Preparation method of nano zinc oxide spunlaced nonwoven fabrics

A nano-zinc oxide, non-woven fabric technology, applied in non-woven fabrics, textiles and papermaking, textile materials processing and other directions, can solve the problems of complex process, affect the non-woven feel and other problems, achieve simple process, excellent antibacterial performance, improve active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

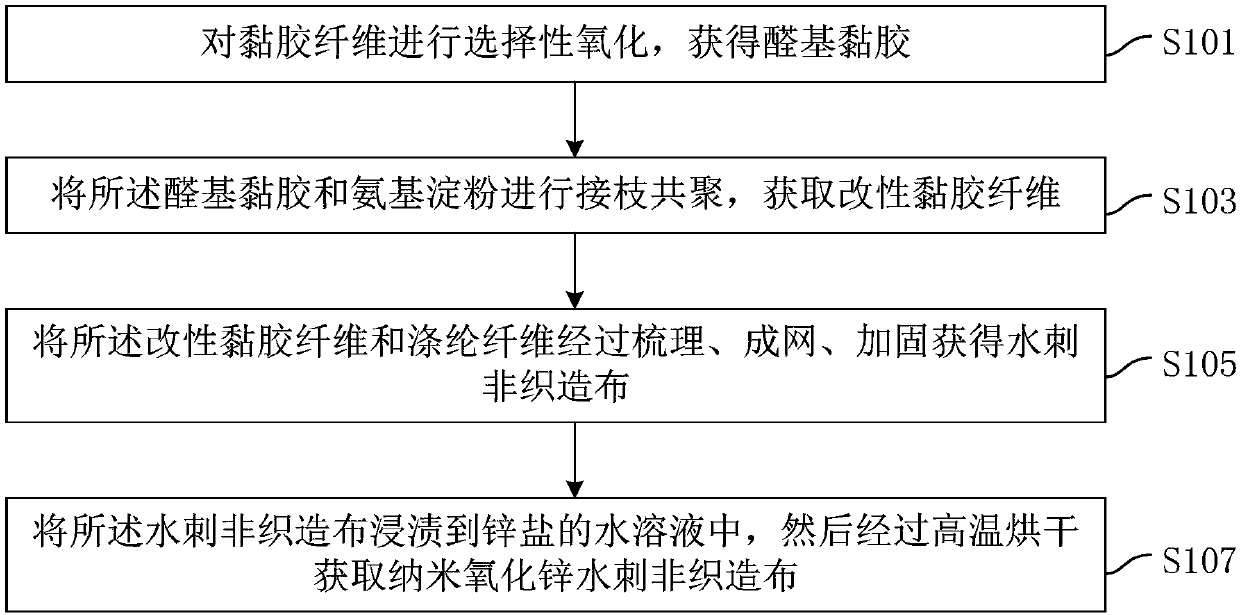

[0026] One embodiment of the present invention provides a kind of preparation method of nano-zinc oxide spunlace nonwoven fabric, such as figure 1 as shown, figure 1 It is a flow chart of the preparation method of nano zinc oxide spunlace nonwoven fabric in one embodiment of the present invention. The preparation method of the nano-zinc oxide spunlaced nonwoven fabric comprises: selectively oxidizing viscose fibers to obtain aldehyde-based viscose, such as figure 1 Step S101 in: Graft-copolymerize the aldehyde-based viscose and amino starch to obtain modified viscose fibers, such as figure 1 In step S103; the modified viscose fiber and polyester fiber are combed, formed into a web, and reinforced to obtain a spunlace nonwoven fabric, such as figure 1 In step S105; the spunlaced nonwoven fabric is immersed in the aqueous solution of zinc salt, and then dried at a high temperature to obtain a nano-zinc oxide spunlace nonwoven fabric, such as figure 1 Step S107 in.

[0027] S...

Embodiment 1

[0041] Select 2kg of viscose staple fiber with a specification of 1.67dtex-38mm, open the viscose staple fiber and put it into 1g / l potassium periodate aqueous solution for impregnation, and then dry it for later use. The liquor ratio is 1:30.

[0042] Put the viscose fiber after potassium periodate treatment into 4g / l amino starch solution, the reaction temperature is 50°C, and the bath ratio is 1:50.

[0043] 2 kg of polyester fibers and viscose fibers were selected for mixing, and after carding, web forming, and reinforcement, spunlace nonwovens were obtained.

[0044] The spunlaced fabric was dipped into 0.01mol / l zinc nitrate solution, and then dried at 100°C to obtain nano-zinc oxide spunlaced nonwoven fabric.

Embodiment 2

[0046] Select 2kg of viscose staple fiber with a specification of 1.05dtex-38mm, open the viscose staple fiber and put it into 1.5g / l sodium periodate aqueous solution for impregnation, and then dry it for later use. The liquor ratio is 1:30.

[0047] Put the viscose fiber after sodium periodate treatment into 6g / l amino starch solution, the reaction temperature is 50°C, and the bath ratio is 1:50.

[0048] Select 4kg of polyester fiber and viscose fiber to mix, after carding, web forming and reinforcement to obtain spunlace nonwoven fabric.

[0049] The spunlaced fabric was dipped into 0.01mol / l zinc acetate zinc solution, and then dried at 100°C to obtain nano-zinc oxide spunlaced nonwoven fabric.

[0050]It has been tested that the antibacterial rate of the nano-silver polypropylene nonwoven fabric to Escherichia coli and Staphylococcus aureus reaches more than 90%.

[0051] In the preparation method of nano-zinc oxide spunlace nonwoven fabric provided in the embodiment o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com