Sulfide-containing industrial wastewater treatment reagent and reaction method thereof

A technology of industrial wastewater and sulfide, applied in the chemical field, can solve the problems of incomplete degradation of organic pollutants, low utilization rate of hydrogen peroxide, increased water treatment costs, etc., and achieve the effect of broadening the application range, reducing the dosage, and reducing the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

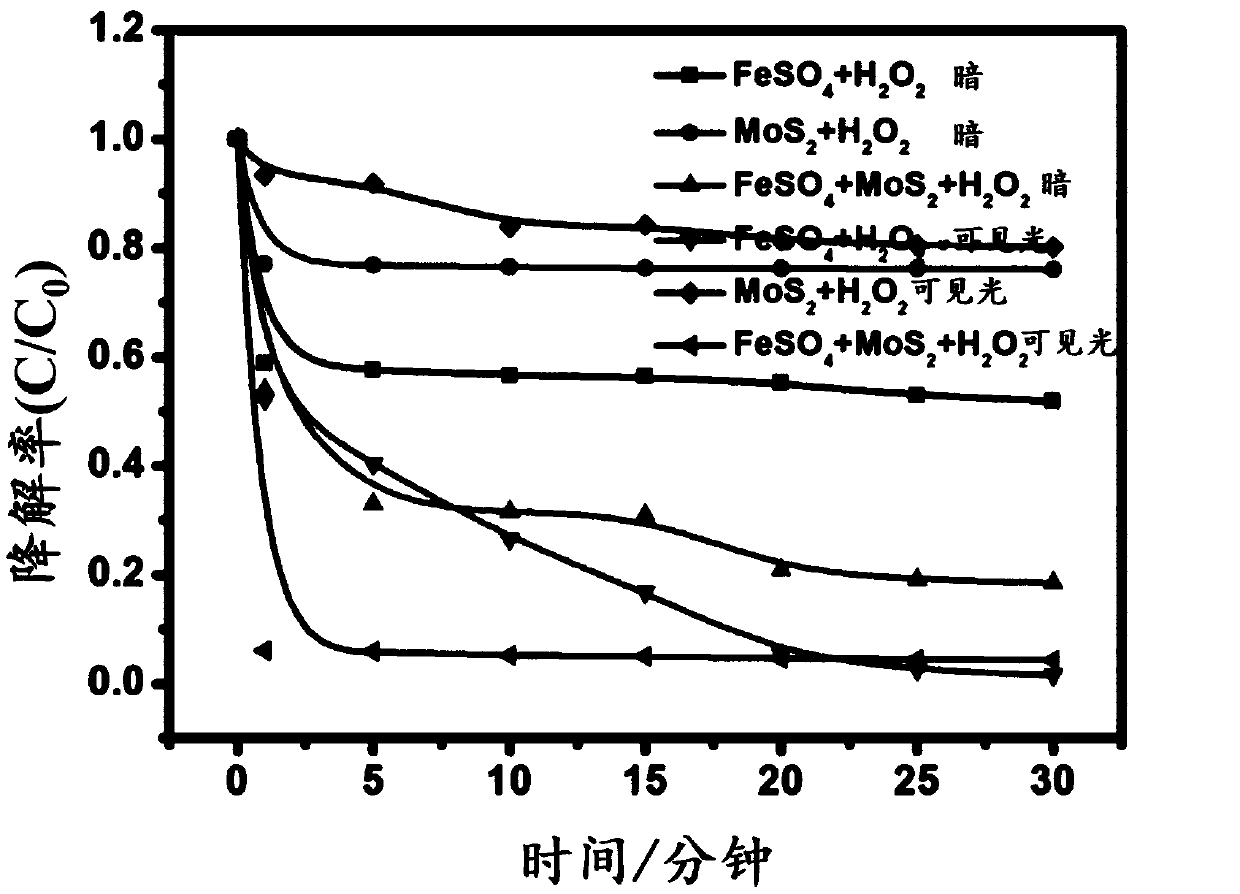

[0047] The control experiment was carried out according to the following six groups of conditions,

[0048] (1) 100L of waste water to be treated, FeSO 4 Concentration 0.02g / L, H 2 o 2 Concentration 0.4mmol / L, no visible light;

[0049] (2) 100L of waste water to be treated, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L, no visible light;

[0050] (3) Wastewater to be treated 100L, FeSO 4 Concentration 0.02g / L, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L, no visible light;

[0051] (4) Wastewater to be treated 100L, FeSO 4 Concentration 0.02g / L, H 2 o 2 Concentration 0.4mmol / L, with visible light;

[0052] (5) Wastewater to be treated 100L, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L, with visible light;

[0053] (6) Wastewater to be treated 100L, FeSO 4 Concentration 0.02g / L, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L, with visible light;

[0054] Experimental results such as figure 1 shown...

Embodiment 2

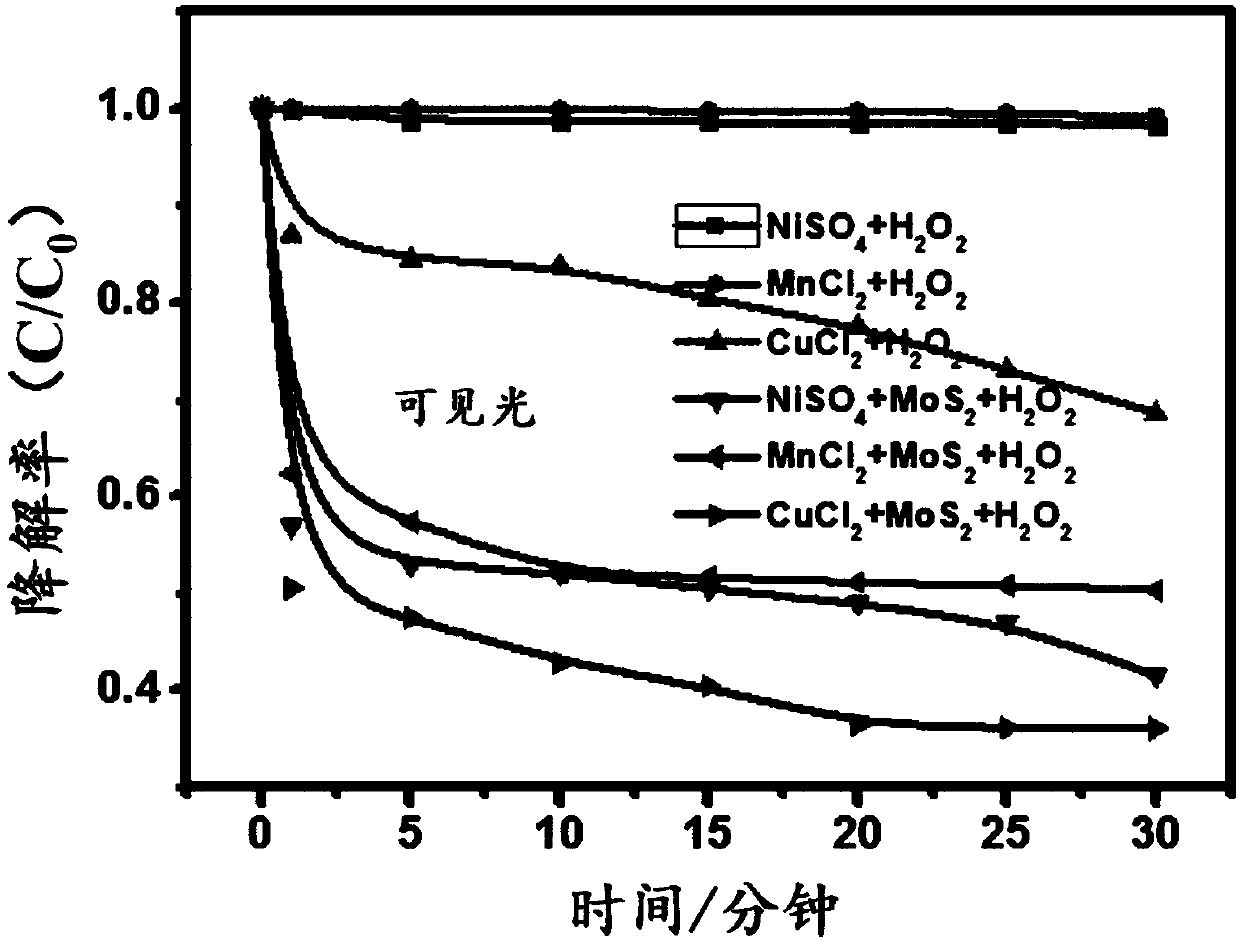

[0058] According to the following six groups of conditions for comparative experiments, the following six groups of conditions are all illuminated with visible light,

[0059] (1) 100mL of waste water to be treated, NiSO 4 Concentration 0.02g / L, H 2 o 2 Concentration 0.4mmol / L;

[0060] (2) 100mL of waste water to be treated, MnCl 2 Concentration 0.02g / L, H 2 o 2 Concentration 0.4mmol / L;

[0061] (3) 100mL of waste water to be treated, CuCl 2 Concentration 0.02g / L, H 2 o 2 Concentration 0.4mmol / L;

[0062] (4) 100mL of waste water to be treated, NiSO 4 Concentration 0.02g / L, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L;

[0063] (5) 100mL of waste water to be treated, MnCl 2 Concentration 0.02g / L, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L;

[0064] (6) Wastewater to be treated 100mL, CuCl 2 Concentration 0.02g / L, MoS 2 Concentration 0.3g / L, H 2 o 2 Concentration 0.4mmol / L;

[0065] Experimental results such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com