Pulverized coal industrial boiler system

A technology for industrial boilers and pulverized coal, which is applied in the direction of block/powder supply/distribution, combustion methods, lighting and heating equipment, etc., can solve the problems of low thermal efficiency, pollution, huge energy waste, etc., and achieve clean discharge and pulverized coal Stable delivery and efficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

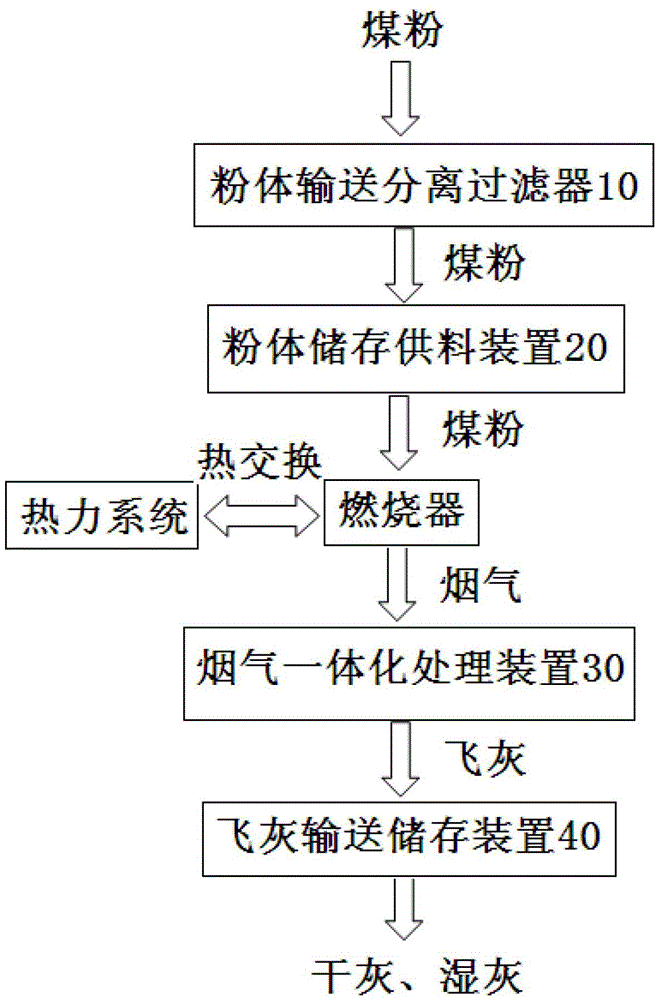

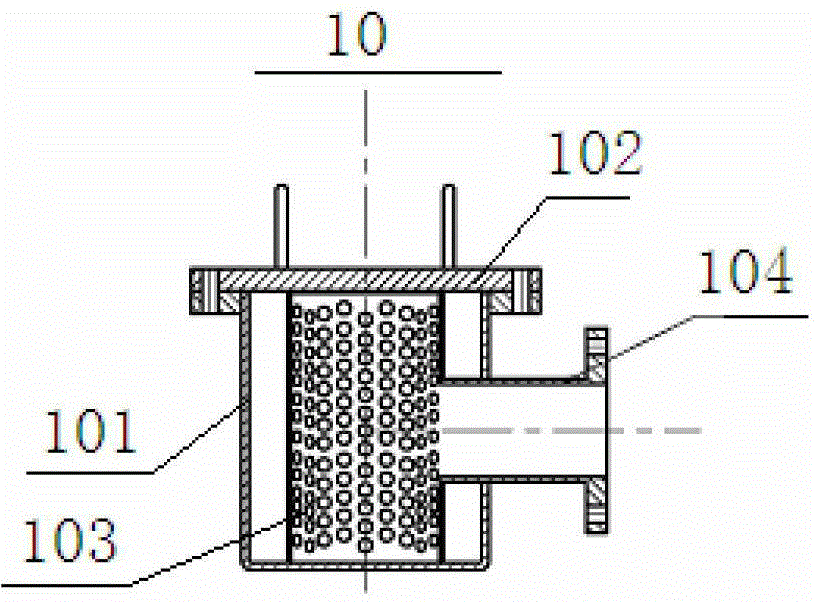

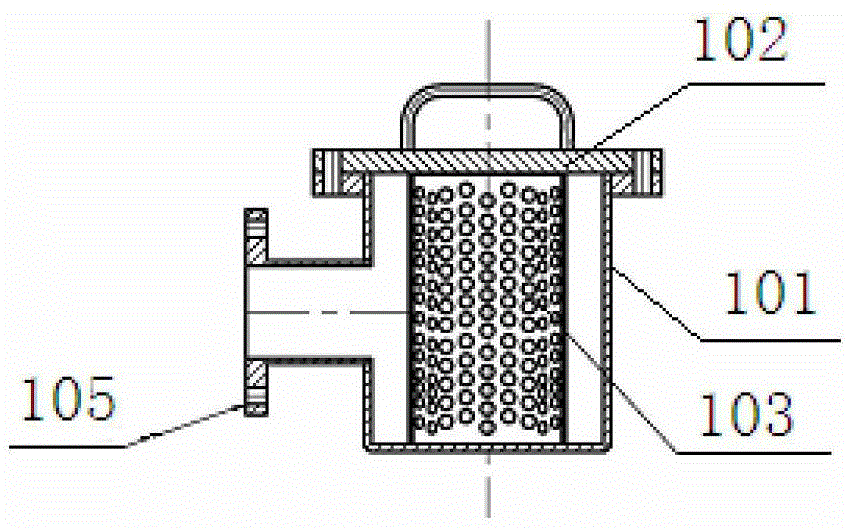

[0028] Such as figure 1 As shown, the present invention includes a powder conveying and separating filter 10 , a powder storage and feeding device 20 , a boiler burner, an integrated flue gas treatment device 30 , a fly ash conveying and storing device 40 and an inert gas protection device 50 . The powder conveying separation filter 10 filters the pulverized coal and then conveys it to the powder storage and feeding device 20. The powder storage and feeding device 20 stores the pulverized coal and supplies it to the boiler burner. The pulverized coal is ignited by igniting oil and gas, and the boiler During the combustion process, the burner exchanges heat with the thermal system and delivers it to users in the form of hot water or steam. The flue gas combusted by the boiler burner is processed by the integrated flue gas processing device 30 and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com