Elastic vibration-reduction ballast bed system

A kind of ballast bed and elasticity technology, applied in the field of elastic vibration damping ballast bed system, can solve the problems of system stiffness and quality restriction, lengthened construction period, and many construction contents, etc., and achieves the effect of strong anti-overload capability and increased lateral stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

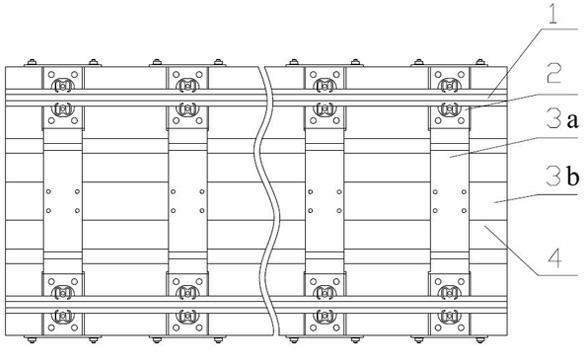

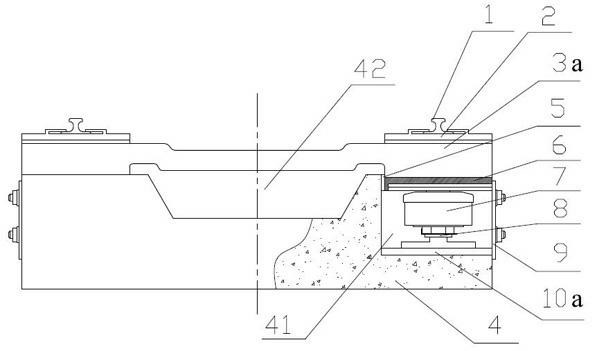

[0058] figure 2 As shown, the concrete ballast bed 4 is formed by pouring on site, and grooves 41 are poured symmetrically in the transverse direction, and drainage ditches 42 are poured in the middle. Connecting bolts are pre-embedded on the lateral end surfaces of the lateral grooves of the concrete ballast bed 4, and the protective cover plate 9 is connected with the concrete ballast bed 4 through the pre-embedded connecting bolts to form a closed space to prevent impurities such as dust and rainwater from entering the grooves.

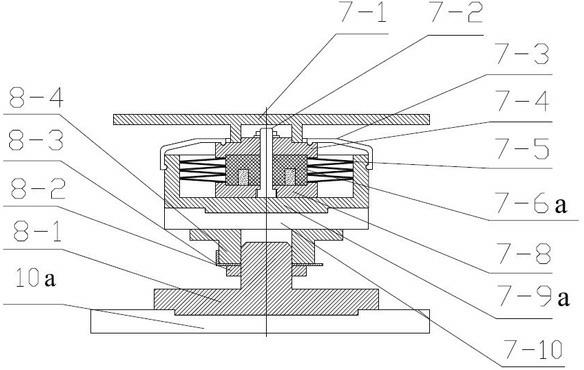

[0059] image 3As shown, there is an elastic gasket 7-10 at the bottom of the low-frequency vibration isolator 7, and the vibration isolator sleeve 7-9a is connected with the elastic gasket 7-10 through a concave-convex structure; the positive and negative stiffness of the vibration isolator sleeve 7-9a are placed Parallel elastic elements, positive and negative stiffness parallel elastic elements are composed of disc spring 7-5 and metal rubber-...

Embodiment 2

[0068] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the positive stiffness elastic element in the low-frequency vibration isolator 7 is composed of a helical steel spring 7-7 and a metal rubber elastic element 7-6b connected in parallel, and the helical steel spring 7-7 sets On the outer side of the metal rubber elastic element 7-6b, the two together provide positive stiffness for the low frequency vibration isolator. The metal rubber elastic element 7-6b can also provide certain damping for the low-frequency vibration isolator, so that the low-frequency vibration isolator has variable damping characteristics, and at the same time meets the different requirements of the vibration isolator for damping in the resonance region and the vibration isolation region. In addition, the helical steel spring and the metal rubber elastic element can also be armored to form an independent positive stiffness elastic element.

[00...

Embodiment 3

[0071] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the low-frequency vibration isolator 7 adopts a separate positive stiffness elastic element, and the positive stiffness elastic element is a helical steel spring 7-7. The lower bottom plate 7-8 is connected with the grooved vibration isolator sleeve 7-9b through a concave-convex structure, and the grooved vibration isolator sleeve 7-9b is filled with damping fluid 7-11a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com