Method for continuously preparing mesocarbon microbeads with co-production of impregnant pitch and coating pitch

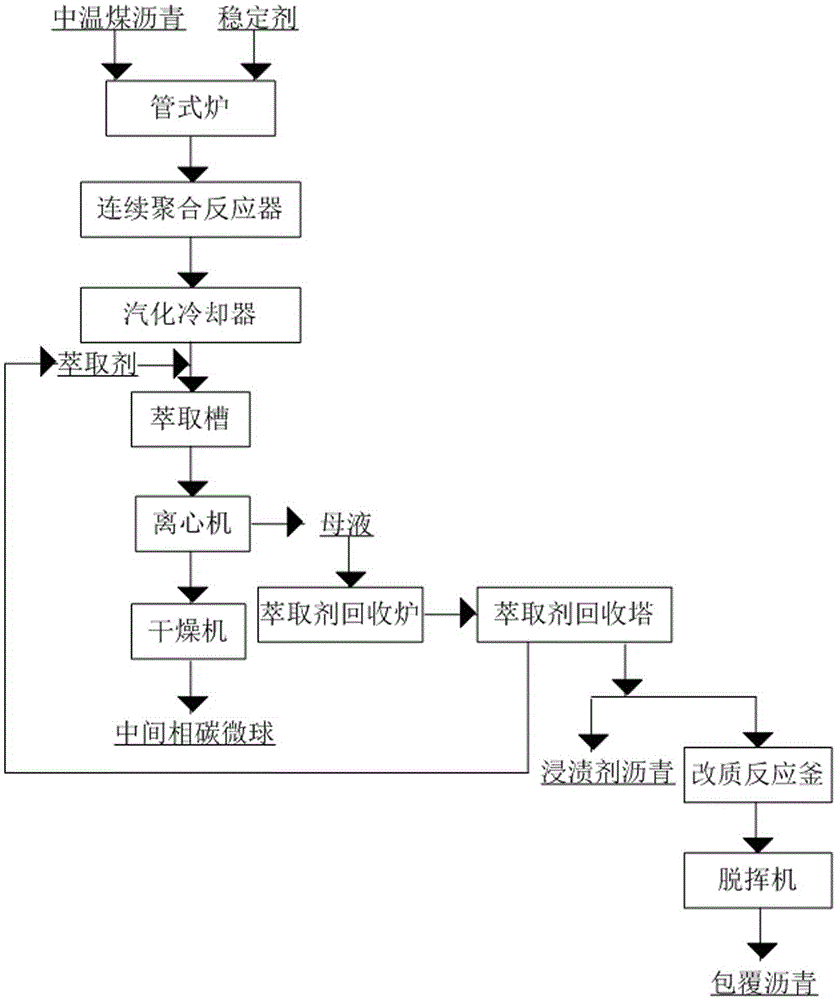

A technology of mesocarbon microspheres and mesocarbon microspheres, which can be used in the processing of tar pitch/petroleum pitch/natural pitch by chemical methods, and the processing of tar pitch/petroleum pitch/natural pitch by selective extraction, which can solve energy consumption Large size, heavy environmental pollution and other problems, to achieve the effect of avoiding material hanging on the wall, fast heating speed, and avoiding asphalt coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

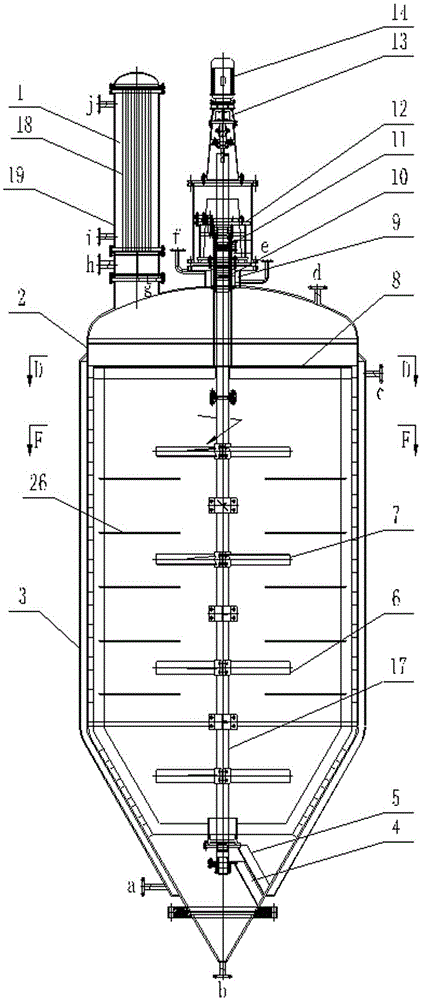

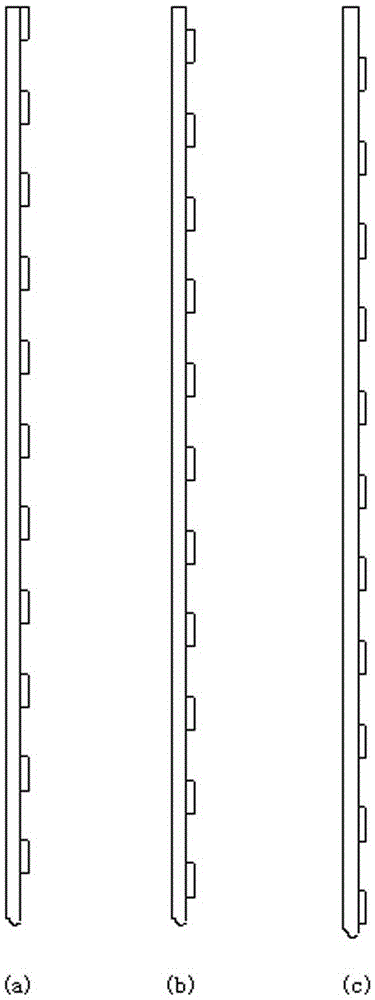

Method used

Image

Examples

Embodiment 1

[0058] Under the condition of nitrogen atmosphere, the temperature is 180 ℃ medium temperature coal tar pitch and the temperature is 180 ℃ stabilizer mixed, mixing ratio is medium temperature coal tar pitch by mass ratio: stabilizer=1:0.1, obtains the mixed material; described stable The agent is anthracene oil;

[0059] The mixed material is heated to 350°C and sent to the rapid temperature riser. In the rapid temperature riser, the temperature of the material is raised to 410°C within 1 second, and then enters the continuous polymerization reactor for polymerization at 410°C. The medium temperature coal tar pitch is controlled to continuously The reaction time in the polymerization reactor is 6h. After the reaction is completed, the material discharged from the continuous polymerization reactor contains polymerized pitch of mesocarbon microspheres;

[0060] Cool the polymerized pitch containing mesocarbon microspheres to 290°C, then mix it with the extractant and send it to ...

Embodiment 2

[0066] Method is with embodiment 1, and difference is:

[0067] (1) Under the condition of nitrogen atmosphere, mix the medium-temperature coal tar pitch with a temperature of 210°C and the stabilizer with a temperature of 210°C, and the mixing ratio is medium-temperature coal tar pitch:stabilizer=1:0.5 according to the mass ratio, and the mixture is obtained; The stabilizer mentioned above is washing oil;

[0068] (2) Heat the mixed material to 360°C and send it to the rapid temperature increaser. In the rapid temperature increaser, the material is heated to 430°C within 3 seconds, and then enters the continuous polymerization reactor to carry out polymerization reaction at 430°C to control the medium-temperature coal The reaction time of asphalt in the continuous polymerization reactor is 5h;

[0069] (3) Cool the polymerized pitch containing mesocarbon microspheres to 310°C, mix it with the extractant and send it to the extraction tank for extraction. The mixing ratio is t...

Embodiment 3

[0072] Method is with embodiment 1, and difference is:

[0073] (1) Under the condition of nitrogen atmosphere, mix the medium-temperature coal tar pitch with a temperature of 200°C and the stabilizer with a temperature of 20°C, and the mixing ratio is medium-temperature coal tar pitch:stabilizer=1:1 by mass ratio to obtain a mixture; The stabilizer mentioned above is steam;

[0074] (2) Heat the mixed material to 380°C and send it to the rapid temperature riser. In the rapid temperature riser, the material is heated to 450°C within 5 seconds, and then enters the continuous polymerization reactor to carry out polymerization reaction at 450°C to control the medium-temperature coal The reaction time of asphalt in the continuous polymerization reactor is 4h;

[0075] (3) Cool down the polymerized pitch containing mesocarbon microspheres to 340°C, then mix it with the extractant and send it to the extraction tank for extraction. The mixing ratio is the polymerized pitch containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com