Equipment and method for recycling raw coke oven gas waste heat for benzene removal and ammonia distillation

A technology for waste gas and debenzene removal, applied in the field of debenzene removal and ammonia distillation, can solve the problems of increasing the difficulty and cost of coking plant wastewater treatment, inefficient heat supply energy, inability to debenzene regeneration process, etc., to reduce purchase costs and The effect of using cost, reducing energy consumption and avoiding emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

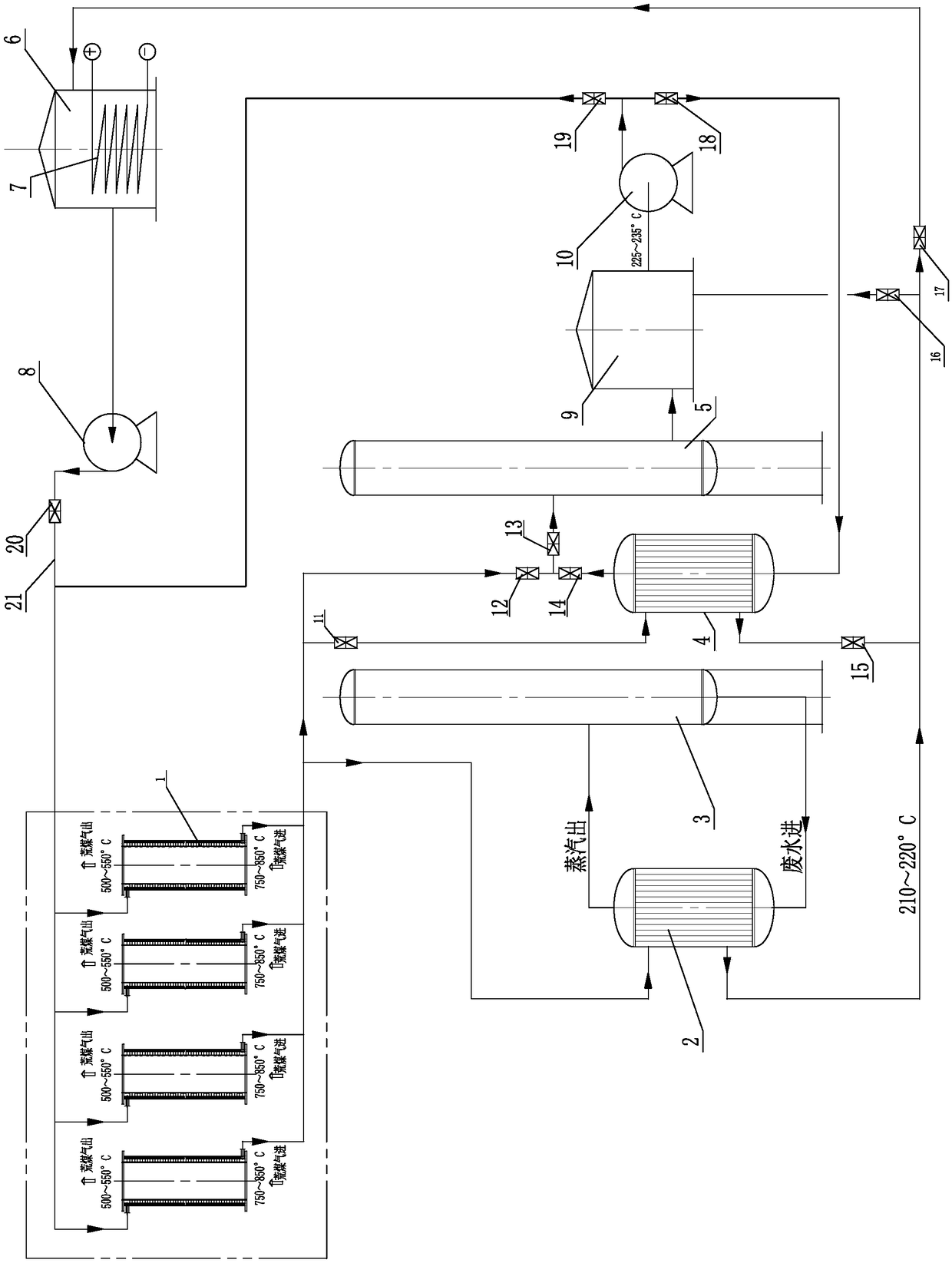

[0043] as attached figure 1 , figure 2 As shown, a device for recovering coke oven waste gas waste heat for debenzene removal and ammonia distillation, including riser heat exchanger 1, ammonia distillation reboiler 2, negative pressure ammonia distillation tower 3, benzene removal reboiler 4, Negative pressure debenzene tower 5, heat medium tank 6, heat lean oil tank 9, valves 11-20 and pipeline 21 forming a closed loop.

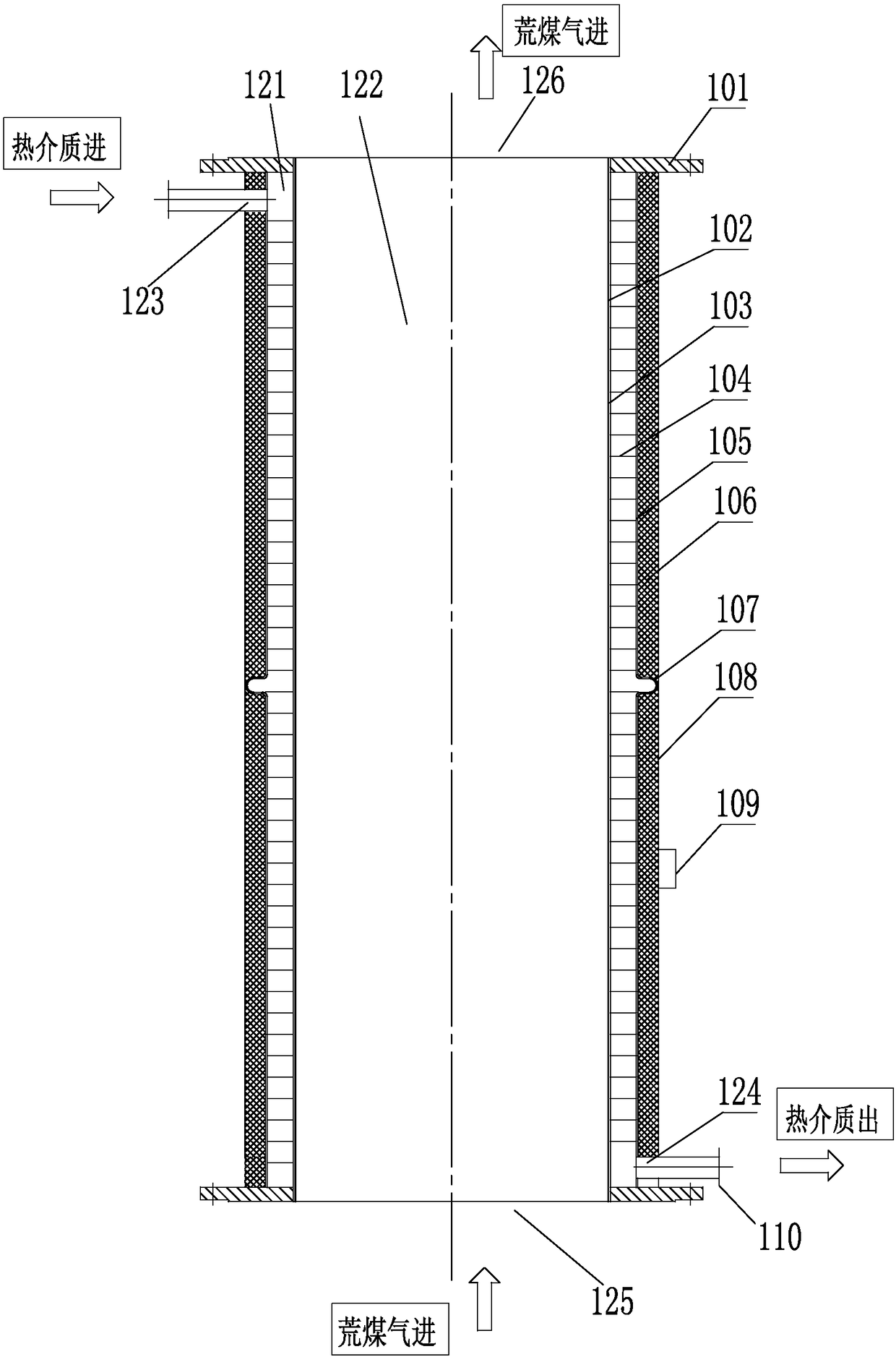

[0044] The riser heat exchanger 1 includes a heat medium inlet and outlet pipe 121 on the outside and a raw gas inlet and outlet pipe 122 in the middle. The heat medium inlet 123 of the heat medium inlet and outlet pipe 121 is in the upper part, the heat medium outlet 124 is in the lower part, and the heat medium inlet and outlet 124 are in the lower part. 123. The heat medium outlets 124 are respectively connected to the external pipes through respective flanges. The heat medium inlet and outlet pipes 121 are provided with heat medium. The raw gas inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com