Patents

Literature

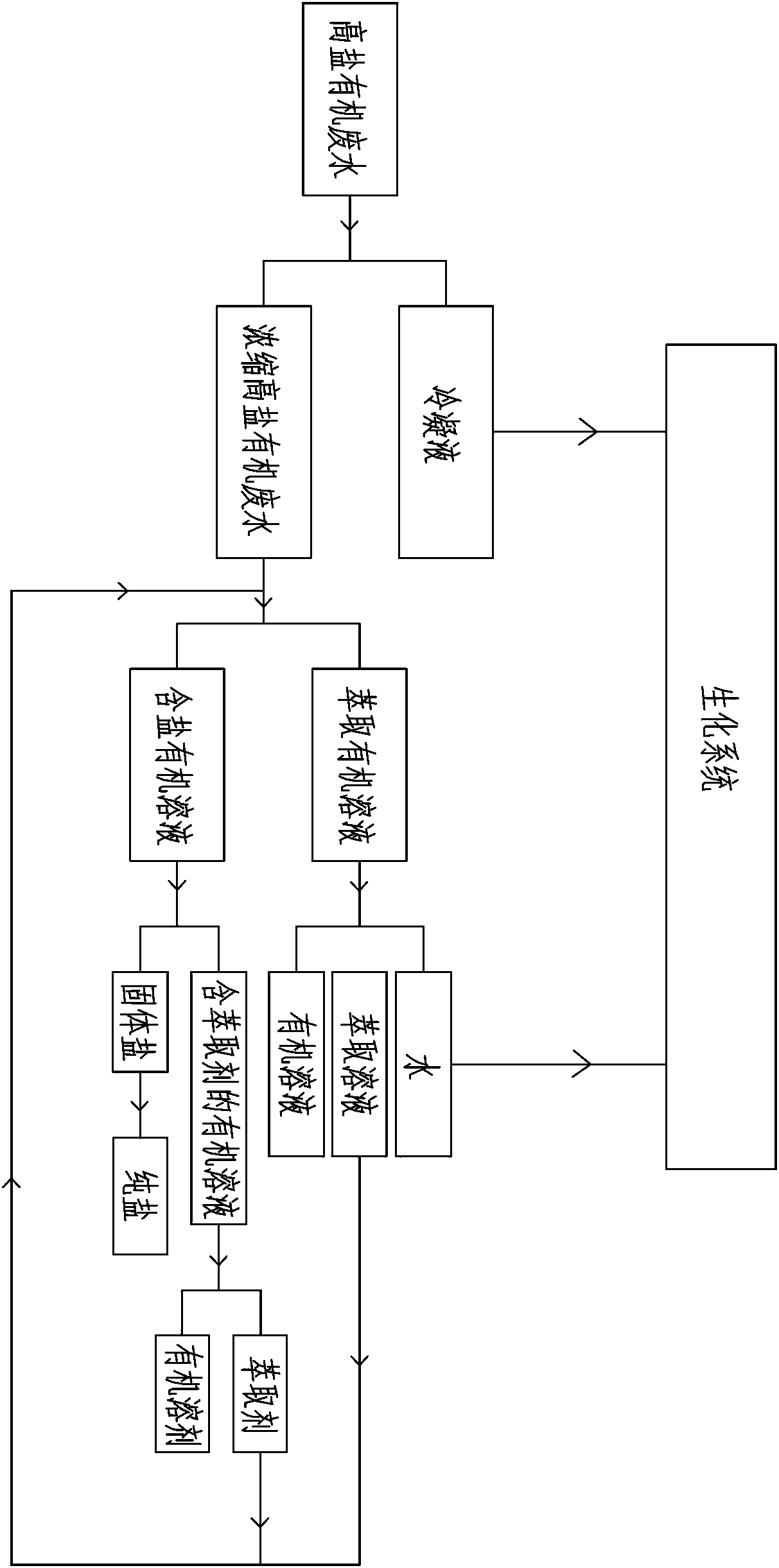

78results about How to "Avoid hanging on the wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

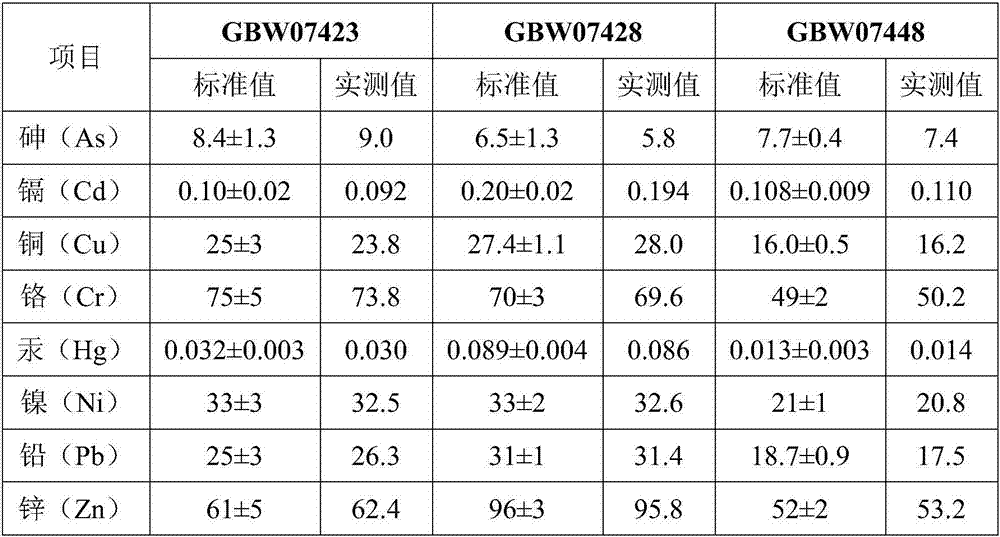

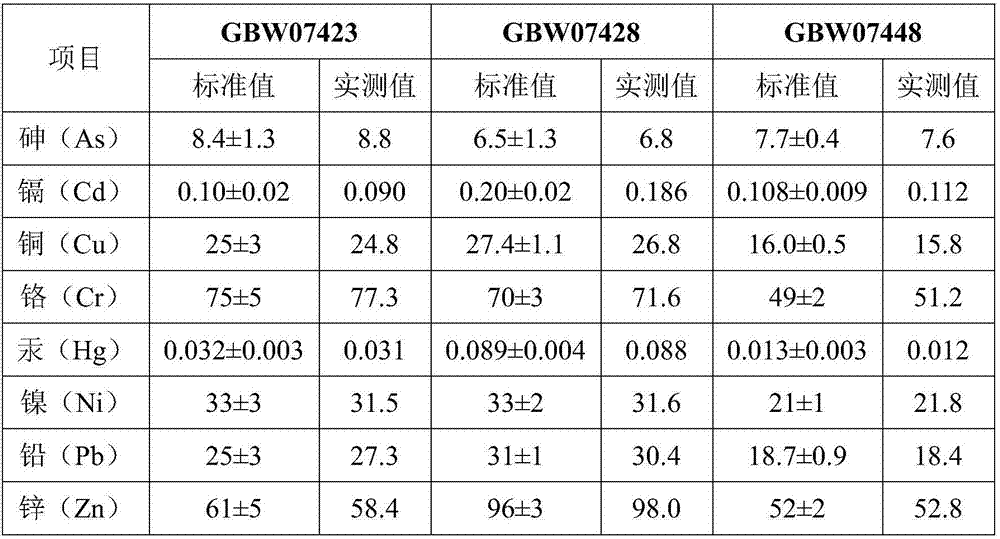

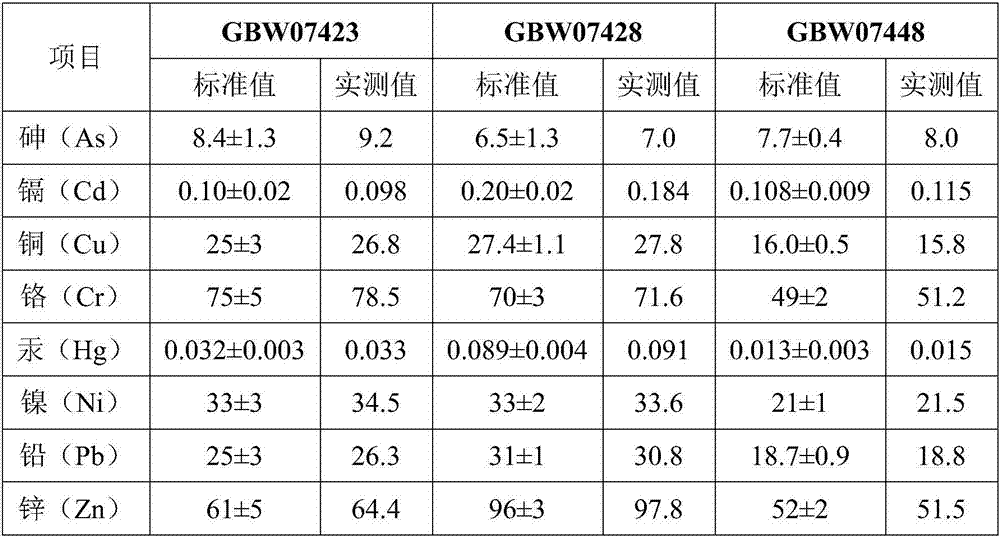

Pretreatment method for determining multiple heavy metal elements in soil simultaneously

InactiveCN107036876AFast digestionSimplify preprocessing stepsPreparing sample for investigationPretreatment methodDigestion

The invention discloses a pretreatment method for determining multiple heavy metal elements in soil simultaneously. The pretreatment method comprises steps as follows: step (1): sample weighing: the soil is air-dried, ground and screened with a nylon sieve, a soil sample is weighed and put into a microwave digestion tube through a polytetrafluoroethylene long-neck funnel, and the funnel is slightly flapped before the funnel is removed so that all the soil sample attached to the wall of the funnel enter the digestion tube; step (2): digestion: nitric acid, hydrochloric acid and hydrofluoric acid are added to the digestion tube, a cover is screwed down, and the digestion tube is put into a microwave digestion instrument for digestion; step (3): acid driving: after microwave digestion is finished, hydrogen peroxide is added to the digestion tube; then the microwave digestion tube is put into a temperature-controlling acid driver in a fume cupboard for direct acid driving until the volume is smaller than 1 mL, then a solution is directly transferred to a volumetric flask, the volume is constant, and a to-be-tested solution is obtained. With the adoption of the pretreatment method, the digestion speed of the sample can be increased, the pre-treatment step of the sample is simplified, and the accuracy of the detection analysis result is guaranteed.

Owner:PUER COMPREHENSIVE TECHN TESTING CENT

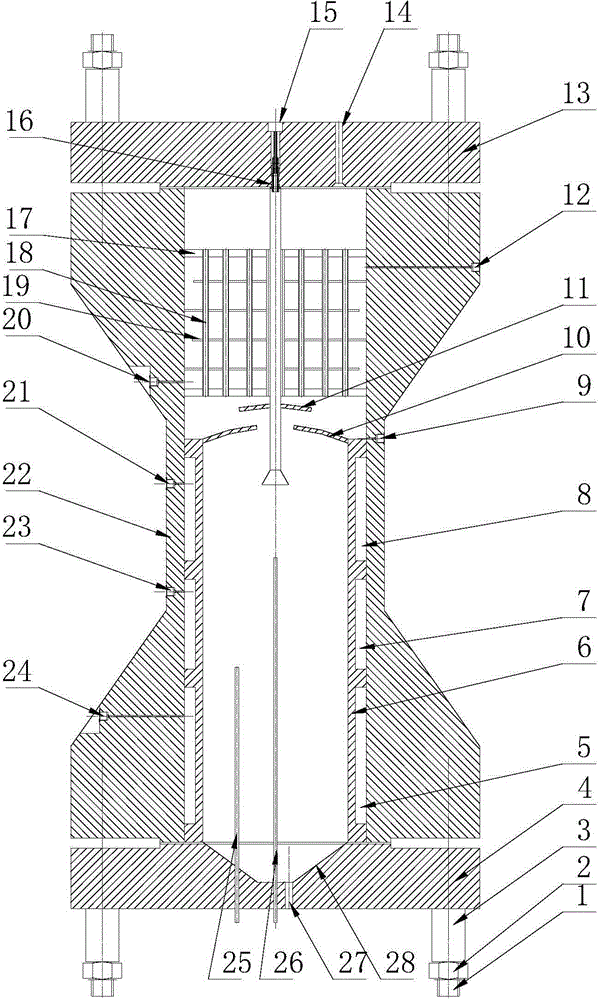

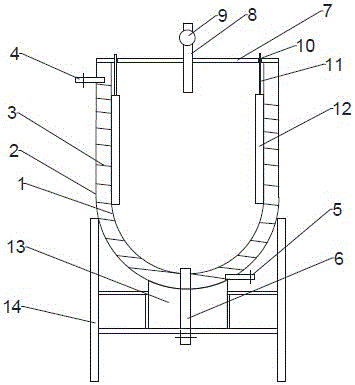

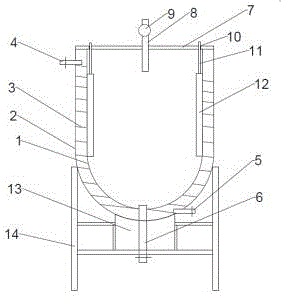

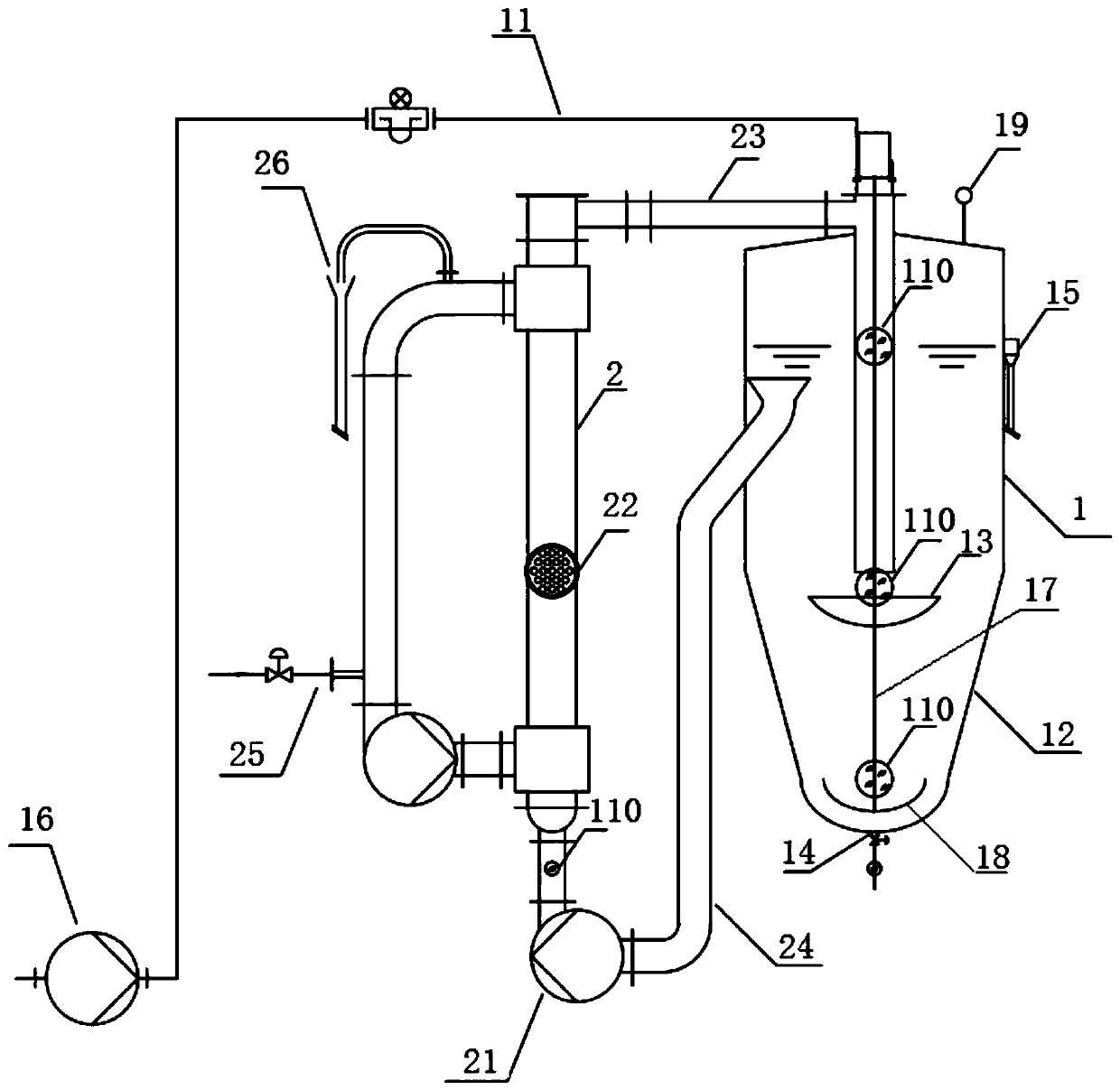

Evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water

ActiveCN104478064AReduce material selectionAchieve separationWater/sewage treatment by oxidationWater useSaline water

The invention relates to an evaporation wall-type supercritical water oxidation reactor capable of directly separating salt and subcritical water. The cylinder is fixed with an upper end cover and a lower end cover; the middle part of the upper end cover is provided with a burner component which extends to the inside of the cylinder; the upper end cover is provided with a gas-phase outlet and a sewage secondary inlet; the upper part in the cylinder is fixedly provided with a shell-and-tube heat exchanger; the upper part of the cylinder is provided with a sewage primary inlet and a normal temperature sewage outlet; the cylinder is provided with a subcritical water outlet; the lower part in the cylinder is fixedly provided with a multilayer evaporation wall; a plurality of annular spaces are formed between the multilayer evaporation wall and the cylinder from top to bottom; the cylinder is sequentially provided with a plurality of evaporation wall water inlets; the upper edge of the multilayer evaporation wall is provided with an evaporation wall spherical baffle; the lower end of the burner component is fixedly provided with a burner spherical baffle; and the bottom of the lower end cover is provided with a brine outlet. The oxidation reactor effectively prevents the preheater, reactor and pipelines from blockage and corrosion, reduces the quantity of pure water used by the evaporation wall, and can reduce the reactor volume and lower the noble alloy consumption.

Owner:碧流天能(北京)科技股份有限公司

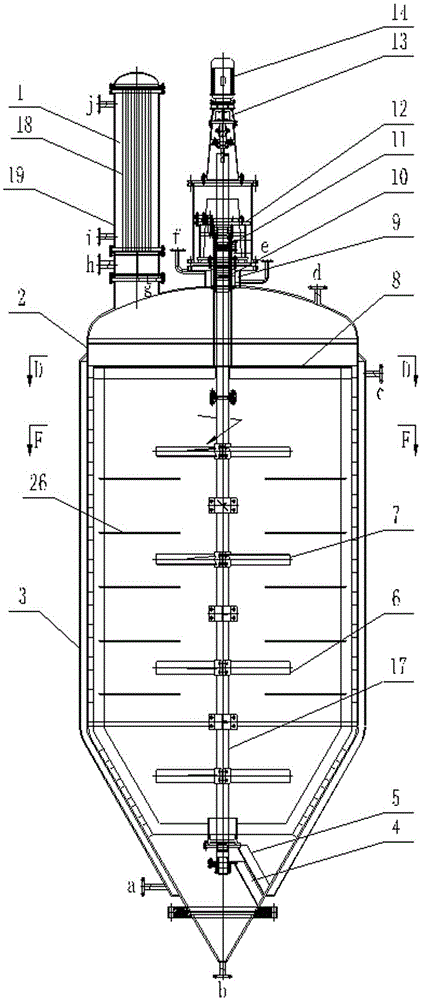

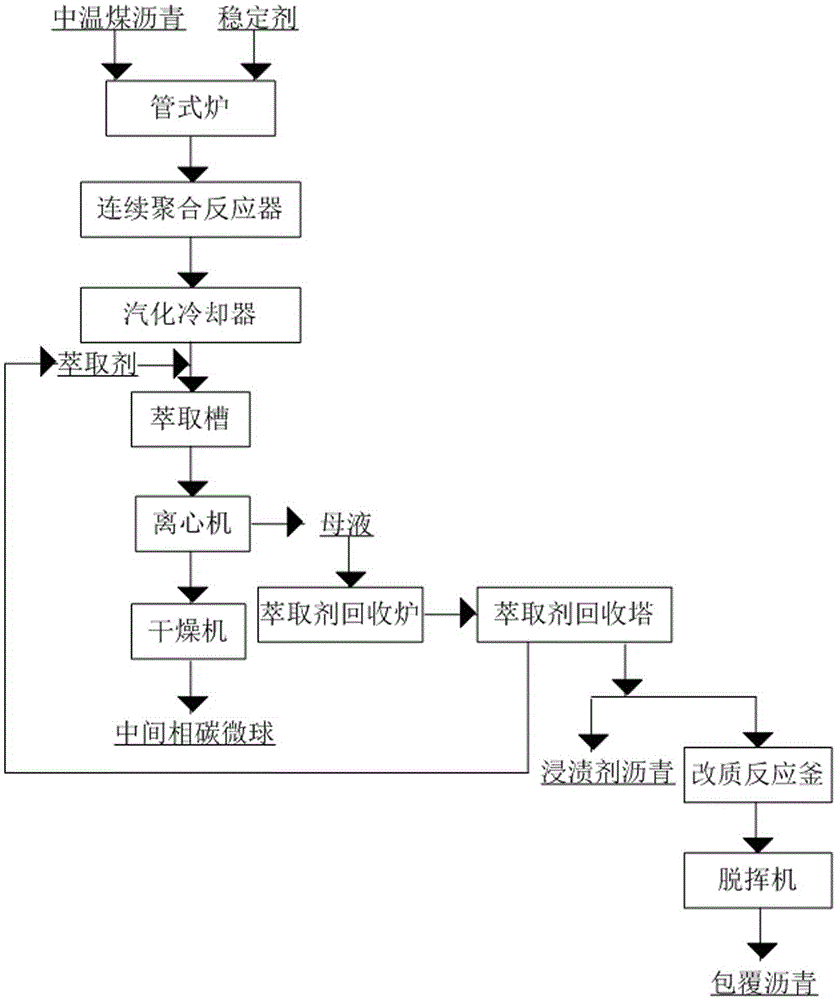

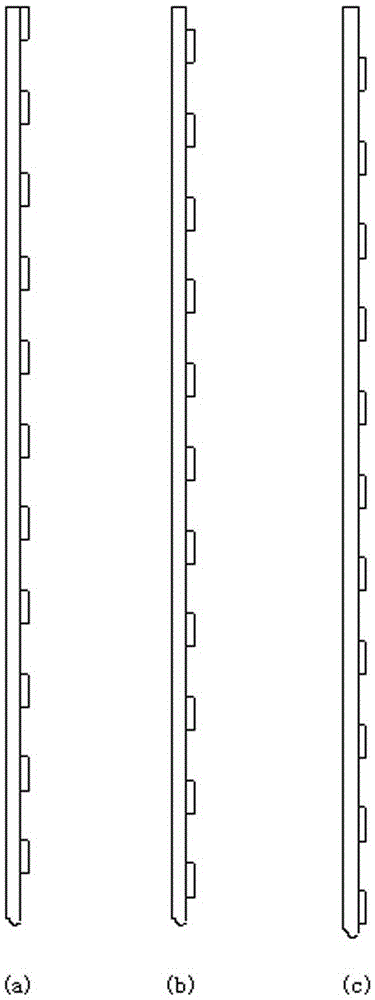

Method for continuously preparing mesocarbon microbeads with co-production of impregnant pitch and coating pitch

ActiveCN105271168AAvoid cokingAvoid hanging on the wallWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereHigh energy

A method for continuously preparing mesocarbon microbeads with co-production of impregnant pitch and coating pitch comprises steps as follows: (1), medium-temperature coal-tar pitch and a stabilizing agent are mixed under the nitrogen atmosphere; (2), a product of the step (1) is heated to 350-380 DEG C, then is sent to a fast heater and is heated to 410-450 DEG C in 1-5 s for a polymerization reaction; (3), a product of the step (2) is cooled to the temperature of 290-340 DEG C and is subjected to mixing extraction with an extracting agent; (4), a mesocarbon microbead product is obtained through centrifugal separation and solid-phase drying; (5), a mother solution is evaporated by a distillation column, the extracting agent is recycled, and the rest of materials at the column bottom is taken as the impregnant pitch or has a modification reaction through a modification reaction kettle. According to the method, the problems of high energy consumption, severe environmental pollution, low product yield, high cost, unstable quality, single variety and the like of a traditional production technology are solved fundamentally.

Owner:ANSHAN XINGDE MATERIAL SCI & TECH

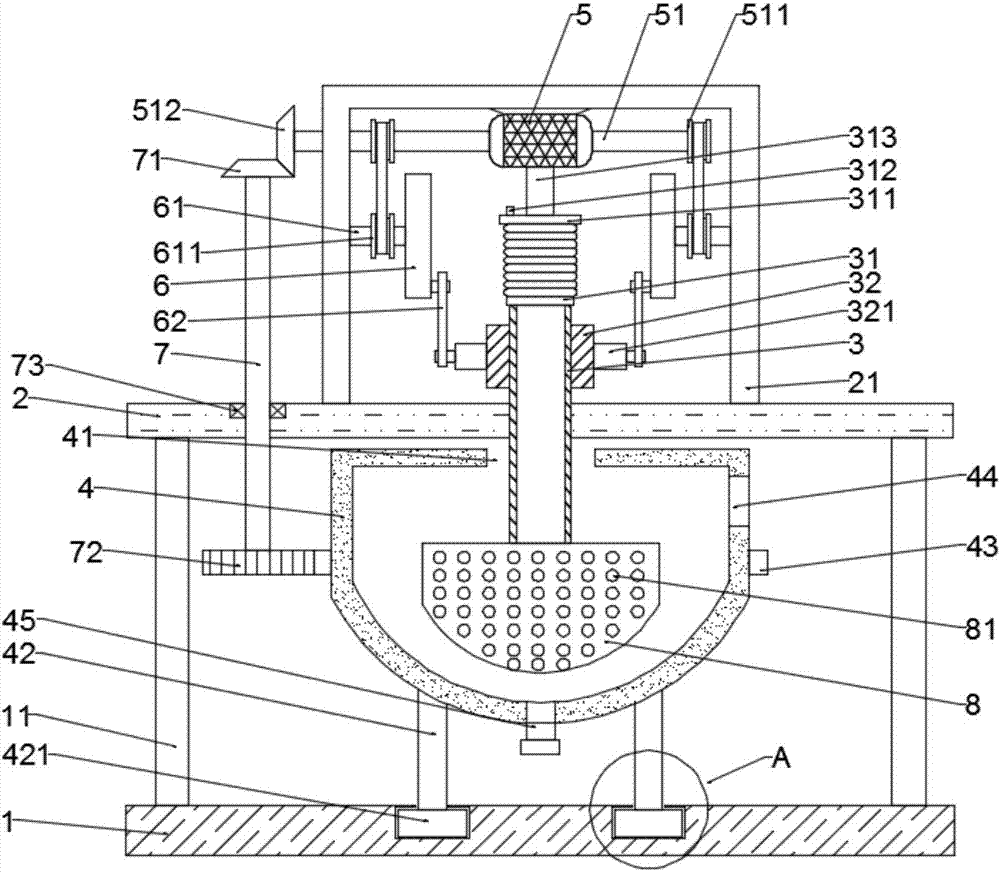

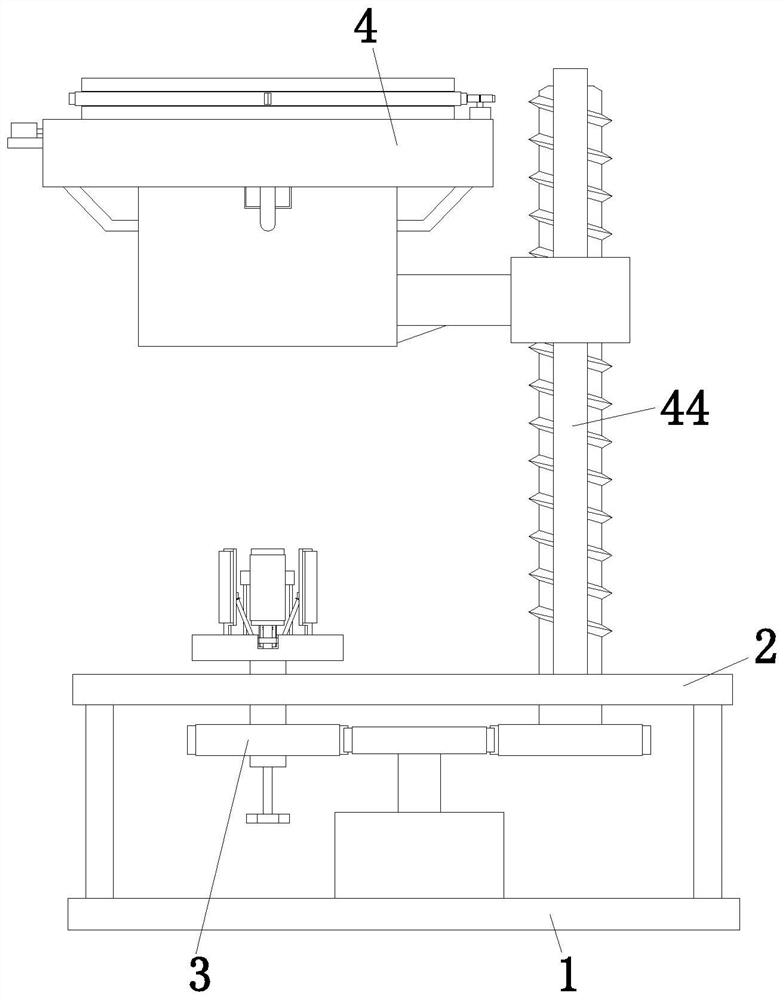

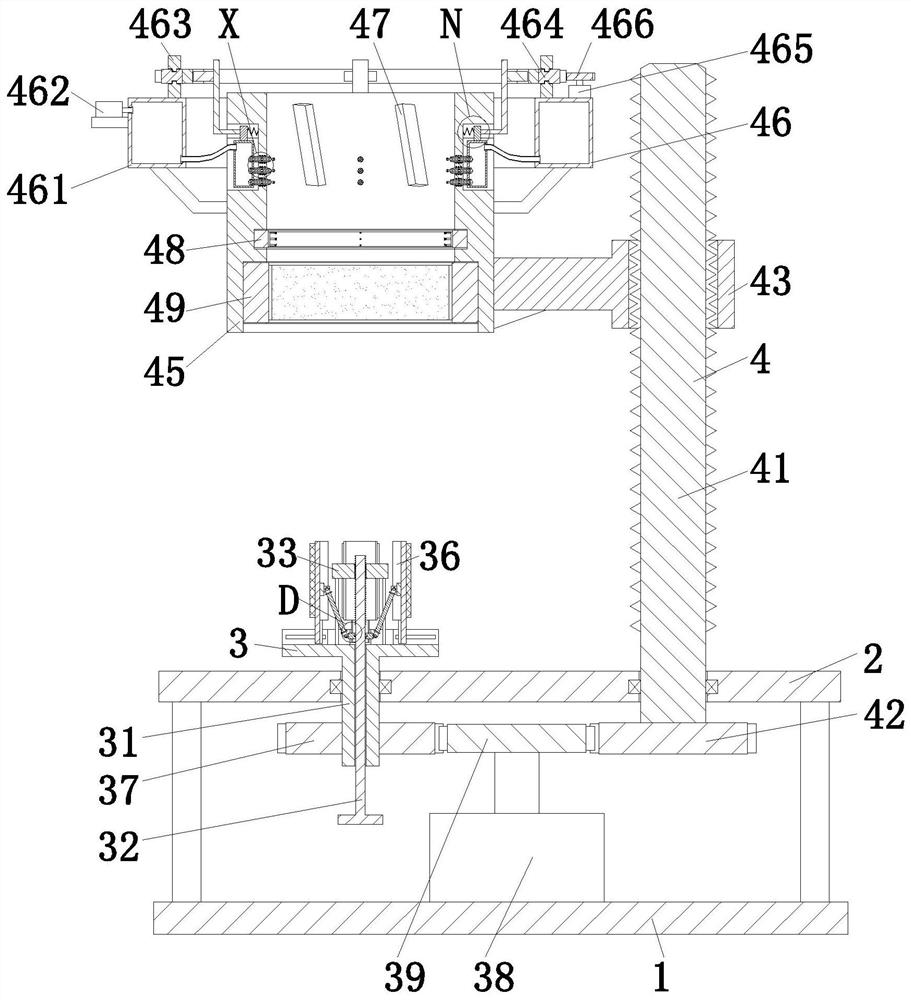

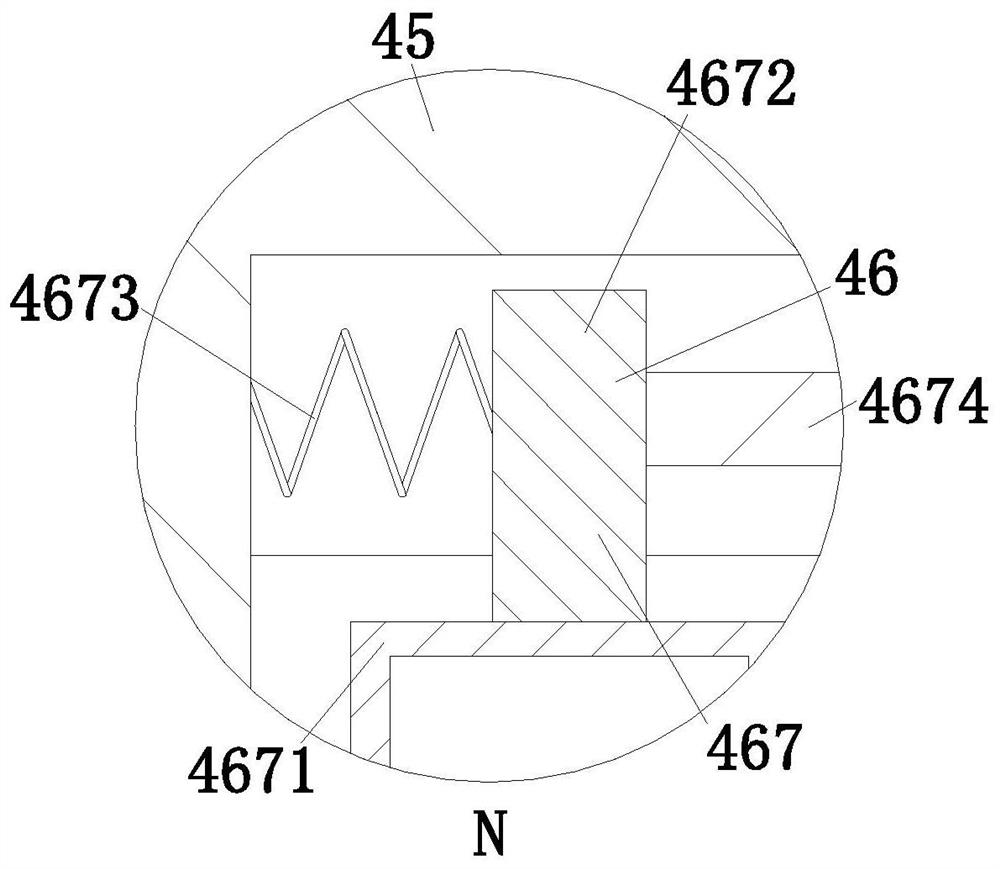

Soybean grinding device capable of preventing soybean powder from hanging on wall

InactiveCN107362863AAvoid hanging on the wallPlay the role of turning soybean flourGrain treatmentsEngineeringMechanical engineering

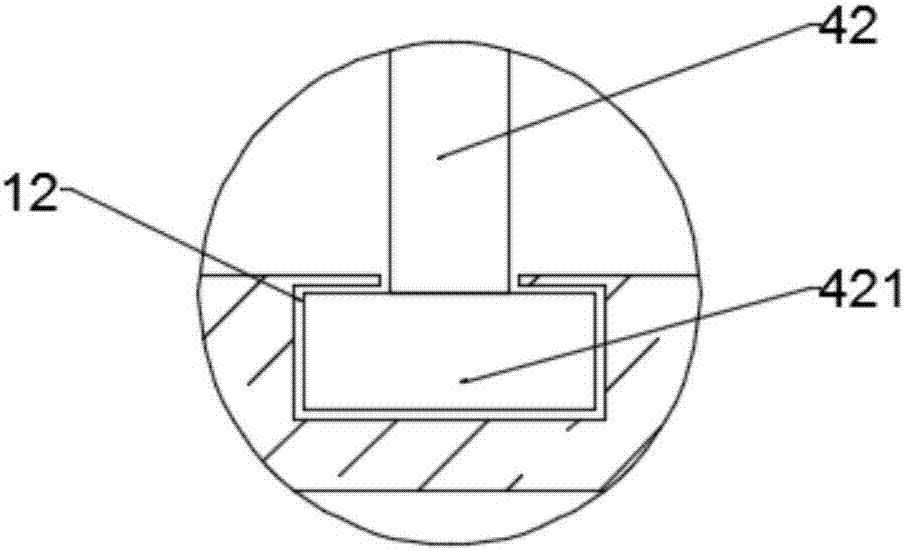

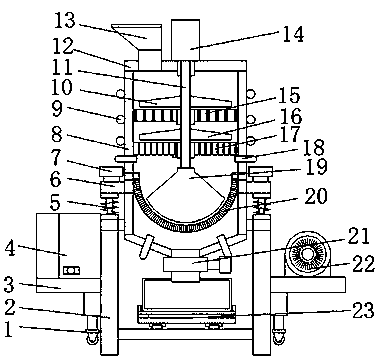

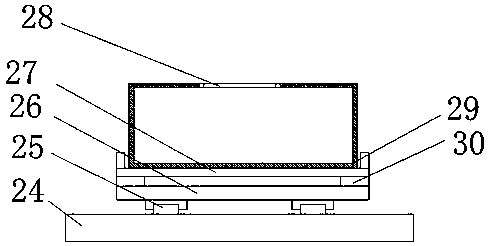

The invention discloses a soybean grinding device for preventing soybean powder from hanging on the wall, which comprises a base, a supporting platform, a movable column, a grinding frame and a double-axis motor; Above the base, a movable column is inserted in the center of the supporting platform, and the movable column is slidingly connected with the supporting platform. The lower end of the movable column is connected with a grinding block with air holes. The movable column is a hollow structure, and the top of the movable column is connected with a telescopic hose. There is a blind plate on the top of the telescopic hose, and the left side of the blind plate is connected to the intake pipe with a one-way valve installed. The motor is located above the blind plate, and a pressing rod is connected between the biaxial motor and the blind plate. The invention can effectively solve the wall-hanging phenomenon in soybean grinding, ensure the uniformity of grinding, and meanwhile has good grinding effect, and is worth popularizing and using.

Owner:胡忠义

Multistage milling device for polymer chemical material particles

PendingCN108405063AGuaranteed grinding effectAvoid quality degradationHollow article cleaningCocoaCompound (substance)Engineering

The invention belongs to the technical field of medical equipment and particularly relates to a multistage milling device for polymer chemical material particles. The multistage milling device aimingat solving the problems that an existing milling device is difficult to clean, meanwhile the heat generated during milling is not completely dissipated, and damage to the milling device is caused easily. According to the multistage milling device, the following scheme is provided, the multistage milling device comprises a support frame, vertically-arranged shock absorbers are connected to the fourcorners of the top of the support frame through bolts, and the tops of the four shock absorbers are all connected with mounting blocks through bolts, and the same milling box is welded to the ends, close to each other, of the four mounting blocks. According to the multistage milling device, the polymer chemical material particles are milled by a first milling disc and a second milling disc and then ball-milled by a ball milling head and a third milling disc, so that the milling effect of the polymer chemical material particles can be ensured, the milling device is easy and convenient to clean, and the corrosion of the residual polymer chemical material to the milling device can be effectively avoided.

Owner:LINYI UNIVERSITY

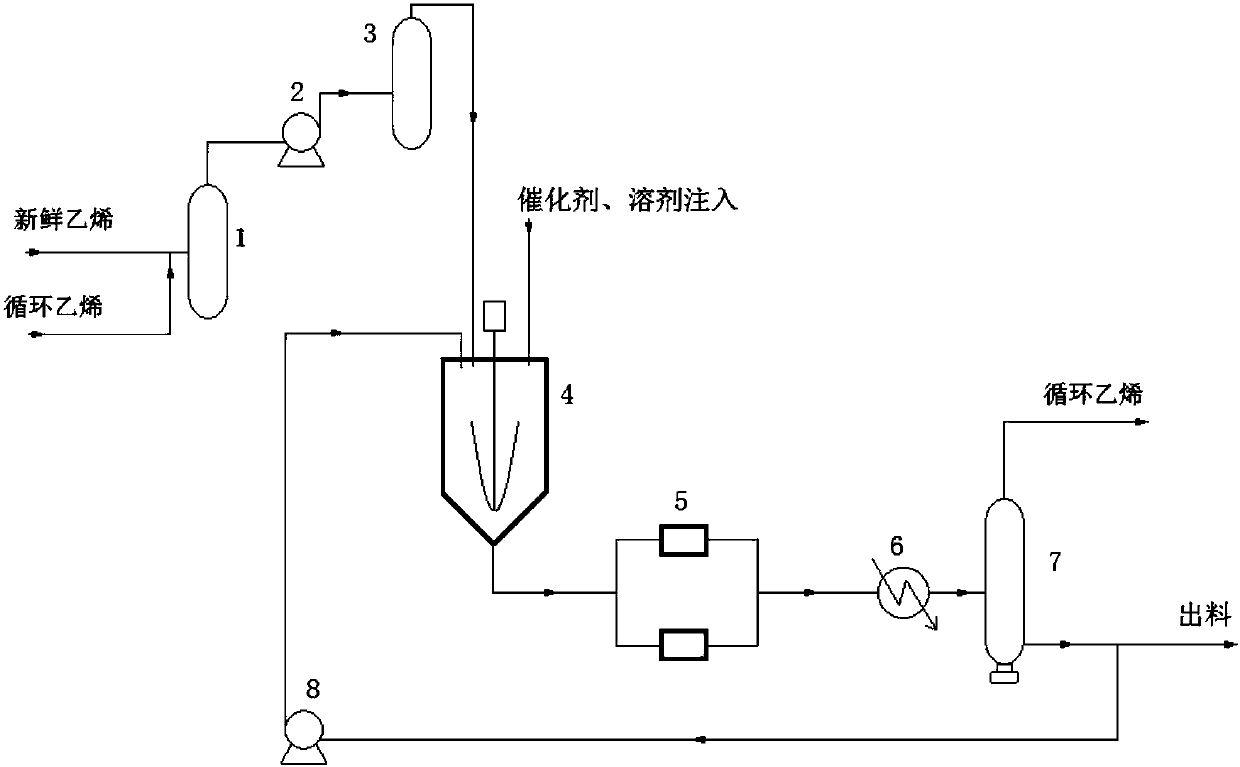

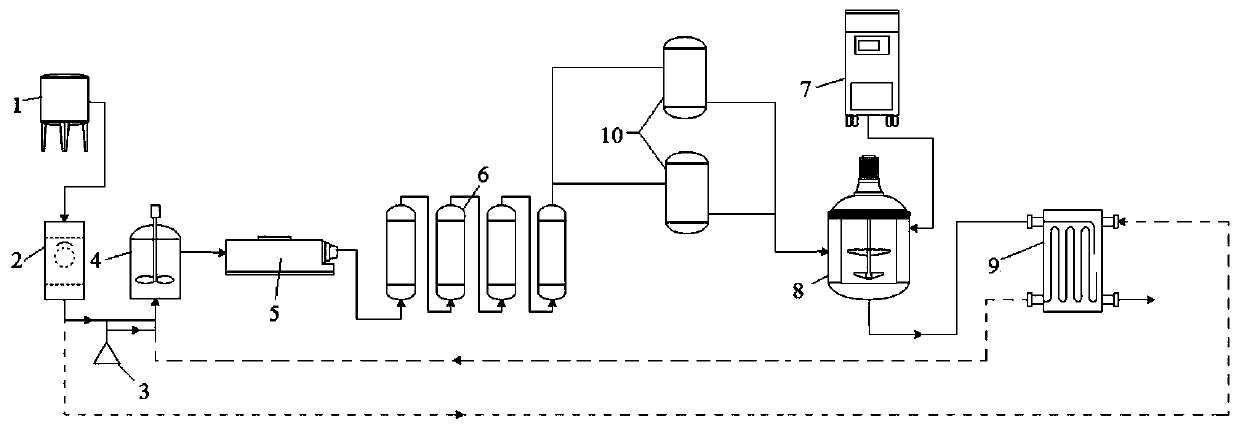

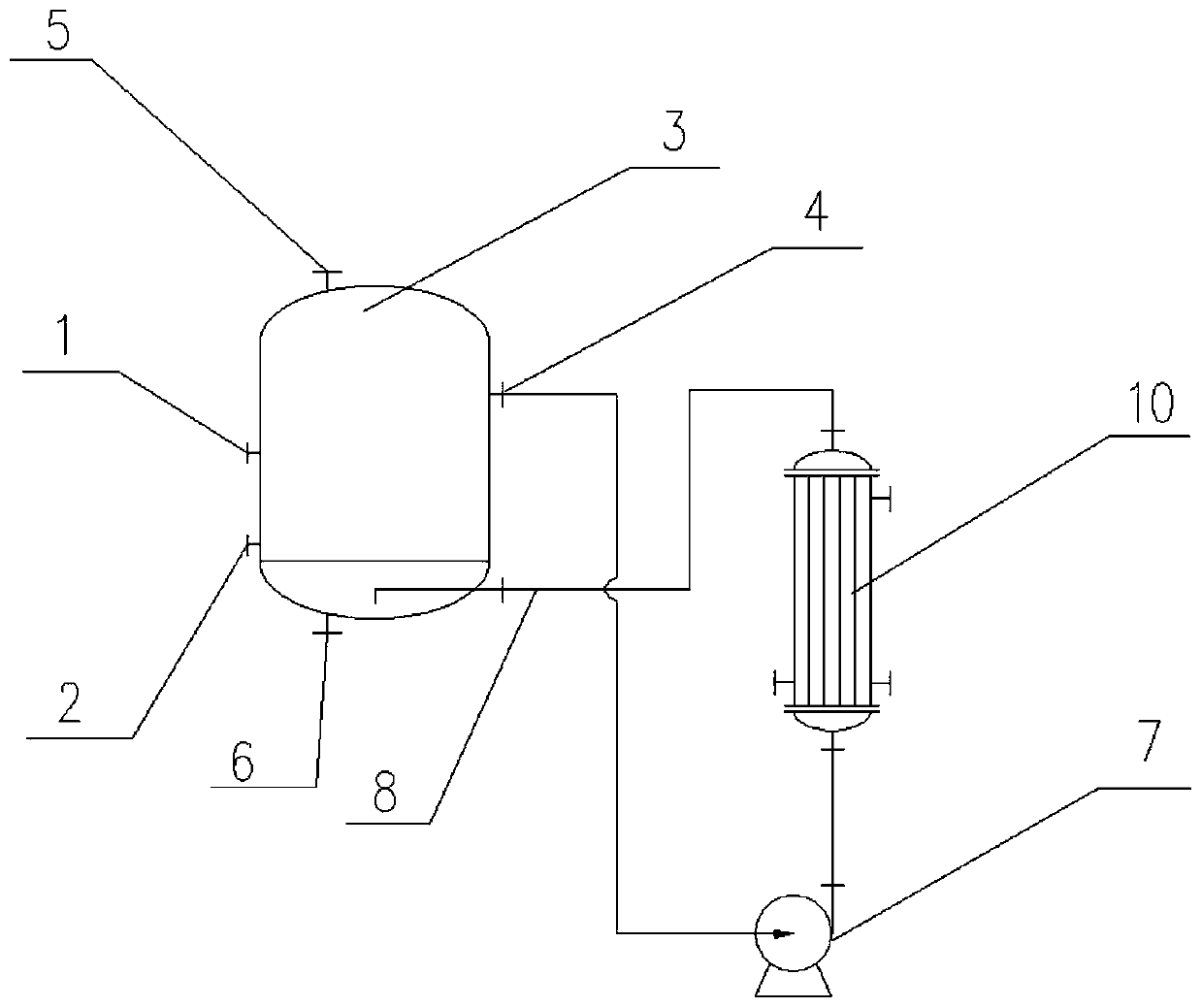

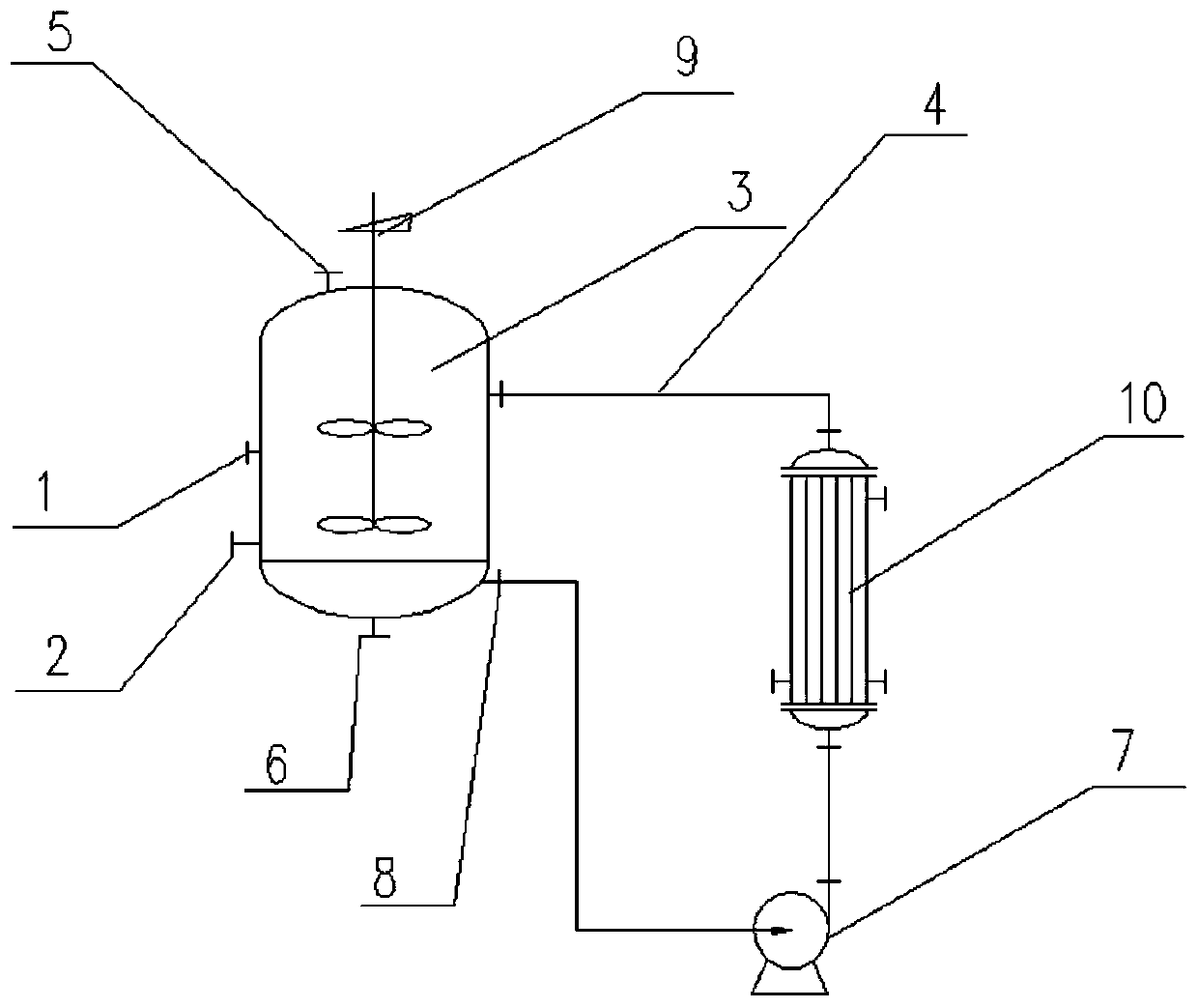

Process method and system for production of alpha-olefin by oligomerization of selective ethylene

InactiveCN107746365AHigh activityHigh selectivityCatalystsHydrocarbon preparation catalystsVapor–liquid separatorReaction temperature

The invention discloses a process method for production of alpha-olefin by oligomerization of selective ethylene; a high-pressure reaction kettle is externally connected with a material circulation pipeline; the material circulation pipeline is provided with a heat exchanger and a gas-liquid separator; in the synthesis process of alpha-olefin, ethylene is inputted to the high-pressure reaction kettle, alpha-olefin synthesized in the presence of a catalyst and a reaction solvent is dissolved in a solvent in the kettle, and a reaction liquid containing a product flows out from the bottom of thekettle, then has heat exchanged by the heat exchanger, enters the gas-liquid separator and is subjected to gas-liquid separation; gas discharged from the top of the gas-liquid separator flows back toa gas mixing tank, and a liquid is sent back to the high-pressure reaction kettle. The invention also relates to a system implementing the process. Heat generated from the reaction is removed in time,the reaction temperature is steadily controlled, and the activity and the selectivity of the catalyst are improved.

Owner:CHINA PETROLEUM & CHEM CORP

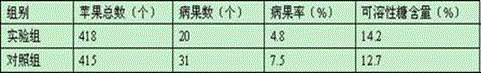

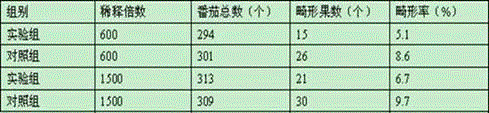

Chelated calcium fertilizer prepared by utilizing shells as well as preparation method and application thereof

InactiveCN105084944AHigh calcium contentNo toxicityAnimal corpse fertilisersClimate change adaptationAlcohol sugarsCalcium EDTA

The invention provides a chelated calcium fertilizer prepared by utilizing shells as well as a preparation method and an application thereof. The chelated calcium fertilizer is mainly prepared from 1.3-2.2 parts by weight of shell powder, 1 part by weight of glacial acetic acid and 0.19-0.66 part by weight of sugar alcohol through the steps of pretreatment, acidolysis, chelating and fine filtering, wherein the sugar alcohol is composed of 1 part by weight of propanetriol, 4 parts by weight of glucose and 9 parts by weight of sorbitol. According to the chelated calcium fertilizer prepared by utilizing shells as well as the preparation method and application thereof, the calcium resource of the shells is fully utilized, and the environment-friendly effect is facilitated; the product has the advantages of being free of heavy metals, high in calcium content, rich in nutrients, easy to absorb and the like, can be used for crops, traditional Chinese medicine materials, and fruit trees for a long term, and does not generate any adverse effects on plants and human bodies.

Owner:南宁汉和生物科技股份有限公司

Feed mixing device capable of preventing material from being attached on inner wall by utilizing impact

InactiveCN108579563AIngenious structureReasonable designRotating receptacle mixersFeeding-stuffInertiaDrive shaft

The invention discloses a feed mixing device capable of preventing a material from being attached on an inner wall by utilizing impact. The feed mixing device comprises a base, a mixing drum, a motor,a rotating shaft and a rack, wherein an impact plate is fixedly arranged on the outer wall of the mixing drum; a vertically-arranged fixed plate is connected with and arranged at the position of thebottom part of a top plate located at the right side of the mixing drum; the motor is arranged at the position of the top part of the top plate located at the right side of an upper connecting column;the output end of the motor is connected with a driving shaft; the tail end of the driving shaft is connected with an incomplete bevel gear matching with a first bevel gear; the rack is arranged at the rear side of the incomplete bevel gear and meshes with the incomplete bevel gear; the rotating shaft is inserted in the upper connecting column; the shaft body of the rotating shaft located in theinterior of the mixing drum is fixedly and equidistantly provided with a plurality of groups of stirring blades along a length direction; two adjacent groups of the stirring blades are in staggered arrangement; and the mixing drum is also connected with a feeding hopper and a discharging pipe. The feed mixing device provided by the invention has ingenious structure and reasonable design, can shakeoff a feed attached on the inner wall of the mixing drum by utilizing inertia, avoids the feed from hanging on a wall, and reduces the waste of the feed.

Owner:何锦国

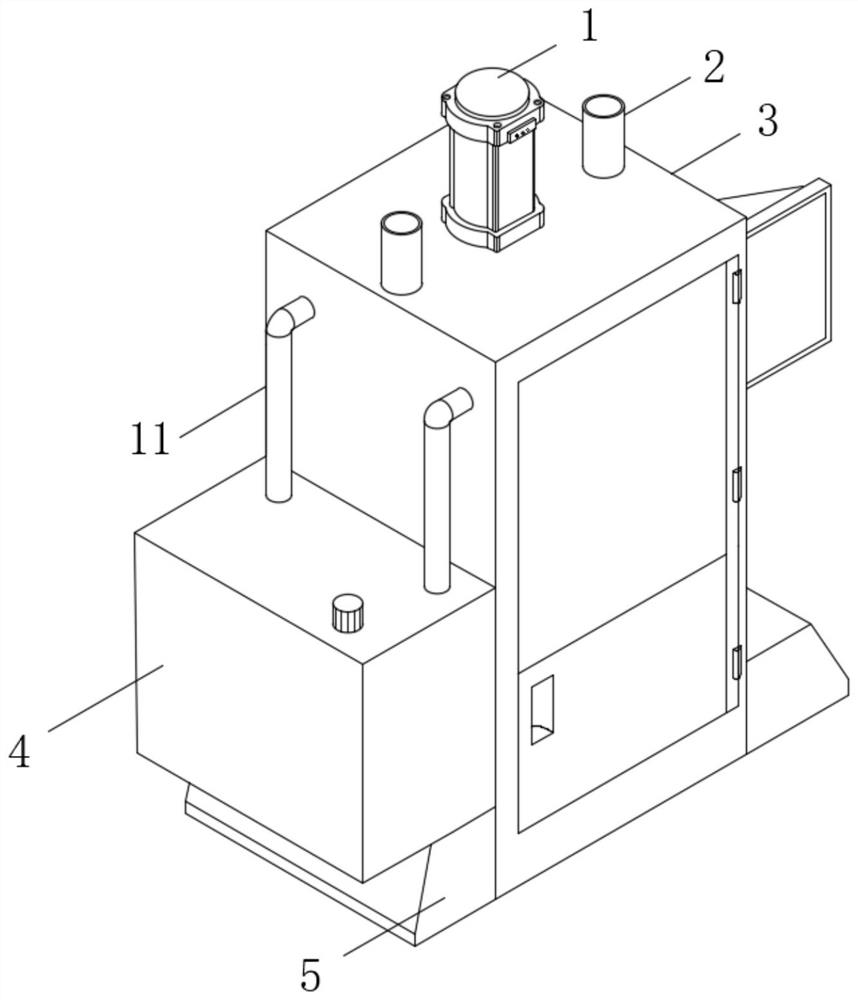

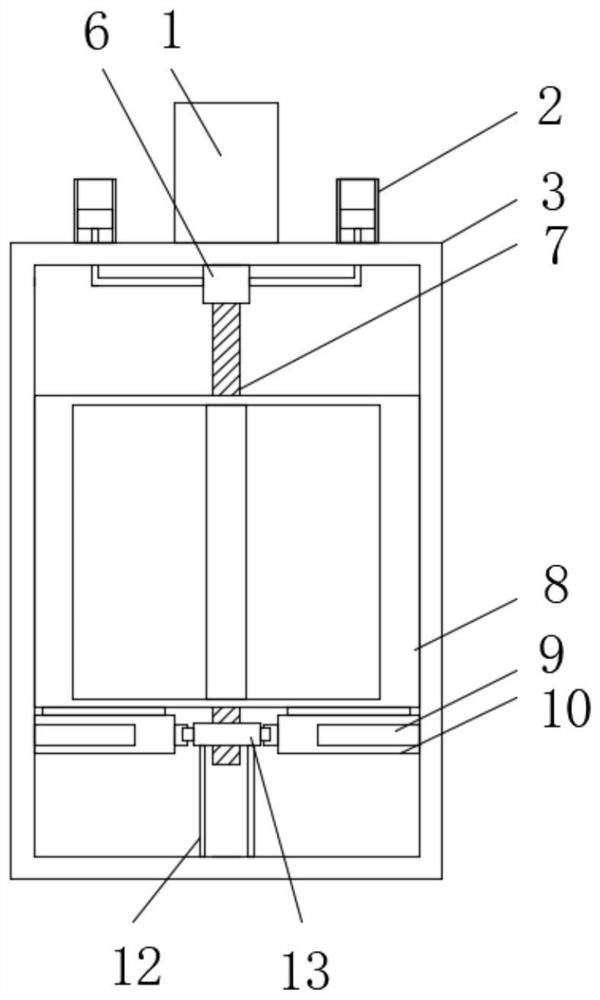

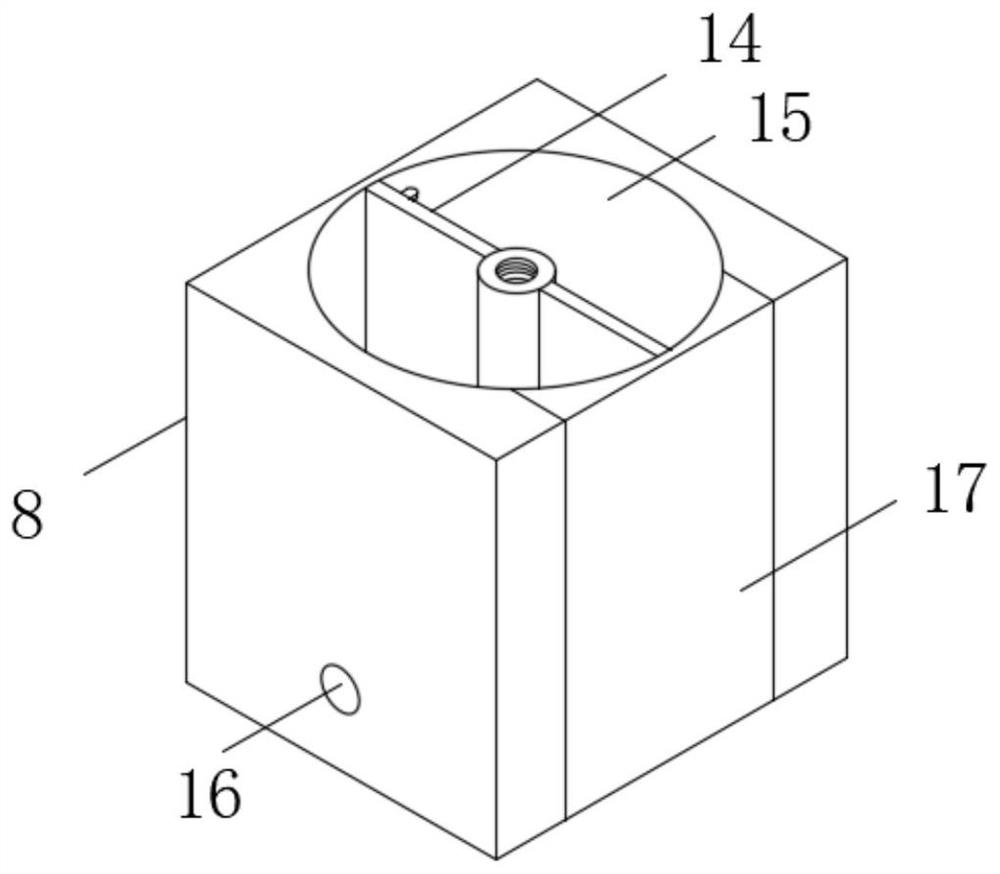

Technology for recycling and treating high-salt organic wastewater resources

InactiveCN107601791AAvoid hanging on the wallAvoid the situationWater contaminantsMultistage water/sewage treatmentOrganic solventWastewater

The invention relates to a treatment method of high-salt wastewater, in particular to a technology for recycling and treating high-salt organic wastewater resources. The technology has the advantagesthat the organic component and salt in the wastewater can be fully extracted, recycled, and utilized, so that the running cost in incineration is reduced; the organic solvent can be recycled, so thatthe obtained mixed salt can be separated and purified in a recrystallizing way, and then recycled, thereby obtaining the pure salt with single component, and saving the resource.

Owner:XINXIANG SHUANGCHENG ENVIRONMNETAL PROTECTION EQUIP CO LTD

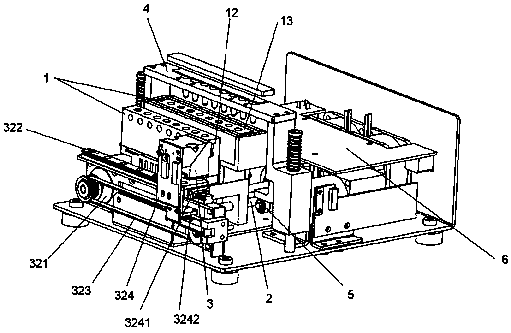

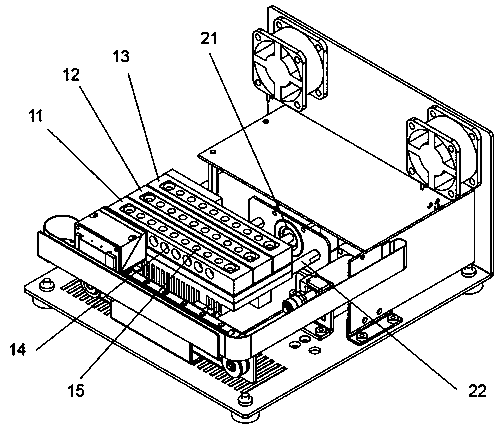

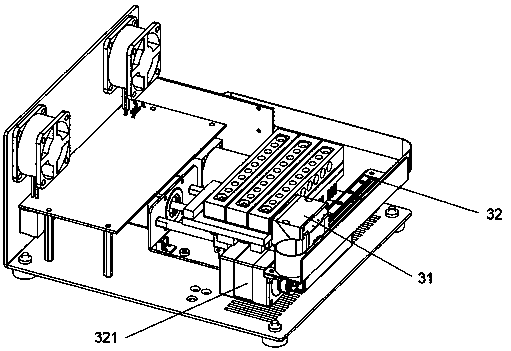

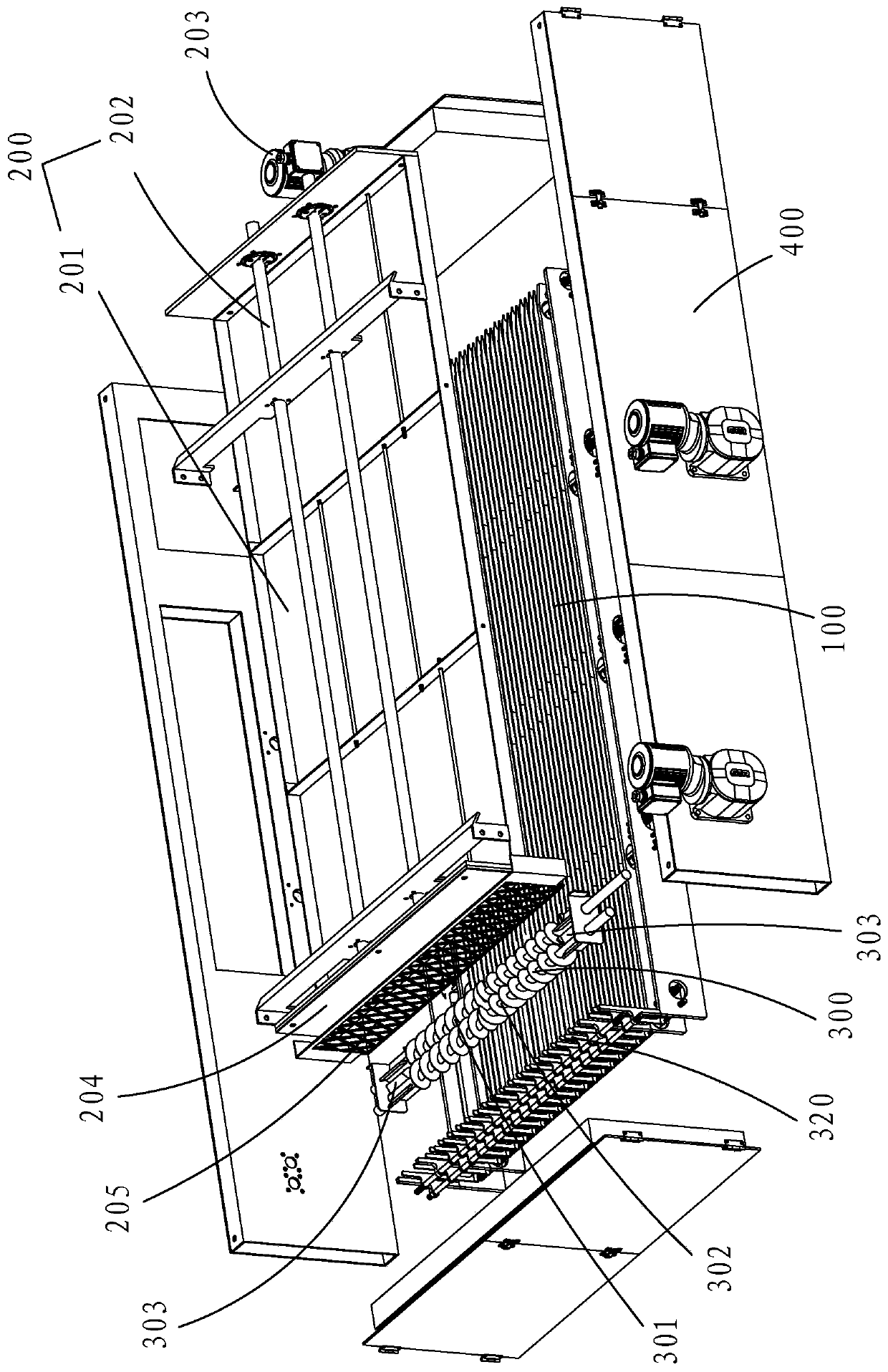

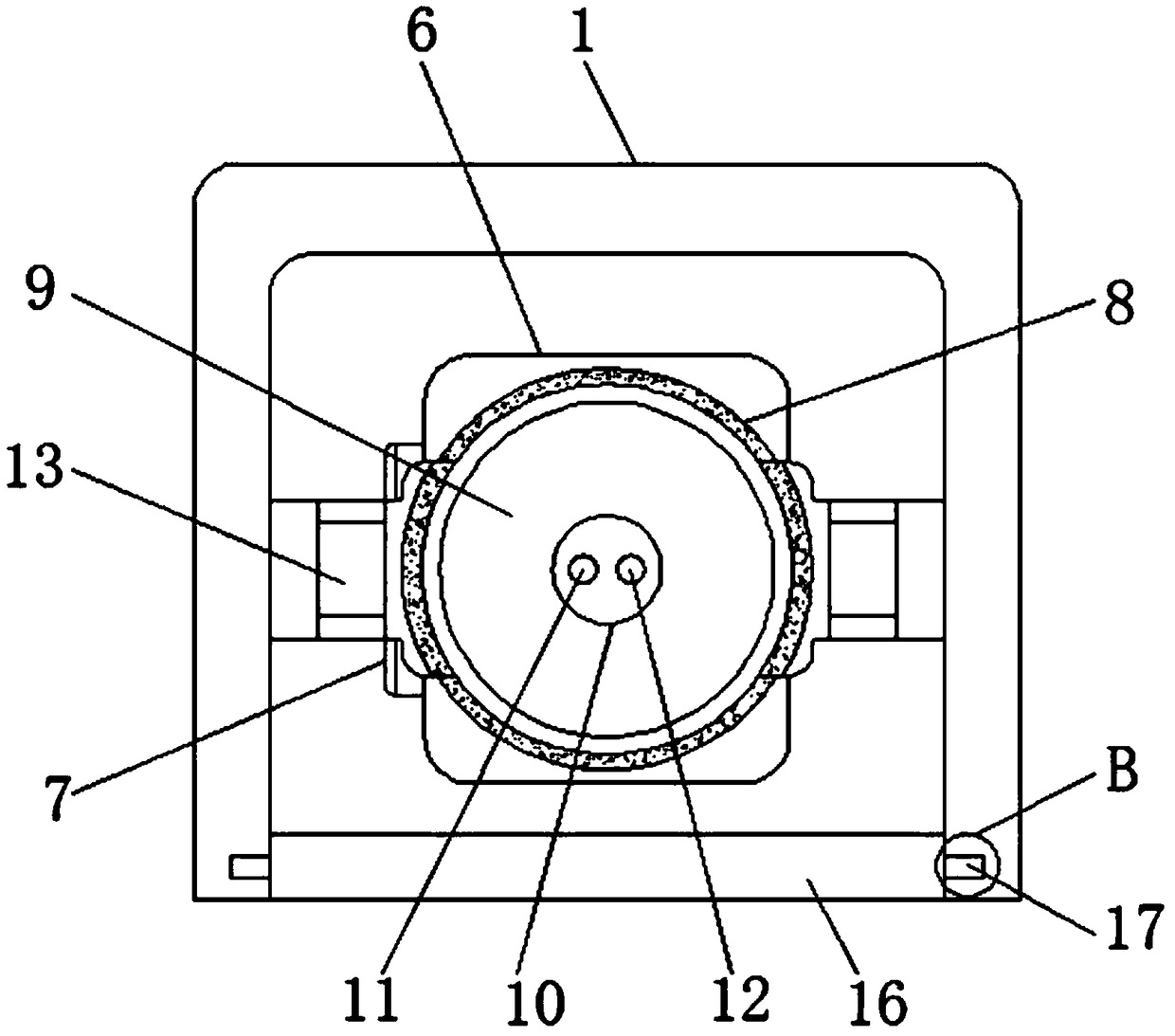

Extreme speed PCR reaction detecting device and detecting method

PendingCN110387325AEasy to moveMove fastBioreactor/fermenter combinationsBiological substance pretreatmentsHorizontal transmissionTemperature control

The invention provides an extreme speed PCR reaction detecting device, which comprises a temperature control system, a horizontal transmission mechanism, a reaction tube fixing device, and a perpendicular transmission mechanism.The horizontal transmission mechanism drives the temperature control system to move horizontally, the reaction tube fixing device is connected with the perpendiculartransmission mechanism and capable of moving up and down along an eccentric wheel of the perpendiculartransmission mechanism so as to realize the relative reciprocating movement of a reaction tube on the reaction tube fixing device between temperature control modules. The extreme speed PCR reaction detecting device is compact in structure, the moving speed is fast, the temperature rising and falling speed of reaction liquid in the reaction tube can be increased by the temperature setting of a high temperature module and a low temperature module, the two aspects of increasing the temperature rising and falling speed of the reaction tube and the moving speed between the reaction tube and the temperature control modules are set about to achieve the purpose of shortening the time required for PCR reaction, at the same time, the detection result of the extreme speed fluorescence PCR reaction detecting device is good in repeatability, and the result is accurate.

Owner:GUANGZHOU ANGEL BIOSAFETY TECH CO LTD

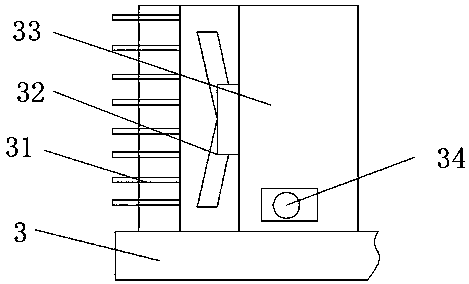

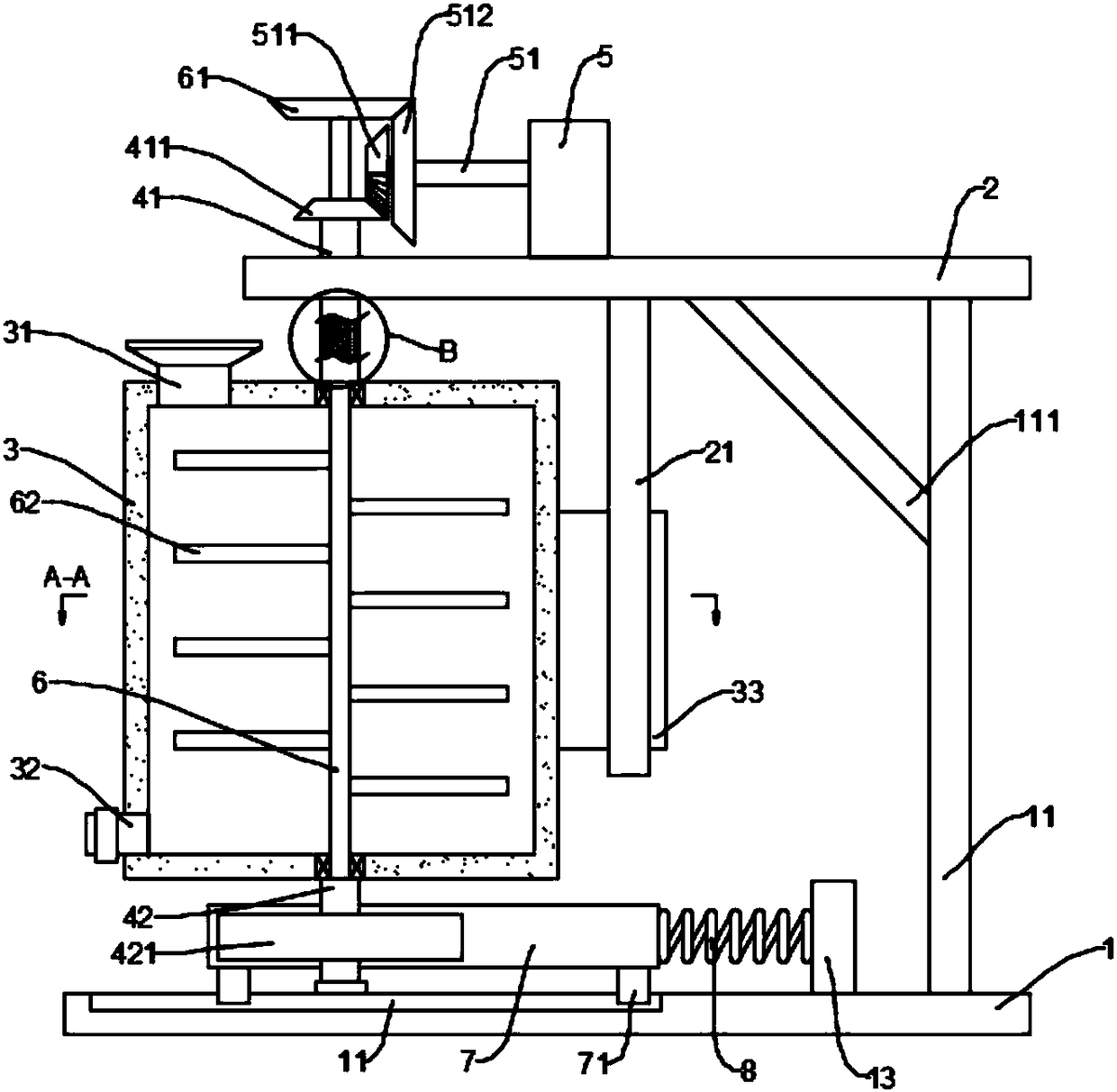

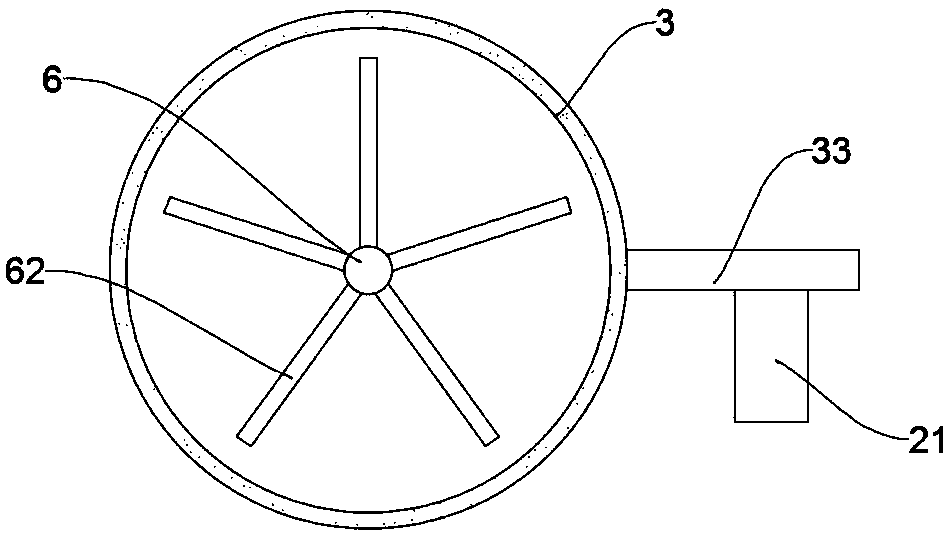

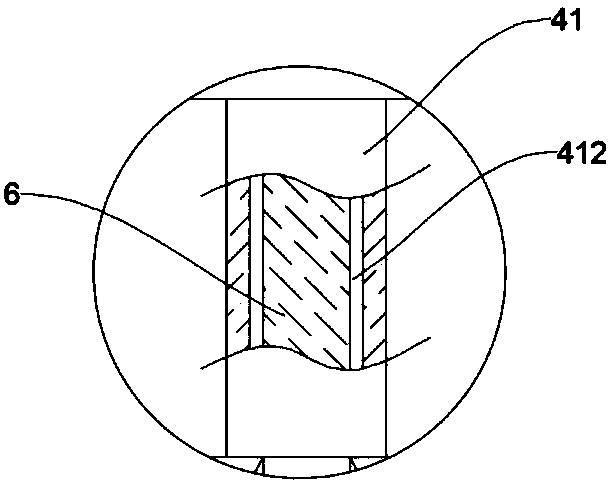

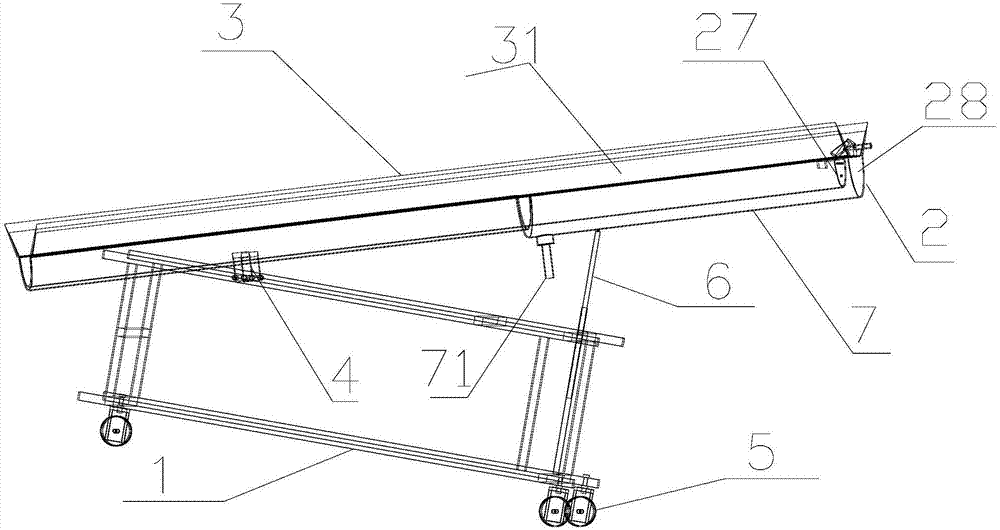

Fast cooling and breaking system for glass melt in kiln

The invention relates to a fast cooling and breaking system for glass melt in a kiln. The system comprises a support frame (1) and a chute (3) obliquely mounted on the support frame (1), wherein the higher end of the chute (3) is connected with a water quenching device (2), and the water quenching device (2) is provided with a cooling water jet hole facing the chute (3); a cooling water flow channel (7) communicated with the water quenching device (2) is arranged on the outer side of the bottom of the chute (3) and extends from the higher end of the chute (3) to the lower end, and a first cooling water inlet (71) is formed in the bottom end of the cooling water flow channel (7). The system can fast cool and break red-hot glass melt to form clean granulated glass capable of being used directly by a production line.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

Material conveying device provided with screw shaft spreading mechanism as well as material conveying channel

PendingCN111439610AAvoid stickingAvoid accumulationLarge containersLoading/unloadingRelative displacementElectric machine

The invention provides a material conveying device provided with a screw shaft spreading mechanism. The material conveying device comprises a fold pushing type material conveying platform, the screw shaft spreading mechanism arranged above the starting end of the conveying platform and a material grinding device arranged above the conveying platform; a first motor drives a first driving mechanismto drive the conveying platform to perform reciprocating synchronous circumferential motion; the material grinding device comprises a grinding platform and a second driving mechanism; a second motor drives the second driving mechanism to drive the grinding platform to perform reciprocating synchronous circumferential motion vertical to the pushing direction of a material; the starting end of the conveying platform is upwarped, exceeds height of a screw shaft, and forms a material conveying channel from top to bottom with side walls of the material grinding device; and a hollow-out plate is arranged on the side wall of one side of the material grinding device and attached to the side wall. The side wall formed by grid strips and the side wall of the material grinding device form relative displacement with the tightly attached hollow-out plate, and material adhesion and accumulation on the side wall of the material conveying channel can be prevented.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

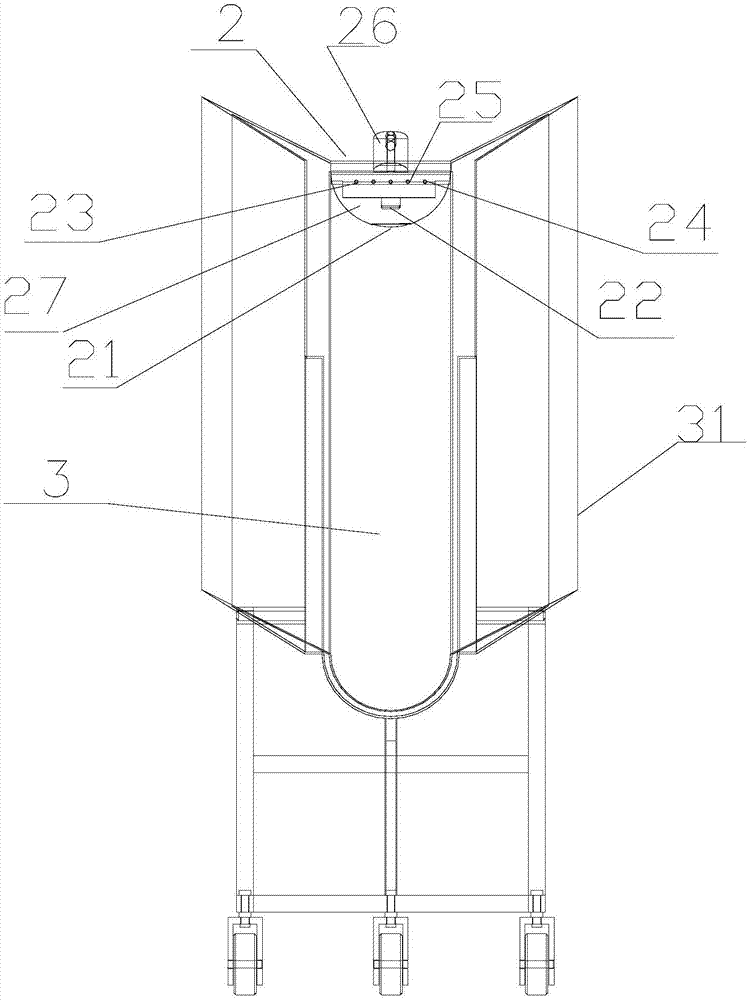

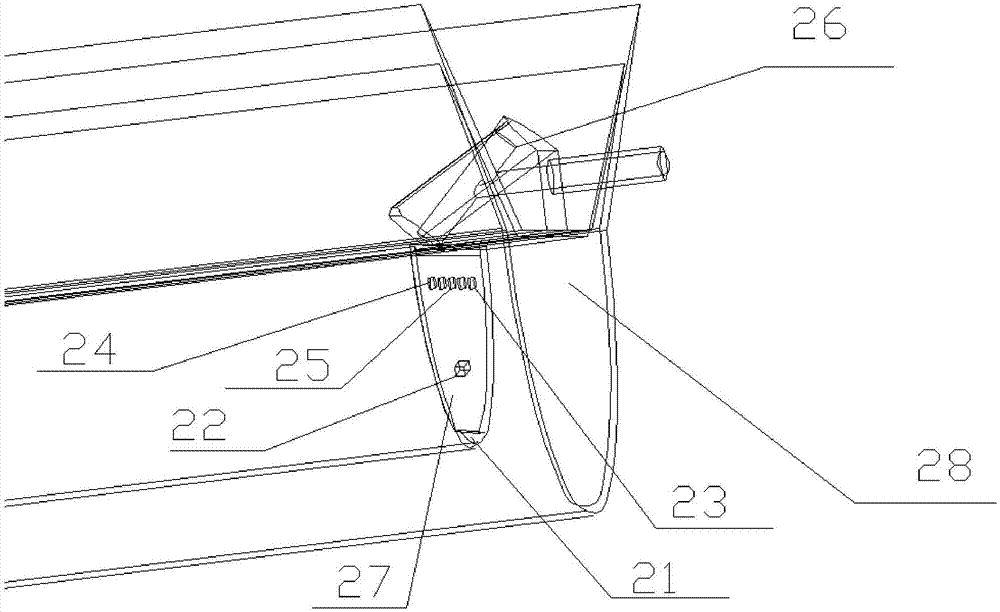

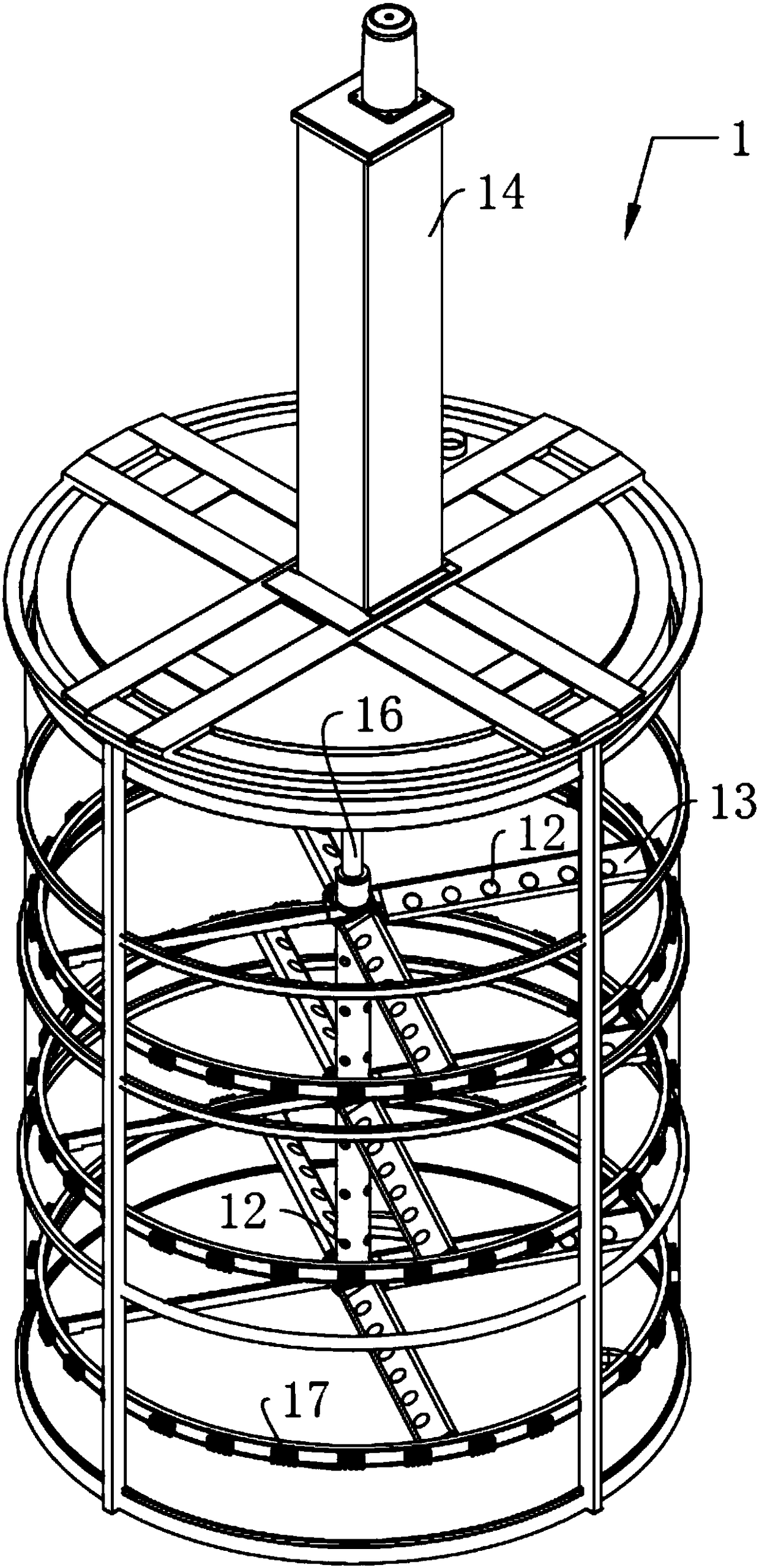

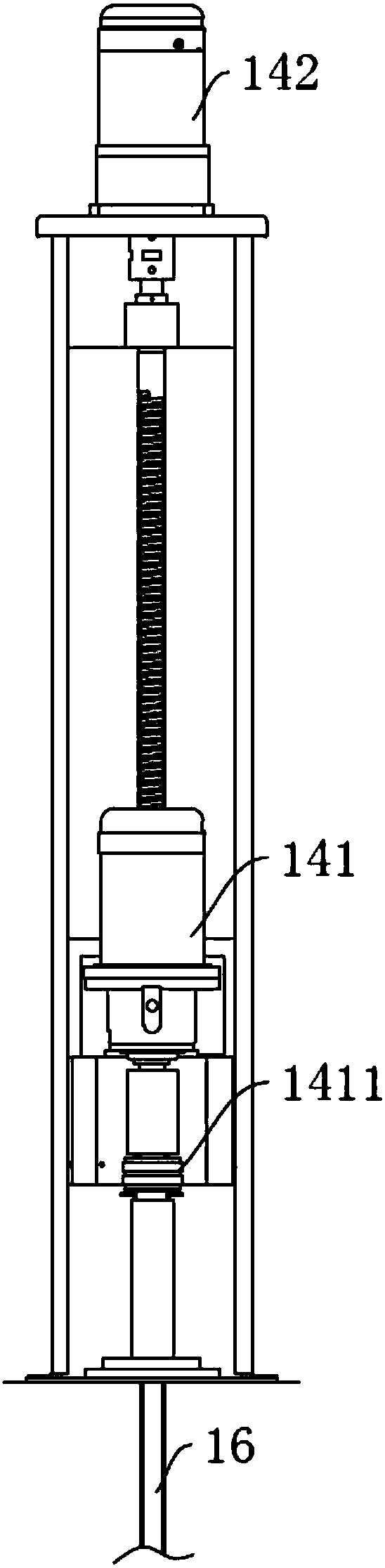

Dynamic photo-bio-reactor and method for culturing microalgae by utilizing dynamic light

InactiveCN108192801AAvoid hanging on the wallTo achieve the purpose of automatically cleaning the barrel wallBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidPropeller

The invention provides a dynamic photo-bio-reactor. The dynamic photo-bio-reactor comprises a culture tank and a light emitting unit; the dynamic photo-bio-reactor further comprises an optical arm blade propeller and a driving mechanism; the light emitting unit is arranged on the optical arm blade propeller; the optical arm blade propeller is arranged in the culture tank; the driving mechanism canbe used for driving the optical arm blade propeller to do rotating and hoisting movement in the culture tank. The invention further provides a method for culturing microalgae by utilizing dynamic light; a culture solution of the microalgae is subjected to rotating and hoisting type stirring; in a stirring process, dynamic light illumination which is synchronized with stirring is carried out. Thedynamic photo-bio-reactor and the method for culturing the microalgae by utilizing the dynamic light, provided by the invention, have the advantages of simplicity in operation, low cost and capabilityof effectively improving the yield of microorganisms (microalgae) cultured by the method.

Owner:约翰李

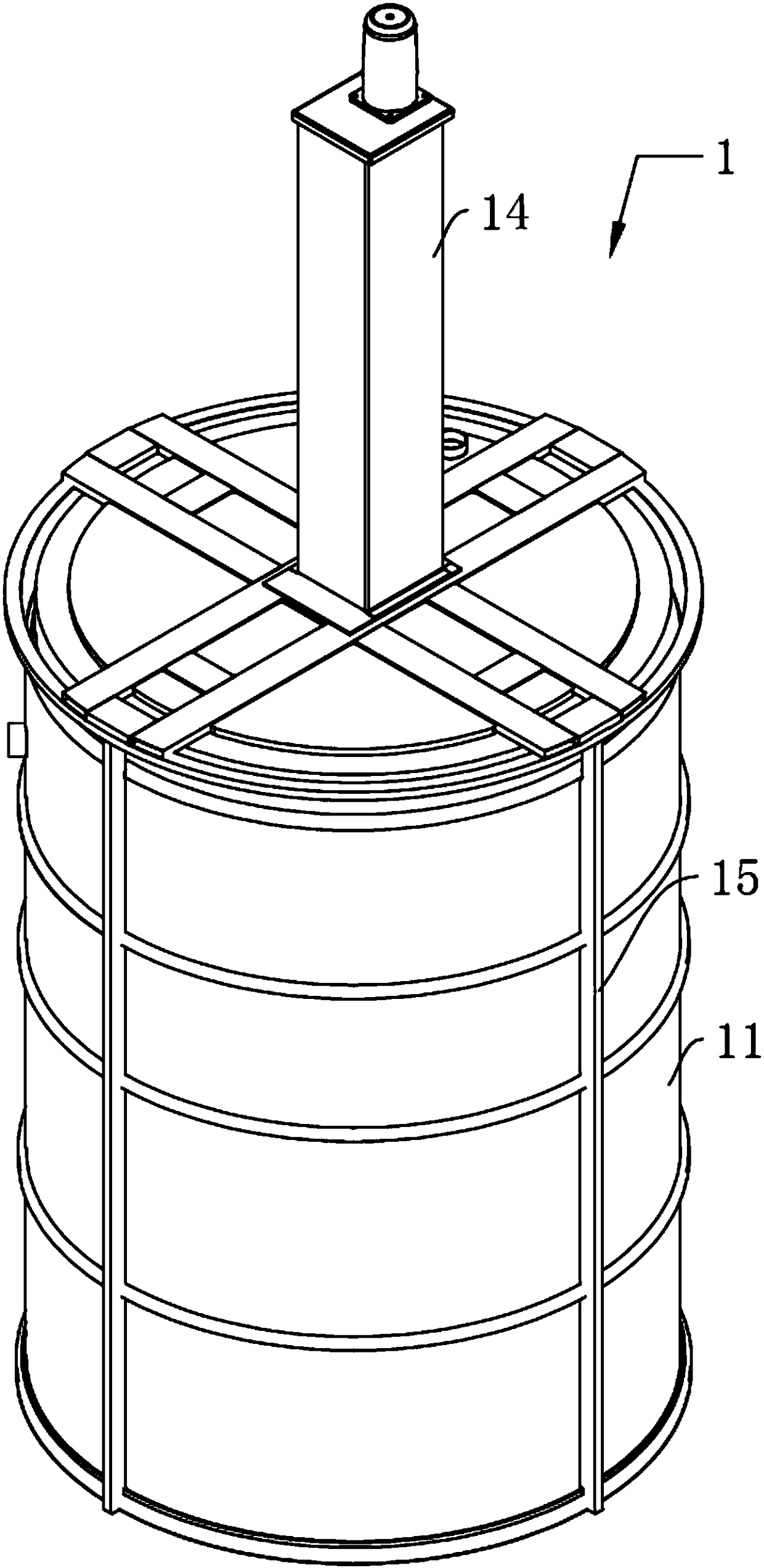

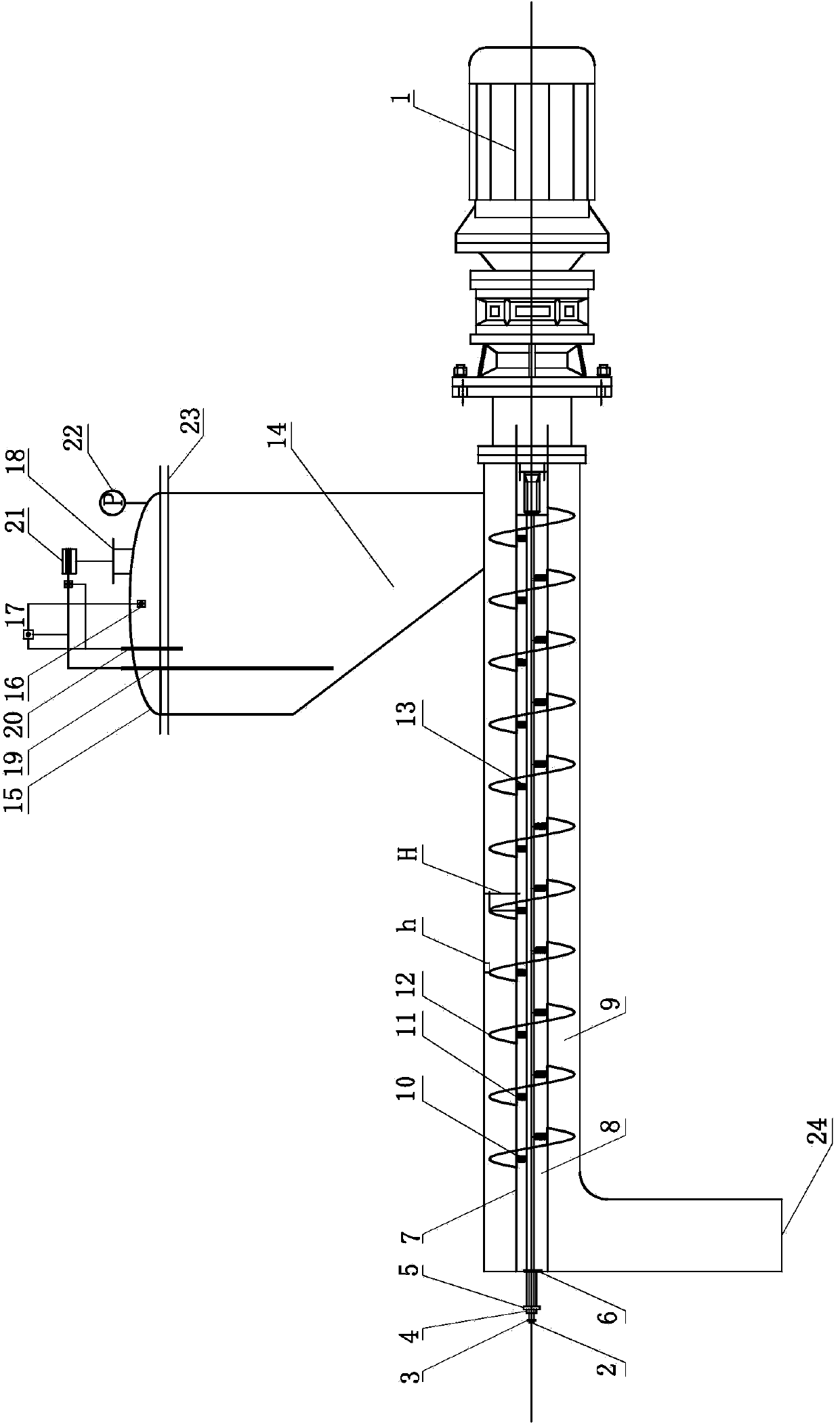

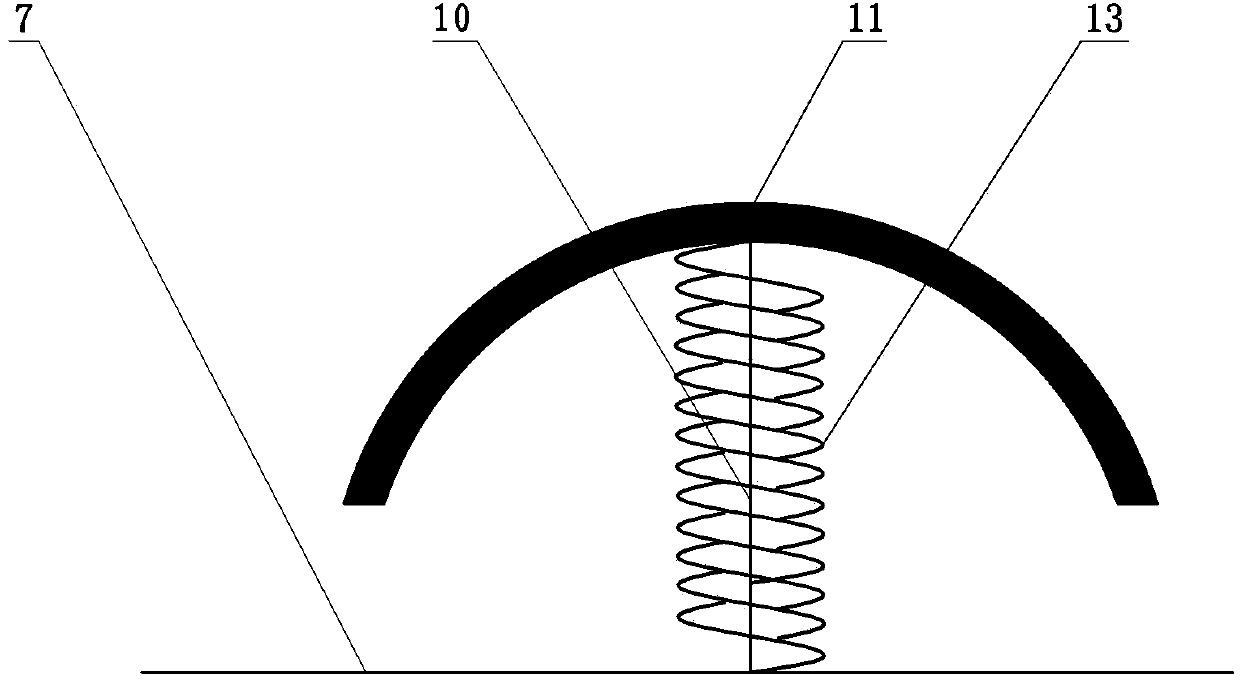

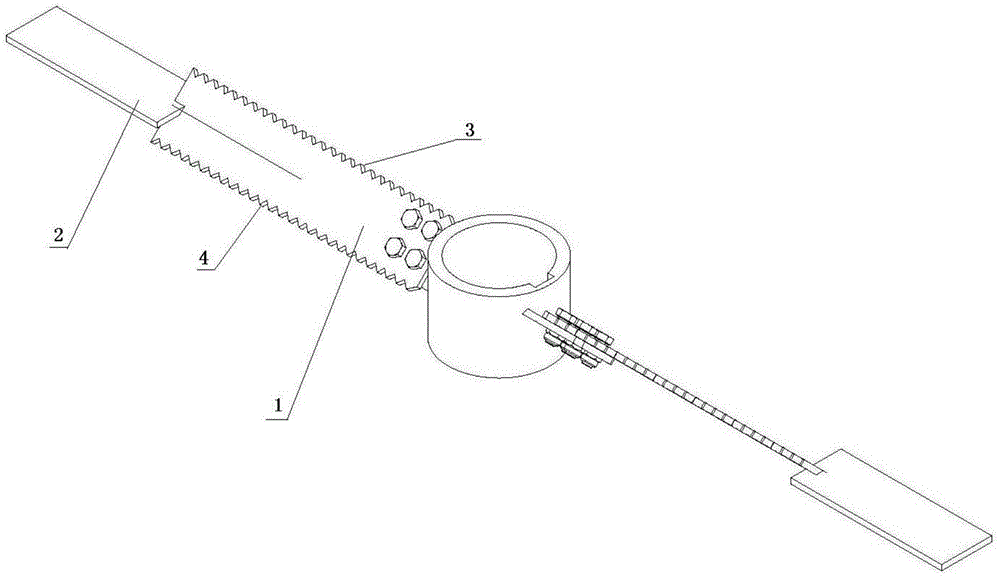

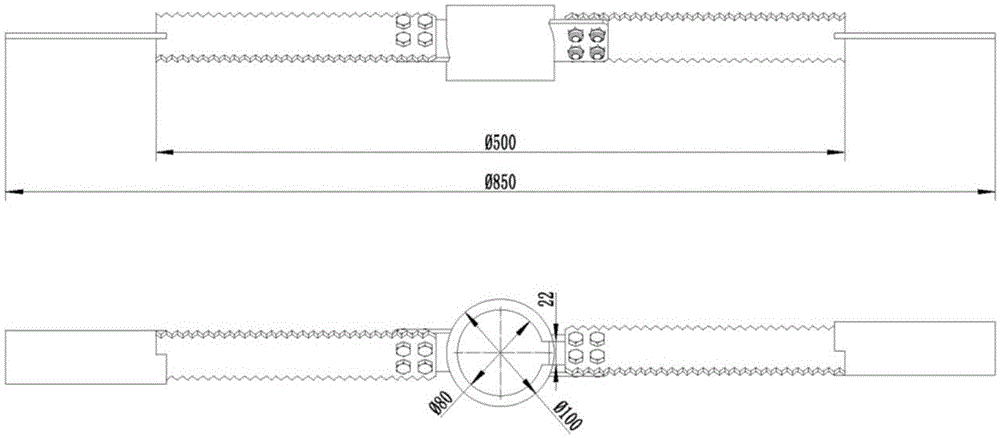

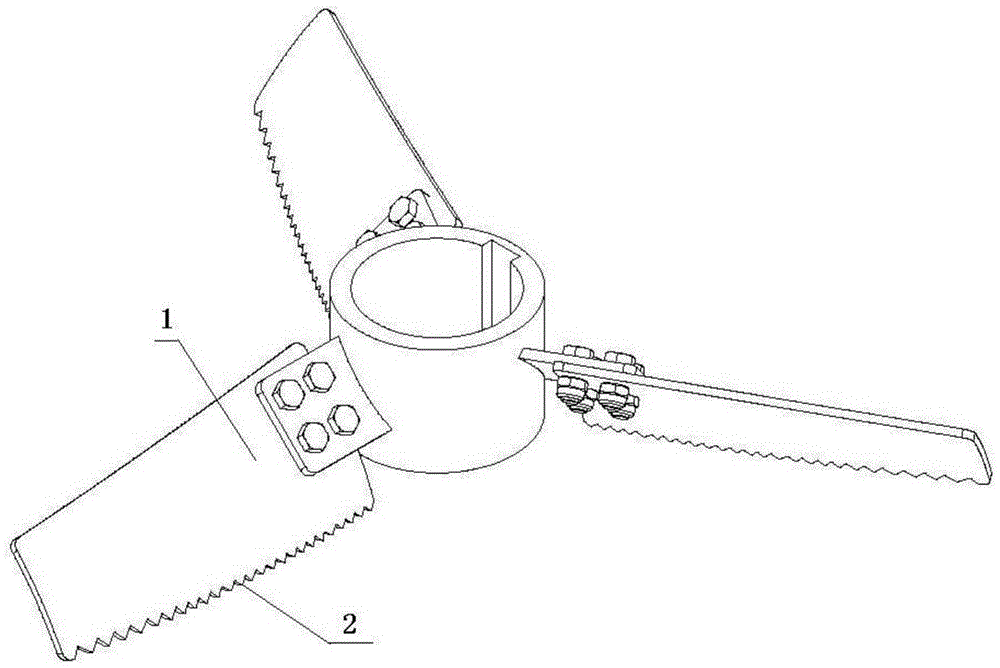

Pressurized rotary screw powder feeder

ActiveCN103771155APrevent fallingAchieving long-term operationLoading/unloadingMechanical engineeringCoal

The invention relates to a pressurized rotary screw powder feeder. The feeder is composed of a speed adjustable motor, a powder chamber and a screw powder feeder body. The pressurized rotary screw powder feeder is capable of conveying a variety of powder such as coal powder, mineral powder, cement and lime; can automatically fill feed in a closed process and is good in environmental protection effects and easy to operate and control; can achieve pneumatic pressurized conveying at the pressure of 5.0MPa and above and is applicable to the section requiring pressure of a post-system; has a simple and reliable pneumatic mixing mechanism to effectively avoid powder bridging or wall hanging and to prevent powder clogging.

Owner:XIAN ORIGIN CHEM TECH

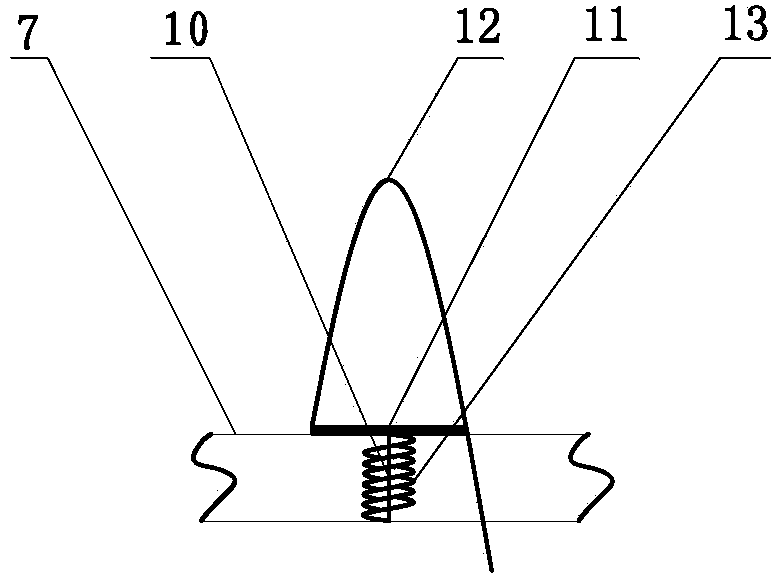

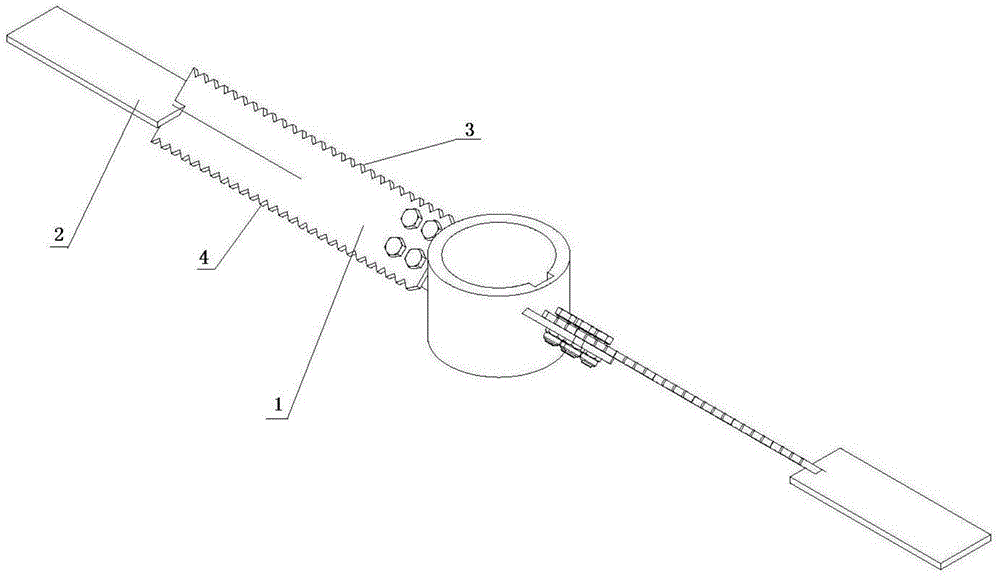

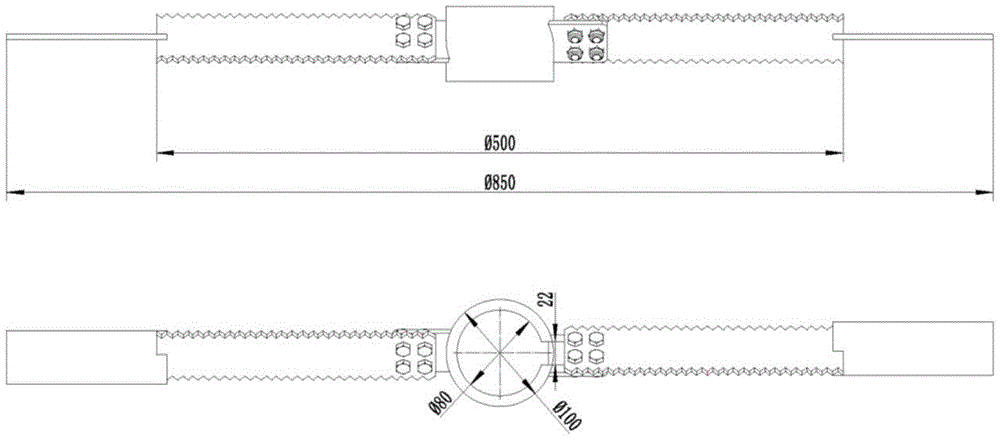

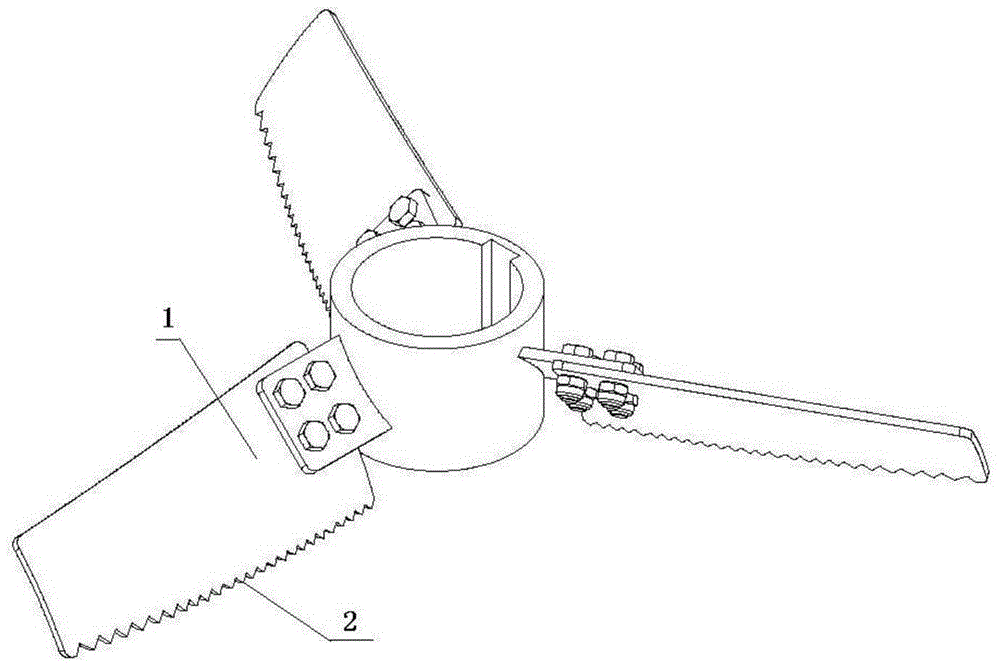

Stirring device and container for preparing colloid class plasma solubilizer

ActiveCN105478039AAvoid hanging on the wallAvoid clumpingRotary stirring mixersTransportation and packagingPulp and paper industryColloid

The invention provides a stirring device for preparing colloid class plasma solubilizer. The stirring device comprises a stirring shaft and double layers of combination blades which are fixed to the stirring shaft; the double layers of combination blades comprise a bottom layer of stirring blades and an upper layer of stirring blades, the bottom layer of stirring blades are fixed to one end of the stirring shaft, and the upper layer of stirring blades are fixed to the stirring shaft; the upper layer of stirring blades are variable-cross-section type two-blade inclined blades; both the front edges and the rear edges of the main blades of the variable-cross-section type two-blade inclined blades are in sawtooth shapes. According to the stirring device, macromolecular gelatin materials can be dispersed, cut and broken effectively, the capacity of maintaining uniform, stable and rapid stirring is achieved, and the optimal stirring flow pattern is achieved, so that molecular weight distribution is effectively controlled, the percent of pass of subsequent products is raised, production time is saved, it can be further guaranteed that liquid medicine is prevented from splashing and hanging on the wall in the stirring process, accordingly the raw material loss is reduced, and production cost is saved.

Owner:吉林省长源药业有限公司

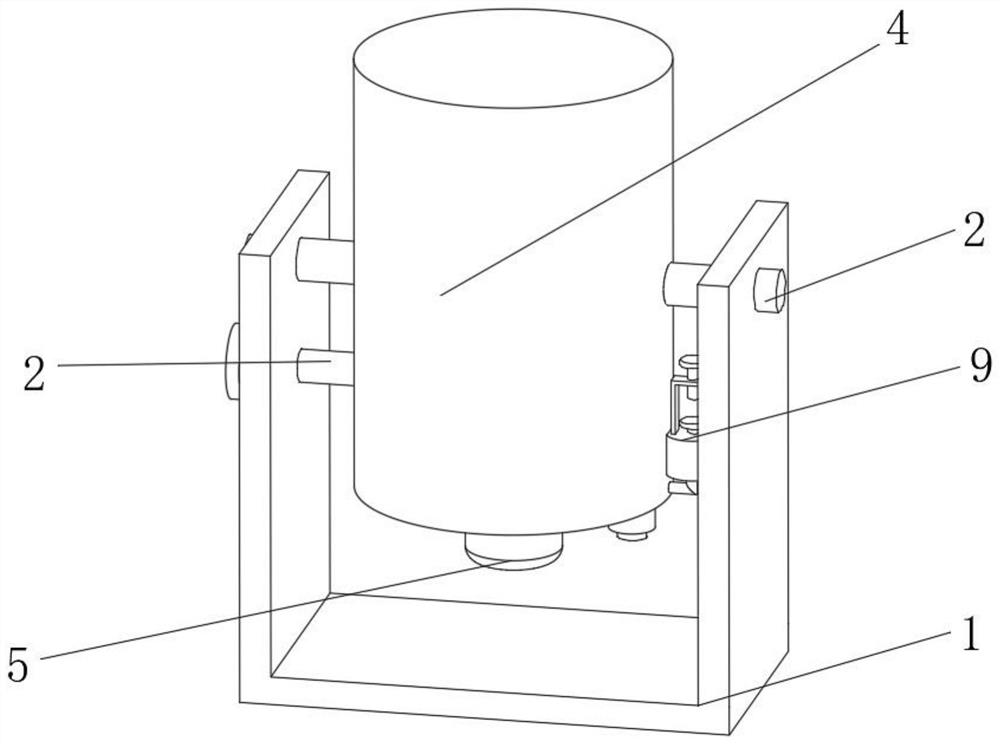

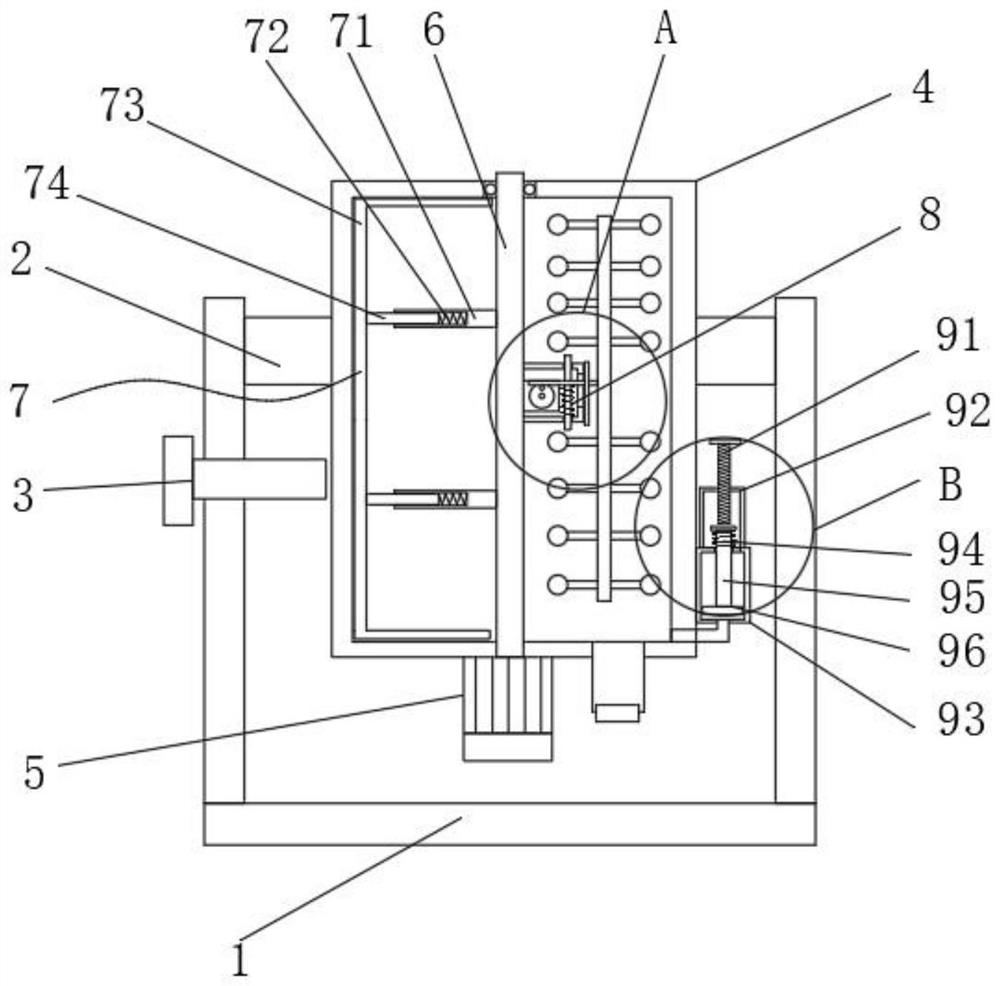

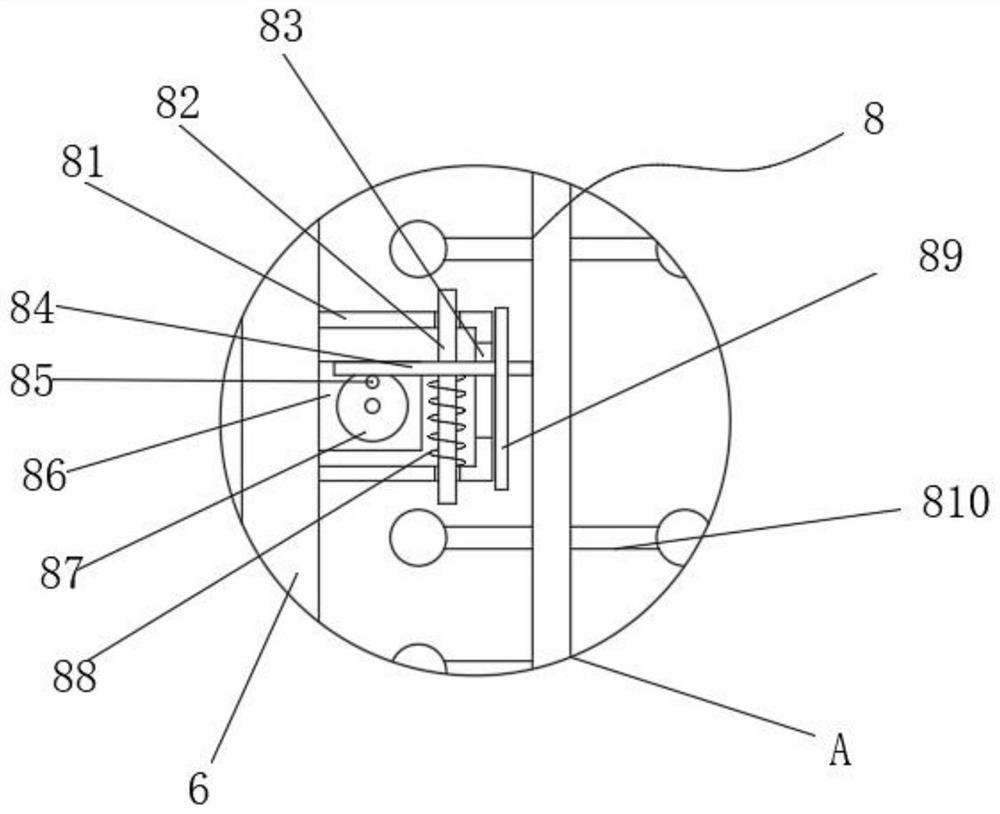

Water-based ink conveying cylinder with stirring function

PendingCN112644902AAchieving Squeeze VibrationAchieving mixing and stirringShaking/oscillating/vibrating mixersWithdrawing sample devicesEngineeringPrinting ink

The invention discloses a water-based ink conveying cylinder with a stirring function. The water-based ink conveying cylinder comprises a support, a fixed shaft, a positioning pin, a cylinder body, a motor, a stirring rod, a wall cutting structure, an oscillating structure and a sampling structure; and fixed shafts are symmetrically installed on the two sides of the circumferential surface of the cylinder body, the two fixed shafts are installed in a bearing seat of the support in a matched mode through bearings, and the positioning pin is transversely arranged in the side wall of the support in a penetrating mode through thread fit. The water-based ink conveying cylinder has the beneficial effects that by arranging the oscillating structure, when the stirring rod rotates, an oscillating motor works to drive a rotating disc to rotate, under the pushing cooperation of the swing rod, extrusion vibration of a vibration strip can be better achieved, under the cooperation of a limiting rod and an extendable spring, reciprocating vibration of the vibration strip in the vertical direction can be achieved, a vibration frame is driven to vibrate up and down in a reciprocating mode, in the vibration process, mixing and stirring of water-based ink can be better achieved, layering and hardening of materials are avoided, meanwhile, solid-liquid separation of the printing ink in centrifugal rotation is avoided, and a better mixing effect is achieved.

Owner:哈尔滨绿科科技有限公司

Chelated calcium fertilizer prepared from oyster shell, and preparation method and application thereof

The invention provides a chelated calcium fertilizer prepared from oyster shell, and a preparation method and application thereof. The chelated calcium fertilizer is mainly prepared by carrying out pretreatment, acid hydrolysis, chelation, refined filtration and the like on the following components in parts by weight: 1.5-2 parts of oyster shell powder, 2.7-5 parts of concentrated hydrochloric acid and 0.2-0.6 part of sugar alcohol. The mass percent of the concentrated hydrochloric acid is 20-37%. The weight ratio of the solute in the concentrated hydrochloric acid to the oyster shell powder is 1:(1.5-2). The sugar alcohol is composed of the following components in parts by weight: 1 part of glycerol, 4 parts of glucose and 9 parts of sorbitol. The chelated calcium fertilizer can fully utilize the calcium agent resource of the oyster shell, is beneficial to environment friendliness, has the advantages of no heavy metal, high calcium content, rich nutrients and the like, can be easily absorbed, can be used on crops, traditional Chinese medicinal materials and fruit trees for a long time, and can not generate any adverse effect on the plant and human body.

Owner:南宁汉和生物科技股份有限公司

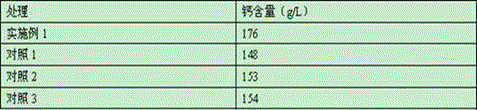

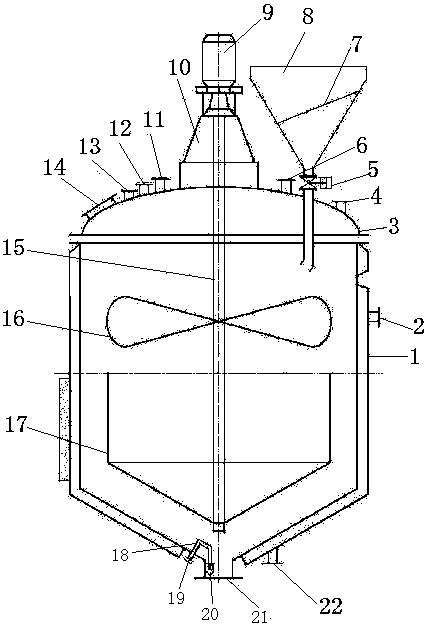

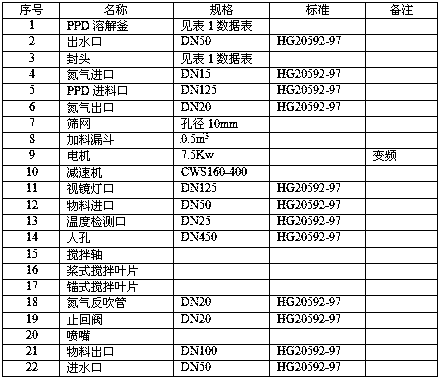

Production method of high-quality PPTA (poly(p-phenylene terephthalamide)) resin and PPD (p-phenylenediamine) stirring vessel

ActiveCN109912795AEfficient mixingAvoid material hanging on the wallRotary stirring mixersMixer accessoriesSolventL&D process

The invention provides a production method of high-quality PPTA (poly(p-phenylene terephthalamide)) resin and a PPD (p-phenylenediamine) stirring vessel, and belongs to the technical field of polymermaterials. The method for obtaining the high-quality PPTA resin comprises the following steps: blending of an NMP / CaCl2 complex solvent; preparation of a PPD solution; measuring of TPC (terephthaloylchloride); condensation polymerization; blank treatment. The PPD stirring vessel is also provided, PPD dissolution parameters such as temperature, stirring speed, dissolution time and the like are optimized, and all PPD can be dissolved and participate in the condensation polymerization. Pre-polymerization and the condensation polymerization are carried out in the same reactor, the technological process is short, the total molar ratio is easy to control, repeated transfer of materials is avoided, and influence of residues in the system on the molar ratio and influence of deterioration of deposited materials at dead corners of a conveying system on the reaction are avoided.

Owner:HENAN SHENMA NYLON CHEM

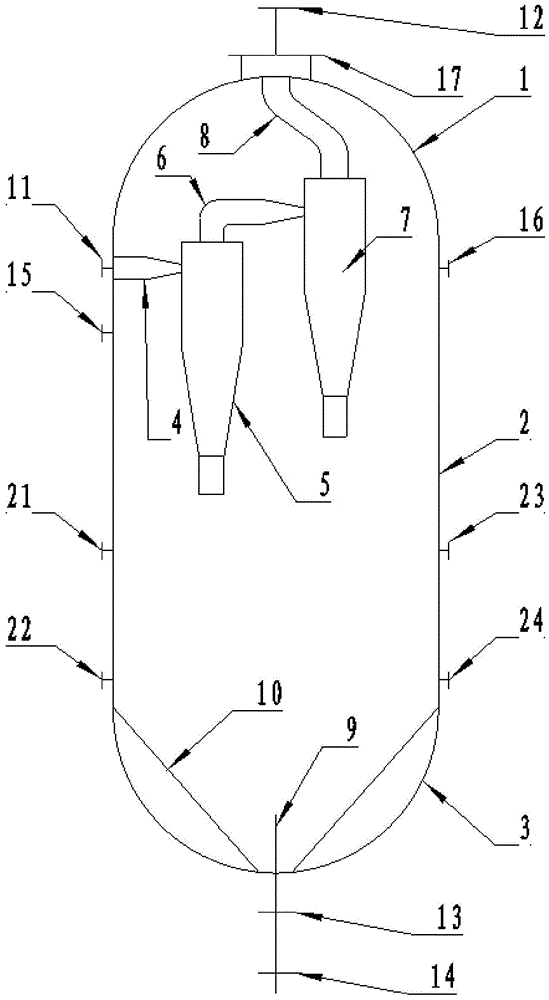

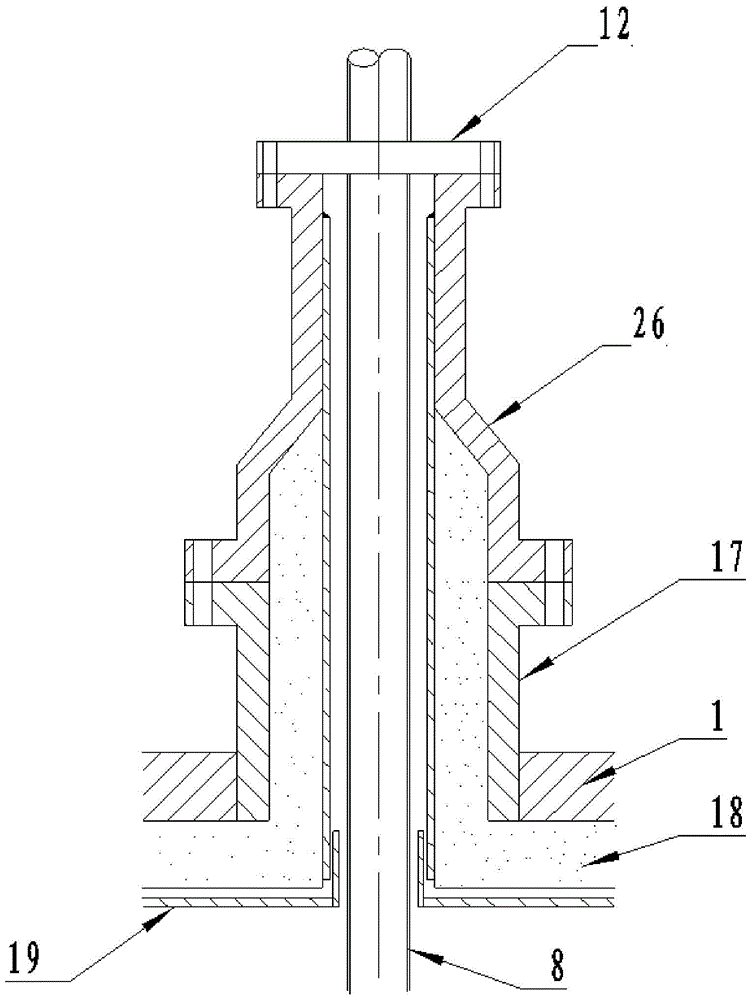

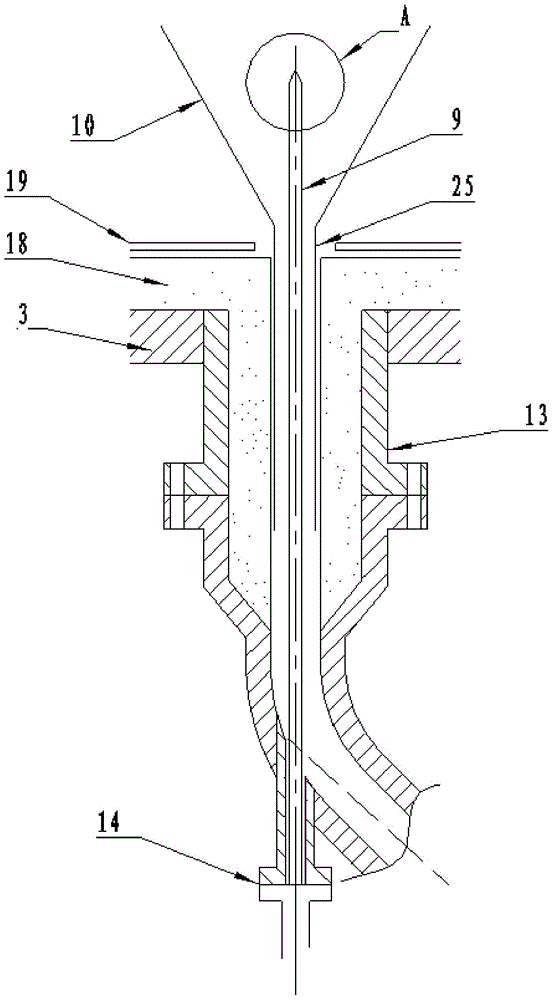

Slurry-bed hydrocracking high pressure hot separator with cyclone separators

ActiveCN104984839AEasy to separateAvoid hanging on the wallReversed direction vortexCycloneProduct gas

The invention provides a slurry-bed hydrocracking high pressure hot separator with cyclone separators, which comprises a housing, wherein the housing is in an upper end and lower end closed cylindrical shape; the housing is externally provided with a reaction product inlet (11) used for injecting a slurry-bed reaction product into the housing, and is further externally provided with a high pressure hot separator gas outlet (12) used for exhausting high pressure hot separator gas in the housing; a high pressure hot separator liquid outlet (13) used for discharging high pressure hot separator liquid in the housing is arranged at the lower part of the housing; and the two cyclone separators are sequentially connected between the reaction product inlet (11) and the high pressure hot separator gas outlet (12), and arranged in the housing. The two cyclone separators are arranged in the slurry-bed hydrocracking high pressure hot separator with the cyclone separators, so that the separating effect of solid is improved.

Owner:BEIJING PETROCHEM ENG

Pre-electrolysis-based wet catalytic oxidation sludge treatment system and method

PendingCN110818213AImprove heating efficiencySolve the problem of low efficiency of jacket heatingSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationElectrolysisSludge

The invention relates to the technical field of sludge treatment systems and methods, and provides a pre-electrolysis-based wet catalytic oxidation sludge treatment system and method, wherein the pre-electrolysis-based wet catalytic oxidation sludge treatment system comprises a sludge storage tank, a spiral slag remover, a homogenizer, an electrolysis electromagnetic heater, a segmented stepped heater assembly and a reaction kettle, and the devices are sequentially connected through pipelines. The defects of the prior art are overcome, the design is reasonable, and the structure is compact; the temperature rise of a sludge inlet and a sludge outlet in each section of heater is constant by adopting a segmented gradient type heating structure, and the heating coil power can be adjusted according to different sludge process parameters to meet the temperature rise requirement. Before sludge enters the heaters, the sludge subjected to primary heat exchange is pretreated in a pre-electrolysis mode, and the viscosity of the sludge is reduced to assist conveying and reaction in the sludge process. And the form of heat exchange between treated sludge and raw sludge is adopted, waste heat recovery is enhanced, and the system heat efficiency is improved.

Owner:WUXI ZHANGHUA MEDICAL EQUIP

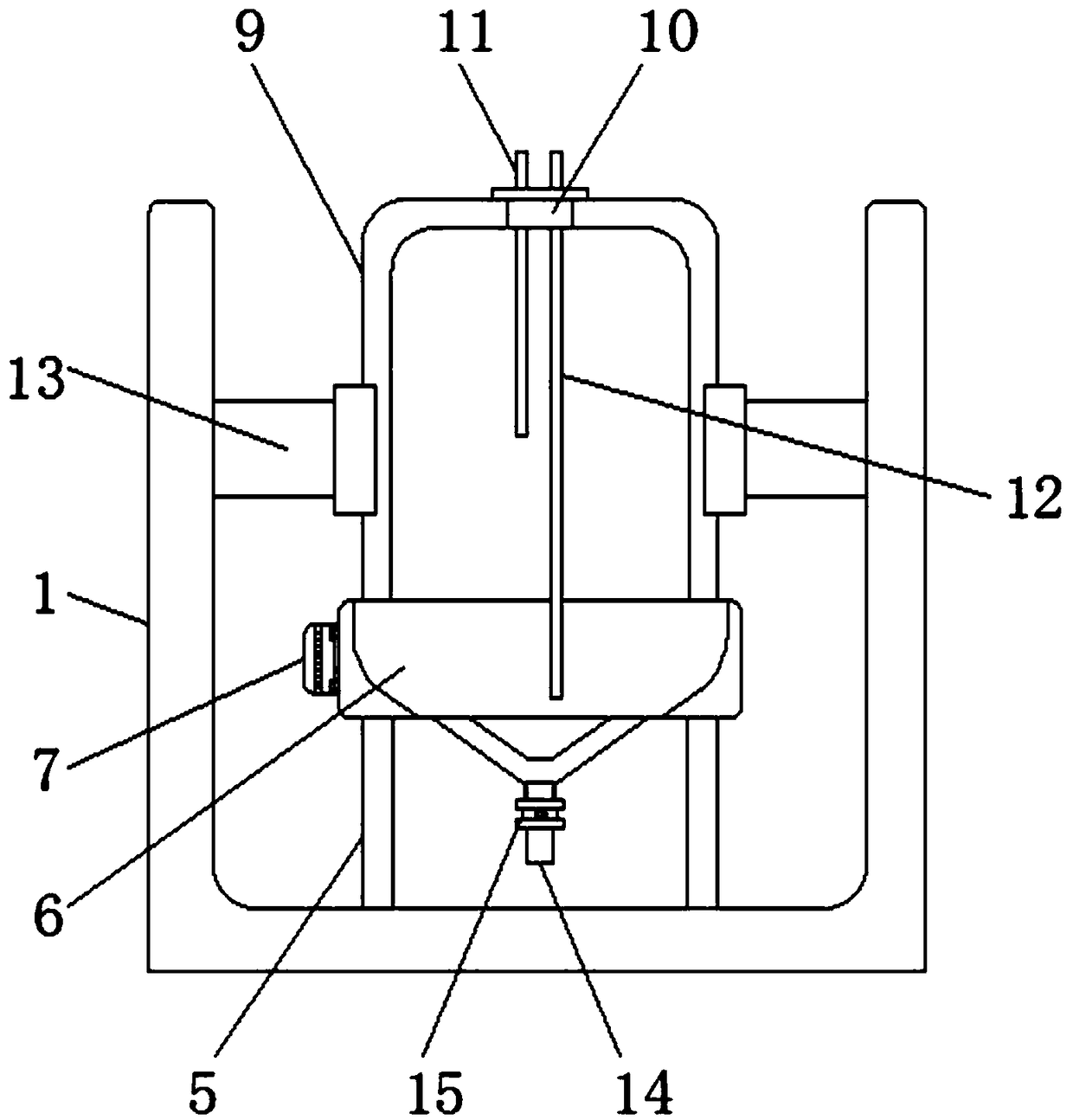

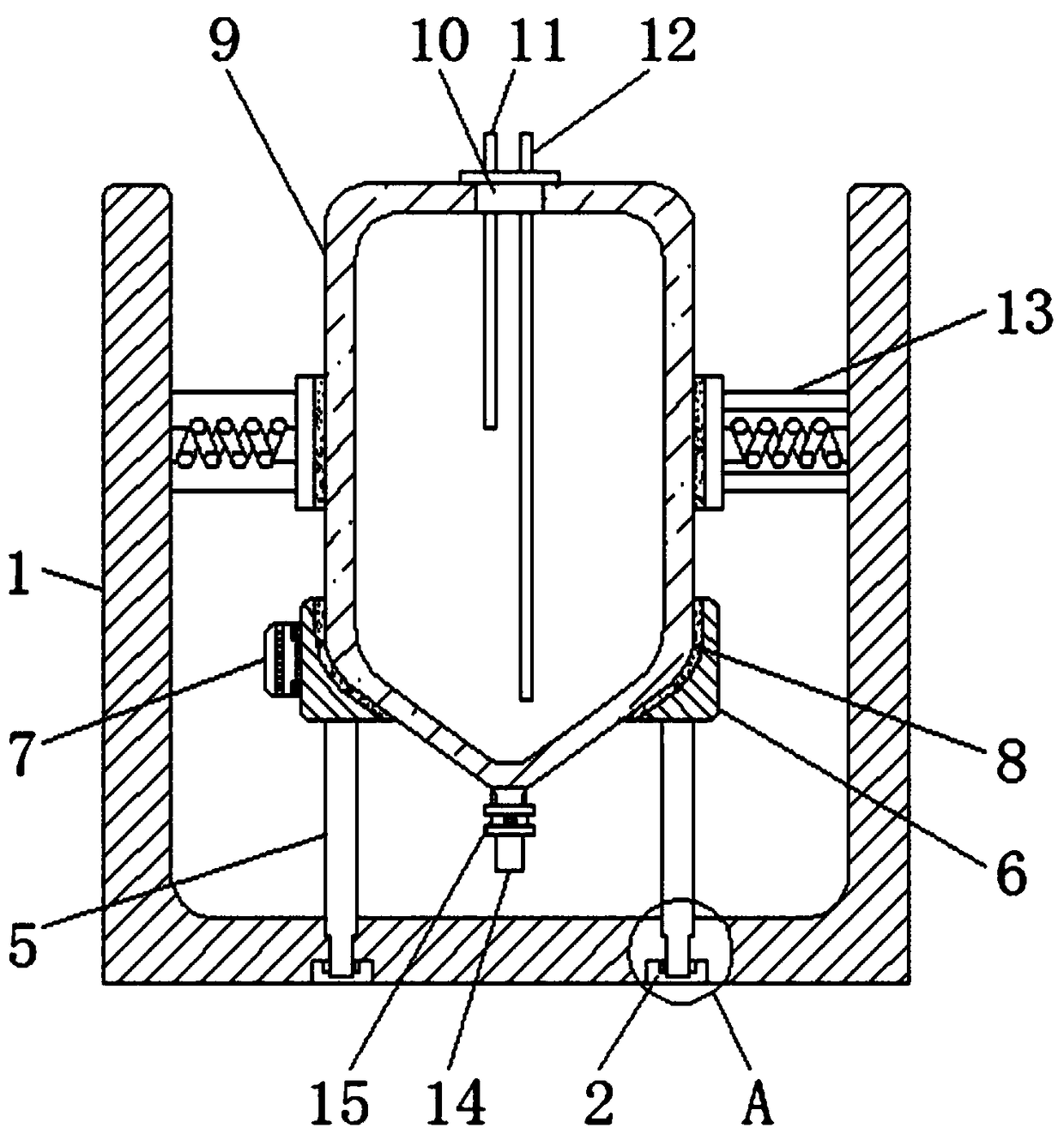

OSLO cooling crystallizer capable of preventing crystal scale

InactiveCN111282308AAvoid dischargeAvoid uneven growthSolution crystallizationCrystallization by component evaporationCirculator pumpMechanical engineering

The invention discloses an OSLO cooling crystallizer capable of preventing crystal scale. The OSLO cooling crystallizer comprises a crystallizer and a cooling device; the cooling device is arranged outside the crystallizer and is communicated with the crystallizer through a pipeline, the crystallizer comprises a raw material feeding pipe, a crystallization chamber and an arc-shaped baffle with anupward opening, the raw material feeding pipe enters the crystallization chamber through the top of the crystallization chamber, and an outlet of the raw material feeding pipe extends into the crystallization chamber; an opening of the arc-shaped baffle plate is arranged upwards and is positioned below an axis extension line of the raw material feeding pipe; the cooling device comprises a circulating pipeline, a circulating pump and a cooler, the crystallization chamber is communicated with the cooler through the circulating pipeline, and the circulating pump is arranged on the circulating pipeline; a nano fluorocarbon coating layer is arranged on the inner wall of the tube pass of the cooler. According to the OSLO cooling crystallizer capable of preventing crystal scale, the problems of scaling of crystals on the inner wall of the tube pass of a cooler and even blockage of a pipeline in the cooling process are solved, the operation efficiency of the device is improved, and the failurerate is reduced.

Owner:宁夏贝利特生物科技有限公司 +2

Antirust treatment device for chemical agent conveying pipeline

ActiveCN111701810AReduce the effect of smearingIncrease consumptionLiquid surface applicatorsCoatingsThermodynamicsProcess engineering

The invention relates to an antirust treatment device for a chemical agent conveying pipeline. The antirust treatment device for the chemical agent conveying pipeline comprises a bottom plate, a supporting table, a rotating unit and a smearing unit, the supporting table is installed at the upper end of the bottom plate, the rotating unit is installed on the supporting table through a bearing, andthe lower end of the rotating unit is installed on the bottom plate. The antirust treatment device for the chemical agent conveying pipeline can solve the problems that when existing equipment carriesout antirust treatment on a chemical agent conveying pipeline, the surface of the pipeline cannot be polished, rust on the surface of the pipeline affects smearing of antirust paint, the smearing effect of the antirust paint is reduced, meanwhile, the surface of the pipeline cannot be intermittently smeared with the antirust paint, and the problems that in the prior art, the antirust paint is prone to being excessively used, so that the consumption of the antirust paint is increased, the treatment cost is increased, the surface of the pipeline cannot be scraped flat, the paint on the surfaceof the pipeline is prone to being accumulated, the wall hanging phenomenon occurs after the surface of the pipeline is smeared, and the smoothness of the surface of the pipeline is reduced are solved.

Owner:马鞍山友基贸易有限公司

Nano-material modified thermal insulation interior wall coating material and processing device

PendingCN111793377AWell mixedImprove fusion effectRotary stirring mixersTransportation and packagingThermal insulationHeat conservation

The invention discloses a nano-material modified heat-preservation interior wall coating material and a processing device. The processing device comprises a body, wherein the top of the body is connected with a feeding hopper, a supporting plate is fixedly installed on one side of the body, the top of the supporting plate is connected with a motor, a discharging port is formed in the bottom end ofthe body, a supporting column is connected to the exterior of the discharging port, and a crushing mechanism is installed at the bottom of the feeding hopper. In the present invention, under the action of the crushing mechanism, raw materials enter the body through the feeding hopper, and fall on the top end of the leakage plate, the first electromagnet and the second electromagnet are electrified in a staggered manner, and the sleeve ring is a magnetic sleeve ring and slides on the outer wall of the fixing rod through the first sliding groove and the first sliding block, so that the connecting rod drives the movable wheel to grind the raw materials on the surface of the leakage plate through the movable shaft, the ground raw materials move downwards through the leakage plate, and throughthe arrangement, the raw materials can be crushed before being stirred, the raw materials can be conveniently crushed and mixed more sufficiently, and the integration of the raw materials is improved.

Owner:浙江埃普瑞纳米新材料股份有限公司

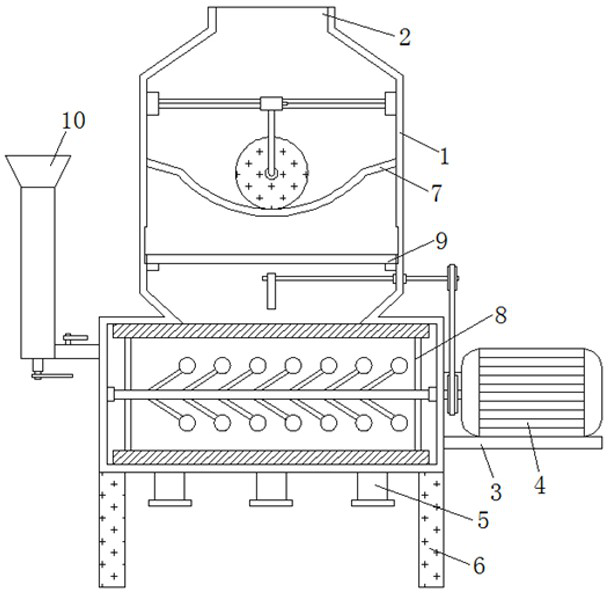

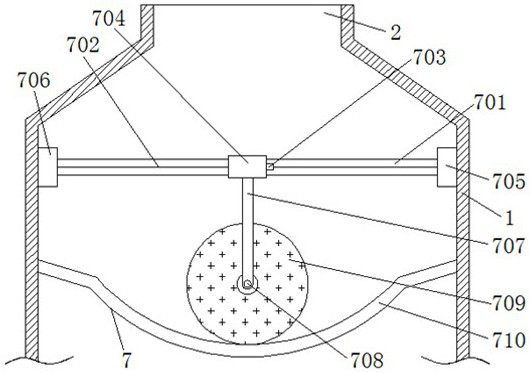

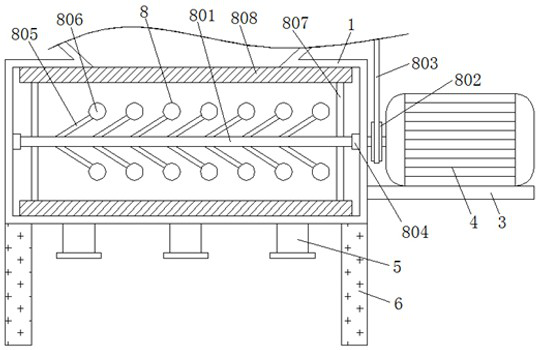

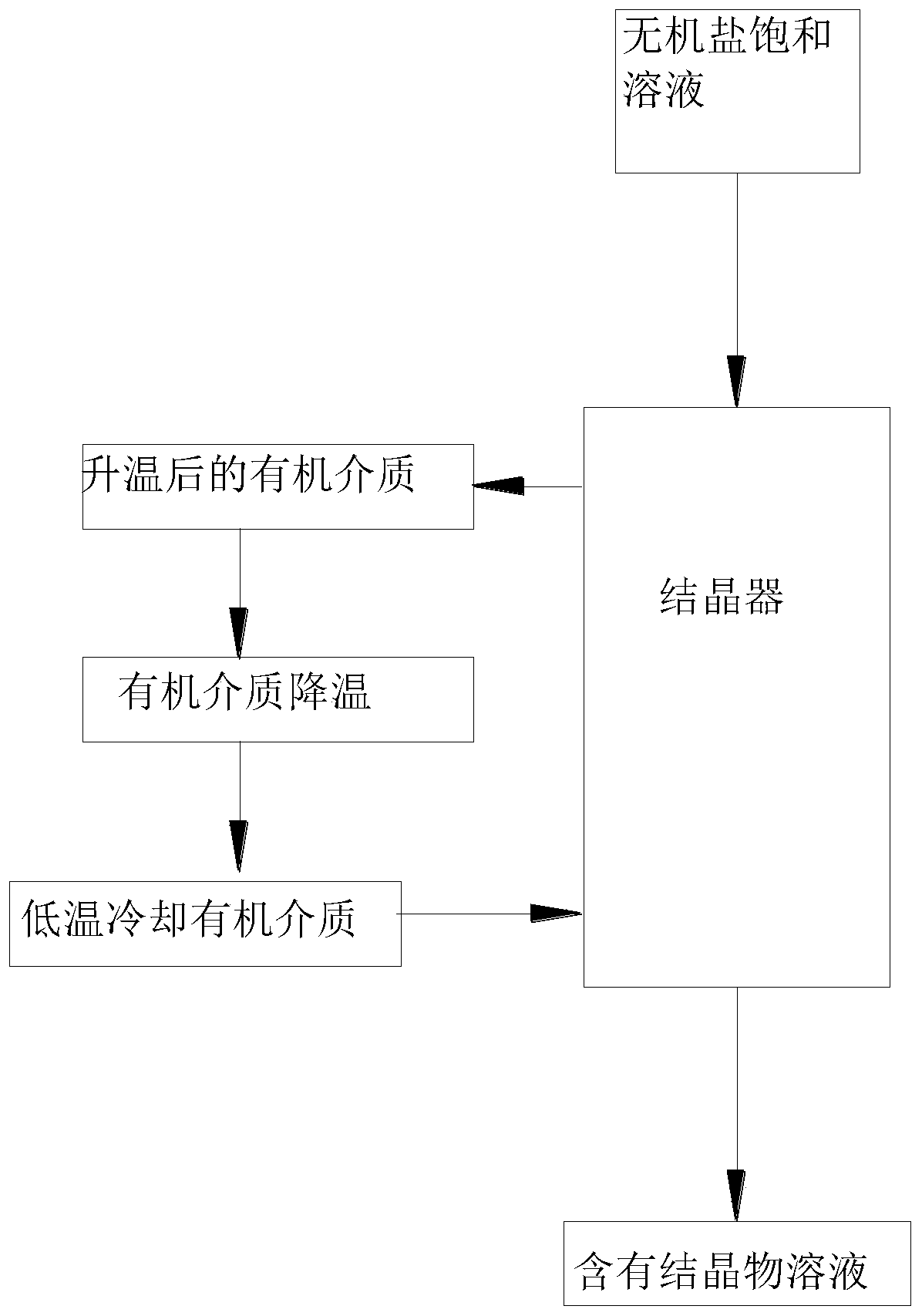

Direct heat exchange based cooling crystallization method

InactiveCN110180209AEasy to operateAvoid hanging on the wallSolution crystallizationHeat exchange cooling cystallizationInorganic saltsBoiling point

The invention relates to a direct heat exchange based cooling crystallization method. The method comprises steps as follows: an organic medium which is insoluble with a solute solution and has a freezing point lower than 5 DEG C and a boiling point higher than 30 DEG C is adopted as a heat transfer medium; the organic medium is cooled to be 1-4 DEG C lower than an aqueous inorganic salt solution,low-temperature organic medium countercurrent and a solution are contacted in a crystallizer for heat exchange, the low-temperature organic medium takes away heat released by crystallization, inorganic salt is separated out from the aqueous solution, the organic medium is sent to outside of the crystallizer and is recycled after being cooled again, and continuous cooling crystallization of the inorganic salt is realized. The method has the advantages of being high in heat exchange efficiency, low in equipment investment and high in operability, avoiding crystallizing blockage and reducing labor intensity, and is applicable to cooling crystallization of multiple materials.

Owner:陕西宏元化工技术有限公司

Full-automatic oil analysis high-performance liquid separation apparatus

InactiveCN109481963AAvoid emulsificationAvoid air bubbles hanging on the wallNon-miscible liquid separationOil analysisEngineering

The invention relates to a full-automatic oil analysis high-performance liquid separation apparatus. The full-automatic oil analysis high-performance liquid separation apparatus comprises a base, liquid separation bottles, a snap-in apparatus, a liquid outlet pipe and a movable plate, wherein a storage frame and the snap-in apparatus are installed inside the base, the inner sides of the storage frame and the snap-in apparatus are respectively provided with the liquid separation bottle, the top end of a supporting leg is connected with the storage frame, the outer side of the storage frame is provided with a micro vibrator, and the inner side of the storage frame is provided with an inner protection mat; a first liquid inlet pipe is arranged inside a conduit plug in a penetrating manner, asecond liquid inlet pipe is arranged inside the conduit plug adjacent to the first liquid inlet pipe in a penetrating manner, one end of the snap-in apparatus is fixed to on the inner wall of the base, the liquid outlet pipe is arranged on the bottom of the liquid separation bottle, and the outer side of the liquid outlet pipe is provided with an electromagnetic valve; and the movable plate is arranged inside the base. According to the full-automatic oil analysis high-performance liquid separation apparatus, the storage frame on the outer side of the liquid separation bottle is provided with the micro vibrator, and the outer micro vibrator can enable micro bubbles to float upwardly, so that the wall hanging of the bubbles can be avoided, and the separation efficiency can be improved.

Owner:SHANDONG MEASUREMENT SCI RES INST

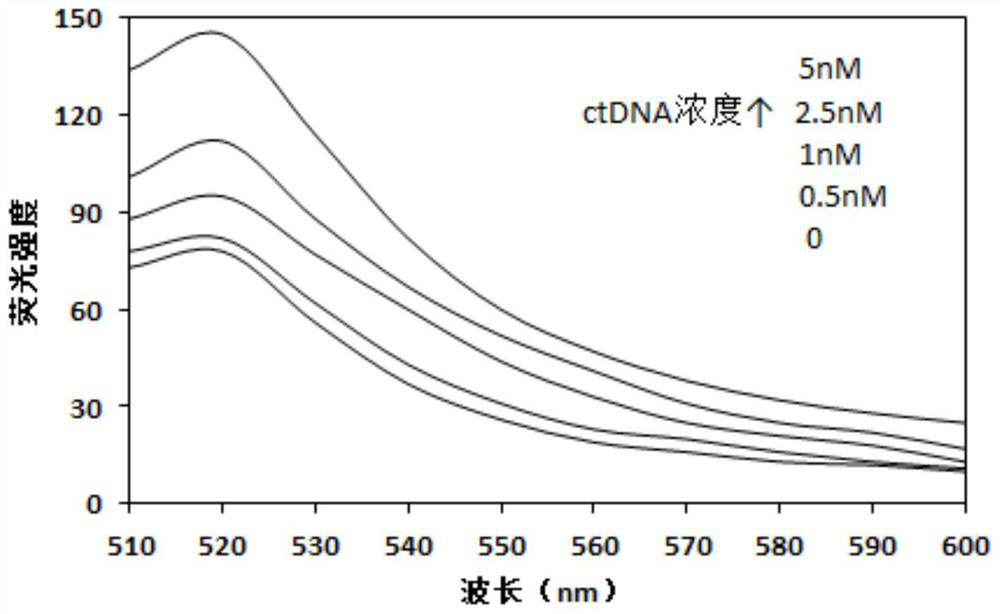

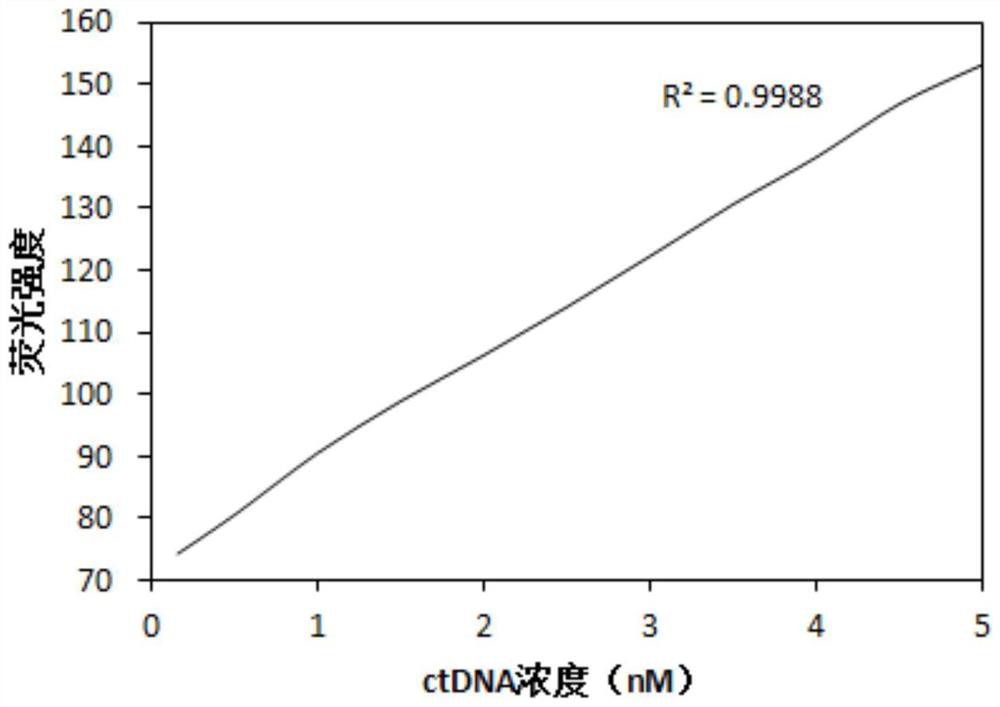

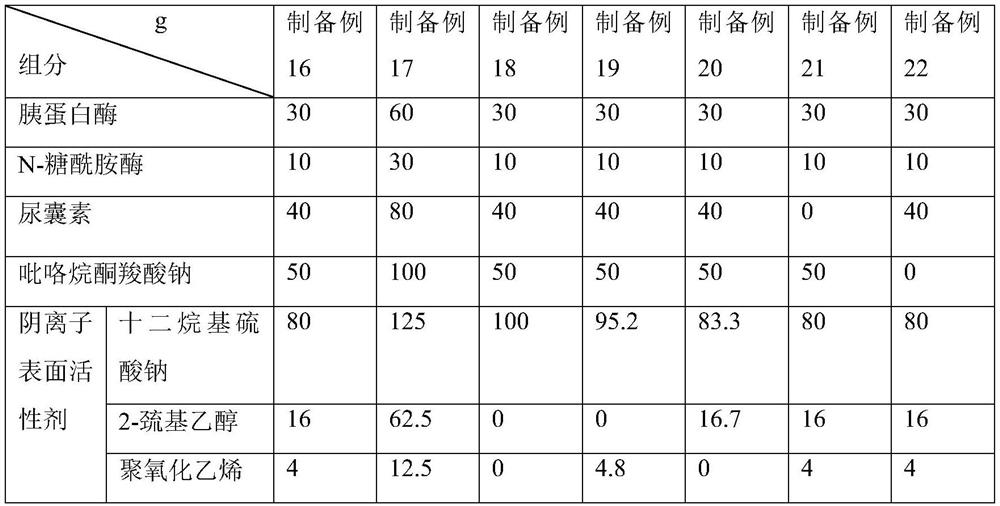

Method for optimizing ctDNA detection accuracy

ActiveCN114292904AImprove stabilityReduced detection time requirementsMicrobiological testing/measurementMaterial electrochemical variablesHigh plasmaBlood plasma

The invention relates to the field of tumor DNA detection, and particularly discloses a method for optimizing ctDNA detection accuracy, which comprises the following steps: S1, blood sample treatment: carrying out the following operations on a blood sample within 2 hours of blood sampling: centrifuging the blood sample, and taking upper-layer plasma; s2, extraction of ctDNA: adding a lysate, a protein enzymolysis agent and silicon dioxide into the plasma, uniformly mixing, centrifuging, taking a lower-layer precipitate, adding an EB buffer solution, carrying out water bath, taking out, centrifuging at room temperature, taking a supernatant as a ctDNA sample, and storing; s3, intermediate treatment of the ctDNA sample: heating the ctDNA sample to 1-10 DEG C, and carrying out ultrasonic treatment; and S4, ctDNA content detection: carrying out PCR amplification on the ctDNA sample, mixing the amplified ctDNA with a biosensor, carrying out a hybridization reaction, and detecting the fluorescence intensity. The ctDNA detection method has the advantages of high plasma extraction rate, short extraction time, high protein hydrolysis degree, high accuracy and high sensitivity.

Owner:武汉承启医学检验实验室有限公司

Chemical compound purification and separation device

InactiveCN113730946AControl rotation rateAdjust the rotation rateVibration crystallizationHollow article cleaningChemical synthesisChemical compound

The invention discloses a chemical compound purification and separation device, and relates to the technical field of chemical compound purification and separation. The chemical compound purification and separation device comprises a separation machine body, the top of the separation machine body is fixedly provided with an electric push rod and a feeding pipe, one end of the output end of the electric push rod is fixedly provided with a rotating shaft, and one end of the rotating shaft is fixedly provided with a telescopic threaded rod; and bases are fixedly mounted on the outer walls of the two sides of the bottom of the separation machine body correspondingly, and a separation box is fixedly mounted in the separation machine body. The separation box and a uniform heating assembly are arranged in the device, the design is reasonable and ingenious, through the linkage effect, the effect of heat source movable heating can be achieved in the process of synchronous stirring treatment of chemical compounds, the crystallization purification efficiency of the chemical compounds can be effectively improved, the heating uniformity of the chemical compounds can be improved, the purification effect is ensured, meanwhile, the rotating speed of an inner liquid stirring mechanism can be adjusted by controlling the working speed of the electric push rod, and adjustment and control are easy.

Owner:LIANYUNGANG SHENGHE BIOTECH

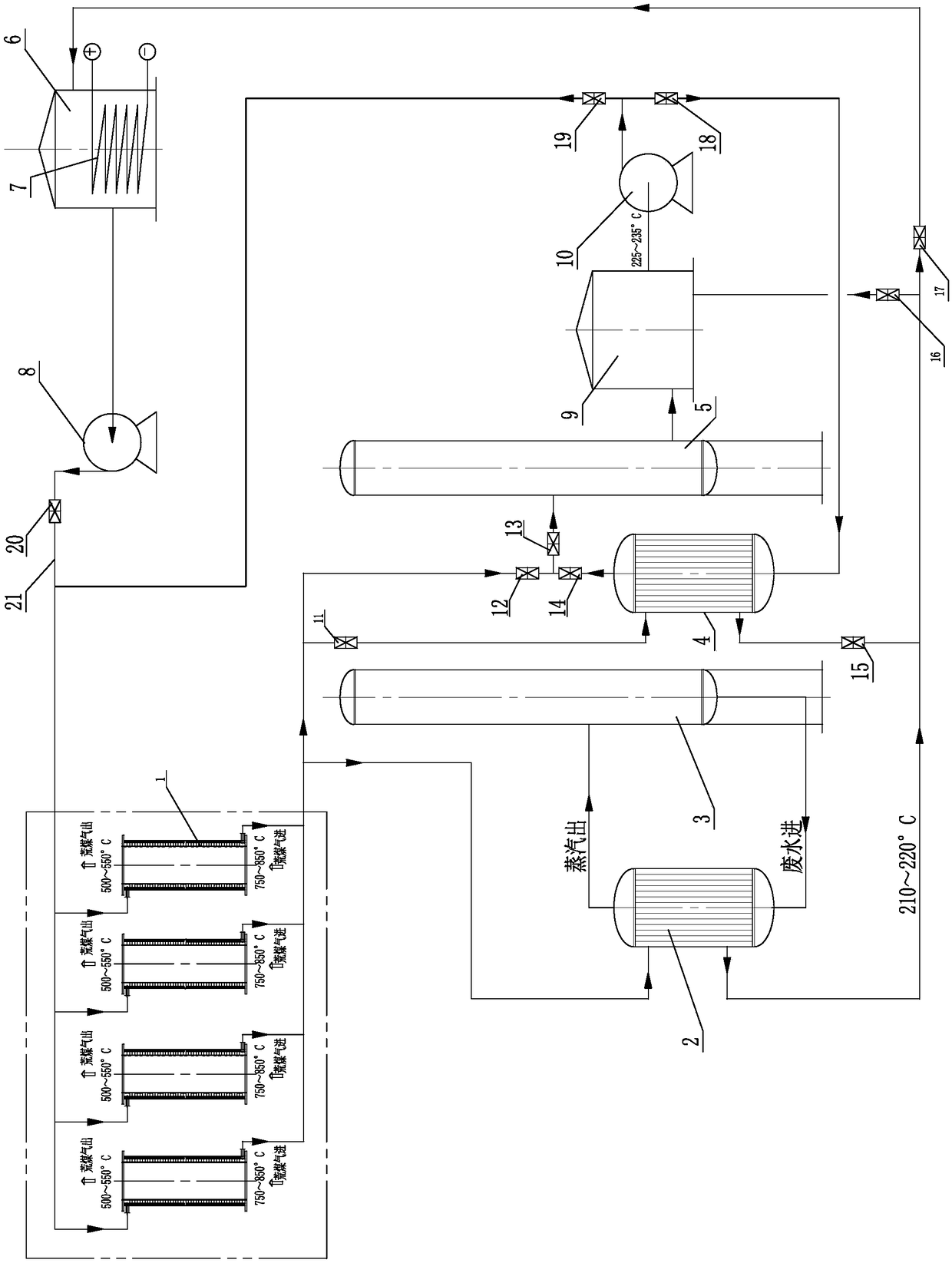

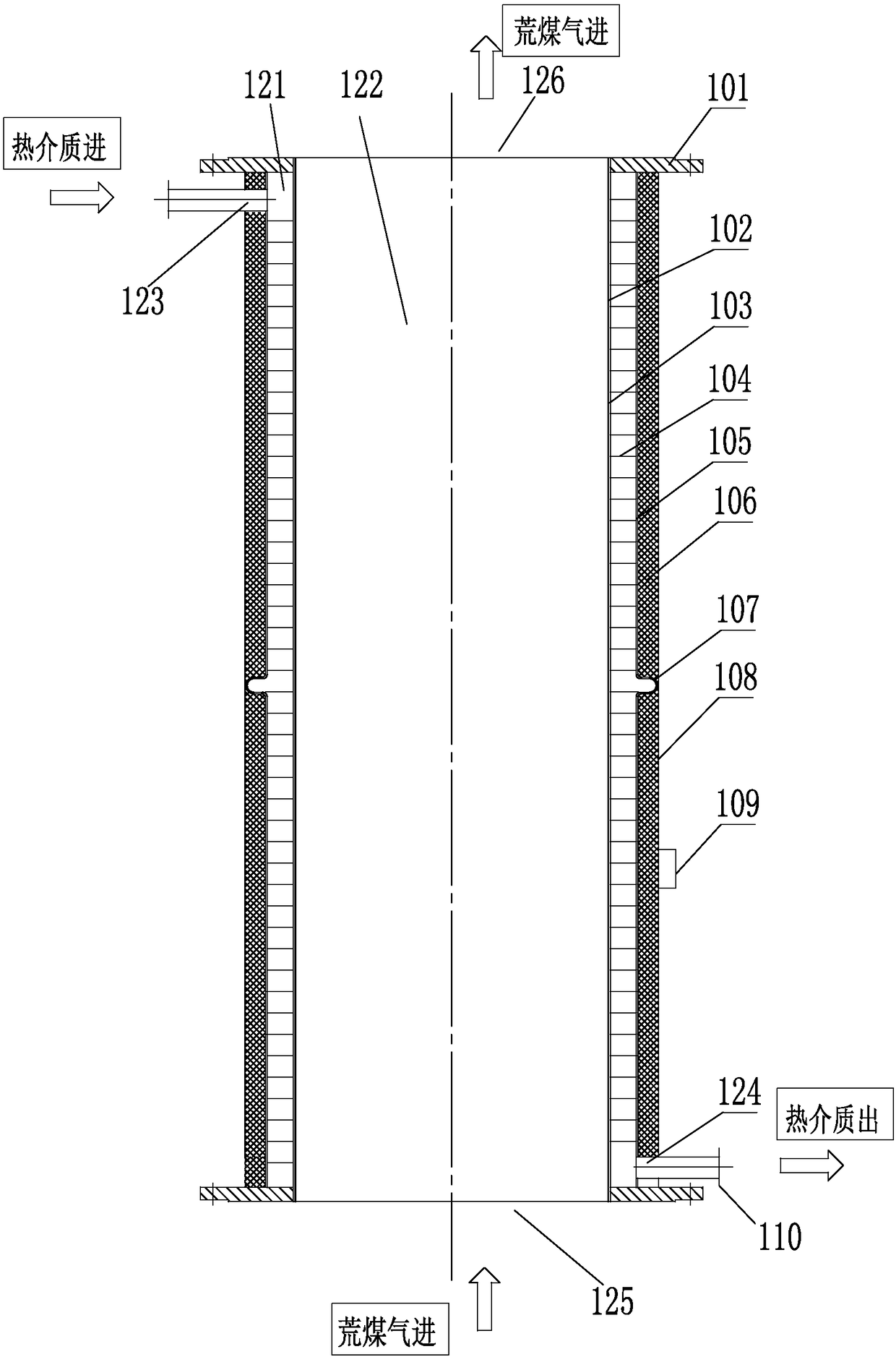

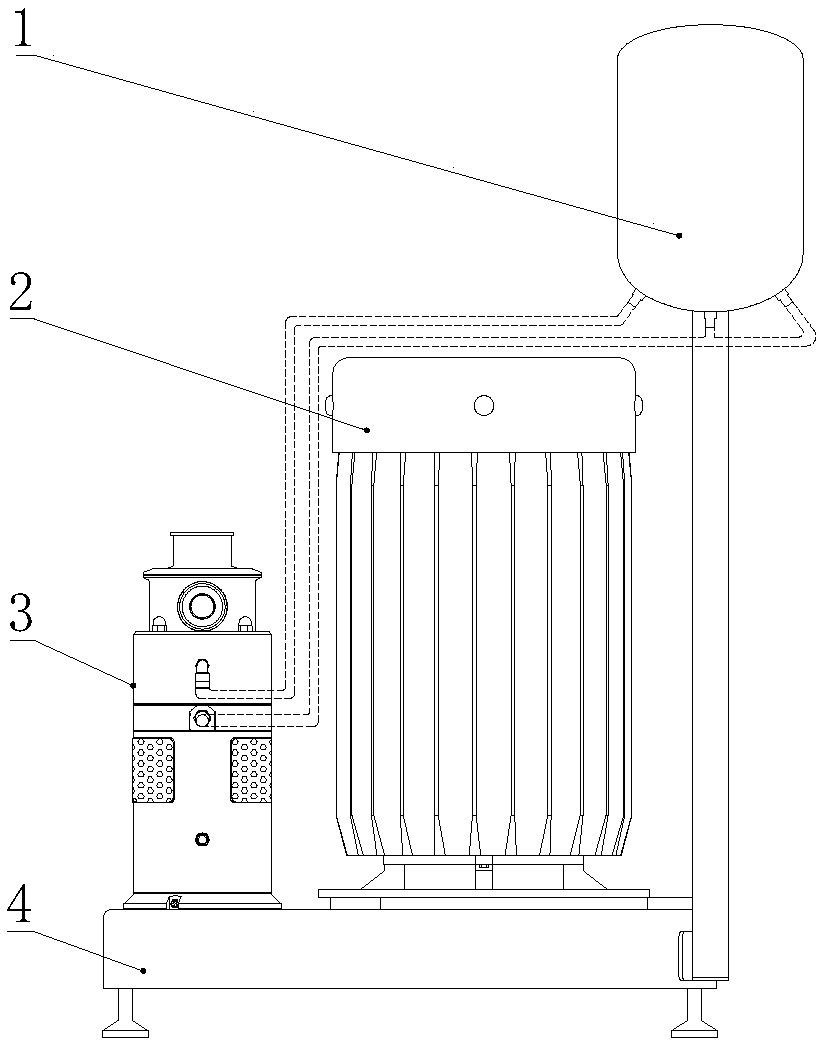

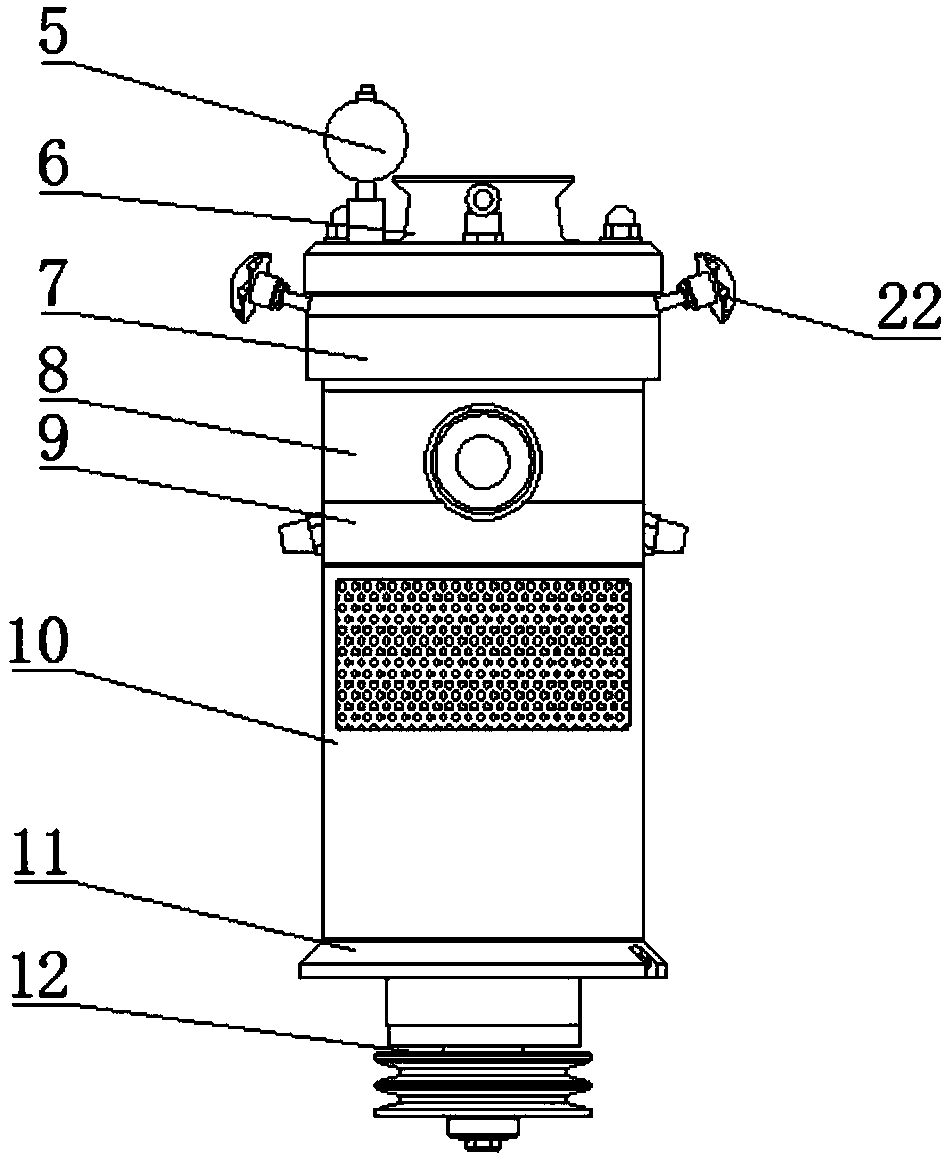

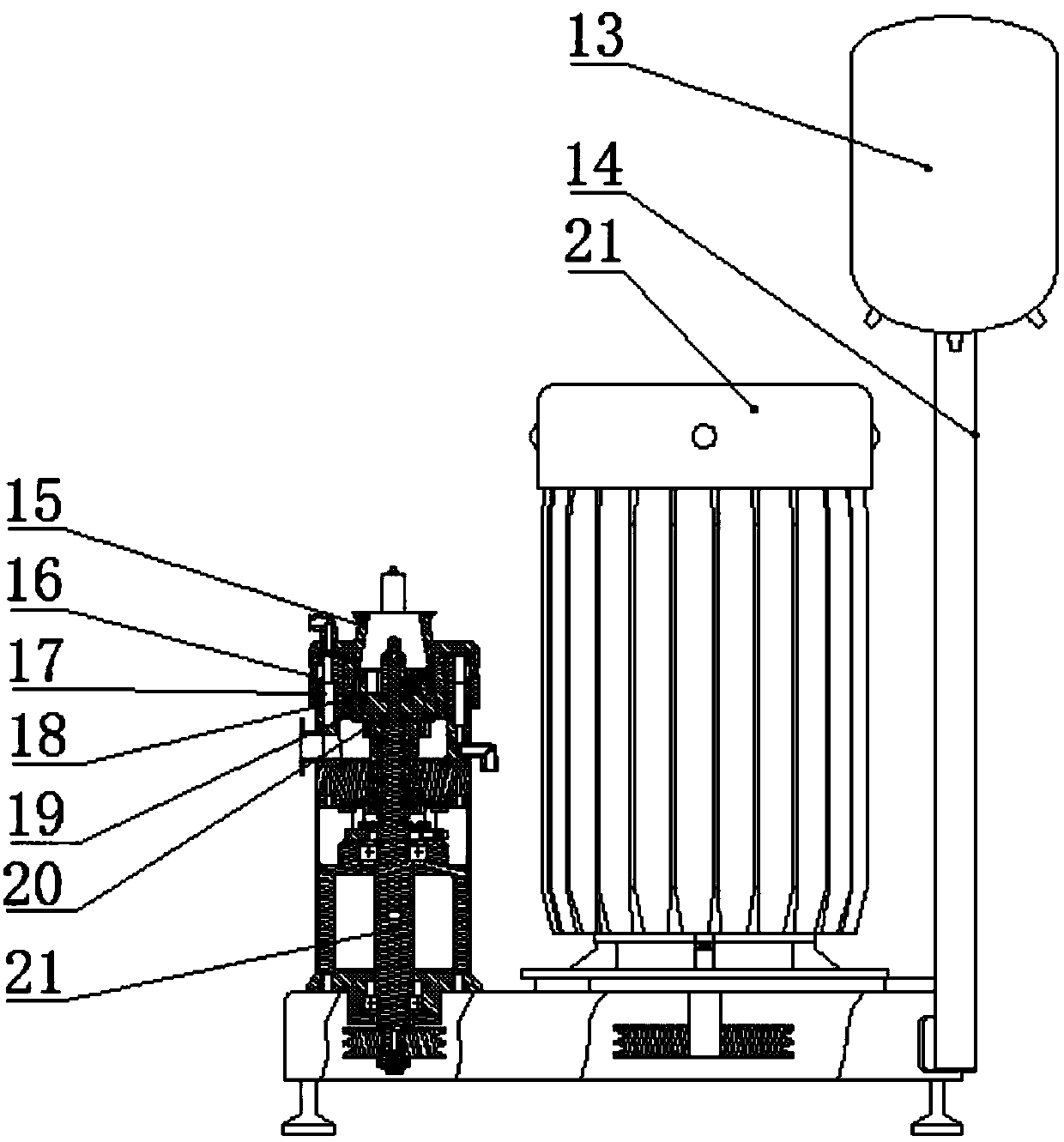

Equipment and method for recycling raw coke oven gas waste heat for benzene removal and ammonia distillation

The invention discloses equipment and method for recycling raw coke oven gas waste heat for benzene removal and ammonia distillation. The equipment comprises riser heat exchangers, an ammonia distilling reboiler, a negative pressure ammonia distilling tower, a benzene removal reboiler, a negative pressure benzene removal tower, a heat medium tank and a hot lean oil tank, wherein heat medium outlets of the riser heat exchangers are connected with the ammonia distilling reboiler, and the heat medium outlets are connected with the benzene removal reboiler; the benzene removal reboiler is connected with the heat medium outlets, a pipeline is connected with the negative pressure benzene removal tower, and the benzene removal reboiler is connected with the hot lean oil tank; the benzene removalreboiler is connected with the heat medium tank, the ammonia distilling reboiler is connected with the hot lean oil tank and the heat medium tank, the ammonia distilling reboiler is connected with thenegative pressure ammonia distilling tower, and the negative pressure ammonia distilling tower is connected with the ammonia distilling reboiler; the negative pressure benzene removal tower is connected with the hot lean oil tank, the hot lean oil tank is connected with a hot lean oil circulating pump, and the the hot lean oil circulating pump is connected with the benzene removal reboiler and the riser heat exchangers; and another pipeline is connected with an outlet of a heat medium pump, and the heat medium pump is connected with the heat medium tank.

Owner:济南冶金化工设备有限公司

High-speed dispersing machine

PendingCN107617350APrevent floatingAvoid hanging on the wallMixing methodsGrain treatmentsSupporting systemSlurry

The invention relates to the technical field of powder and liquid high-speed dispersing, mixing and emulsifying machines in lithium battery industry, in particular to a high-speed dispersing machine.The high-speed dispersing machine comprises a driving system, a premixing and dispersing system, a cooling system and a support system, wherein the premixing and dispersing system comprises a gap adjusting meter, a material charging cavity, a grinding cavity, a material discharging cavity, a sealing mechanism, a support base, a hinge disc, a belt wheel and a plum blossom rotary button; the gap adjusting meter is arranged on the material charging cavity; the grinding cavity and the material discharging cavity are sequentially arranged at the lower part of the material charging cavity; the material discharging cavity is connected with the support base through the sealing mechanism; the hinge disc is arranged at the lower part of the support base, and the belt wheel is arranged at the bottompart of the support base; a driven rotary shaft, a centrifugal material discharging disc, a conical grinding head, the grinding cavity, a gap adjusting inner cover, a gap adjusting outer cover and a material charging cover are sequentially arranged in the premixing and dispersing device; the cooling system comprises a cooling liquid tank and a support rod, and is driven by a motor. The high-speeddispersing machine has the advantages that the powder and the liquid are mixed, so as to reach the uniformity of slurry; the floating, balling and the like are avoided; the speed is high, and the dispersing efficiency is high.

Owner:东莞大蜥蜴智能系统有限公司

A stirring device and container for preparing colloidal plasma solubilizer

ActiveCN105478039BAvoid hanging on the wallAvoid clumpingTransportation and packagingRotary stirring mixersDrugs solutionPass rate

The invention provides a stirring device for preparing a colloidal plasma solubilizer, comprising a stirring shaft and a double-layer combined blade fixed on the stirring shaft; the double-layer combined blade includes a bottom stirring blade and an upper stirring blade blade, the bottom stirring blade is fixed on one end of the stirring shaft, and the upper stirring blade is fixed on the stirring shaft; The front and rear edges of the main blade of the cross-section two-blade oblique blade are serrated. The stirring device provided by the present invention can effectively disperse, shear and break the macromolecular gelatin raw material, has a uniform, stable and high-speed stirring ability, and achieves the best stirring flow pattern, thereby effectively controlling the molecular weight distribution. Improve the qualification rate of subsequent products, save production time, and ensure that the liquid medicine does not splash or hang on the wall when stirring, thereby reducing the loss of raw materials and saving production costs.

Owner:吉林省长源药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com