Rubbish pyrolysis gasification furnace with point acquisition charging function

A technology of pyrolysis gasification and garbage, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problem of affecting the effect of pyrolysis gasification of domestic garbage, the inability to effectively control the surface temperature of garbage in the furnace, and the failure to control the recovery of burn-through points. Restoration layer and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

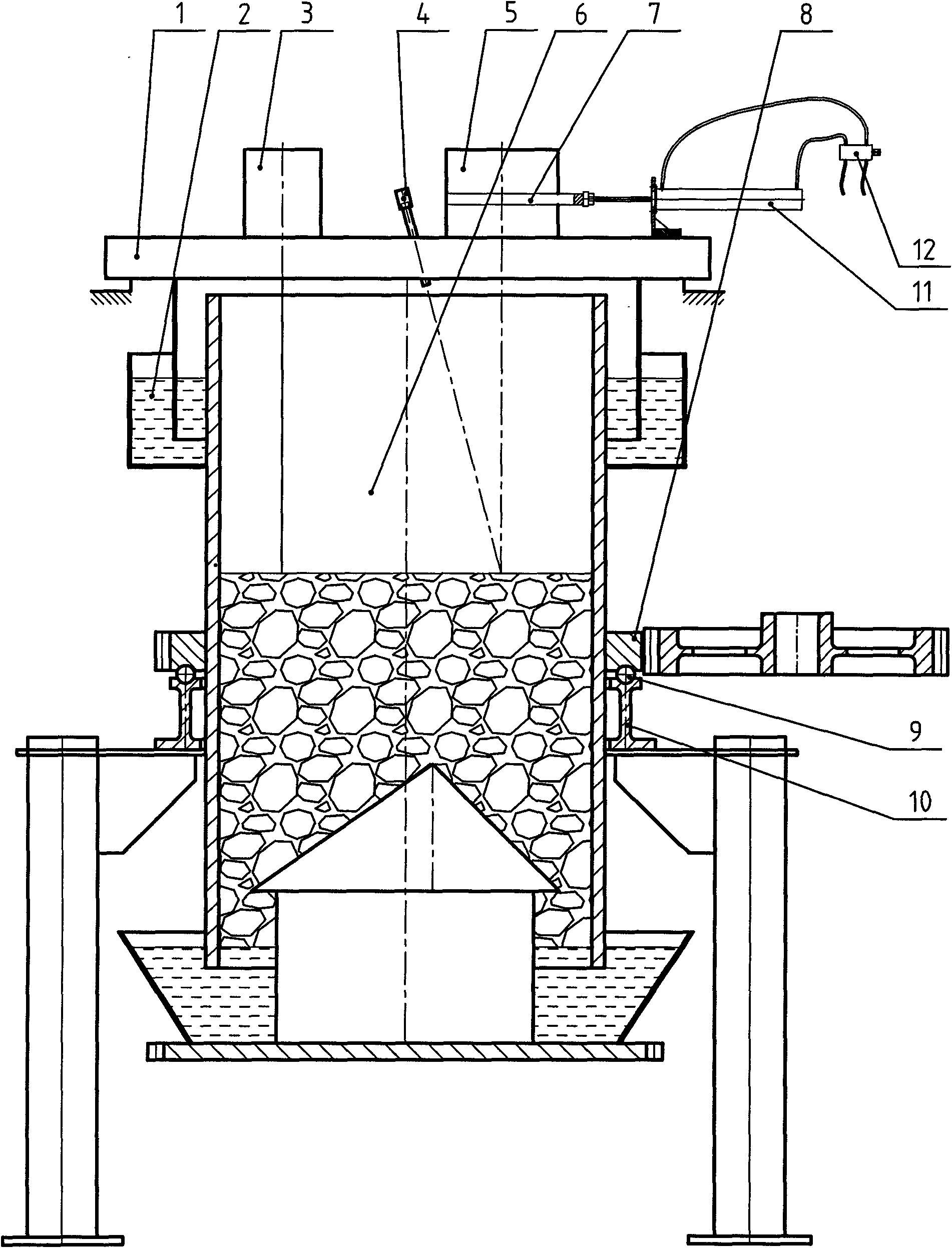

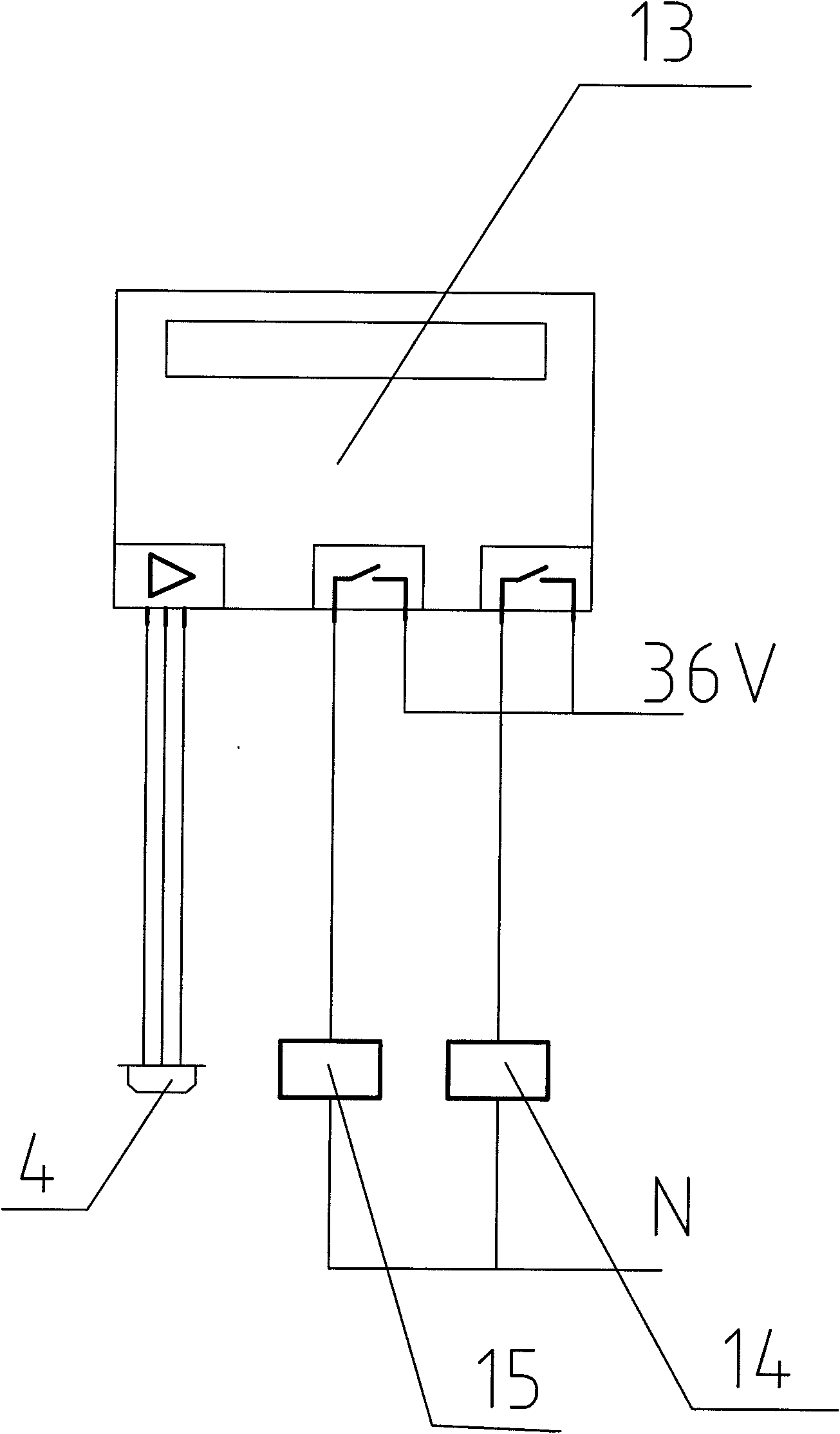

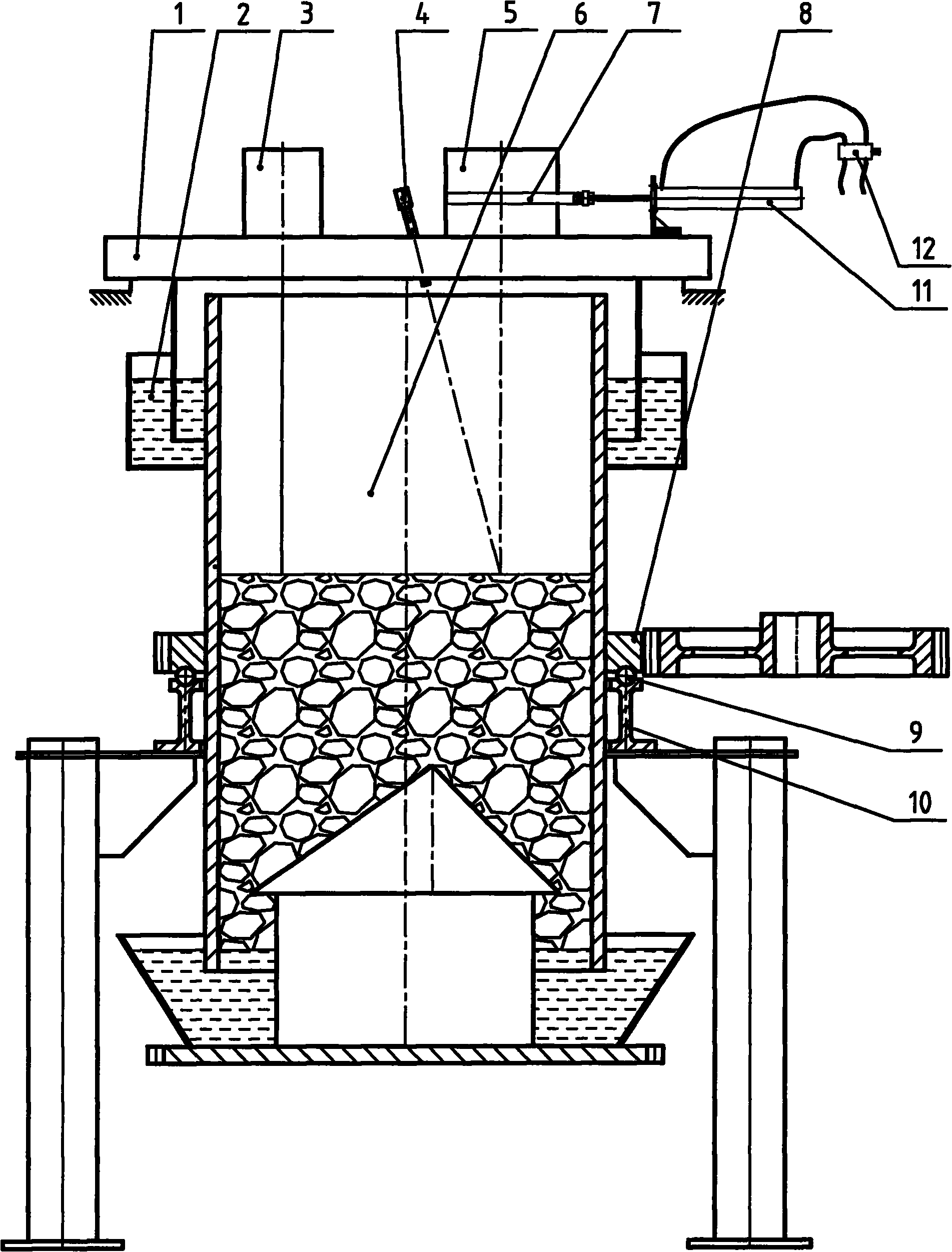

[0009] like figure 1 As shown, this embodiment includes a furnace body 6, a furnace cover 1, a water sealing device 2, a furnace body fixing frame 10, an infrared temperature measuring sensor 4, an output gear 8 in a gear transmission mechanism and a feeding control mechanism.

[0010] The furnace cover 1 is covered on the top opening of the furnace body 6, and the furnace cover 1 and the furnace body 6 are sealed by a water sealing device 2. The furnace cover 1 is provided with an exhaust port 3 and a feeding Port 5, the infrared temperature sensor 4 is arranged on the furnace cover 1, and monitors the surface temperature of the garbage in the furnace directly below the feeding port 5; the furnace body 6 and the furnace body fixing frame 10 are supported and connected by a plane bearing 9, The furnace body 6 is fixedly connected with the output gear 8 in the gear transmission mechanism.

[0011] The feeding control mechanism includes a pumping valve 7, an oil cylinder 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com