Patents

Literature

36results about How to "Improve arch breaking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feeding device

ActiveCN105620952AGood arch breaking strengthImprove arch breaking effectLarge containersNatural stateEngineering

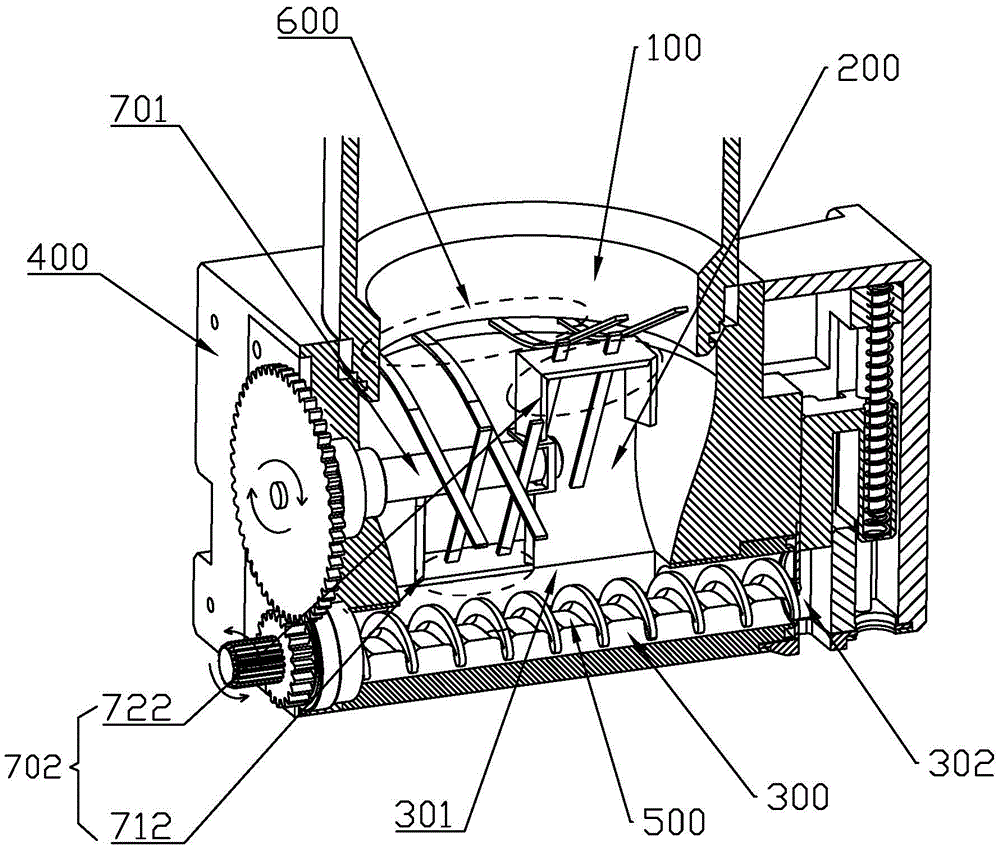

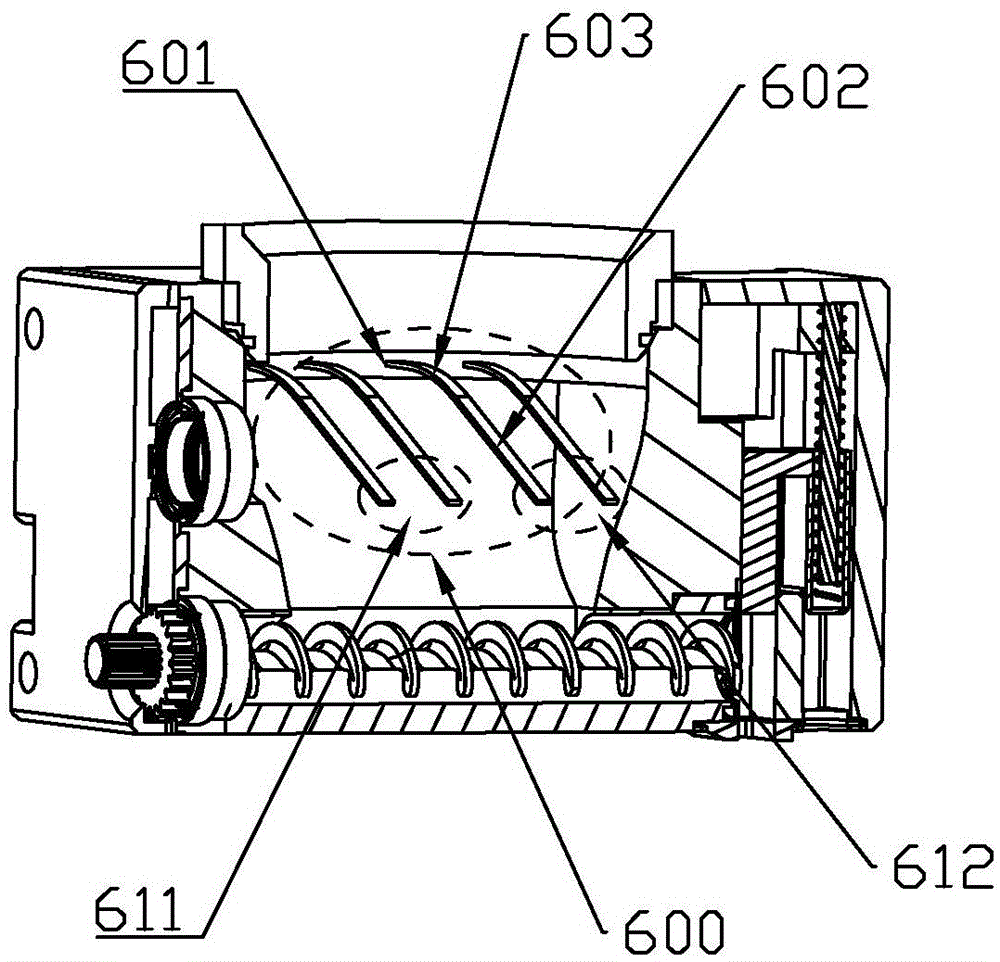

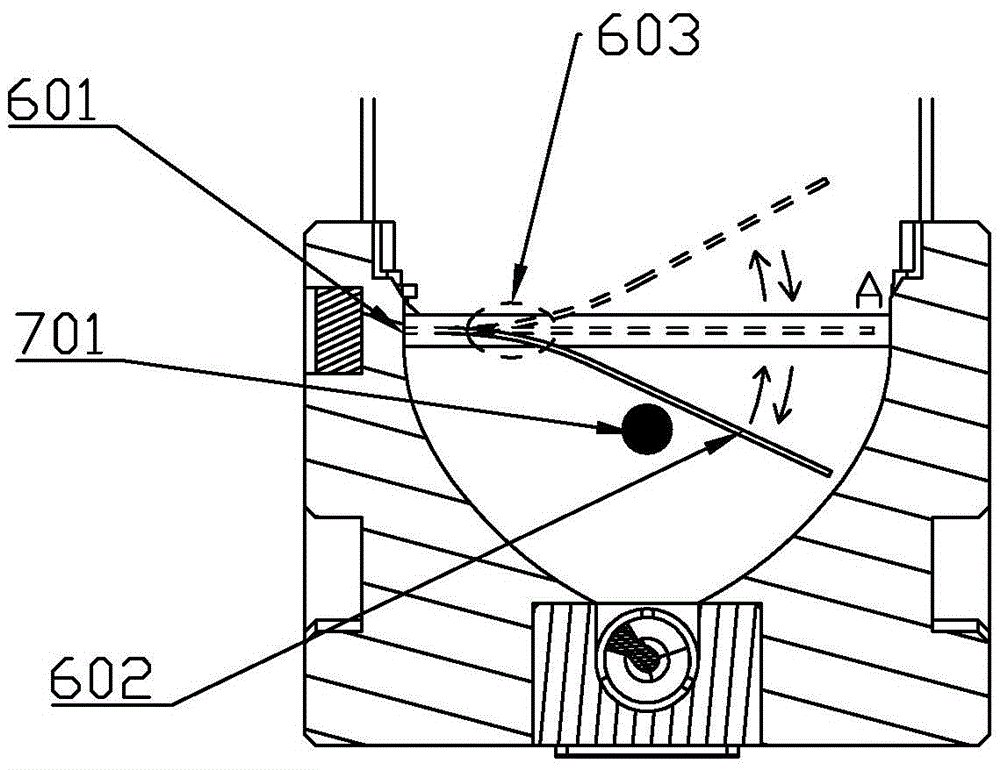

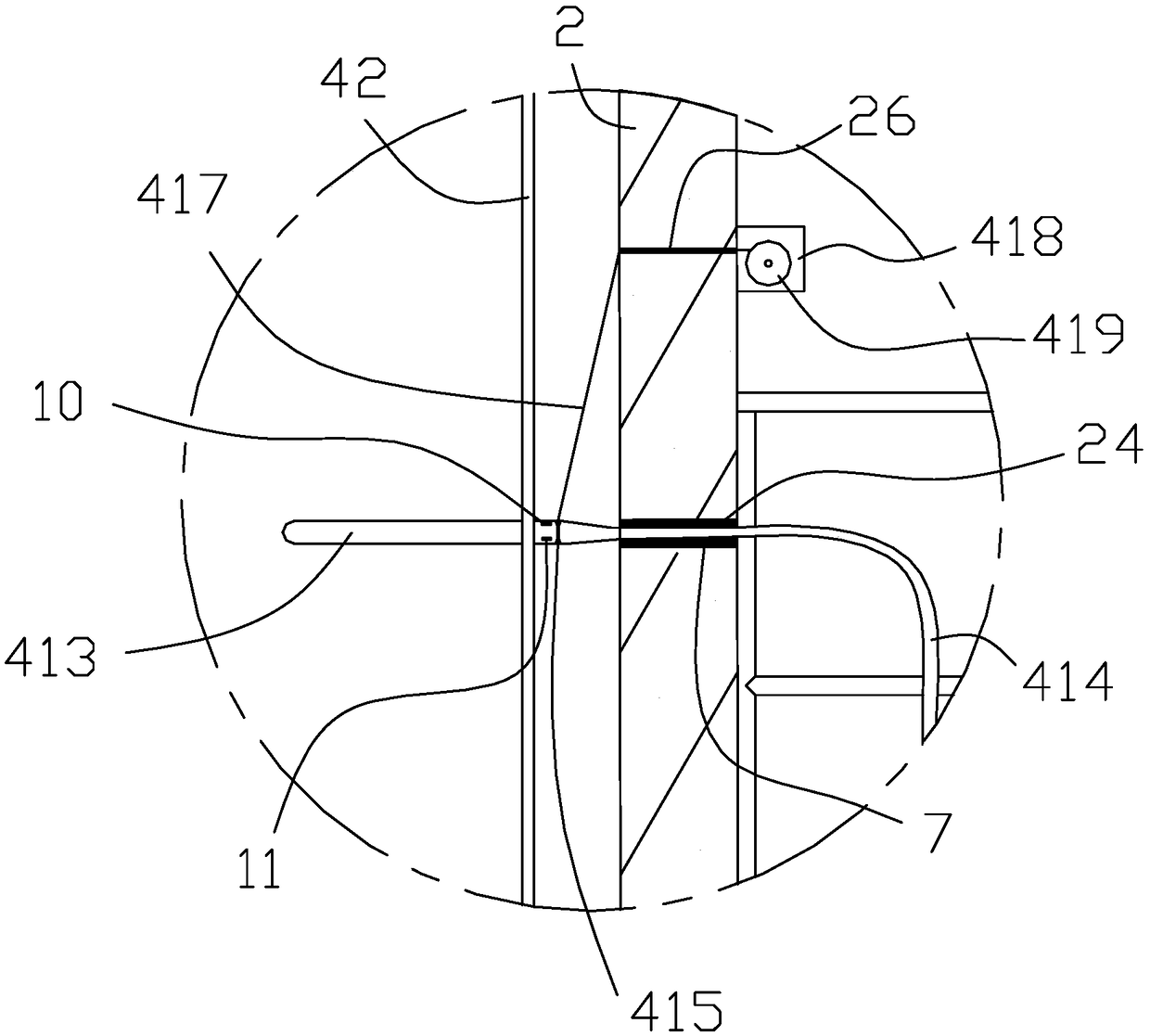

The invention provides a feeding device. The feeding device comprises a feeding inlet, a stirring cavity and a feeding cavity, wherein the stirring cavity is arranged between the feeding inlet and the feeding cavity; a feeding threaded rod penetrates through the feeding cavity; an arc breaking elastic piece is arranged in the stirring cavity, one end of the arc breaking elastic piece is fixedly installed in the combination position of the stirring cavity and the feeding inlet, and the other end of the arc breaking elastic piece is suspended; a stirring mechanism matched with the arc breaking elastic piece is further arranged in the stirring cavity and comprises a rotary shaft and a stirring paddle; in the rotation process of the stirring mechanism, the stirring paddle periodically makes contact with the arc breaking elastic piece, and the contact position of the arc breaking elastic piece deforms elastically, so that the suspended end of the arc breaking elastic piece is driven to swing, and arc breaking is carried out on materials; when the stirring paddle and the arc breaking elastic piece are separated, the arc breaking elastic piece recovers the natural state. According to the feeding device, the arc breaking elastic piece is triggered by the stirring mechanism to swing vertically, arc breaking is carried out on the materials within a large range, the effect that the feeding threaded rod receives materials uniformly is guaranteed, and the discharging precision is effectively improved.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

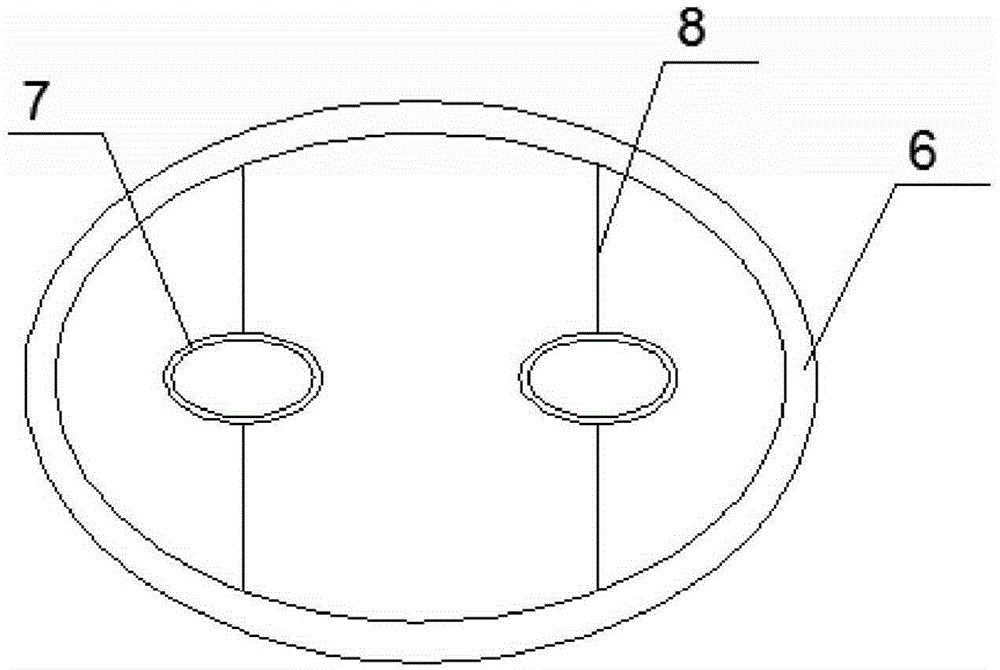

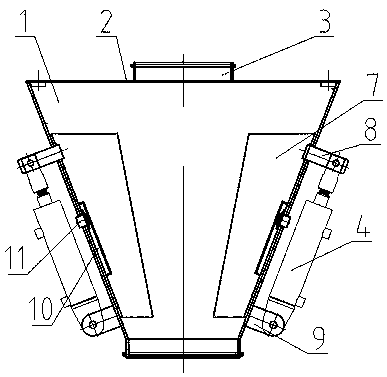

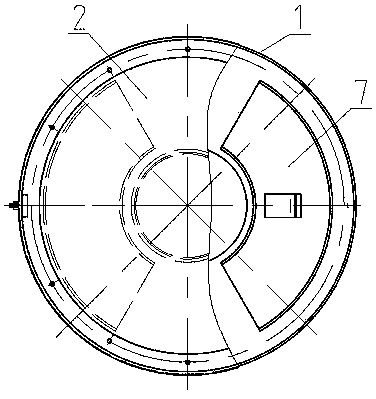

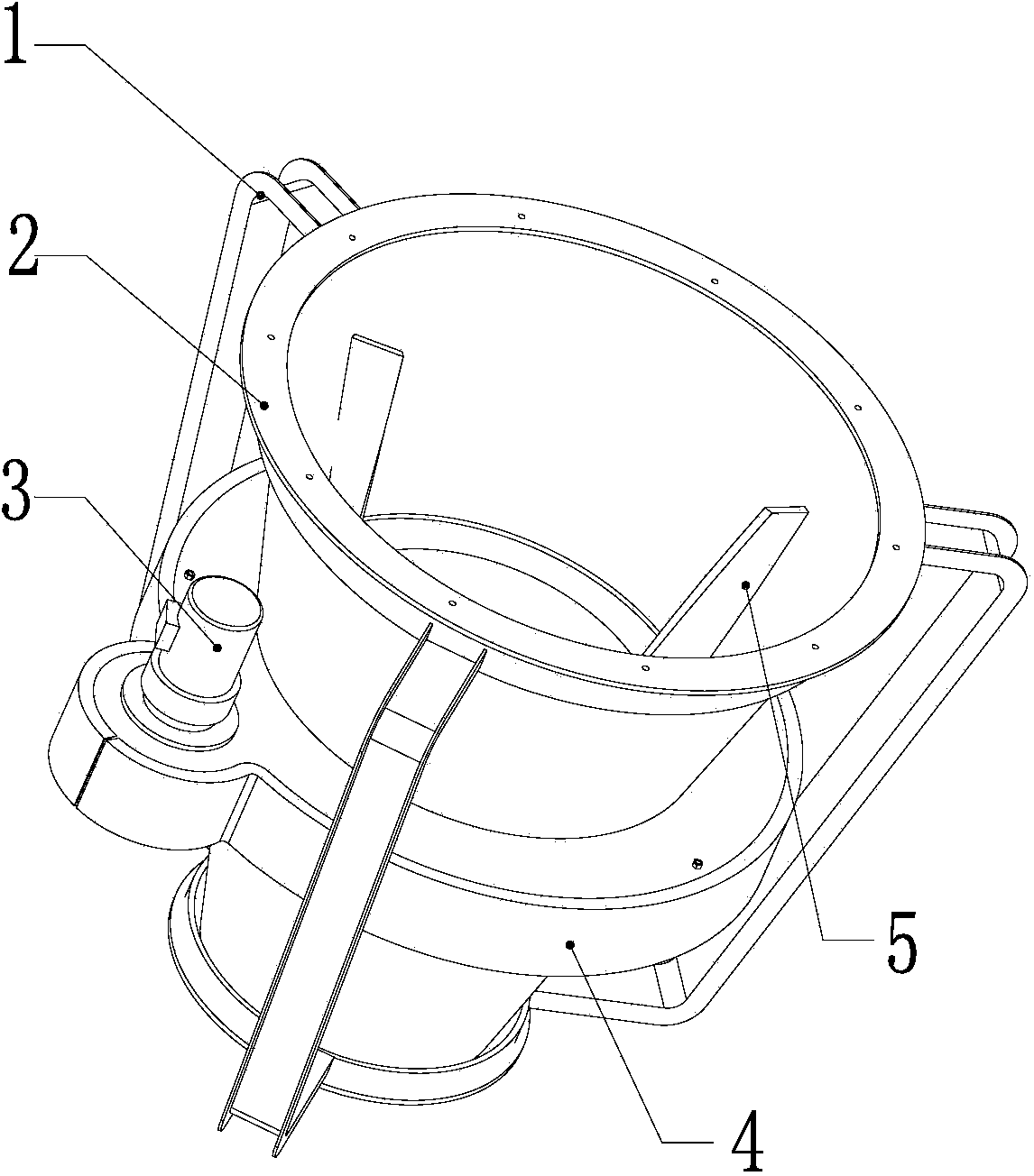

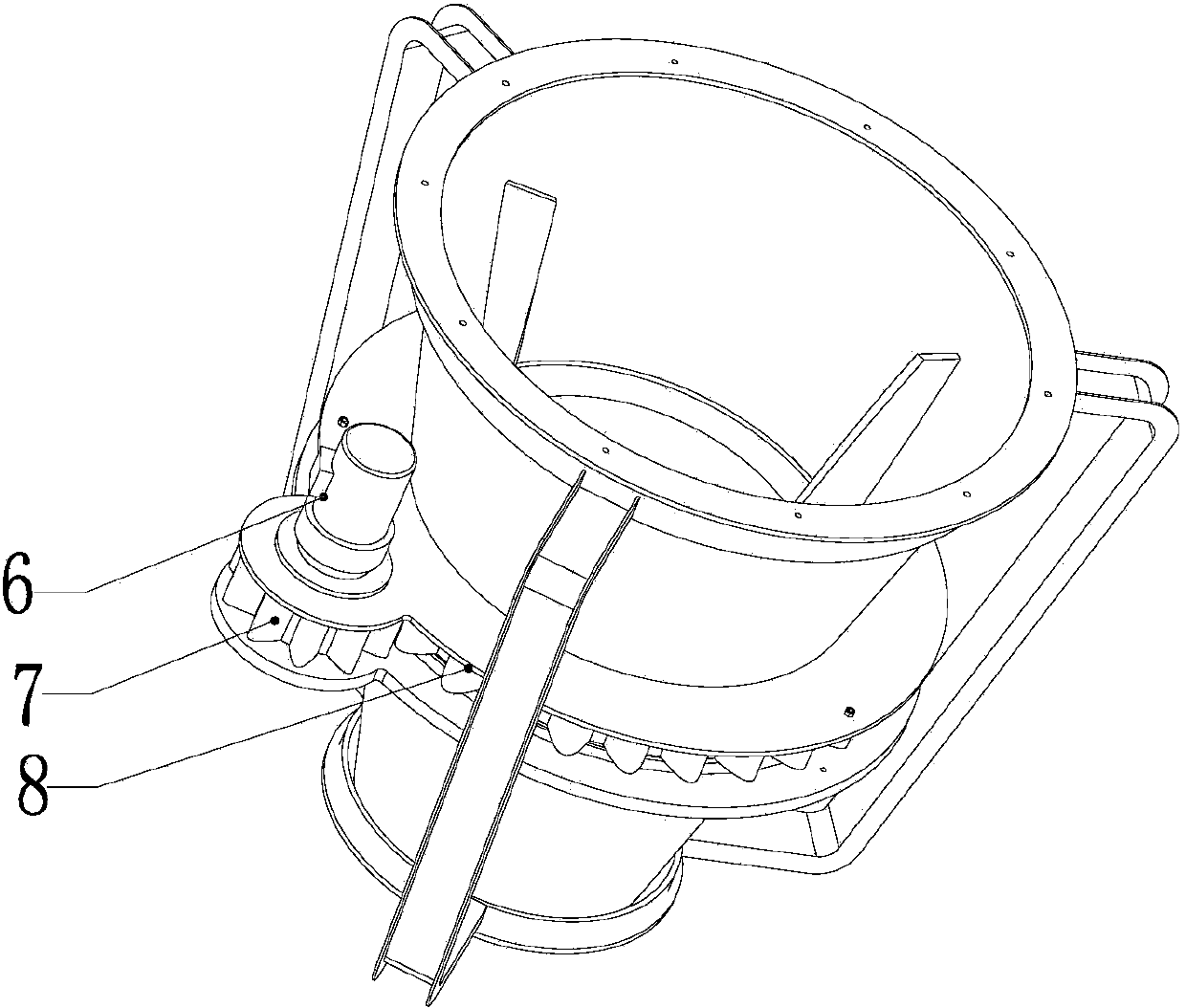

Anti-blocking switch gear of discharge bin

ActiveCN105346876AAvoid blocking problems such as archingIncrease the output speedLarge containersEngineeringMechanical engineering

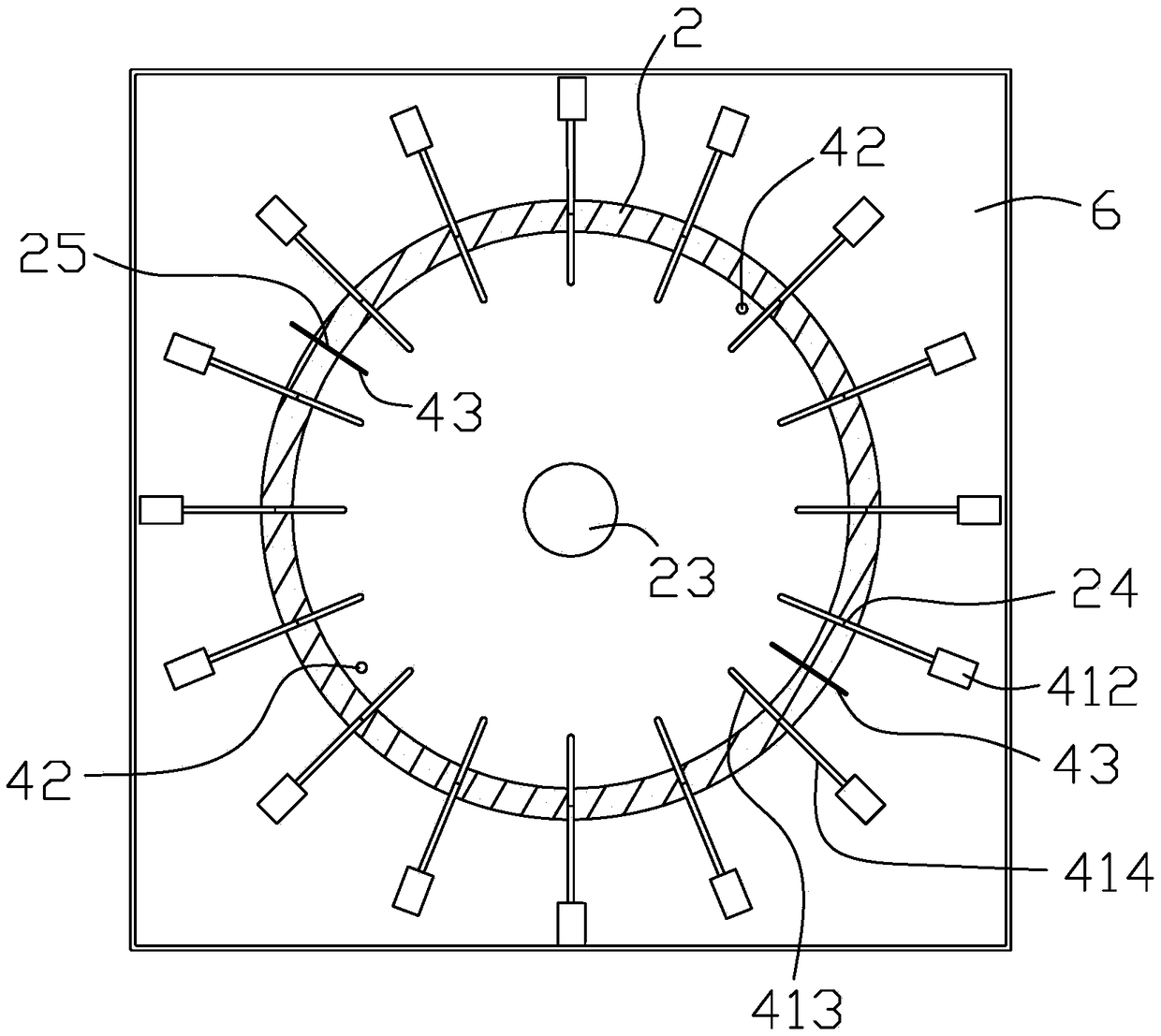

The invention discloses an anti-blocking switch gear of a discharge bin, the anti-blocking switch gear is arranged above a discharge hole in the bottom of the discharge bin, and the cross section of the discharge hole is circular. The anti-blocking switch gear comprises a discharge mechanism, an arch breaking mechanism and a rotary mechanism, wherein the discharge mechanism comprises a baffle plate, an air cylinder and a circular ring; the circular ring is connected with a motor, so that the motor drives the circular ring to rotate for driving the air cylinder and the baffle plate to rotate; the arch breaking mechanism comprises a circular-ring-shaped base and a cylindrical supporting base; the base is hinged with the baffle plate to realize linkage; the side edge of the upper surface of the supporting base is provided with a plurality of spiral pawls which are in upward right-handed rotation, so that a plurality of spiral openings are formed; the rotary mechanism comprises an outer rod, an inner rod extending into a space formed by the pawls, and a plurality of blades, wherein one blade is blocked into one opening, so that the corresponding blade is driven to rotate in a rotary process of the supporting base. The anti-blocking switch gear has the advantages of being capable of effectively preventing the discharge hole from arching, uniform in discharge of the discharge bin, simple in structure, high in working efficiency and the like.

Owner:GUANGXI SHENTA MACHINERY EQUIP CO LTD

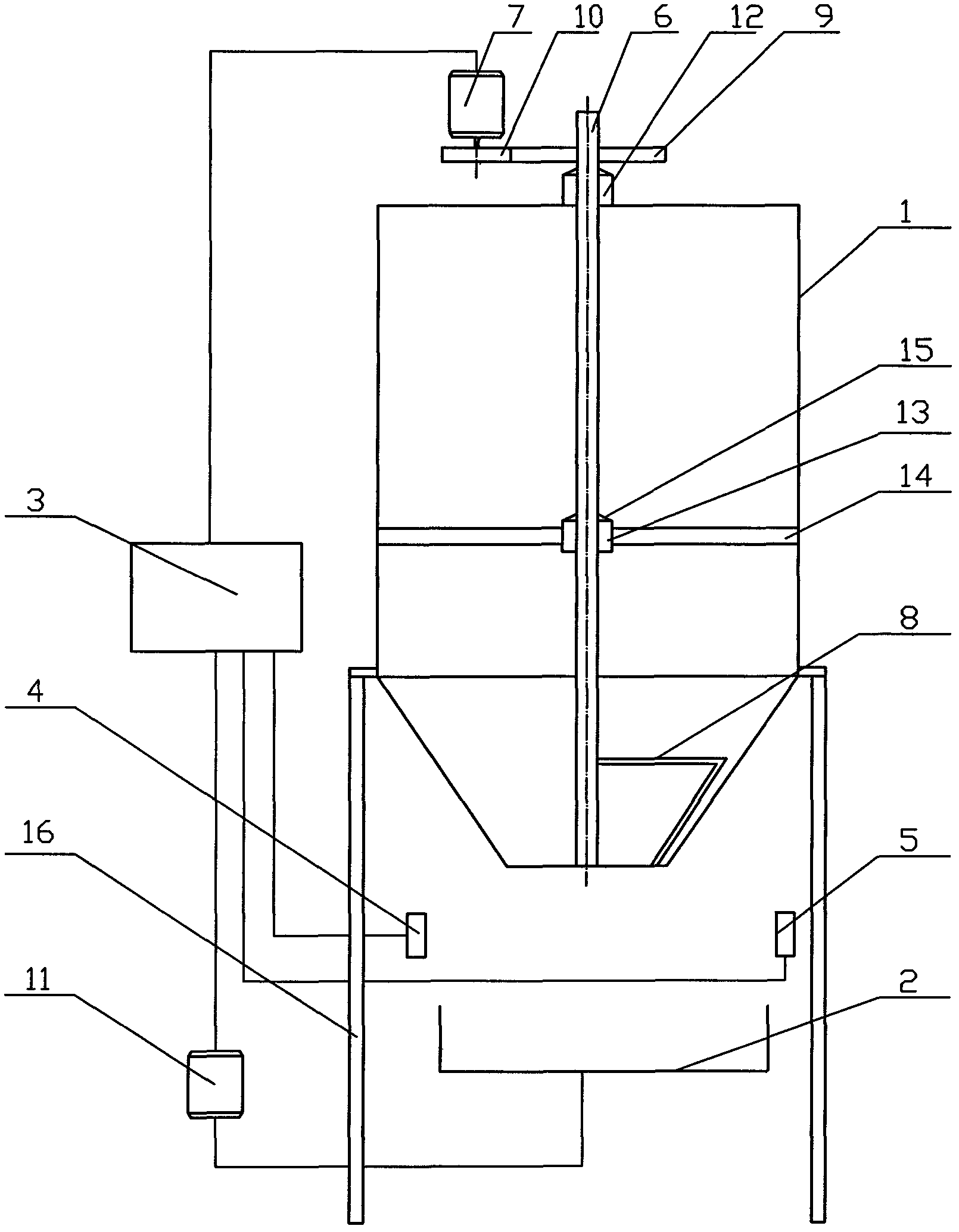

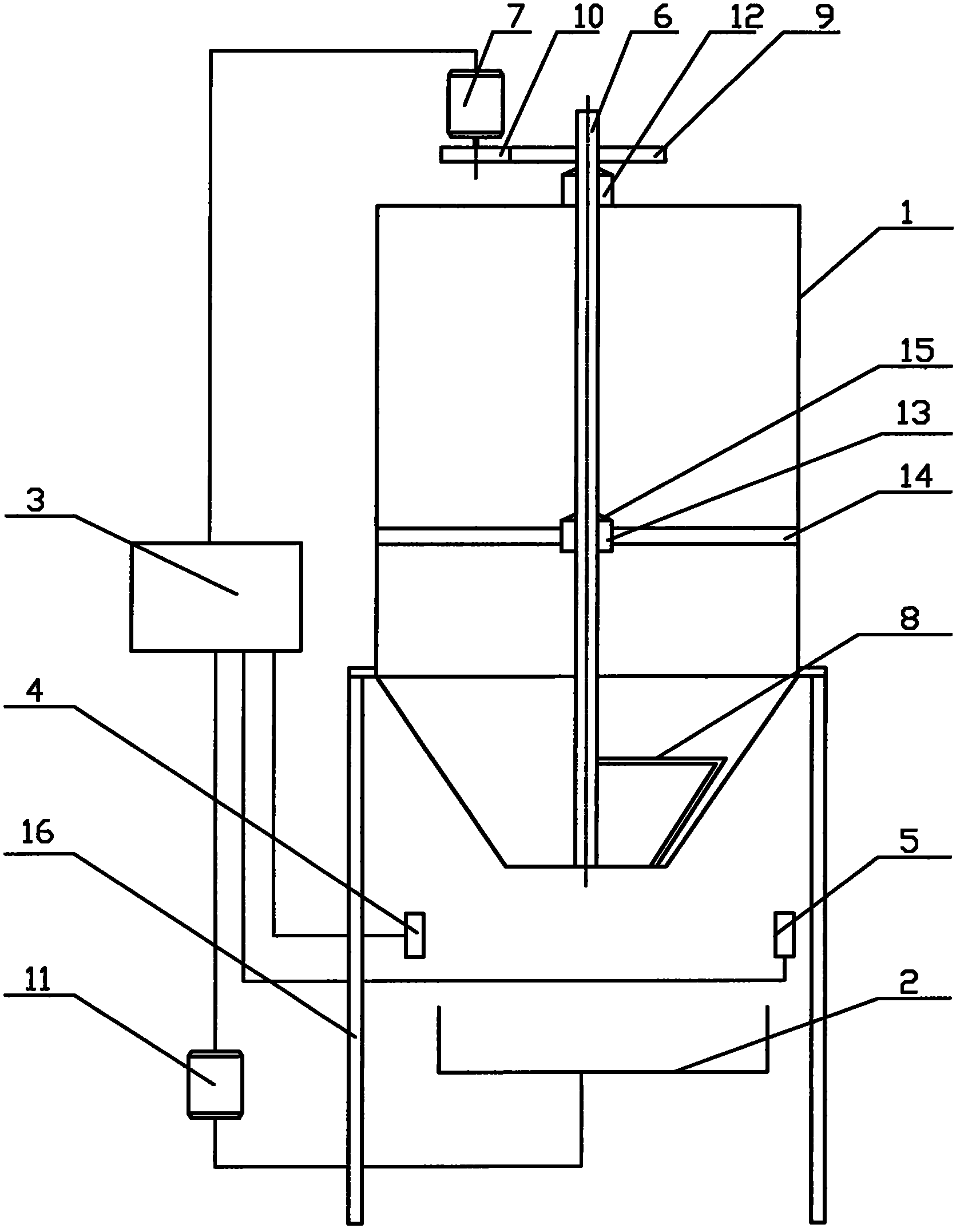

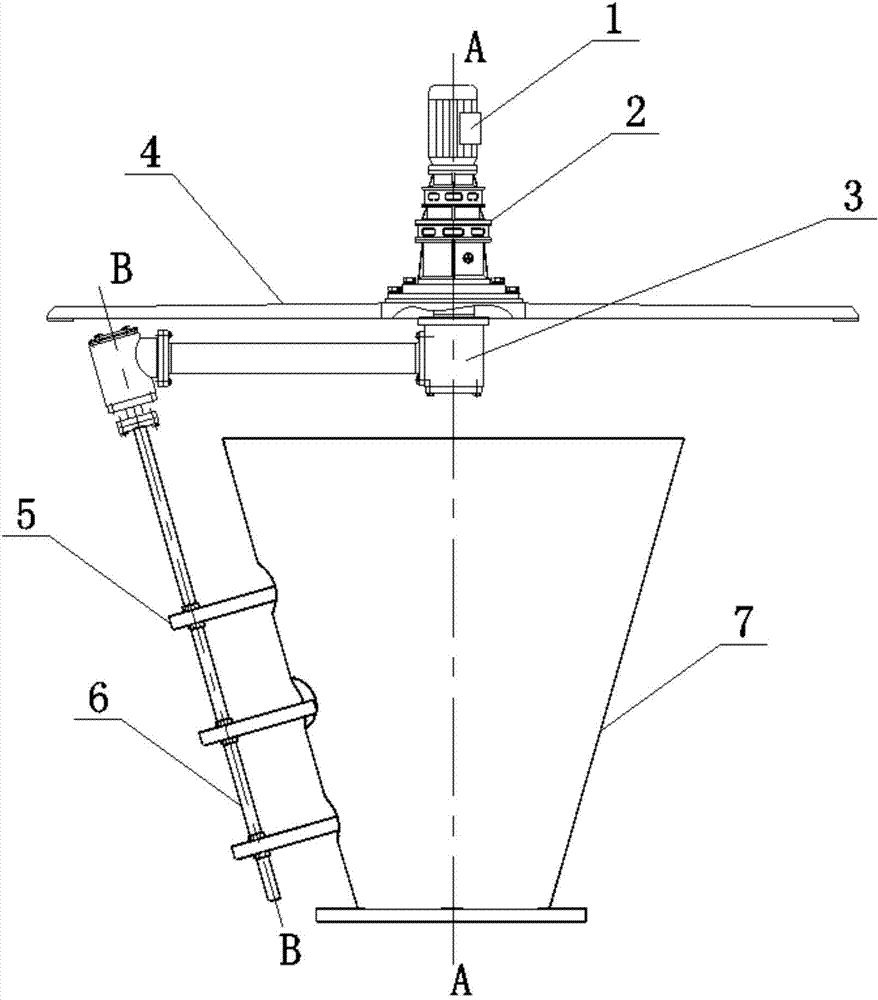

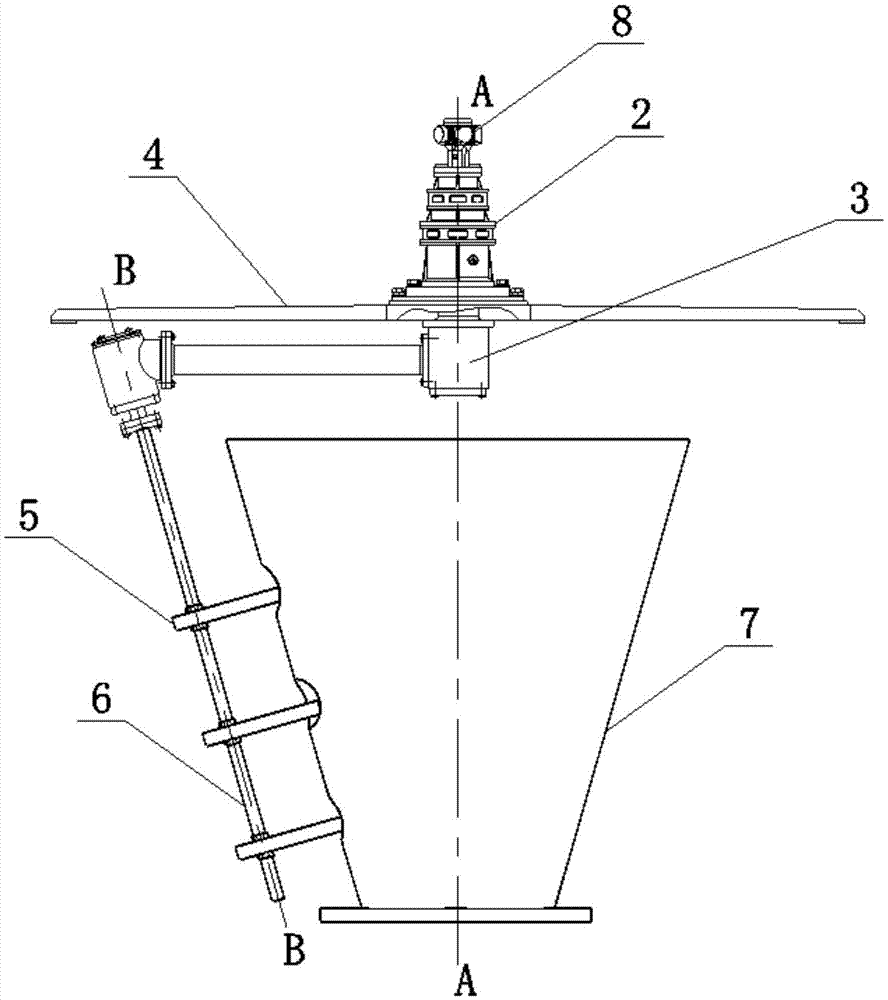

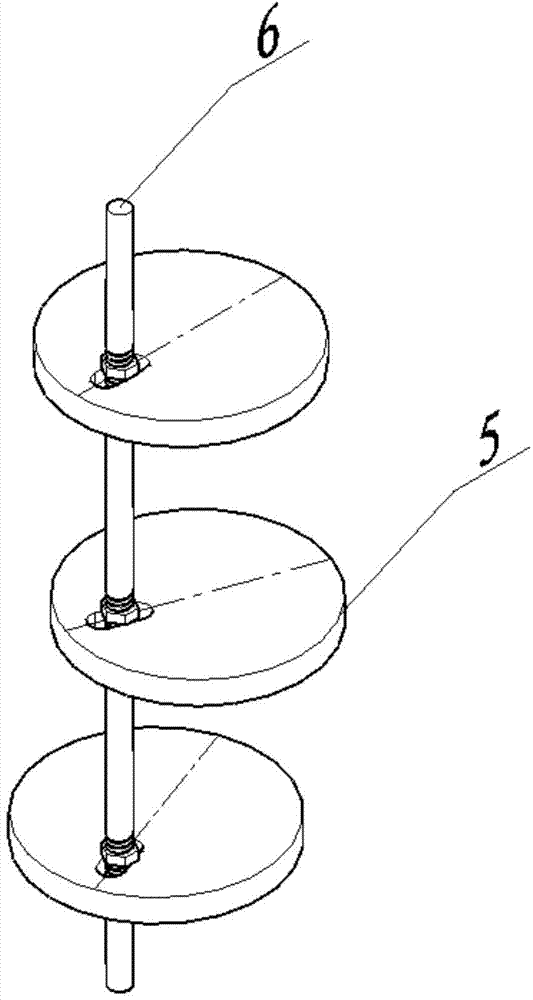

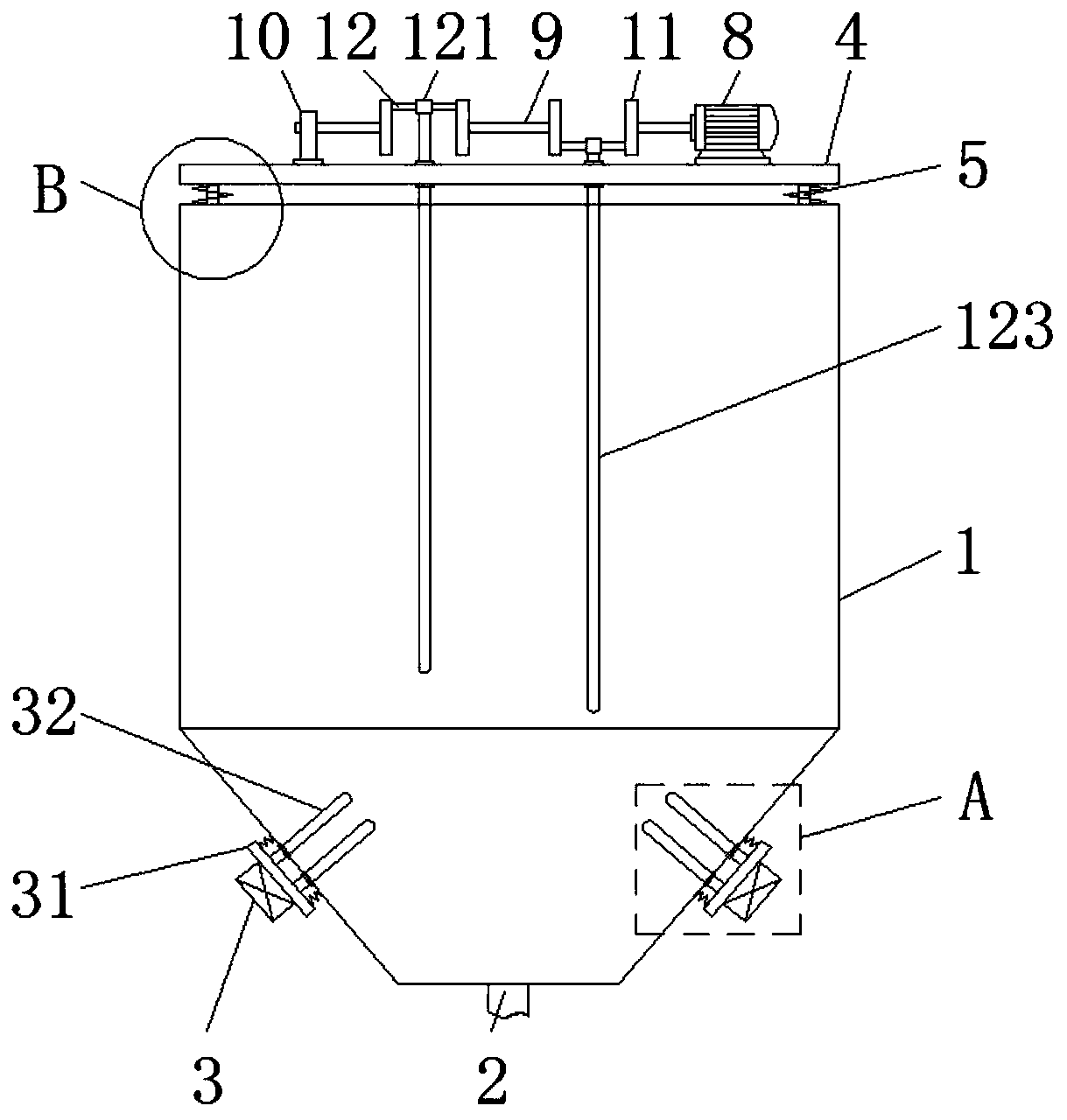

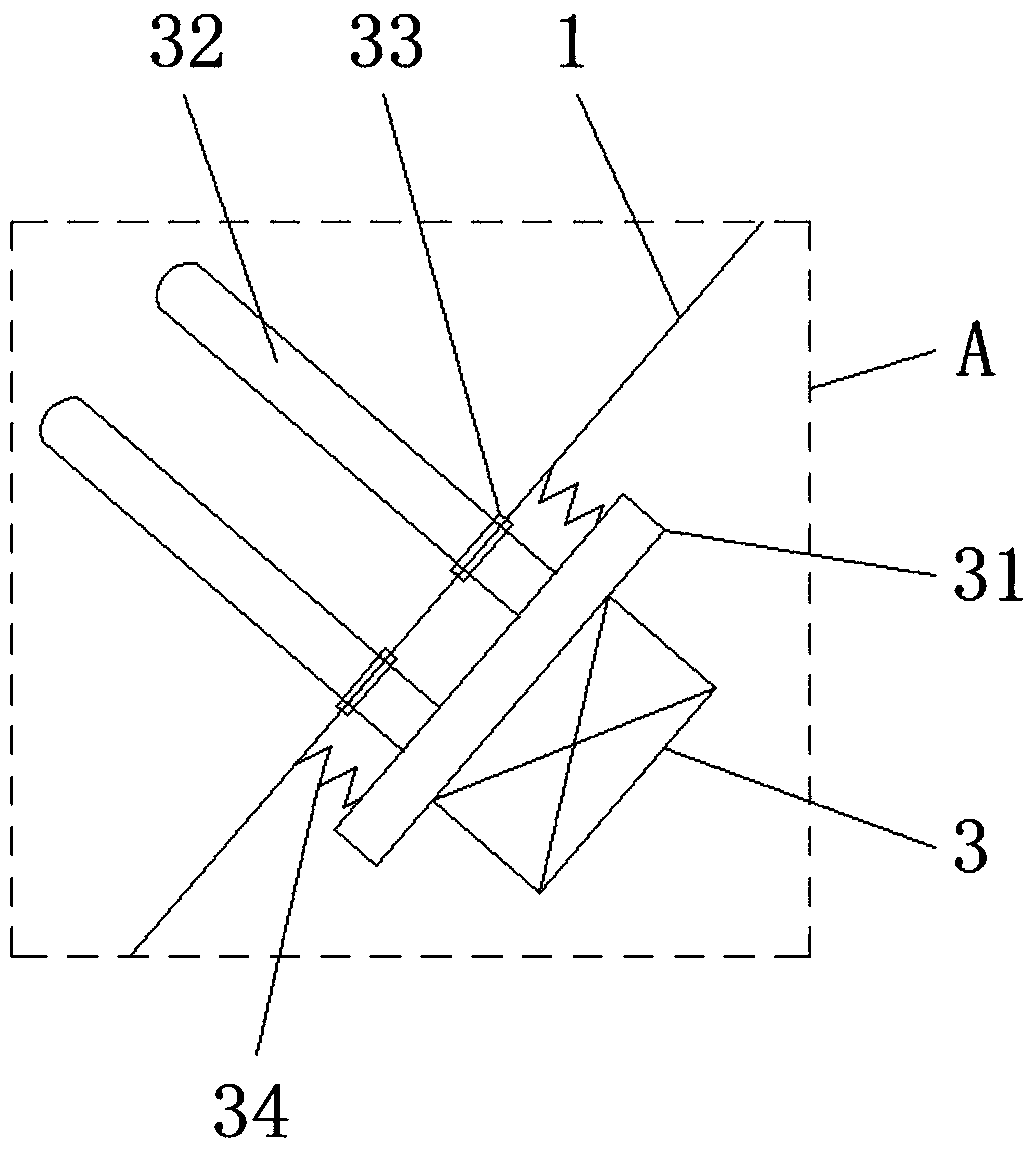

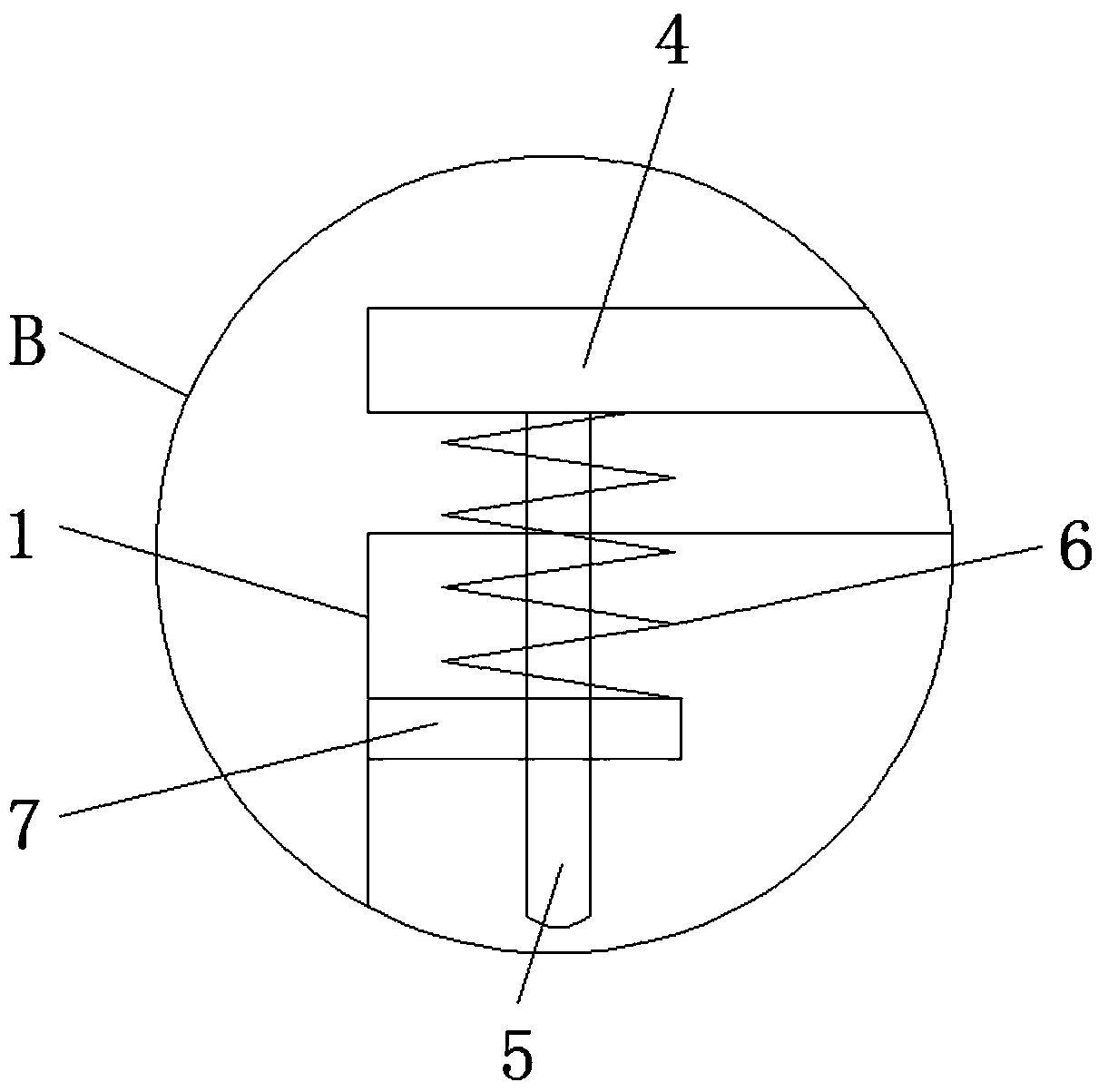

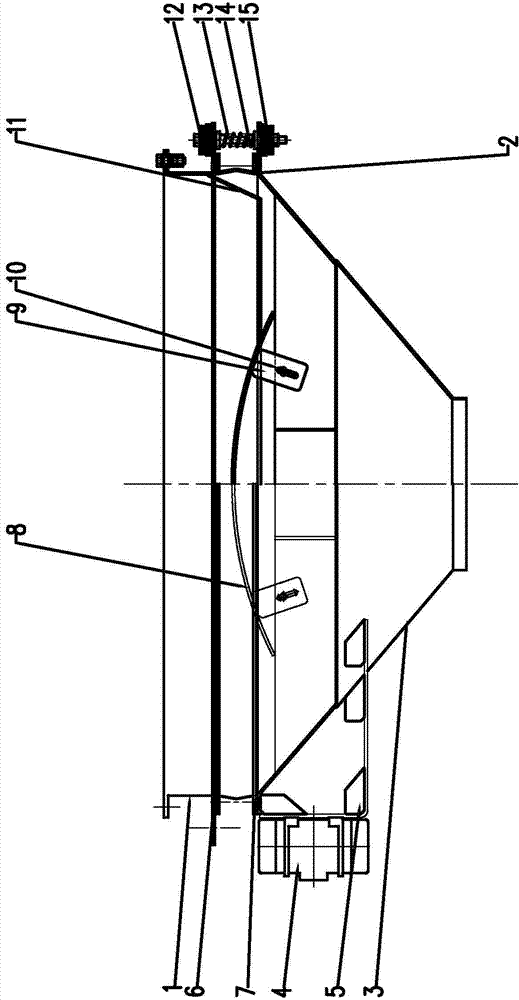

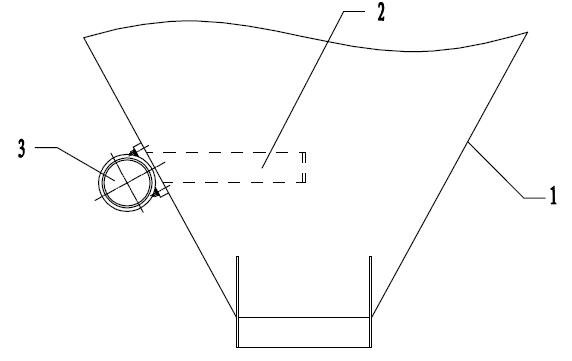

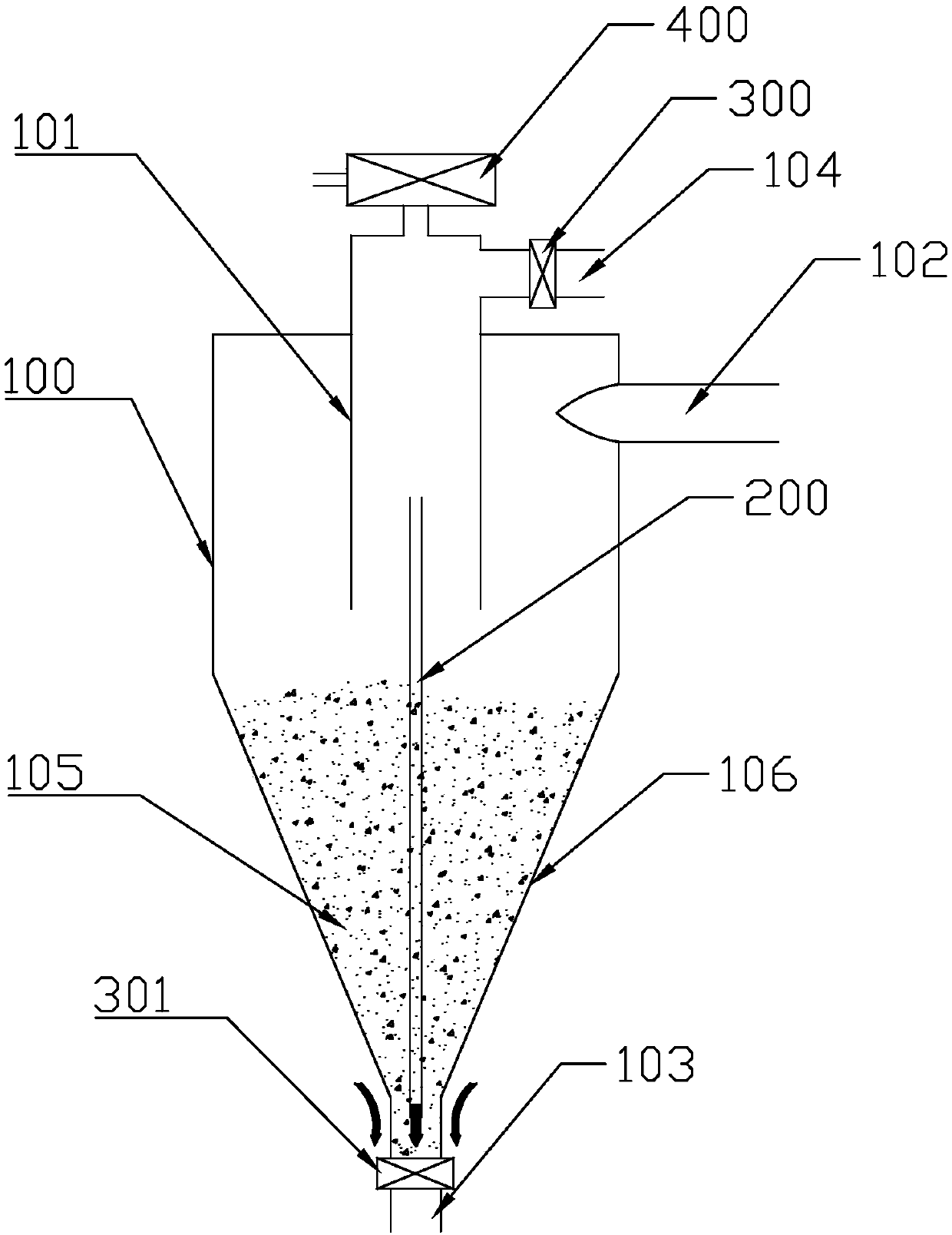

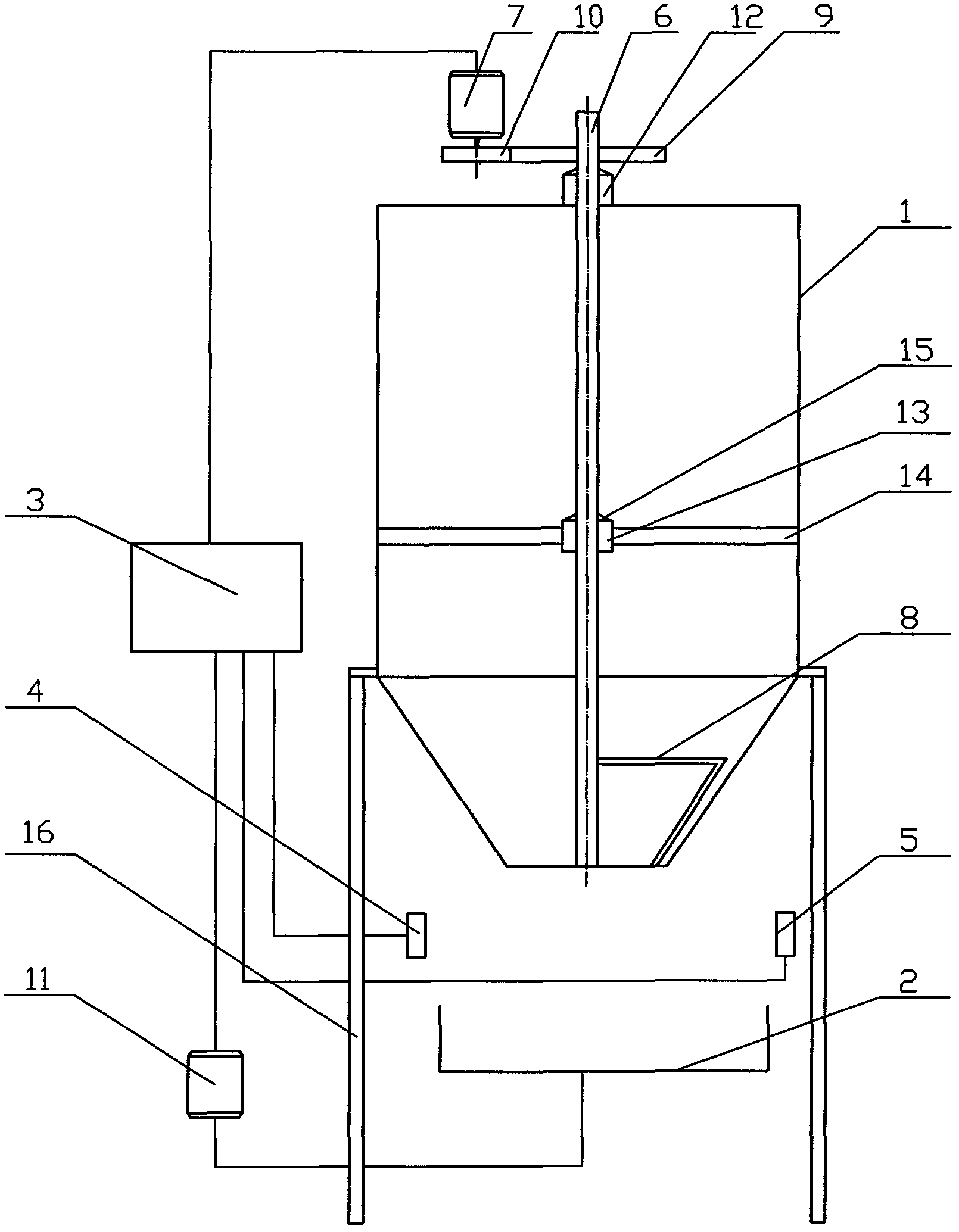

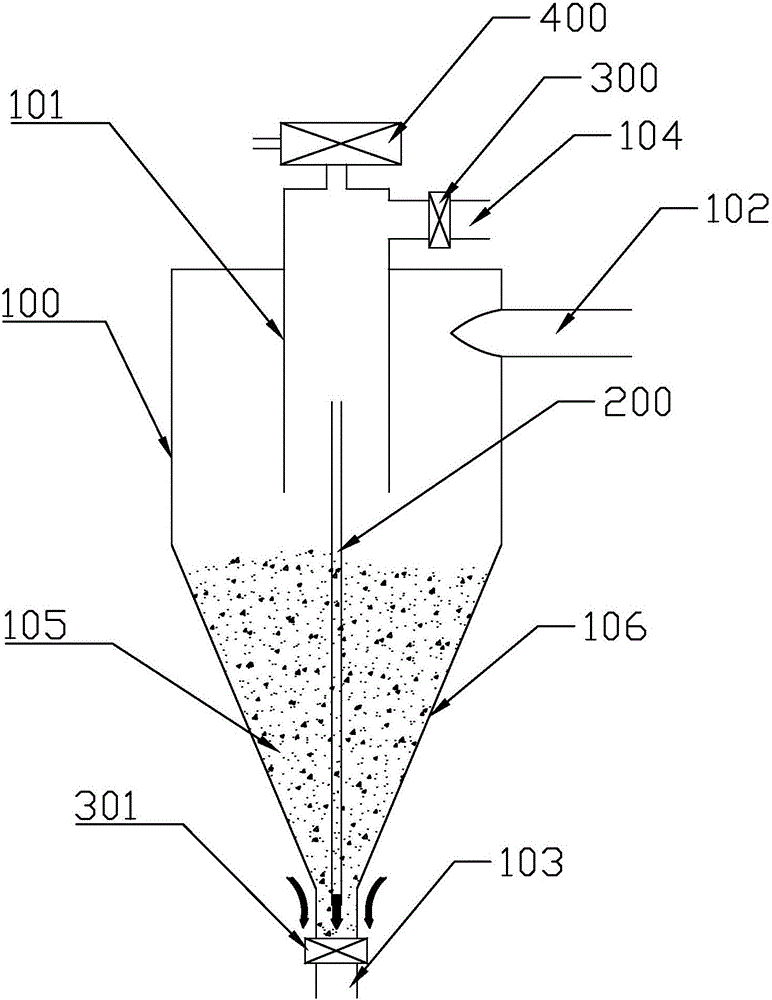

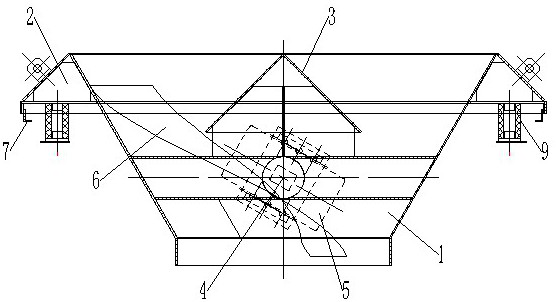

Storage bin with arch breaking device

The invention discloses a storage bin with an arch breaking device, comprising a storage bin body (1) and a material conveying mechanism (2). The upper part of the storage bin body (1) is in a cylindrical shape, and the lower part of the storage bin body (1) is in a tapered funnel shape. The material conveying mechanism (2) is arranged below the storage bin body (1), and the arch breaking device is arranged on the storage bin body (1). The storage bin with the arch breaking device also comprises a controller (3) and an infrared inductor, wherein the infrared inductor is electrically connected with the controller (3). The infrared inductor comprises an infrared transmitter (4) and an infrared receiver (5), wherein the infrared transmitter (4) and the infrared receiver (5) are respectively arranged between the storage bin body (1) and the material conveying mechanism (2), and are respectively distributed at two sides of a lower outlet of the storage bin body (1). By adopting the storage bin with the arch breaking device, whether blocking and arch forming in the storage bin occurs or not can be automatically judged, whether the arch breaking device is started to work or not can be judged according to the arch forming condition, and furthermore, relatively uniform conveying of material can be achieved.

Owner:CHINA JILIANG UNIV

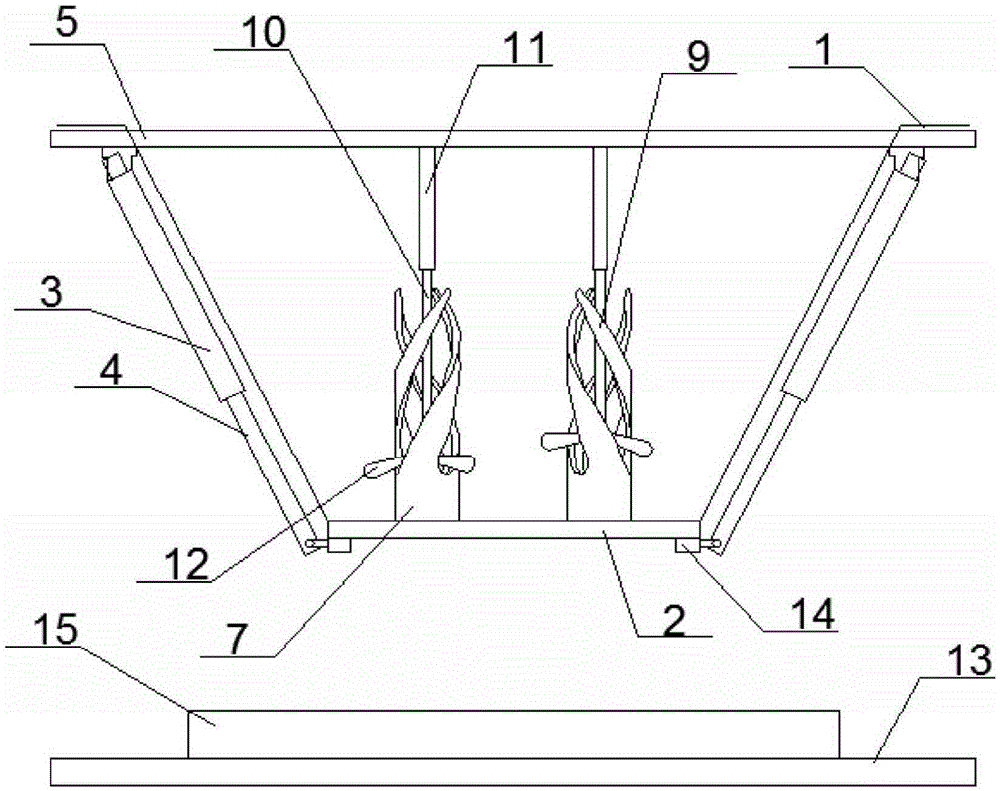

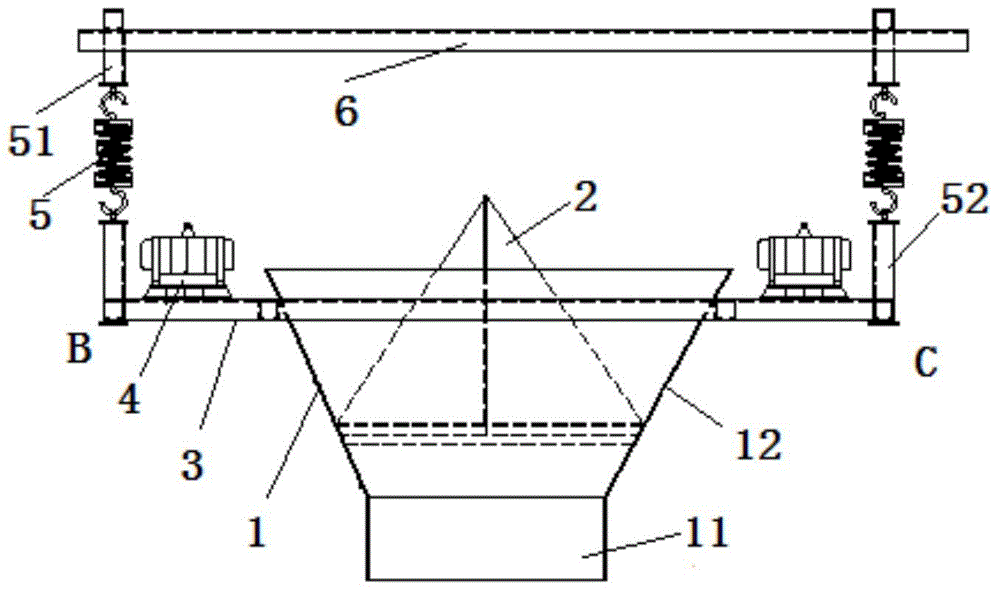

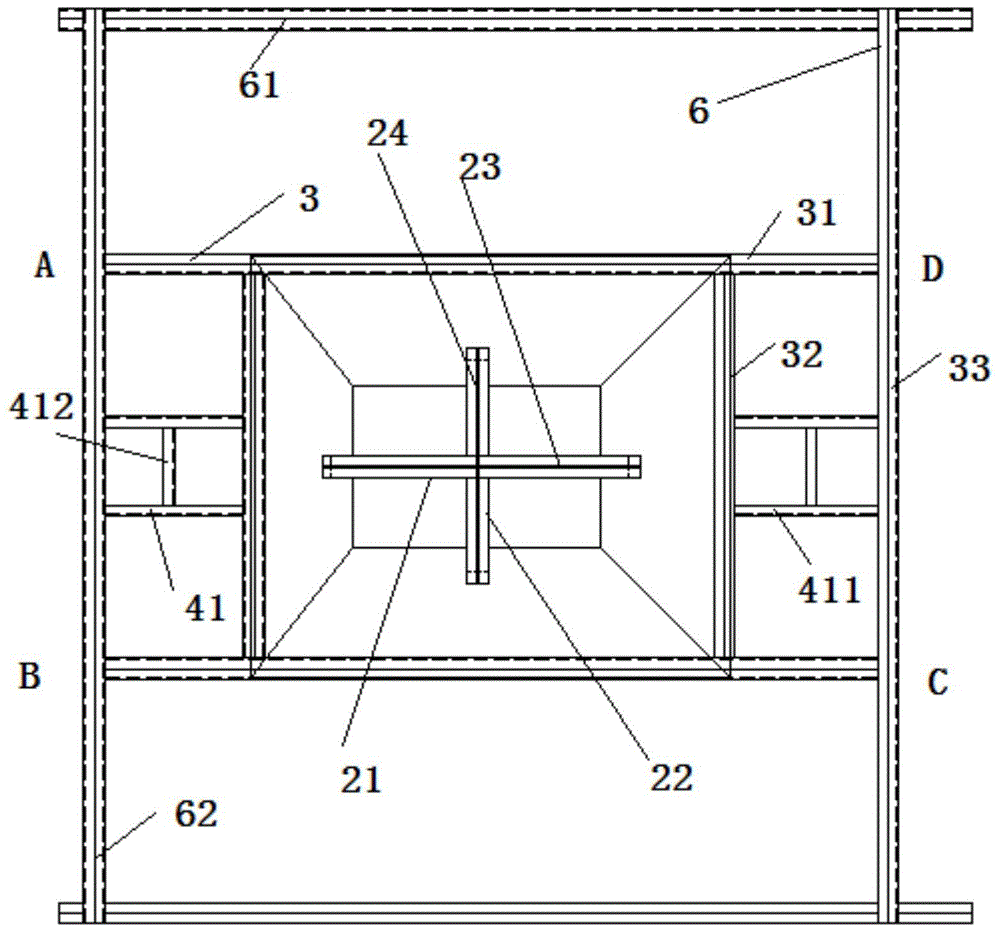

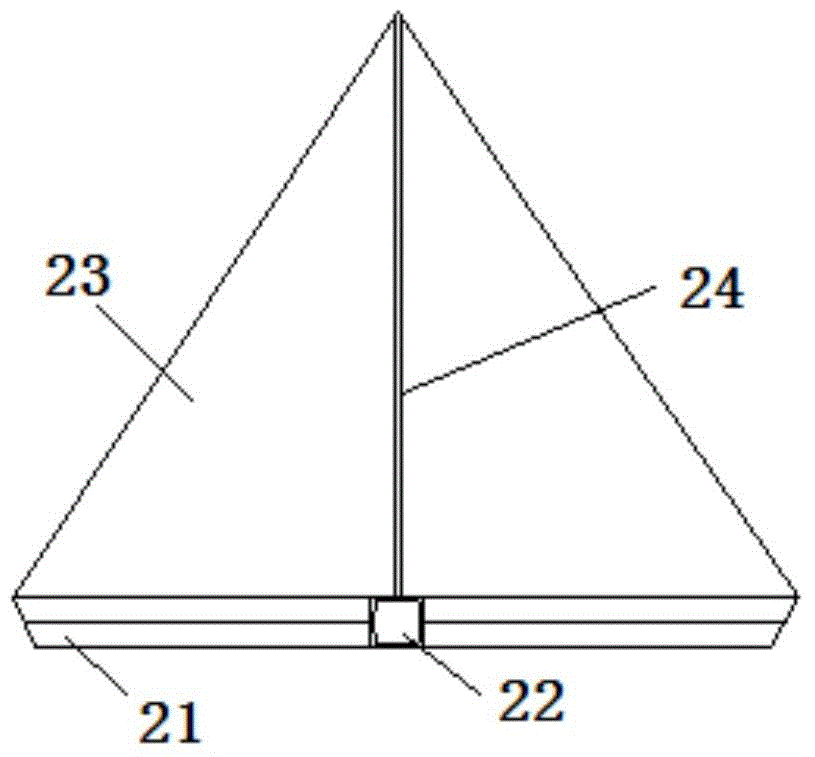

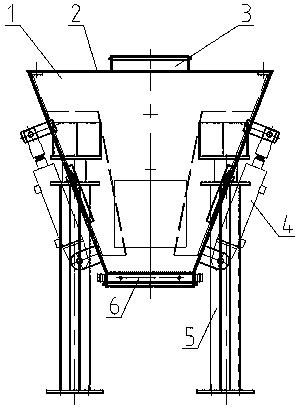

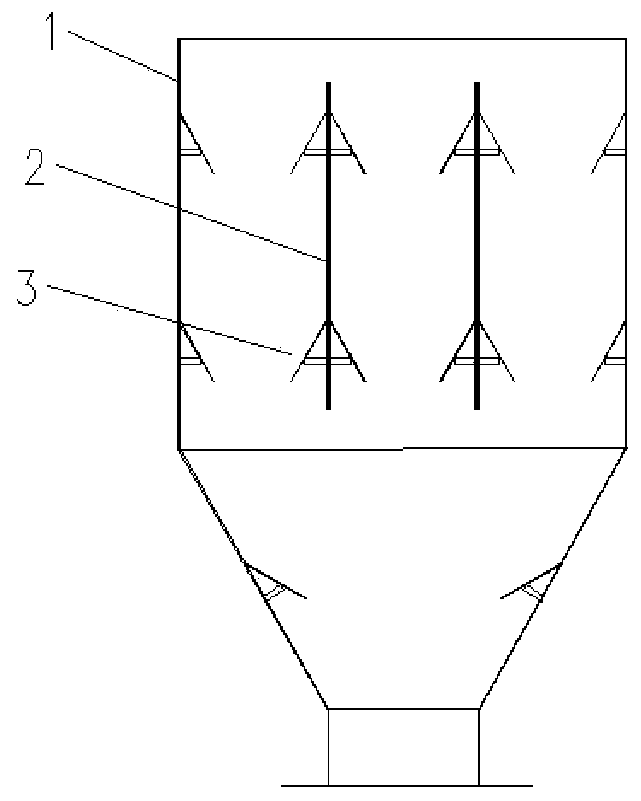

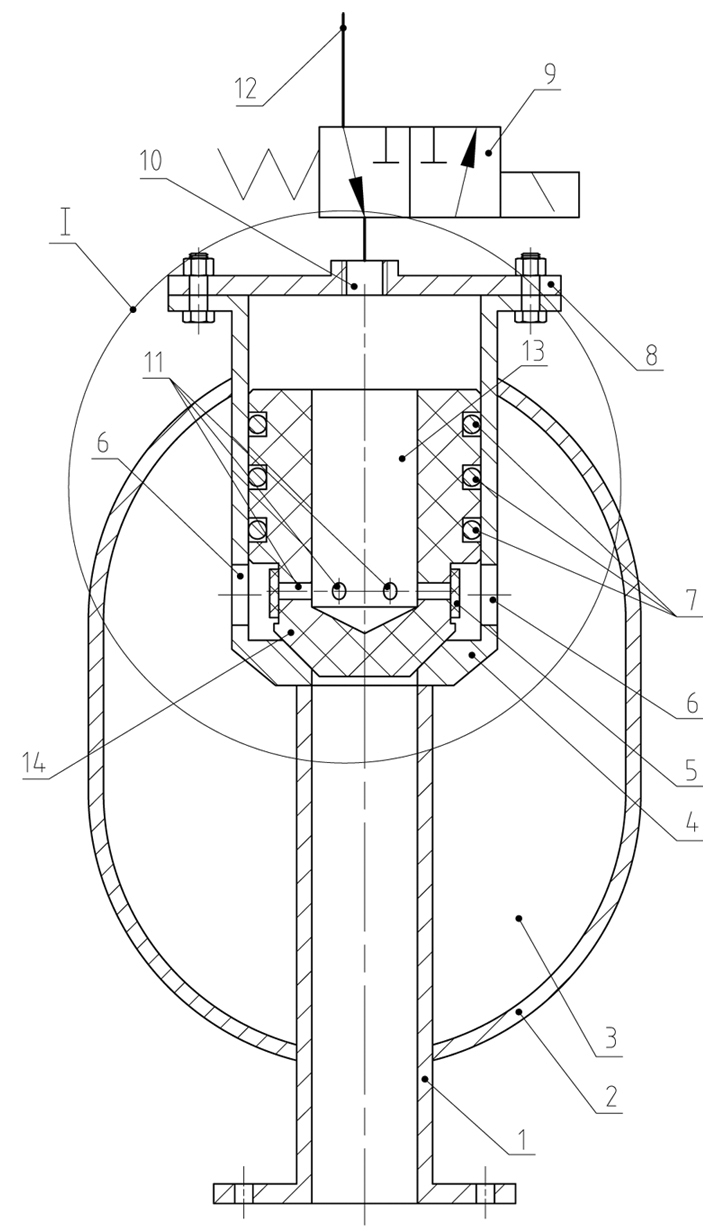

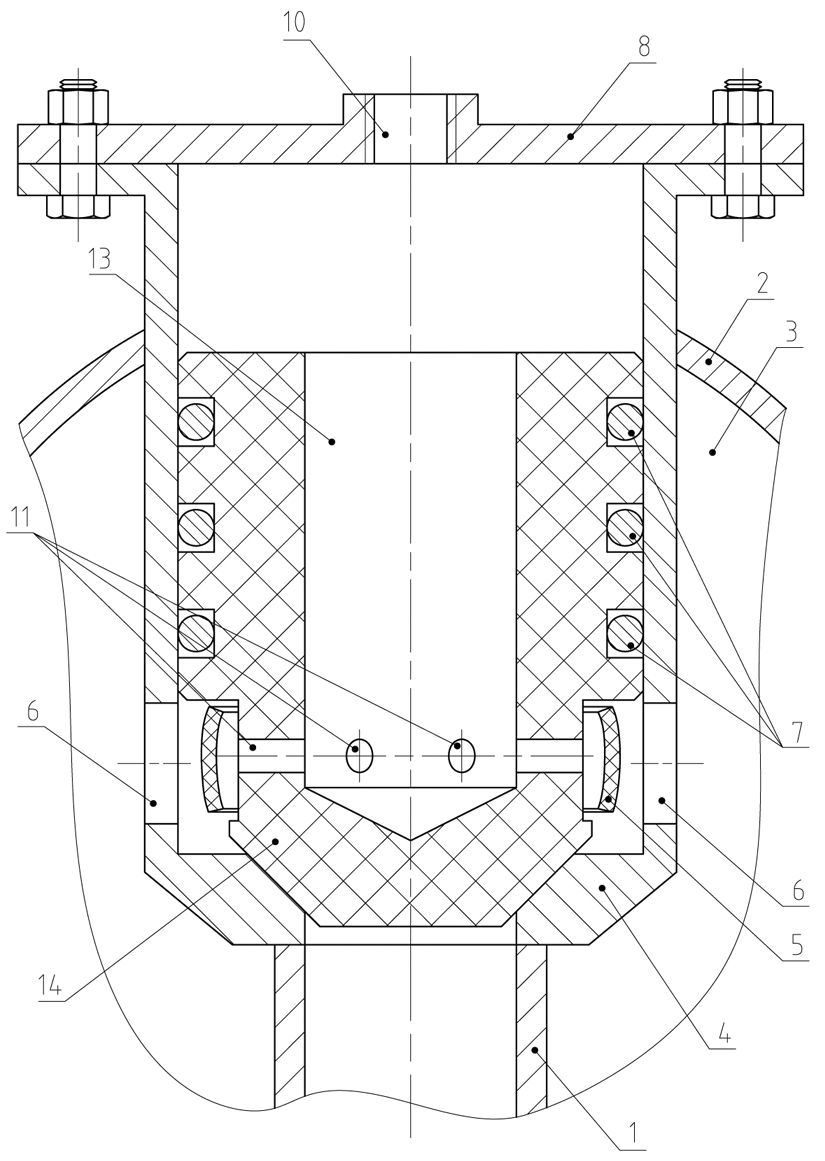

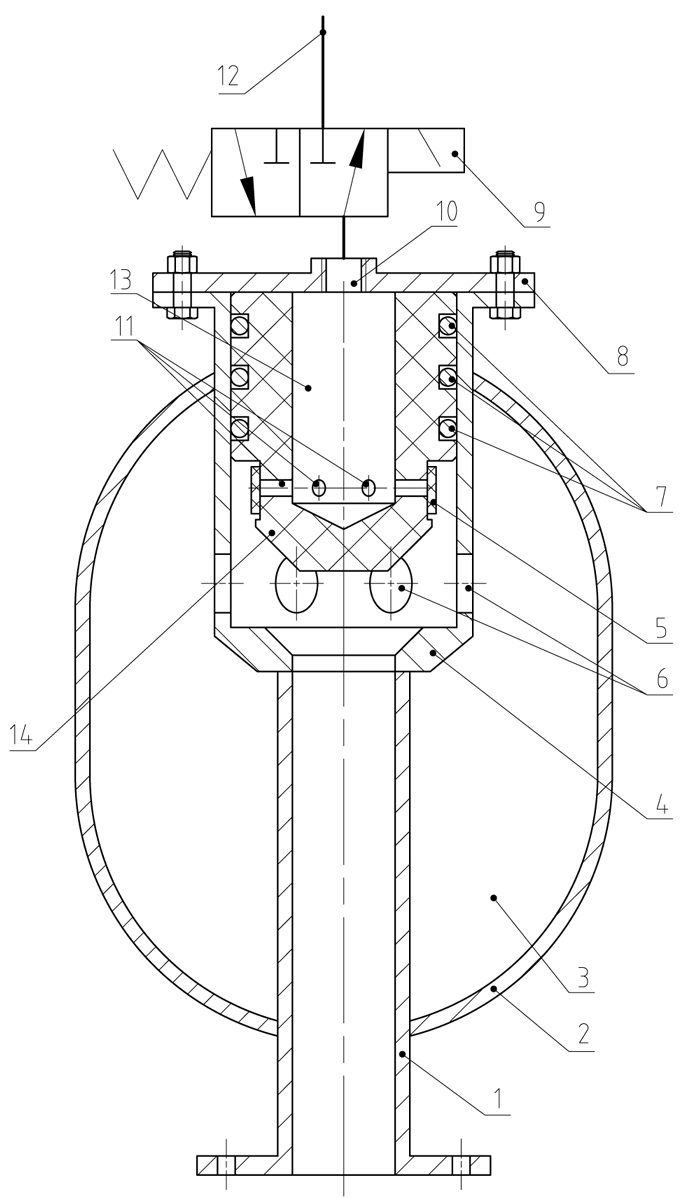

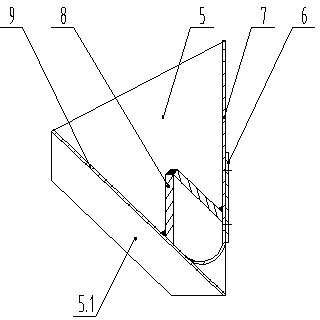

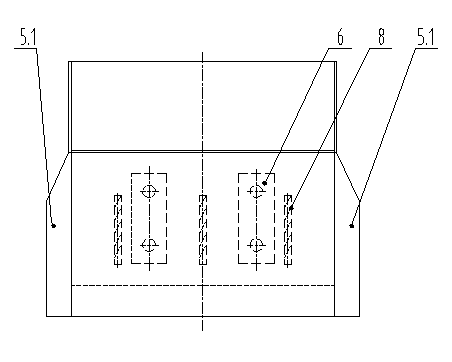

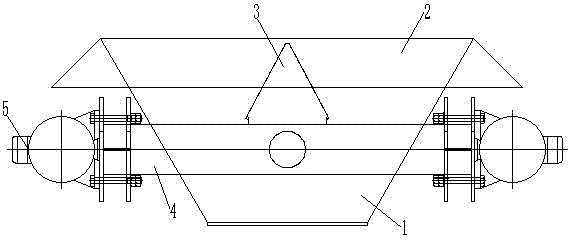

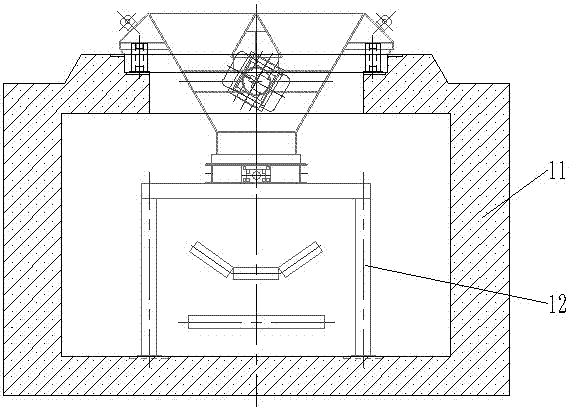

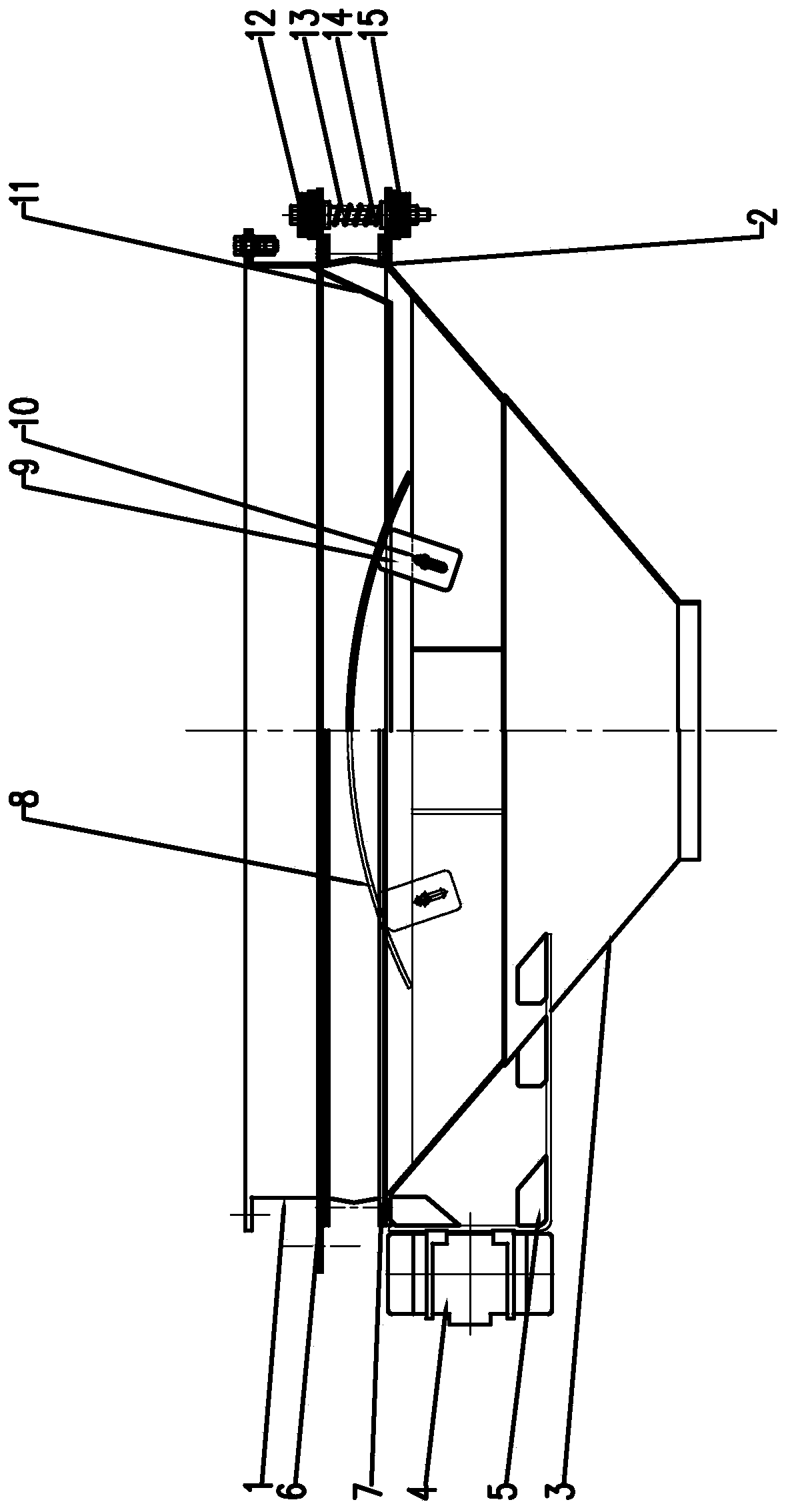

Vibration arch breaking device and using method thereof

ActiveCN104828410AEasy installationEasy to operateLarge containersStructural engineeringVibration motor

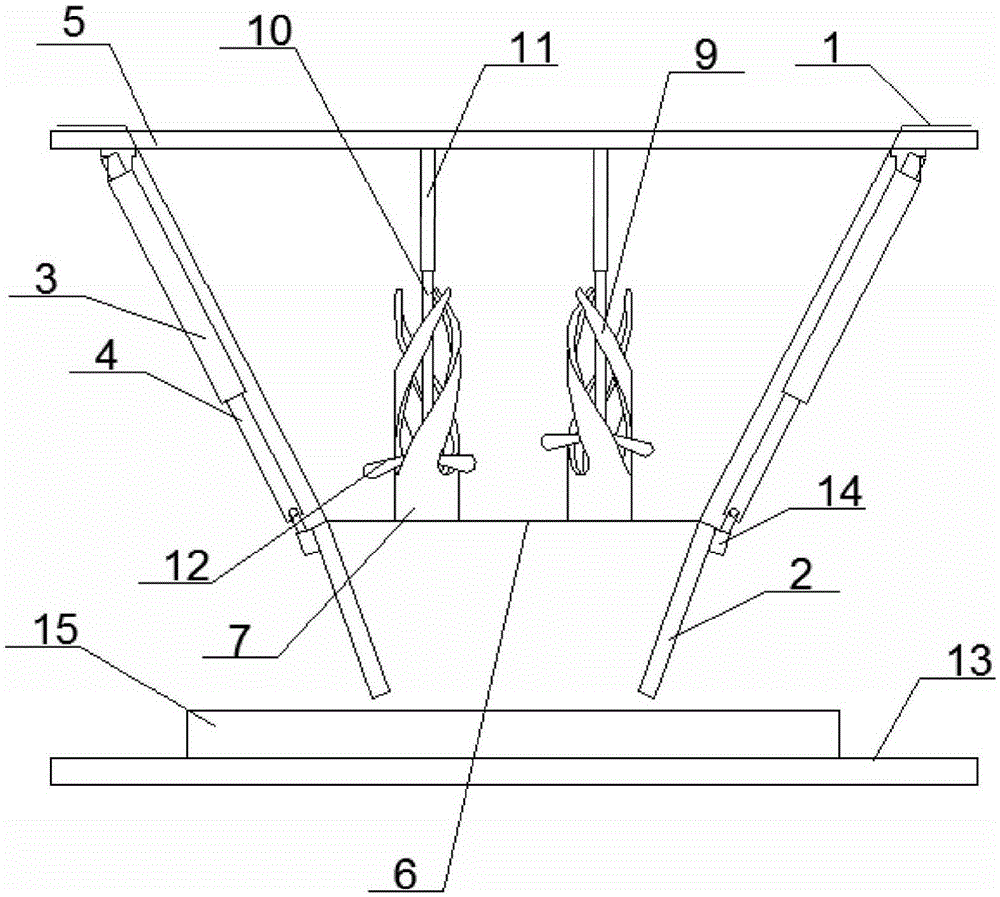

The invention discloses a vibration arch breaking device and a using method thereof, and belongs to the field of port and pier bulk cargo loading and unloading. The vibration arch breaking device comprises an arch breaking hopper, a vibration motor and a spring and further comprises an arch breaking structure and a frame structure. The arch breaking hopper comprises a hopper body and a hopper outlet. The hopper outlet is formed in the bottom of the hopper body, the arch breaking structure is arranged inside the hopper body, the upper end of the arch breaking structure is located in a bulk cargo hopper, the top end outside the hopper body is connected with the frame structure, the vibration motor is installed on the frame structure, the frame structure is connected with a fixing frame through the spring, the arch breaking structure is composed of a supporting rod I, supporting rods II, a triangular plate I and a triangular plate II, and the supporting rods II are perpendicularly welded to the two sides of the middle point in the length direction of the supporting rod I respectively. The problem of arching and blocking caused by viscous cargos is solved, and maintenance and replacement are convenient due to the combined structure.

Owner:马鞍山港口(集团)有限责任公司

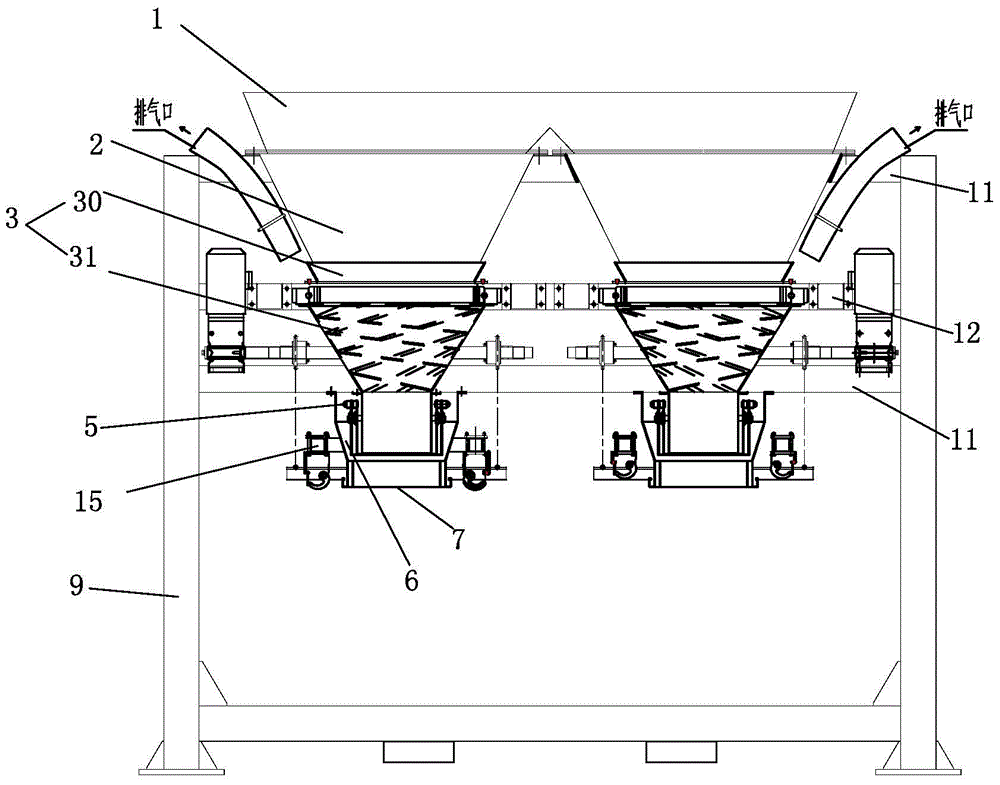

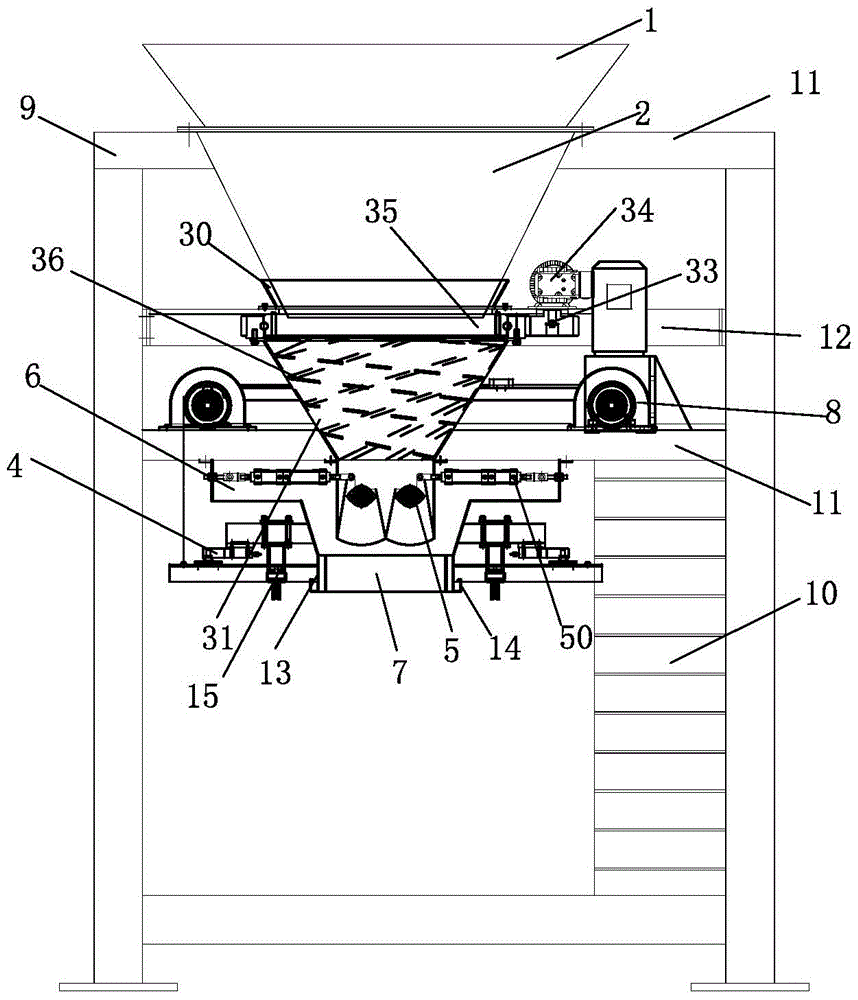

Material arch breaking system, arch breaking method and discharging bin with material arch breaking system

PendingCN108839965AGood arch breaking effectReduce energy consumptionLarge containersEngineeringEnergy consumption

The invention provides a material arch breaking system. The material arch breaking system comprises a plurality of vibrators, at least one level meter, a plurality of material level switches and a controller; the plurality of sets of vibrators are divided into a plurality of groups, the plurality of sets of vibrators are distributed at intervals in the height direction of a material bin, and eachset of vibrators is arranged at intervals around the periphery of the material bin; the material level meter is arranged on the material bin and used for detecting the height of the material level inthe material bin; the material level switches are used for being arranged on the material bin, the plurality of material level switches are divided into a plurality of groups by corresponding to a plurality of sets of vibrators, each set of the material level switches is located below the corresponding group of vibrators or in the same plane as the corresponding group of vibrators, and is used fordetecting the height of the material in the material bin, and materials do not exist in the empty height range; and the material level switches and the vibrators are connected with the controller. According to the material arch breaking system, the arch breaking can be performed for the arch position, the arch breaking effect is good, and the energy consumption can be reduced. The invention further provides an arch breaking method of the material arch breaking system and a discharging bin with the material arch breaking system.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

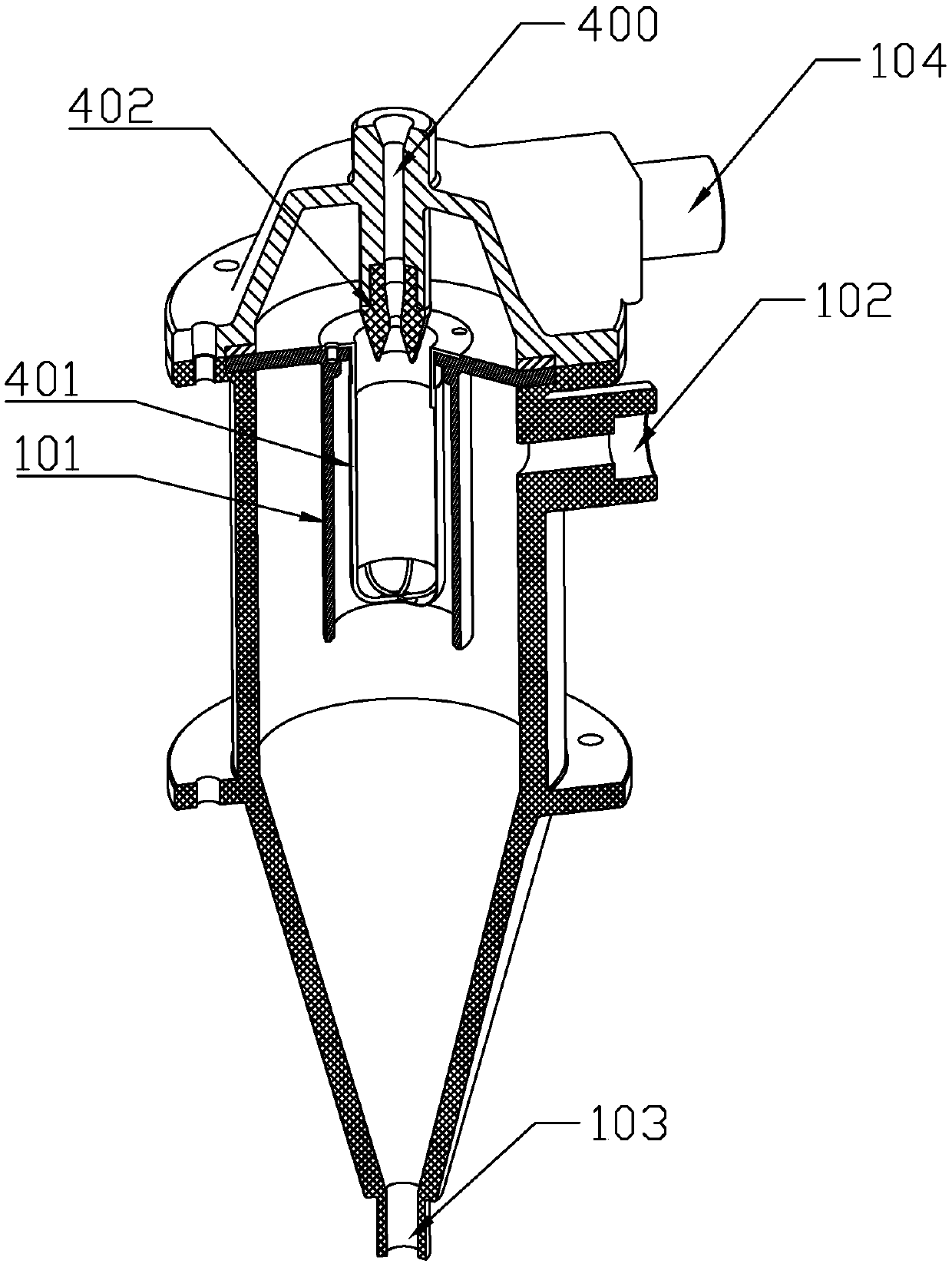

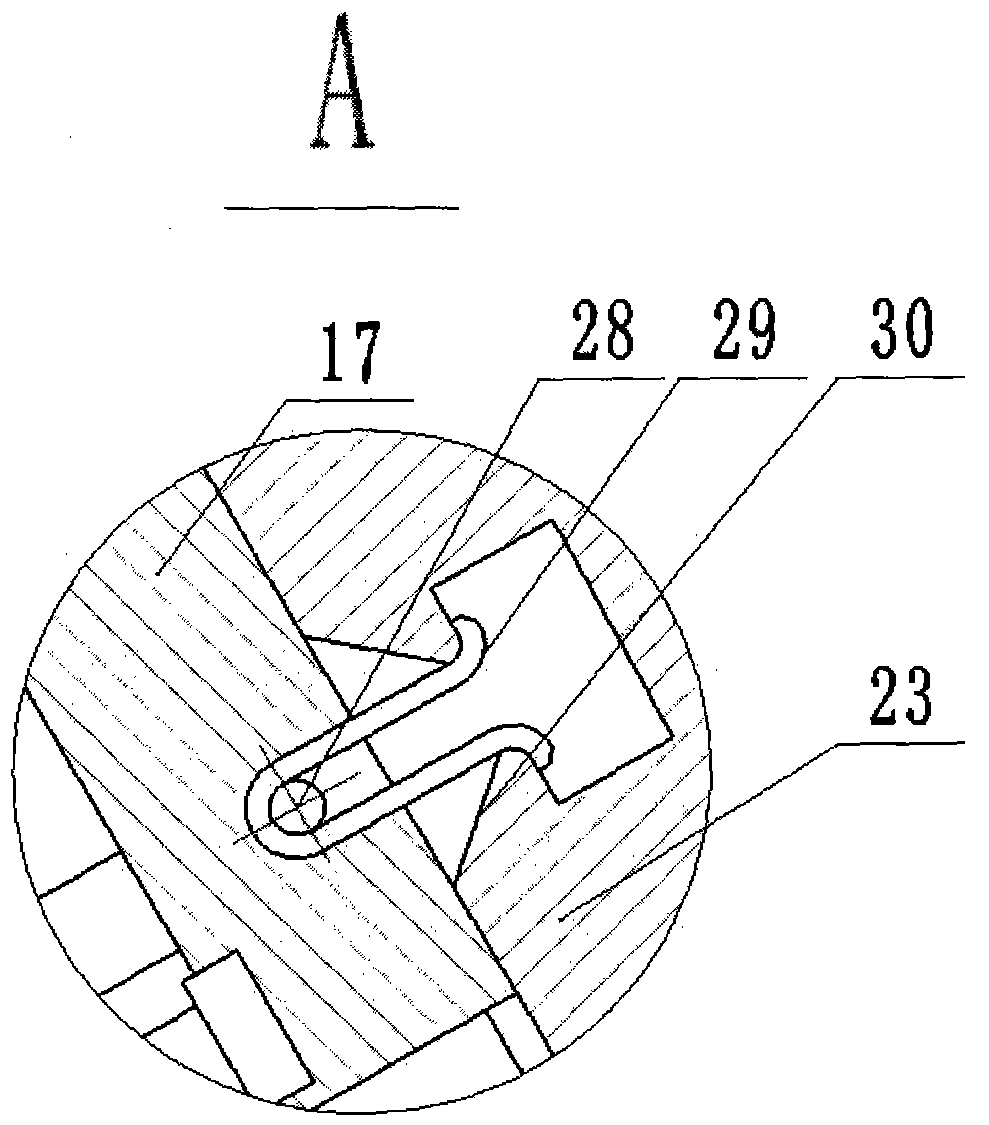

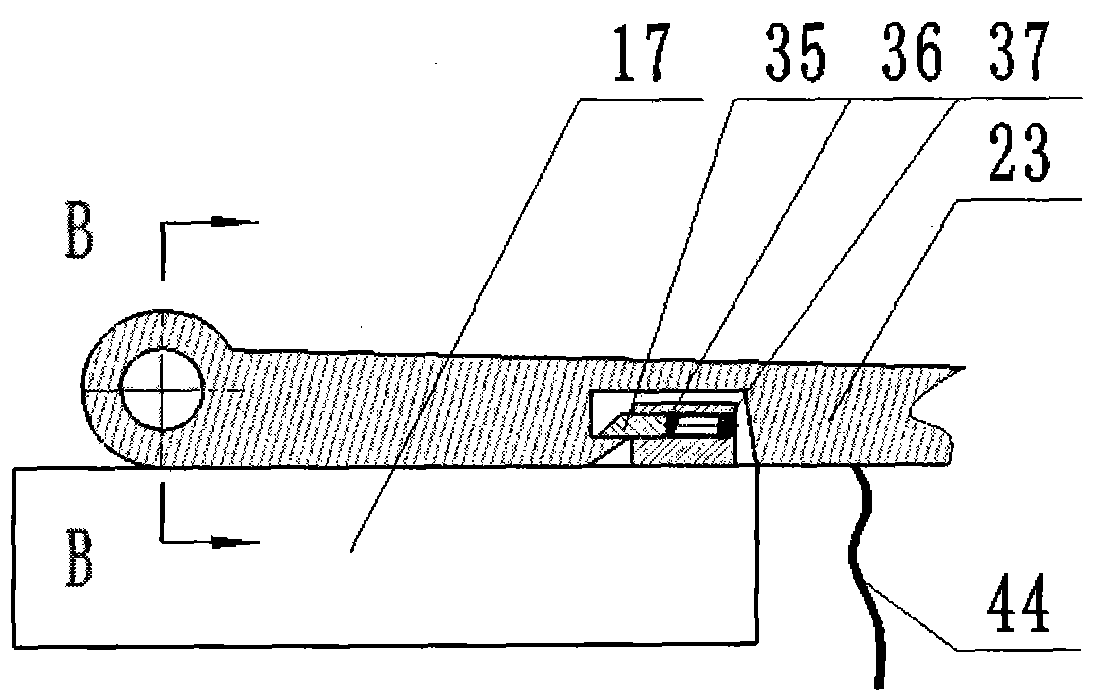

Rotary direct-driving arch breaking device

ActiveCN104555153ACompact structureEasy to install on siteLarge containersOperation safetyOperations security

The invention relates to a rotary direct-driving arch breaking device, belonging to the field of material conveying. A lengthening rod is arranged at the end part of the arch breaking device, and meanwhile, the lengthening rod rotates under the driving of a rotary driving device. Compared with an arch breaking range that the diameter of an arch breaking sleeve per se reaches, the arch breaking range of the rotary direct-driving arch breaking device disclosed by the invention is greatly expanded. Moreover, the rotary direct-driving arch breaking device is compact in structure, the quantity of assembling parts in a field installing process is greatly reduced and thus the field installation of the arch breaking device is facilitated. Since the rotary driving device drives a rotary cover and the lengthening rod to rotate through a rotating shaft in a process of rotary arch breaking and fewer rotating components are used, extra rotary friction resistance caused hereby is greatly reduced, the action force of rotary arch breaking can be sufficiently exerted and the arch breaking effect is improved. According to the arch breaking device disclosed by the invention, a stock bin does not need to be cleared in an assembling and disassembling process, operating personnel are unnecessary to enter the stock bin, and thus the operation safety is improved.

Owner:河南辉强机械设备有限公司

Hopper arch breaking device for materials sensitive to friction and impact

The invention discloses a hopper arch breaking device for materials sensitive to friction and impact and belongs to the field of solid material feeding. The hopper arch breaking device is suitable for the process of feeding solid materials sensitive to friction and impact and uses a conductive polymeric material as a material for making a hopper; an arch breaking shaft drives an arch breaking wheel to rotate along the axial direction of the arch breaking shaft when rotating around the direction of the symmetry axis of the hopper, so that elastic deformation is sequentially generated at different positions on the wall of the hopper, flowing of the materials in the hopper is prompted and the arching phenomenon of the materials in the hopper is eliminated. Due to no contact between the arch breaking wheel and the materials, friction and impact to the materials cannot be generated, so that safety of the feeding process is effectively ensured. The hopper arch breaking device has the advantages of high safety, good arch breaking effect, flexible use mode and the like.

Owner:XIAN MODERN CHEM RES INST

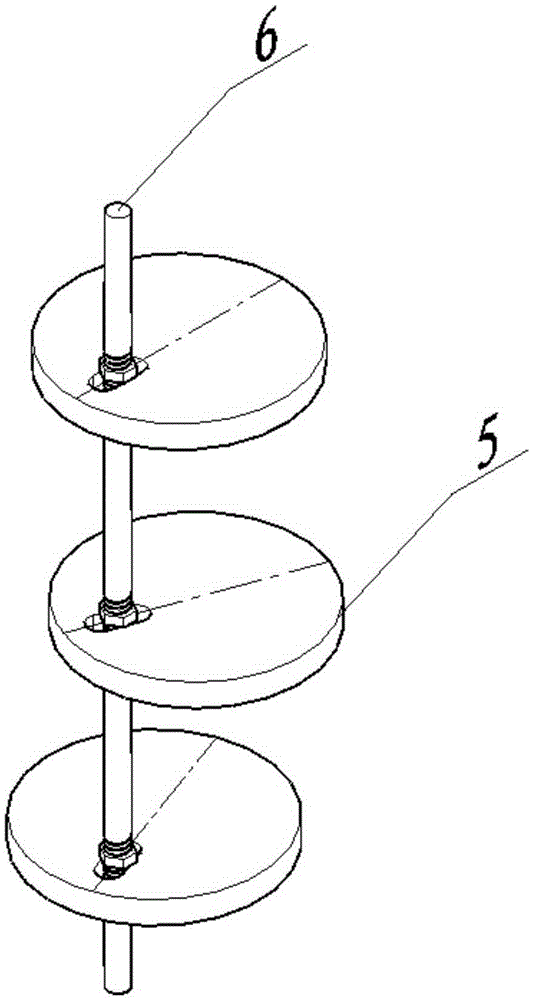

Device for solving powder material coking arch

InactiveCN109353704AImprove arch breaking effectGood for arch breakingLarge containersDevice PlateEngineering

The invention discloses a device for solving powder material coking arch. The device comprises a material bin, shaking devices and a driving motor, wherein the bottom end of the material bin is provided with a material outlet, the shaking devices are arranged on the edge sides of the material bin, the top of the material bin is provided with device plates horizontally distributed, the inner wall of the top end of the material bin is provided with horizontal plates horizontally distributed in a welded manner, the driving motor is installed on the upper end faces of the device plates and connected with a rotating shaft, round plates connected with the rotating shaft are arranged above the device plates, and every two adjacent round plates are connected through horizontal rods. According to the device for solving the powder material coking arch, by means of redesign on the top structure of an existing material bin, arch breaking operations on middle-lower portion materials inside the material bin are facilitated, by means of use of the shaking devices and related structures, the use of a traditional fluidization device is replaced, the bottom arch breaking effect of the material bin can be made to be better, and meanwhile, the material unloading process is made to be more unobstructed.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

Lime bin capable of stably discharging

InactiveCN109484774ASimple structureImprove arch breaking effectLarge containersReciprocating motionEngineering physics

The invention discloses a lime bin capable of stably discharging. The lime bin comprises a bin body; two broken arch plates are symmetrically arranged on the inner wall surface of the bin body; the broken arch plates are bonded with the inner wall surface of the bin body, and can perform a reciprocating motion along the inner surface of the bin body; and the broken arch plates are driven by brokenarch push rods. The upper ends of the broken arch plates are fixedly connected with broken arch plate brackets; the broken arch plate brackets penetrate through the bin wall of the bin body to hingewith one ends of the broken arch push rods; and the other ends of the broken arch push rods are hinged to the bin body through broken arch push rod brackets. Two broken arch plate guide blocks are fixedly connected to the bin body; each broken arch guide block corresponds to one broken arch plate; and the broken arch plate guide blocks are slidingly positioned in broken arch plate guide grooves ofthe corresponding broken arch plates. Openings of the broken arch plate guide grooves are towards the bin wall of the bin. The lime bin capable of stably discharging has the advantages of simple structure, good arch breaking effect and stable discharge, and in particular, is suitable for bulk or powder material bins.

Owner:JINGSU HUALIANG MACHINERY

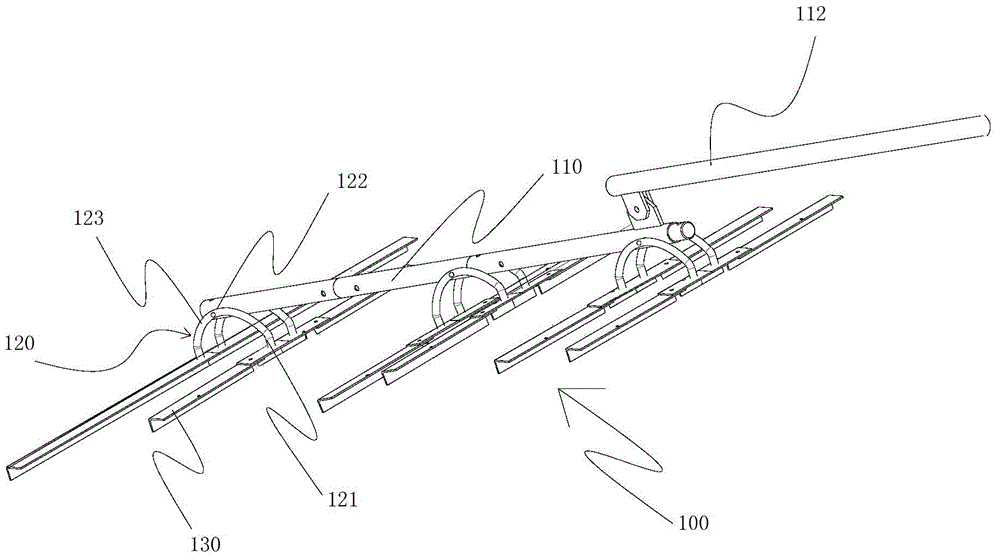

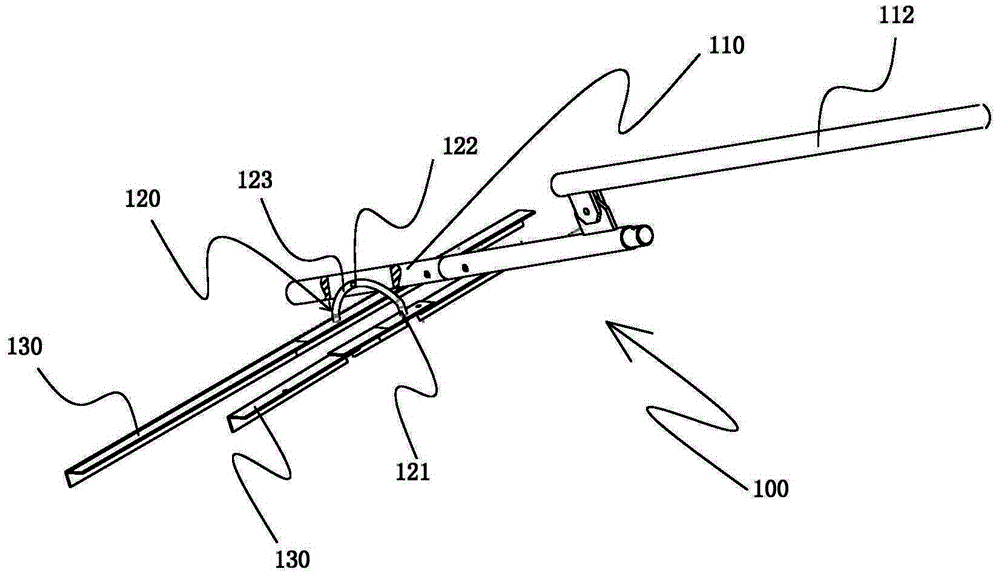

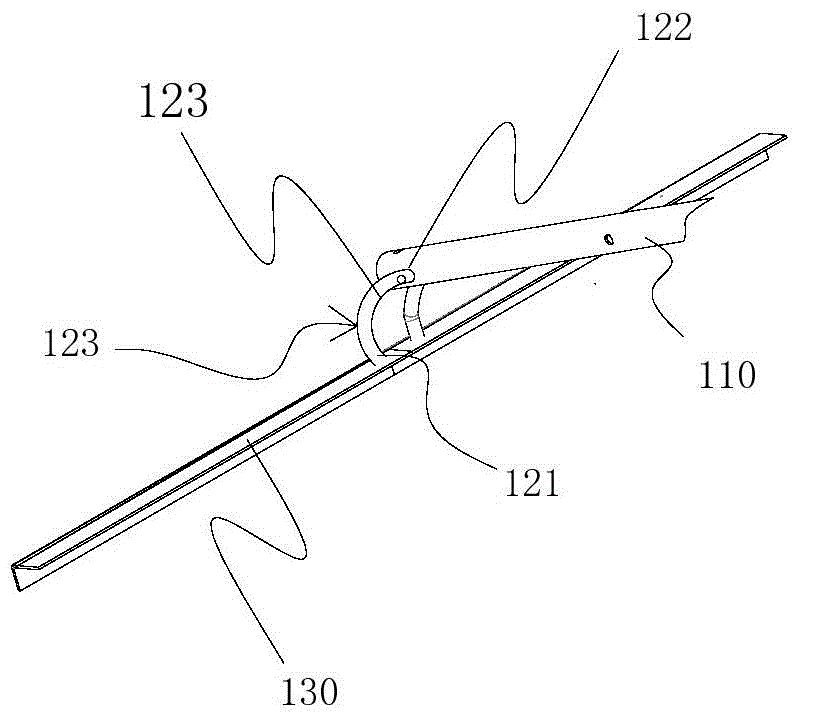

Arch breaking unit and stock bin

InactiveCN104816894APrevent rigid breakageReduce loss rateLarge containersReciprocating motionEngineering

An arch-breaking unit (100) comprising a connecting rod (110) actuated into a reciprocating movement by an actuating mechanism (112). The connecting rod (110) is connected along the axial direction to one or more connecting elements (120). The connecting elements (120) are pivotally connected to the connecting rod (110). Material-paddling arms (130) are connected to at least one cantilever end (121) of the connecting elements (120). The material-paddling arms (130) are arranged at an angle with the connecting rod (120). When the connecting rod (120) is moving in the axial direction, under the effect of an arching resistance, the cantilever ends (121) of the connecting elements (120) connected to the material-paddling arms (130) generate an angular displacement relative to where the connecting elements (120) and the connecting rod (110) are pivotally connected, thus regulating an arch-breaking resistance exerted on the material-paddling arms (130). The arch-breaking unit increases the freedom of movement of the material-paddling arms, reduces the rate of wear, and extends service life. Also disclosed is a material chamber (300) equipped with the arch-breaking unit (100).

Owner:车战斌

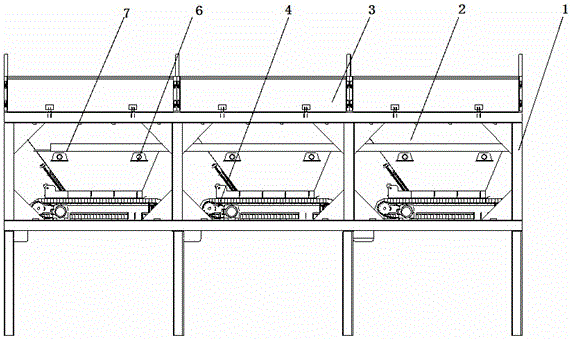

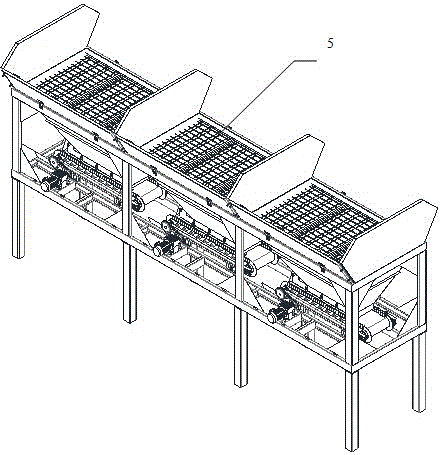

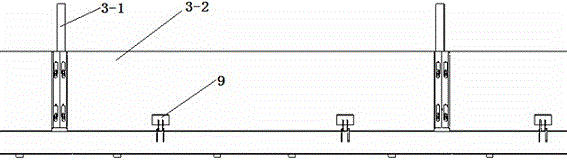

Asphalt milling and planing material distributing machine for asphalt plant mix hot recycling

InactiveCN106012764AImprove product qualityIntelligent adjustment of adding ratioRoads maintainenceEngineeringAsphalt

The invention provides an asphalt milling and planing material distributing machine for asphalt plant mix hot recycling. The asphalt milling and planing material distributing machine for asphalt plant mix hot recycling can effectively solve the problem of material blocking and is accurate in feeding and weighing. The asphalt milling and planing material distributing machine for asphalt plant mix hot recycling comprises a steel structure body, one or more storage bins, belt weighers, vibrating devices and pneumatic arch breaking devices. A material baffle is arranged at the top of the steel structure body. The storage bins are fixed to the steel structure body. Screens are installed at feeding ports of the storage bins. The belt weighers are arranged at discharging ports of the storage bins. The vibrating devices are arranged on the two sides of the storage bins respectively and located below the screens, each vibrating device comprises a vibrating motor and vibrating beams, the vibrating motors are fixed to the storage bins, and the vibrating beams penetrate through the storage bins and are connected with the vibrating motors. Each pneumatic arch breaking device comprises a main pipeline and a pneumatic arch nozzle, the main pipelines are installed on the steel structure body and located above the vibrating beams, and the pneumatic arch nozzles are arranged on the inner walls of the storage bins.

Owner:SHANDONG LUQIAO GROUP

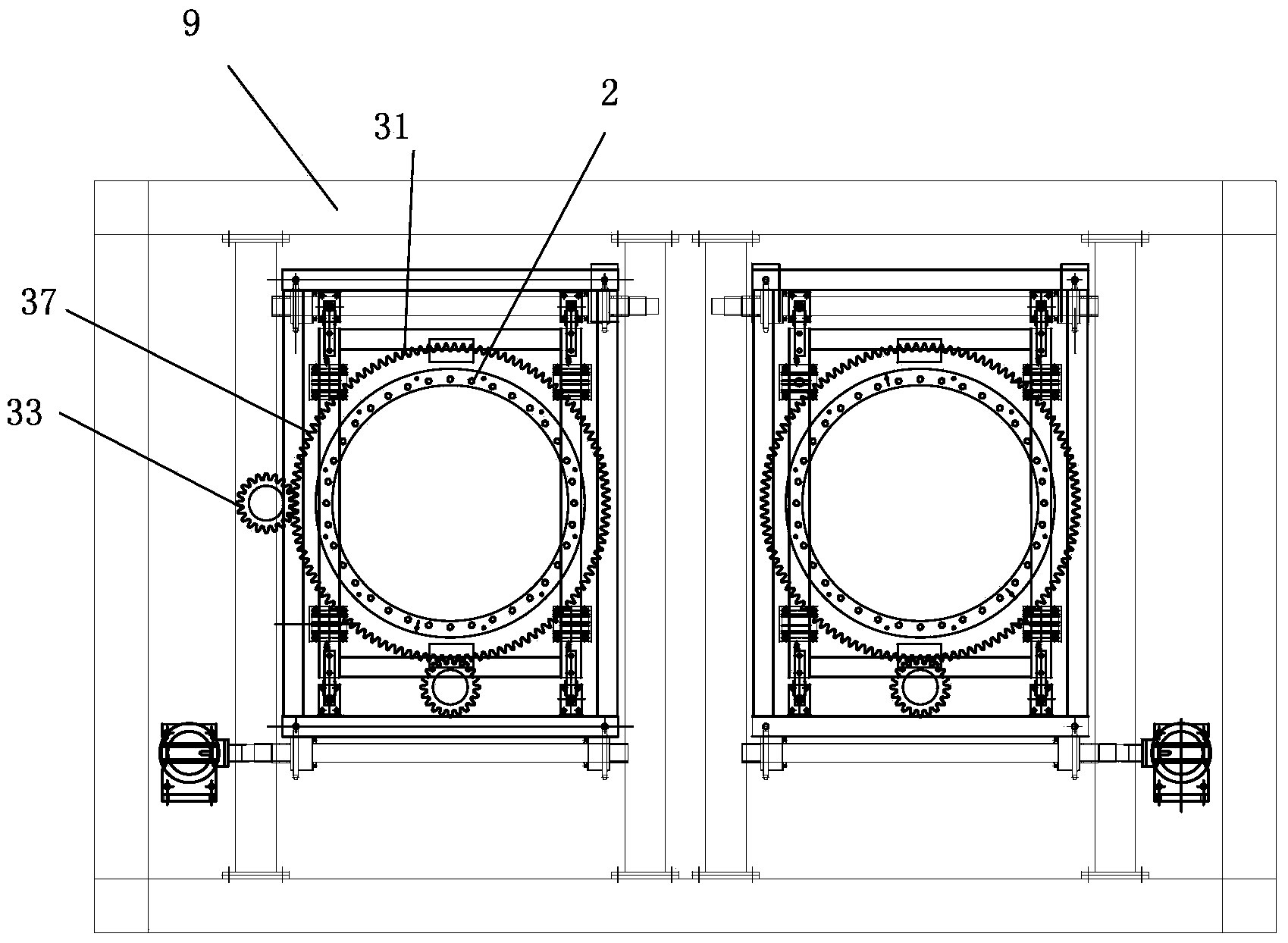

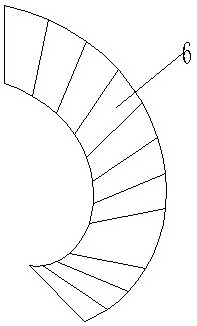

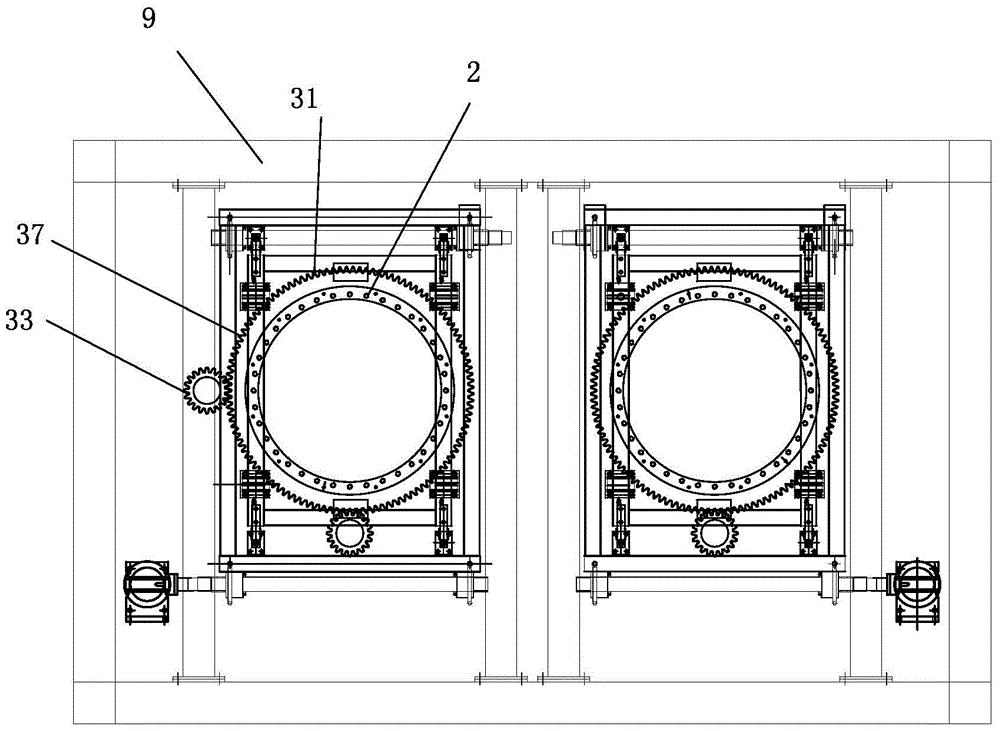

Rotary arch breaking machine

The invention relates to a rotary arch breaking machine, which comprises a support frame body, a rotary cone body, a driving device, a protecting hood, a spiral three-dimensional arch breaking cone, a motor speed reducing machine, a pinion and a gearwheel, wherein the support frame body is fixedly connected with the outer wall of the rotary cone body, the driving device comprises the motor speed reducing machine, an installation fixing flange, a driving protecting hood and a connecting element, the motor speed reducing machine is electrically connected with the pinion, the pinion is engaged with the gearwheel, the gearwheel is fixedly connected with the spiral three-dimensional arch breaking cone, the spiral three-dimensional arch breaking cone is arranged in the rotary cone body, in addition, the gearwheel is annularly arranged at the outer wall of the rotary cone body and is arranged in the protecting hood, and the protecting hood is fixedly connected with the rotary cone body. The rotary arch breaking machine can thoroughly solve the powdery material blockage problem and the blockage problem in the material discharging process of the particle materials in a conical material cabin.

Owner:洛阳广盈机械设备有限公司

Stock bin arch breaking device

PendingCN111361871AAvoid and destroy bridge arching phenomenonStrong arch breaking abilityLarge containersStructural engineeringMechanical engineering

The invention provides a stock bin arch breaking device. The stock bin arch breaking device comprises multiple arch breaking pieces arranged in a bin body in a staggered mode, wherein the arch breaking pieces comprise hinge pieces arranged on the inners wall of contact plates and capable of rotating relative to the inner wall of the bin body; and the arch breaking pieces further comprise vibrationplates connected with the hinge pieces and capable of rotating relative to the inner walls of the contact plates, wherein clamping openings gradually shrinking from bottom to top are formed between the vibration plates and the inner walls of the contact plates, elastic assemblies are arranged in the clamping openings, one ends of the elastic assemblies are connected with the inner walls of the contact plates, and the other ends of the elastic assemblies abut against the vibration plates. According to the stock bin arch breaking device, the bridging and arching phenomena of materials in a stock bin can be effectively avoided and damaged through changing an internal structure of the stock bin, and the arch breaking capacity is high.

Owner:CHINA TIANCHEN ENG

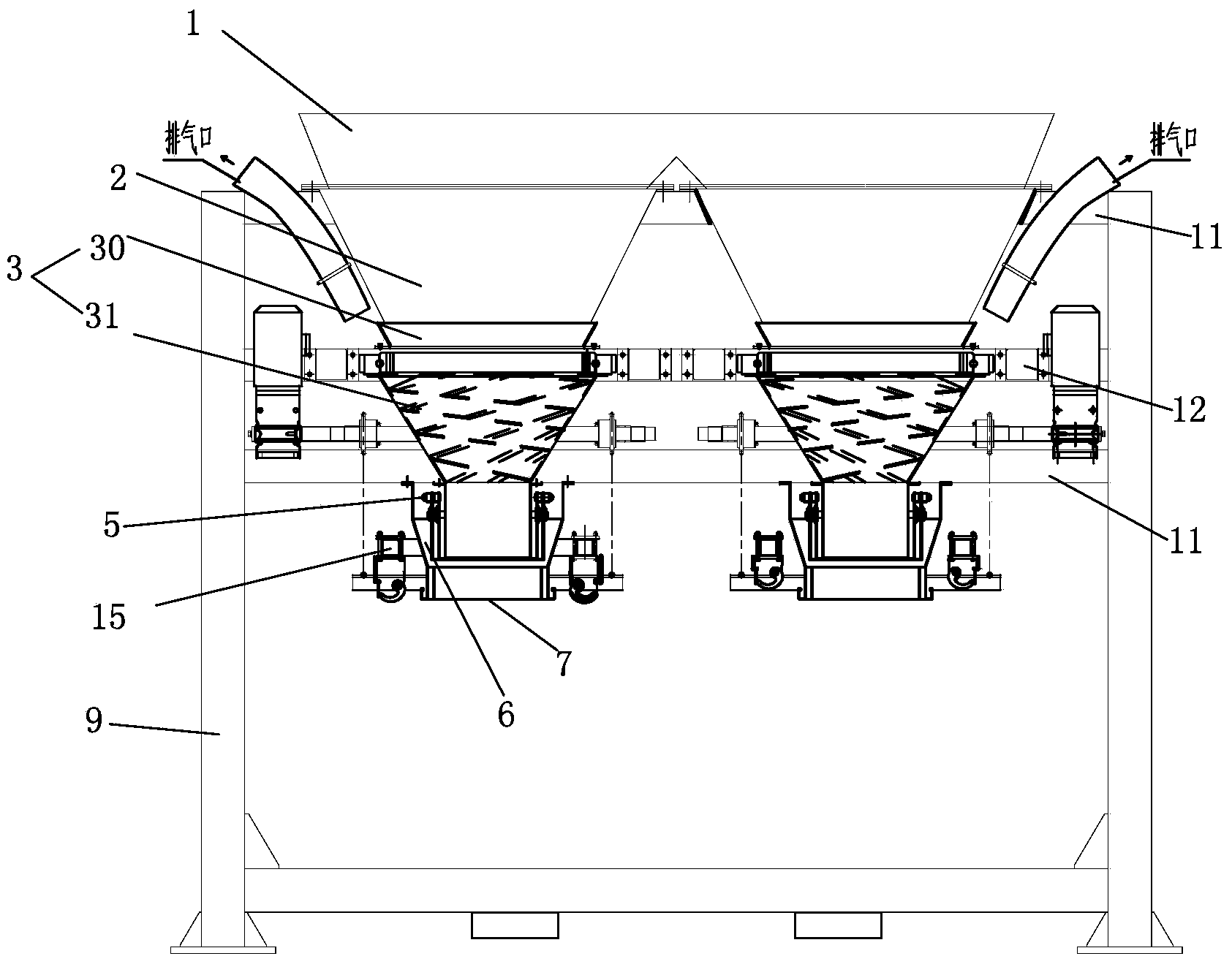

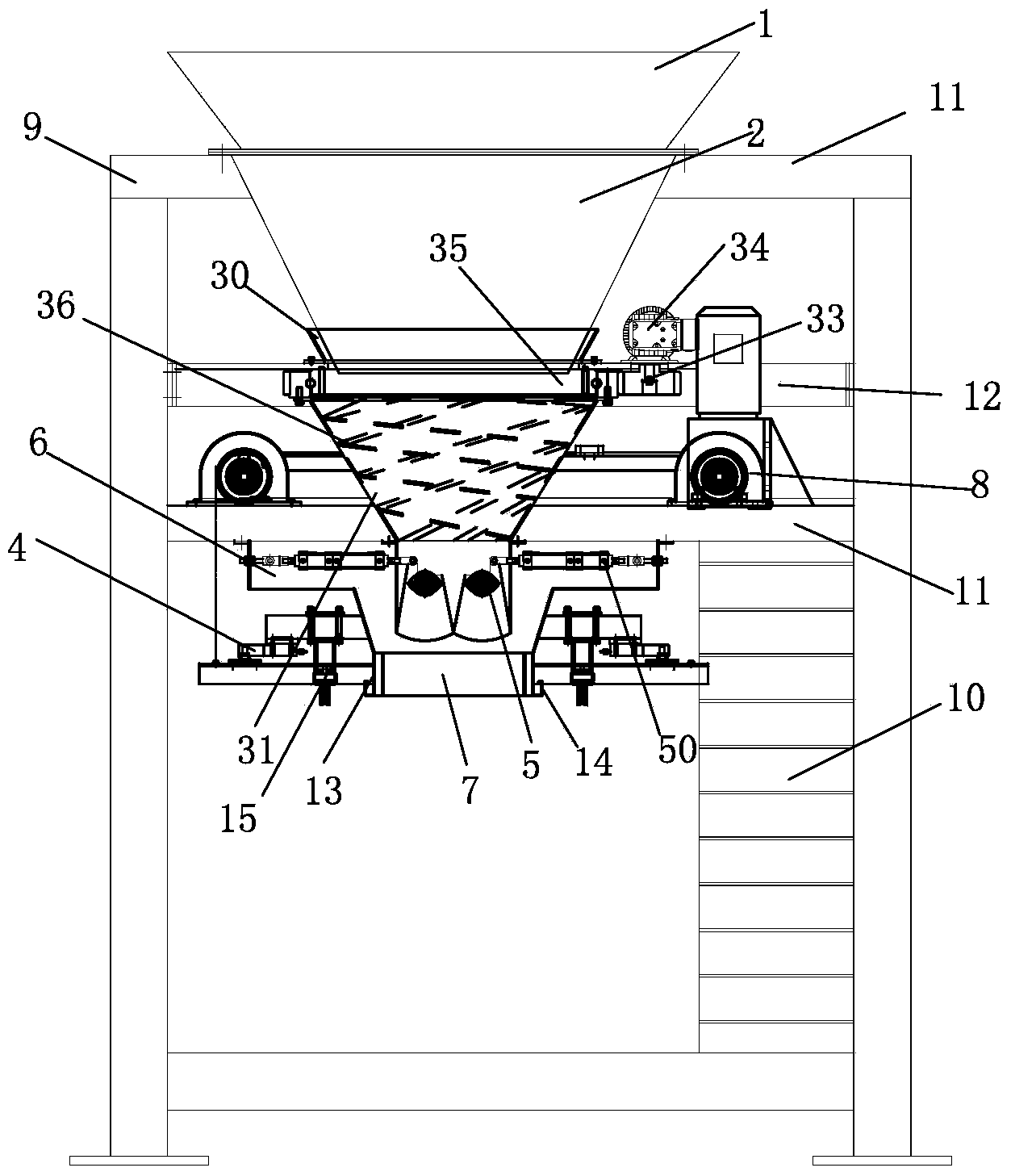

Tonnage-load bag filling equipment

ActiveCN103895978AImprove arch breaking effectAccurate measurementLarge containersEngineeringHigh pressure

The invention discloses tonnage-load bag filling equipment which comprises a frame assembly and one or more circular bins. Section steel is directly welded to form the frame assembly, the circular bins are directly arranged in the frame assembly and are conical, a funnel is fixedly arranged on the tops of the circular bins, materials can be conveniently fed into the circular bins via the funnel, gate assemblies are arranged at the bottoms of the circular bins, air fluidizing devices are arranged at the gate assemblies and the outer bottoms of the circular bins, high-pressure air can flow into the circular bins by the aid of the air fluidizing devices, and conical protective cover barrel devices are arranged at the outer bottoms of the gate assemblies. The tonnage-load bag filling equipment has the advantages that physical properties of the side walls of the bins are changed, and the tonnage-load bag filling equipment is provided with compound technological configuration for combining the physical properties of the side walls of the bins with material fluidizing by the aid of aerodynamic force, so that the materials can be uniformly discharged, and an accurate metering effect of the bag filling equipment can be guaranteed.

Owner:肖龙

Under-bin vibrating unloader

ActiveCN104843364AGuaranteed service lifeExtended service lifeLarge containersHigh archesEngineering

The invention relates to an under-bin vibrating unloader, in particular to an under-bin vibrating unloader with high arch breaking force and good sealing performance, and belongs to the field of grain machinery. The under-bin vibrating unloader comprises an upper cylinder body, a soft connection body and a lower cylinder body, a reset screw is connected between an upper connection flange and a lower connection flange and sleeved with a reset spring, and the upper end and the lower end of the reset spring are in contact with the upper connection flange and the lower connection flange respectively. A depressurization cylinder is arranged at the lower end of the inner side of the upper cylinder body and located on the inner side of the soft connection body. The inner side wall of the lower cylinder body is connected with an arc breaking support, and an arc breaking disk is arranged on the arc breaking support.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

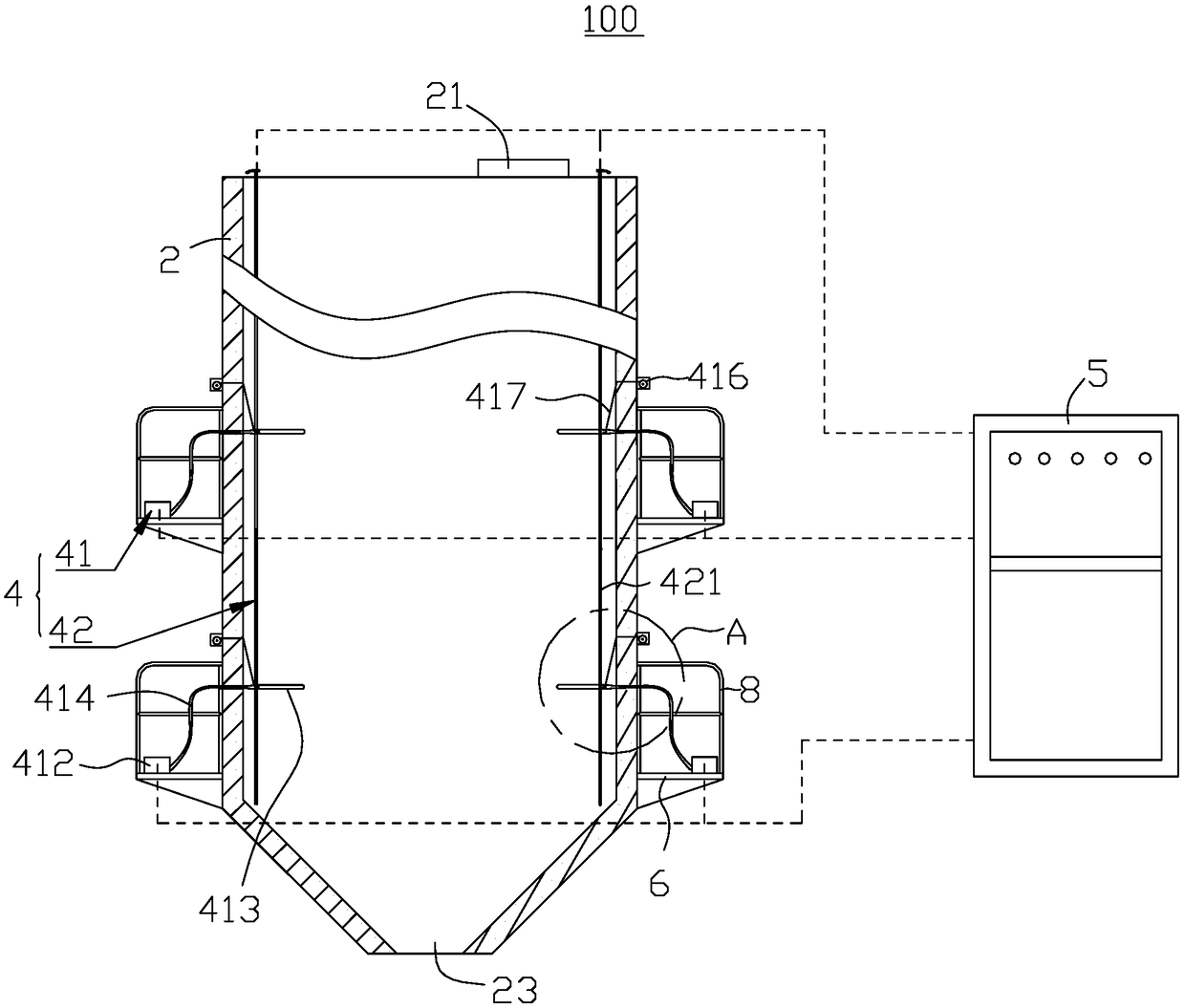

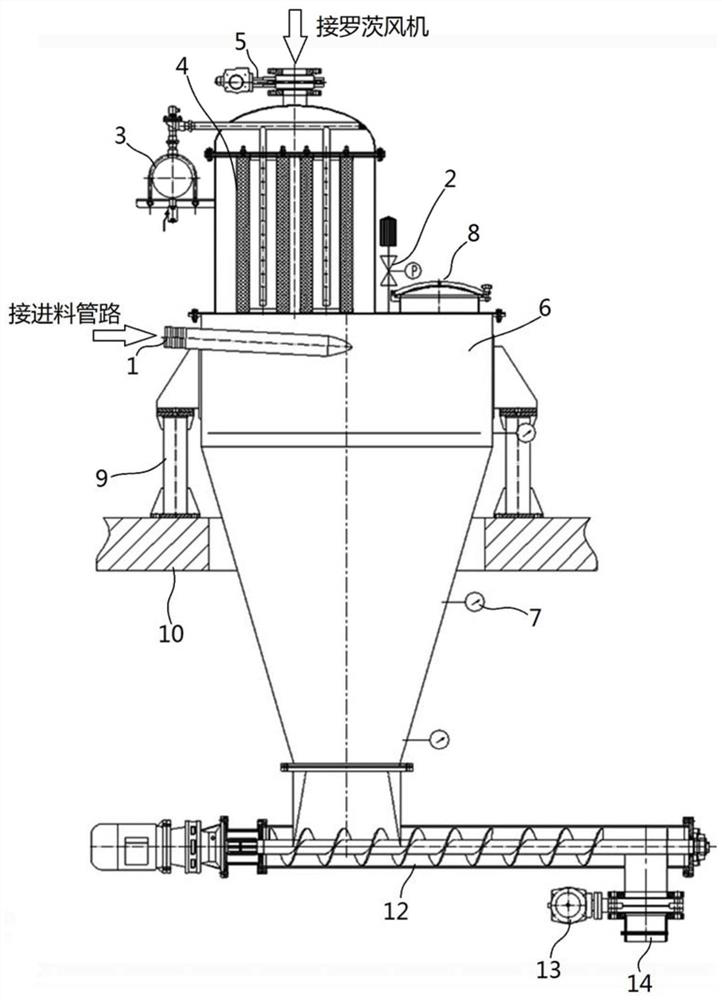

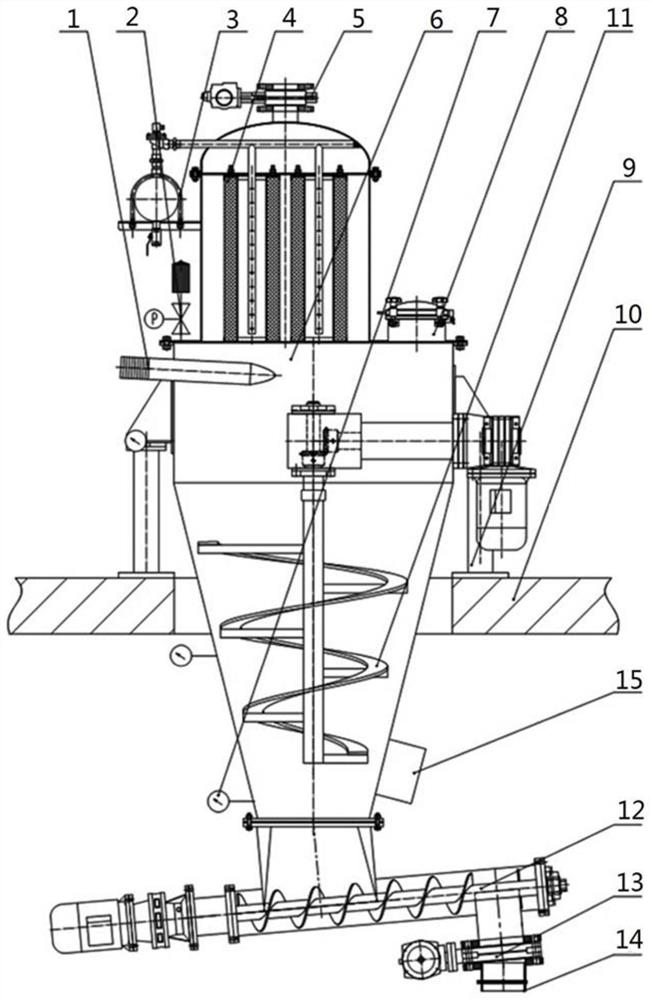

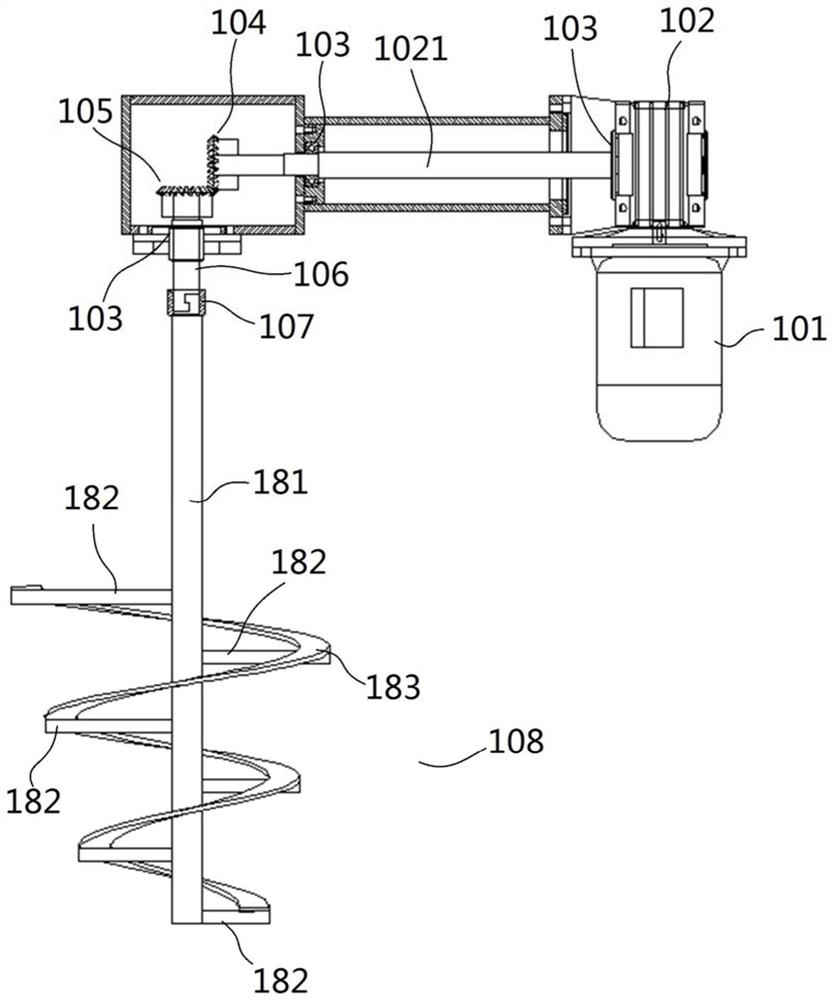

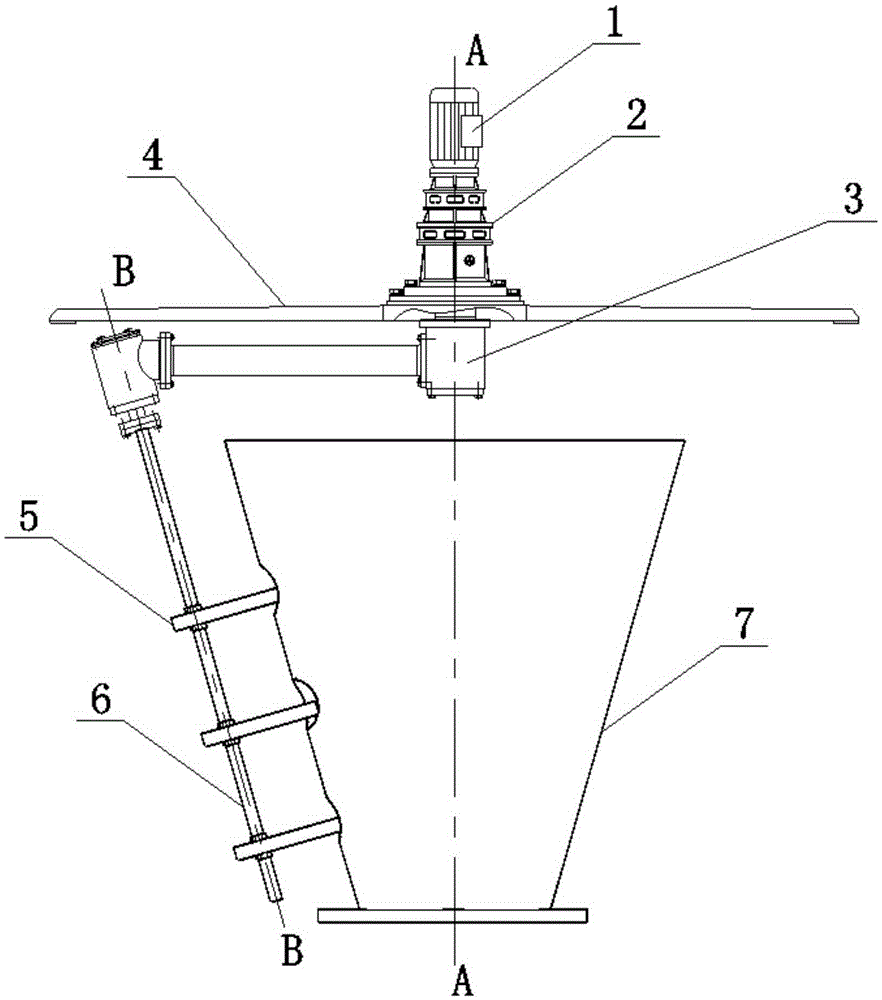

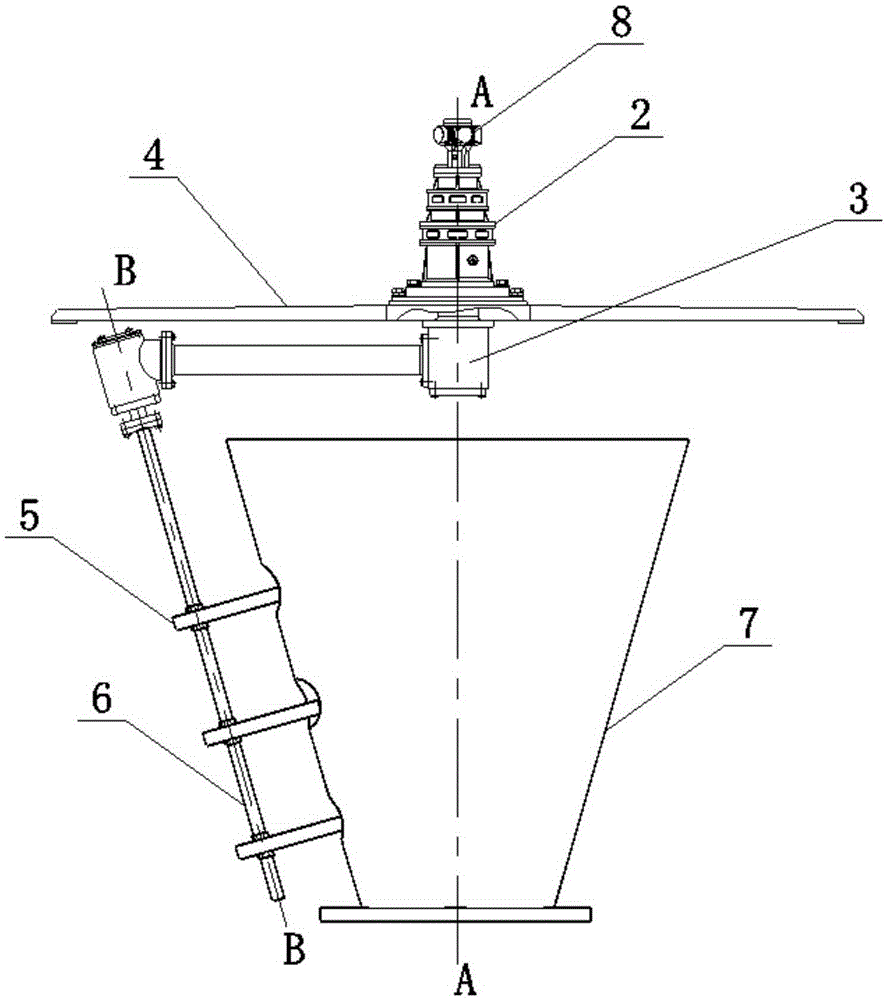

Powder storage tank

PendingCN111824610AImprove liquidityReduce liquidityLarge containersLoading/unloadingDrive shaftElectric machinery

The invention relates to a powder storage tank. The powder storage tank comprises a tank body; the lower part of the tank body is conical; a feeding pipe is arranged at the upper part of the tank body; the tank body is provided with an upper cover; a respirator, a blowback air pocket component, an air and material separator and an air suction port are arranged on the upper cover; a screw conveyeris arranged at the lower end of the tank body; an arch breaking mechanism is arranged on the tank body and comprises a drive motor, a reduction gearbox, a bevel gear set, a transmission shaft and a stirrer in drive joint sequentially; the bevel gear set comprises a driving bevel gear and a driven bevel gear; the driving bevel gear is mounted at the outer end of a horizontally arranged output shaftof the reduction gearbox; the driven bevel gear is mounted at the upper end of the transmission shaft; the drive motor and the reduction gearbox are mounted at the external part of the tank body; theoutput shaft of the reduction gearbox penetrates through the tank body and is in rotary seal fit with the tank body; the stirrer comprises a stirring paddle, and the axis of the stirring paddle is vertically arranged; the stirring paddle is positioned a conical structure at the lower part of the tank body; and the lowest end of the stirring paddle extends to the conical opening of the conical structure. The powder storage tank is small in noise, high in arch breaking capacity and is suitable for material with poor fluidity and likely to absorb moisture for caking.

Owner:上海富昶环保科技有限公司

Novel arch-breaking device

The invention belongs to the field of warehouses, and in particular relates to a novel arch-breaking device. The novel arch-breaking device comprises a shell, an exhaust pipe, a cylinder sleeve, a seal plate, a piston and an elastic sleeve, wherein the cylinder sleeve is fixed at one end of the shell; one inner end of the shell is provided with a conical hole, and the sidewall of the shell is provided with a vent hole for communicating an inner space and an outer space of a cavity of the cylinder sleeve; the piston is arranged in the cylinder sleeve, one end of the piston is conical and the other end of the piston is provided with a ventilation main hole; small ventilation holes are radial distributed and are communicated with the ventilation main hole inwards and are communicated with the exterior of the piston outwards; a conical end of the piston is provided with an annular surface; the elastic sleeve is sleeved on the piston and can cover the small ventilation holes; the vent hole is communicated with a cavity and an air-storage cavity in the cylinder sleeve; and one end of the cylinder sleeve towards the shell is connected with the seal plate, and the seal plate is provided with a gas port. The novel arch-breaking device disclosed by the invention has the beneficial effects of short exhaust time, energy source conservation, good arch-breaking effect and simple structure.

Owner:济宁市支点机电设备有限公司

Regenerative hopper

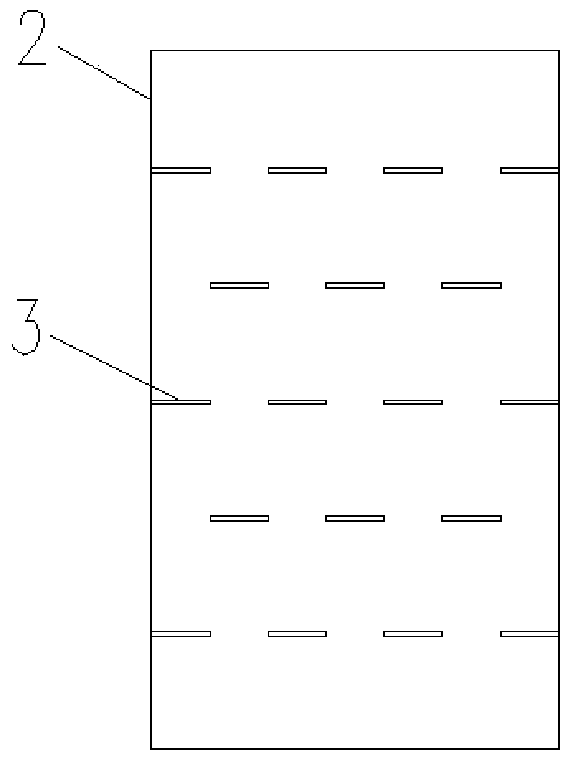

InactiveCN101973436AImprove arch breaking effectReduce labor intensityLarge containersEngineeringMechanical engineering

The invention relates to a regenerative hopper. The regenerative hopper comprises a stock bin and a vibrator arranged on the stock bin, wherein a sounding board is arranged in the stock bin; and one end of the sounding board is in transmission connection with a vibration head of the vibrator, and the other end of the sounding board overhangs into the middle part of the stock bin. In the regenerative hopper, the sounding board is arranged in the stock bin and is in transmission connection with the vibrator arranged on the stock bin, so a vibration plate starts to vibrate in the stock bin under the action of the vibrator; and one end of the sounding board overhangs into the stock bin, and an overhanging structure has the function of amplifying motion, so the overhanging end of the vibration plate has the large amplitude, and the arch-breaking effect is enhanced greatly. Therefore, the operation of artificial arch breakage is avoided, and the labor strength of labors is reduced.

Owner:WUXI HUAZHONG TECH

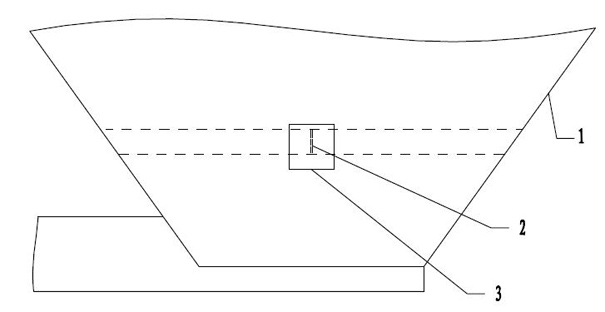

Ilmenite powder lifting hopper

The invention discloses an ilmenite powder lifting hopper. The ilmenite powder lifting hopper comprises a rear base plate, a front base plate, a guide plate and a fixing and reinforcing plate, wherein the lower end of the rear base plate and the lower end of the front base plate are fixedly connected in a sealing mode to form a hopper V-shaped structure with an acute included angle; the guide plate is fixedly connected with the two sides of the rear base plate and the front base plate of the hopper V-shaped structure, and one end of the guide plate extends out of the front base plate to form a guide part; the fixing and reinforcing plate for installing a lifting chain is fixedly connected with the back surface of the rear base plate; the lower end of the rear base plate and the lower end of the front base plate are fixedly connected through an arc plate in a sealed mode. Furthermore, at least one arch breaking device is arranged in the hopper V-shaped structure, and the guide part of the guide plate is splayed outwards. The ilmenite powder lifting hopper can obviously reduce materials stuck to the inner wall of the hopper in the wet mineral lifting process and can unload the materials normally depending on the self weight, the materials will not fall down as blocks, the material returning phenomenon of a hopper lifter is obviously reduced, and the hopper lifter is well protected.

Owner:TAIZHOU DIXIN TRANSPORTATION MACHINERY EQUIP

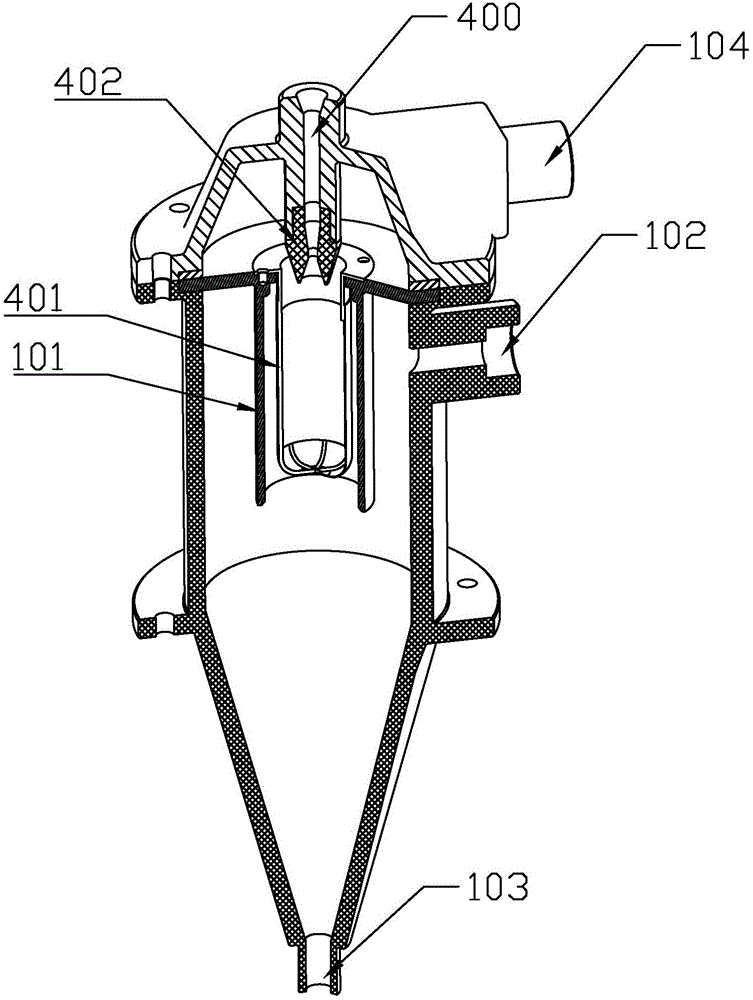

A broken arch bin and a cutting machine with the same

ActiveCN106473628BImprove versatilityGuaranteed uniformityKitchen equipmentGrain treatmentsEngineeringCrystallization

The invention discloses an arch breaking bin, comprising an outer separation barrel; a feed port is arranged in the sidewall of the outer separation barrel, a condiment is fed from the feed port into the outer separation barrel, gas subjected to gas-solid separation is discharged from a gas outlet, and the condiment is dropped into the outer separation barrel and discharged from a discharge port. The arch breaking bin is characterized in that the outer separation barrel is also provided with a pulse valve, the pulse valve can provide a pulse flow, an arch breaking tube is also arranged between the pulse valve and a discharge port passage and is provided with pores, and part of the pulse flow passes through the arch breaking tube and is scattered via the pores to break an arch of the condiment during discharging. The invention also discloses a discharge unit comprising the arch breaking bin. The arch breaking bin is simple in structure, can effectively eliminate arching and bridging due to dampening and crystallization of the condiment, allows smooth discharging, and provides improved discharging stability.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Vortex arch breaking feeder

Owner:王建喜

Storage bin with arch breaking device

The invention discloses a storage bin with an arch breaking device, comprising a storage bin body (1) and a material conveying mechanism (2). The upper part of the storage bin body (1) is in a cylindrical shape, and the lower part of the storage bin body (1) is in a tapered funnel shape. The material conveying mechanism (2) is arranged below the storage bin body (1), and the arch breaking device is arranged on the storage bin body (1). The storage bin with the arch breaking device also comprises a controller (3) and an infrared inductor, wherein the infrared inductor is electrically connected with the controller (3). The infrared inductor comprises an infrared transmitter (4) and an infrared receiver (5), wherein the infrared transmitter (4) and the infrared receiver (5) are respectively arranged between the storage bin body (1) and the material conveying mechanism (2), and are respectively distributed at two sides of a lower outlet of the storage bin body (1). By adopting the storage bin with the arch breaking device, whether blocking and arch forming in the storage bin occurs or not can be automatically judged, whether the arch breaking device is started to work or not can be judged according to the arch forming condition, and furthermore, relatively uniform conveying of material can be achieved.

Owner:CHINA JILIANG UNIV

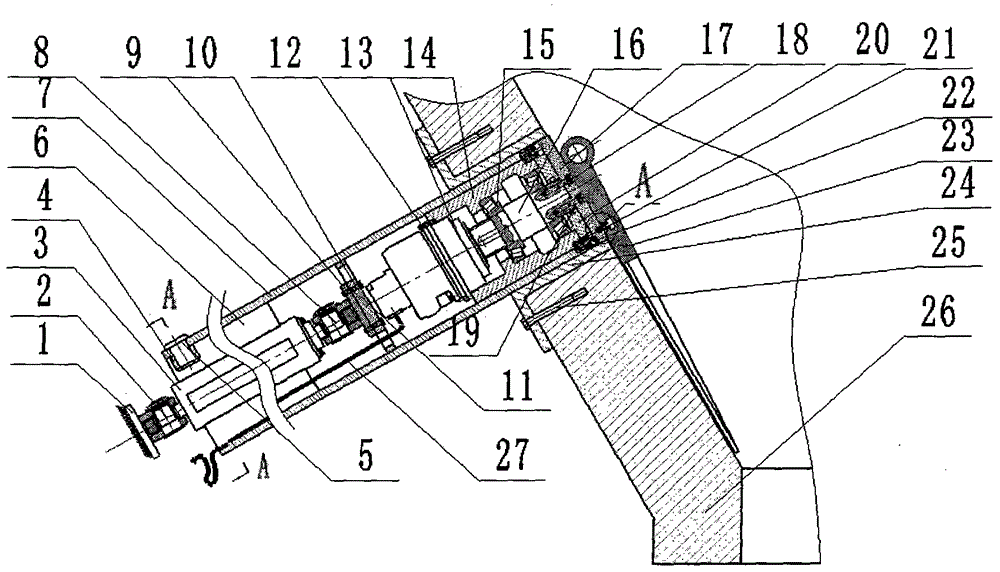

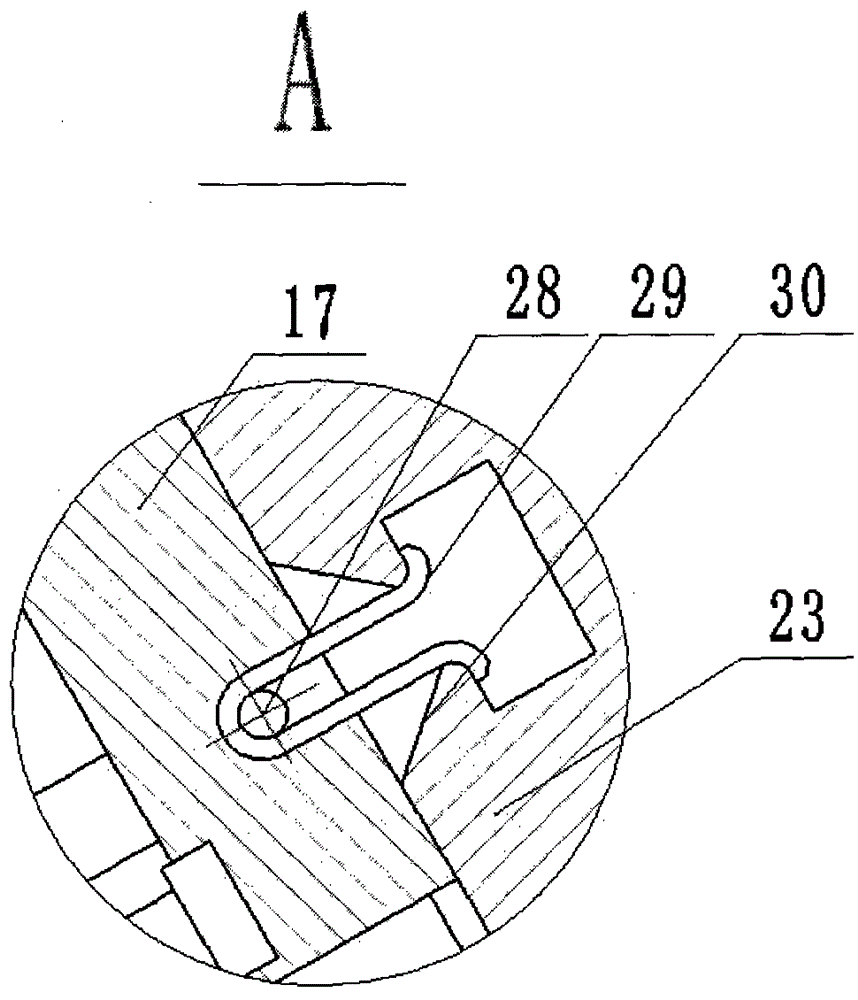

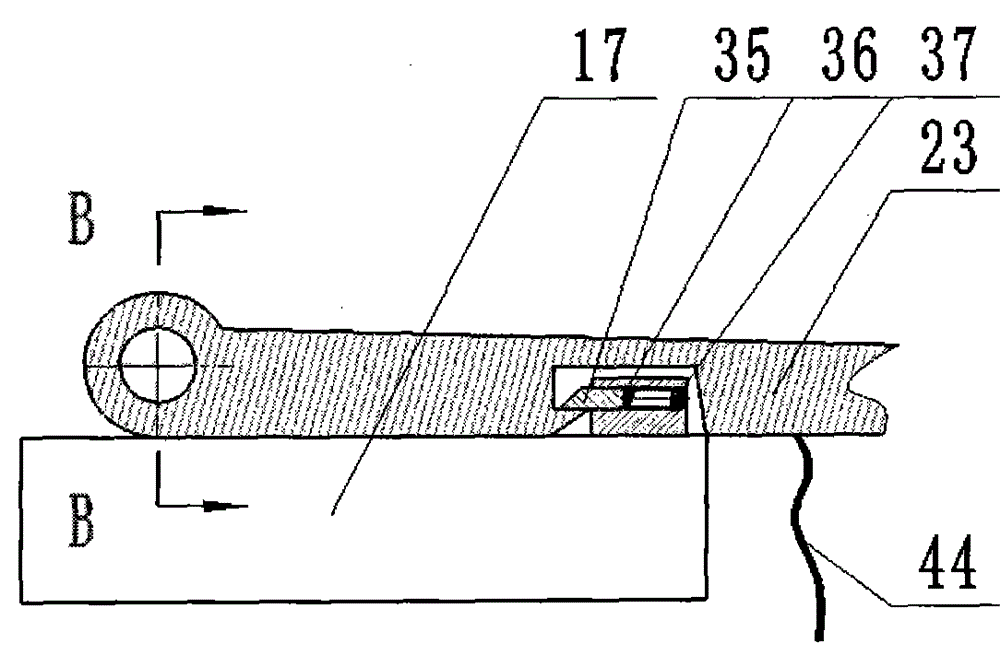

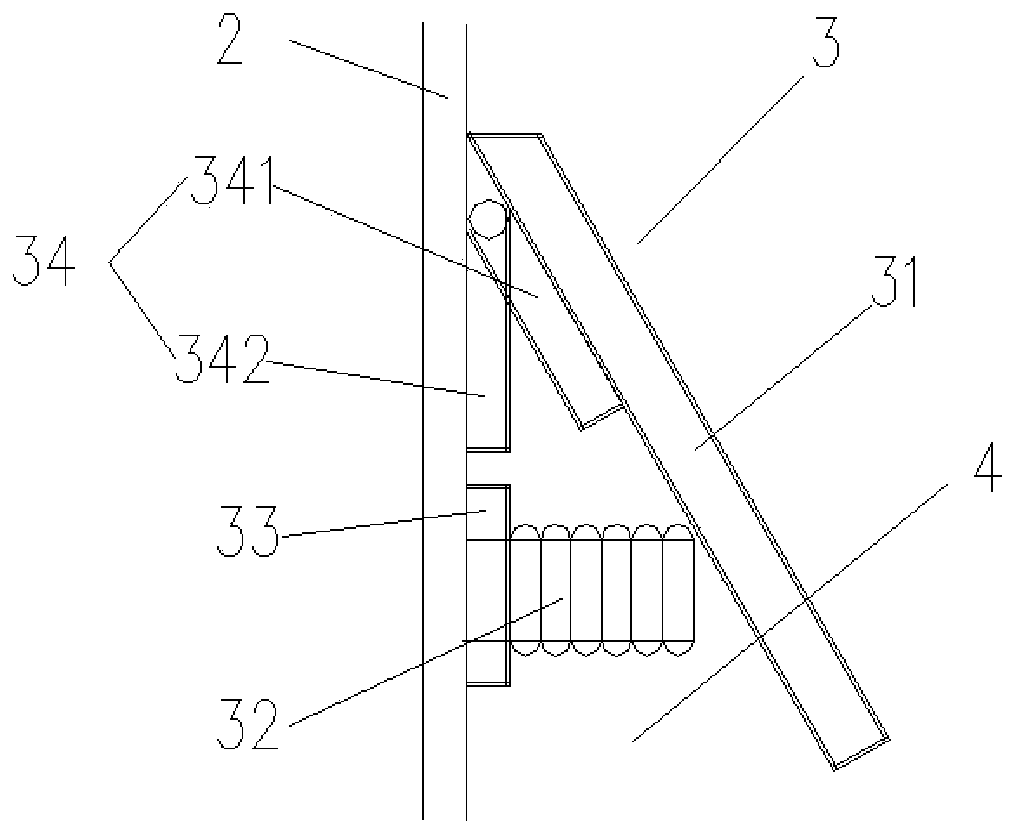

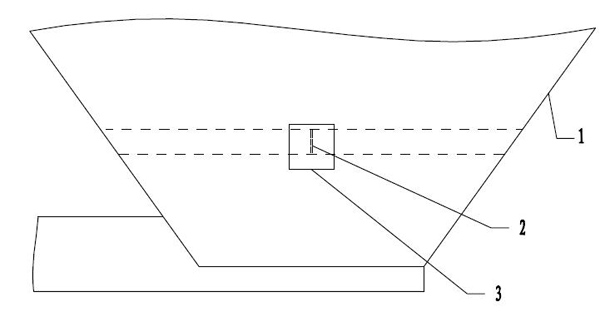

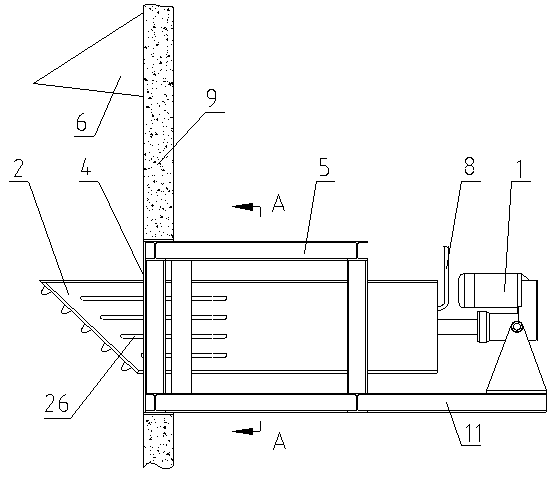

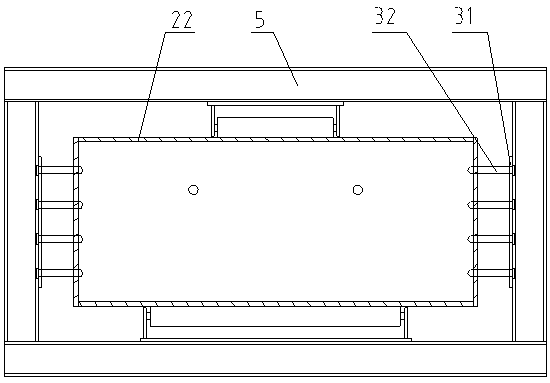

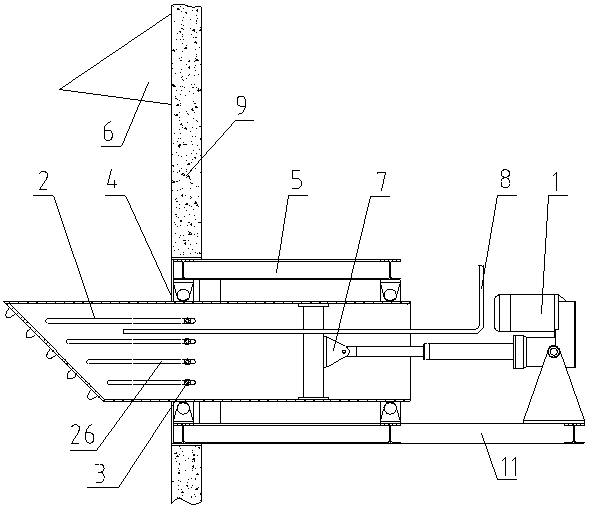

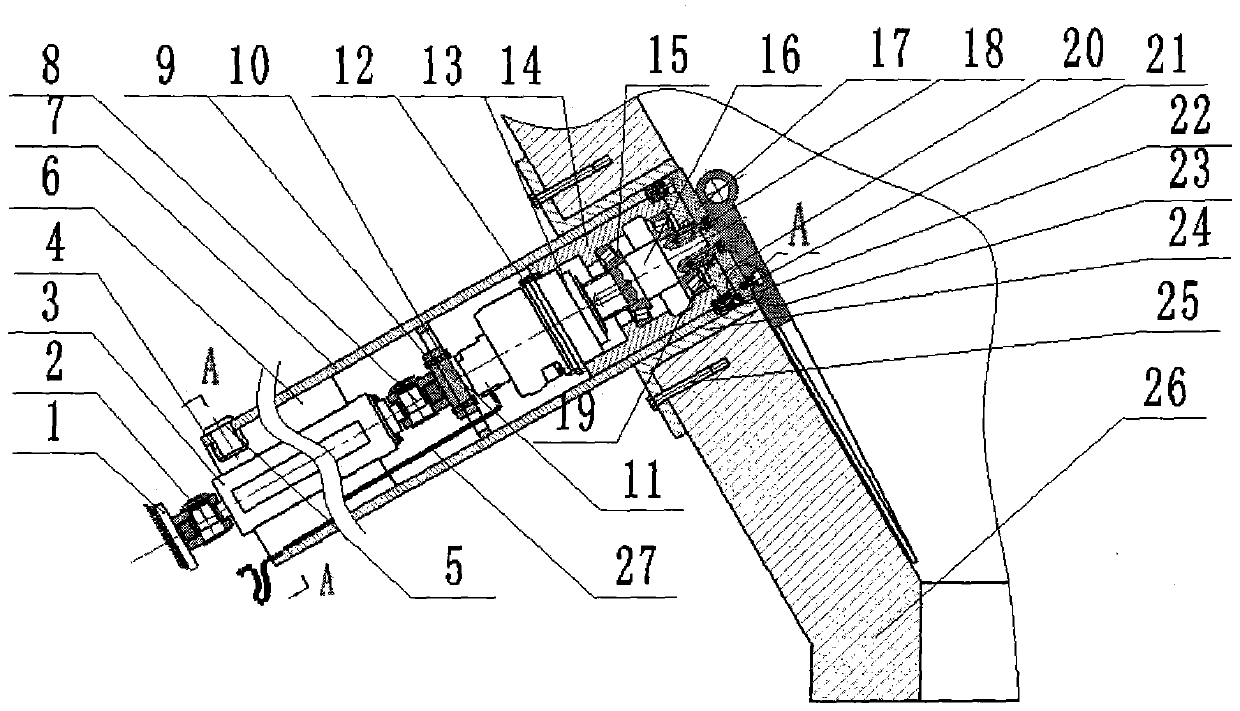

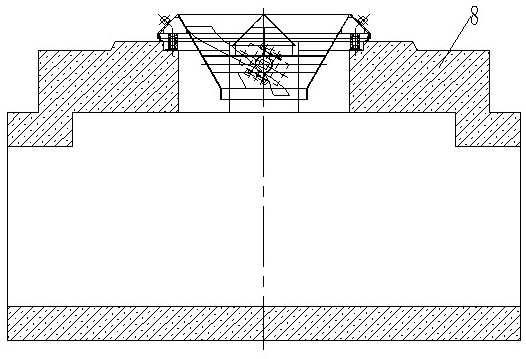

Wedge-shaped telescopic flow guide device for leachate from garbage storage bin

PendingCN110756292ALower height requirementReduce maintenance workloadGrain treatmentsKnife bladesWater spray

The invention discloses a wedge-shaped telescopic flow guide device for leachate from a garbage storage bin. The wedge-shaped telescopic flow guide device for leachate from the garbage storage bin comprises a telescopic transmission assembly, a wedge-shaped cutter head cylinder assembly (2), a poking needle disc assembly (3), a sealing baffle (4), a base (5) and a water spraying system (8). The wedge-shaped cutter head cylinder assembly comprises blades (21), a wedge-shaped flat cylinder (22), a supporting rod (23), flow guide holes (25) and flow guide grooves (26). The wedge-shaped flat cylinder is of a flat cylindrical structure with a rectangular section, and the inner end of the wedge-shaped flat cylinder is an inclined downward wedge-shaped face. The base is arranged in a reserved hole of a bin wall (9). The wedge-shaped flat cylinder and the base are blocked through the sealing baffle. The telescopic transmission assembly drives the wedge-shaped flat cylinder to stretch and retract. The water spraying system sprays water to the flow guide holes and the flow guide grooves. Poking needles (32) of the poking needle disc assembly are inserted into the flow guide grooves. According to the wedge-shaped telescopic flow guide device for leachate from the garbage storage bin, the wedge-shaped flat cylinder stretches and retracts to drive the blades to poke and break garbage such as plastic bags and cloth strips in the storage bin, garbage movement in a local area is caused, blockage is avoided, and it is guaranteed that leachate is smoothly guided out through the flow guide holes and the flow guide grooves.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD +1

Bottom vibration unloader

ActiveCN104843364BGuaranteed service lifeExtended service lifeLarge containersHigh archesEngineering

The invention relates to an under-bin vibrating unloader, in particular to an under-bin vibrating unloader with high arch breaking force and good sealing performance, and belongs to the field of grain machinery. The under-bin vibrating unloader comprises an upper cylinder body, a soft connection body and a lower cylinder body, a reset screw is connected between an upper connection flange and a lower connection flange and sleeved with a reset spring, and the upper end and the lower end of the reset spring are in contact with the upper connection flange and the lower connection flange respectively. A depressurization cylinder is arranged at the lower end of the inner side of the upper cylinder body and located on the inner side of the soft connection body. The inner side wall of the lower cylinder body is connected with an arc breaking support, and an arc breaking disk is arranged on the arc breaking support.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

A hopper arch breaking device for friction and impact sensitive materials

ActiveCN103693320BEliminate archingEnsure safetyLarge containersMechanical engineeringSolid material

The invention discloses a hopper arch breaking device for materials sensitive to friction and impact and belongs to the field of solid material feeding. The hopper arch breaking device is suitable for the process of feeding solid materials sensitive to friction and impact and uses a conductive polymeric material as a material for making a hopper; an arch breaking shaft drives an arch breaking wheel to rotate along the axial direction of the arch breaking shaft when rotating around the direction of the symmetry axis of the hopper, so that elastic deformation is sequentially generated at different positions on the wall of the hopper, flowing of the materials in the hopper is prompted and the arching phenomenon of the materials in the hopper is eliminated. Due to no contact between the arch breaking wheel and the materials, friction and impact to the materials cannot be generated, so that safety of the feeding process is effectively ensured. The hopper arch breaking device has the advantages of high safety, good arch breaking effect, flexible use mode and the like.

Owner:XIAN MODERN CHEM RES INST

Arch breaking bin and discharge unit with same

ActiveCN106473628AImprove versatilityGuaranteed uniformityKitchen equipmentGrain treatmentsEngineeringSmall hole

The invention discloses an arch breaking bin, comprising an outer separation barrel; a feed port is arranged in the sidewall of the outer separation barrel, a condiment is fed from the feed port into the outer separation barrel, gas subjected to gas-solid separation is discharged from a gas outlet, and the condiment is dropped into the outer separation barrel and discharged from a discharge port. The arch breaking bin is characterized in that the outer separation barrel is also provided with a pulse valve, the pulse valve can provide a pulse flow, an arch breaking tube is also arranged between the pulse valve and a discharge port passage and is provided with pores, and part of the pulse flow passes through the arch breaking tube and is scattered via the pores to break an arch of the condiment during discharging. The invention also discloses a discharge unit comprising the arch breaking bin. The arch breaking bin is simple in structure, can effectively eliminate arching and bridging due to dampening and crystallization of the condiment, allows smooth discharging, and provides improved discharging stability.

Owner:珠海优特智厨科技有限公司

Rotary direct motion arch breaking device

ActiveCN104555153BCompact structureEasy to install on siteLarge containersEngineeringOperation safety

The invention relates to a rotary direct-driving arch breaking device, belonging to the field of material conveying. A lengthening rod is arranged at the end part of the arch breaking device, and meanwhile, the lengthening rod rotates under the driving of a rotary driving device. Compared with an arch breaking range that the diameter of an arch breaking sleeve per se reaches, the arch breaking range of the rotary direct-driving arch breaking device disclosed by the invention is greatly expanded. Moreover, the rotary direct-driving arch breaking device is compact in structure, the quantity of assembling parts in a field installing process is greatly reduced and thus the field installation of the arch breaking device is facilitated. Since the rotary driving device drives a rotary cover and the lengthening rod to rotate through a rotating shaft in a process of rotary arch breaking and fewer rotating components are used, extra rotary friction resistance caused hereby is greatly reduced, the action force of rotary arch breaking can be sufficiently exerted and the arch breaking effect is improved. According to the arch breaking device disclosed by the invention, a stock bin does not need to be cleared in an assembling and disassembling process, operating personnel are unnecessary to enter the stock bin, and thus the operation safety is improved.

Owner:河南辉强机械设备有限公司

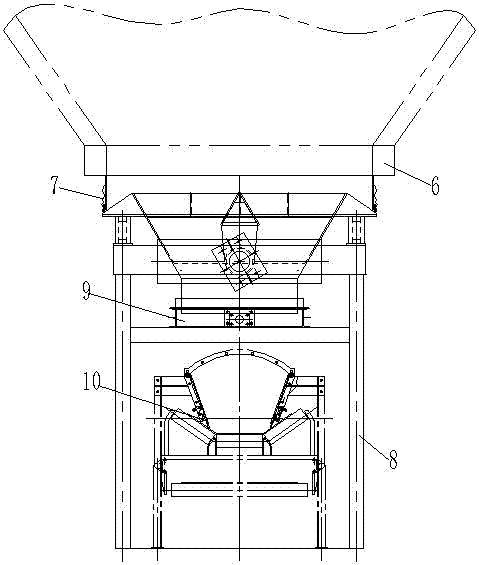

Vortex arch-breaking vibrating feeder with self-locking function

PendingCN111977203AAvoid hanging on the wallAvoid Stock PhenomenonLarge containersElectric machineStructural engineering

The invention discloses a vortex arch-breaking vibrating feeder with a self-locking function. The vortex arch-breaking vibrating feeder comprises a discharging hopper and a supporting cone arranged atthe top of the discharging hopper, an arch-breaking cone is arranged in the center of the inner side of the discharging hopper through a supporting beam fixed to the conical hole wall of the discharging hopper, the top of the arch-breaking cone is arranged in the supporting cone, multiple spiral partition plates used for achieving material falling and self-locking functions of the vibrating feeder are arranged on the inner wall of a conical hole of the discharging hopper, the inner edges of the spiral partition plates are fixedly connected with the arch-breaking cone, the middles of the spiral partition plates are fixed to the supporting beam, two vibrating motors with adjustable inclination angles are arranged at the positions, on the outer side of the discharging hopper, of the supporting beam, and the two vibration motors are symmetrically arranged in a crossed mode at the angle of 180 degrees and operate in opposite directions to form vortex type vibration. According to the vortexarch-breaking vibrating feeder, the technical problem that material conveying interruption is caused by arching and blocking of stored materials and coal yard materials is effectively solved, and thevortex arch-breaking vibrating feeder has the self-locking function so that material falling stopping of the feeder can be automatically achieved after the vibration motors stop running.

Owner:王建喜

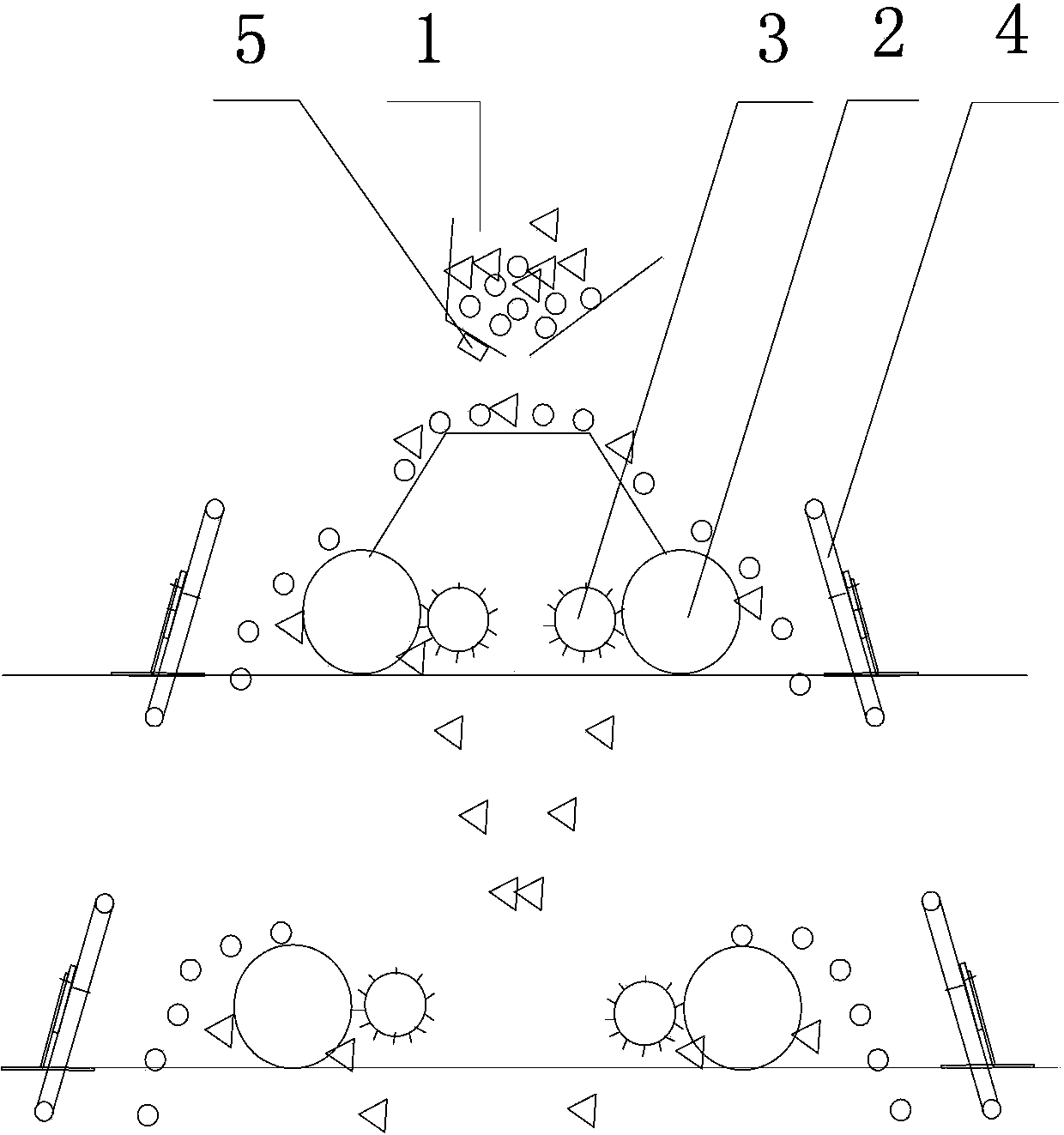

Dry type electrostatic separator for dry type recovery production line of waste circuit board

InactiveCN103785543ARealize falls intoSolve the adsorption problemElectrostatic separationProduction lineEngineering

The invention relates to a dry type electrostatic separator for a dry type recovery production line of a waste circuit board, which comprises a feeding hopper, grounded separating cylinders, separating hair brushes and electrostatic frames, wherein at least one electromagnetic shaker is at least arranged on an outlet of the feeding hopper, so as to drive the feeding hopper and a crushed material in the hopper to be shaken together; four groups of the grounded separating cylinders, the separating hair brushes close to two-two opposite inner sides of the grounded separating cylinders and the electrostatic frames arranged oppositely on two-two opposite outer sides of the grounded separating cylinders are distributed in a trapezoid; the grounded separating cylinders and the electrostatic frames pass through an electrostatic generator, so that an electric field is generated between the grounded separating cylinders and the electrostatic frames; when the crushed material passes, metal particles and non-metal particles in the crushed material are separated by the electric field; and the separating hair brushes are used for brushing off the crushed material adsorbed on the grounded separating cylinders. Thus, the problems of low separating efficiency and high impurity amount can be solved, the separating efficiency is high, and no secondary pollution is caused.

Owner:CHANGZHOU XIANGYU RESOURCE RECYCLING TECH +1

Ton packing equipment

ActiveCN103895978BImprove arch breaking effectAccurate measurementLarge containersEngineeringHigh pressure

The invention discloses tonnage-load bag filling equipment which comprises a frame assembly and one or more circular bins. Section steel is directly welded to form the frame assembly, the circular bins are directly arranged in the frame assembly and are conical, a funnel is fixedly arranged on the tops of the circular bins, materials can be conveniently fed into the circular bins via the funnel, gate assemblies are arranged at the bottoms of the circular bins, air fluidizing devices are arranged at the gate assemblies and the outer bottoms of the circular bins, high-pressure air can flow into the circular bins by the aid of the air fluidizing devices, and conical protective cover barrel devices are arranged at the outer bottoms of the gate assemblies. The tonnage-load bag filling equipment has the advantages that physical properties of the side walls of the bins are changed, and the tonnage-load bag filling equipment is provided with compound technological configuration for combining the physical properties of the side walls of the bins with material fluidizing by the aid of aerodynamic force, so that the materials can be uniformly discharged, and an accurate metering effect of the bag filling equipment can be guaranteed.

Owner:肖龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com