Mechanism for the deployment of endovascular implants

An implant and user technology, applied in the field of coupling components, can solve problems such as limitations, and achieve the effect of control improvement and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

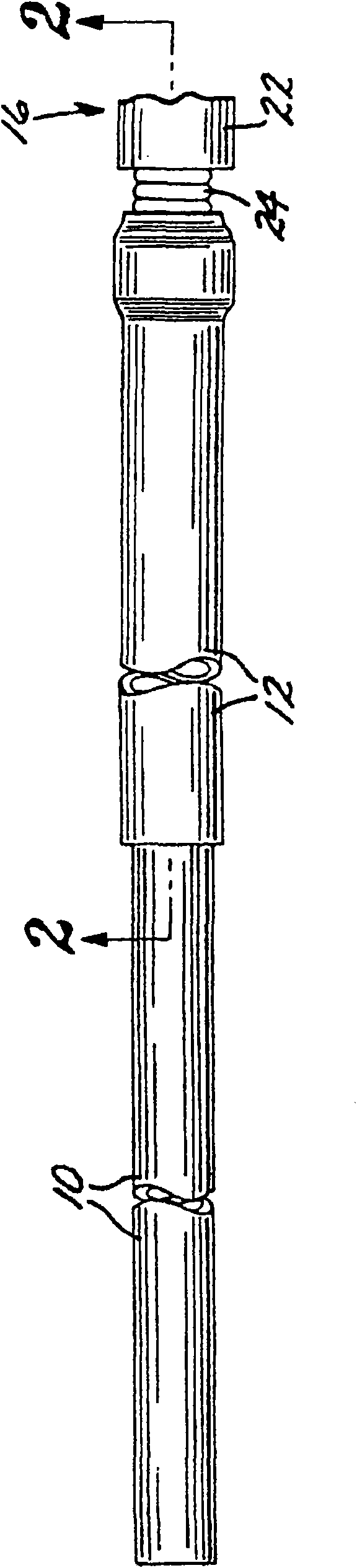

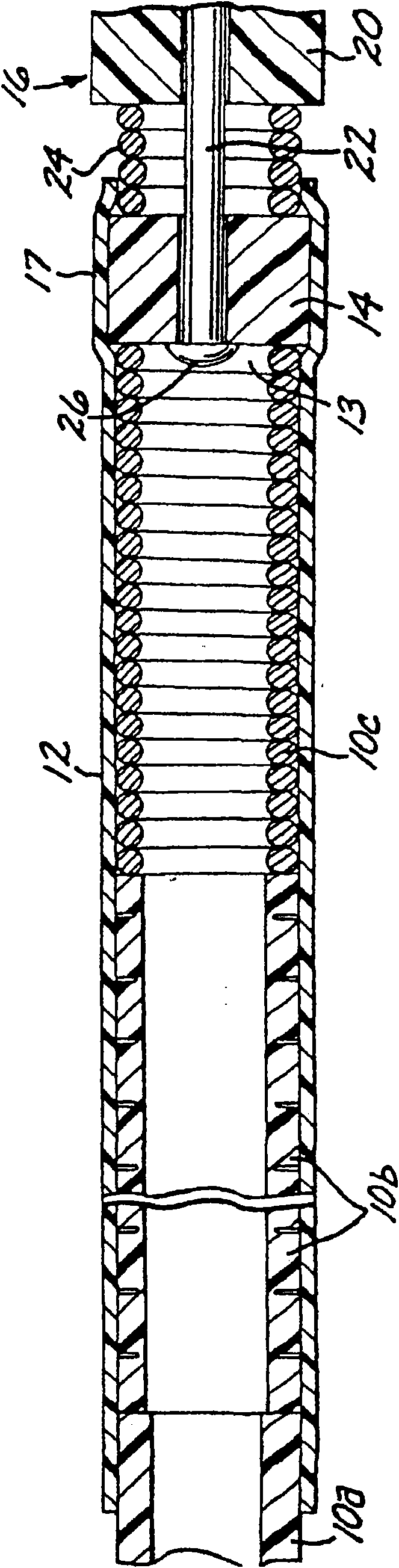

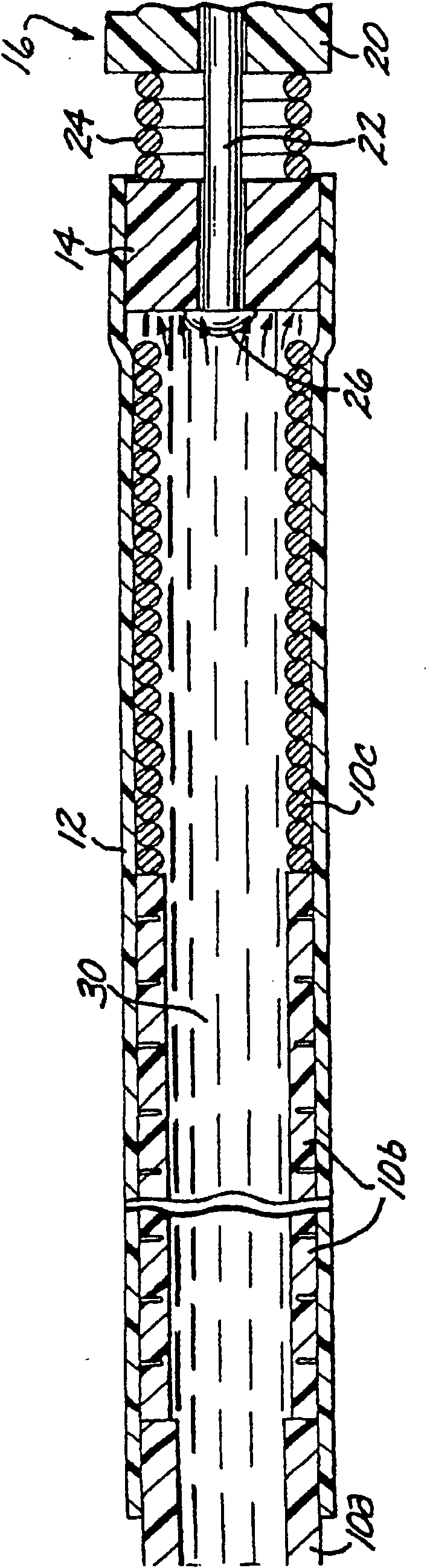

[0052] first reference figure 1 , according to the present invention, a deployment mechanism for an intravascular device comprises a proximal end 11 having an open (see Figure 11 ) and an extended flexible hollow arrangement tube 10 terminating in the distal portion of the open distal end 13, forming a continuous fluid passage lumen 15 between the proximal and distal ends. A retaining sleeve 12 is secured around the distal portion of the deployment tube 10 and includes a distal extension 17 extending a short distance beyond the distal end 13 of the deployment tube. The deployment mechanism also includes a coupling element 14 secured to the proximal end (only the proximal end of which is shown) of a filamentary intravascular device 16, which may be, for example, an embolic implant.

[0053] The deployment tube 10 is made of stainless steel and is preferably formed in three sections, each sized to pass through a typical microcatheter. The proximal or trunk portion 10a is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com