Low-alloy steel for resisting carbon dioxide corrosion and manufacturing method thereof

A low-alloy steel and carbon dioxide technology, which is applied in earth-moving drilling, drilling equipment, drill pipes, etc., can solve the problems of inability to meet CO corrosion resistance, and it is difficult to achieve the best cost performance for oil pipes, and simplify the heat treatment process and manufacturing process. Simple, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below through specific examples.

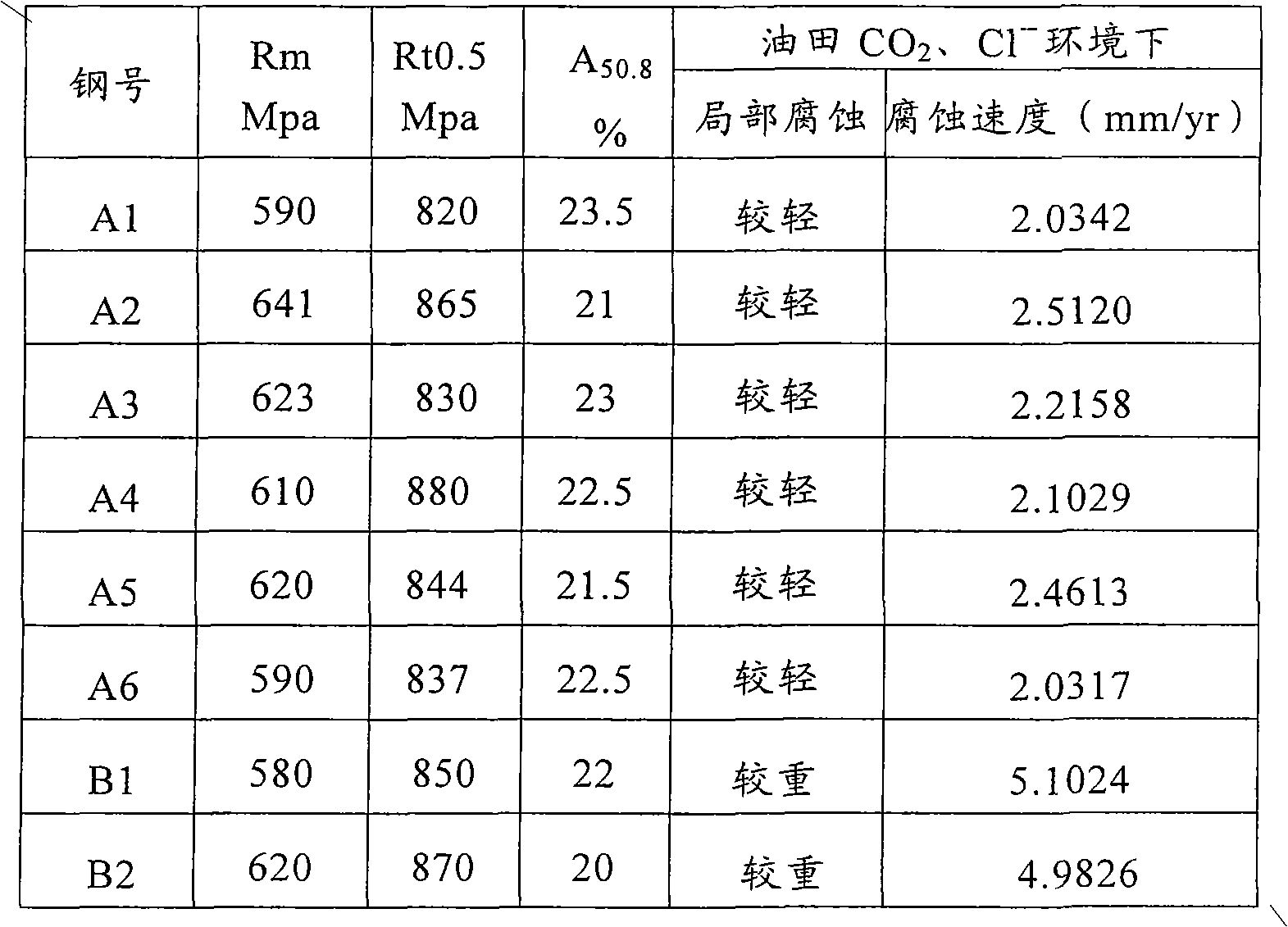

[0024] Table 1 is the chemical composition of the steel of the present invention and the comparison steel. Wherein A1-A6 are alloy steels of the present invention, B1-B2 are reference steels, and B1 and B2 are N80 oil pipes commonly used at present.

[0025] The key process parameters of the production process of control steels B1~B2 are as follows: the tapping temperature at the beginning of steelmaking is about 1650°C; the starting temperature of continuous casting is about 1550°C; The temperature after diameter reduction is about 900°C. After hot rolling, the steel pipe is air-cooled to room temperature without subsequent heat treatment. The production of steels A1-A6 of the present invention adopts the same process and parameters as B1-B2. After hot rolling and air-cooling to room temperature, normalizing treatment in the two-phase zone at about 820-870°C is sufficient.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com