Patents

Literature

91results about How to "Timely feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

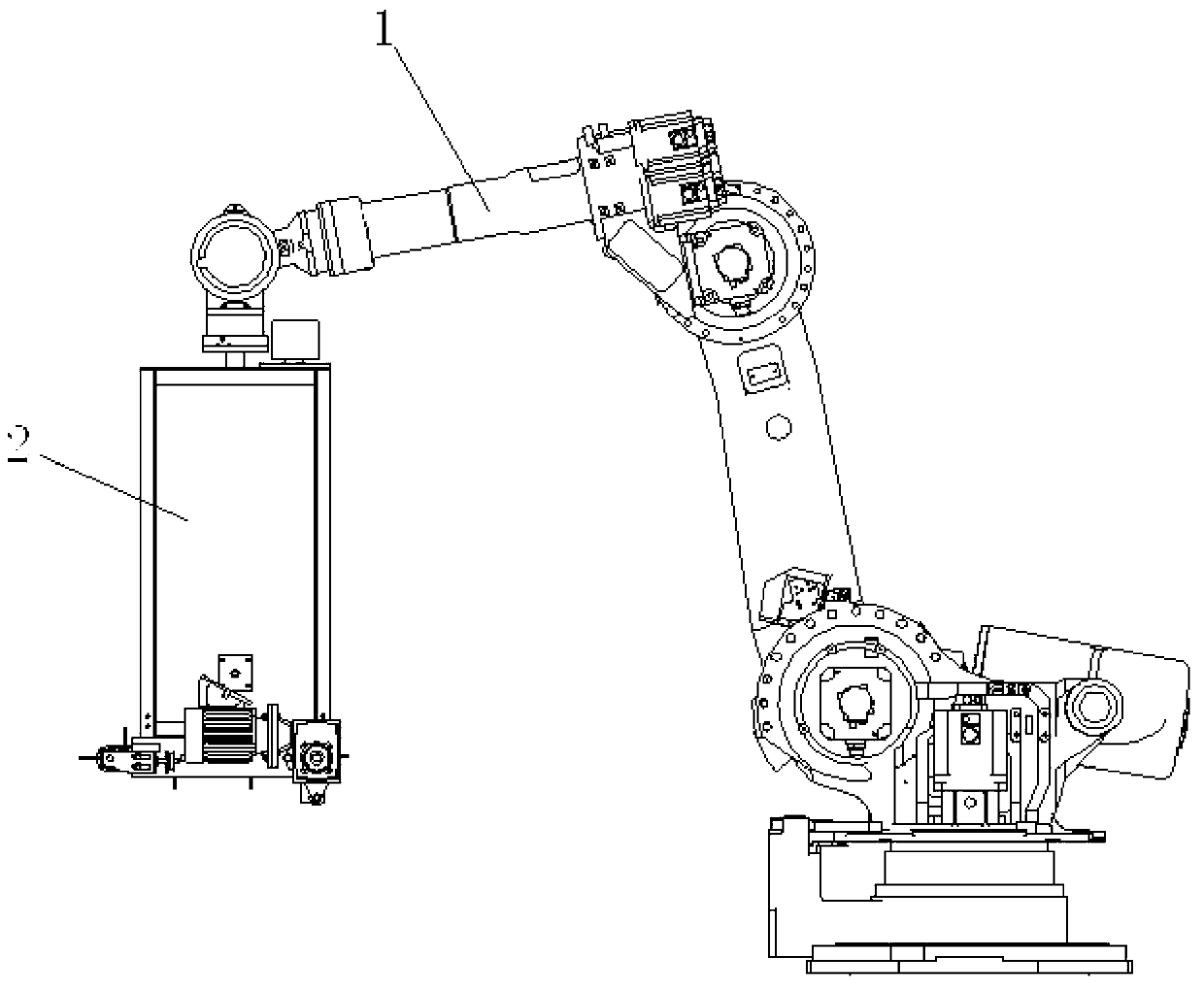

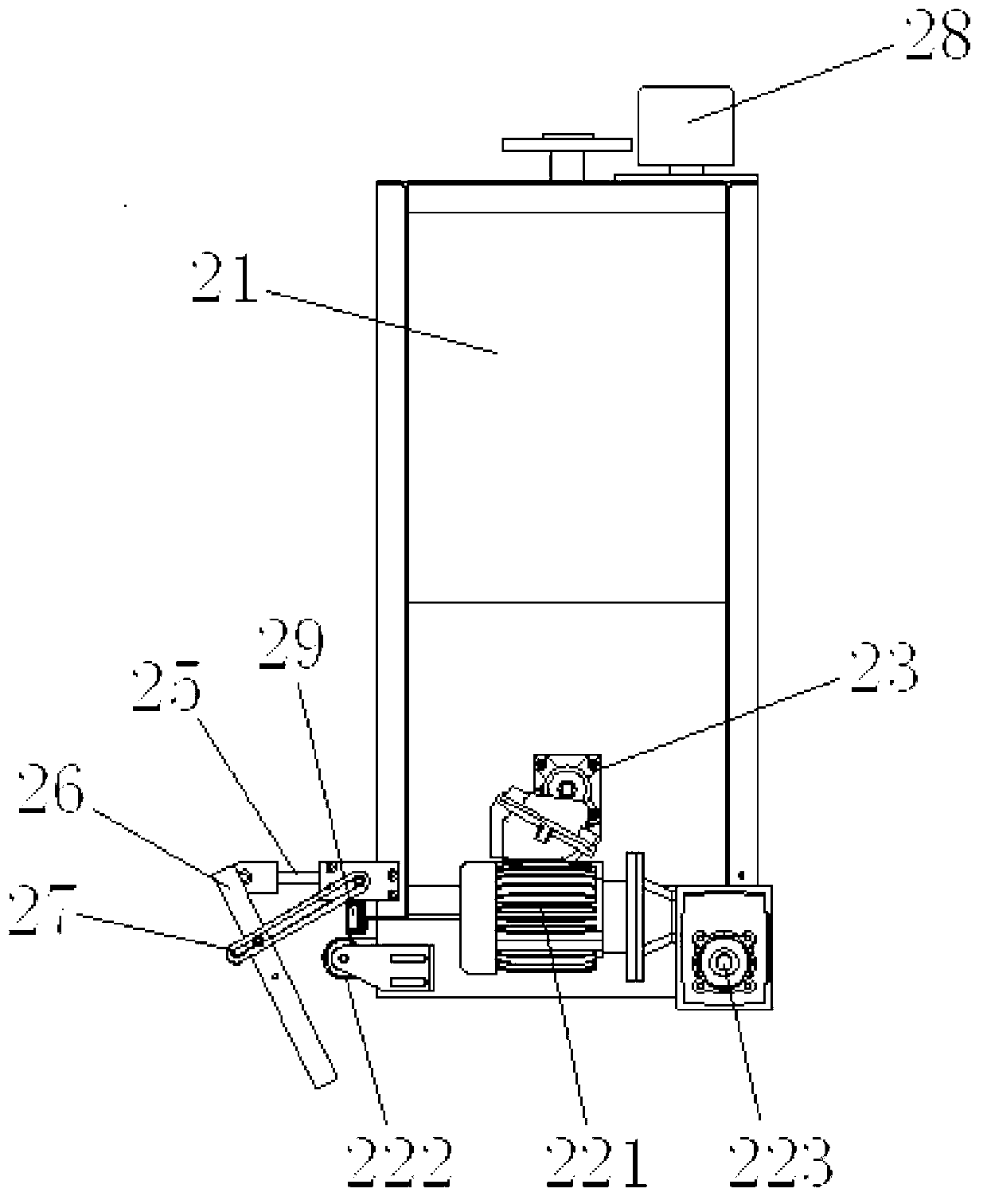

Full-automatic retort installing system and retort installing method thereof

ActiveCN103101773AAchieve mechanical propertiesRealize informatizationLoading/unloadingInformatizationEngineering

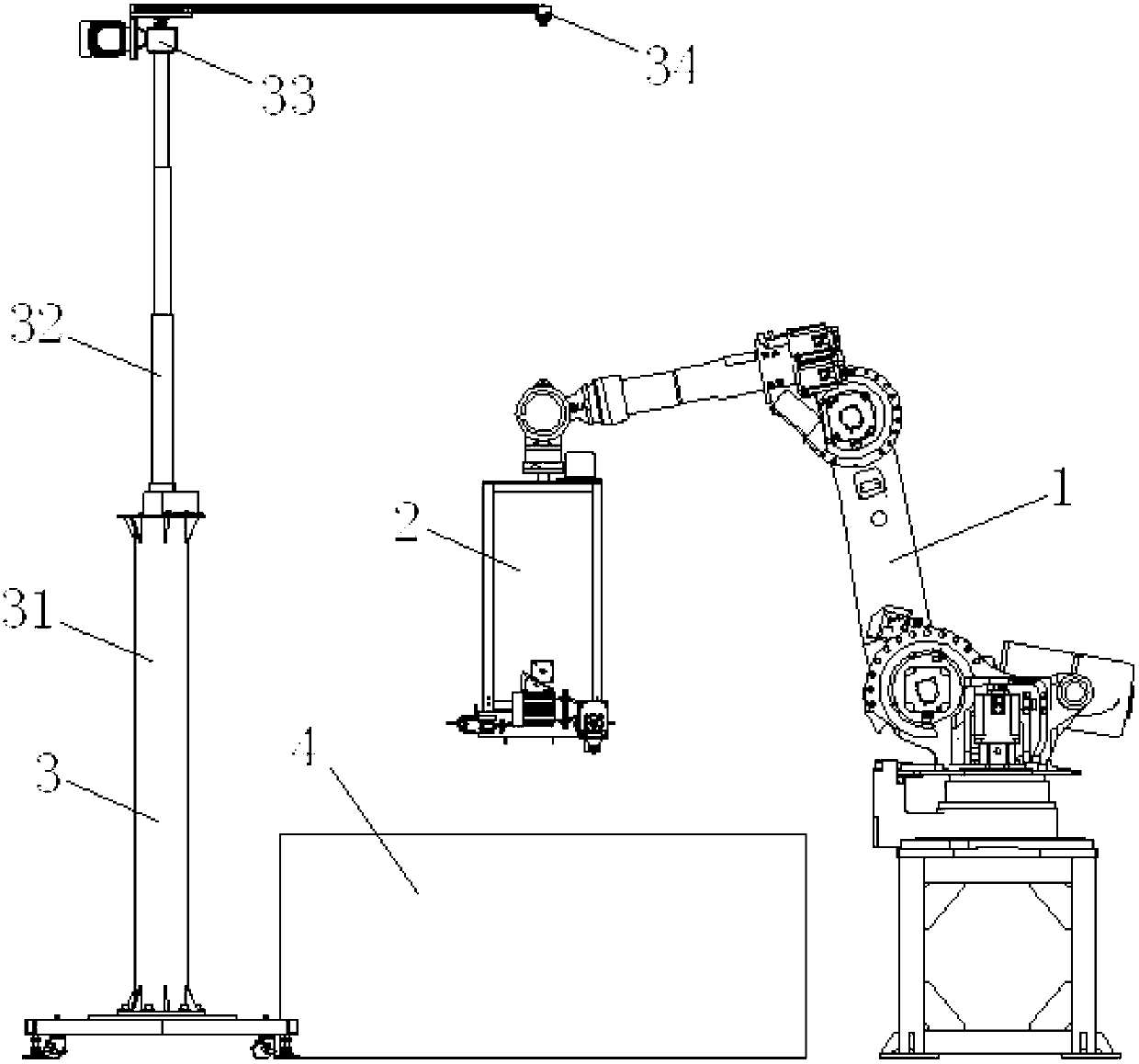

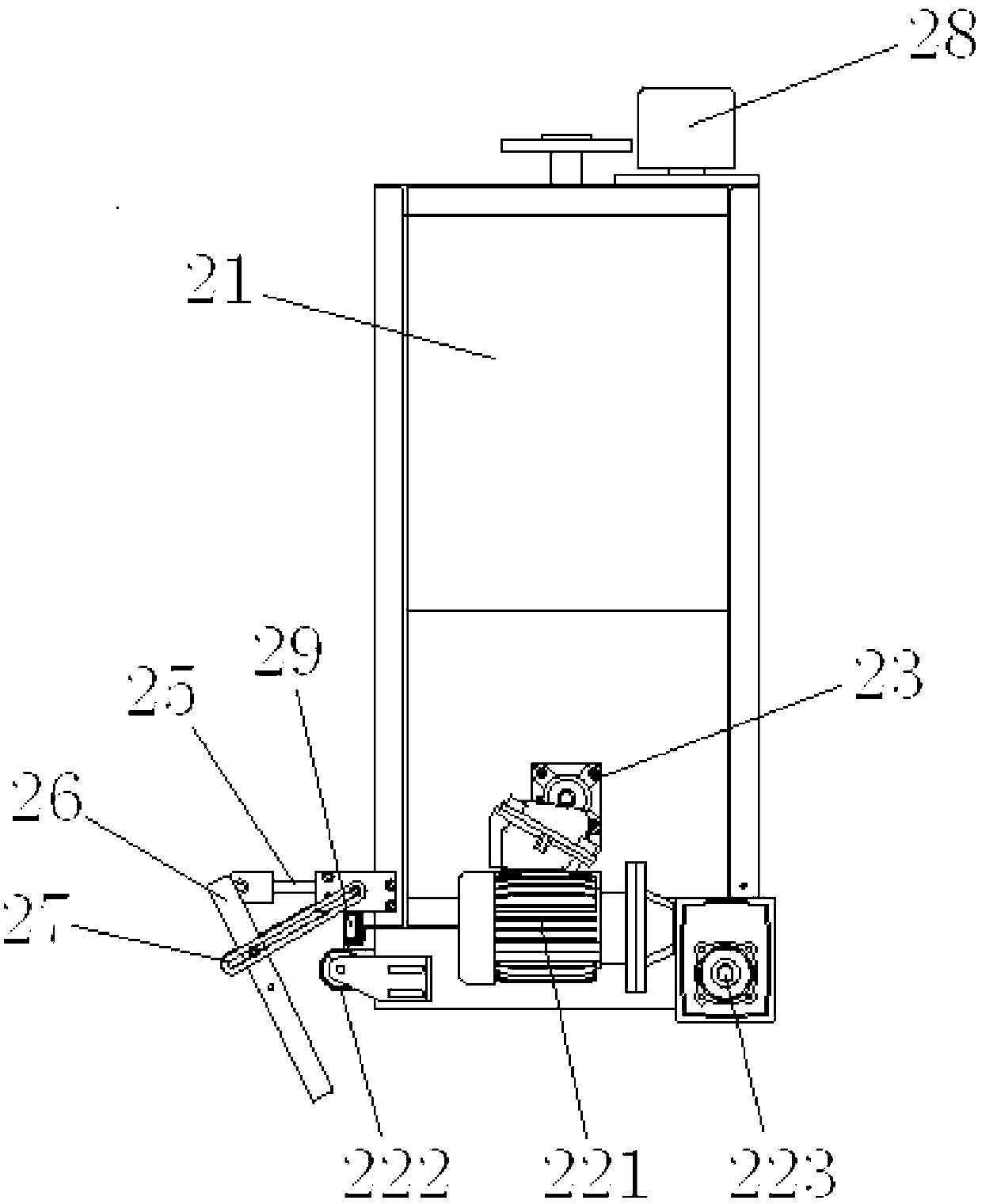

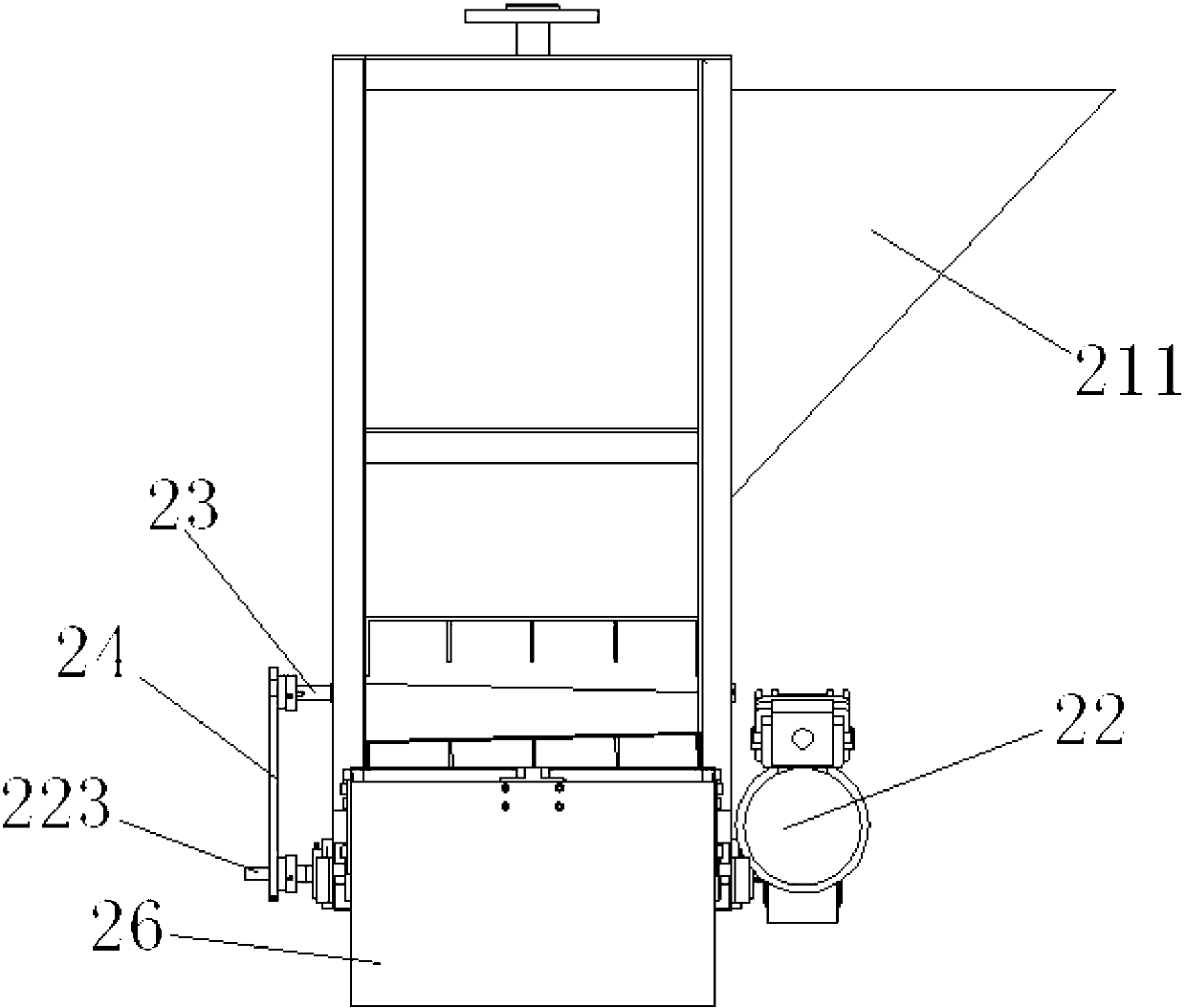

The invention discloses a full-automatic retort installing system and a retort installing method of the full-automatic retort installing system. The full-automatic retort installing system comprises a multi-joint robot, a retort installing executing mechanism, a retort installing vision measurement and control mechanism, a center control mechanism and a feeding mechanism. The retort installing executing mechanism is fixed at the tail end of the multi-joint robot and is located above a retort barrel. The retort installing vision measurement and control mechanism monitors and controls temperature and height of a charge level in the retort barrel in real time. The center control mechanism receives information collected by the retort installing vision measurement and control mechanism and sends control information to the multi-joint robot and the retort installing vision measurement and control mechanism. The feeding mechanism feeds the retort installing executing mechanism. The full-automatic retort installing system can fully simulate manual retort installing, is more high-efficient and accurate, and achieves full mechanization and informatization of wine making retort installing technology.

Owner:百特(福建)智能装备科技有限公司

Livestock raising feeding trough convenient to adjust

InactiveCN106106218AAvoid shaking from side to sideAvoid stayingAnimal feeding devicesAgricultural scienceGear wheel

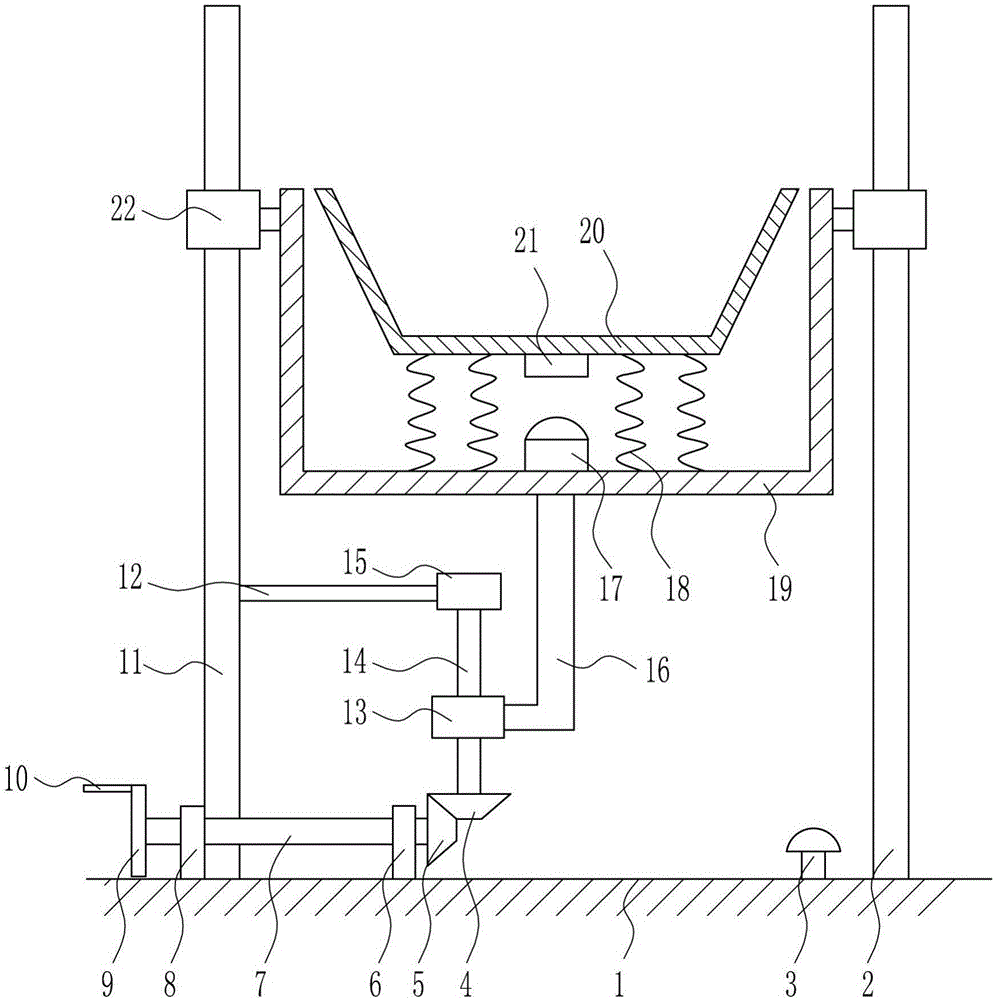

The invention relates to a livestock raising feeding trough convenient to adjust, in particular to a livestock raising feeding trough convenient to adjust. The technical effect of providing a livestock raising feeding trough convenient to adjust, the height is convenient to adjust, livestock can be fed in time, and a great deal of time and labor are saved is achieved. In order to achieve the technical effect, the livestock raising feeding trough convenient to adjust comprise a right guide rail, an alarm device, a second bevel gear, a first bevel gear, a second bearing pedestal, a rotating shaft, a first bearing pedestal, a rotating disc, a handle, a left guide rail, a supporting rod, a nut, a threaded rod, a third bearing pedestal, a support, a button, springs, a placing frame, a feeding trough, a press block and guide blocks. The left guide rail and the right guide rail are symmetrically arranged at the left side and the right side of the ground, and guide blocks are arranged on the left guide rail and the right guide rail respectively. By means of the guide rails and the guide blocks, the placing frame is driven to move up and down, cow is quantitatively fed at regular time, and balanced and regular feeding is achieved.

Owner:杨国锋

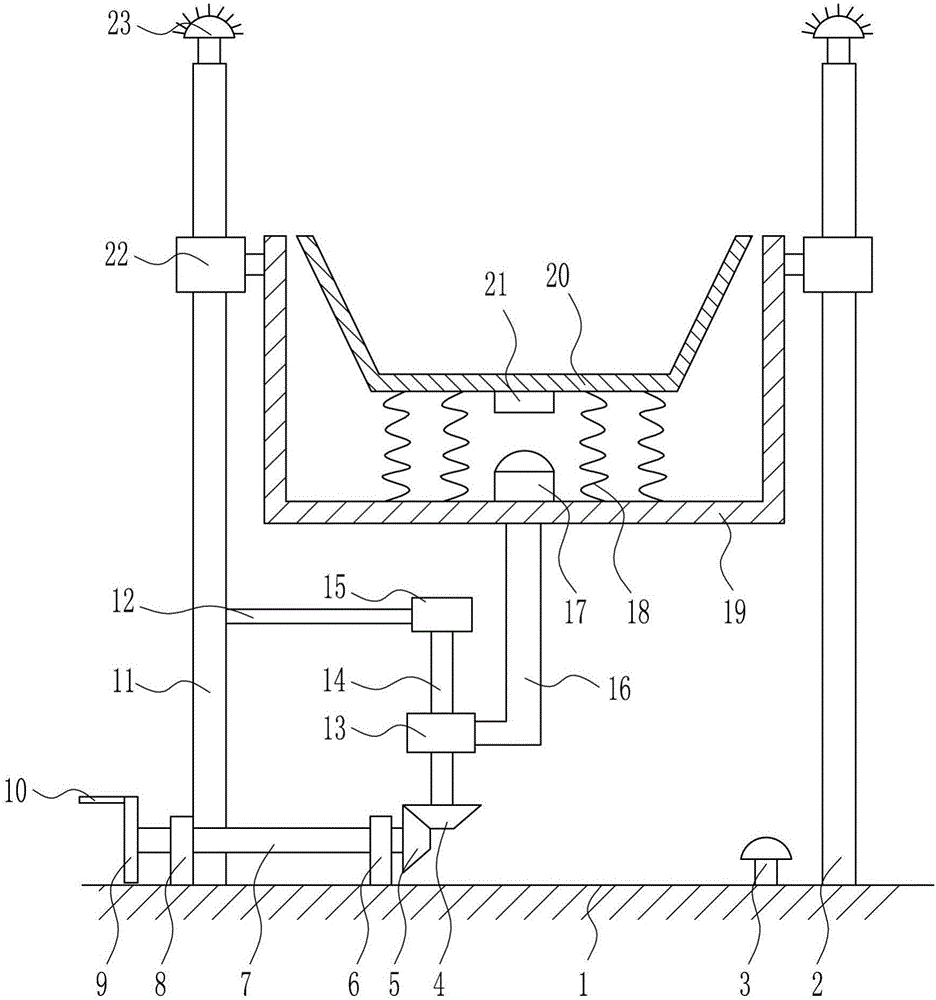

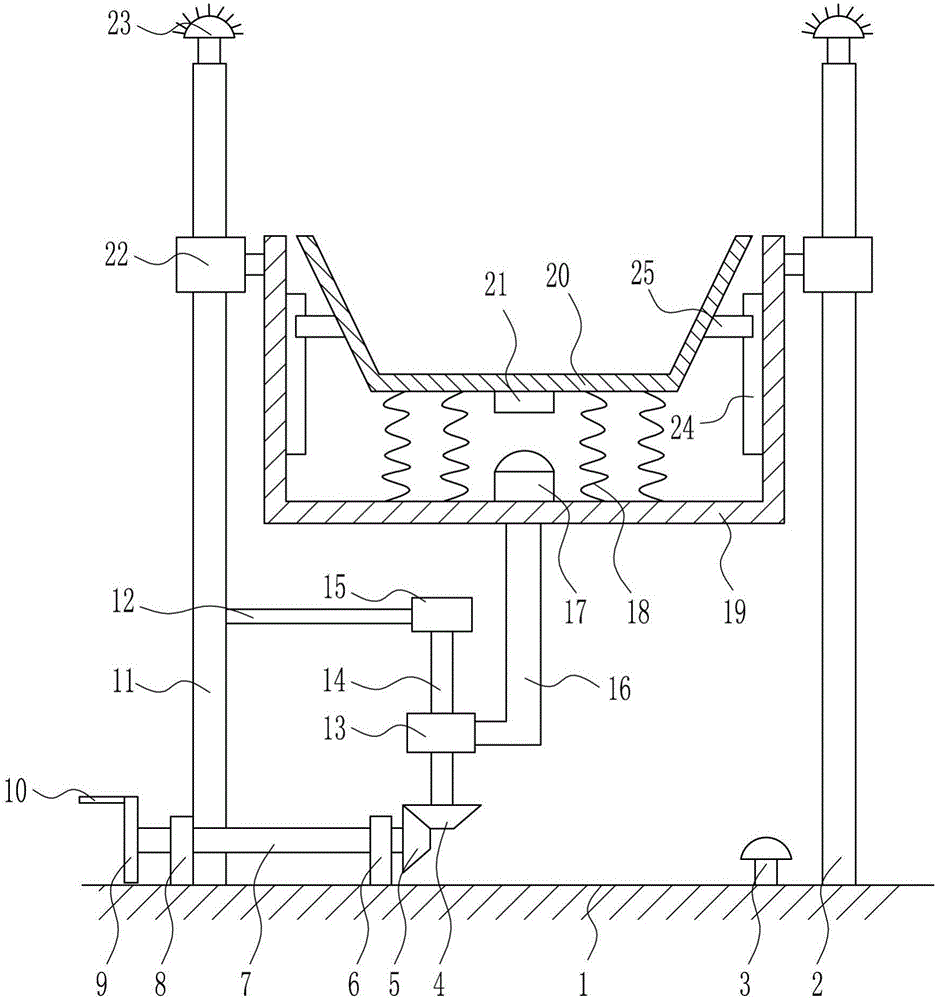

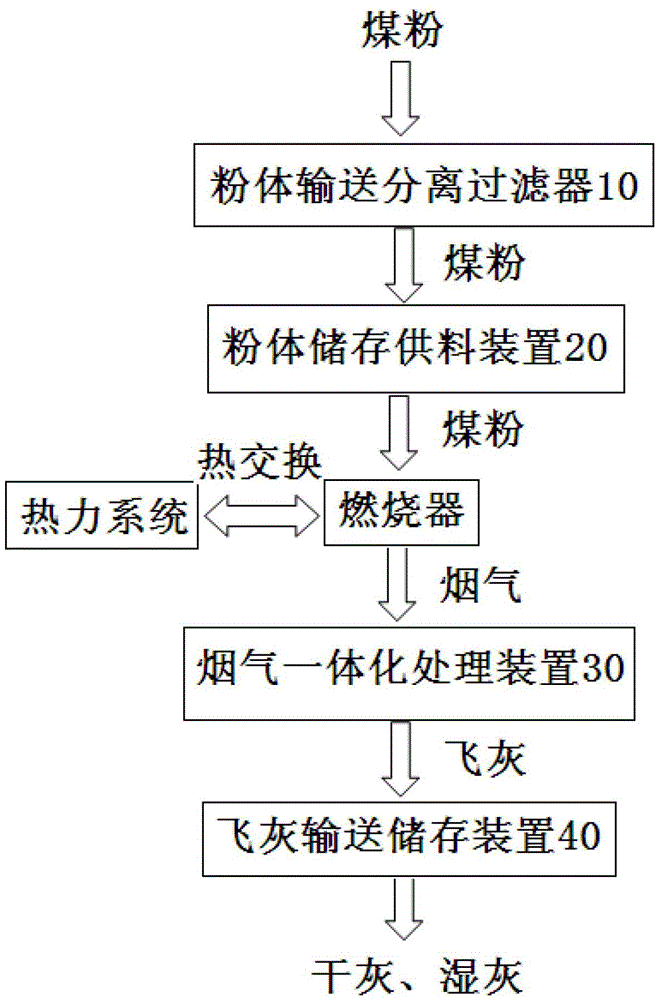

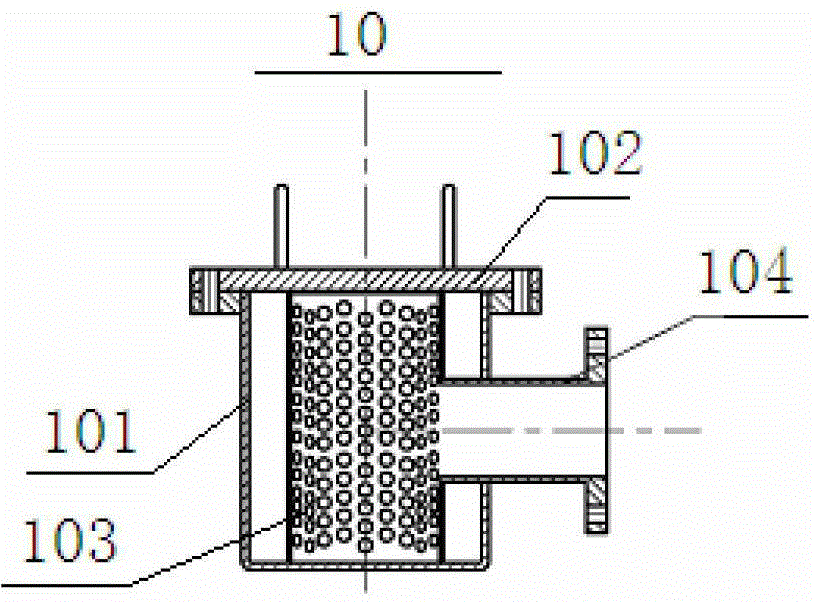

Pulverized coal industrial boiler system

ActiveCN102980200AStable deliveryDischarge cleaningSolid removalLump/pulverulent fuel feeder/distributionCombustorFlue gas

The invention relates to a pulverized coal industrial boiler system. The pulverized coal industrial boiler system is characterized by comprising a pulverized coal feeding and separating filter, a pulverized coal storing and feeding device, a boiler burner, a flue gas integrated treatment device, a fly ash delivering and storing device and an inert gas protecting device; the feeding and separating filter filters pulverized coal and then conveys the pulverized coal to the pulverized coal storing and feeding device, the pulverized coal storing and feeding device stores the pulverized coal and supplies the pulverized coal to the boiler burner, the boiler burner exchanges heat with a thermodynamic system during the burning process and supplies hot water or steam to users; and flue gas after the combustion of the boiler burner is treated through the flue gas integrated treatment device and is delivered to the fly ash delivering and storing device, wherein the pulverized coal in the pulverized coal storing and feeding device needs to be protected through inertia gases which are provided by the inert gas protecting device during the storing process. The system integrates pulverized coal delivering, storing, feeding, flue gas treating and recycling into a whole, has high function integration level, a small occupation area, low operation cost, high economy and no dust and flue gas leakage, cannot cause environmental pollution and can be widely used for a pulverized coal feeding process.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

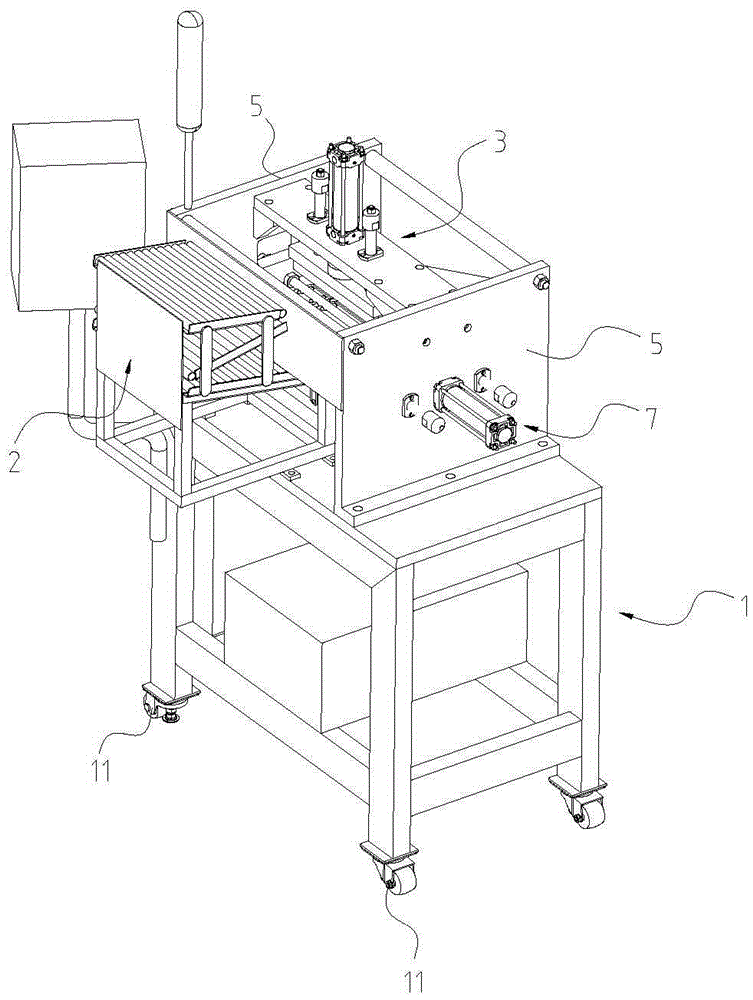

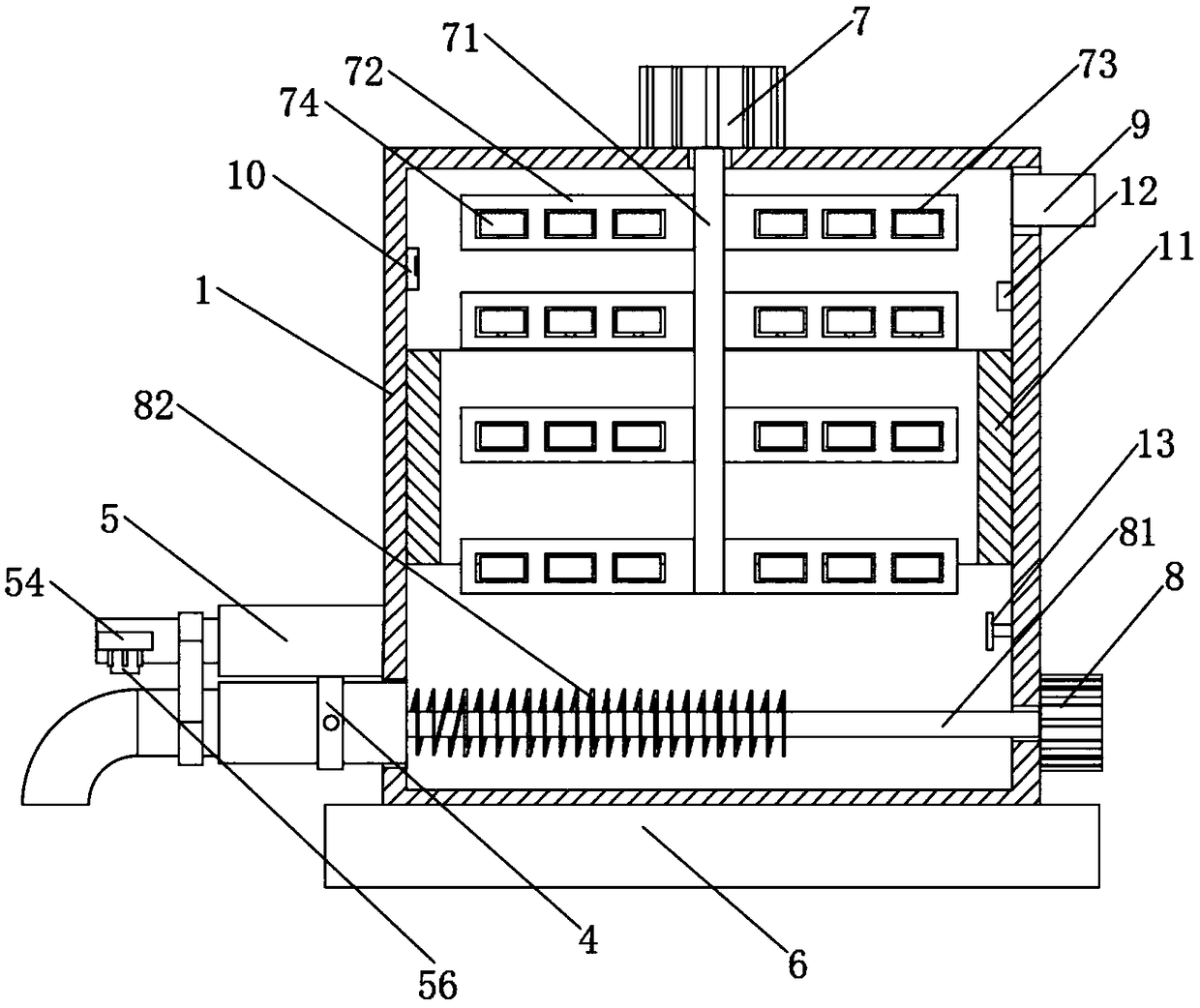

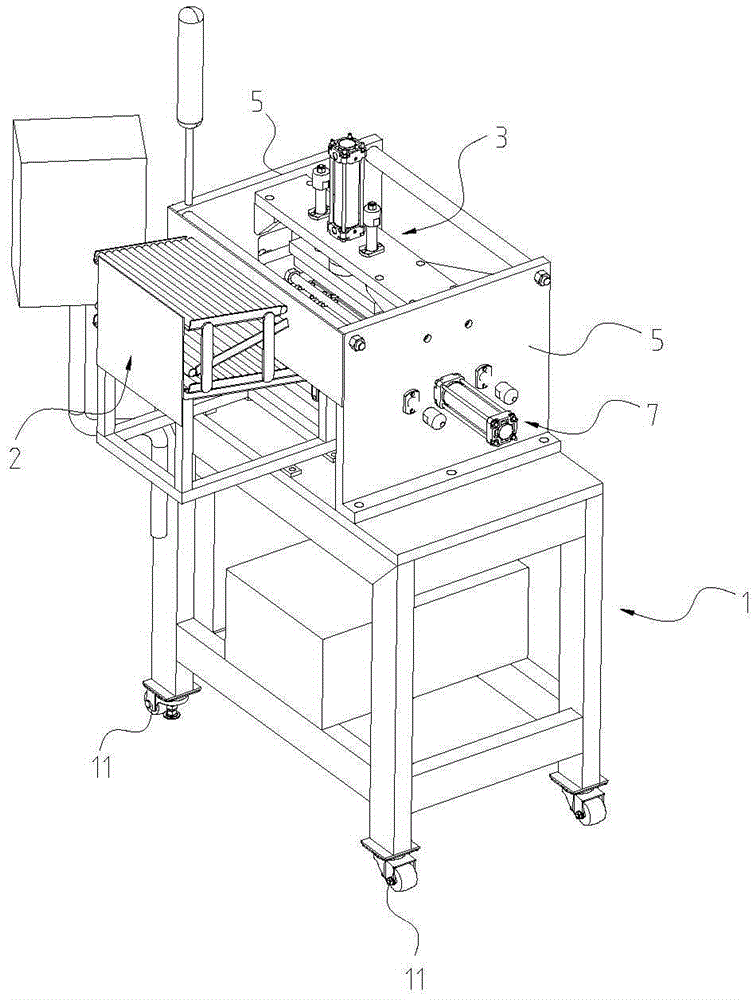

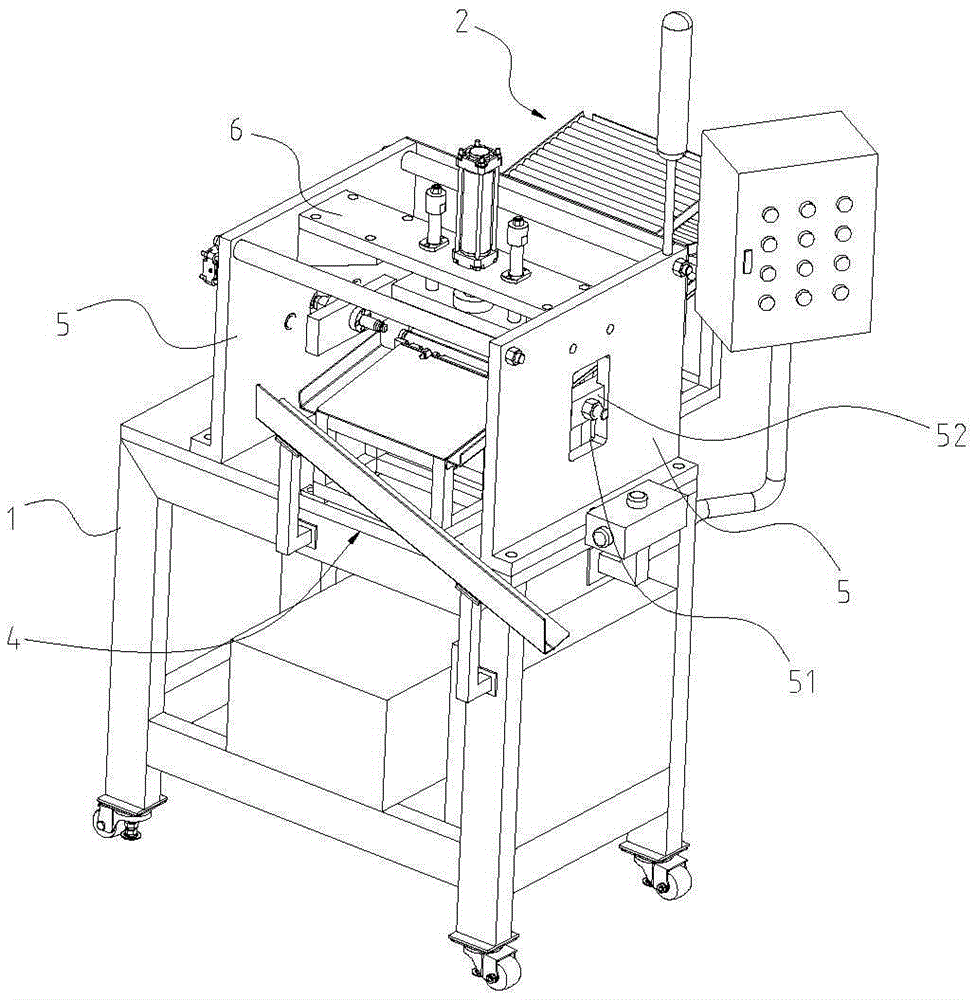

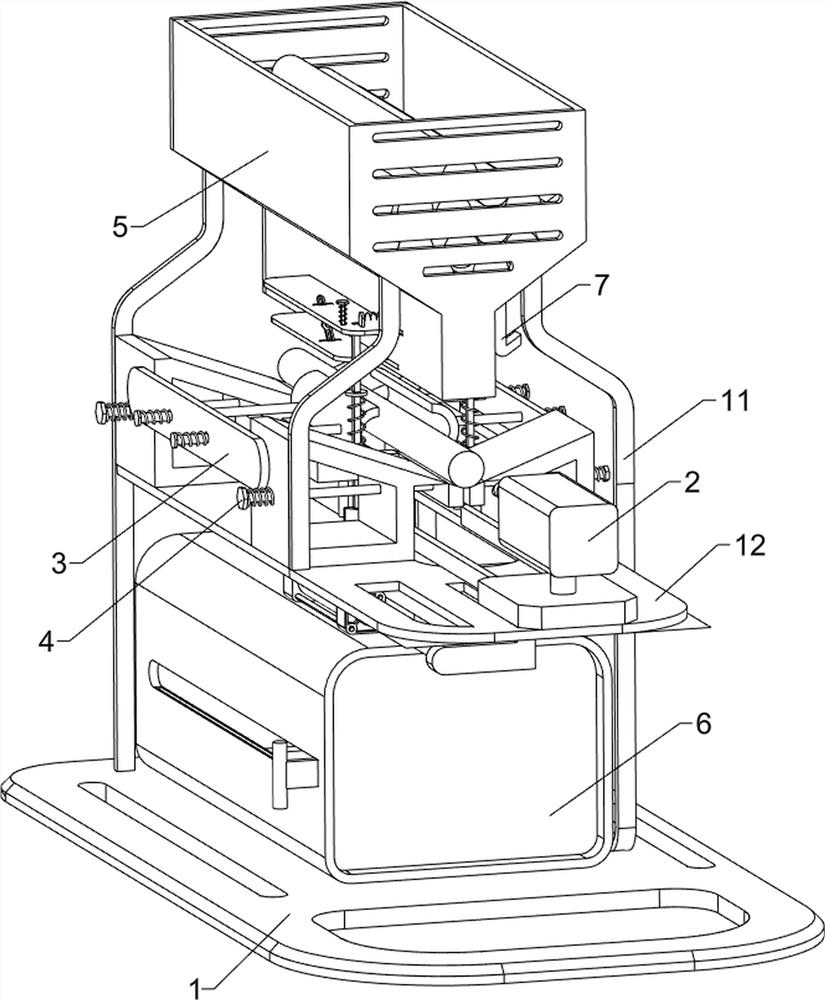

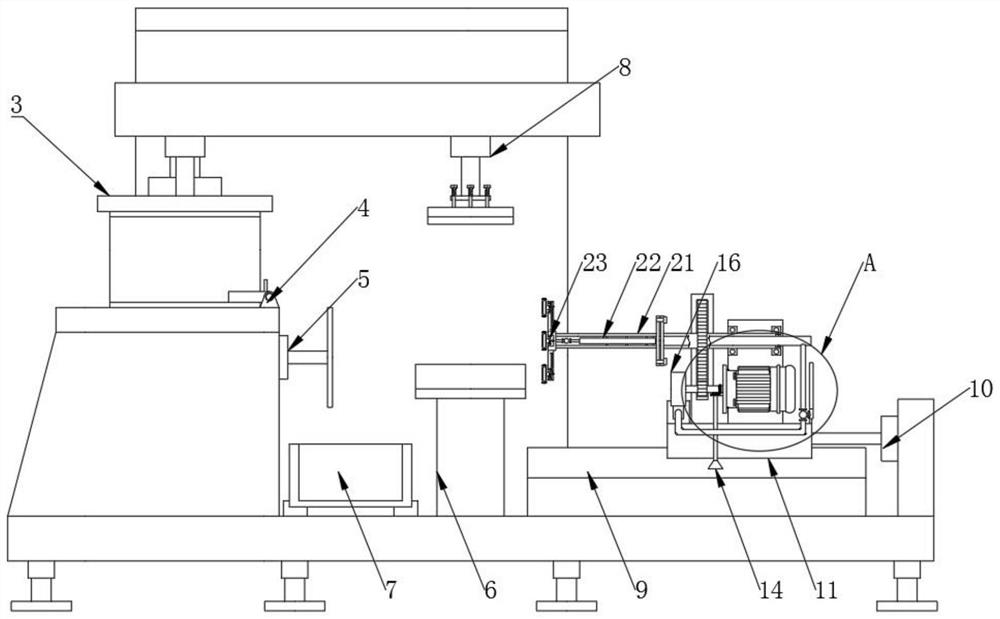

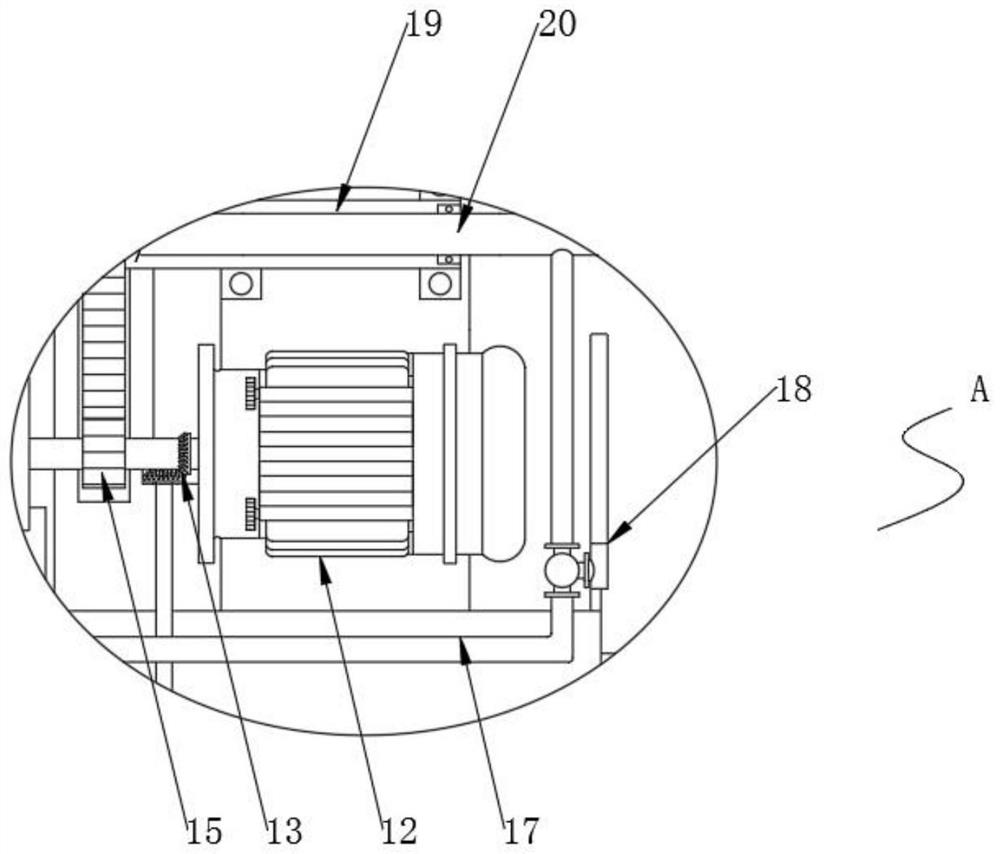

Automatic pipe-expanding machine

InactiveCN105328058AOrderly rowsSave spaceMetal-working feeding devicesPositioning devicesEngineeringAutomation

The invention discloses an automatic pipe-expanding machine. The automatic pipe-expanding machine comprises a feeding device, a compressing device, a pipe-expanding device and a material falling device. According to the automatic pipe-expanding machine, materials are stored and conveyed through the feeding device; the feeding device is connected with the compressing device in a butt joint mode; a pipe in the feeding device is smoothly conveyed into the compressing device to be compressed through the compressing device; the pipe-expanding technique is conducted on a compressed pipe through pipe-expanding device; and after the pipe-expanding action is completed, compression of the compressing device on the pipe is removed, and the pipe-expanded steel pipe is conveyed to the material falling device to fall down. Accordingly, the full-automation production is completed, and the production efficiency is high.

Owner:于建林

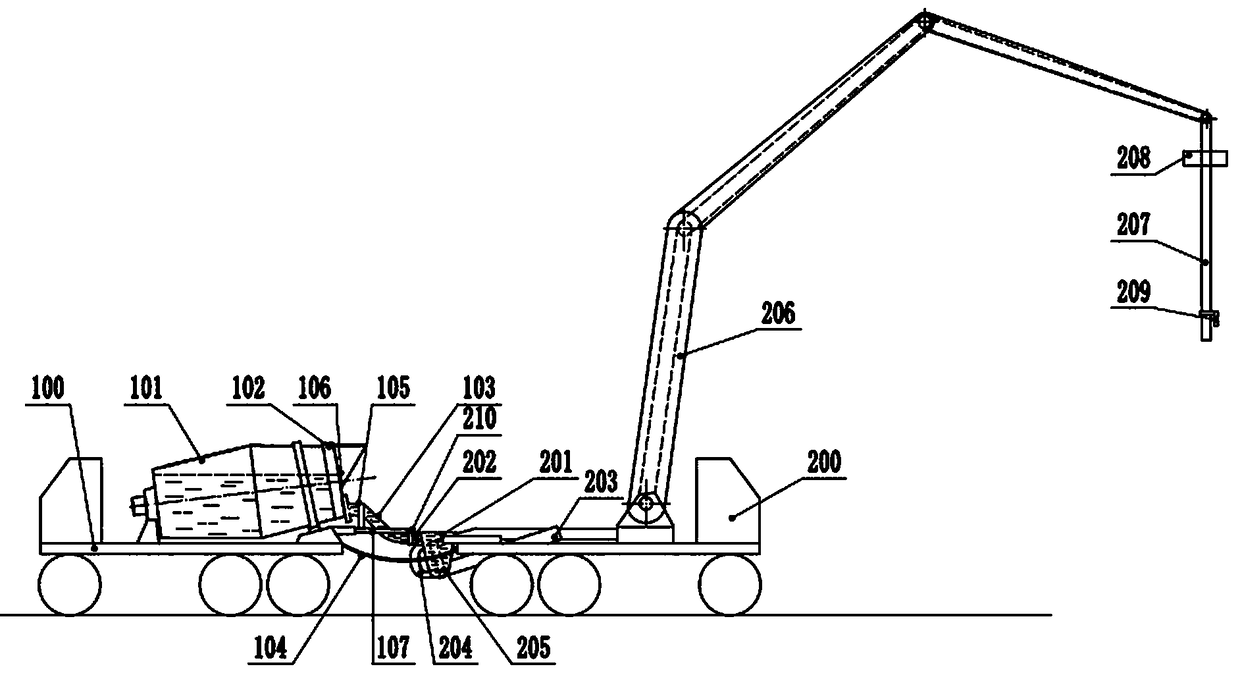

Integrated double concrete supplying and pouring system and supplying method

ActiveCN108331351AReduce volumeAvoid spillingBuilding material handlingThermal insulationEvaporation

The invention discloses an integrated double concrete supplying and pouring system and supplying method. The supplying system comprises a stirring truck and a pump truck, wherein the stirring truck isprovided with a stirring barrel and a sealing end cover, the pump vehicle comprises a closed supplying system, the stirring truck and the pump truck are communicated through a closed supplying pipe and a feeding pipe, so that a communicated concrete fluid with pressure difference is formed, and concrete in a receiving hopper of the pump truck is endowed with lasting supplying pressure. Integratedand concentrated control of the stirring truck and the pump truck is realized by connecting operating systems of the stirring truck and the pump truck. Integrated and automatic operation of the stirring truck and the pump truck is convenient to realize, the concrete pouring construction efficiency is improved, water adding in the pumping position due to concrete water evaporation and slump loss is also avoided, the concrete quality is ensured, overflow leakage of the concrete at the receiving hopper is eradicated, the thermal insulation effect is improved, and the purpose of continuous concrete supply to the pump truck under certain pressure conditions is achieved.

Owner:盛富春

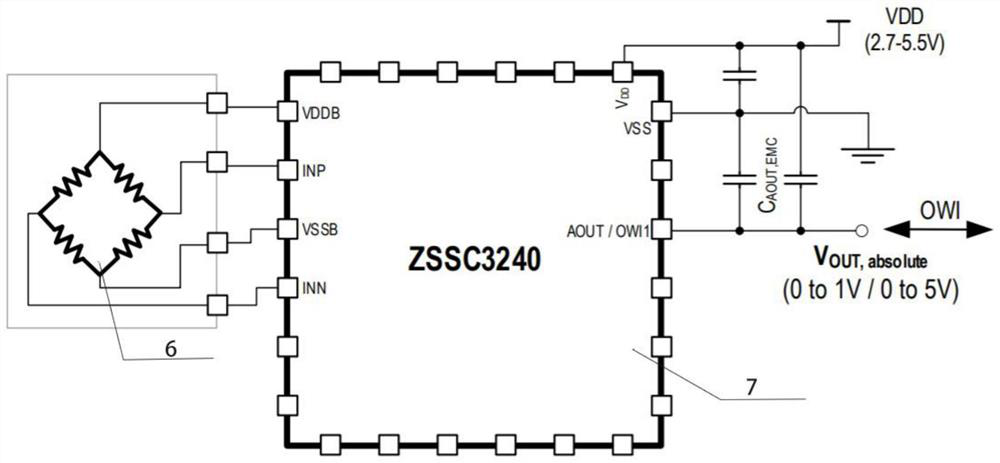

Method for detecting starved feeding alarming of ice cream machine

ActiveCN102578354ASolve the problem of lack of material alarm accuracyTimely feedingFrozen sweetsAlarmsAlarm stateEngineering

Disclosed is a method for detecting a starved feeding alarming of an ice cream machine, which is capable of improving detecting accuracy of the starved feeding alarming and reducing false alarm rate. The method includes the following steps : (1), after starting up, detecting a rotating speed of a stirring mechanism of the ice cream machine and the temperature of an evaporating cylinder, when the detected rotating speed during starting up is in correspondence with an initial forming proportion A and the temperature is above a setting temperature value F in initial forming, recording a preforming temperature X when the ice cream reaches a preforming proportion B, and being saved in a system, and being covered when restarting and the requirements are met; (2), when the rotating speed is in correspondence with the forming proportion, forming and shutting down and no alarming; when the rotating speed can not reach the forming proportion and the temperature measuring value is maintained fora period of time T1 and below alarming threshold value X-N1, sending a starved feeding alarming signal and maintaining alarming state for a period of time T2; (3), automatically shutting down and entering into standby when the temperature value is always below the shutting down setting temperature X-N2 during the period of time T2 and the rotating speed can not reach the forming proportion after the starved feeding alarming signal is sent out.

Owner:GUANGZHOU GUANGSHEN ELECTRIC PROD CO LTD

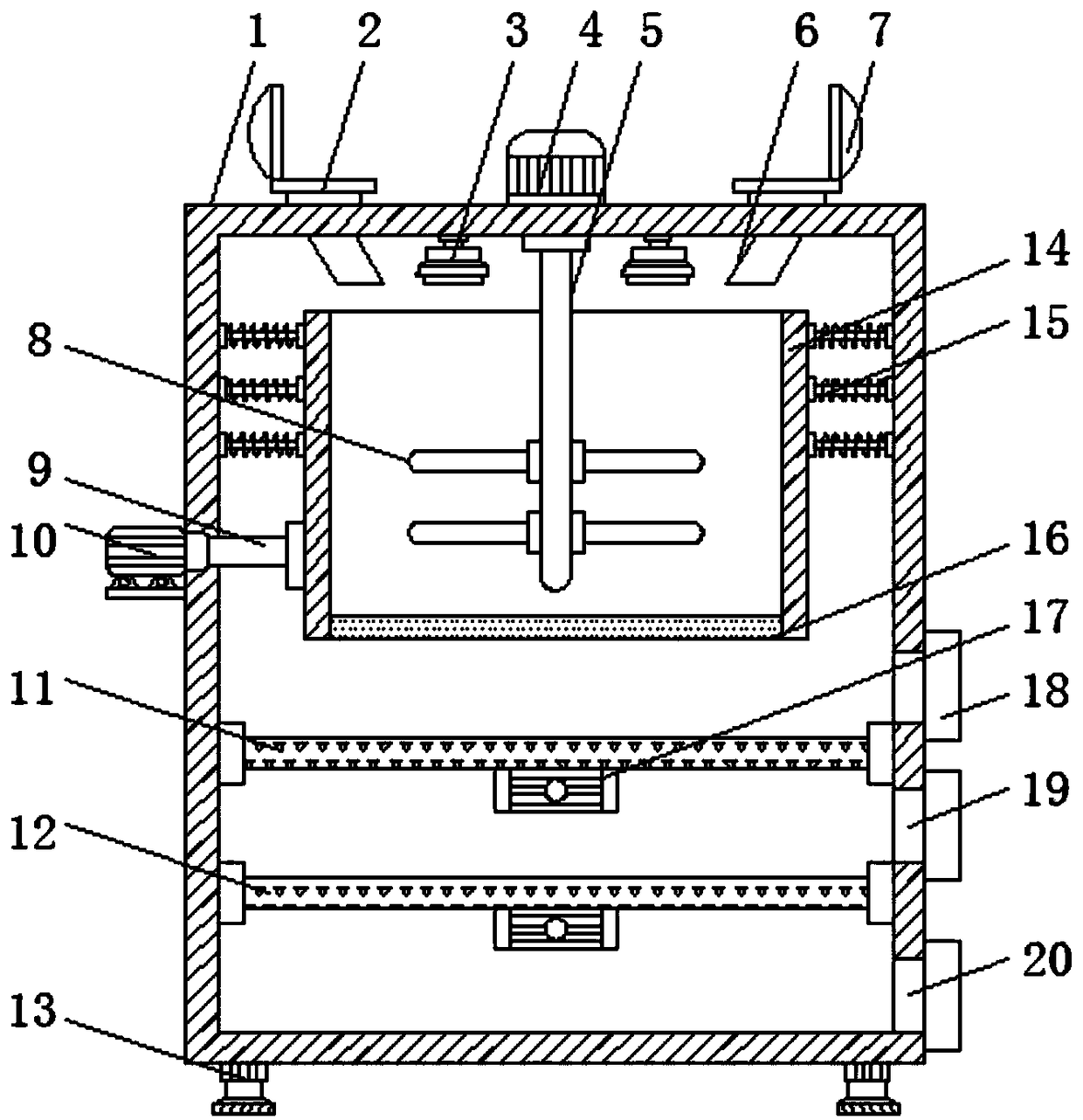

Screening device for engineering plastic processing equipment

InactiveCN109013298AScreening impactEasy to filterSievingScreeningHydraulic cylinderScreening effect

The invention discloses a screening device for engineering plastic processing equipment. The screening device comprises a screening box. The interior of the screening box is equipped with a receivingbox. The upper ends two sides of the receiving box are connected with the inner wall of the screening box by springs, and the bottom of the receiving box is provided with a coarse screen. A qualifiedvibrating screen is arranged below the receiving box, a fine vibrating screen is arranged below the qualified vibrating screen, a stirring motor is arranged between feeding ports, and the output end of the stirring motor is fixedly connected with a stirring shaft. The stirring shaft passes through the top of the screening box and extends into the receiving box. One outer side of the screening boxis provided with a hydraulic cylinder, and the interior of the hydraulic cylinder is provided with a piston rod, and one end of the piston rod extends into the screening box and is fixedly connected to the receiving box. A hot air blower is connected to the back of the screening box, and the hot air blower is connected with a hot air hood through an air duct. The screening device disclosed by theinvention can be used for scattering and drying treatment when engineering plastic is screened, thus the engineering plastics are ensured to be thoroughly screened, the screening effect is good, and the screening efficiency is high.

Owner:合肥瀚鹏新能源有限公司

Device and method for breeding cattle

ActiveCN109349147APrevent archingEasy to moveAnimal feeding devicesHollow article cleaningEngineeringFodder

The invention discloses a device and method for breeding cattle. The cattle breeding device comprises a base, a left support frame, a right support frame and a food trough, wherein the left support frame and the right support frame are arranged on the base, and the food trough is arranged on the horizontal section of the left support frame and the right support frame and is rectangle; the food trough comprises a front side wall, a rear side wall, a left side wall, a right side wall and a U-shaped bottom plate, wherein the rear side wall is in a backward arched arc shape, and the height of theupper end of the rear side wall is higher than the height of the upper end of other side walls; a cavity is formed in the base, a horizontally extending air bag is arranged in the cavity, a push plateis arranged at the lower portion of the air bag, a plurality of rollers which can extend out of the lower surface of the base are arranged on the push plate, the air bag is connected with an inflation pump, and the inflation pump is electrically connected with a controller. The device and method for breeding the cattle has the characteristics that the feed can be saved, the cattle can take reasonable nutrition, and the healthy growth of the cattle can be ensured.

Owner:重庆耕盈农业发展有限公司

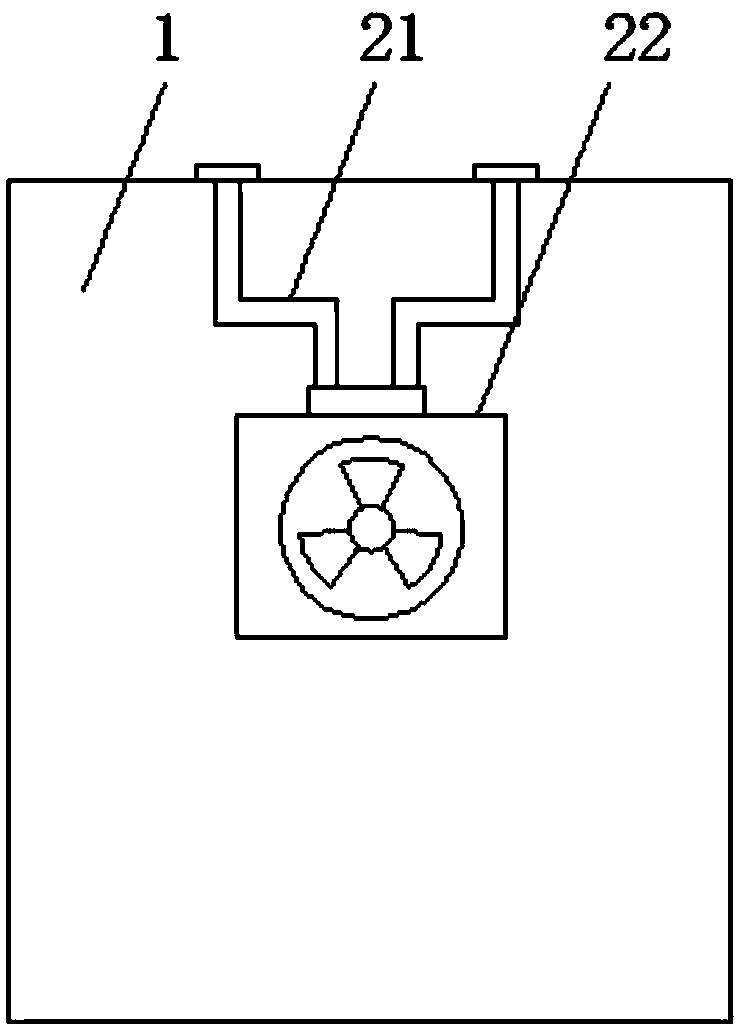

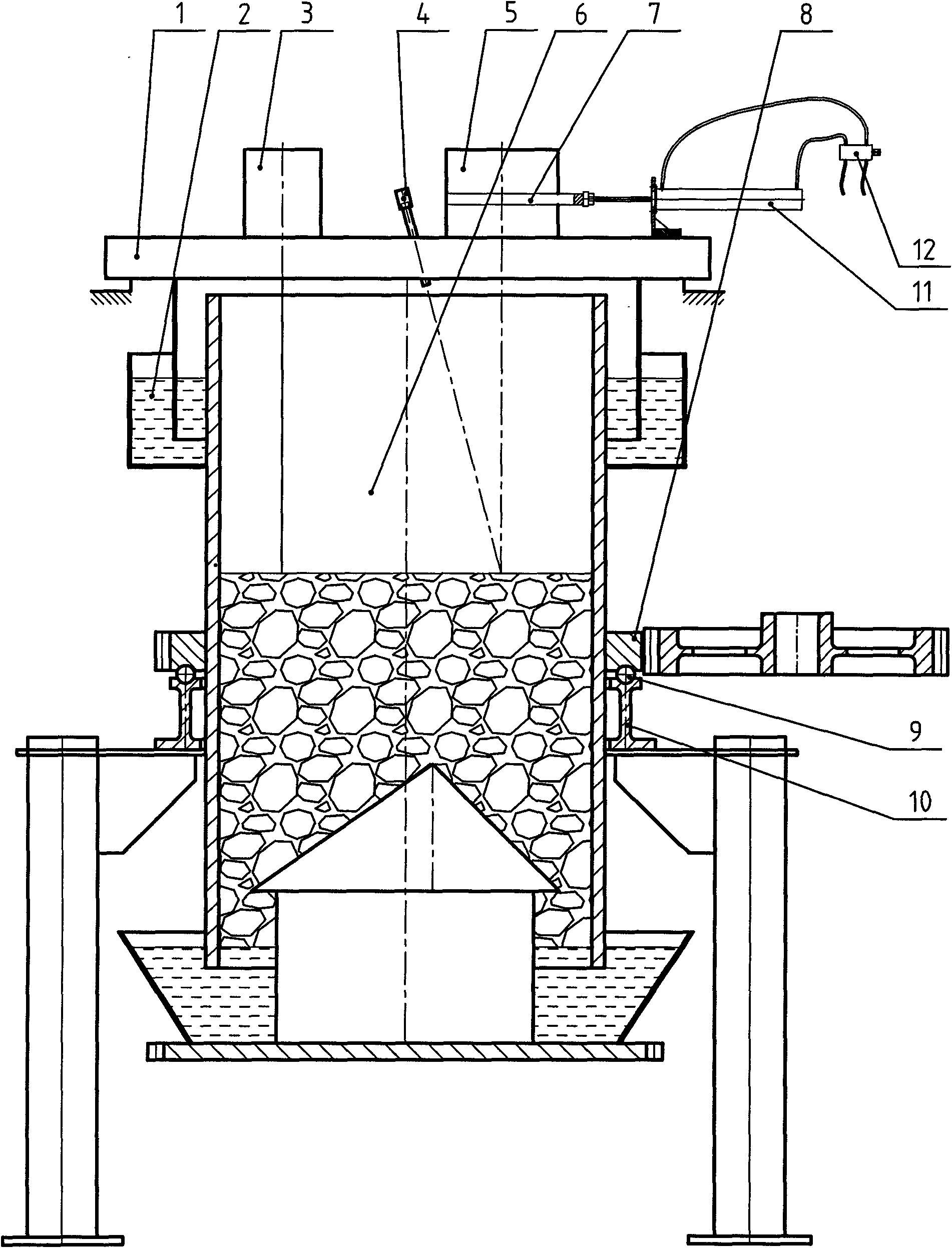

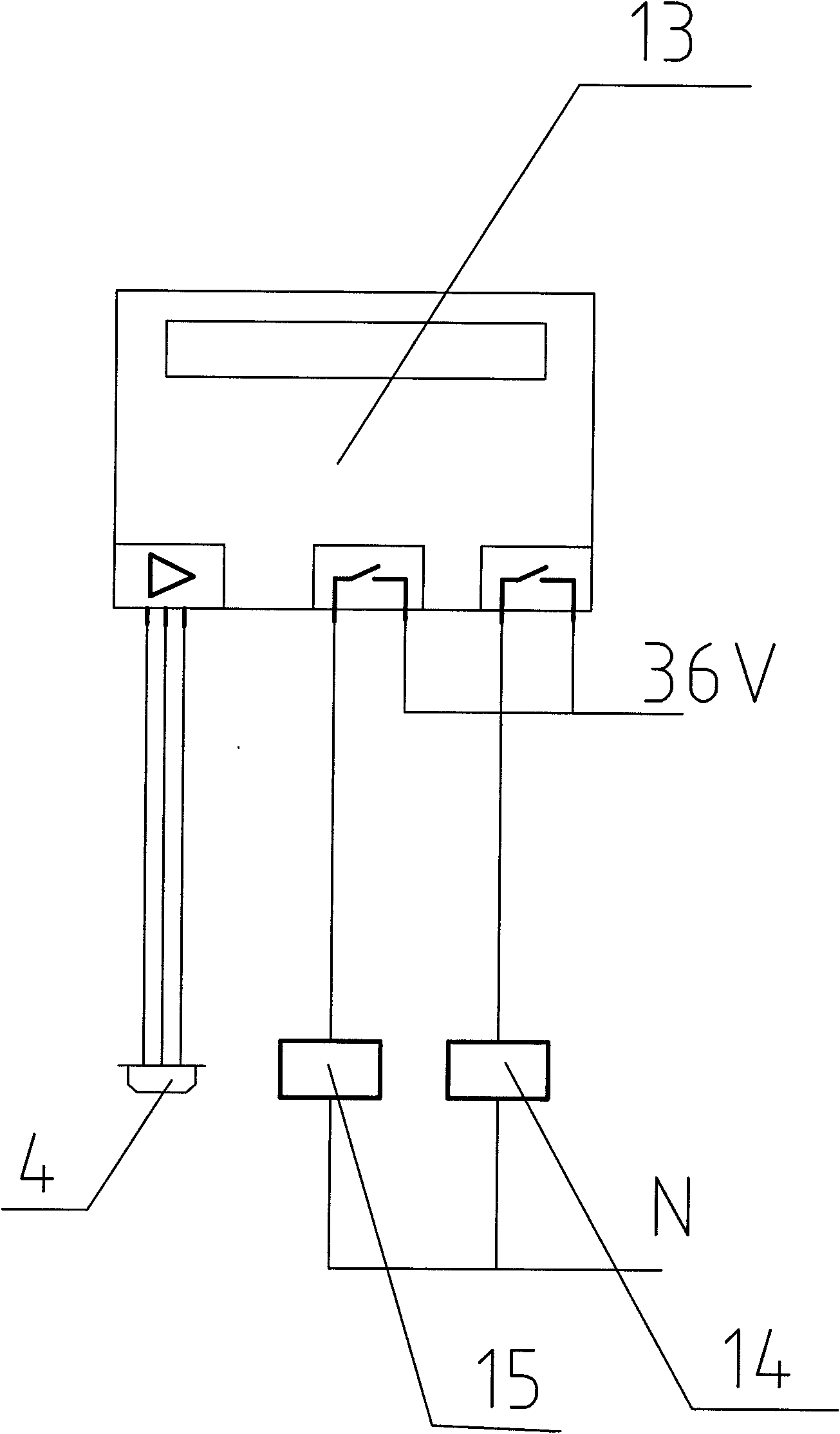

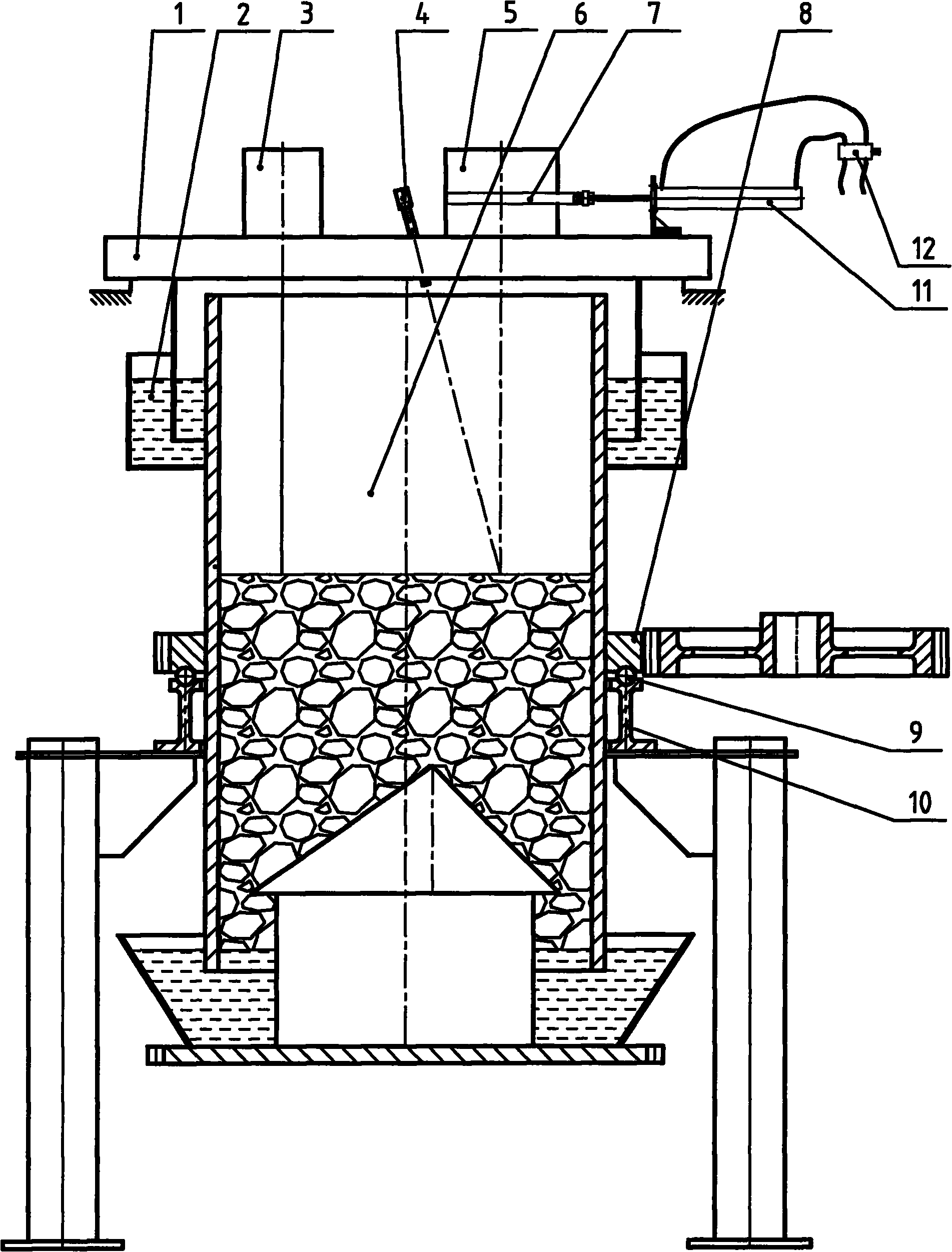

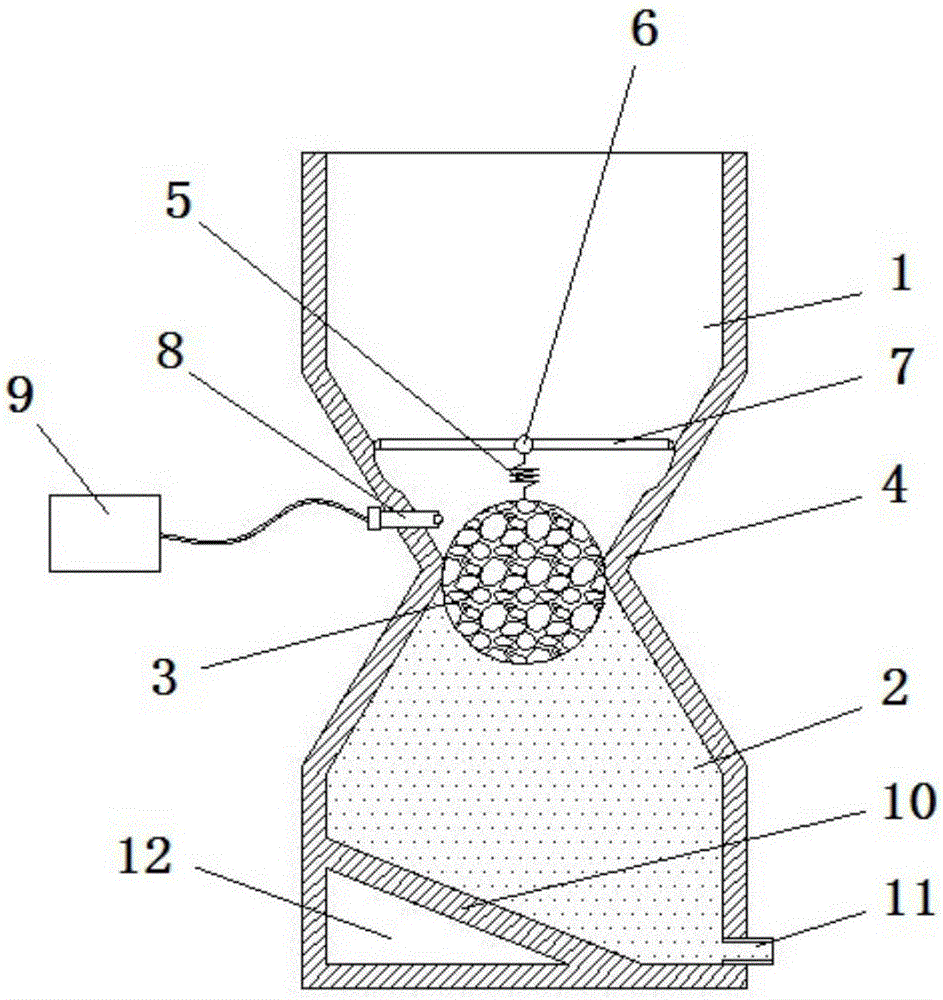

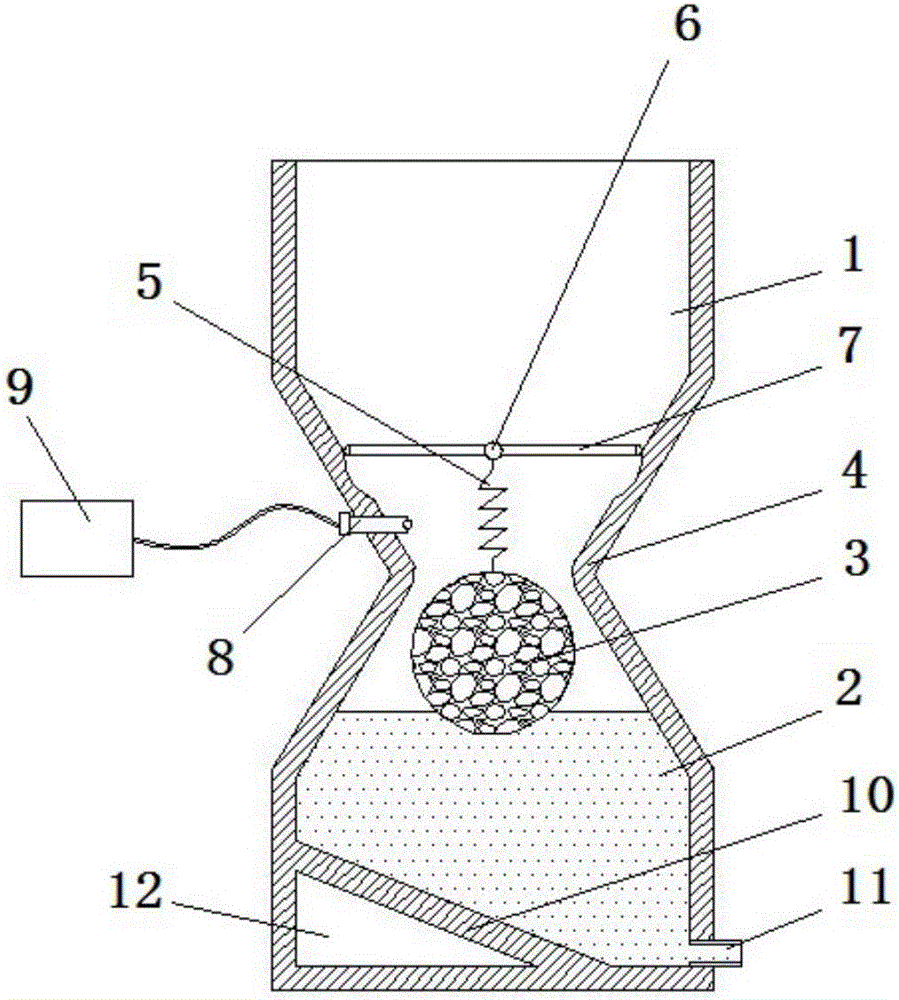

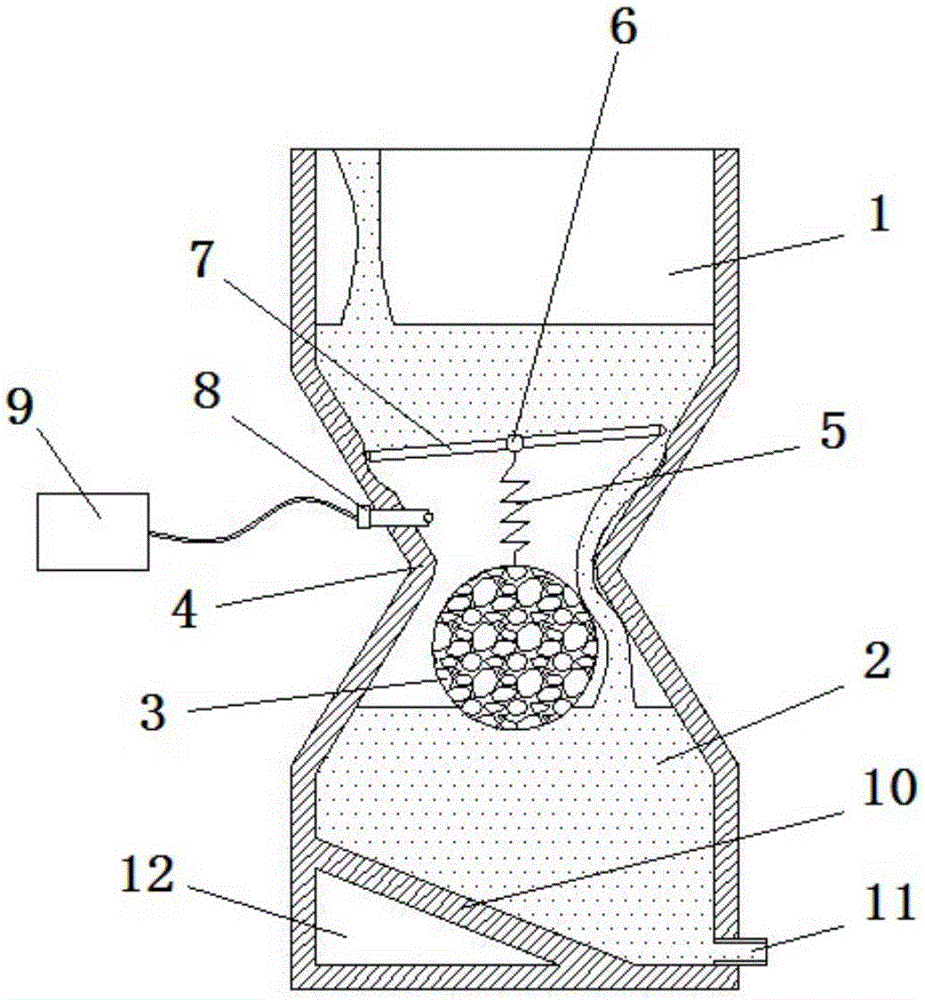

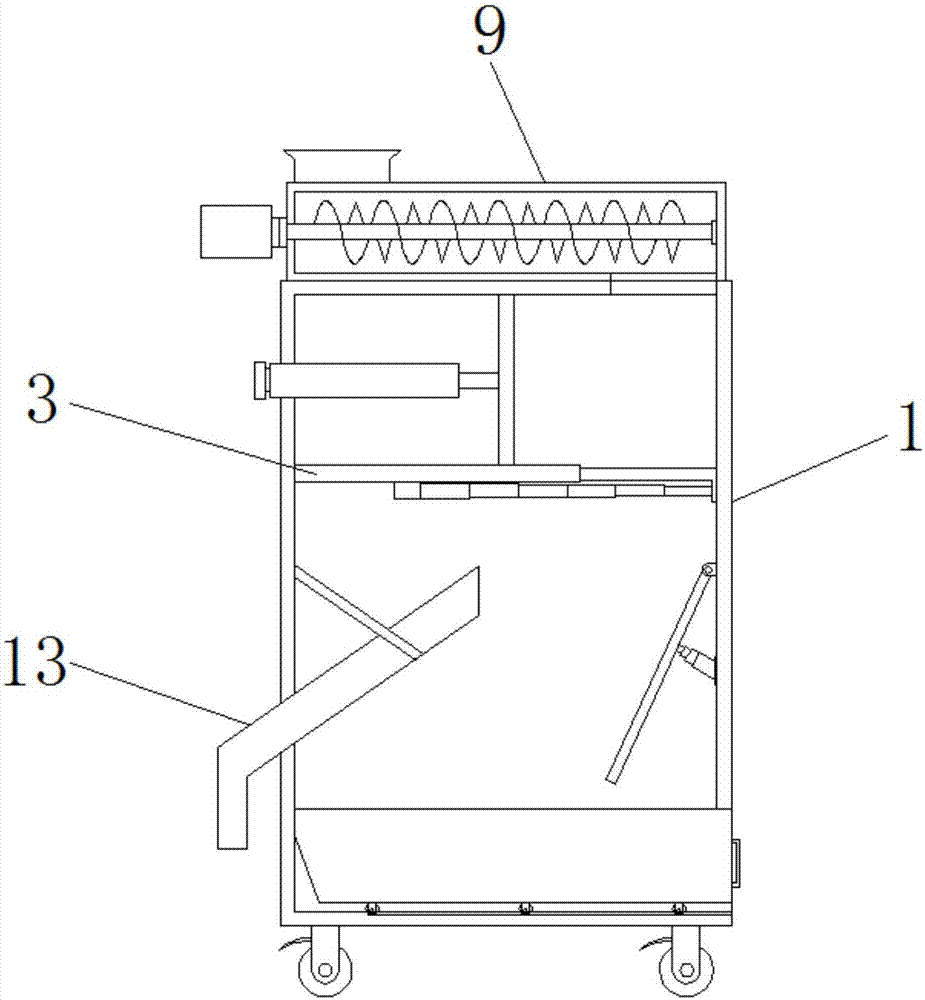

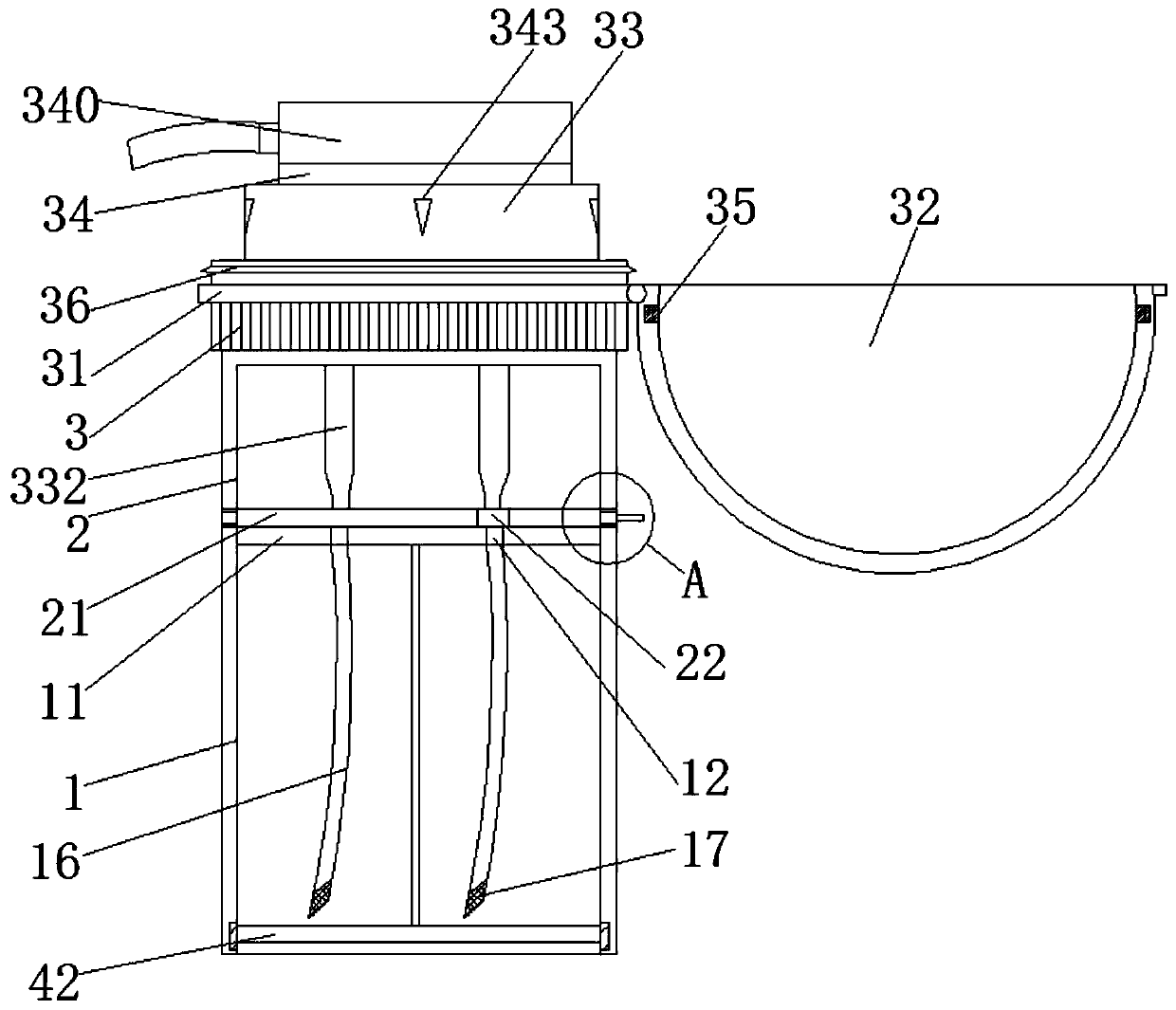

Rubbish pyrolysis gasification furnace with point acquisition charging function

InactiveCN102206513ATimely feedingPrecise feedingCombustible gas productionProduction rateTemperature control

The invention relates to a rubbish treatment technology, in particular to a rubbish pyrolysis gasification furnace with a point acquisition charging function. The furnace comprises a furnace body, a furnace cover, a water seal device and a furnace body fixing frame, and is characterized in that: an infrared temperature measuring sensor is arranged on the furnace cover; the furnace body is in supporting connection with the furnace body fixing frame through a plane bearing; the furnace body is fixedly connected with an output gear in a gear transmission mechanism; a signal output end of the infrared temperature measuring sensor is connected with a data input end of a temperature controller; and a switching value output end of the temperature controller is connected with a motor control end of the gear transmission mechanism. The invention aims to provide the rubbish pyrolysis gasification furnace with the point acquisition charging function, so that the surface temperature of rubbish inthe furnace can be monitored, a burn through point can be found, the charging is fed back, the generation of the burn through point can be controlled in time, a pyrolysis gasification effect can be improved, and gas production rate can be increased. Compared with the prior art, the furnace has the advantages of high degree of automation, good rubbish treatment effect and the like, and makes charging timely and accurate.

Owner:杭州明炜环保科技有限公司

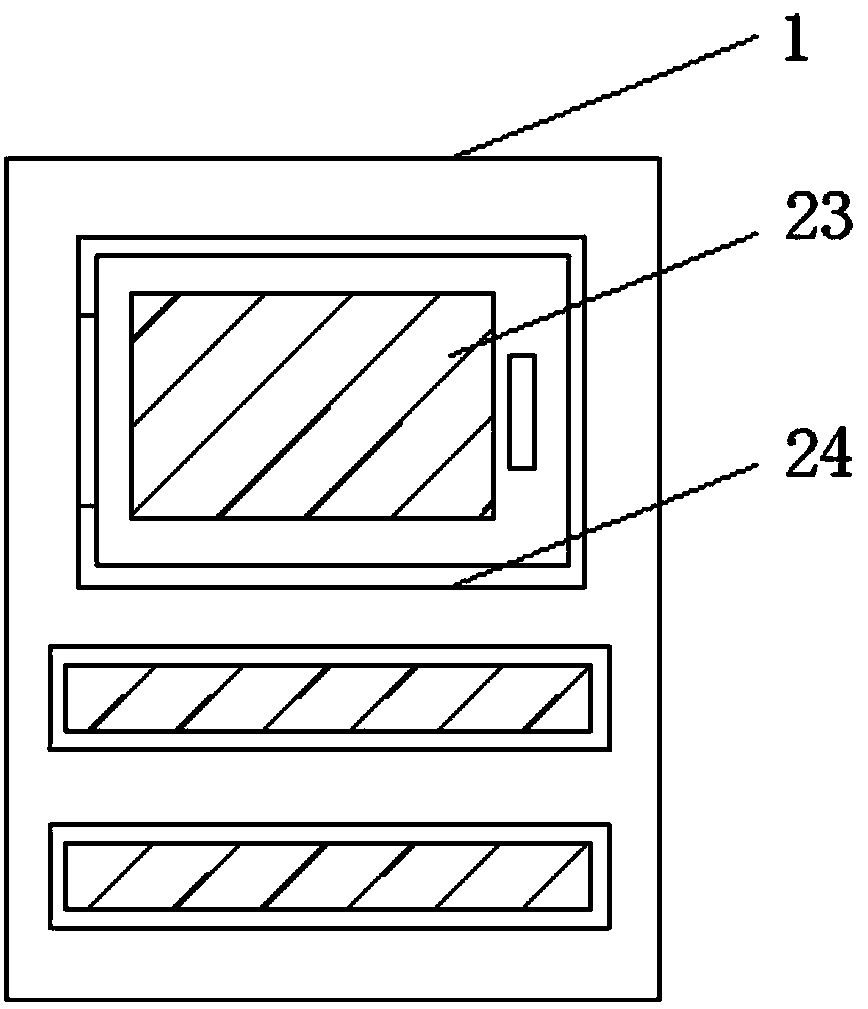

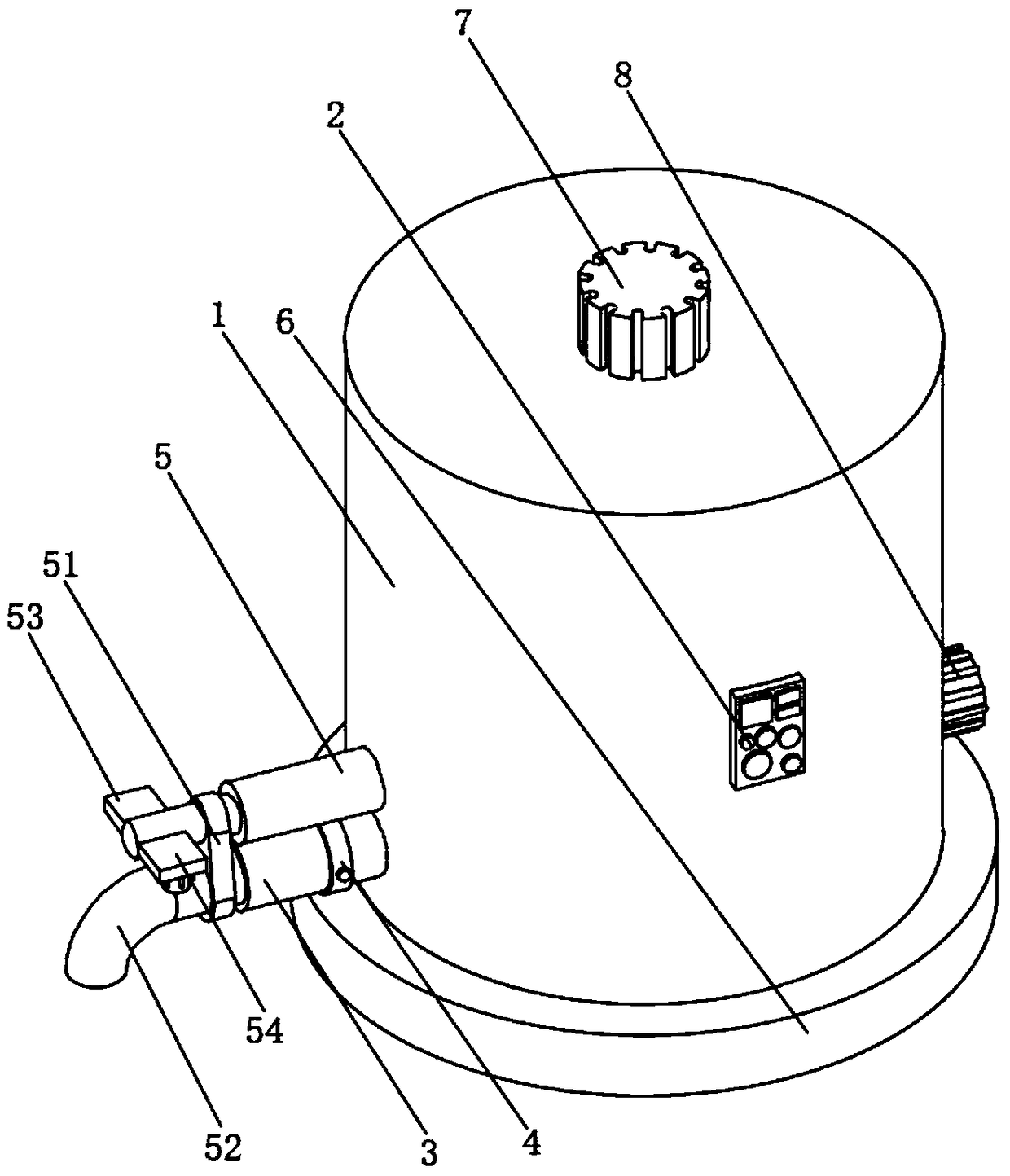

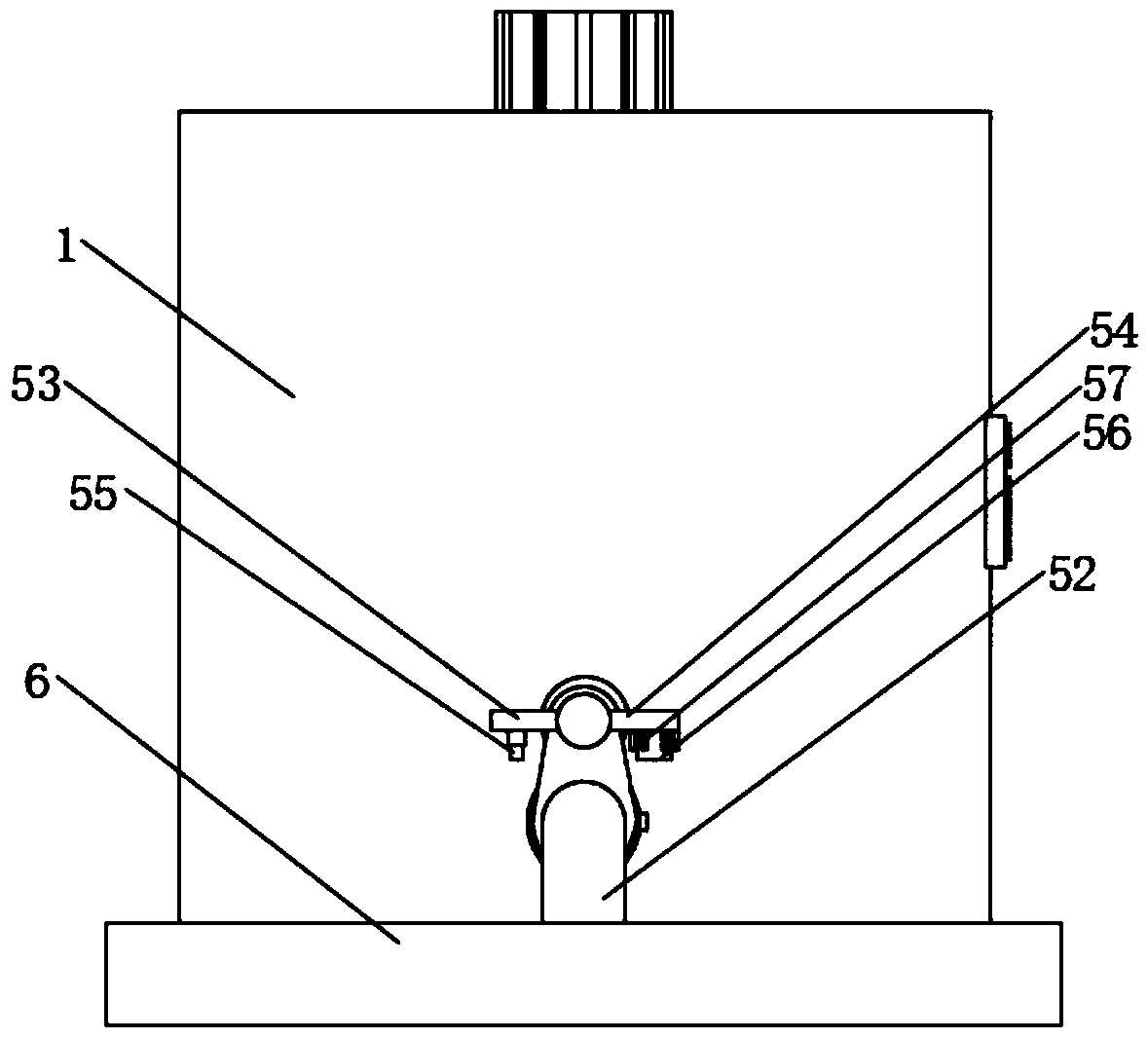

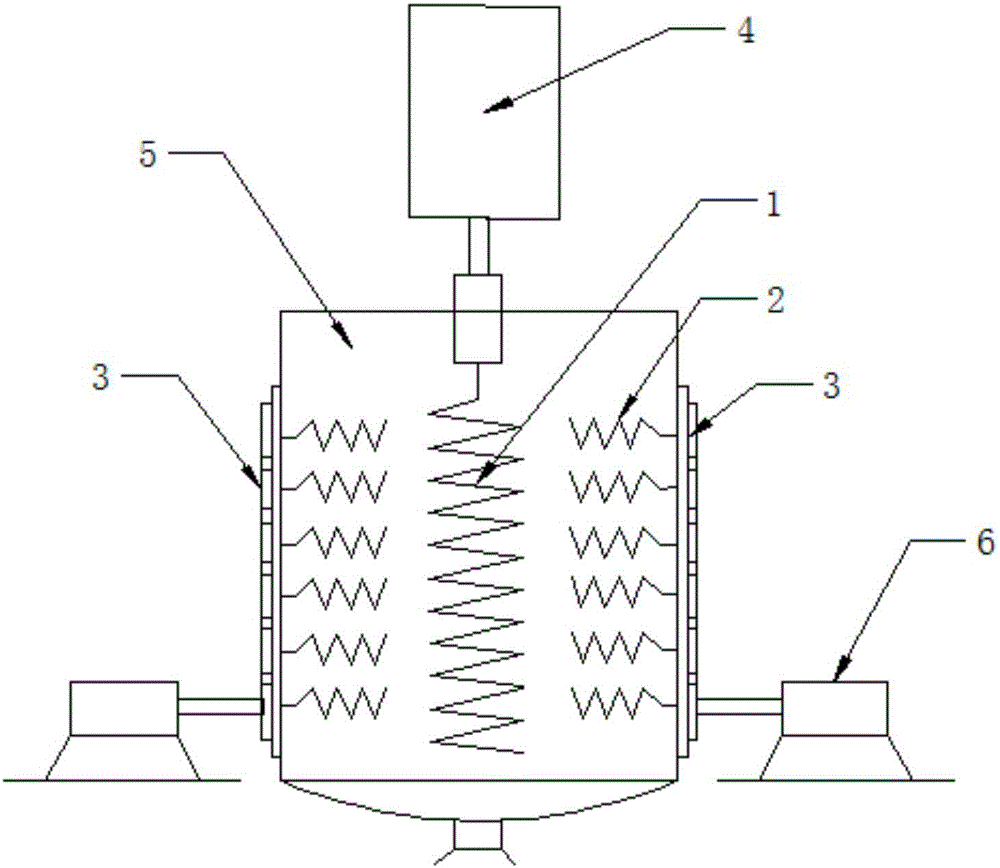

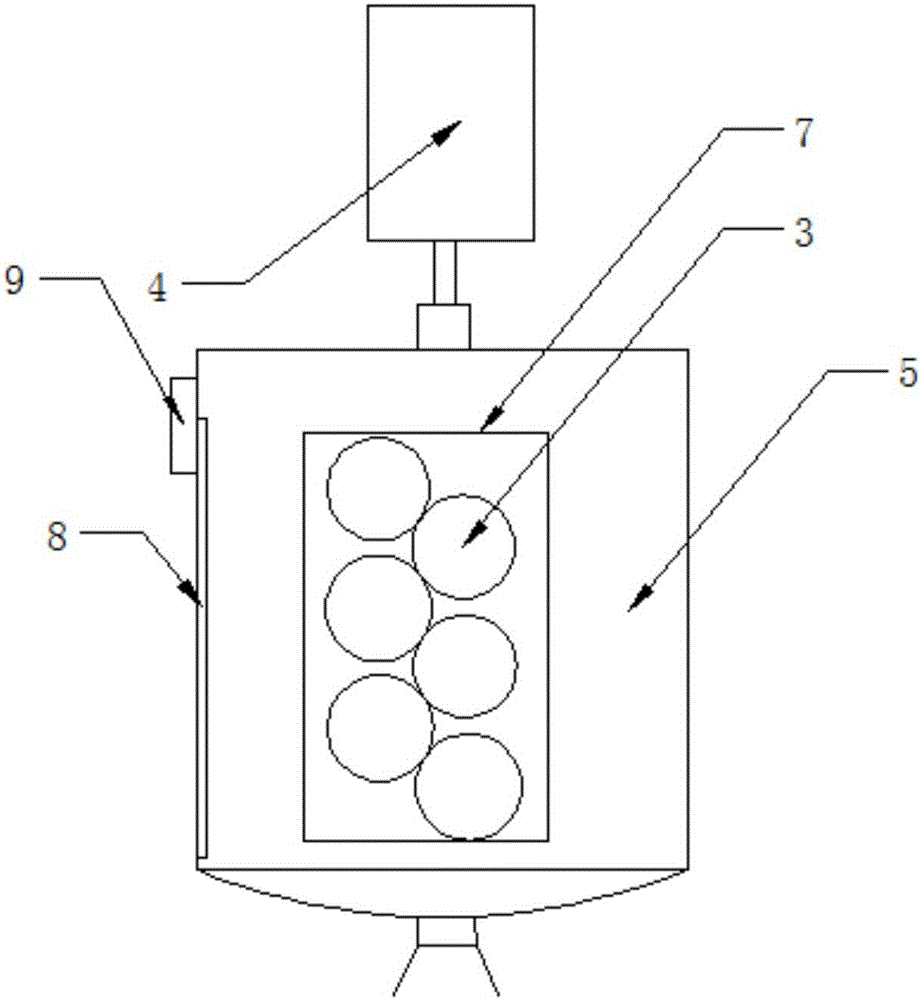

Intelligent pouring system

InactiveCN109047742AHigh degree of intelligenceEasy to operateMelt-holding vesselsDischarging apparatusElectricityAutomatic control

The invention discloses an intelligent pouring system. The intelligent pouring system comprises a placing barrel; a PLC is arranged on the outer side surface of the placing barrel; an input end of thePLC is electrically connected with an output end of a transformer; an input end of the transformer is electrically connected with an output end of an external power supply; a base is arranged on thelower surface of the placing barrel; a feed pipe is arranged at the top of one side surface of the placing barrel; a discharge pipe is arranged at the bottom of the other side surface of the placing barrel; a flow control valve is arranged on the discharge pipe; the flow control valve is in two-way electric connection with the PLC; and the inner side surface of the discharge pipe is slidingly connected with an extension pipe. In the intelligent pouring system, through a heater and a temperature sensor, poured materials can be automatically heated, so that the temperature of the poured materials is maintained; a stirring motor uses a stirring shaft for driving stirring blades to stir the poured materials, so that the viscosity of the poured materials is maintained; a viscosity meter is rotated to detect the viscosity of the poured materials; and a switch of a stirring motor is automatically controlled through the PLC to improve the intelligence degree.

Owner:扬中腾达金属制品有限公司

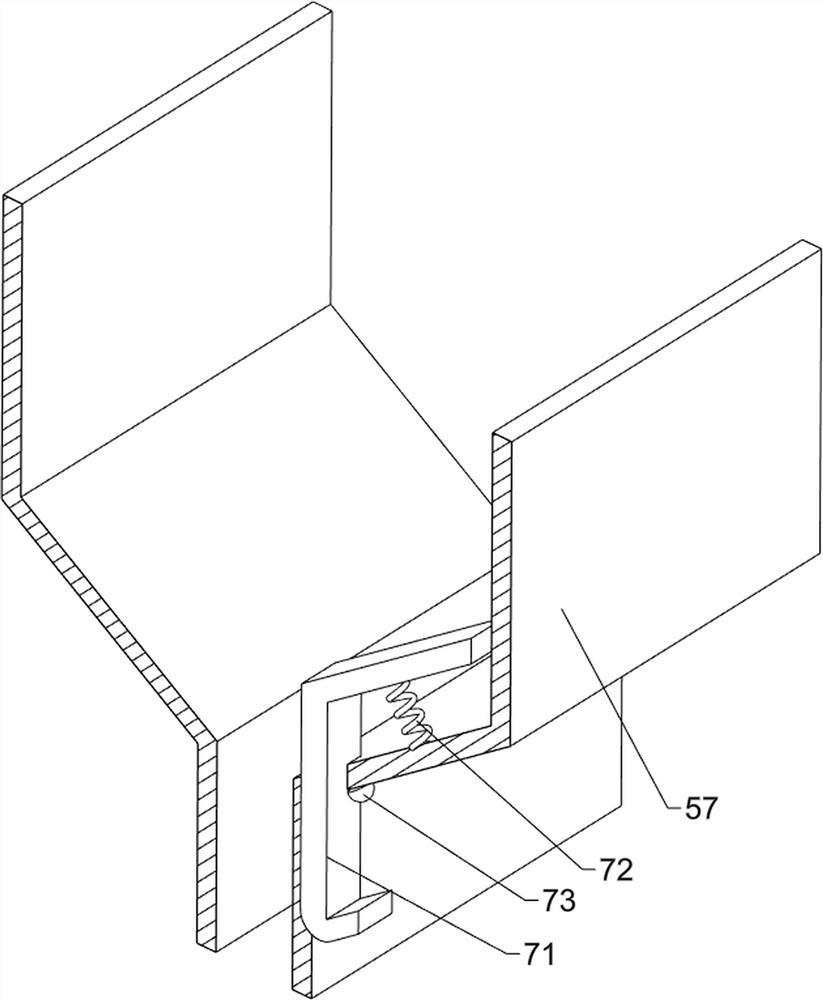

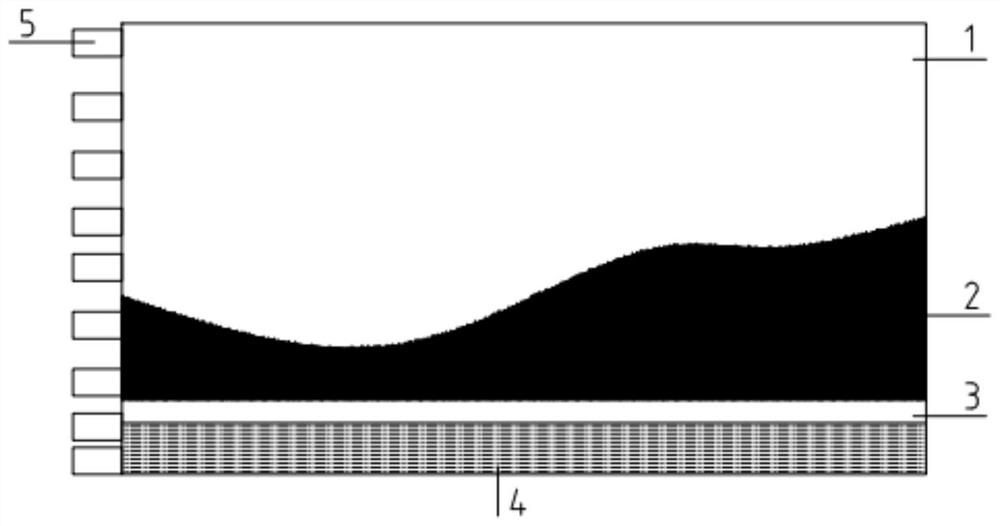

Automatic printing machine ink adding mechanism based on floating ball seal

ActiveCN106827802AModerate resistanceExtend your lifePrinting press partsMachine partsPrinting press

The invention discloses an automatic printing machine ink adding mechanism based on floating ball seal. The automatic printing machine ink adding mechanism comprises an ink box, wherein the ink box is divided into a charging chamber and a safety ink measuring chamber, a neck for limiting a floating ball is arranged between the charging chamber and the safety ink measuring chamber, the floating ball is located in the safety ink measuring chamber and is fixed to a rotary shaft in the charging chamber through a pull rope, the rotary shaft limits a rotary plate, and a position sensor is arranged at the position, close to the neck, of the inner wall of the charging chamber in a penetrating mode. The ink box is provided with the safety ink measuring chamber. When the ink amount is insufficient, the floating ball moves down with the ink liquid level, the position sensor gives out an alarm signal, further ink is added in time, and the service life of printing machine parts are guaranteed.

Owner:HANGZHOU WEICHENG PRINTING

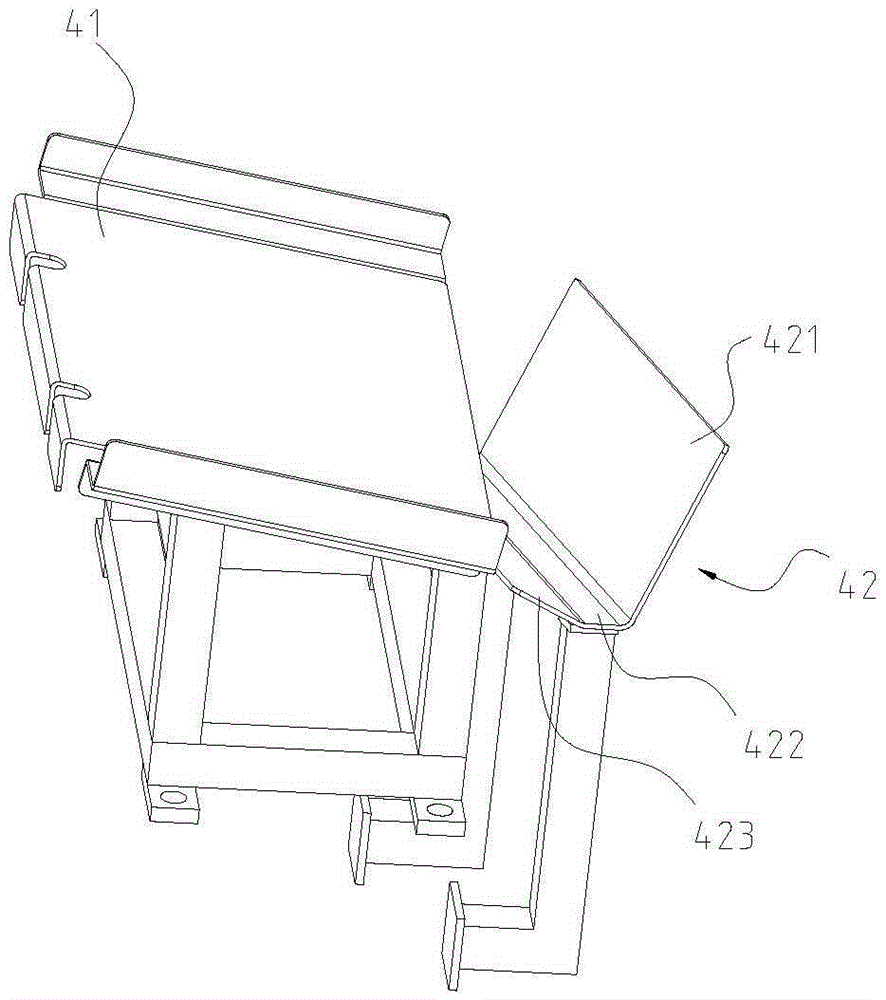

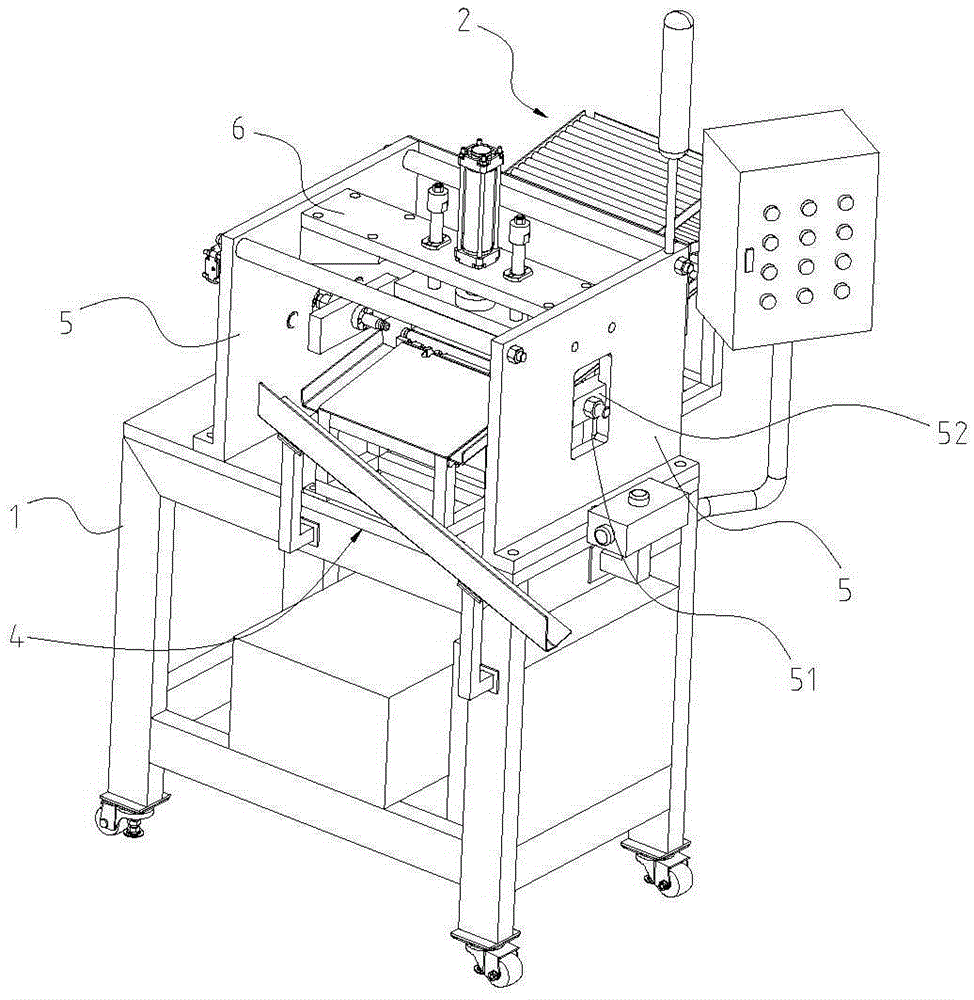

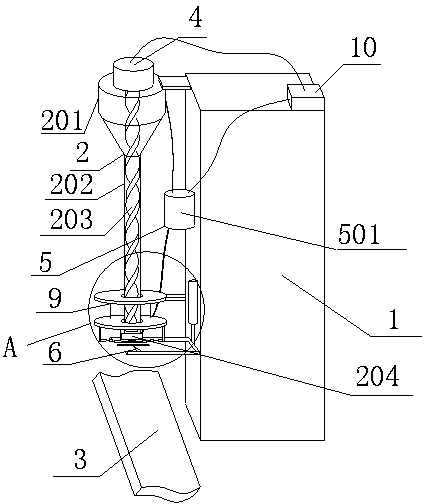

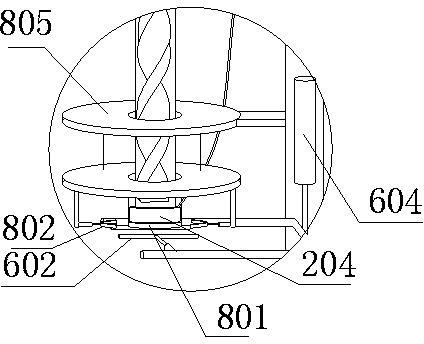

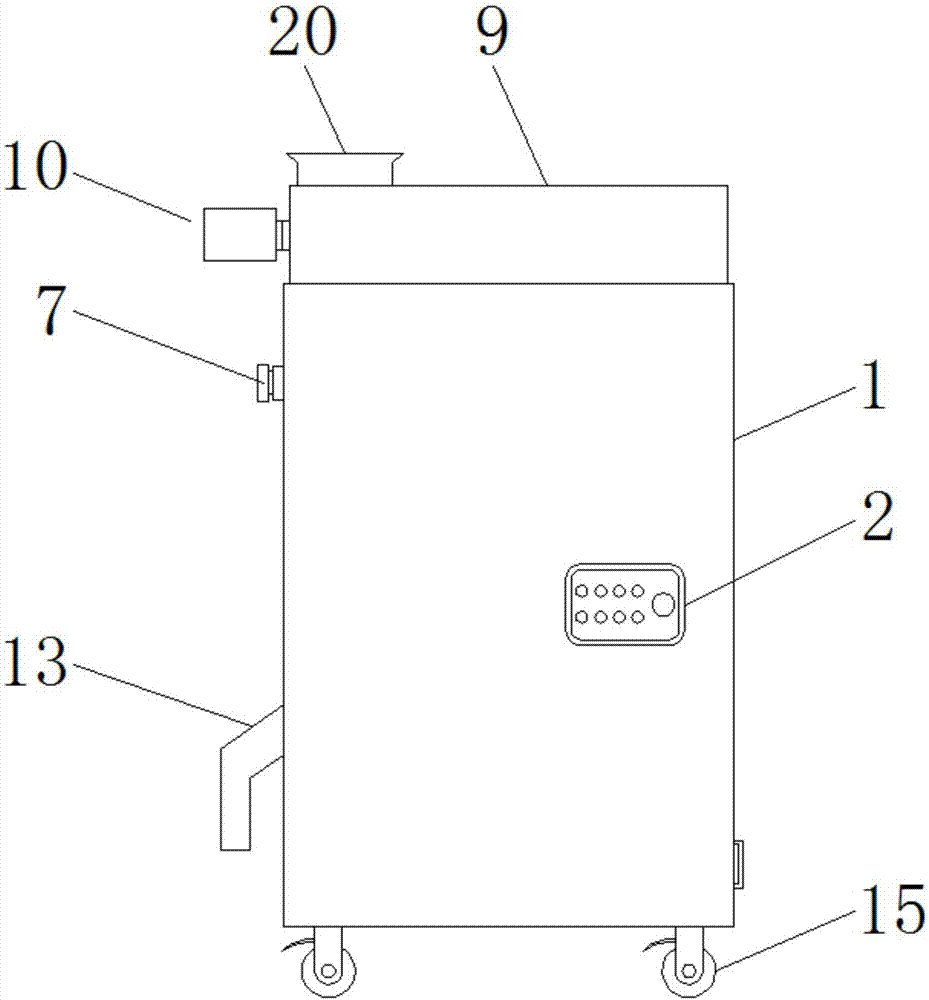

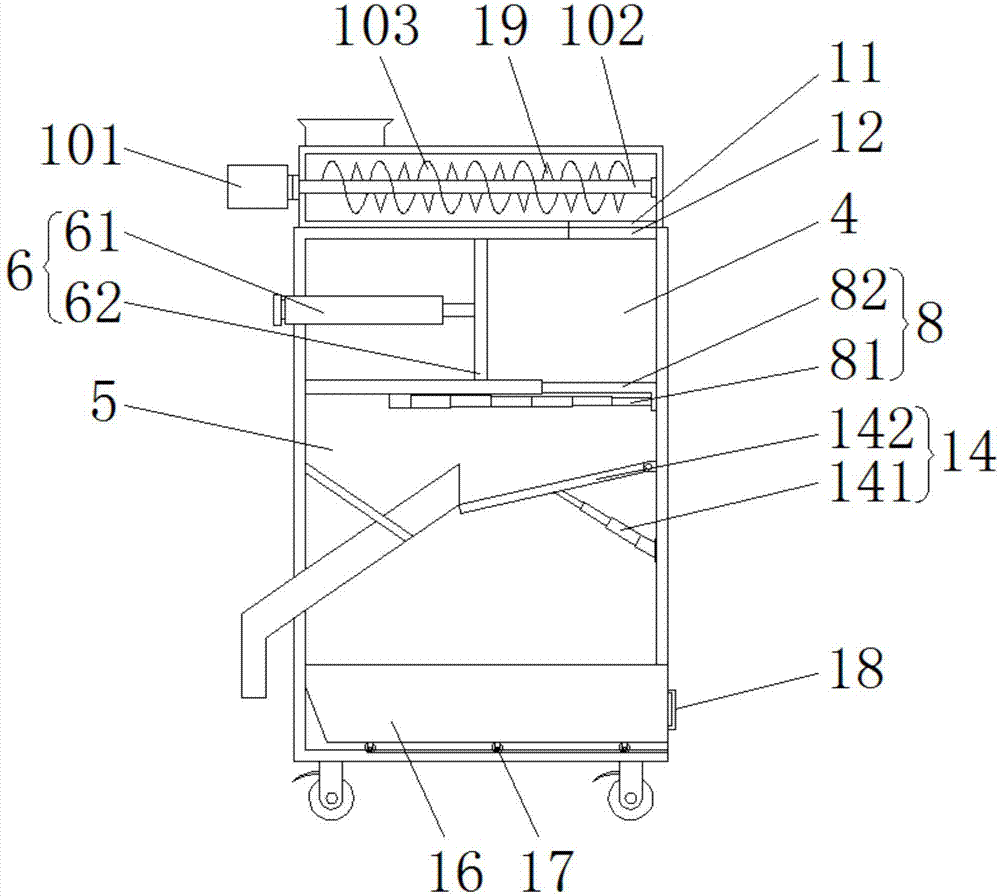

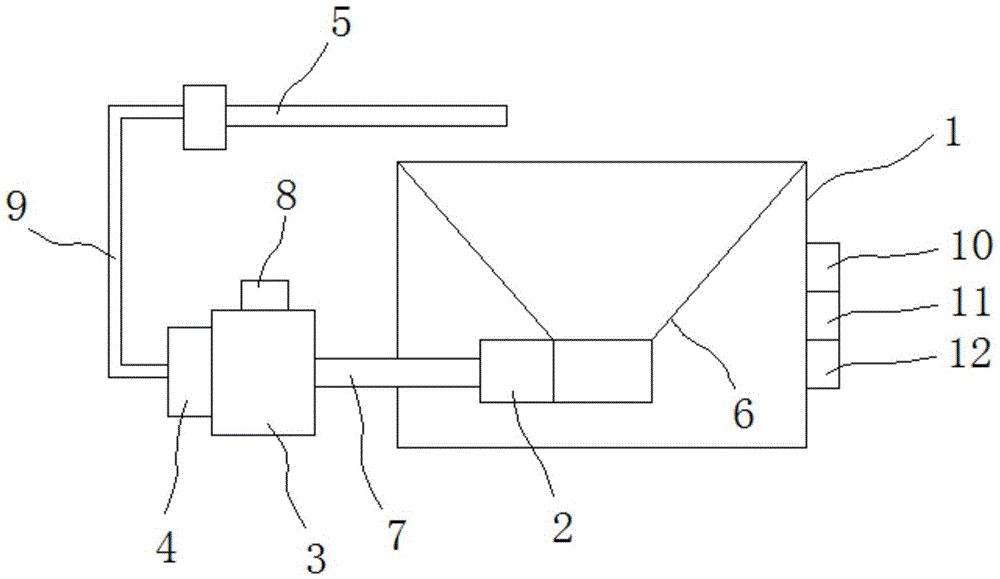

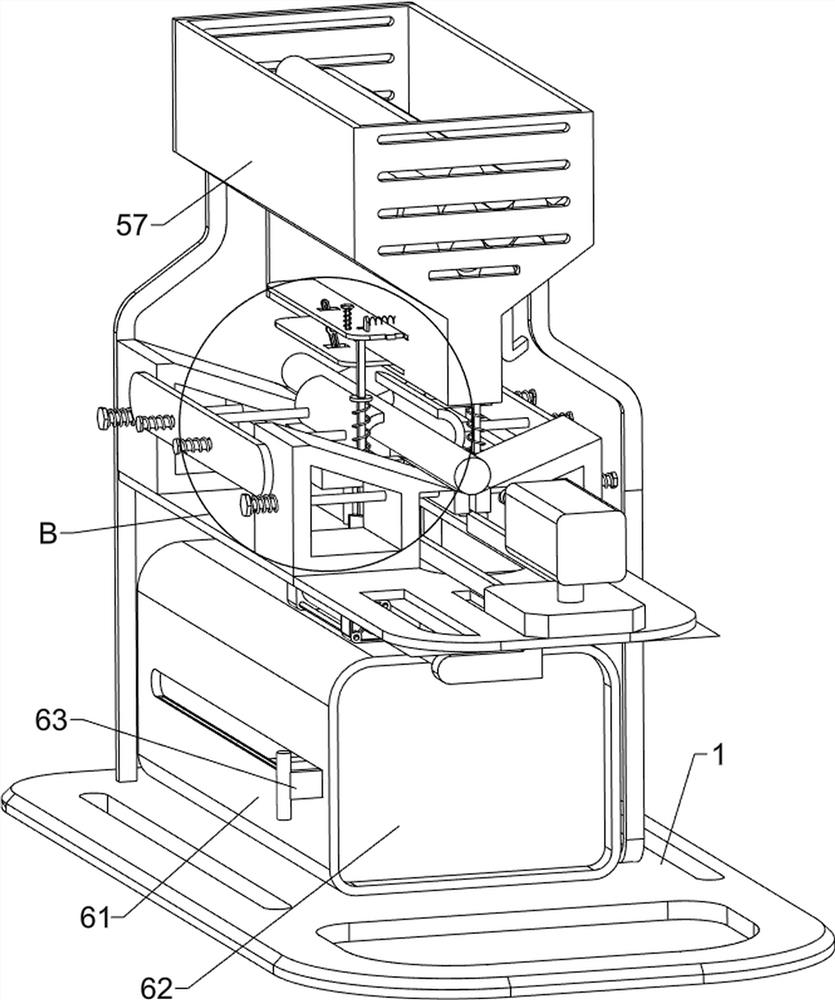

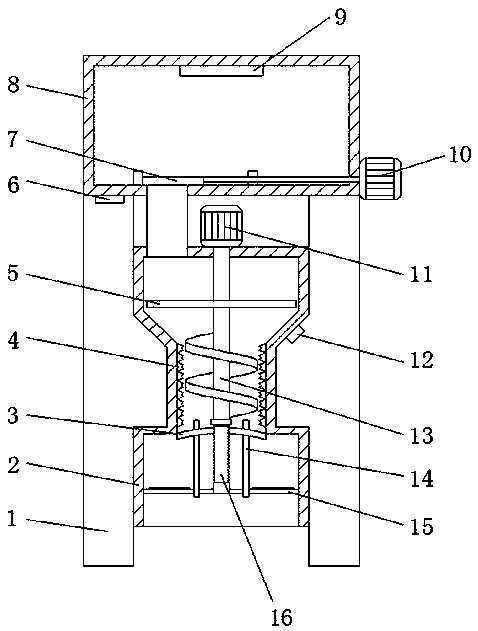

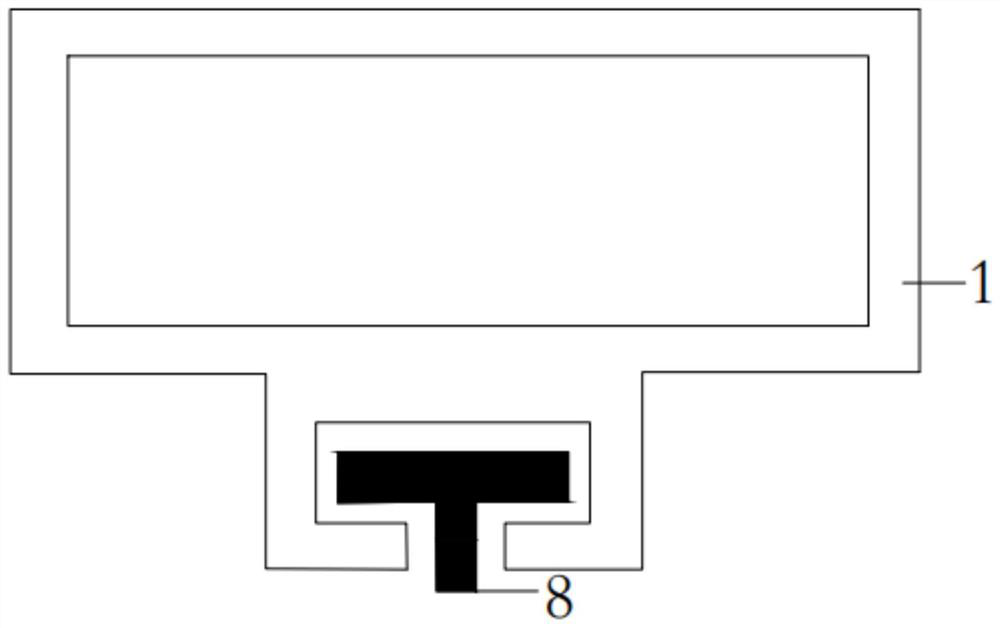

Efficient fine powder packaging machine

InactiveCN104029832AEasy to useTimely feedingPackaging automatic controlSolid materialEngineeringFine powder

The invention discloses an efficient fine powder packaging machine. The efficient fine powder packaging machine comprises a rack (1), a conveying device (3), a feeding device (2), a material returning device (5), a clamp holder (6), a bag clamping device (8) and a PLC (10), wherein the feeding device (2), the material returning device (5), the clamp holder (6), the bag clamping device (8) and the PLC (10) are installed on the rack (1), and the clamp holder (6) comprises two clamping strips (601). The efficient fine powder packaging machine has the advantages that a gravity sensor for calculating the weight of materials is arranged on the bag clamping device, an opening of a bag is immediately clamped through the clamp holder after the weight of fine powder in the bag reaches a preset value, the fine powder will not be fed to the bag any more, in this way, accuracy of the weight of the fine powder in the bag is ensured, the clamp holder further conveys the fine powder bag to a conveying belt below, and therefore it is avoided that the fine powder is scattered due to vibration because the material bag directly falls on the conveying belt.

Owner:CHENGDU FENGFAN TECH

Pipe expander

InactiveCN105414368AOrderly rowsSave spaceMetal-working feeding devicesPositioning devicesButt jointEngineering

Provided is a pipe expander. The pipe expander comprises a feeding device, a pressing device, a pipe expanding device and a dropping device. Materials are stored and conveyed through the feeding device which is in butt joint with the pressing device. A pipe inside the feeding device is smoothly carried to the pressing device to be pressed through the pressing device. A pipe expanding process is conducted on the pressed pipe through the pipe expanding device. After the pipe expanding action is completed, pressing on the pipe is removed through the pressing device and the expanded steel pipe is carried to the dropping device to be dropped, and thus the full automatic production is completed, so that the production efficiency is high.

Owner:于建林

Forage grass discharge machine for livestock raising

InactiveCN107535200AReasonable structural designEasy to operateCuttersShaping pressLivestockAgricultural engineering

The invention discloses a pasture feeder for animal husbandry, which comprises a main box body, a PLC controller is fixedly installed on the outer wall of the main box body, and the inner cavity of the main box body is divided into a compression chamber by a partition plate and a distribution chamber, the compression chamber is provided with a compression device, the compression device includes a hydraulic cylinder and a pressure plate, a solenoid valve is fixedly installed on the hydraulic cylinder, an electric door is provided on the partition, and the main box A conveying cylinder is arranged on the upper side of the conveying cylinder, and a conveying device is arranged in the inner cavity of the conveying cylinder. The right end of the top plate of the main box body is provided with a material inlet matching the discharge port, and the left side of the material distribution chamber is A discharge pipe is arranged on the side wall, and a material distribution device is fixedly installed on the right side wall of the material distribution chamber. The forage feeder for livestock breeding has reasonable structural design and simple operation, which can be used for timely feeding and compressed storage of forage, which improves work efficiency and reduces labor intensity of workers.

Owner:姜斌

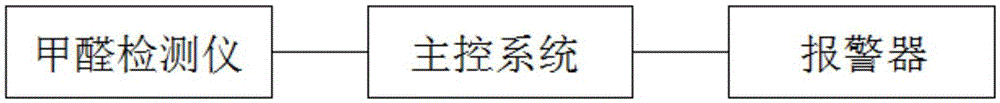

Casting flow coating device with warning function

InactiveCN105108047AGuaranteed purityGuarantee the quality of sprayingFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to a casting flow coating device with a warning function. The casting flow coating device comprises a spraying workbench, a filter device, a charging tank, a water pump and a spray gun, wherein a funnel-shaped paint recycling device is arranged in the spraying workbench; the upper end surface of the paint recycling device is parallel to the upper end surface of the spraying workbench; the lower end of the paint recycling device is communicated with the charging tank through a first pipeline; the filter device is arranged at a communicated part of the paint recycling device and the first pipeline; a charging hole is formed in the upper end of the charging tank; the water pump is arranged at one side, far from the first pipeline, of the charging tank; a feeding hole of the water pump is communicated with the charging tank; a discharging hole of the water pump is communicated with the spray gun through a second pipeline; the spray gun is arranged above the spraying workbench; a formaldehyde detector, a master control system and an alarm are arranged on the side wall of the spraying workbench; and the formaldehyde detector, the master control system and the alarm are sequentially connected through a circuit. Compared with the prior art, the casting flow coating device can warn the formaldehyde concentration, can improve the spraying efficiency and can improve the spraying quality.

Owner:廖子贵

Round stick section drilling equipment

ActiveCN113370322AAchieve the effect of section drillingEasy to placeStationary drilling machinesControl devices for conveyorsEngineeringWorkbench

The invention relates to drilling equipment, in particular to round stick section drilling equipment. To solve the technical problem, the invention provides round stick section drilling equipment, which easily completes round wood stick section drilling, automatically places round wood sticks, achieves automatic quantitative discharging, conveniently receives and collects materials and automatically reminds the situation that round wood sticks are insufficient. The round stick section drilling equipment comprises: a bottom plate, wherein one side of the upper portion of the bottom plate is connected with a supporting frame; a workbench, wherein the middle part of the supporting frame is connected with the workbench; a drilling mechanism which is arranged on the workbench; and a clamping mechanism which is arranged on the drilling mechanism. According to the round stick section drilling equipment provided in the invention, after round sticks fall into a discharging box and are stacked to a certain amount, a handle and a push plate are pushed to move leftwards, so that the round sticks are pushed out of the discharging box and collected in a unified mode, and thus, the effects that materials are conveniently collected and pushed out and collected in a unified mode are achieved, and the round sticks can be prevented from being broken.

Owner:南京祥鑫固废利用科技有限公司

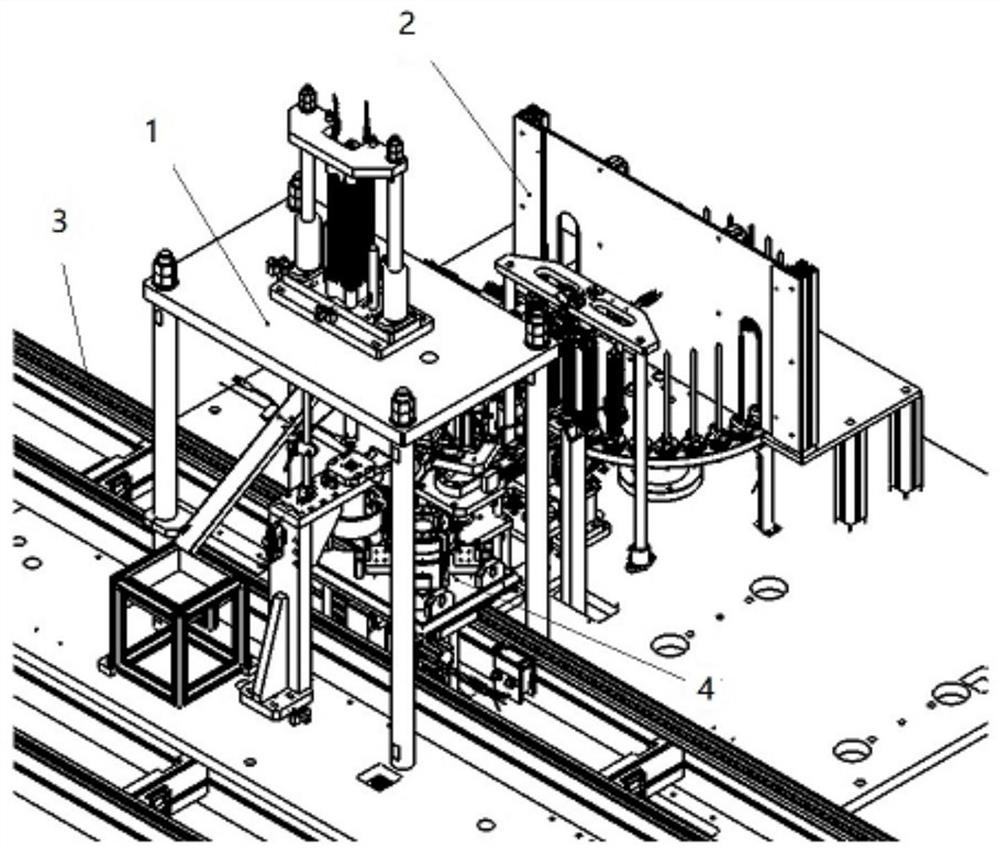

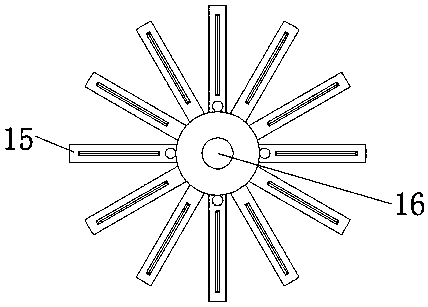

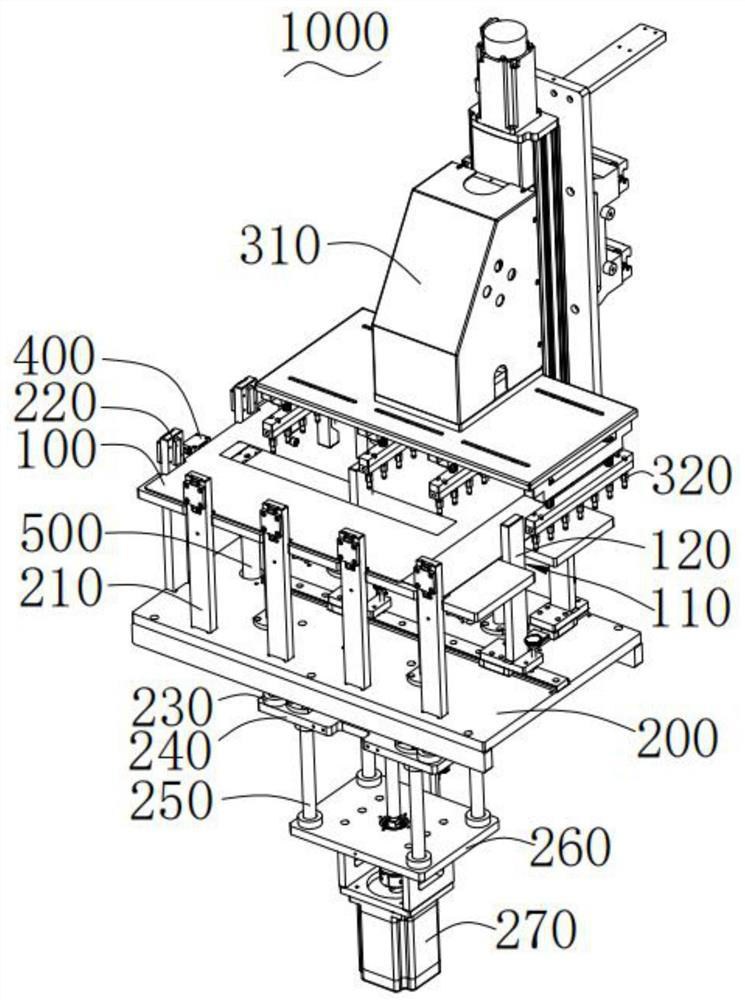

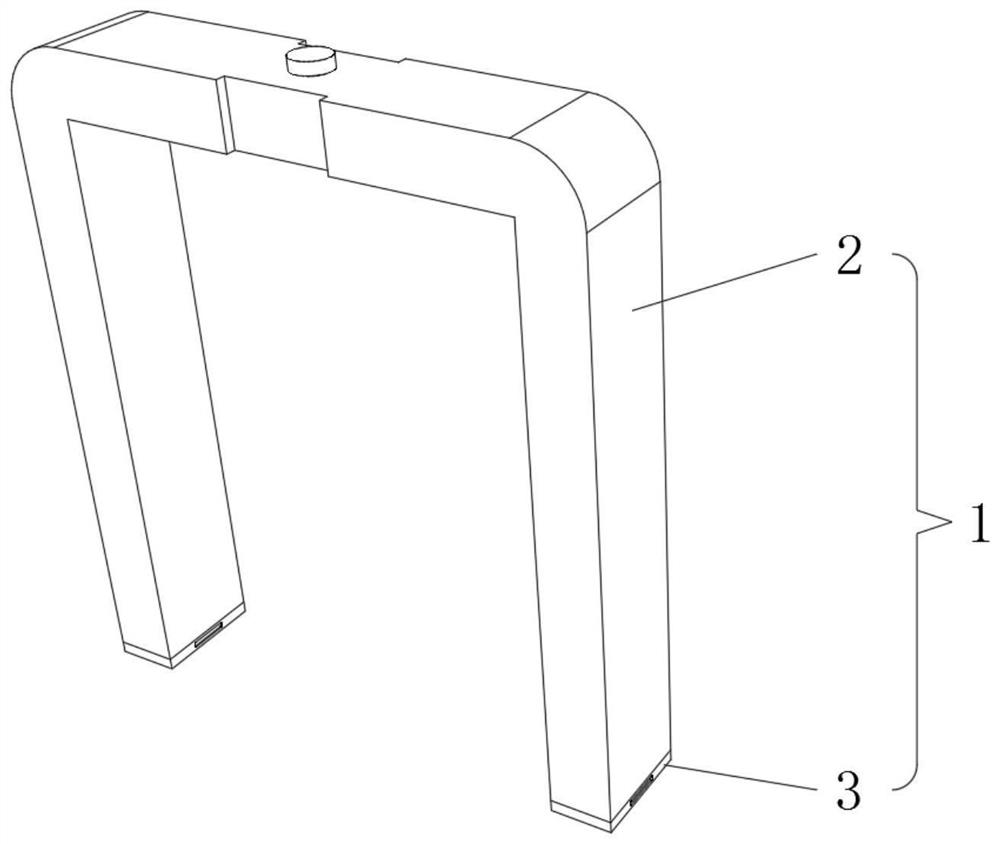

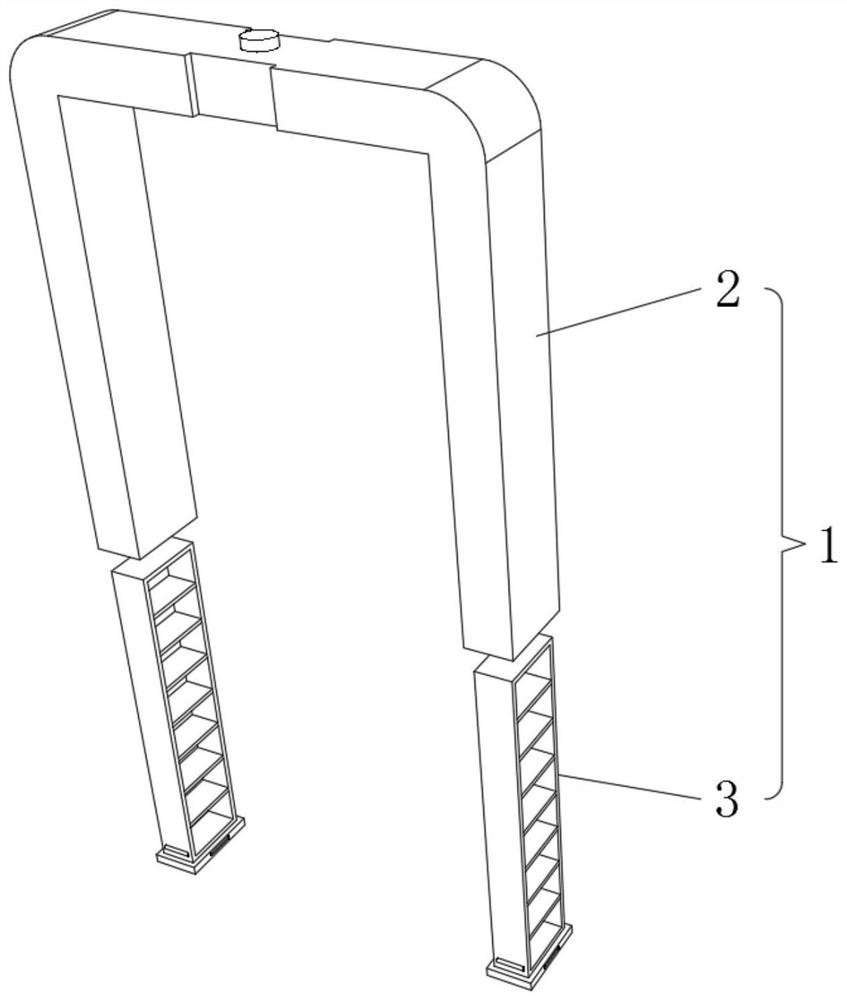

Press-fitting manufacturing equipment for bearing

The invention discloses press-fitting manufacturing equipment for a bearing. The press-fitting manufacturing equipment comprises a rack body, wherein the middle position of the rack body is vertically connected with a bearing press-fitting structure, the side face of the bearing press-fitting structure is provided with a bearing rotating disc, the bearing press-fitting structure is in a frame body shape, and a speed multiplication chain is arranged at the bottom end of the bearing press-fitting structure; and a tray is further arranged in the middle of the inner side of the bearing press-fitting structure, a bearing lifting mechanism is arranged at the gap between the bearing press-fitting structure and the bearing rotating disc, a jacking mechanism is further arranged under the bottom of the bearing press-fitting structure, and a bearing feeding mechanical arm is arranged on the side face of the bearing lifting mechanism. According to the technical scheme, automatic press fitting of a machine shell and the bearing is achieved, it is guaranteed that the bearing is fed in time, and therefore it is guaranteed that the takt time is 10 s or below, the labor cost is saved, and the production efficiency is improved.

Owner:安徽托展智能科技有限公司

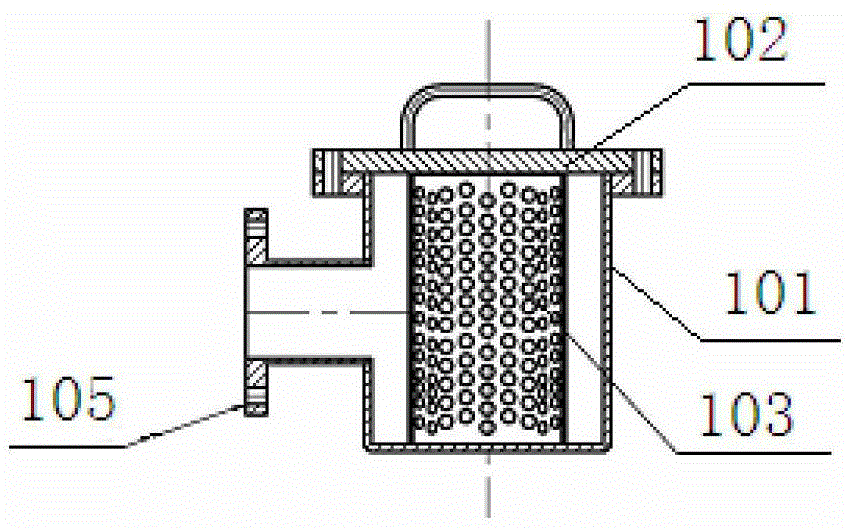

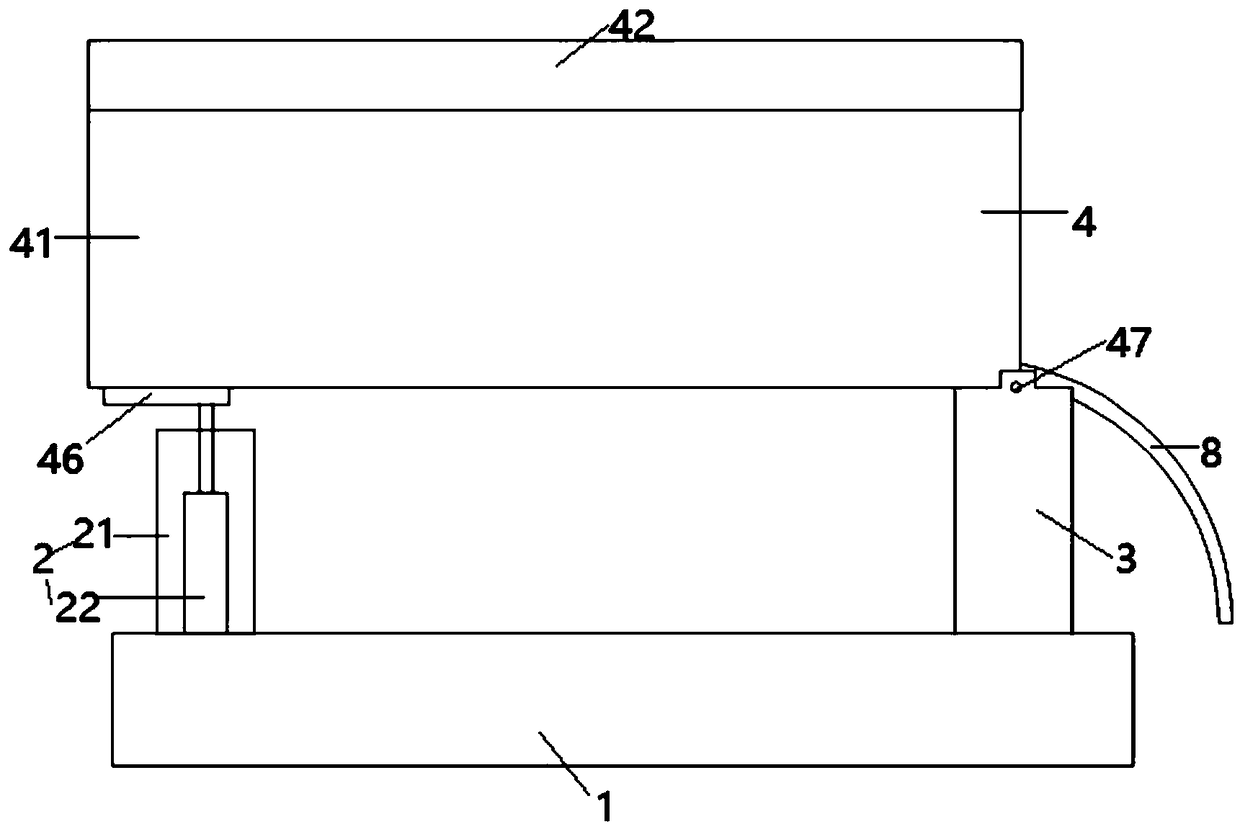

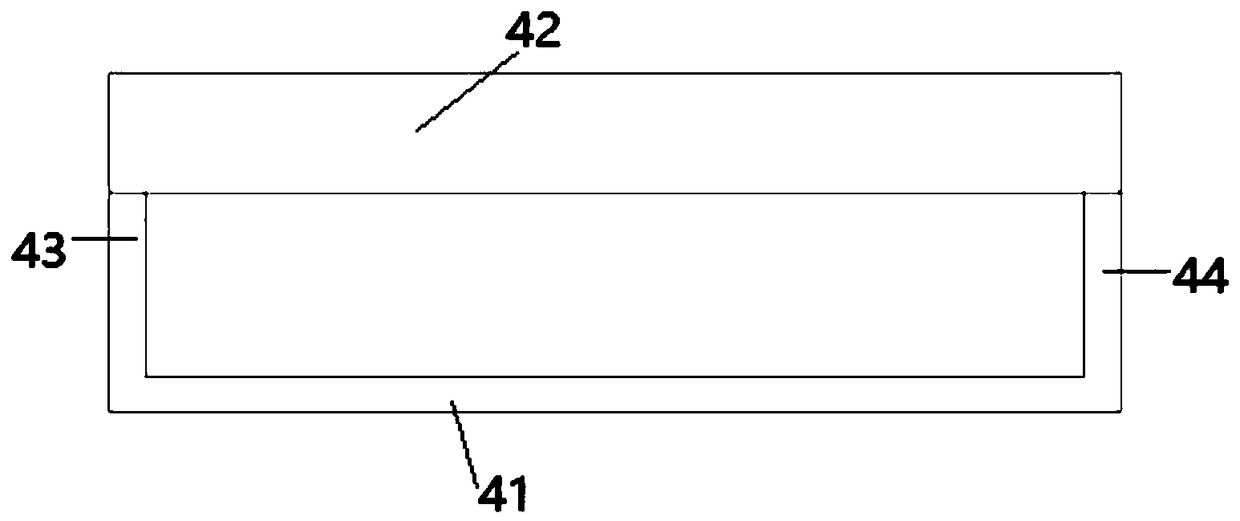

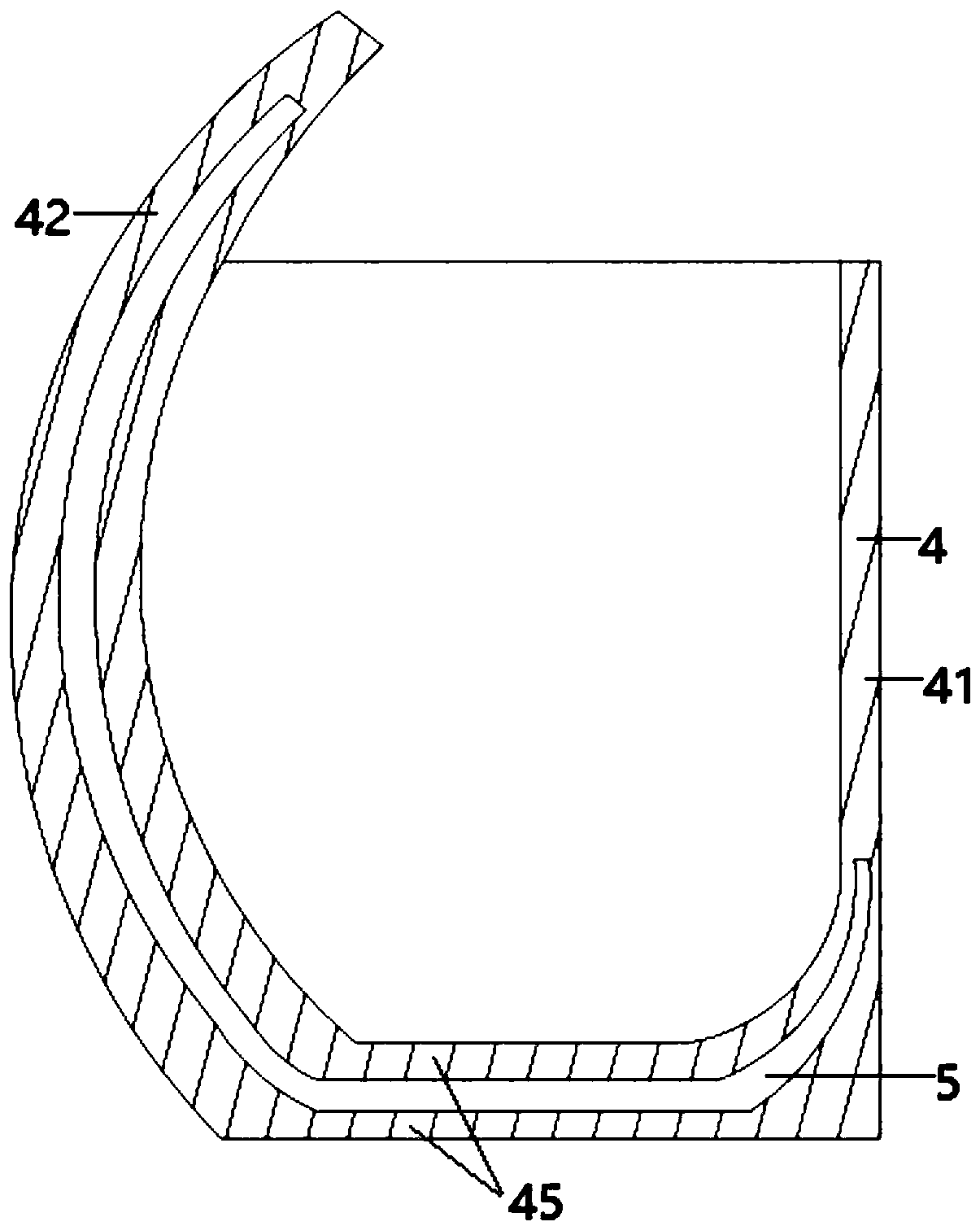

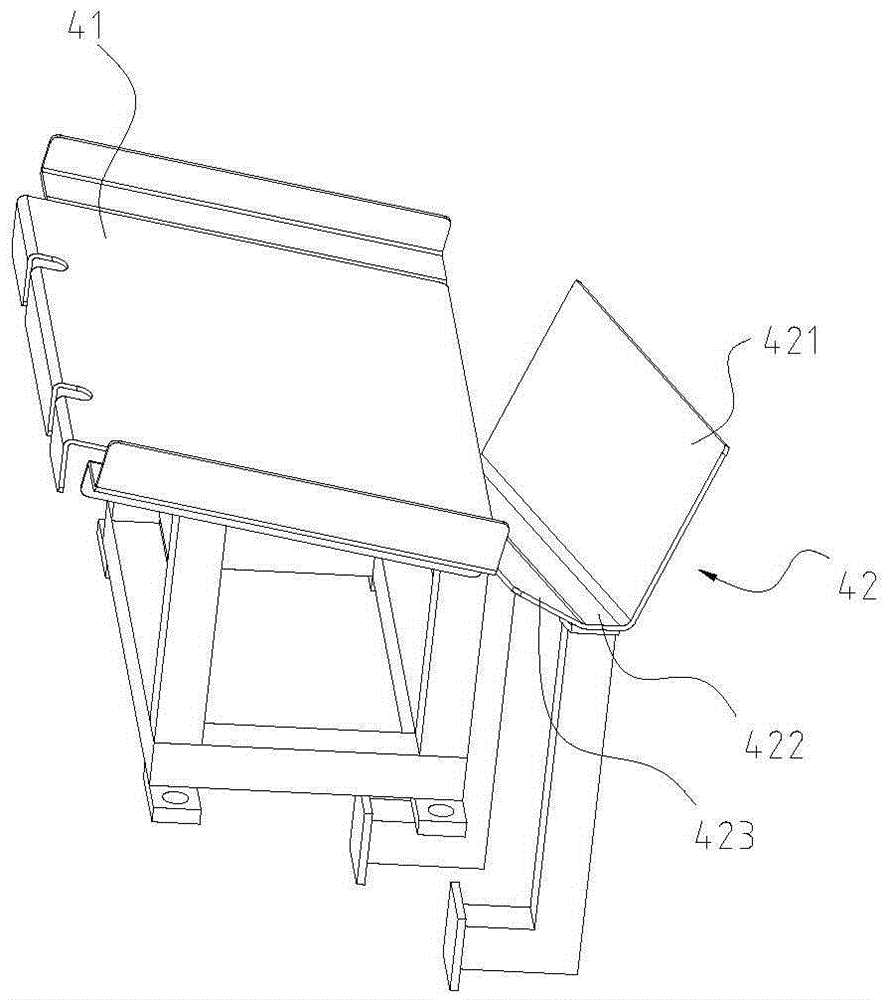

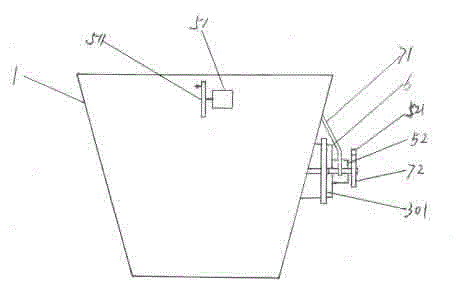

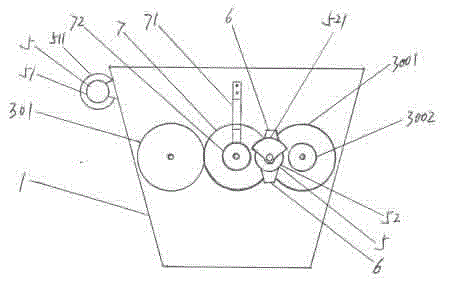

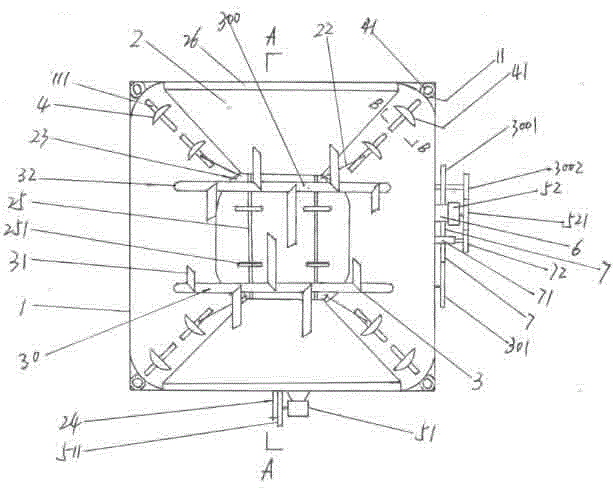

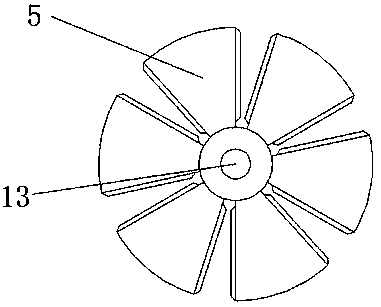

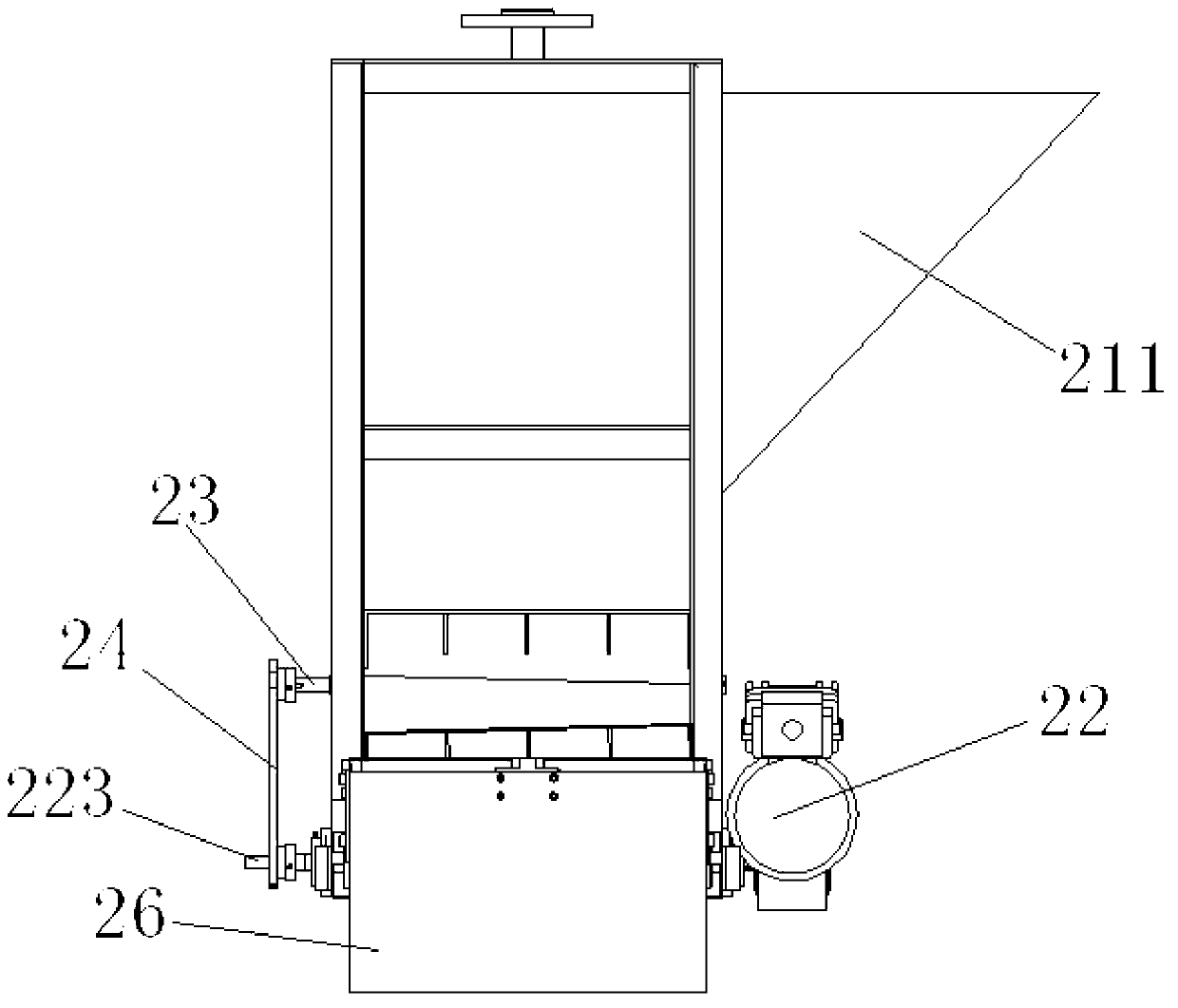

Robot batch hopper

InactiveCN104608250AFalling smoothlyIncrease temperatureSold ingredients supply apparatusEngineeringFrustum

The invention provides a robot batch hopper. The robot batch hopper comprises a quadrangular frustum pyramid shaped hopper, trapezoidal seesaws, breakers, arc-shaped scrapers, variable-frequency motors and a control module, wherein the trapezoidal seesaws are connected on the inner walls of the quadrangular frustum pyramid shaped hopper by supports; the breakers are connected on the quadrangular frustum pyramid shaped hopper by bearings; the arc-shaped scrapers are connected with the four corners of the quadrangular frustum pyramid shaped hopper by guide cylinders and are connected with micro axles at the lower end corners of the trapezoidal seesaws by first drive rods; the variable-frequency motors are connected on the outer walls of the quadrangular frustum pyramid shaped hopper by bolts, are connected with small axles on the seesaws by second drive rods and are meshed with gears at the axle ends of the breakers by sector gears; the variable-frequency motors are connected with the control module by conductors. The robot batch hopper has a novel structure, is smooth in feeding, is free from blockage, has stable properties and strong practicability and is firm and durable.

Owner:河南恒禹水利工程有限公司 +1

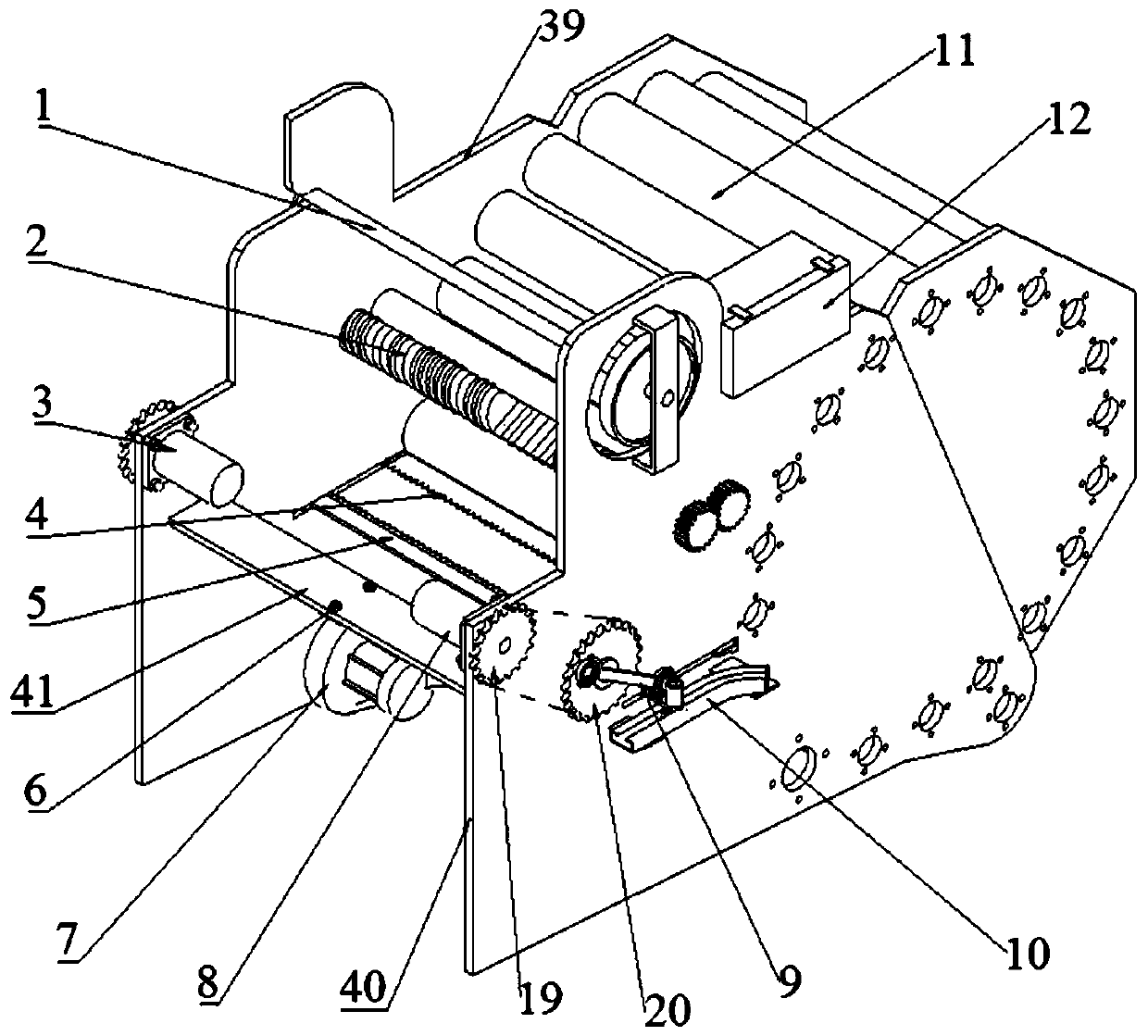

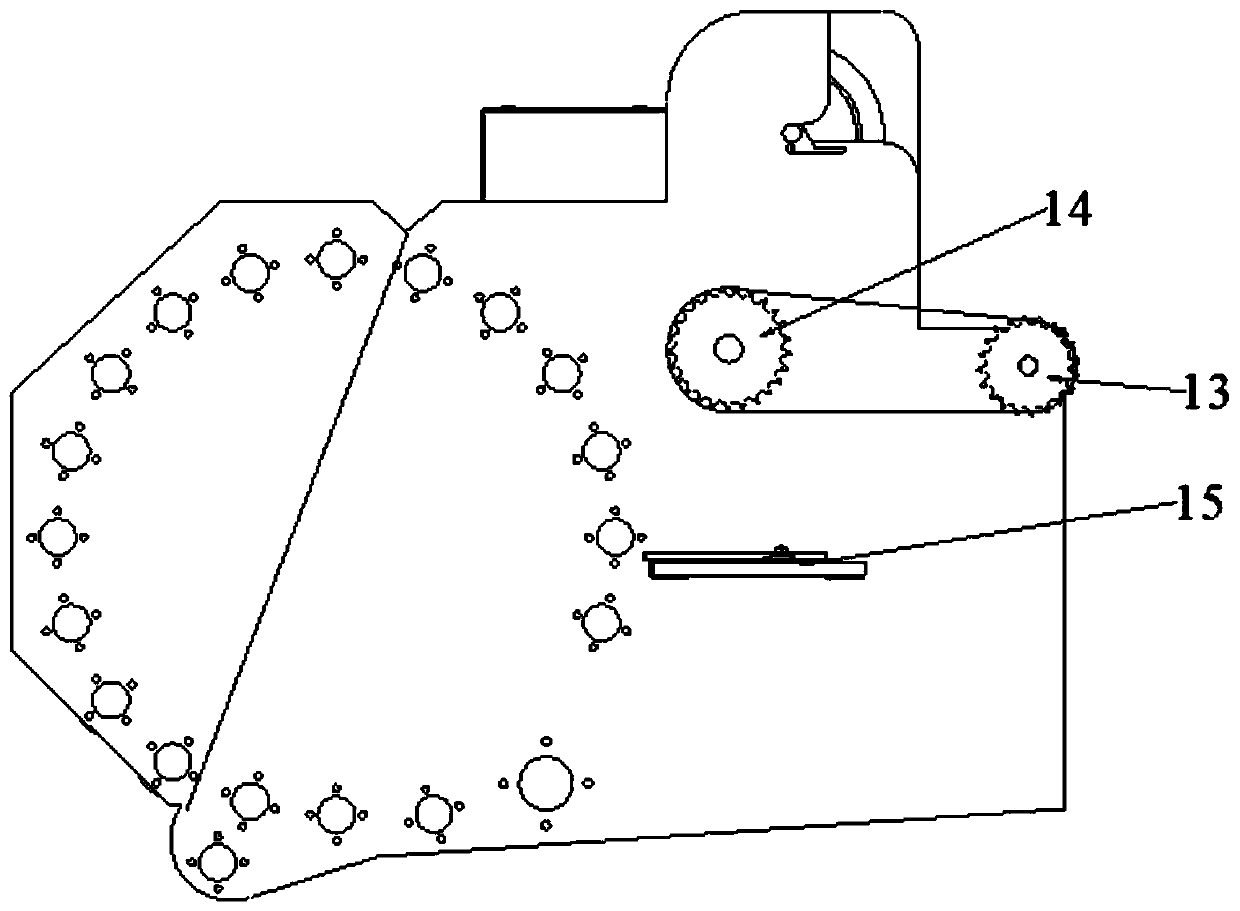

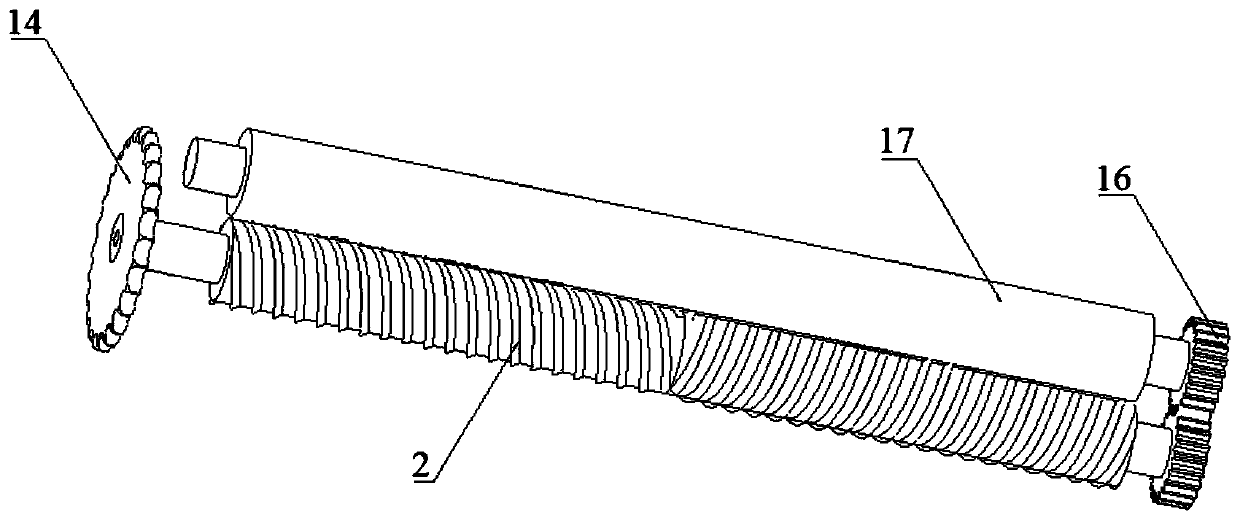

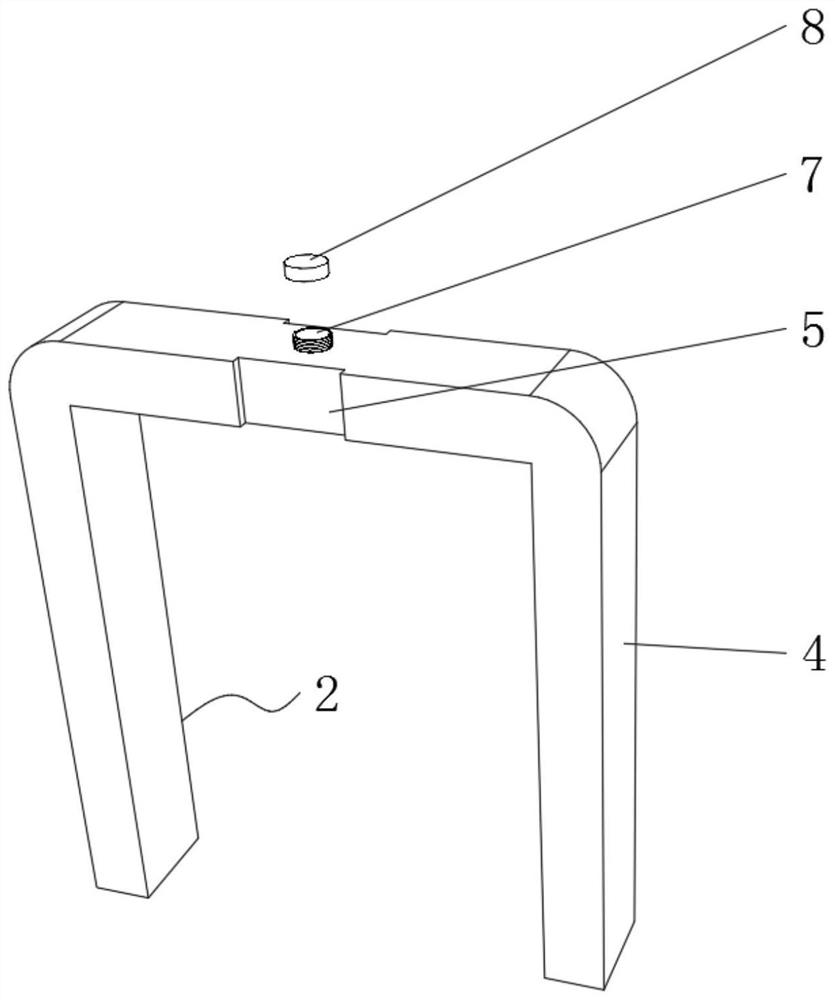

Net winding device and method of circular bundling machine

The invention belongs to the technical field of agricultural machinery and equipment, in particular to a net winding device of a circular bundling machine. The device comprises a machine frame, a silknet hanging rod 1, a stepping motor I 3, a stepping motor II 8, a PLC control system 12, a net guiding mechanism, a wind power net feeding mechanism and a net cutting mechanism. According to the device, the PLC control system controls three operation processes of net guiding, net feeding and net cutting, the net guiding mechanism adopts a double-direction thread net guiding roller and a rubber smooth roller to form a pair of rollers, and extends the silk net to two sides while guiding the net; the wind power net feeding mechanism rectifies the wind blown by a fan through a blowing head, stably blows out the wind flow scattered along the horizontal direction, and cleanly blows the silk net guided by the net guiding mechanism to a feed inlet of a bundling chamber of the circular bundling machine; and the net cutting mechanism adopts the form of a crank connecting rod driving a sliding knife, and the displacement curve of the sliding knife is limited to two sections of'straight line+curve'through slideways. The invention further relates to a net winding method of the circular bundling machine. The device and the method have high reliability, the round straw bundles are evenly wound on the net, and the net cutting is complete, so that the success rate of net cutting and the uniformity of net breaking can be improved.

Owner:CHINA AGRI UNIV

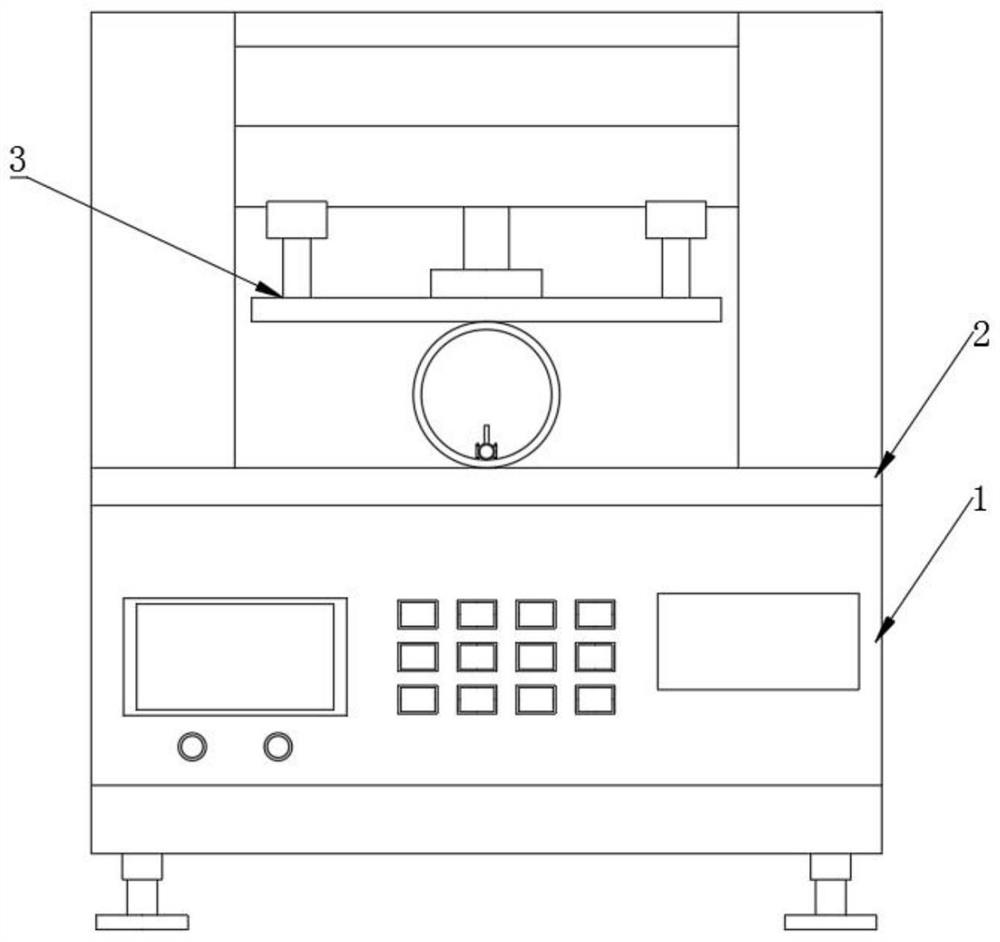

Industrial paper tube strength automatic analysis control system and repairing method

PendingCN114414369AEasy to detectDetection impactGrinding carriagesMechanical working/deformationControl systemTester device

The invention discloses an industrial paper tube strength automatic analysis control system and a repairing method.The industrial paper tube strength automatic analysis control system comprises a paper tube strength tester body, a workbench is connected with a positioning piece, the lower end of the paper tube strength tester body is fixedly connected with a base, the paper tube strength tester body is connected with a fixing piece, the base is fixedly connected with a sliding rail, and the sliding rail is fixedly connected with a sliding block. The base is fixedly connected with a third air cylinder, the sliding rail is slidably connected with a moving seat, the moving seat is fixedly connected with a motor, the output end of the motor is connected with a bevel gear assembly, and the bevel gear assembly is connected with a cleaning brush. According to the industrial paper tube strength automatic analysis control system and the repairing method, the shifting piece is shifted to enable the pressing rod to rotate to a proper angle, the paper tube is placed at the corresponding position, the shifting piece is loosened, the pressing rod presses the inner wall of the industrial paper tube under the action of the torsion spring, the industrial paper tube is positioned at the corresponding position, and follow-up detection is facilitated.

Owner:杭州九鼎纸管有限公司

Automatic quantitative ice adding equipment for pigment reaction kettle

InactiveCN108126638AThe size is easy to controlTemperature controlChemical/physical/physico-chemical processesGrain treatmentsCooling effectEngineering

The invention discloses automatic quantitative ice adding equipment for a pigment reaction kettle. The automatic quantitative ice adding equipment for the pigment reaction kettle comprises a machine frame; an ice material box placing groove is formed in the outer wall of the top of the machine frame; an ice material box is placed on the inner wall of the ice material box placing groove; a baffle sliding groove is formed in the inner wall of the bottom of the ice material box; the inner wall of the baffle sliding groove is in sliding connection with a baffle; a push rod motor is fixed on the outer wall of one side of the ice material box through screws; an output shaft of the push rod motor is fixed on the outer wall of one side of a baffle through screws; an ice adding pipe is placed on the inner wall of the one side of the machine frame; a feeing shaft mounting hole is formed in the outer wall of the top of the ice adding pipe; and the inner wall of the feeding shaft mounting hole isconnected with a feeding shaft through a bearing. The automatic quantitative ice adding equipment for the pigment reaction kettle contributes to rapidly cooling, can effectively control the temperature in the reaction kettle, contributes to alleviating the phenomenon of raw material splattering caused by falling of ice blocks, can quantitatively add ice and can control the cooling speed and the cooling effect of the reaction kettle conveniently.

Owner:盐城信立颜料有限公司

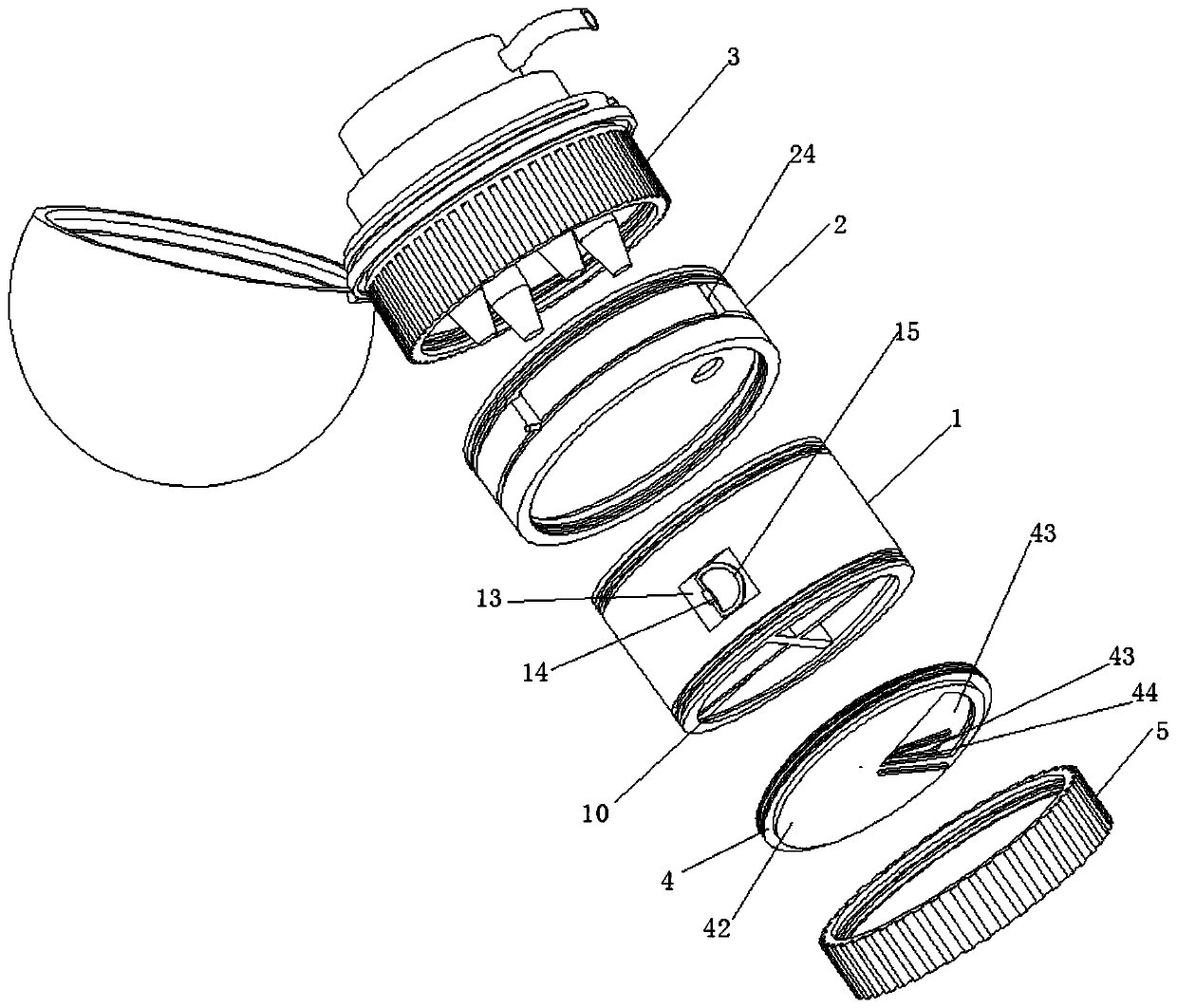

Cover film feeding device of encapsulating machine and separation method thereof

The invention provides a cover film feeding device of an encapsulating machine and a separation method of the cover film feeding device. The cover film feeding device of the encapsulating machine comprises a material placing platform used for placing a cover film and a material taking assembly, the lower side of the material placing platform is fixedly connected with a lifting mechanism used for driving the material placing platform to move up and down, the lifting mechanism comprises a carrying plate, and a plurality of fixing plates are fixedly connected to the carrying plate. According to the cover film feeding device of the encapsulating machine and the separation method of the cover film feeding device, the situation that a mechanical arm possibly grabs a plurality of stacked cover films at a time due to the influence of vacuum and static electricity when the cover films are stacked can be prevented through arrangement of a brush; and meanwhile, the cover film feeding device is provided with a stroke adjusting sliding block, the purpose of controlling the size of the cover film can be achieved through movement of the stroke adjusting sliding block in a limiting groove, a photoelectric sensor can send a material shortage signal to external equipment after the cover film is used out, and therefore a user can feed materials in time, and the working efficiency is improved.

Owner:深圳市正光智能自动化有限公司

Artificial nursery stock growing method for wild Spanish mackerel

ActiveCN101317556ATimely feedingFull predationClimate change adaptationPisciculture and aquariaSpanish mackerelSalinity

The invention discloses an artificial breeding method for wild Spanish mackerel. A rearing pond is internally provided with other fries with the density of not less than 10000 / m<3> during the period from hatching to opening the mouth; the Spanish mackerel fries in a hatching pond are fished out and poured into the rearing pond during the period from 24 hours before the hatching of the prelarva to 12 hours after the hatching of the prelarva; the pouring quantity of the Spanish mackerel fries is 500-10,000 / m<3>; the water temperature of the rearing pond is controlled within 18-25 DEG C and the salinity thereof is controlled within 1.7-2.5%; the cultivation management is carried out according to the cultivation condition of other fries; when other fries are reduced to less than 10,000 / m<3>, the other fries are poured in time so as to lead the density of other fries to be controlled more than 10,000 / m<3>; after the cultivation for 20-30 days, the Spanish mackerel fries with the length being more than 3cm which are artificially raised can be obtained. Therefore, the Spanish mackerels eat other fries, the carnage between the Spanish mackerel fries is reduced, the cultivation rate is improved and can achieve 10-30%, and the conditions are created for the artificial cultivation in large scale.

Owner:NINGBO ACAD OF OCEAN & FISHERY

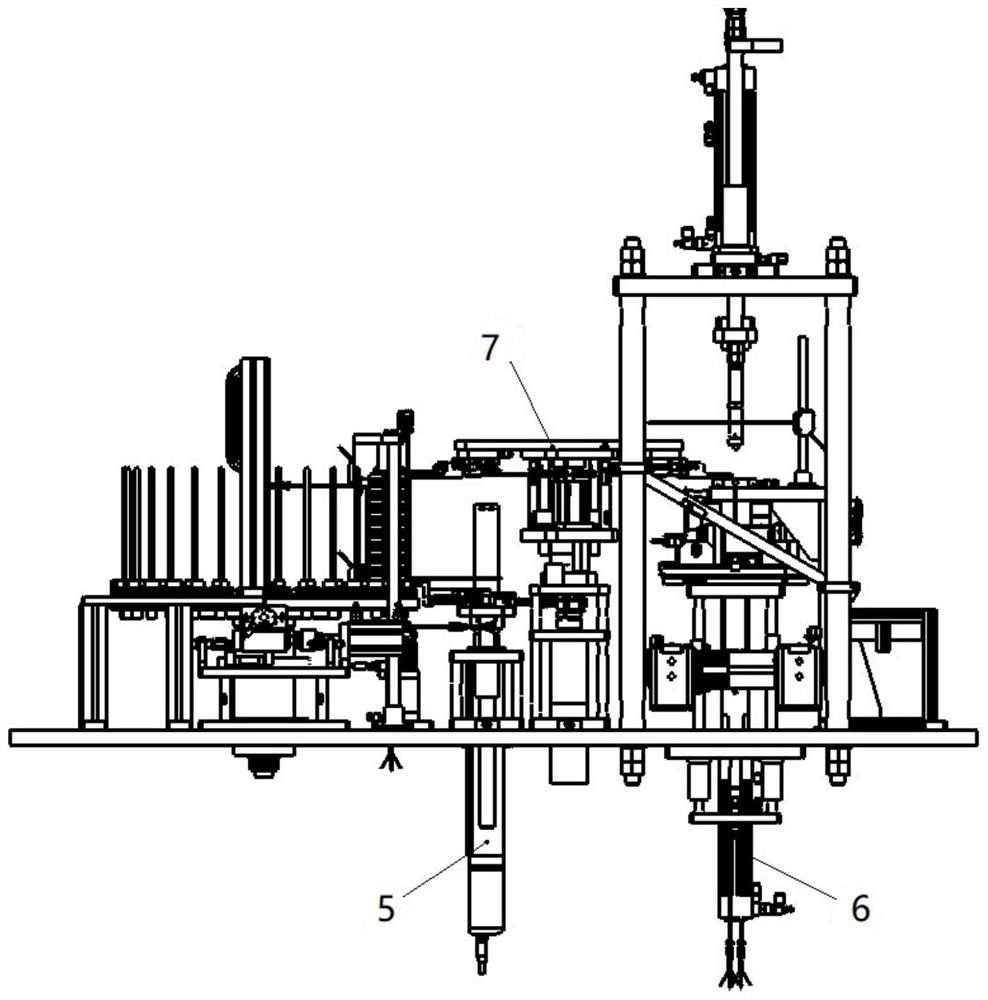

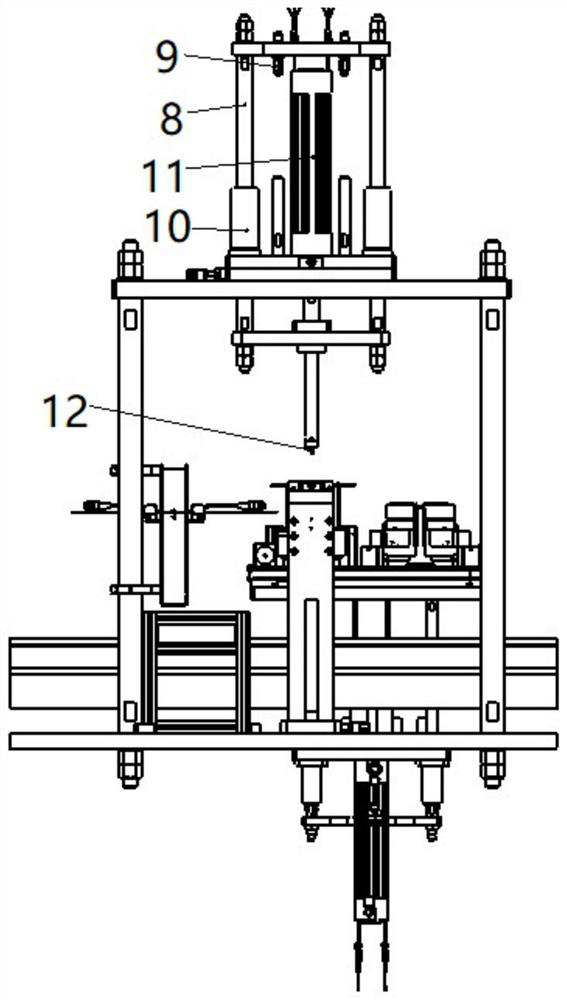

Robot for steamer

ActiveCN103101051AQuick responseFlexible controlProgramme-controlled manipulatorAlcoholic beverage preparationClassical mechanicsMachine

The invention discloses a robot for steamer. The robot for steamer comprises mechanical arms and a steamer executing mechanism, wherein the steamer executing mechanism is fixed at the tail end of each mechanical arm, and each mechanical arm adopts a multi-joint robot. Due to the fact that the multi-joint robots are adopted, the robot for steamer has the advantages of being high in response speed, flexible in control and capable of achieving material paving layer by layer and comprehensive material paving.

Owner:百特(福建)智能装备科技有限公司

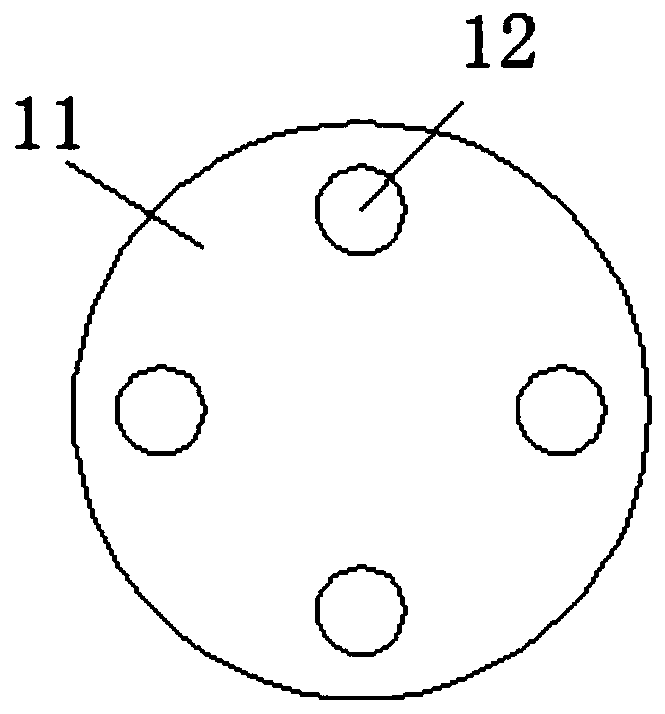

Feeding device and method for calculating amount of feed in feeding device

ActiveCN114568330AReduce wasteTimely feedingClimate change adaptationAnimal feeding devicesAnimal scienceEngineering

The invention relates to a feeding device, comprising: a pressure detection tank for holding a liquid; the bracket is fixed on the pressure detection groove; the feed trough is arranged in the pressure detection trough, the feed trough and the support are assembled in a guiding and sliding mode, and the feed trough is used for containing feed; wherein the pressure detection groove is internally provided with a pressure sensor, and the pressure sensor is used for outputting a pressure value so as to respond to the change of the amount of the feed in the feed groove. According to the technical scheme, the pressure detection groove is additionally arranged below the feed groove, the feed groove and the feed in the feed groove extrude the pressure sensor in the pressure detection groove to obtain the pressure value, and the amount of the residual feed in the feed groove can be accurately judged according to the pressure value. The automatic feeding device is simple in structure and convenient to use, breeding technicians do not need to inspect in person, labor cost is reduced, timely feeding and accurate feeding of animals are guaranteed, feed waste is reduced, and breeding cost is further reduced.

Owner:MUYUAN FOODS CO LTD

Agitator

InactiveCN106738325AStir wellSimple equipmentCement mixing apparatusControl apparatusWave shapeEngineering

The invention discloses an agitator comprising an agitating box, a main agitating shaft, a plurality of auxiliary agitating shafts and gear sets; the agitating box is cylindrical, and the bottom of a box body is arc-shaped; the main agitating shaft is vertically mounted on the top surface of the agitating box and is wave-shaped; each inner side surface of the agitating box is provided with the plurality of auxiliary agitating shafts which are wave-shaped; a raised platform is arranged on the outer surface corresponding to each inner side surface, provided with the auxiliary agitating shafts, of the agitating box; the gear sets are arranged on the corresponding raised platforms; the gears in each gear set are correspondingly connected with the corresponding auxiliary agitating shafts; and the adjacent gears in each gear set are engaged in pairs. The agitator can be used for carrying out all-dimensional and three-dimensional agitation on a material needed to be agitated, so that the material is more sufficiently agitated.

Owner:CHENGDU YITIAN TECH CO LTD

Tachysurus fulvidraco extruded pellet compound feed and production method thereof

InactiveCN108740573AEasy to observe feeding situationKeep abreast of health conditionsFodderClimate change adaptationAnti stressCulture environment

The invention relates to the field of feeds and particularly relates to a tachysurus fulvidraco extruded pellet compound feed and a production method thereof, wherein the tachysurus fulvidraco extruded pellet compound feed comprises an energy feed raw material, a protein feed raw material, a compound premix feed and auxiliary materials. The tachysurus fulvidraco extruded pellet compound feed can float on the water surface, so that the ingestion situation of tachysurus fulvidraco can be conveniently observed, and the feeding amount is controlled, and thus the health situation of tachysurus fulvidraco can be learned in time. By virtue of culturing the tachysurus fulvidraco with the extruded pellet compound feed, the cultured tachysurus fulvidraco is natural in color, uniform in tachysurus fulvidraco body, fresh and tender in flesh, anti-stress, anti-transportation, and low in feed coefficient, so that the tachysurus fulvidraco culturing cost is reduced, labor is reduced, wastes are reduced, the growth speed is increased, tachysurus fulvidraco diseases are reduced, thus the culture benefits are improved, resources are saved, and the culture environment is protected.

Owner:岳阳市新宏饲料有限公司

Novel oxidation-resistant and high-temperature-resistant soldering tin bar

ActiveCN112658531AReduce labor intensityEnsure timelinessWelding/cutting media/materialsSoldering mediaOxidation resistantSoldering

The invention discloses a novel oxidation-resistant and high-temperature-resistant soldering tin bar, and relates to the technical field of soldering tin bars. The novel oxidation-resistant and high-temperature-resistant soldering tin bar comprises a soldering tin bar body, the soldering tin bar body is composed of a main body framework and two tin oxidation-resistant reduction powder boxes, the main body framework comprises a U-shaped prefabricated part, clamping grooves are formed in the front side and the rear side of the top of the U-shaped prefabricated part, a soldering flux filling cavity is formed in the inner side of the top of the U-shaped prefabricated part, and the top of the soldering flux filling cavity extends upwards in the vertical direction to form a threaded wall. According to the novel oxidation-resistant and high-temperature-resistant soldering tin bar, an integral structure of a traditional soldering tin bar is split, the tin oxidation-resistant reduction powder boxes and the soldering flux filling cavity are formed inside the soldering tin bar, the soldering tin bar can be filled with the tin oxidation-resistant reduction powder boxes and the soldering flux, therefore when the soldering tin bar is molten, the tin oxidation-resistant reduction powder and the soldering flux can conduct anti-oxidation protection on molten tin, and the timeliness and effectiveness of oxidation resistance can be guaranteed.

Owner:深圳市鑫福源锡材有限公司

Combined bottle for liquid cooking seasoning kitchen

The invention provides a combined bottle for a liquid cooking seasoning kitchen. The bottle comprises a transparent bottle body, an adjusting cover, a bottle cover, a separating cover and a bottle bottom cover and is characterized in that a cross-shaped separating plate is installed in the transparent bottle body and divides the interior of the transparent bottle body into four identical containing cavities. A fixing plate is installed on the inner wall of one end of the transparent bottle body, and a through hole is formed in one side of the fixing plate. According to the combined bottle forthe liquid cooking seasoning kitchen, the combined bottle is formed by connecting and assembling every two of the transparent bottle body, the adjusting cover, the bottle cover, the separation cover and the bottle bottom cover through threads, so that the disassembly is convenient, and the interior of the combined bottle is cleaned; when the combined bottle is used, the bottle bottom cover of thecombined bottle is opened, a convex block on a fan-shaped cover is pulled to enable the fan-shaped cover to be contained in the containing groove, so that a fan-shaped hole is opened; a turntable is rotated to enable the fan-shaped hole to be aligned with a cavity needing to be added with seasonings and feed the seasonings; the turntable can prevent the added seasonings from entering other cavities, so that the operation is convenient.

Owner:泉州睿开商贸有限公司

Puffed granule compound feed for ietalurus punetaus and production method thereof

InactiveCN108813208ANatural body colorWell-proportioned fishFood processingClimate change adaptationAnti stressIctalurus catus

The present invention relates to the field of feeds and particularly relates to a puffed granule compound feed for ietalurus punetaus and a production method thereof. The puffed granule compound feedcomprises energy feed raw materials, protein feed raw materials, a compound premixed feed and auxiliary materials. The puffed granule compound feed can enable the bred ietalurus punetaus to be naturalin body color, well-proportioned in fish body, fresh and tender in meat quality, anti-stress, and resistant to transportation; besides, the puffed granule compound feed is also low in feed coefficient and high in economic benefits; and at the same time, the puffed granule compound feed reduces the breeding cost of the ietalurus punetaus, reduces labor and waste, increases growth rate, reduces fish diseases, and thus improves breeding benefits, saves resources and protects breeding environment.

Owner:岳阳市新宏饲料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com