Efficient fine powder packaging machine

A packaging machine and fine powder technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as manual operation and waste of manpower, and achieve the effect of ensuring accuracy and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

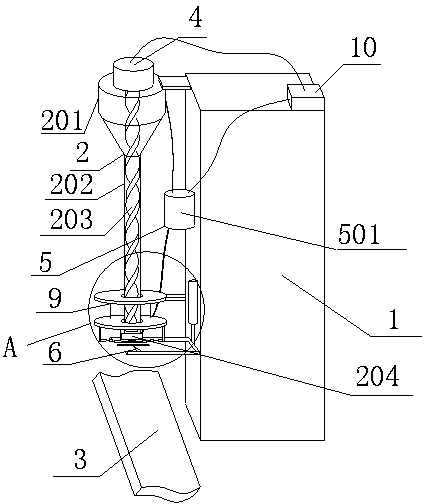

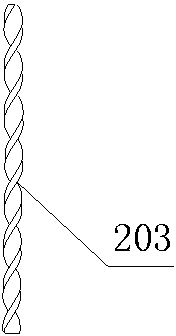

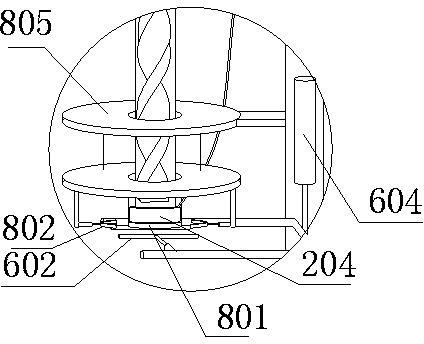

[0021] like Figure 1-5 As shown, the high-efficiency fine powder packaging machine includes a frame 1, a conveying device 3, a feeding device 2 installed on the frame 1, a feeder 5, a gripper 6, a bag gripper 8 and a PLC controller 10 , the feeding device 2 includes a material box 201, a material guide pipe 202 and a screw rod 203. The lower end of the material box 201 is in the shape of a funnel, and the material guide pipe 202 is vertically arranged under the material box 201 and communicates with the material box. 201, the screw rod 203 runs through the entire material guide pipe 202, the lower end of the screw rod 203 is flush with the material guide pipe 202, the upper end penetrates the material box 201 and is connected to the motor 4 above the material box 201, the screw rod 203 is driven by the motor 4 to rotate, and the screw The outer diameter of the rod 203 is consistent with the inner diameter of the material guide pipe 202. The lower end of the material guide pip...

Embodiment 2

[0024] like Image 6 , the structure of the device is basically the same as that of the first embodiment, the difference is that the device also includes a vacuum pump 7, and the suction end of the vacuum pump 7 is connected to the material box 201, so that the air content of the fine powder in the material box 201 is reduced, so that the The fine powder is relatively compact, and it will not easily raise dust after falling into the bag, which further ensures the accuracy of weighing, because the dust in the bag also affects the weighing. After the dust is stationary, the whole becomes heavier.

Embodiment 3

[0026] like Figure 7 , the structure of this device is basically the same as that of Embodiment 1, the difference is that a voice prompter 9 is also set on the rack 1, and the voice prompter 9 is a speaker, and its control end is also electrically connected with the PLC controller 10 . After the re-installation completes the work, the PLC controller 10 also turns on the voice prompter to remind the staff that the feeding is completed, so that the staff can continue the bag-loading work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com