Robot batch hopper

A technology of batching hoppers and robots, which is applied in the direction of selling raw material supply devices, etc., can solve problems such as loss of fluidity, non-compliance, and high bonding strength, and achieve the effects of reducing power loss, stable performance, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

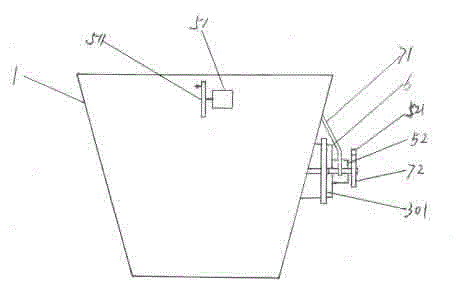

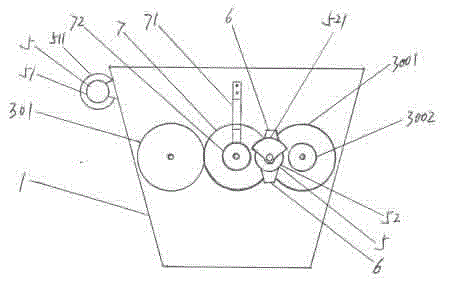

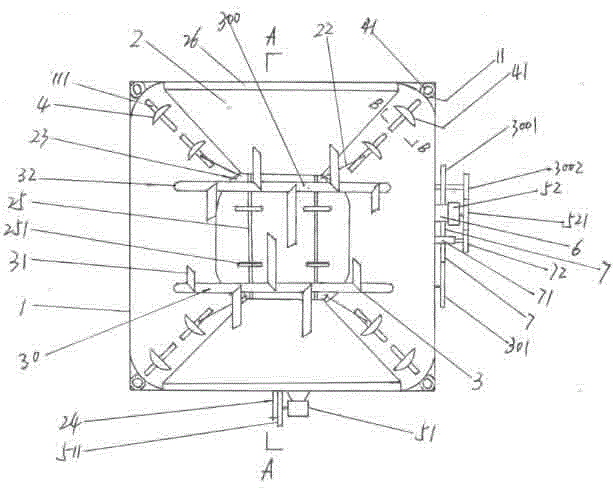

[0017] The invention is attached figure 1 , 2 , 3, the equipment consists of a quadrangular table-shaped hopper 1, a trapezoidal seesaw 2, a breaker 3, an arc-shaped scraper 4, a frequency conversion motor 5 and a control module 8, and the trapezoidal seesaw 2 is connected to four On the inner wall of the truss-shaped hopper 1, the crusher 3 is connected to the truss-shaped hopper 1 through bearings, and the arc-shaped scraper 4 is connected to the inner four corners of the truss-shaped hopper 1 through the guide cylinder 11, and connected to the trapezoidal hopper 1 through the first transmission rod 22. The miniature shaft 23 at the lower end corner of the seesaw 2 is connected, and the frequency conversion motor 5 is connected to the outer wall of the quadrangular platform-shaped hopper 1 through the fixing frame 6 and bolts, and is movably connected to the upper small shaft of the trapezoidal seesaw 2 through the second transmission rod 24 , the variable frequency motor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com