Vortex arch-breaking vibrating feeder with self-locking function

A vibrating feeder and arch breaking technology, which is applied in the directions of containers, packaging, transportation and packaging, can solve the problems of material conveyance interruption, and achieve the effects of uninterrupted material conveying, high arch breaking efficiency and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

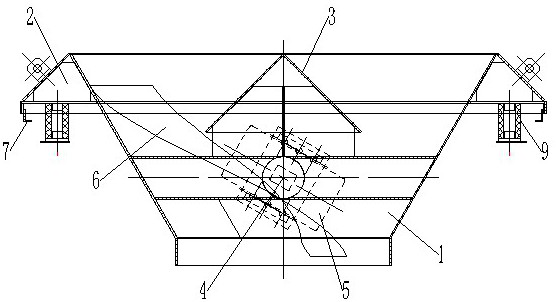

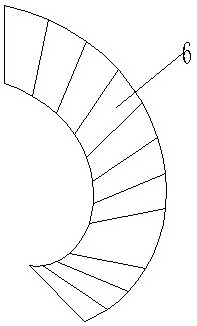

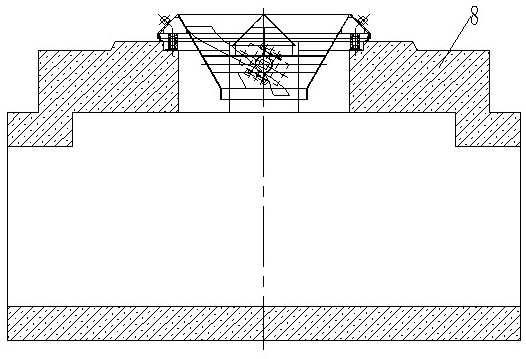

[0021] Describe technical scheme of the present invention in detail in conjunction with accompanying drawing, as Figure 1-2 As shown, a vortex arch-breaking vibrating feeder with self-locking function includes a lower hopper 1 and a support cone 2 arranged on the top of the lower hopper 1, and the arch-breaking cone 3 is fixed on the wall of the cone hole of the lower hopper 1 The support beam 4 is set at the center of the inner side of the lower hopper 1, the top of the arch breaking cone 3 is placed in the support cone 2, and the inner wall of the cone hole of the lower hopper 1 is provided with multiple sets of spirals for realizing the self-locking function of the vibrating feeder. Partition 6, the inner edge of the spiral partition 6 is fixedly connected with the arch-breaking cone 3 and the middle part of the spiral partition 6 is fixed on the support beam 4, and the support beam 4 outside the lower hopper 1 is provided with two tilt-adjustable Vibration motors 5, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com