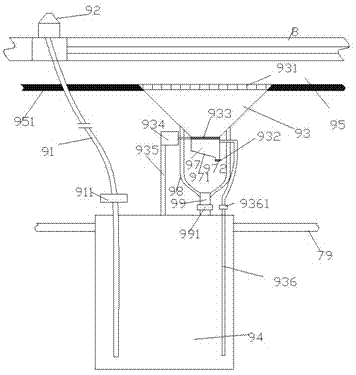

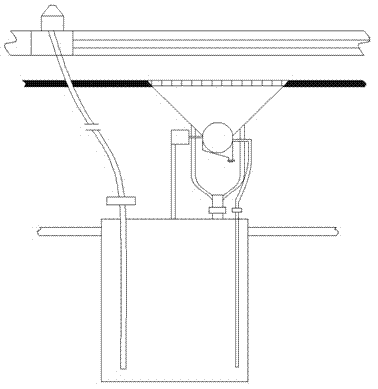

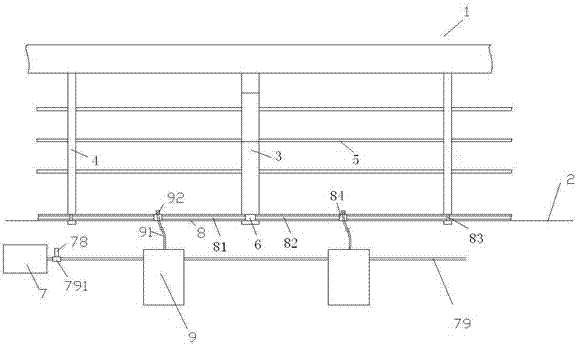

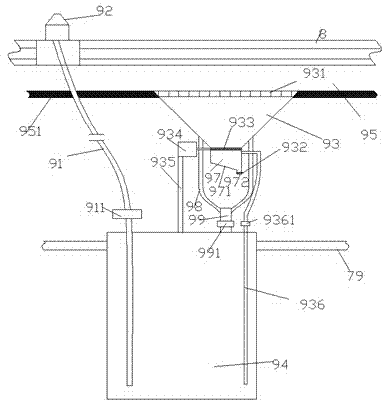

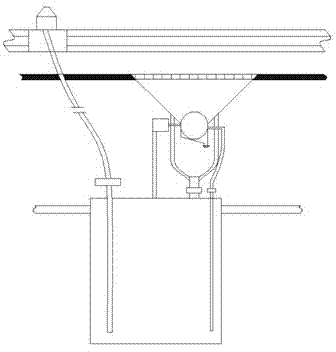

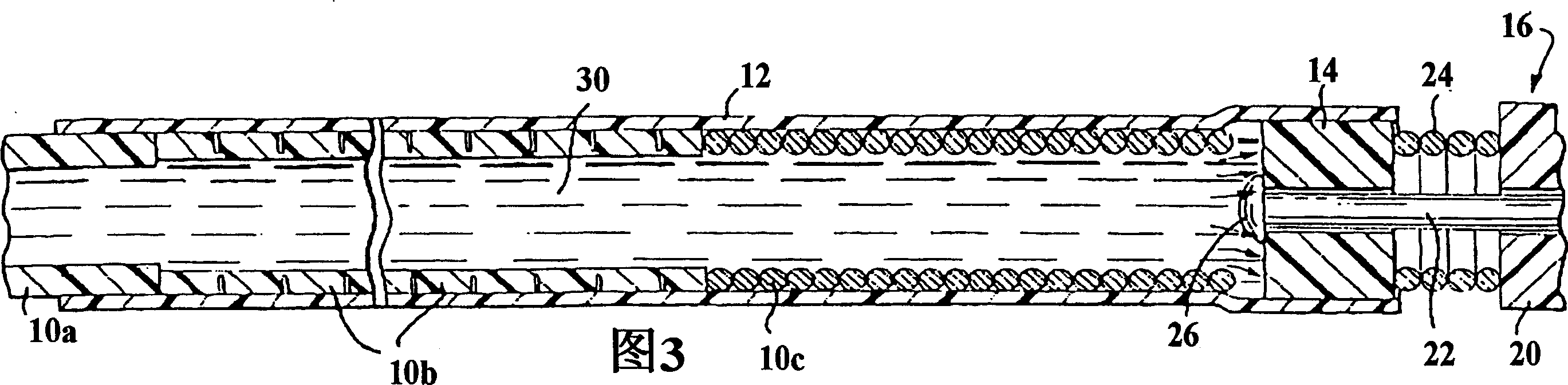

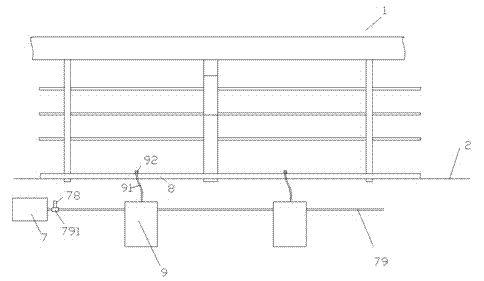

Cleaning device for municipal bridge guardrail with V-shaped bottom and using method thereof

InactiveCN104727259AUniform control of the emptying openingEnsure normal excretionGeneral water supply conservationBridge structural detailsWater collectionWaste management

The invention discloses a cleaning device for a municipal bridge guardrail with the V-shaped bottom and a using method thereof. The device is used for cleaning the municipal bridge guardrail (1) and comprises a plurality of water collection box assemblies (9), a plurality of cleaning nozzles (92) and a pressure supply device (7), wherein the water collection box assemblies (9) are connected with the cleaning nozzles (92) through water conveying pipes (91) one to one, and the cleaning nozzles (92) are installed on a nozzle installation frame (8) exposed out of the ground (2).

Owner:GUIZHOU NAIERFU SHUNCHENG BUILDING MATERIAL CO LTD

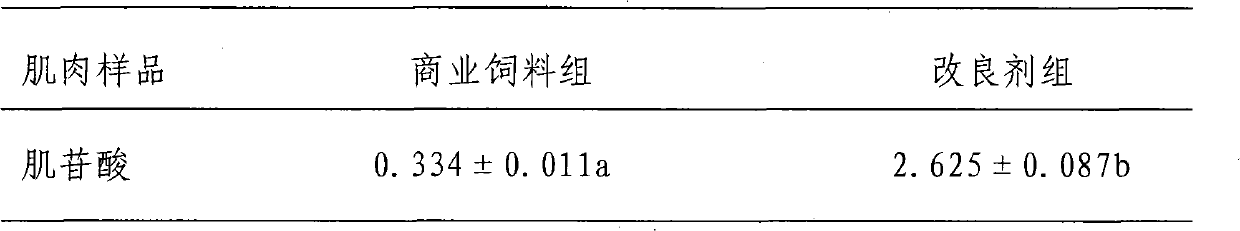

Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate

InactiveCN101973960ANo significant increase in costOvercome the defect of low yieldOrganic chemistryBromineChemistry

The invention relates to a synthesis method of benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate. The synthesis method comprises the following main steps of: performing esterification on m-aminobenzoic acid serving as an initiative raw material and methanol so as to obtain m-aminobenzoic acid methyl ester; in the presence of a surfactant, reacting the m-aminobenzoic acid methyl ester and thiocyanate so as to obtain N-(3-carbomethoxy phenyl)-thiourea; adding bromine into the N-(3-carbomethoxy phenyl)-thiourea in chlorobenzene or glacial acetic acid to perform a cyclization reaction so as to obtain 2-amino-7-carbomethoxy benzothiazole; performing heating and loop opening on the 2-amino-7-carbomethoxy benzothiazole in aqueous solution of KOH and performing diazotization and loop closing under an acid condition so as to obtain 7-carboxylic acid-[1,2,3] diazosulfide; and in the presence of oxalyl chloride, performing an esterification reaction on the 7-carboxylic acid-[1,2,3] diazosulfide and trifluoroethanol so as to obtain a target product. Compared with the prior art, the method increases the yield of the benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate.

Owner:EAST CHINA UNIV OF SCI & TECH

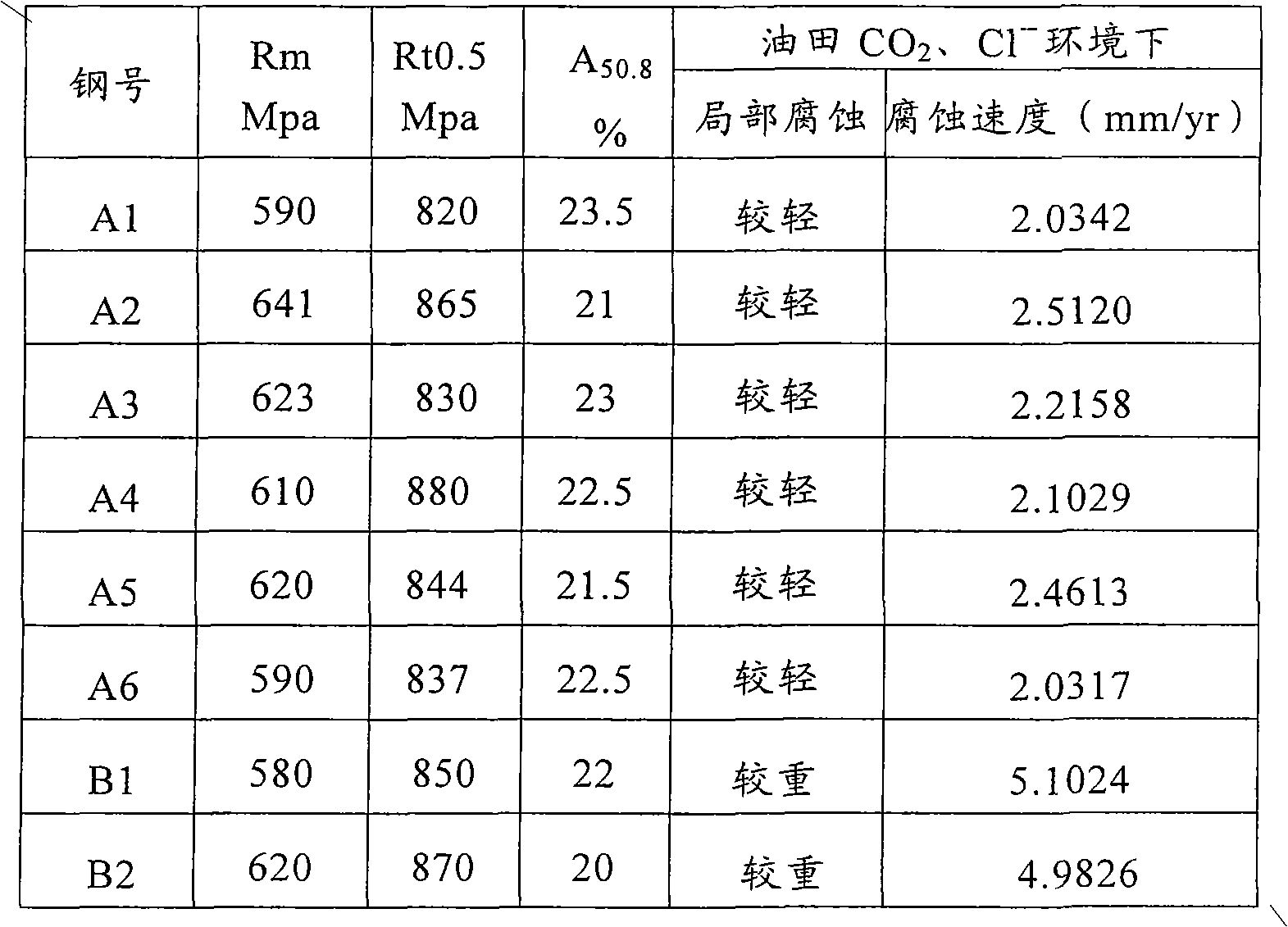

Low-alloy steel for resisting carbon dioxide corrosion and manufacturing method thereof

ActiveCN101928888AGood value for moneySimple preparation processDrilling rodsDrilling casingsChemical compositionCarbon dioxide corrosion

The invention discloses low-alloy steel for resisting carbon dioxide corrosion. The low-alloy steel comprises the following chemical components in percentage by weight: 0.20 to 0.35 percent of C, 0.10 to 1.0 percent of Si, 0.20 to 1.5 percent of Mn, 0.5 to 1.5 percent of Cr, 0.02 to 0.1 percent of V, 0.01 to 0.10 percent of Al and the balance of Fe and inevitable impurities, wherein the total amount of the impurity elements is lower than 0.05 weight percent. A manufacturing method for the low-alloy steel for resisting the carbon dioxide corrosion comprises steel making, continuous casting, hot rolling and normalizing in a two-phase area at the temperature of between 820 and 870 DEG C. The strength of the alloy steel reaches 80ksi level, the alloy steel has good CO2 corrosion resistance and low price, and an oil well pipe made of the alloy steel can be widely applied to an oil gas well with light CO2 corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

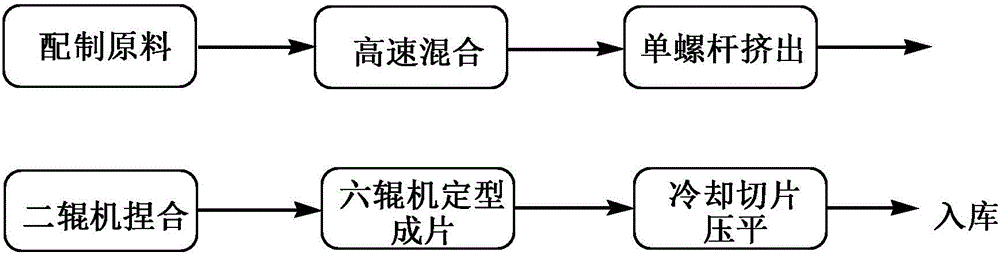

Method for preparing semihomogeneous cation exchange membrane

The invention discloses a method for preparing a semihomogeneous cation exchange membrane, and the method comprises the following steps: step 1), thermoplastic polyethylene-sulfonated polystyrene based cation exchange composite resin powder, non-thermoplastic cross-linked sulfonated polystyrene cation exchange resin powder, polyethylene powder and polyisobutylene powder are mixed evenly; step 2), a prefabricated membrane is obtained by successively melting blending in an internal mixer, discharging slices with a two-roller open mill, continuously rolling with a four-roller machine, cooling with a cold roll machine and cutting with a cutting machine; and step 3), the upper surface and the lower surface of the prefabricated membrane are covered with reinforced mesh cloth, and the semihomogeneous cation exchange membrane is obtained by pressing with a hot press. Sulfonic acid groups with cation exchange effect in the semihomogeneous cation exchange membrane prepared by the method are connected mutually without interruption, so that membrane surface resistance is greatly reduced. All kinds of membrane-forming materials are well compatible and tightly bonded, selective transmission of the membrane is higher, and the comprehensive performance is better than that of a heterogeneous cation exchange membrane in the prior art.

Owner:HANGZHOU IONTECH ENVIRONMENTAL TECH

Quality improver for low-salt or freshwater aquiculture of Litopenaeus vannamei Boone and preparation method thereof

The invention relates to feed additives in aquiculture, in particular to a quality improver for low-salt or freshwater aquiculture of Litopenaeus vannamei Boone and a preparation method thereof. one kilogram of the improver comprises the following components: 30-50g of freeze-dried green algae powder, 20-50g of krill powder, 200-300g of eucommia ulmoides powder, 10-20g of inosinic acid, 10-20g ofsodium glutamate and the balance of zeolite powder. By adoption of the quality improver, the content of bromophenol which is a seafood flavor substance in muscle of low-salt or freshwater cultivated Litopenaeus vannamei Boone can be effectively increased, the content of inosinic acid which is a main seafood flavor substance in muscle of Litopenaeus vannamei Boone can be effectively enhanced, the body color of Litopenaeus vannamei Boone can be effectively improved, the contents of protein and flavoring amino acid in muscle of Litopenaeus vannamei Boone can be effectively increased, the attraction effect of feed of Litopenaeus vannamei Boone can be promoted and the growth property of Litopenaeus vannamei Boone can be improved to a certain extent, and the taste and flavor of Litopenaeus vannamei Boone can be improved finally.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

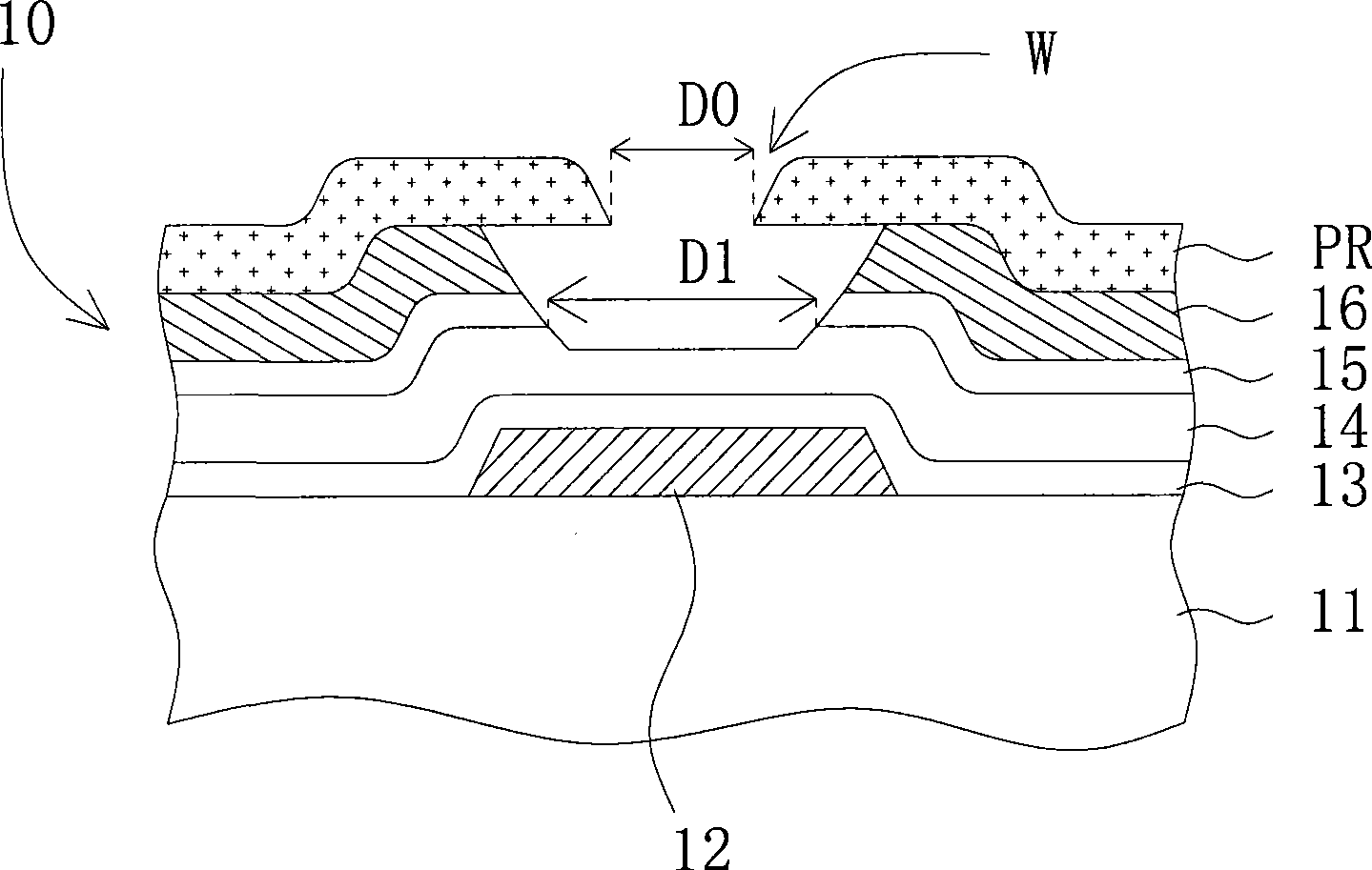

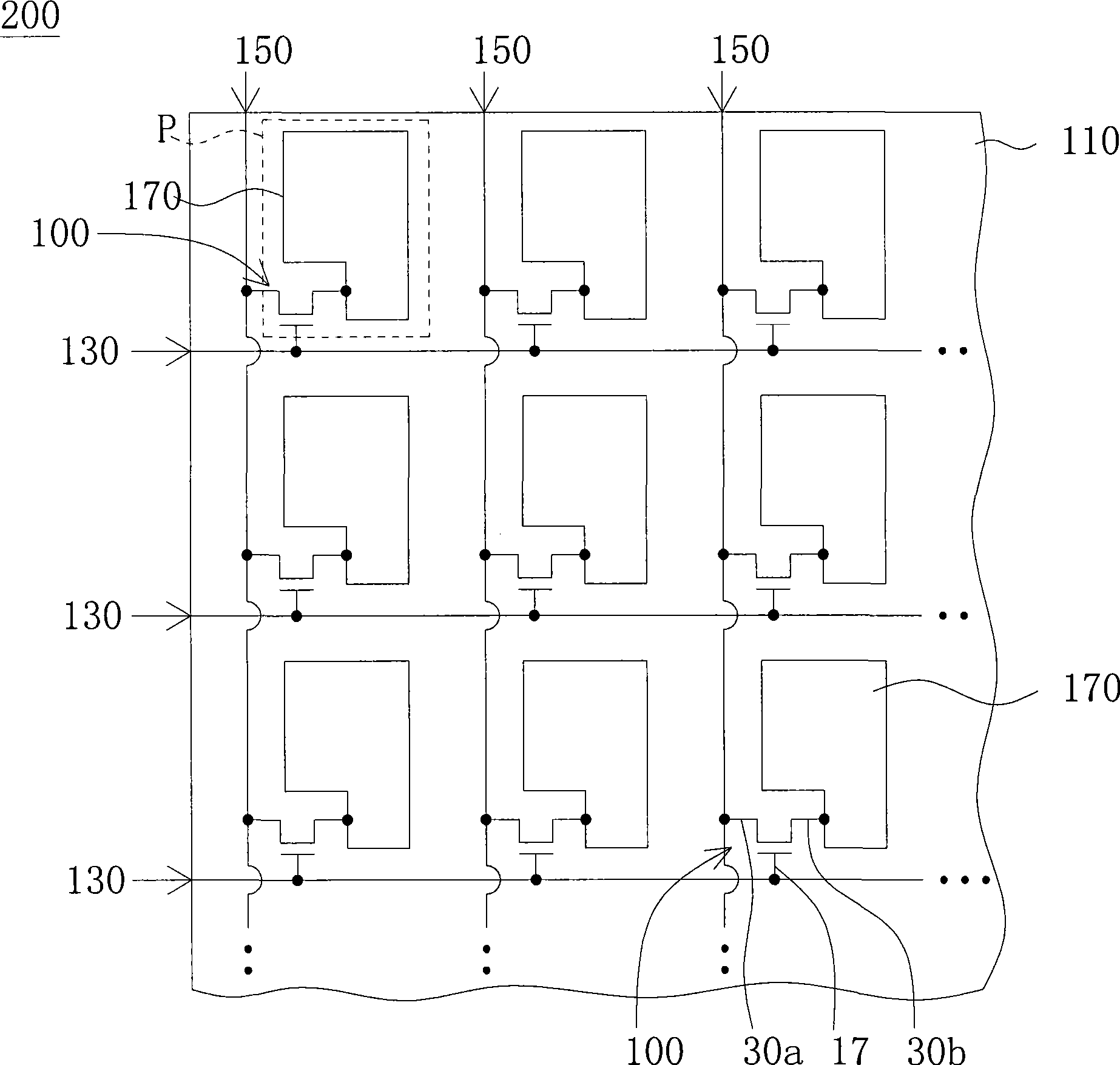

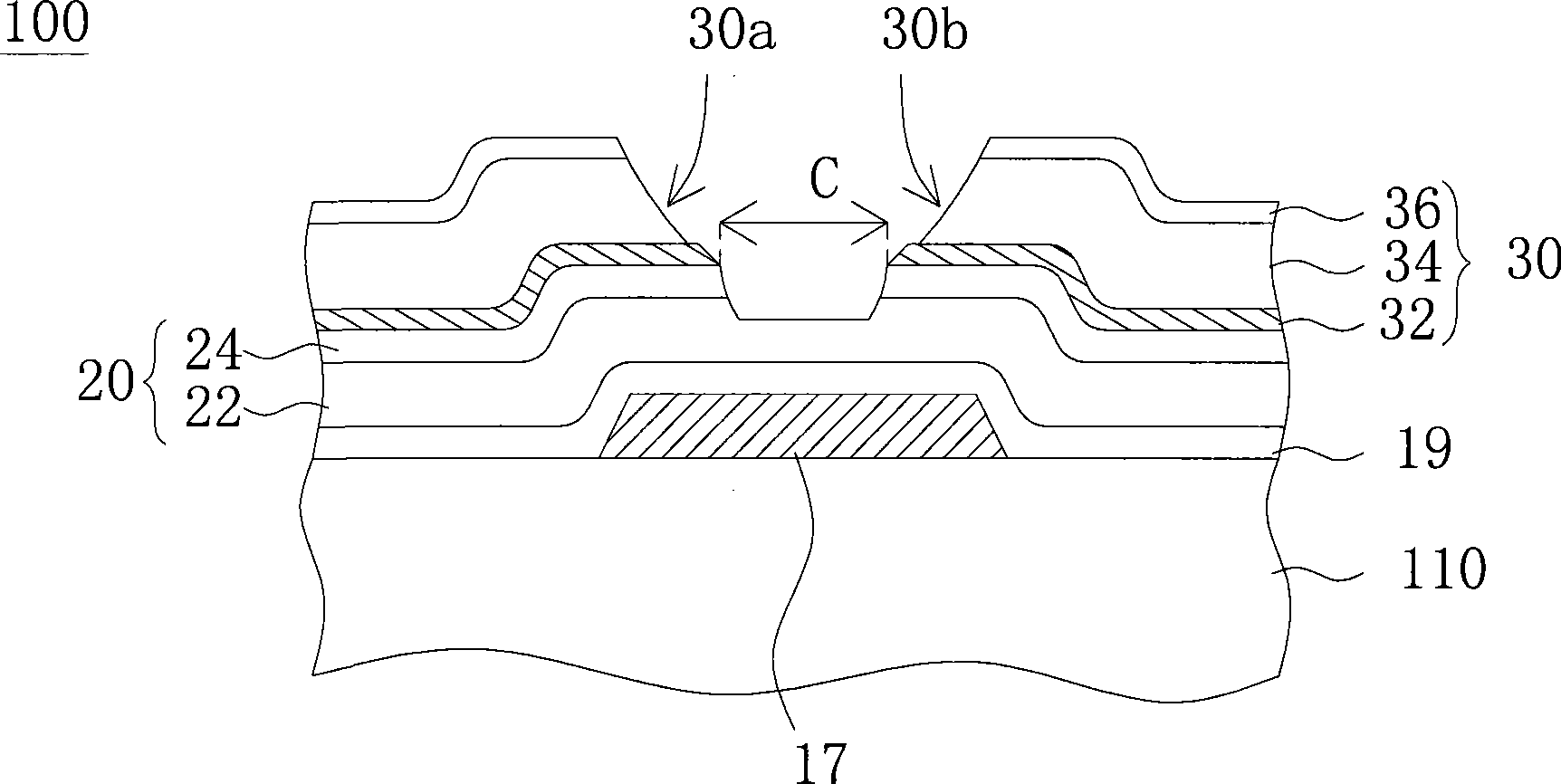

Thin-film transistor, manufacturing method thereof and liquid crystal display panel

InactiveCN101388413AEffective control of channel widthMaintain process qualityTransistorSemiconductor/solid-state device manufacturingElectrical conductorLiquid-crystal display

The invention discloses a thin film transistor, a production method and a liquid crystal display panel thereof, wherein the thin film transistor comprises a grid electrode, a grid insulating layer, a semiconductor layer, a source electrode and a drain metalizing layer, wherein the grid electrode and the grid insulating layer are arranged on a base plate, and the grid insulating layer covers the grid electrode, the semiconductor layer is arranged on the grid insulating layer, the source electrode and the drain metalizing layer are located on two sides of the semiconductor layer, a first conductor layer, a second conductor layer and a third conductor layer are provided, and each conductor layer is arranged on the semiconductor layer in turn. The lower surface of the first conductor layer is completely contacted with the upper surface of the semiconductor layer without exposure, the upper surface of the first conductor layer is partially exposed on the second conductor layer, and the lower surface of the third conductor layer is completely contacted with the upper surface of the second conductor layer without exposure. The invention can effectively control the channel width of the thin film transistor in a process, further keeps the process quality of the thin film transistor, and has the advantages of no needing to buy extra process devices, and being compatible with a tradition process.

Owner:INNOLUX CORP

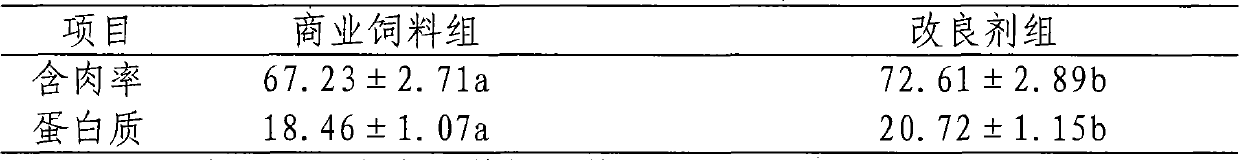

Meat quality and flavor improver for tilapia mossambica and preparation method thereof

The invention relates to a feed additive in aquaculture industry, in particular to a meat quality and flavor improver for tilapia mossambica and a preparation method thereof. Each kilogram of improver comprises 50-100 g of ulva powder, 20-30 g of carnitine, 30-50 g of dimethylpropiothetin, 15-25 g of cysteamine HCl, 200-300 g of sodium chloride and the balance of zeolite powder. The preparation method comprises the following steps of: firstly, pulverizing the ulva powder, the carnitine, the dimethylpropiothetin, the cysteamine HCl and the sodium chloride, and sieving with a 100-mesh sieve; secondly, mixing the pulverized solid materials according to the proportions; and finally, mixing and stirring the mixed solid materials and the zeolite powder so that the coefficient of variation (CV) of uniformity of the mixture is less than 5%. The improver can efficiently increase the content of inosinic acid as a delicate flavor substance in tilapia mossambica meat, can efficiently increase the content of proteins, the content of essential amino acids and the content of taste amino acids in the tilapia mossambica meat, can improve the taste and the flavor of the tilapia mossambica meat, and can eliminate fishy smell.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

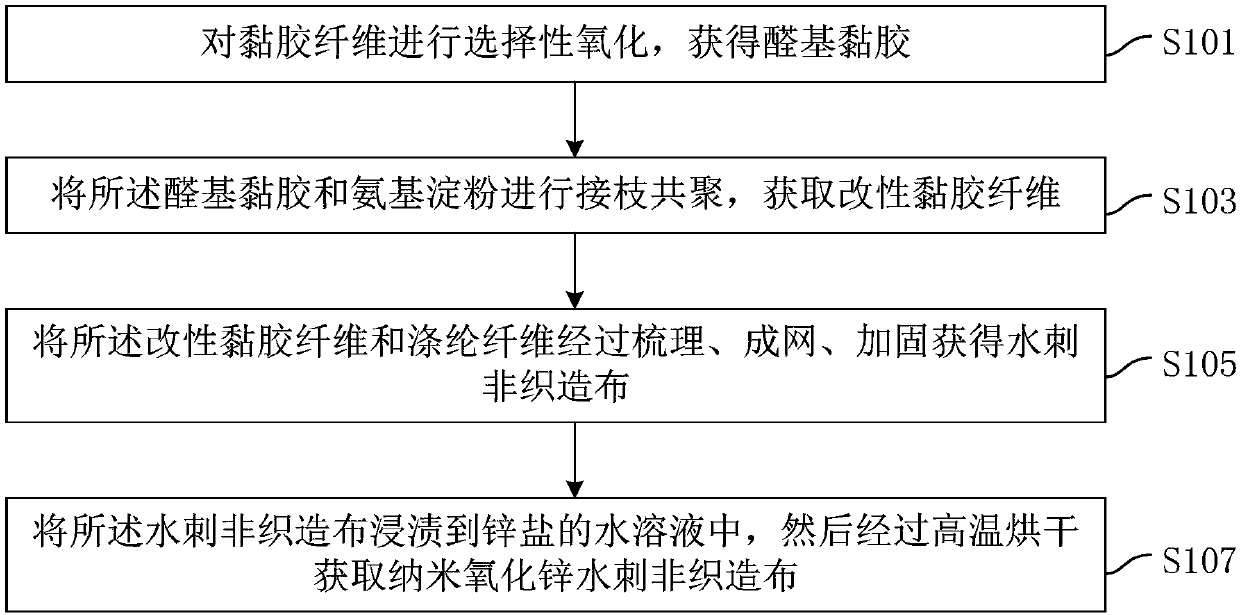

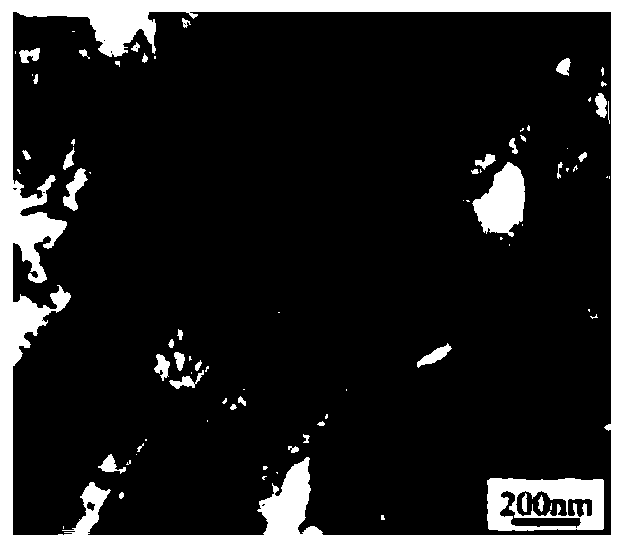

Preparation method of nano zinc oxide spunlaced nonwoven fabrics

ActiveCN107829216ANo significant increase in costImprove antibacterial propertiesBiochemical fibre treatmentLiquid/gas/vapor removalPolyesterAdhesive

The invention provides a preparation method of nano zinc oxide spunlaced nonwoven fabrics. The preparation method of nano zinc oxide spunlaced nonwoven fabrics comprises the following steps: selectively oxidizing viscose fibers to obtain aldehyde adhesive; carrying out graft copolymerization on the aldehyde adhesive and amino starch to obtain modified viscose fibers; carrying out carding, net forming and reinforcing on the modified viscose fibers and polyester fibers to obtain spunlaced nonwoven fabrics; dipping the spunlaced nonwoven fabrics in an aqueous solution of zinc salt; and drying thespunlaced nonwoven fabrics at high temperature to obtain the nano zinc oxide spunlaced nonwoven fabrics. The preparation method of the nano zinc oxide spunlaced nonwoven fabrics has the beneficial effects that the viscose fibers are subjected to activating finishing, and thus, the activity of fibers is improved. Polyester fibers in a certain proportion are added in viscose, and the strength of the fibers can be improved. The modified viscose fibers can adsorb the zinc salt well, and nano zinc oxide is produced on the surface of the nonwoven fabrics under the effect of hot air in an in-situ manner. The preparation method is simple in process, the costs of the produced nonwoven fabrics are not increased obviously, and the obtained nonwoven fabrics have excellent antibacterial property.

Owner:JIANGSU DEBANG SANITARY PROD +1

PU solid bicycle tire containing ETPU foaming particles and manufacturing method of PU solid bicycle tire

ActiveCN107443644AIncrease elasticityReduce weightBicycle tyresNon-inflatable tyresSingle vehicleCentrifugal force

The invention discloses a PU solid bicycle tire containing ETPU foaming particles and a manufacturing method of the PU solid bicycle tire. The manufacturing method comprises the following steps: using existing production equipment for producing the PU solid bicycle tire for production, and adding the ETPU foaming particles into a mold in advance, wherein the volume of the ETPU foaming particles is 15% to 20% of the total volume of the mold; pouring raw materials for synthesizing PU into the mold through a casting machine; during centrifugal pouring, controlling the rotating speed of a centrifugal mold to be 850 to 1000 r / min; and during pouring, under the effect of centrifugal force, gathering the ETPU foaming particles with relatively small density towards the inner ring part of the tire, wherein relatively few ETPU foaming particles are arranged at the outer ring part of the tire, and micro foaming PU is mainly arranged at the outer ring part of the tire. The PU solid bicycle tire has the advantages that the elasticity and riding comfort level are greatly improved, and the elasticity is increased by 20% to 30%; the weight of the solid bicycle tire is reduced, and the weight of each tire is reduced by about 1 kg; and existing production equipment for polyurethane solid bicycle tires can be used for processing, so that the cost is not obviously increased.

Owner:SHANGHAI WINNER ENG

Method for detecting starved feeding alarming of ice cream machine

ActiveCN102578354ASolve the problem of lack of material alarm accuracyTimely feedingFrozen sweetsAlarmsAlarm stateEngineering

Disclosed is a method for detecting a starved feeding alarming of an ice cream machine, which is capable of improving detecting accuracy of the starved feeding alarming and reducing false alarm rate. The method includes the following steps : (1), after starting up, detecting a rotating speed of a stirring mechanism of the ice cream machine and the temperature of an evaporating cylinder, when the detected rotating speed during starting up is in correspondence with an initial forming proportion A and the temperature is above a setting temperature value F in initial forming, recording a preforming temperature X when the ice cream reaches a preforming proportion B, and being saved in a system, and being covered when restarting and the requirements are met; (2), when the rotating speed is in correspondence with the forming proportion, forming and shutting down and no alarming; when the rotating speed can not reach the forming proportion and the temperature measuring value is maintained fora period of time T1 and below alarming threshold value X-N1, sending a starved feeding alarming signal and maintaining alarming state for a period of time T2; (3), automatically shutting down and entering into standby when the temperature value is always below the shutting down setting temperature X-N2 during the period of time T2 and the rotating speed can not reach the forming proportion after the starved feeding alarming signal is sent out.

Owner:GUANGZHOU GUANGSHEN ELECTRIC PROD CO LTD

Cleaning device for solar municipal bridge guardrail and use method of cleaning device

InactiveCN104818680AUniform control of the emptying openingEnsure normal excretionRoad cleaningEngineeringWater pipe

Owner:德冠环境工程有限公司

Hydraulic lifting municipal bridge guardrail cleaning device and use method thereof

InactiveCN104746462AUniform control of the emptying openingEnsure normal excretionGeneral water supply conservationBridge structural detailsWaste management

Owner:台州国丰建设有限公司

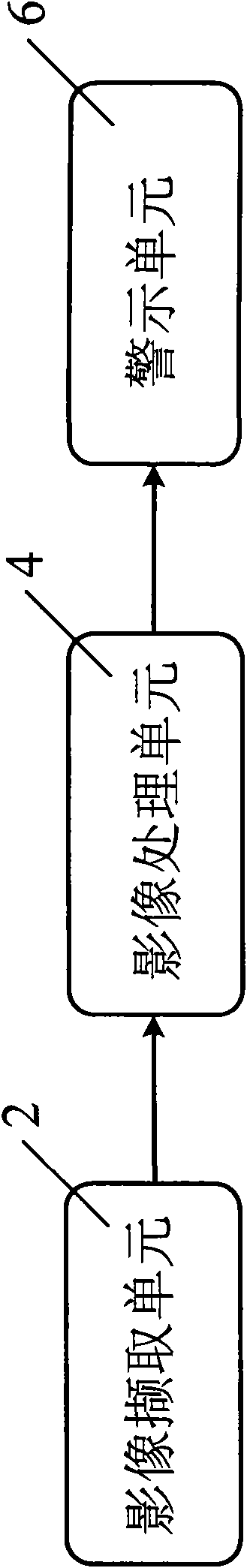

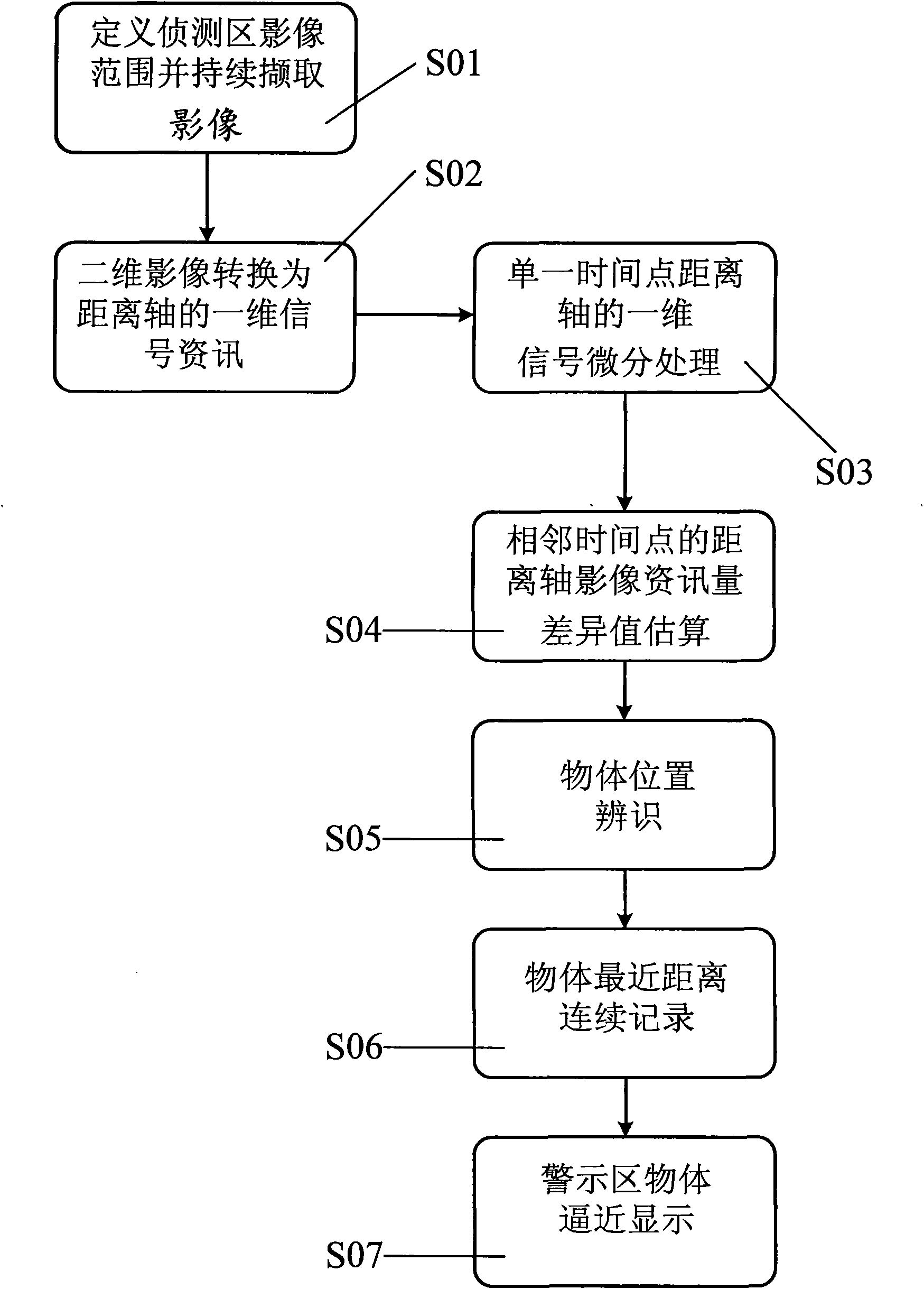

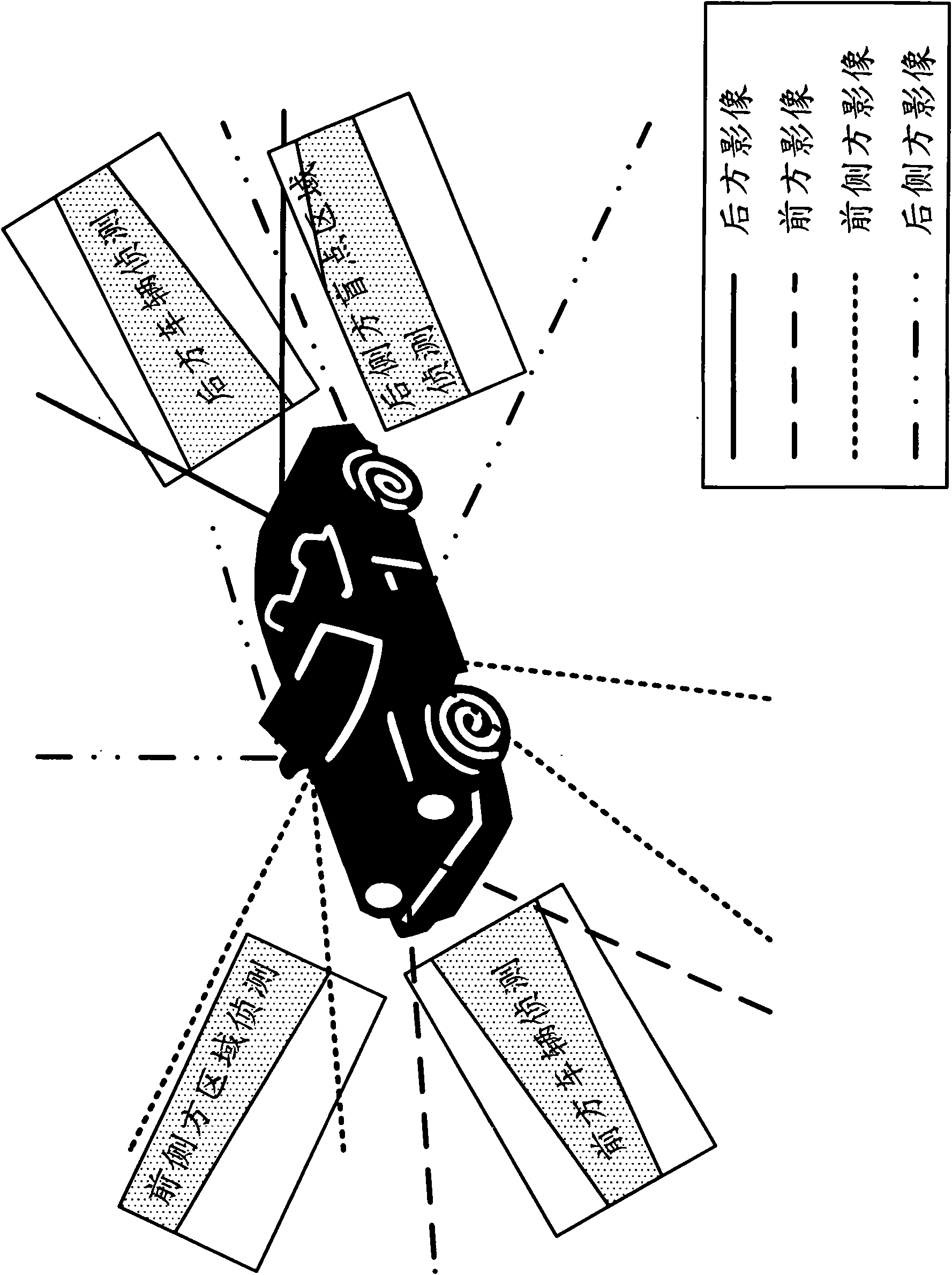

Device and method for sensing object position

ActiveCN101685014ASmall amount of calculationQuick calculationPicture interpretationImaging processingRelevant information

The invention discloses a device and a method for rapidly sensing an object position, in particular the device and the method for sensing the object position directly applied to various image systems.The invention mainly aims at carrying out image pick-up on an area in a direction to be sensed through the image system according to a user, and an image processing unit judges the position and relevant information of the object through selection of images of scene areas and an object recognition method. The method for processing image data comprises a step of converting two-dimension image datainto one-dimension signal information of a distance axle, and object recognition comprises steps of judging the position of the object by means of utilizing numerical value differential estimation tothe one-dimension signal information, and judging the approach state of the object to the difference of the one-dimension signal information of two adjacent images which are continuously input. The algorithm has small computation and favorable transportability.

Owner:AUTOMOTIVE RES & TESTING CENT

Manufacture method of semihomogeneous anion-exchange membrane

ActiveCN106512761ASimple structureGood compatibilitySemi-permeable membranesThermoplasticPolystyrene

The invention discloses a manufacture method of a semihomogeneous anion-exchange membrane, comprising the following steps: 1) mixing thermoplastic polyethylene-quaternary amino polystyrene anion-exchange composite resin powder, non-thermoplastic crosslinked quaternary amino polystyrene anion-exchange resin powder, polyethylene powder and polyisobutylene powder according to a ratio; 2) melt-blending by an internal mixer, extruding by a two-roller open mill, continuously rolling by a four-roller mill, cooling by a cold-roll, and cutting by a cutting machine so as to obtain a prefabricated membrane; and 3) coating upper and lower surfaces of the prefabricated membrane with enhanced screen cloth, and compacting by a hot press so as to obtain the semihomogeneous anion-exchange membrane product. According to the prepared anion-exchange membrane product, internal quaternary amine groups with anion exchange effect are connected to each other and ceaseless such that membrane area resistance is greatly reduced. Various film forming materials have good compatibility and are tightly combined. Selective transmittance of the membrane is higher, and comprehensive properties of the membrane are obviously better than comprehensive properties of a conventional homogeneous anion-exchange membrane.

Owner:HANGZHOU IONTECH ENVIRONMENTAL TECH

Municipal bridge guardrail cleaning device capable of moving left and right and use method thereof

InactiveCN104762908AUniform control of the emptying openingEnsure normal excretionGeneral water supply conservationBridge structural detailsEngineeringWater collection

The invention discloses a municipal bridge guardrail cleaning device capable of moving left and right and a use method of the device. The device is used for cleaning a municipal bridge guardrail (1) and comprises water collection tank assembles (9), cleaning spraying heads (92) and a pressure supply device (7). The number of the water collection tank assemblies (9) and the number of the cleaning spraying heads (92) are both plural, and the water collection tank assemblies (9) are in one-to-one connection with the cleaning spraying heads (92) through water conveying pipes (91). The cleaning spraying heads (92) are arranged above spraying head mounting frames (8) protruding from the ground (2).

Owner:ZHEJIANG WANRUI MUNICIPAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka.patsnap.com/patent_img/ce3022ab-8482-4ecb-a12b-ab2f73846741/BSA00000268271500021.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka.patsnap.com/patent_img/ce3022ab-8482-4ecb-a12b-ab2f73846741/BSA00000268271500022.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka.patsnap.com/patent_img/ce3022ab-8482-4ecb-a12b-ab2f73846741/BSA00000268271500031.PNG)