Agitator

A mixer and mixing box technology, which is applied in cement mixing devices, control devices, clay preparation devices, etc., can solve the problems of poor mixing effect, insufficient mixing, and affecting the speed and quality of building construction, so as to achieve sufficient mixing and energy saving , the effect of streamlining equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

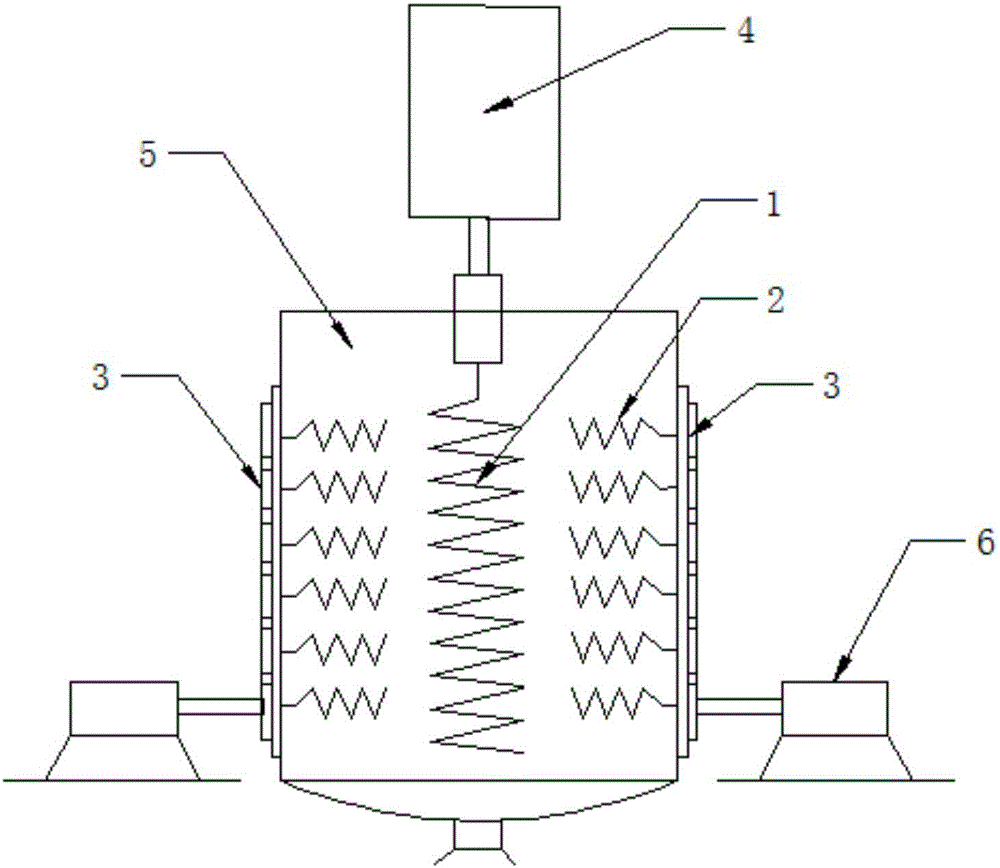

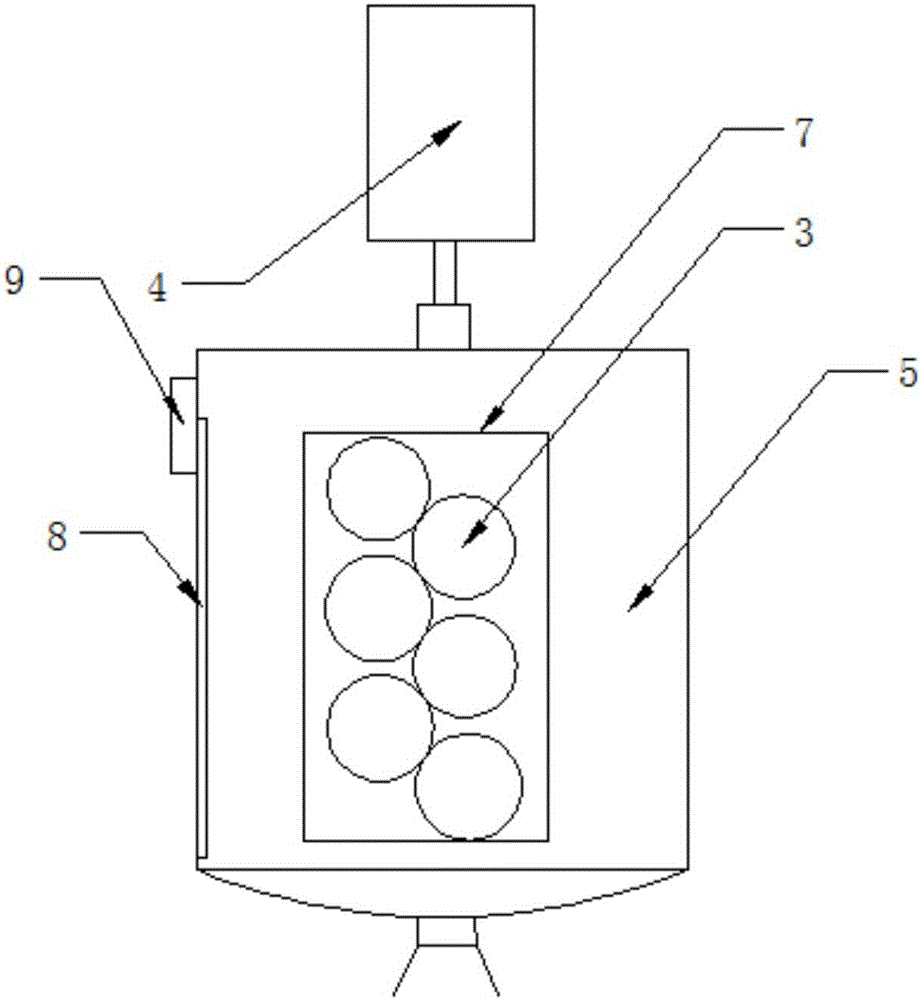

[0017] like Figure 1-Figure 2 Shown, a kind of agitator comprises a stirring box 5, a main stirring shaft 1, a plurality of auxiliary stirring shafts 2 and a gear set 3, the stirring box 5 is a cylinder and the bottom of the box is arc-shaped, and the main agitating shaft 1 vertically installed on the top surface of the stirring box 5, the main stirring shaft 1 is wave-shaped; the inner surface of the stirring box 5 is provided with a plurality of auxiliary stirring shafts 2, and the auxiliary stirring shafts 2 are wave-shaped; stirring The case 5 is provided with a raised platform 7 on the outer surface corresponding to the inner surface of the auxiliary stirring shaft 2, and the gear set 3 is arranged on the raised platform 7, and the gears in the gear set 3 are arranged in a straight line and staggered, so The gears in the gear set 3 are respectively connected to an auxiliary stirring shaft 2, and the adjacent gears in the gear set 3 are meshed in pairs.

Embodiment 2

[0019] like Figure 1-Figure 2 Shown, a kind of agitator comprises a stirring box 5, a main stirring shaft 1, a plurality of auxiliary stirring shafts 2 and a gear set 3, the stirring box 5 is a cylinder and the bottom of the box is arc-shaped, and the main agitating shaft 1 vertically installed on the top surface of the stirring box 5, the main stirring shaft 1 is wave-shaped; the inner surface of the stirring box 5 is provided with a plurality of auxiliary stirring shafts 2, and the auxiliary stirring shafts 2 are wave-shaped; stirring The case 5 is provided with a raised platform 7 on the outer surface corresponding to the inner surface of the auxiliary stirring shaft 2, and the gear set 3 is arranged on the raised platform 7, and the gears in the gear set 3 are arranged in a straight line and staggered, so The gears in the gear set 3 are respectively connected to an auxiliary stirring shaft 2, and the adjacent gears in the gear set 3 are meshed in pairs.

[0020] At least...

Embodiment 3

[0022] like Figure 1-Figure 2 Shown, a kind of agitator comprises a stirring box 5, a main stirring shaft 1, a plurality of auxiliary stirring shafts 2 and a gear set 3, the stirring box 5 is a cylinder and the bottom of the box is arc-shaped, and the main agitating shaft 1 vertically installed on the top surface of the stirring box 5, the main stirring shaft 1 is wave-shaped; the inner surface of the stirring box 5 is provided with a plurality of auxiliary stirring shafts 2, and the auxiliary stirring shafts 2 are wave-shaped; stirring The case 5 is provided with a raised platform 7 on the outer surface corresponding to the inner surface of the auxiliary stirring shaft 2, and the gear set 3 is arranged on the raised platform 7, and the gears in the gear set 3 are arranged in a straight line and staggered, so The gears in the gear set 3 are respectively connected to an auxiliary stirring shaft 2, and the adjacent gears in the gear set 3 are meshed in pairs.

[0023] At least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com