Patents

Literature

92results about How to "Achieving mixing and stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

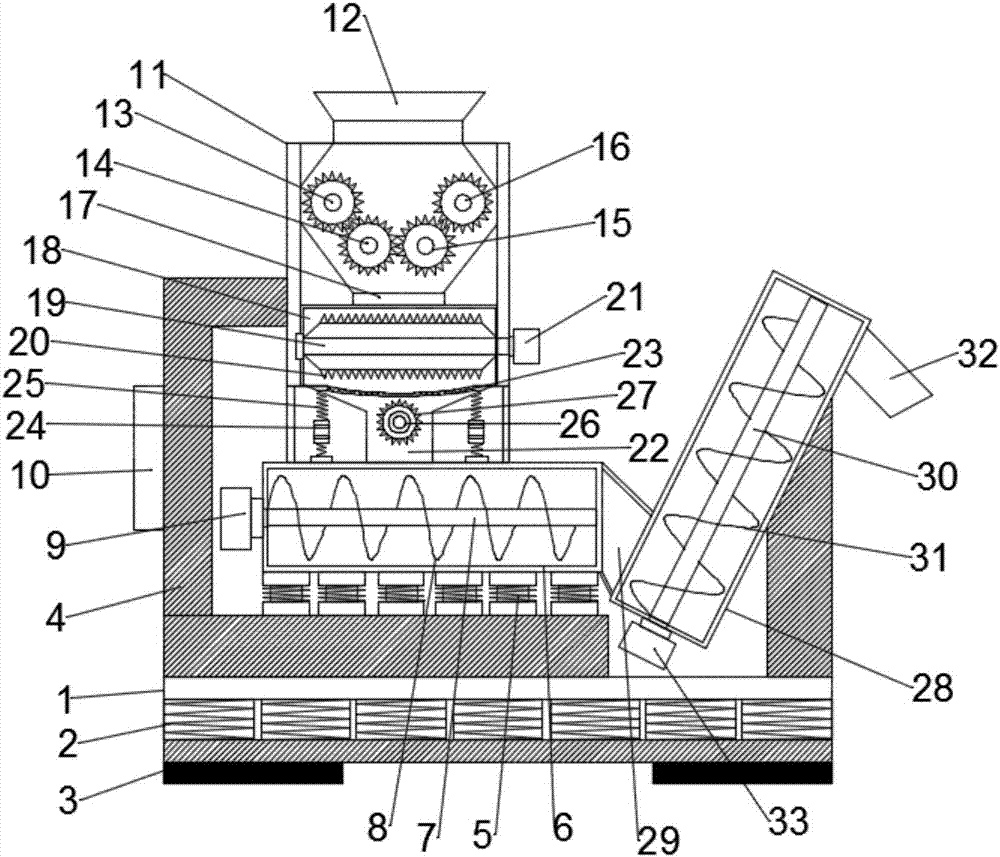

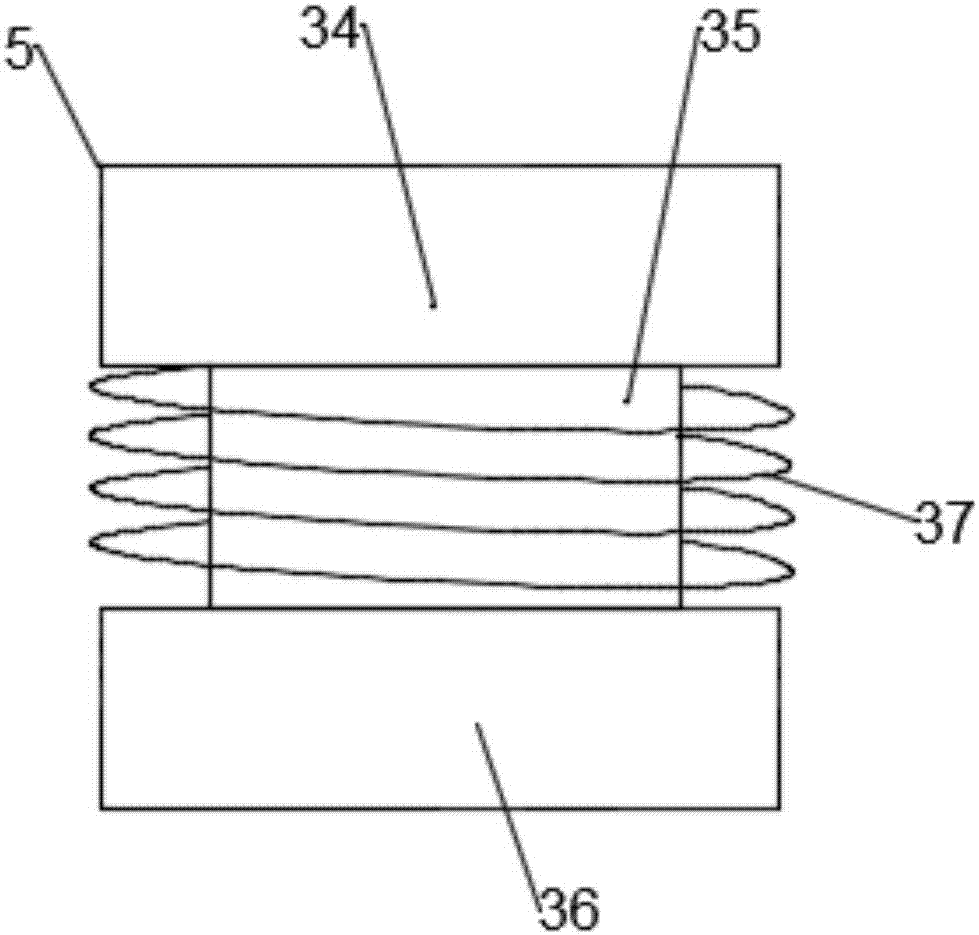

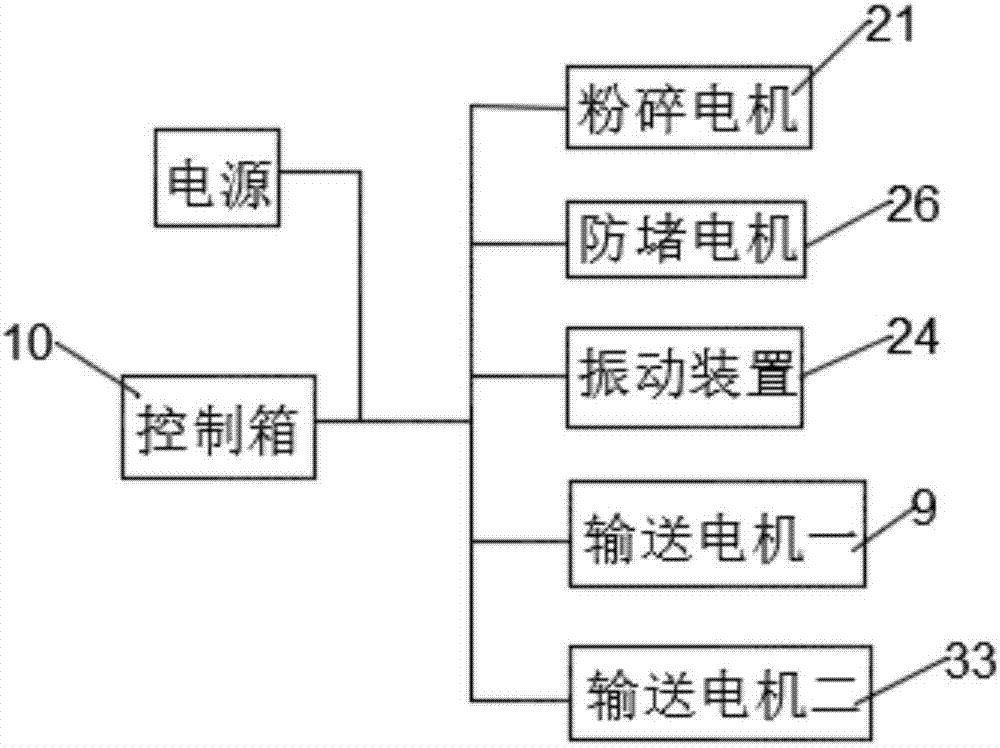

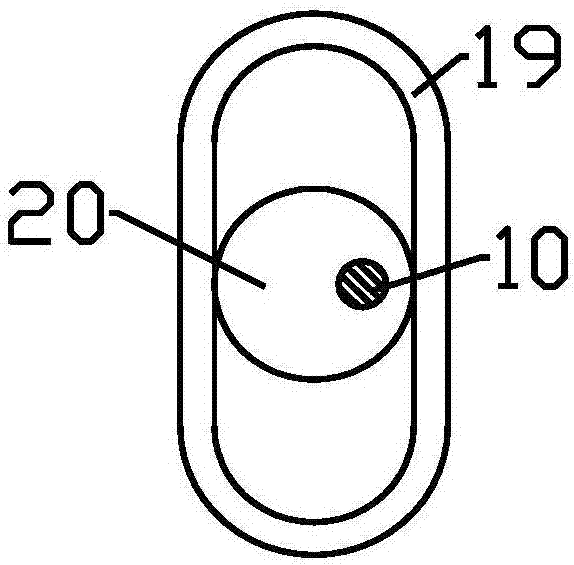

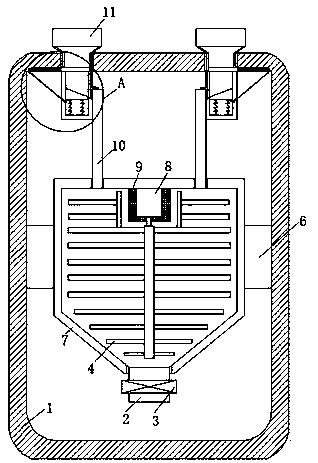

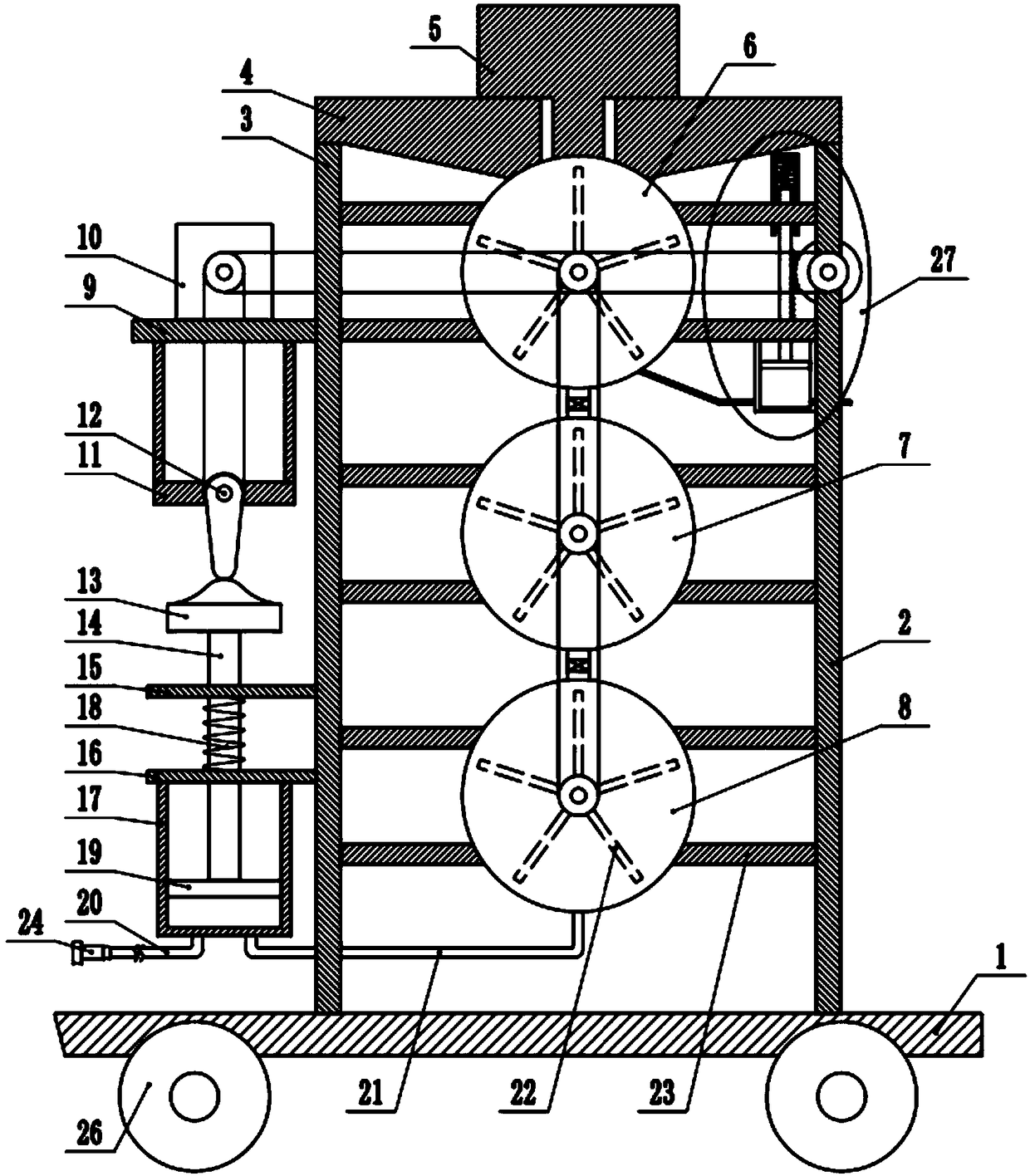

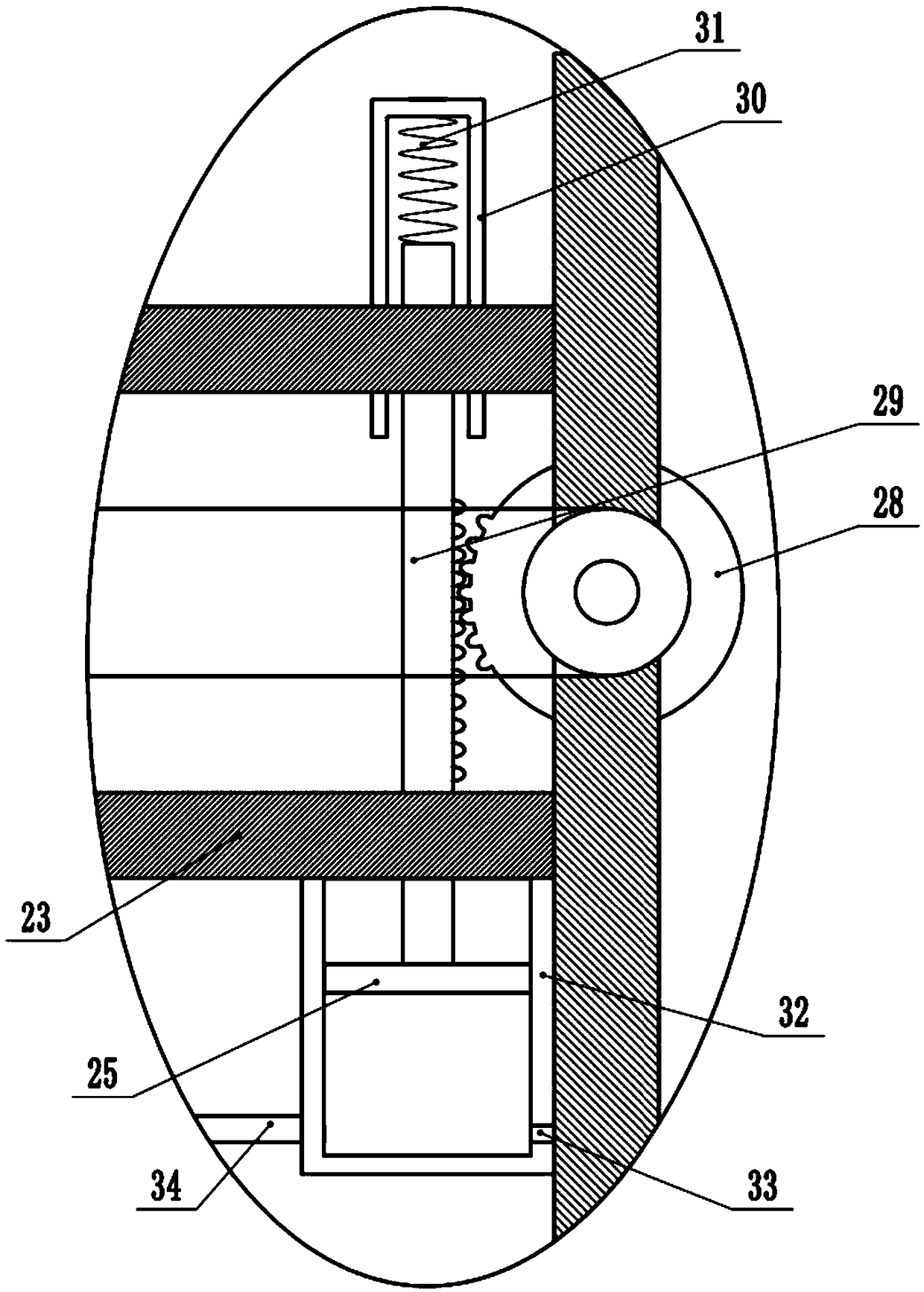

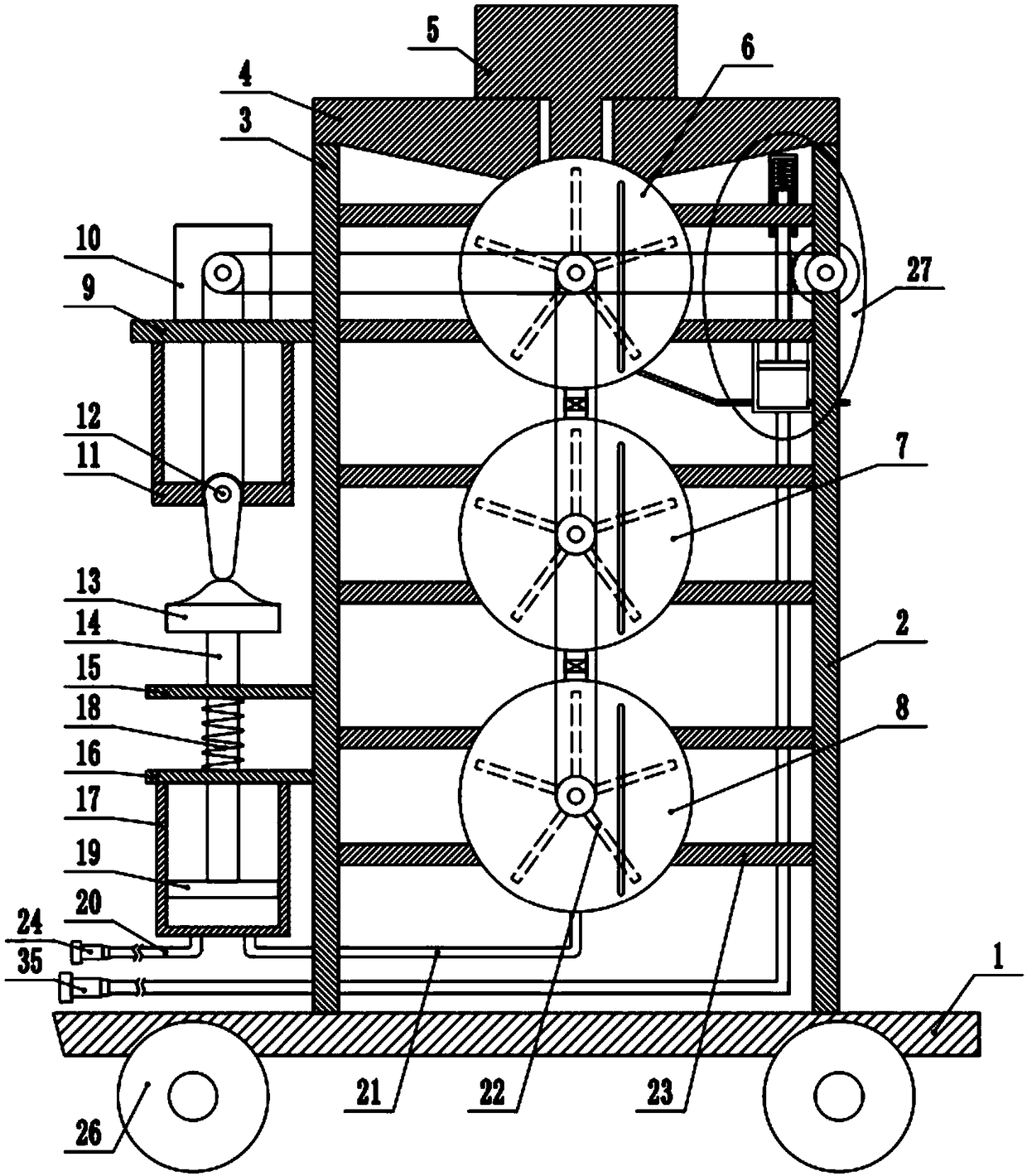

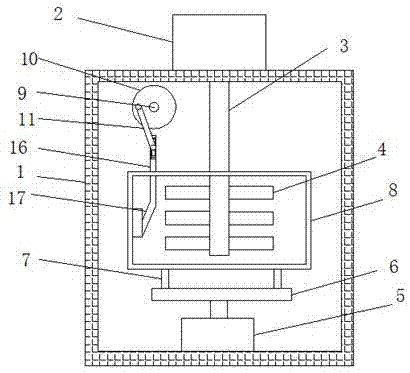

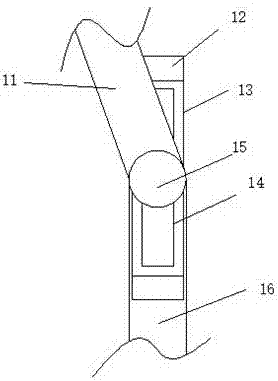

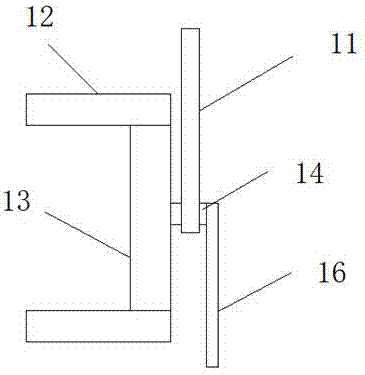

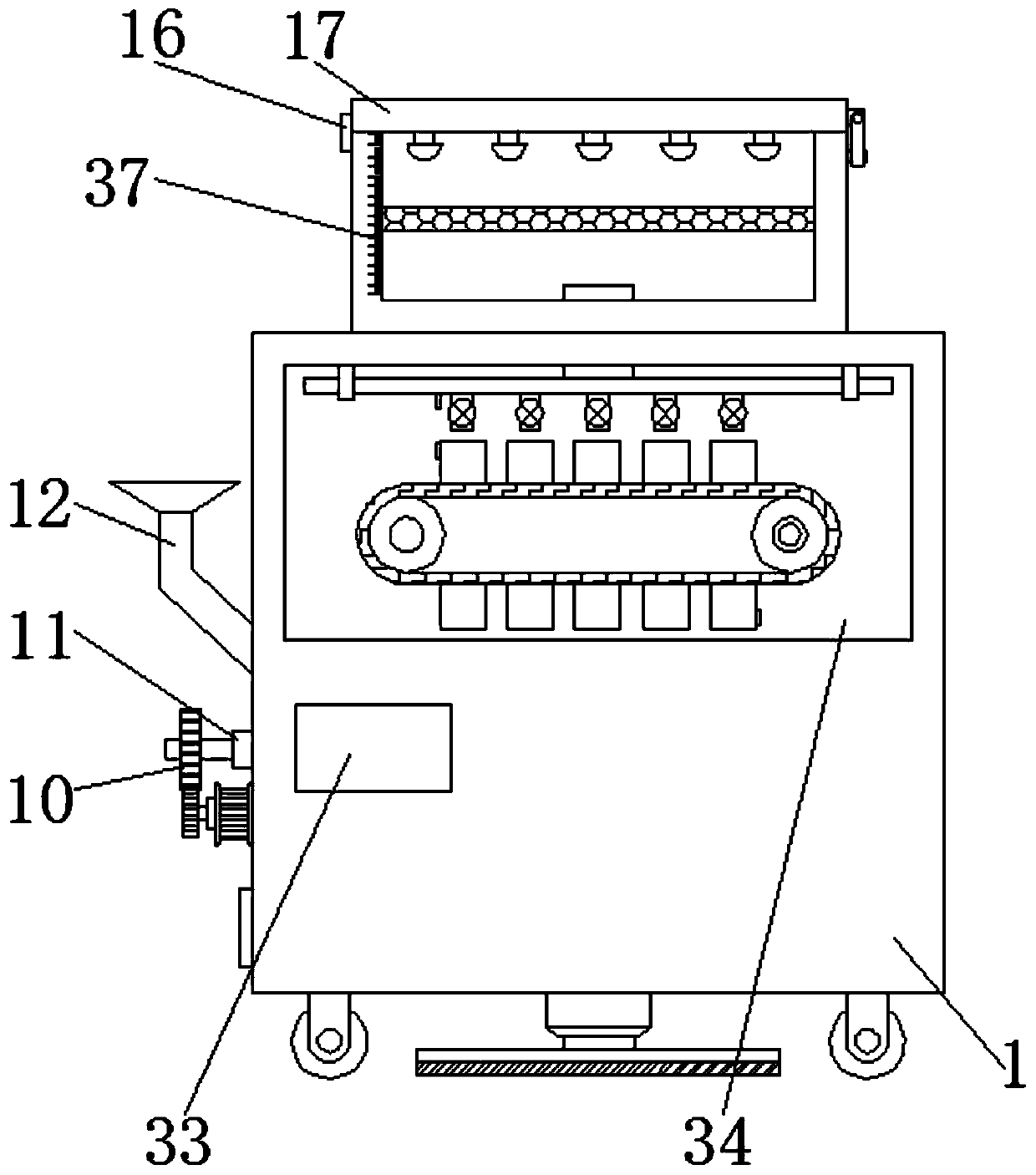

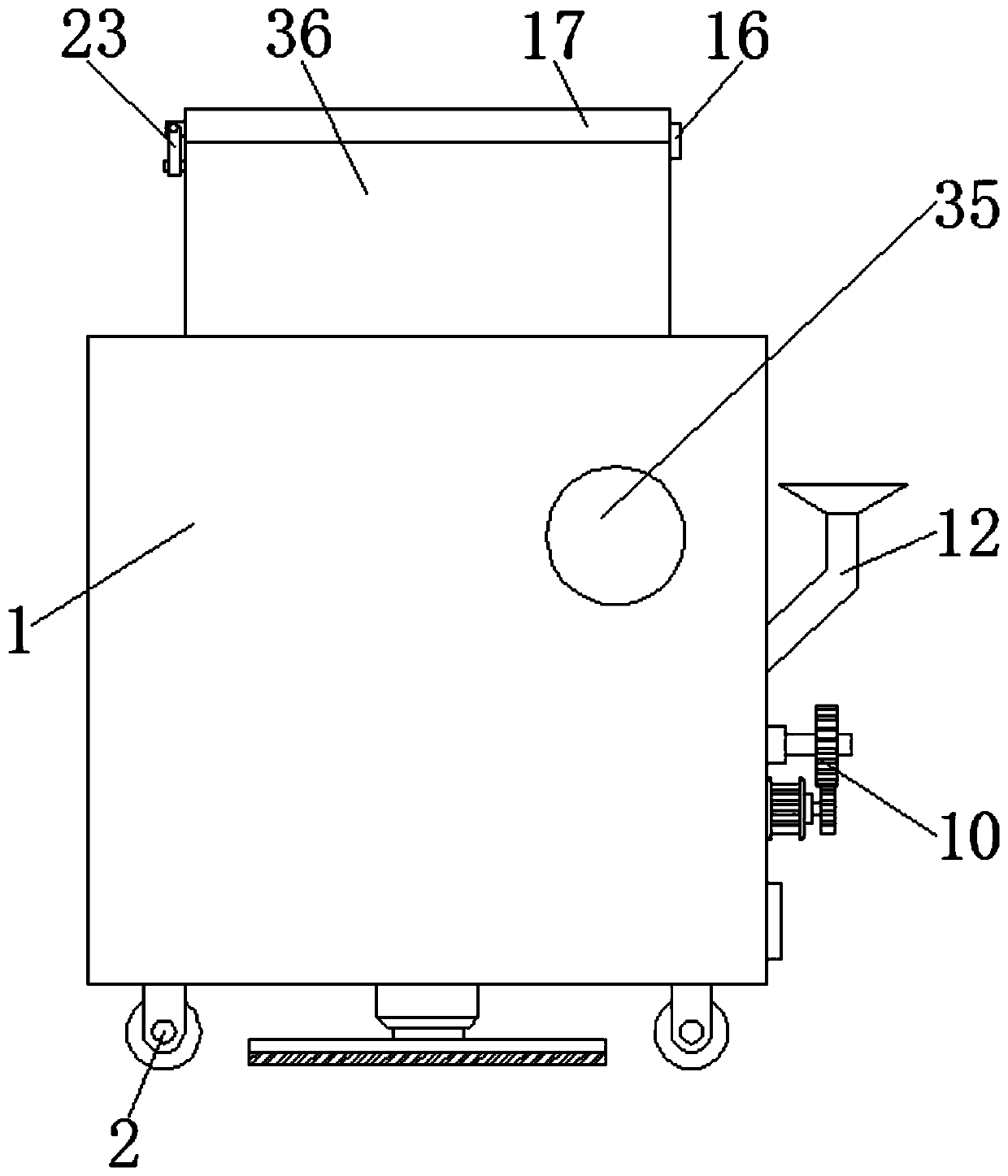

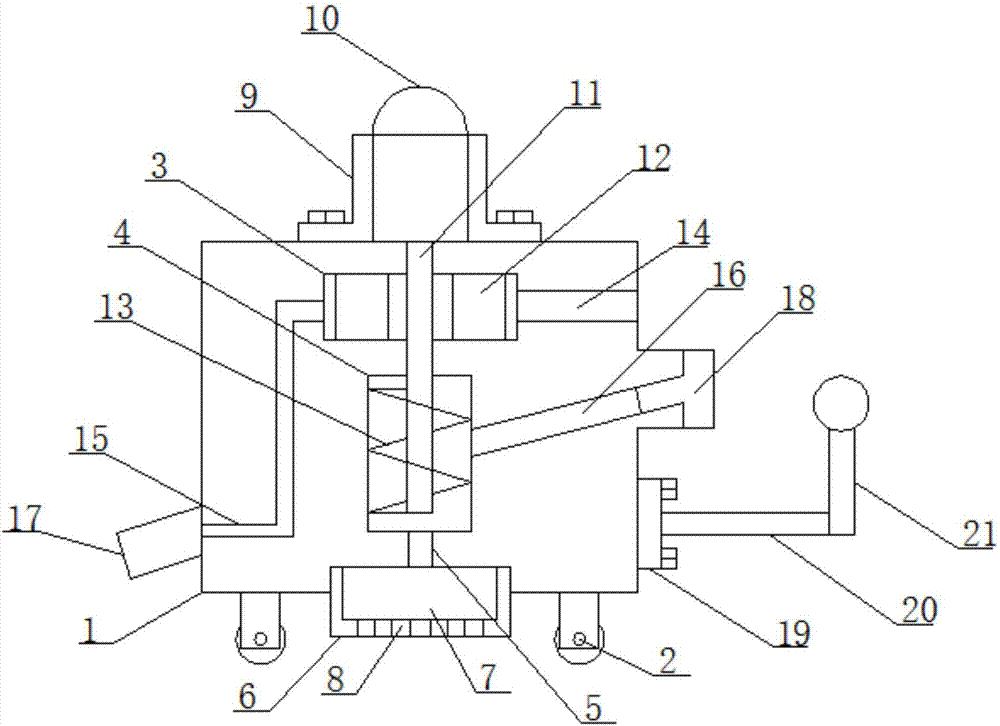

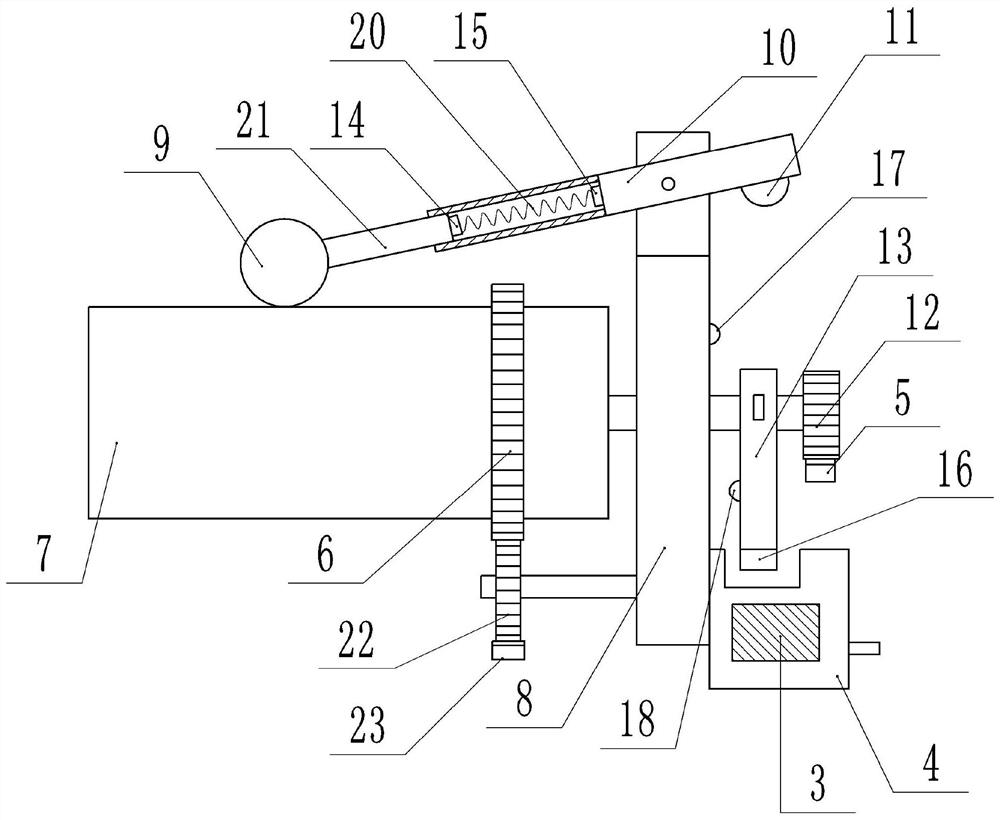

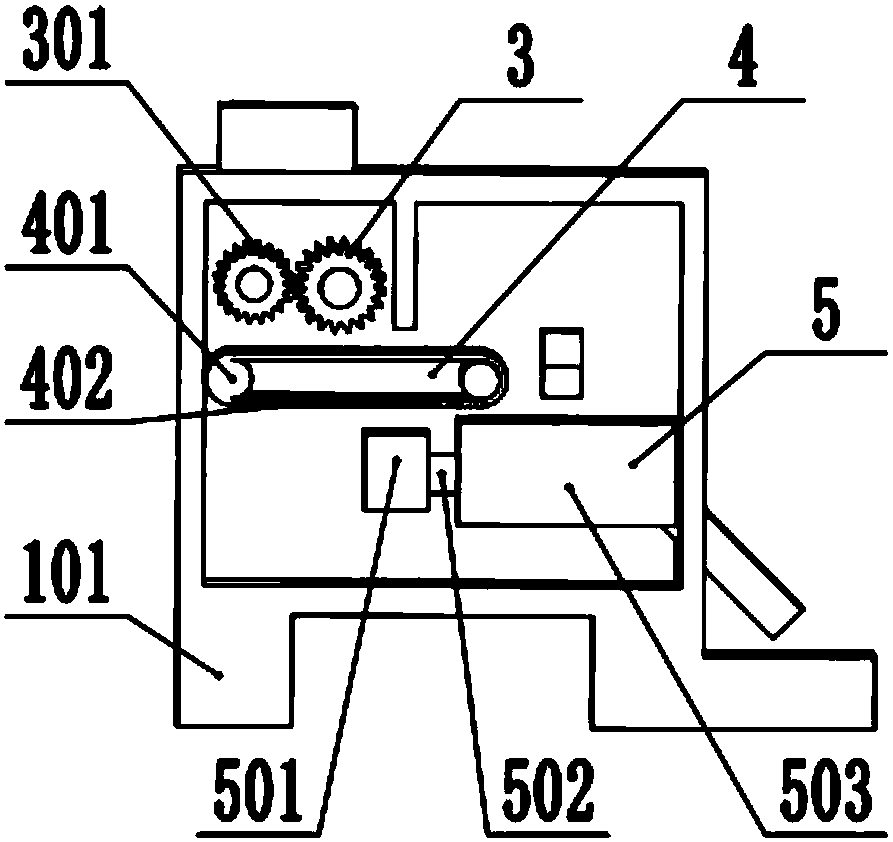

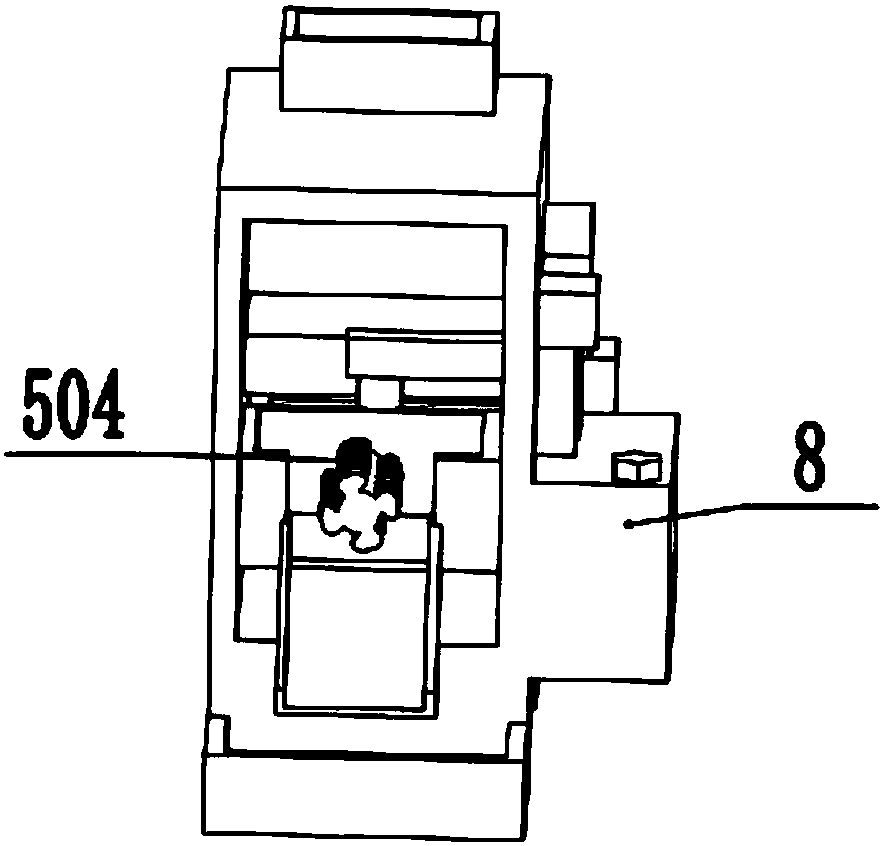

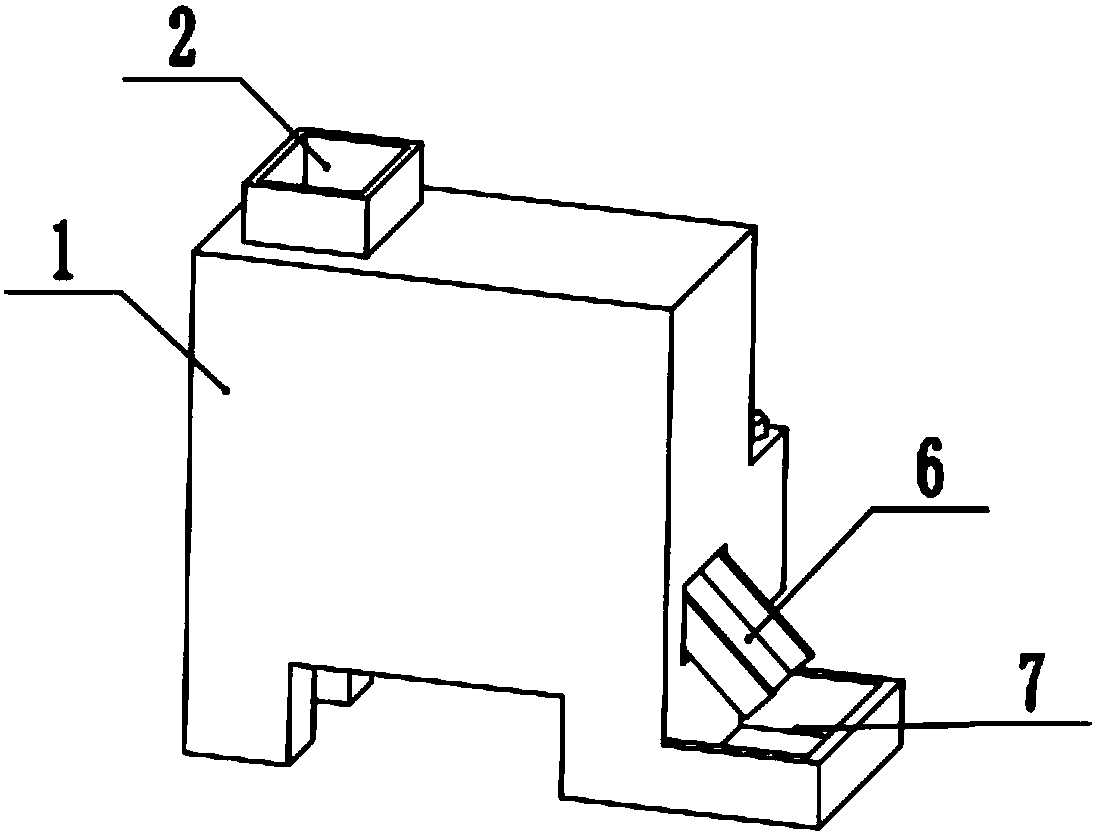

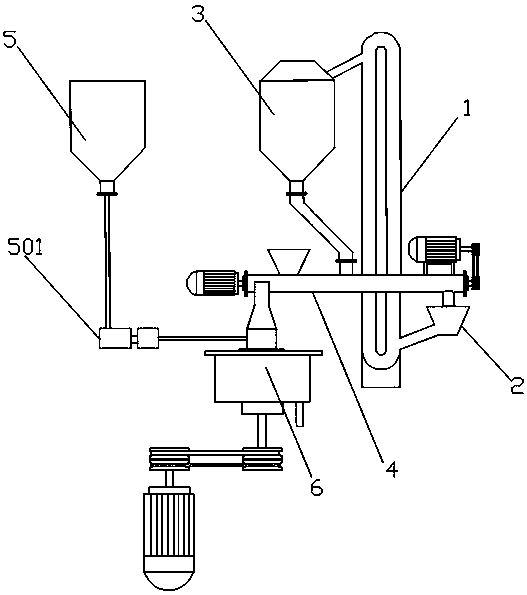

Crushing, stirring and lifting device for construction

InactiveCN107127038ASimple and reasonable designEasy to operatePackagingGrain treatmentsQuality assuranceBuilding material

The invention discloses a crushing and stirring lifting device for building construction, which comprises a bottom frame, a shock-absorbing layer and a base. A second crushing box is provided, the lower end of the second crushing box is provided with a feeding channel, the lower end of the feeding channel is provided with a first conveying cylinder, the right end of the first conveying cylinder is provided with a conveying port, and the lower right end of the conveying port is provided with a second Two delivery cylinders. This device realizes double crushing and mixing of building materials, ensures the quality of material crushing and mixing, and realizes the lifting of materials from low to high, which brings great convenience to construction and can greatly reduce the labor intensity of workers , which is conducive to improving the efficiency of construction. The shock absorbing mechanism and the shock absorbing layer have a good shock absorbing and buffering effect, which can reduce the vibration caused by the equipment during operation, protect the device, and prolong the service life of the device. .

Owner:蔡政伟

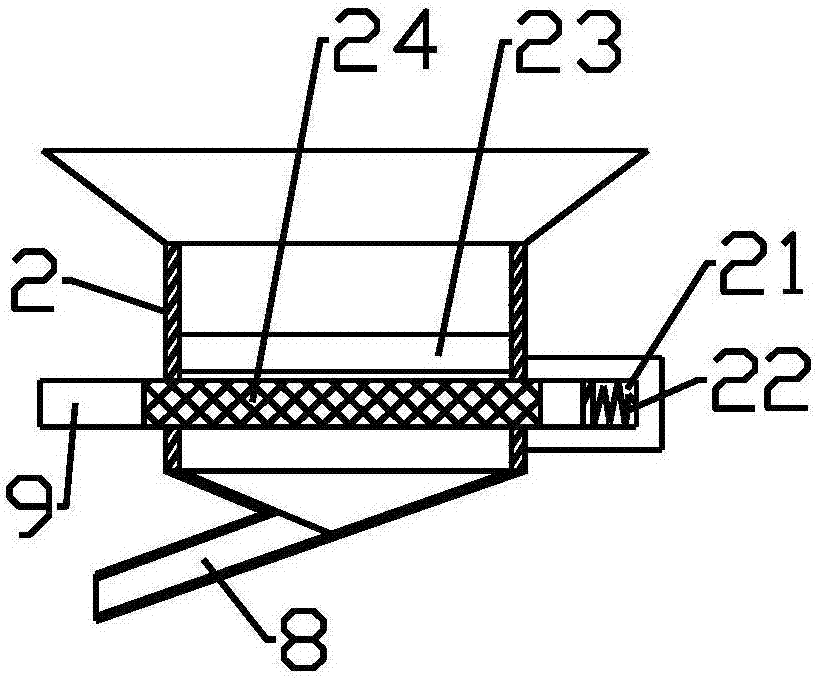

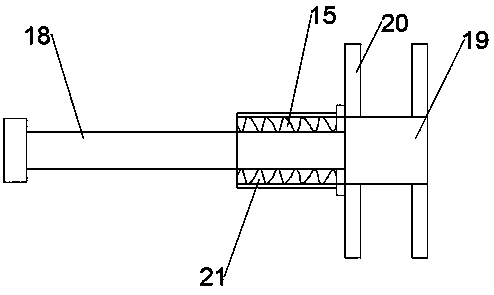

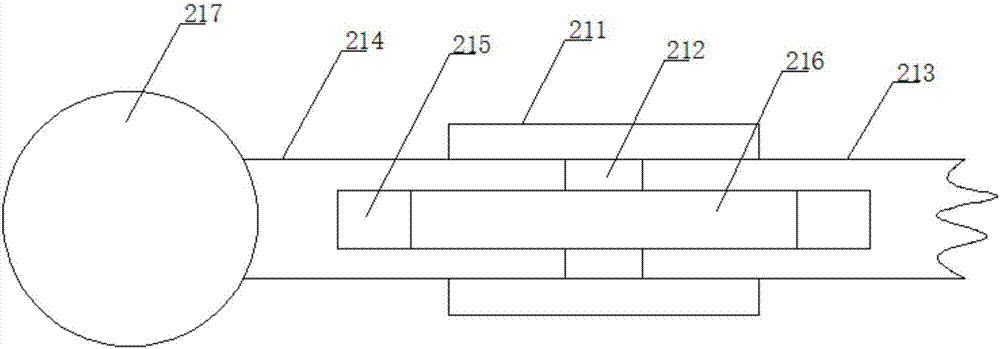

Efficient mixing device for water-soluble fertilizer processing

InactiveCN107224909AAchieving stirringAchieve sievingSievingTransportation and packagingPush pullEngineering

The invention discloses an efficient mixing device for water-soluble fertilizer processing. The efficient mixing device comprises a mixing box, feeding boxes and guide sliding sleeves, wherein a rotating rod is rotationally arranged in an inner cavity of the mixing box; a spiral stirring rod is fixedly arranged at the outer ring of the rotating rod; a stirring blade is arranged and erected on the bottom end of the rotating rod; two guide sliding sleeves are symmetrically and fixedly welded and erected on the upper surface of a top plate of the mixing box; guide sliding holes are formed in the guide sliding sleeves; the guide sliding holes are internally connected with push-pull rods in a left-right sliding way; an eccentric wheel is fixedly arranged on the outer ring of the top end of the rotating rod in a sleeving way; an annular guiding sleeve is arranged on the outer ring of the eccentric wheel in a sliding and sleeving way; two mutually-parallel side plates on the annular guiding sleeve are respectively and fixedly arranged on the end parts of the two push-pull rods; the other ends of sieve plates are fixedly connected with the end parts of the push-pull rods. The efficient mixing device disclosed by the invention is simple in structure, convenient in operation, good in dissolution effect of fertilizer granules, fast in dissolution speed and high in transmission efficiency, is energy-saving and environment-friendly and is suitable for being popularized and used.

Owner:汪辉

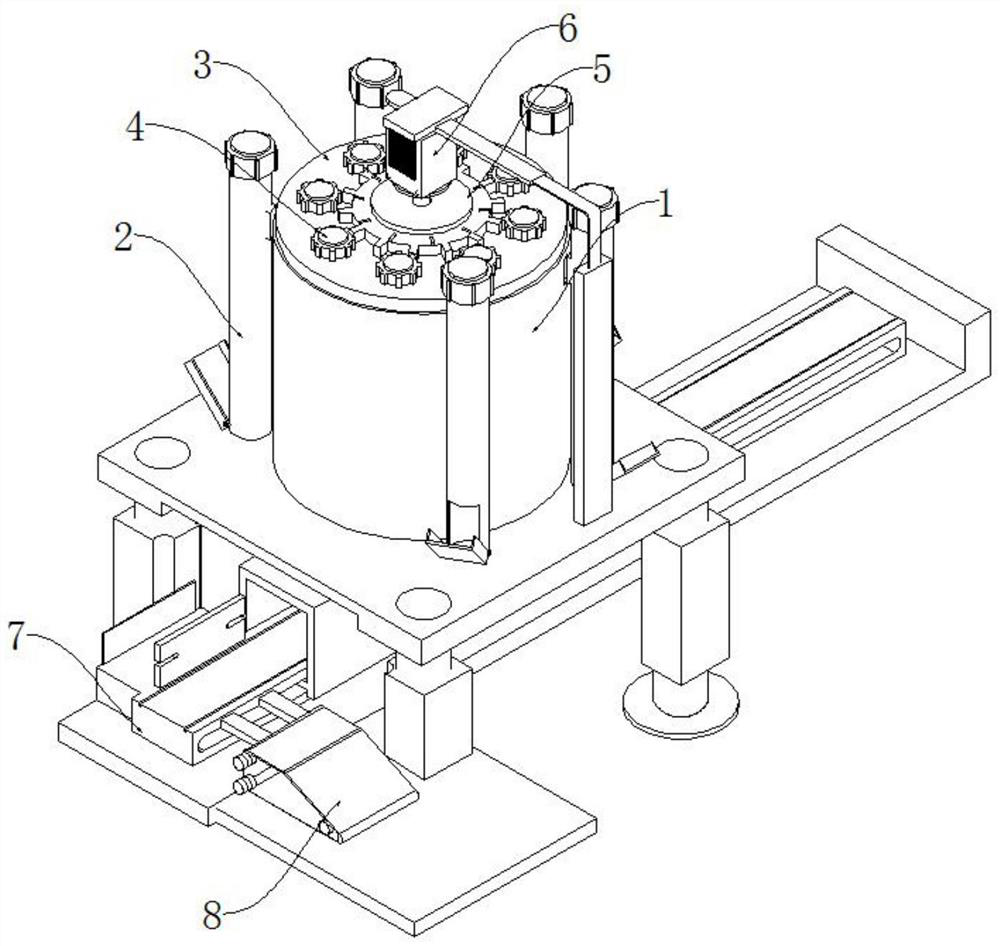

Manufacturing device for producing weather-resistant environment-friendly anticorrosive coating

ActiveCN111569760AScientific and reasonable structureEasy to useTransportation and packagingMixer accessoriesWeather resistanceElectric machine

The invention discloses a manufacturing device for producing a weather-resistant environment-friendly anticorrosive coating. The manufacturing device comprises a mounting support, wherein a dispersingbarrel is fixedly connected to one end of the top of the mounting support; a fixed mounting rack is fixedly connected to the middle part of the top end of the dispersing barrel; a dispersing motor isfixedly connected to the middle part of the top end of the fixed mounting rack; the input end of the dispersing motor is electrically connected with the output end of a mains supply; and an efficientdispersing and discharging mechanism is arranged on the inner side of the dispersing barrel. According to the invention, powdery raw materials are added into the dispersing barrel through a materialadding port; under the action of a driving gear and a rotating gear ring, the rotating gear ring, a connecting inclined rod, a mounting ring and a dispersing rotating shaft are driven to rotate in opposite directions, and therefore, stirring vertical plates, stirring arc plates and a mounting ring on the dispersing rotating shaft rotate in opposite directions in the dispersing barrel at the same time; and thus, efficient stirring in the dispersing barrel is achieved, the mixing rate of raw materials in the dispersing barrel is increased, the mixing time of anticorrosive paint is shortened, andthe processing efficiency of the anticorrosive paint is improved.

Owner:丹阳市美尔鑫化工有限公司

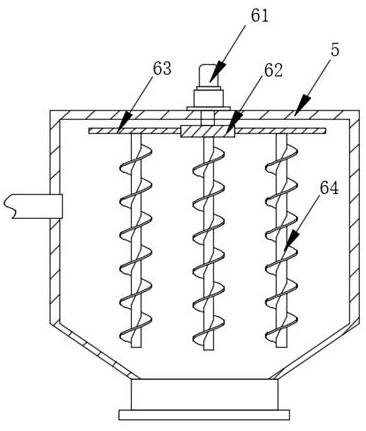

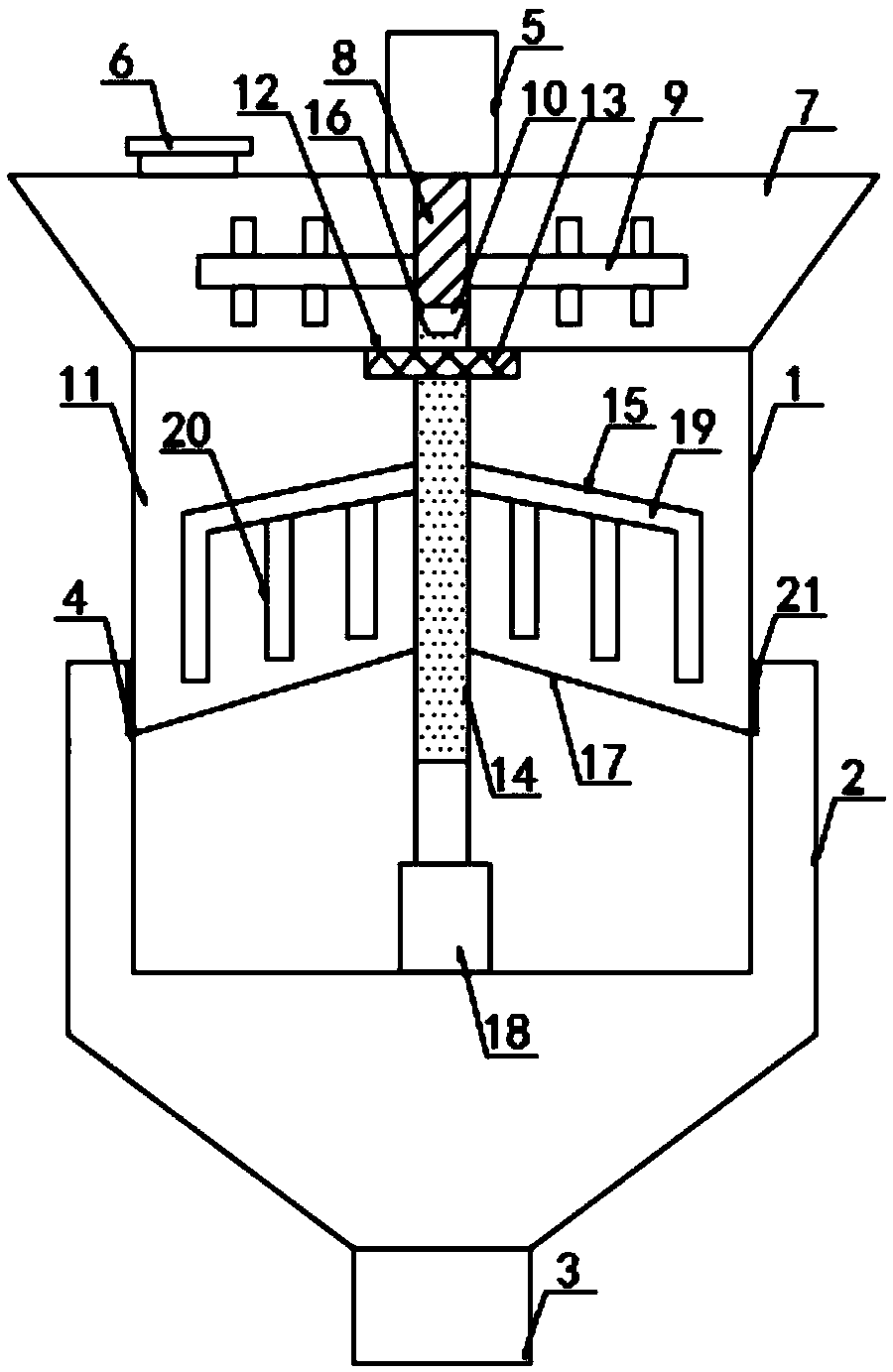

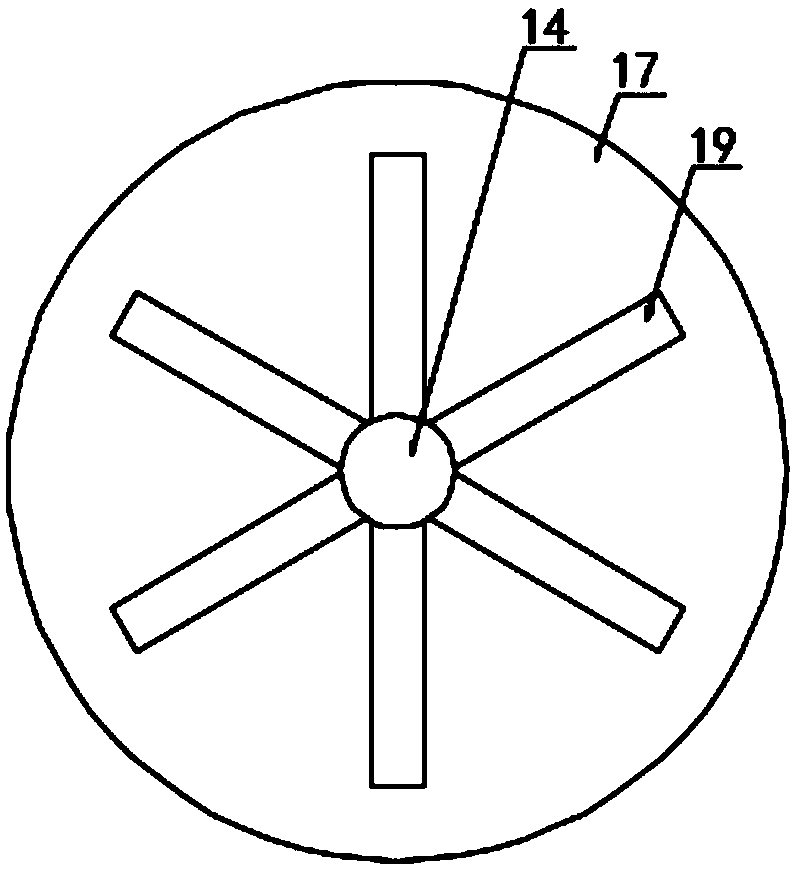

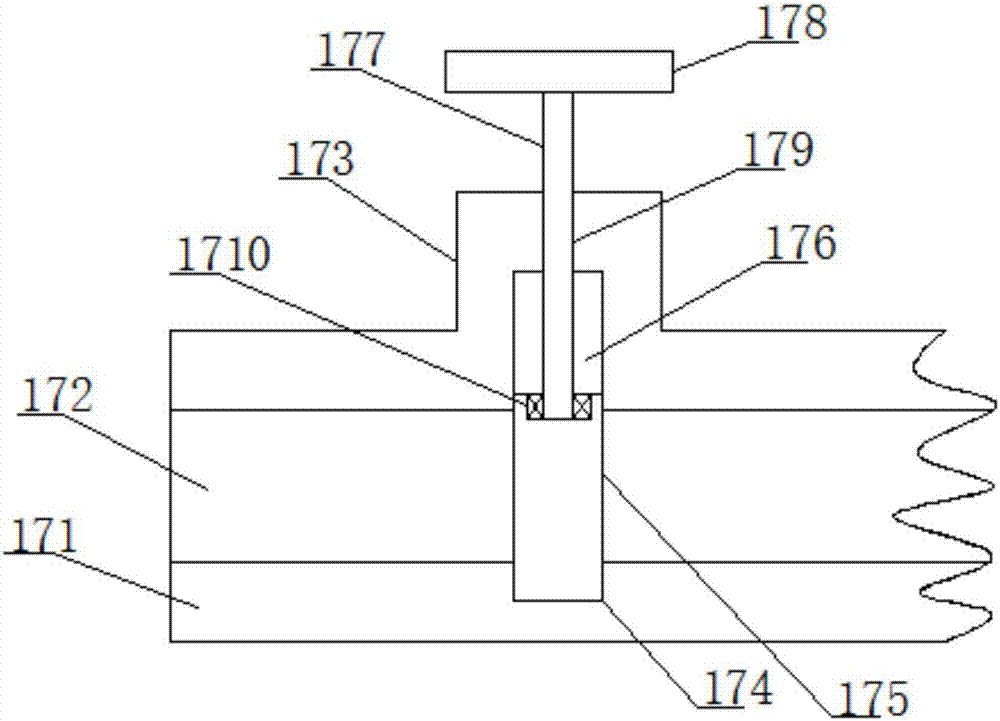

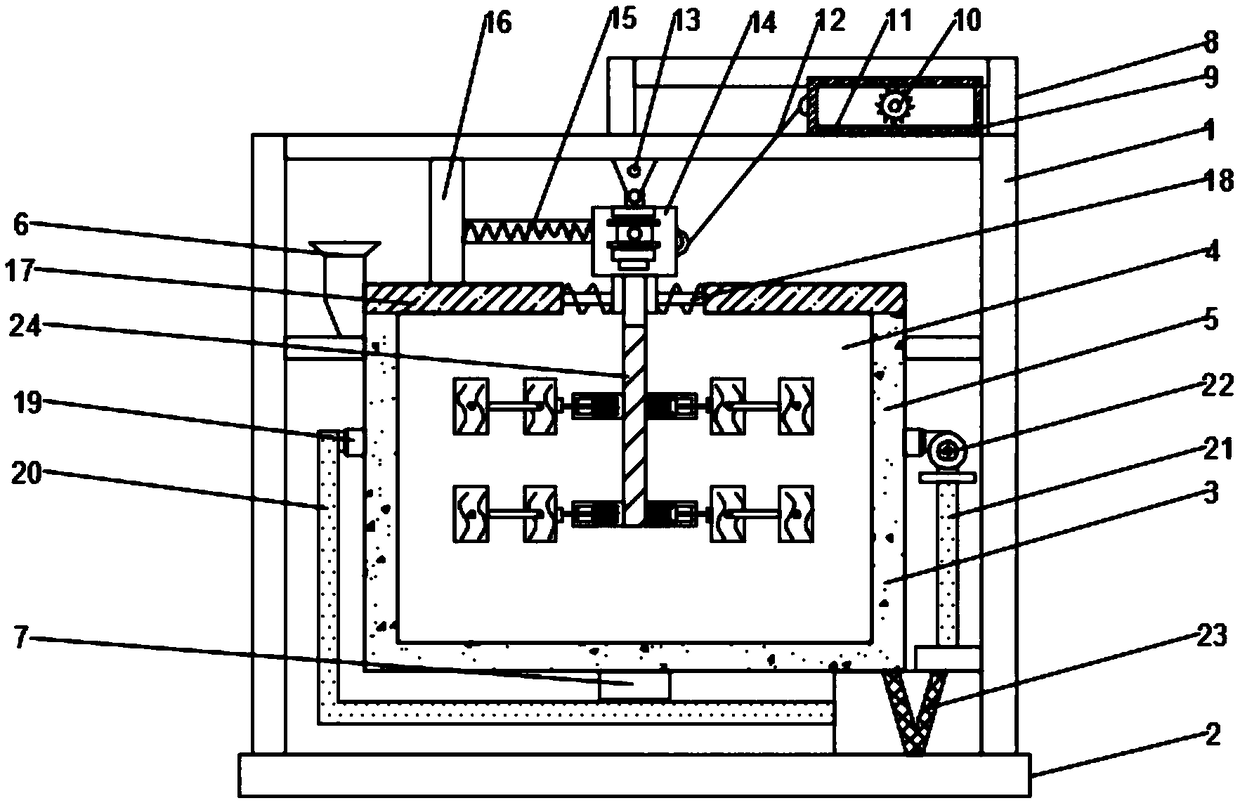

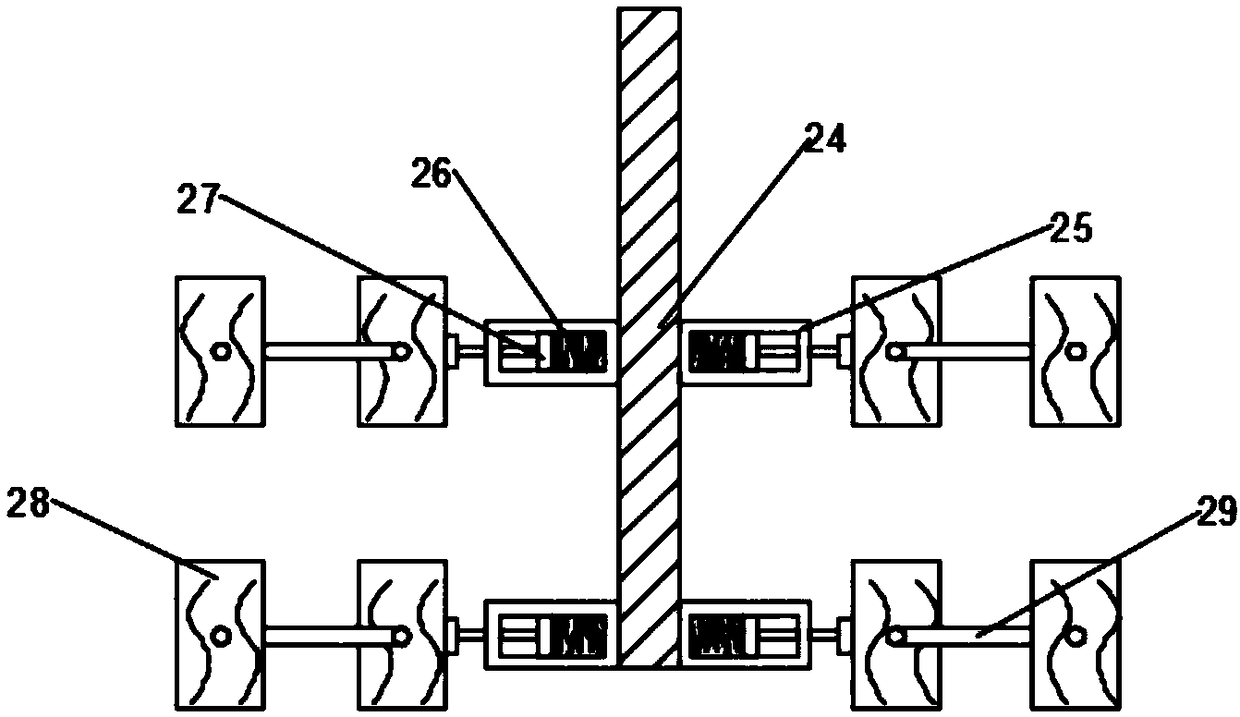

Chemical raw material mixing tank with lifting and stirring device

PendingCN108927043AAvoid accumulationImprove mixing effectTransportation and packagingRotary stirring mixersChemical productsMixing tank

The invention discloses a chemical raw material mixing tank with a lifting and stirring device. The chemical raw material mixing tank comprises a support base, a tank body, a lifting plate, a scrapingassembly and a stirring assembly, wherein the tank body is arranged above the support base, support legs are welded to four corners of the bottom surface of the tank body, and the support legs are fixed on the support base; a support crossbar is arranged above the tank body in a parallel mode, the right end of the support crossbar is welded to the tank body, and a material filling mouth is formedin the upper part of the rear wall of the tank body; the material filling mouth communicates with the tank body, a material discharge mouth is formed in the bottom of the left side wall of the tank body, and the material discharge mouth communicates with the inner cavity of the tank body; the chemical raw material mixing tank has the characteristics that the lifting plate is slidably mounted on the top of the inner cavity of the tank body, the scraping assembly is welded to both ends of the lifting plate, and the stirring assembly is arranged in the middle of the lower part of the lifting plate. The chemical raw material mixing tank has efficient stirring, and the mixed materials can be discharged quickly and conveniently, so that the production quality of chemical products is ensured, and the chemical raw material mixing tank is suitable for application and promotion.

Owner:嘉兴迪迈科技有限公司

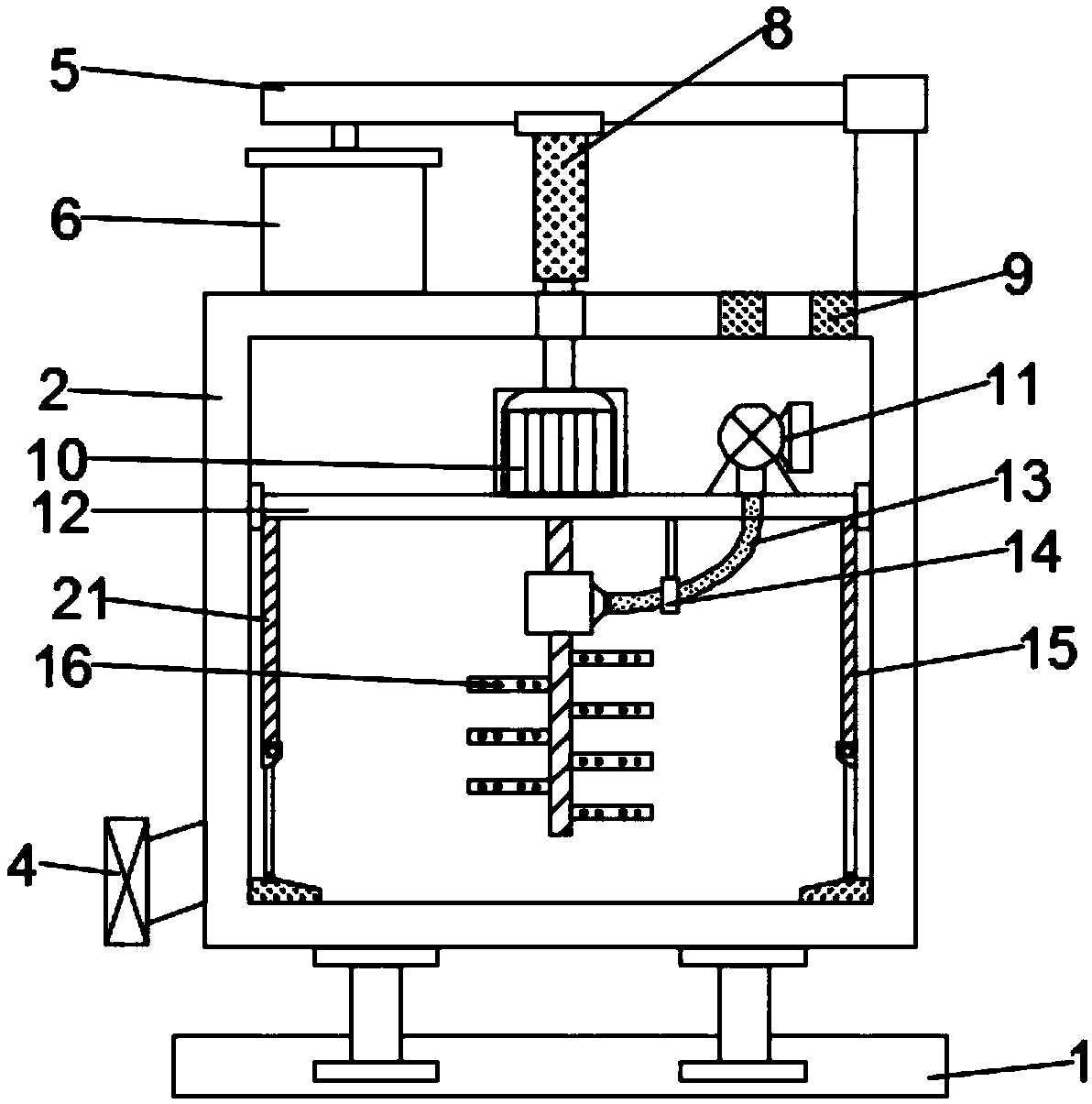

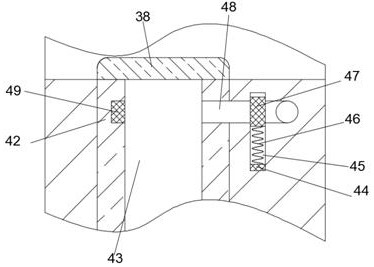

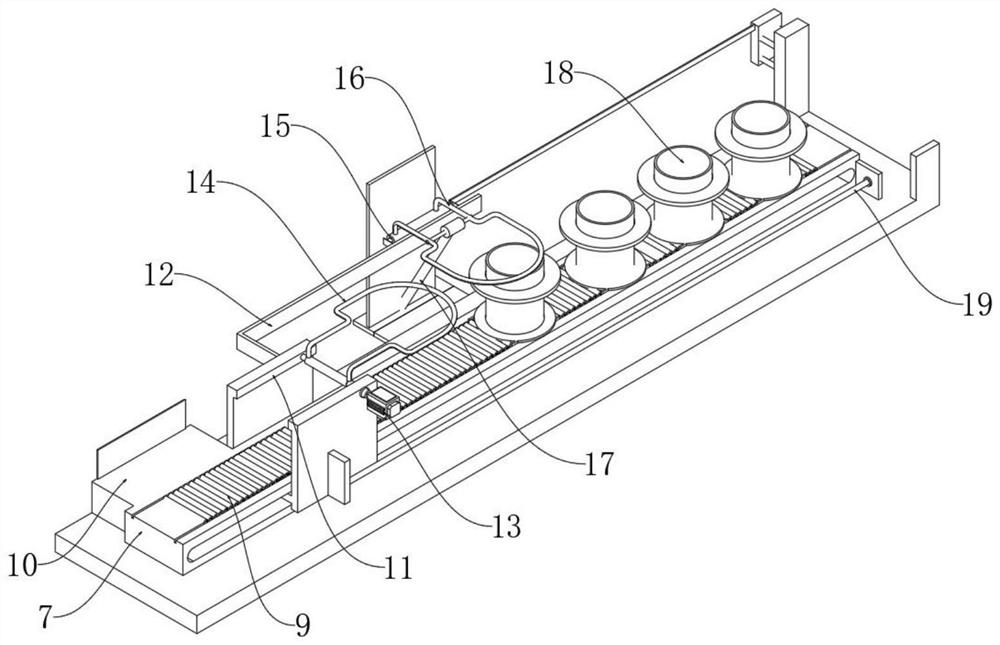

Multifunctional medical western medicine blending and identifying device

InactiveCN110694545AAchieving mixing and stirringGuaranteed to proceed normallyRotary stirring mixersTransportation and packagingWestern medicineElectric machinery

The invention discloses a multifunctional medical western medicine blending and identifying device, and belongs to the field of western medicine blending. The multifunctional medical western medicineblending and identifying device comprises a box body; fixing plates are symmetrically arranged on the inner side wall of the box body; a stirring mechanism is fixedly mounted on the opposite sides ofthe two fixing plates; quantifying mechanisms are symmetrically arranged at the inner top of the box body; the two quantifying mechanisms are connected with the upper end of the stirring mechanism through communicating pipes; a feeding pipe is arranged on the side wall of the upper end of the box body in a penetrating mode. According to the multifunctional medical western medicine blending and identifying device, a stirring box, a stirring shaft, a discharging pipe, a valve, a driving motor and a mounting block are matched for use, so that mixing stirring on western medicine is realized, normal work is guaranteed; through cooperative use of a discharging plate, a first spring, a second spring, a third spring, a connecting rod, a movable plate, a pull rope, a sealing plate and a feeding pipe, quantitative adding of western medicine is achieved, then the tedious weighing process is reduced, and the work efficiency is effectively improved.

Owner:龚淼

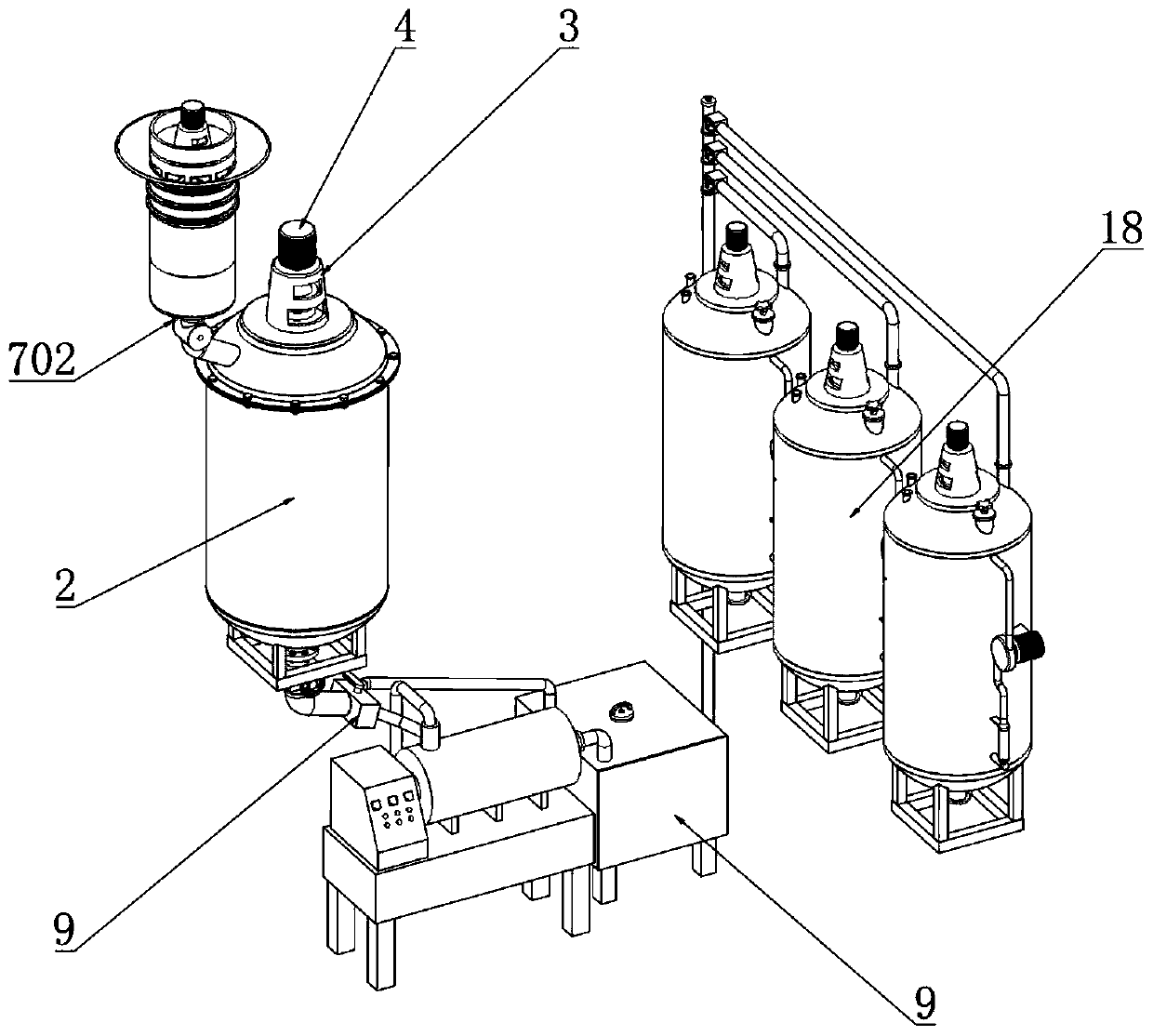

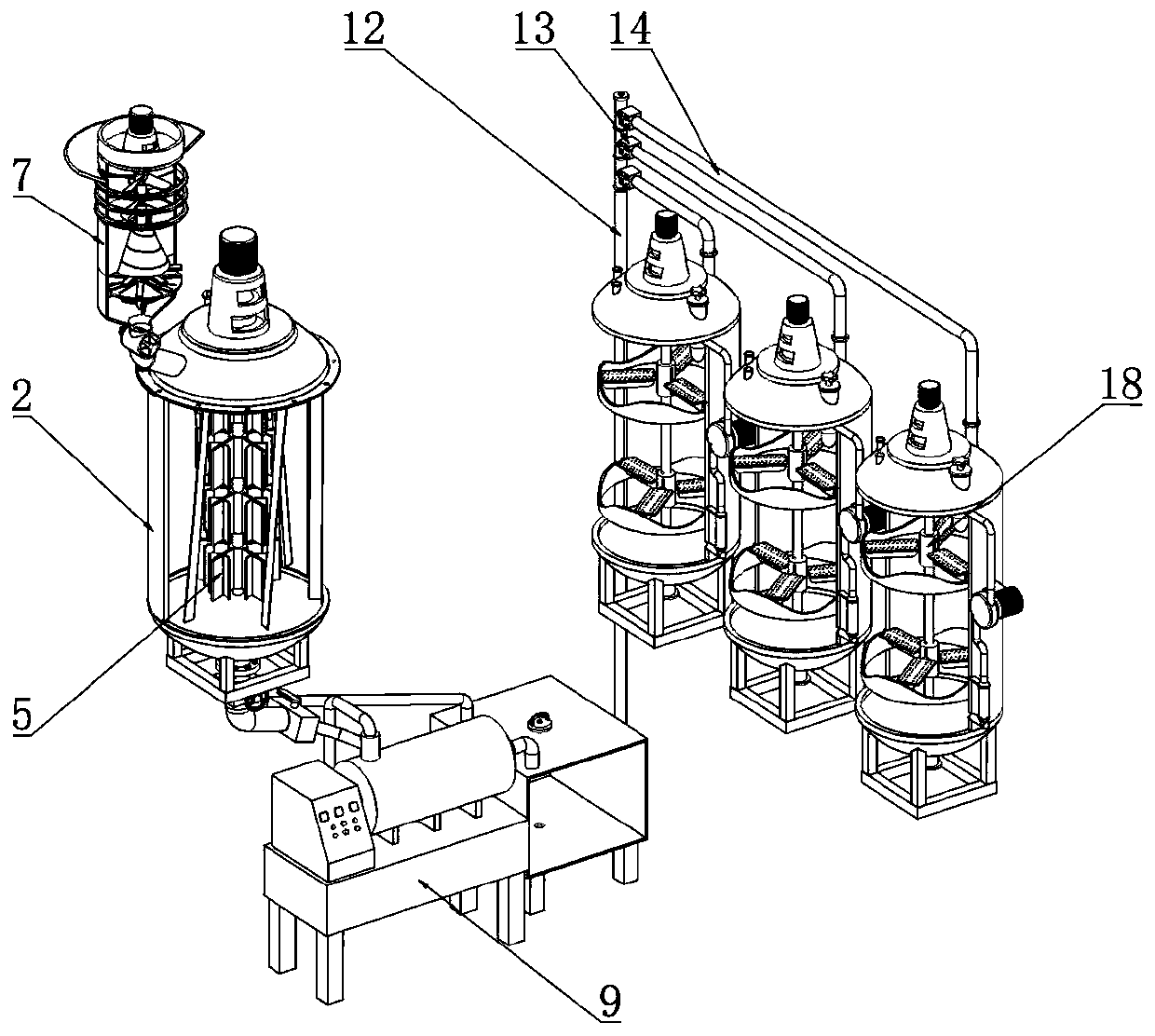

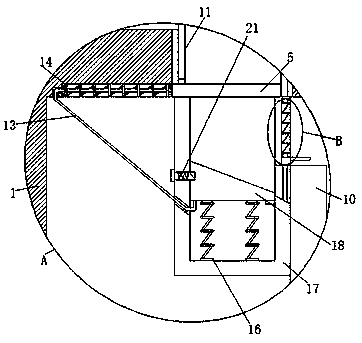

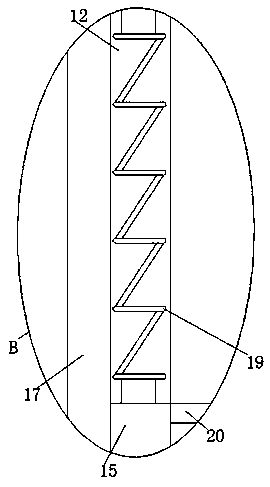

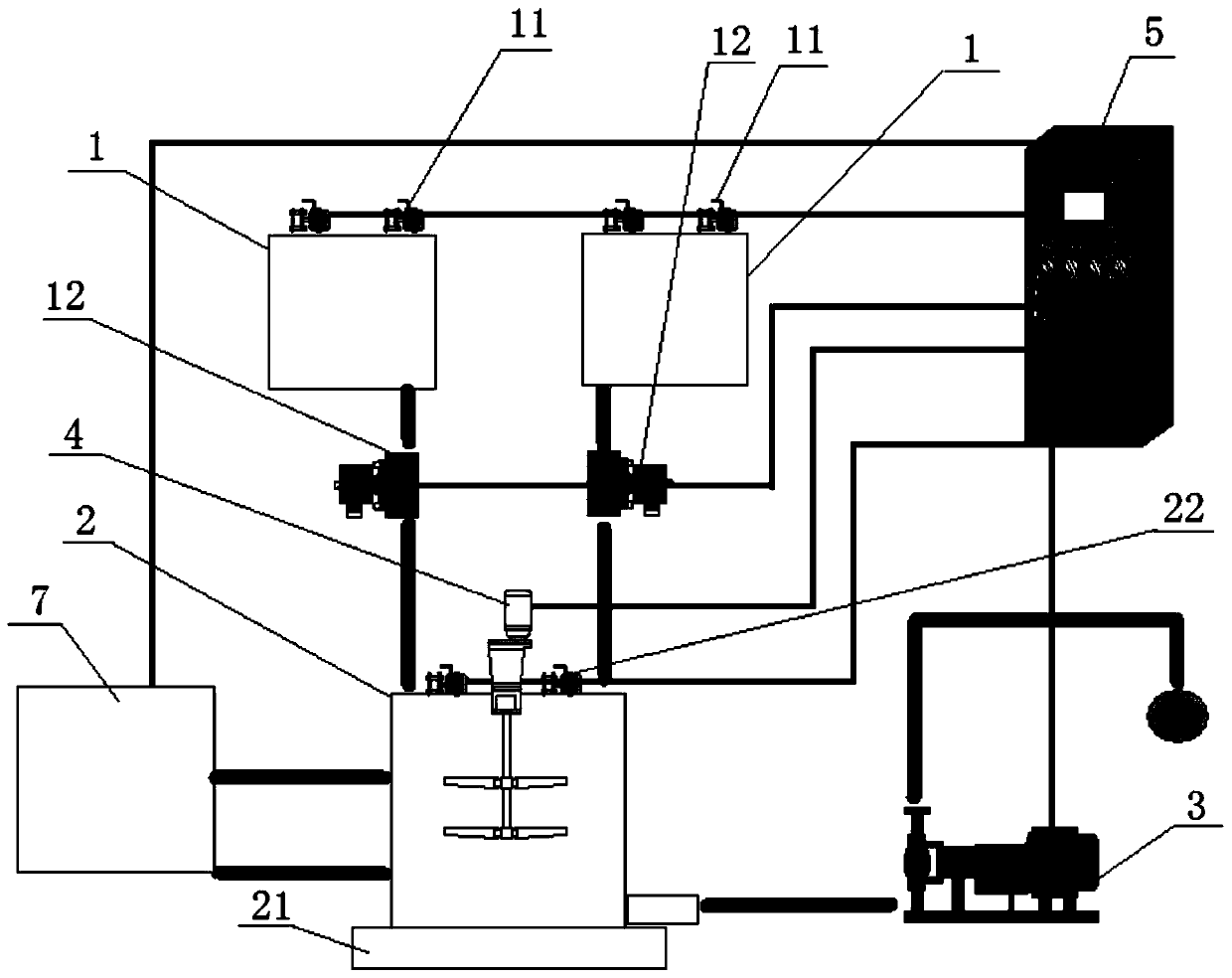

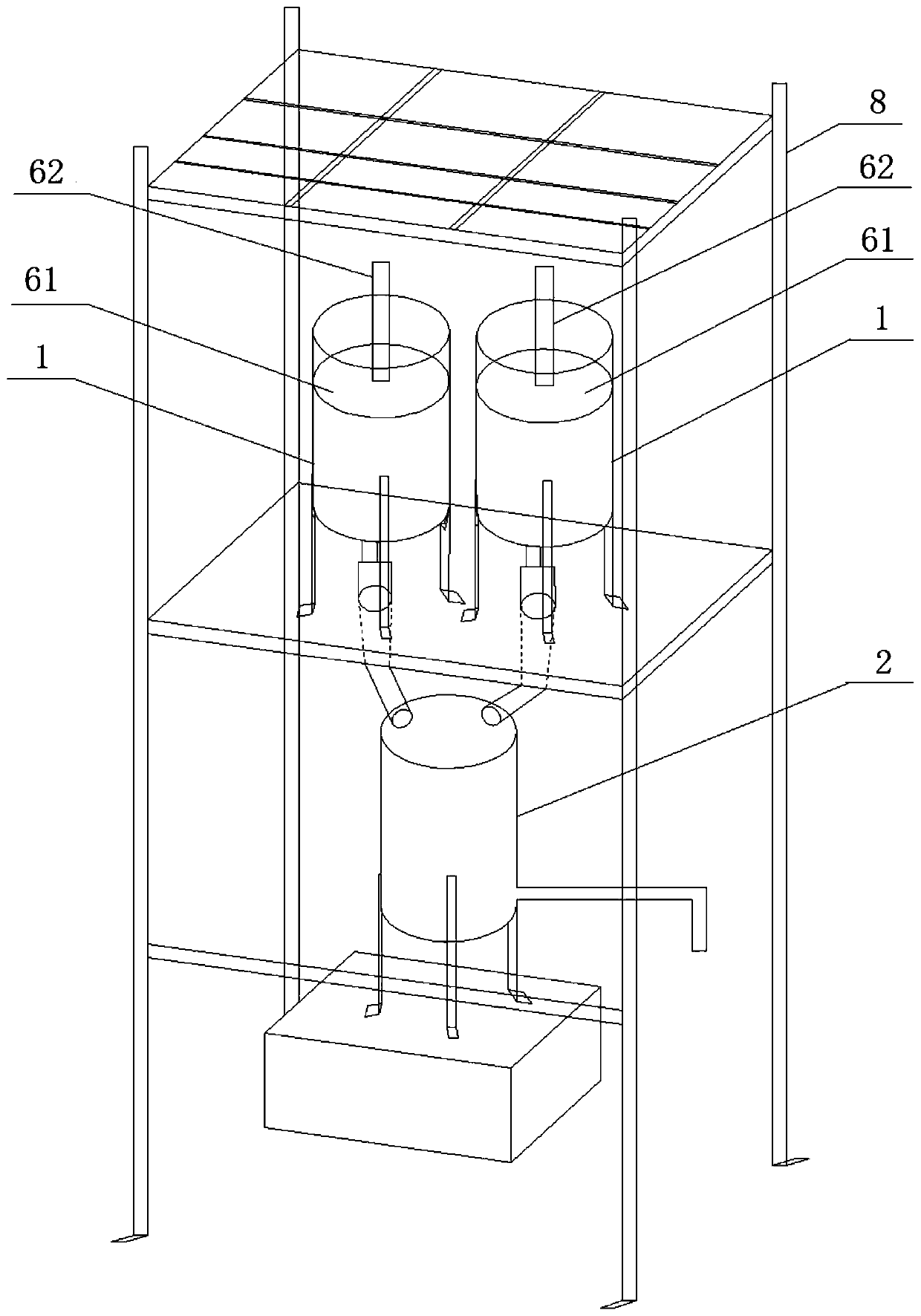

Automatic grouting and stirring system

PendingCN110449068AAchieving mixing and stirringReal-time adjustment of injection volumeTransportation and packagingRotary stirring mixersElectrical connectionLiquid level sensor

Relating to the technical field of grouting control, the invention discloses an automatic grouting and stirring system, which includes at least two raw material barrels, a stirring barrel, a stirrer,a grouting pump, and a host computer. Each raw material barrel is provided with a discharge port, the stirring barrel is provided a feed inlet, the discharge ports are both located above the feed inlet, and are communicated with the feed inlet respectively, the discharge ports are both equipped with a flow valve respectively, the raw material barrels are both internally equipped with liquid levelsensors, the stirrer is disposed in the stirring barrel, the stirring barrel is placed on an electronic scale, the stirring barrel is communicated with the grouting pump, and all the flow valves, thegrouting pump, the stirrer, all the liquid level sensors and the electronic scale are respectively in electrical connection with the host computer. The automatic grouting and stirring system providedby the invention has the technical effect of precise adjustment of the slurry ratio.

Owner:WUHAN CHANGJIANG KECHUANG TECH DEV

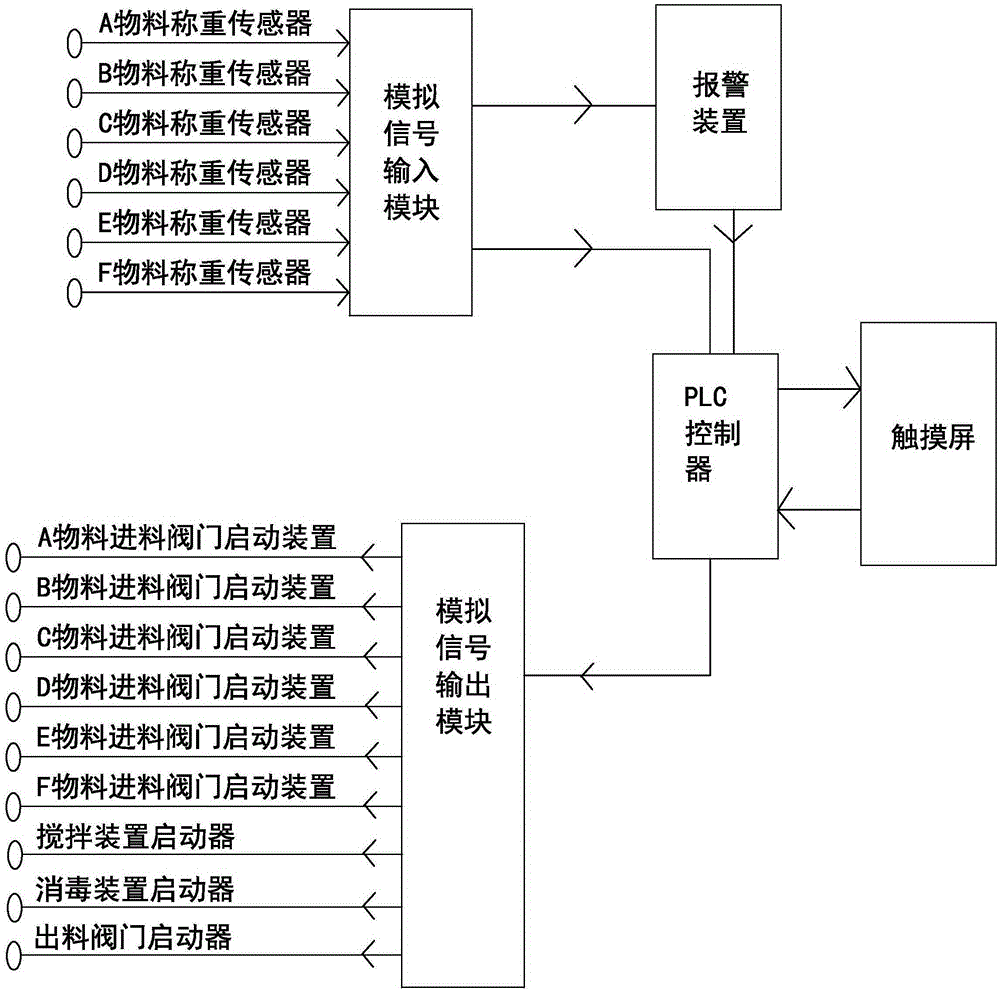

Automatic feed blending system with alarm function

InactiveCN106665390AImprove work efficiencyGuarantee ingredient quality and safetyAnimal feeding devicesFeed processingEngineering

The invention relates to an automatic feed blending system with an alarm function, and belongs to the technical field of feed processing. The automatic feed blending system comprises an analog signal input module, a controller, an analog signal output module, a display screen and an alarm device. The analog signal input module is connected with a material A weighing sensor, a material B weighing sensor, a material C weighing sensor, a material D weighing sensor, a material E weighing sensor and a material F weighing sensor, and the analog signal output module is connected with a material A feeding valve starting device, a material B feeding valve starting device, a material C feeding valve starting device, a material D feeding valve starting device, a material E feeding valve starting device, a material F feeding valve starting device, a stirring device starter, a disinfection device starter and a discharging valve starter. The automatic feed blending system has the advantages that feed can be automatically blended, mixed, stirred and disinfected, the automatic feed blending system has the alarm function, and accordingly the blending quality and safety can be guaranteed.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

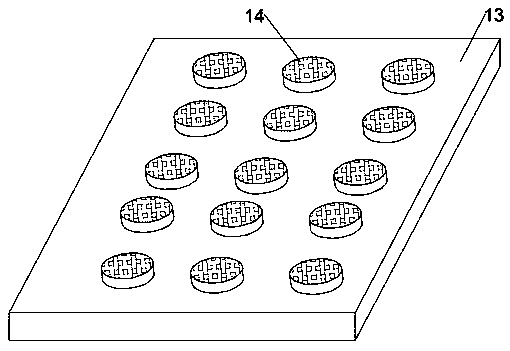

Lithium-ion battery slurrying and mixing plate

InactiveCN109078541AAchieving mixing and stirringWell mixedTransportation and packagingRotary stirring mixersSlurryEngineering

The invention discloses a lithium-ion battery slurrying and mixing plate, and belongs to the technical field of battery production equipment. The problems that slurry is quite high in viscosity, and is easily attached to side walls, so that a mixing plate is difficult to clean are solved. The lithium-ion battery slurrying and mixing plate is technically characterized by comprising a battery slurrystirring structure, and further comprises a shell, a stirring cavity and scraping assemblies, wherein a stirring cavity is formed in the shell; a flow guiding plate is obliquely arranged on the bottom of the stirring cavity, a discharging opening is formed in the position, which is in contact with the right side wall of the shell, of the right end of the flow guiding plate, a supporting cross plate is vertically arranged on the top of the stirring cavity, a feeding opening is formed in the position, which is in contact with the side wall of the shell, of the left end of the supporting cross plate, the feeding opening communicates with the stirring cavity, and the scraping assemblies are symmetrically arranged on the two sides of the stirring cavity. Residual slurry of the inner wall of the shell can be scraped off, meanwhile, it can be ensured that the slurry is mixed uniformly and fully, the work load of people is greatly relieved, and the quality of produced lithium batteries is also ensured.

Owner:山东天瀚新能源科技有限公司

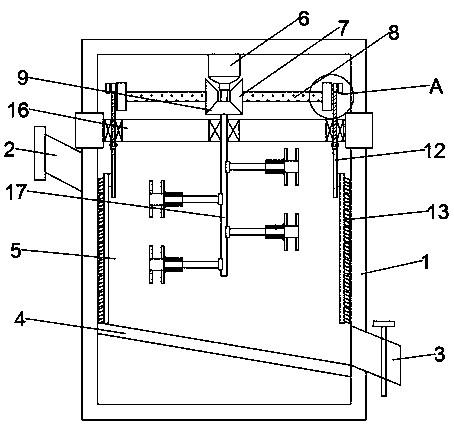

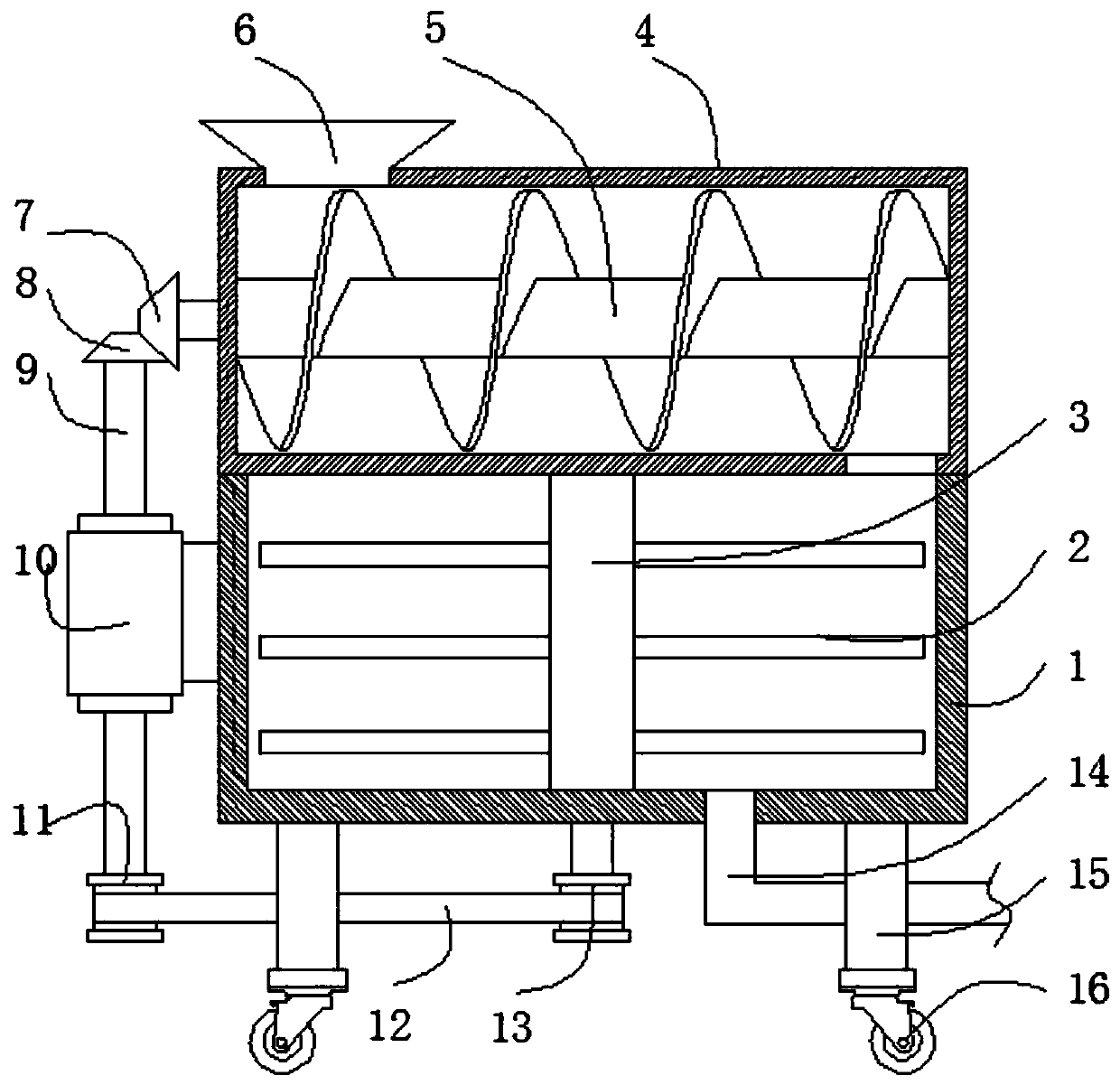

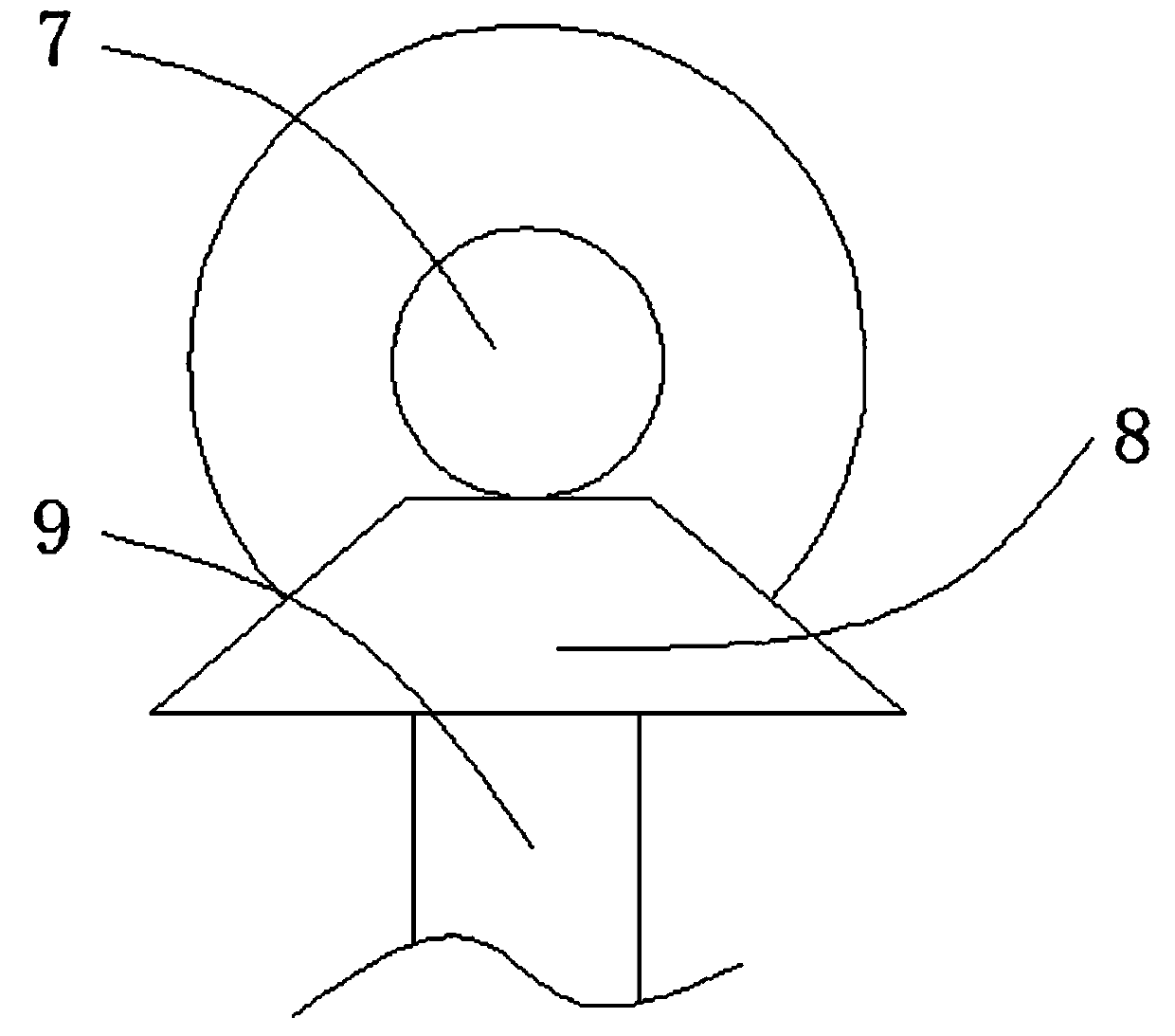

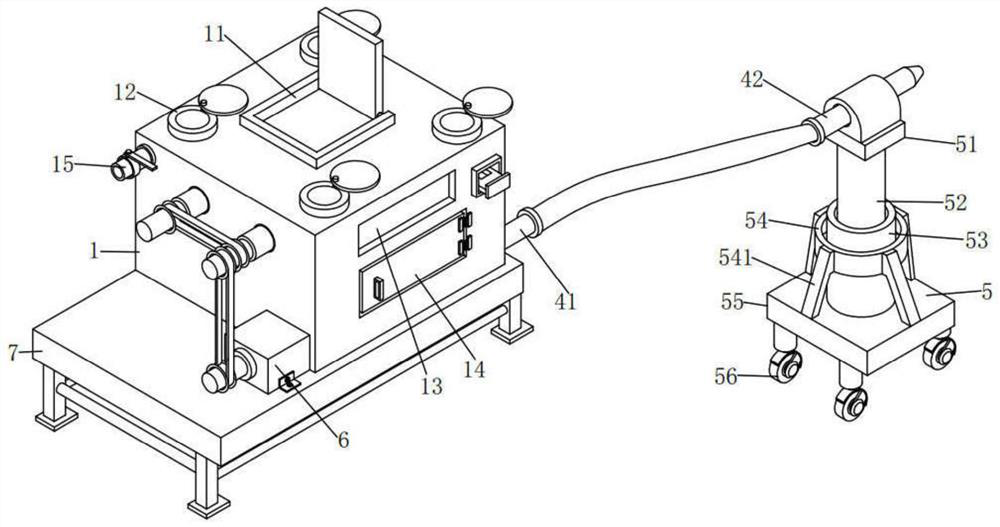

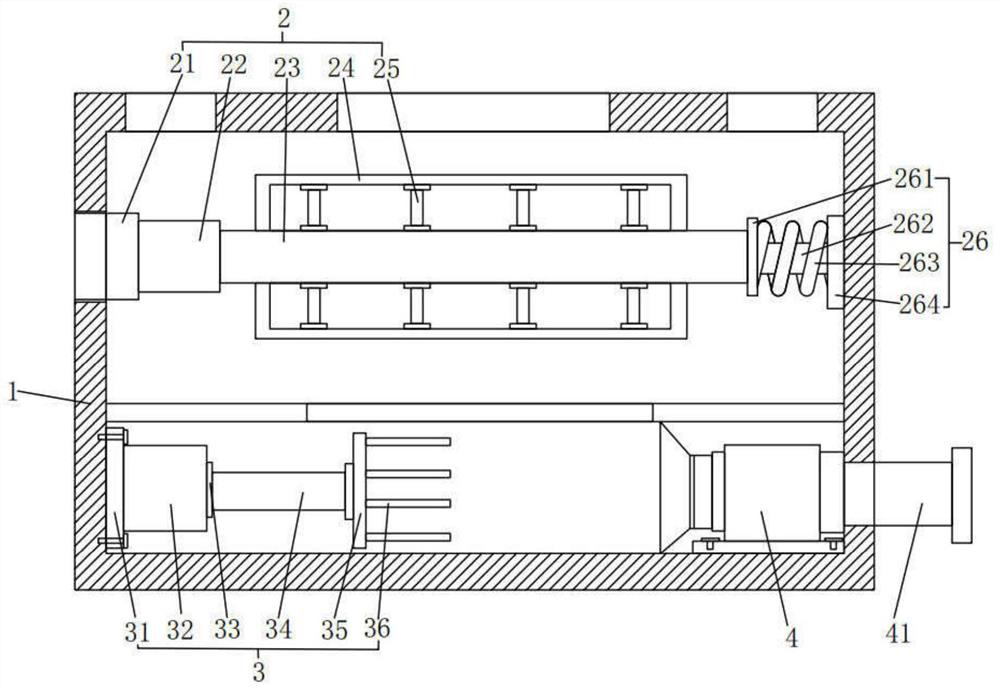

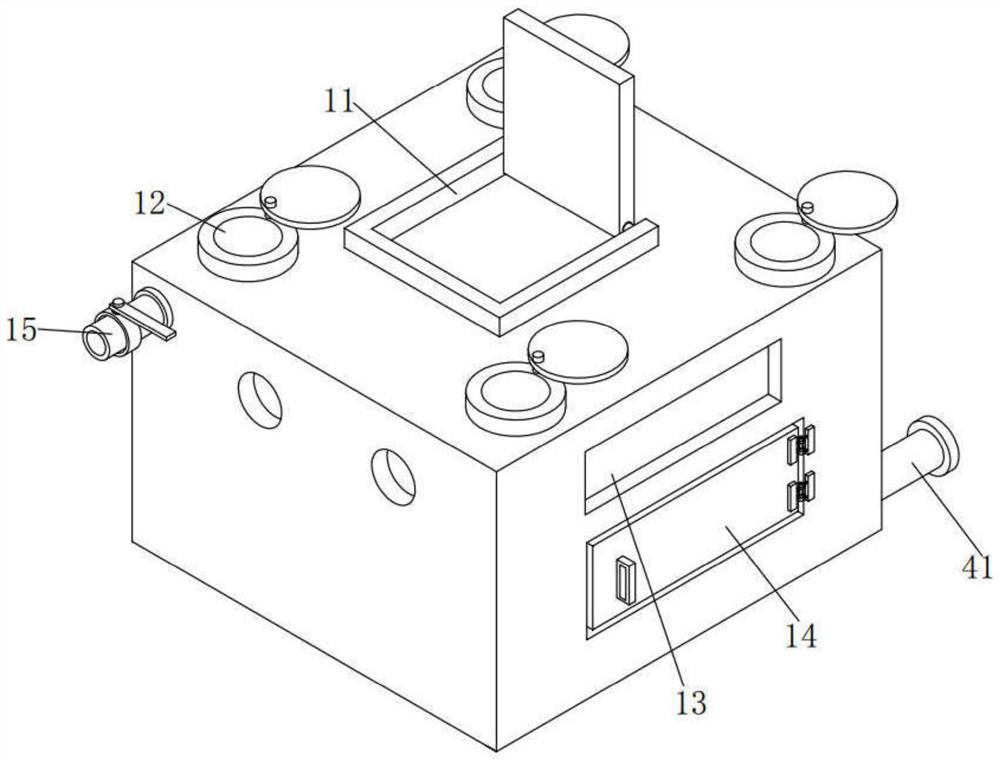

On-site stirring, and mixing coating integrated device for coating in building industry

InactiveCN109173889AImprove spraying effectAchieving mixing and stirringTransportation and packagingMixer accessoriesDrive motorIntermediate storage

The invention discloses an on-site stirring, and mixing coating integrated device for a coating in a building industry, which relates to the field of building decoration. The device comprises a base plate, the top end of the base plate is fixedly provided with a first side frame and a second side frame, a raw material mixing cylinder is arranged between the first side frame and the second side frame, a feeding mechanism is arranged at a top end of the raw material mixing cylinder, the bottom end of the raw material mixing cylinder is connected to an intermediate storage cylinder through a first blanking tube, the bottom end of the intermediate storage cylinder is connected with a finished product taking cylinder passes through a second blanking tube, the second side frame is fixedly connected to a first fixed plate, a driving motor is arranged on the first fixed plate, and rotating shafts are arranged in the raw material mixing cylinder, the intermediate storage cylinder and the finished product taking cylinder, the rotating shafts are fixedly connected to stirring paddles, and the driving motor is connected to a spraying mechanism. The device can realize the function of mixing andstirring of raw materials of the coating, short-term storage of the finished product, and timely taking of the finished product, and enables continuous supply of the coating, can carry out negative-pressure ash removal operation on the sprayed surface before spraying the coat, and can increase the spray effect of the coating.

Owner:霸州市辉月网络技术有限公司

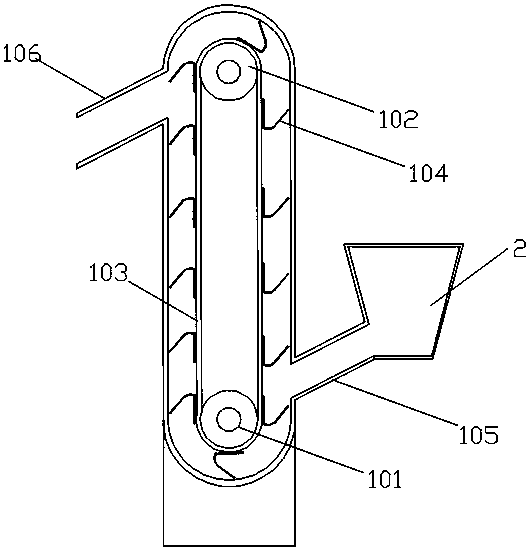

Stirring device for quick-frozen steamed bread production

InactiveCN107114432AAchieving mixing and stirringWell mixedMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringSteamed bread

The invention discloses a stirring device for the production of quick-frozen steamed buns, which comprises a device body, the device body is a cavity structure, a first motor is fixedly installed on the top of the device body, and a through hole is opened on the top of the device body. A vertical rotating rod is installed in the through hole, and the top of the rotating rod is fixedly connected with the output shaft of the first motor. There is a second motor, the output shaft of the second motor is fixedly installed with a horizontally arranged installation plate, and the top of the described installation plate is fixedly installed with a vertically arranged support column, and the top of the support column is fixedly installed with a mixing chamber. The top of the mixing chamber is provided with an opening. The invention not only realizes the uniform mixing of raw materials, but also cleans the raw materials adhered to the inner wall of the mixing chamber, avoids waste and ensures uniform mixing of raw materials, has simple structure, is convenient to use, and is easy to popularize.

Owner:JIANGSU HAIDA FOOD

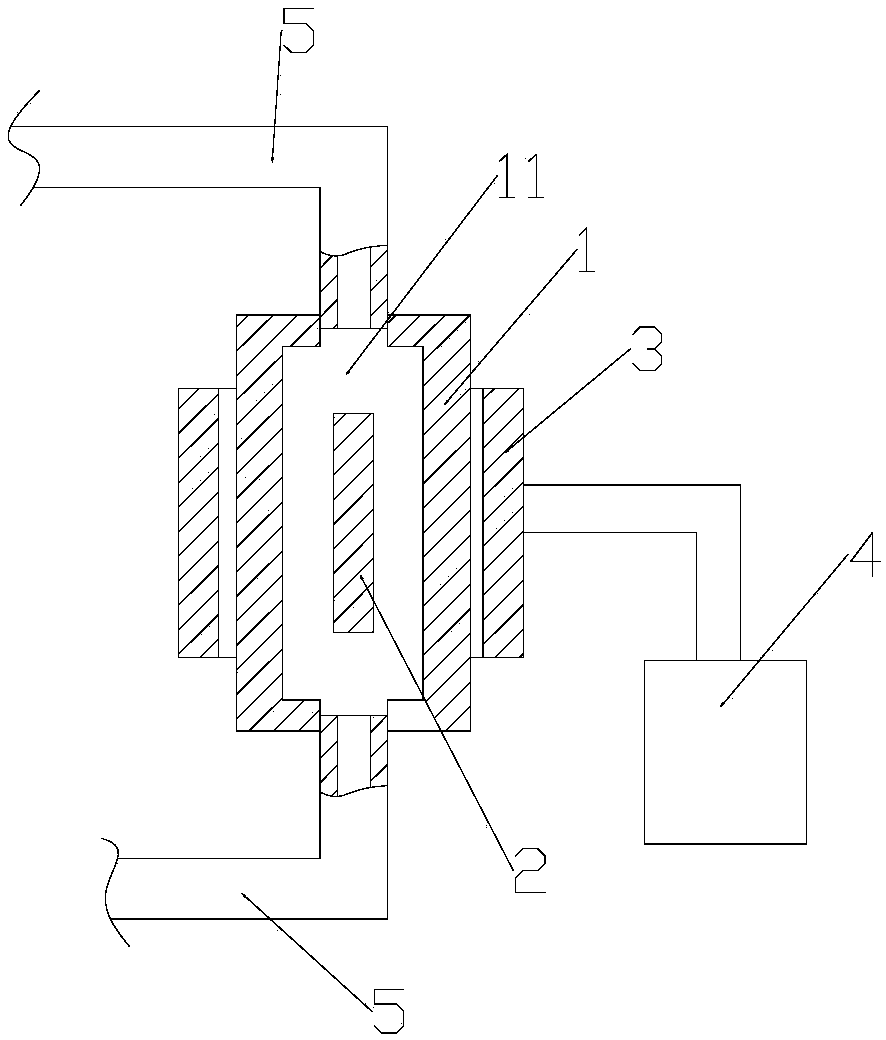

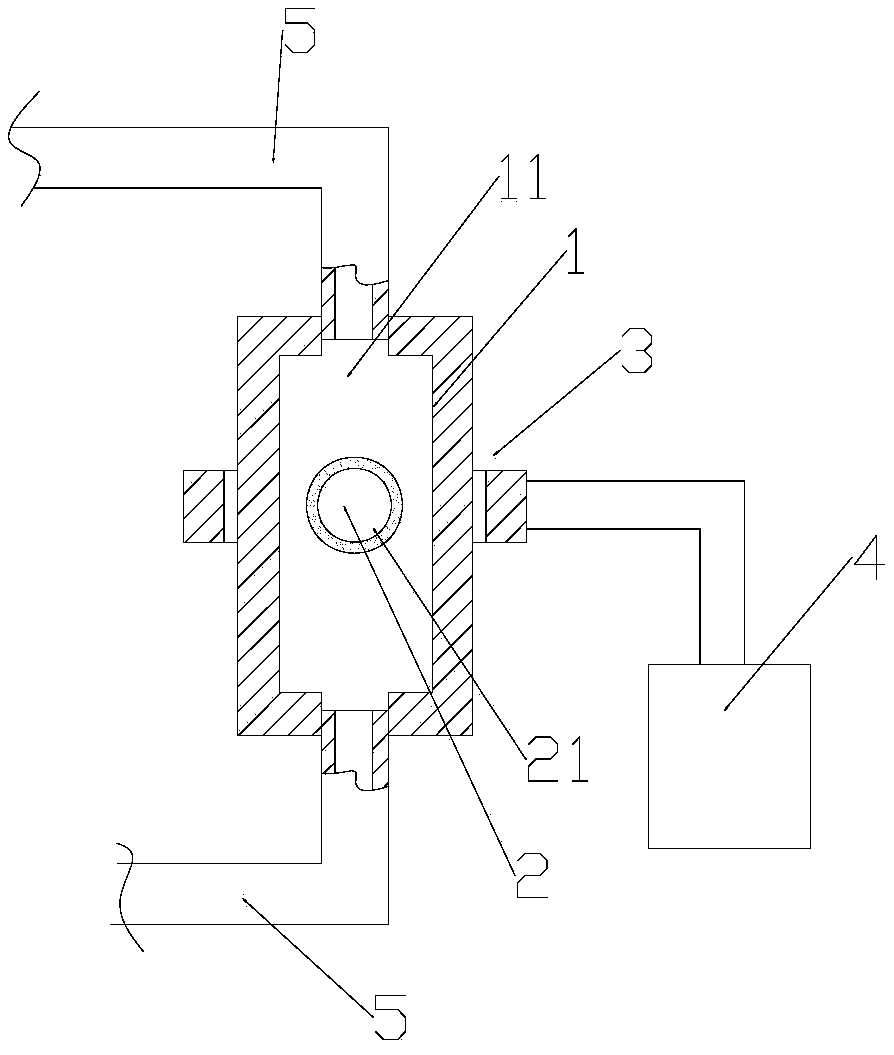

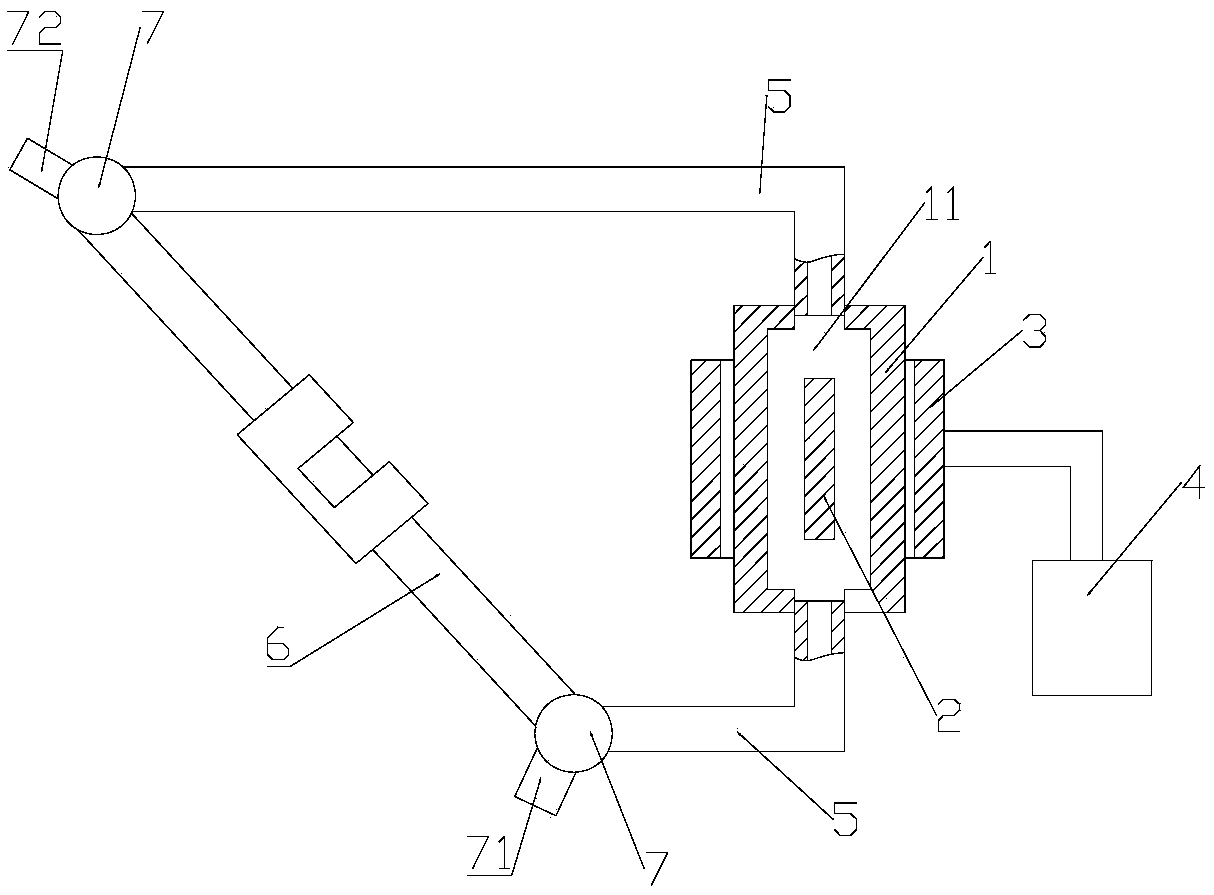

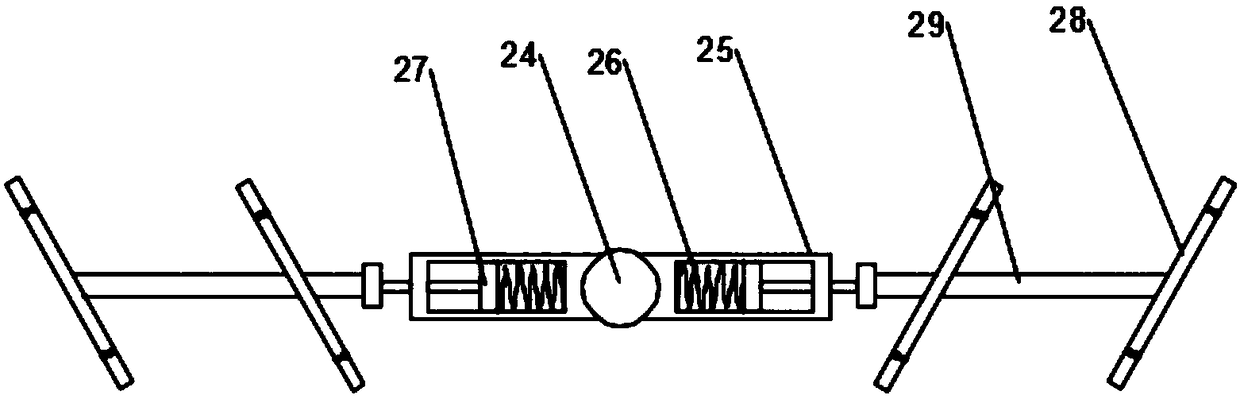

Liquid stirring oscillation device, application and liquid stirring method

ActiveCN109261039AAchieving mixing and stirringTransportation and packagingMixersReaction temperatureEngineering

The invention discloses a liquid stirring oscillation device. The liquid stirring oscillation device is used for stirring liquid in reactors and comprises an isolation body, a magnetic jacket, an inner core, a power source and connecting pipelines. The isolation body is in the shape of a columnar body, a flow channel is formed on the isolation body and is provided with two ports, and the two portsare positioned on two end surfaces of the isolation body; the magnetic jacket sleeves the outer surface of the isolation body; the inner core is positioned in the flow channel and can be attracted bythe magnetic jacket to move along with the magnetic jacket; the power source is connected with the magnetic jacket, and the magnetic jacket can be driven by the power source to carry out reciprocating linear movement on the isolation body along the axis of the isolation body; the flow channel can be connected with the reactors by the connecting pipelines; closed circuits are formed by the connecting pipelines, the flow channel and the reactors. The invention further discloses application of the liquid stirring oscillation device and a liquid stirring method. The liquid stirring oscillation device, the application and the liquid stirring method have the advantages that the liquid in the reactors can be stirred in external back-and-forth oscillation modes, and the liquid stirring oscillation device and the liquid stirring method are free of influence of the spatial sizes and layout of the reactors, the reaction temperatures, the pressures and atmosphere and are widely applicable to diversified reaction systems.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

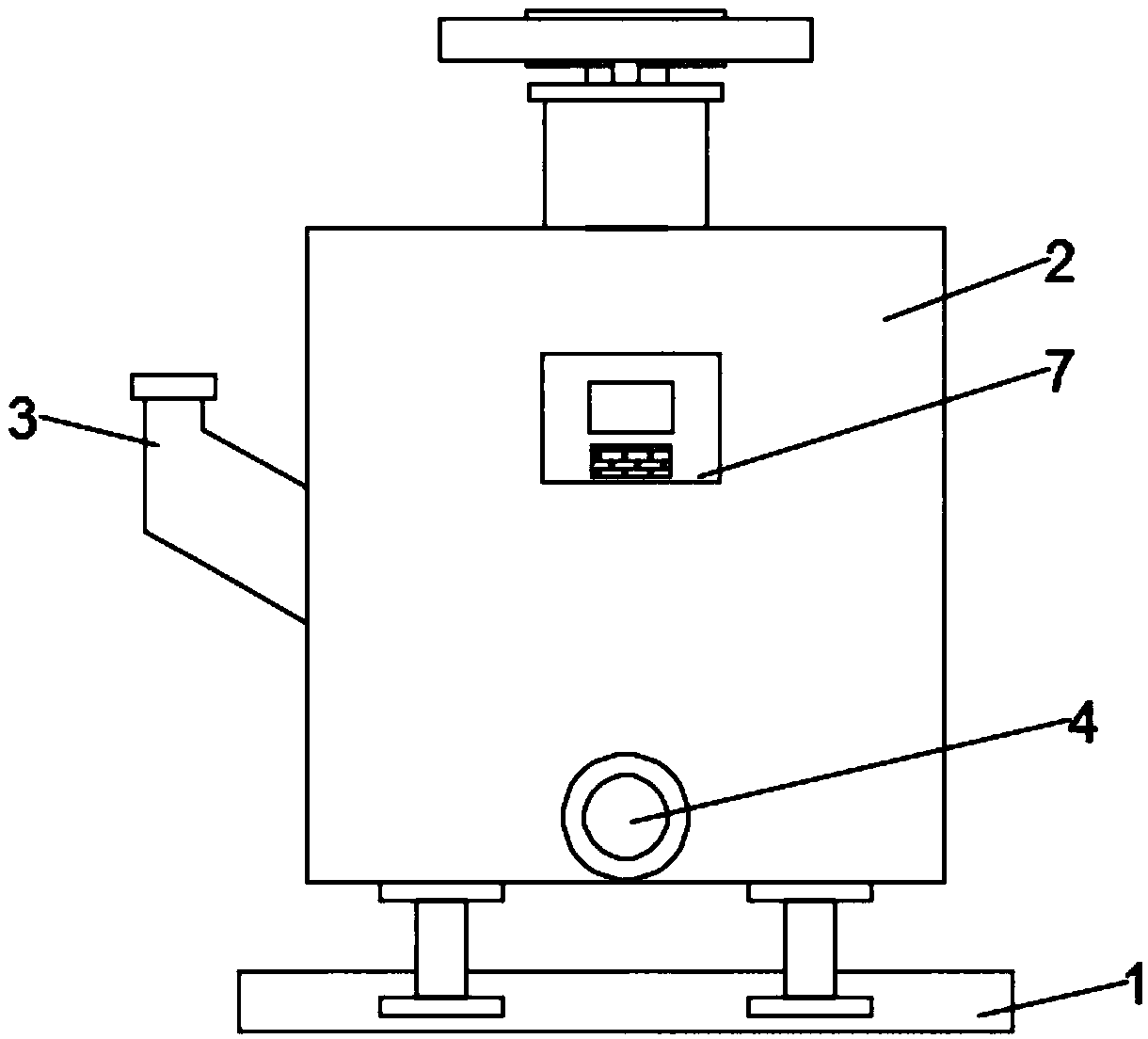

Food waste microbial degradation network cloud

PendingCN111925954AAchieving mixing and stirringWell mixedFungiBacteriaActivated carbonEnvironmental engineering

The invention discloses a food waste microbial degradation network cloud which comprises a supporting base, supporting columns, a conveying mechanism, a fermentation tank and a waste gas treatment tank. There are two supporting columns which are fixedly mounted on one side of the upper end of the supporting base. The conveying mechanism is arranged at the upper ends of the two supporting columns;one end of the conveying mechanism is connected with one side of the fermentation tank; the waste gas treatment tank is arranged on one side, far away from the conveying mechanism, of the fermentationtank; the fermentation tank is communicated with the waste gas treatment tank through a gas conveying pipe; supporting legs are fixedly installed on the two sides of the bottom end of the supportingbase. A controller is mounted on one side of the bottom end of the supporting seat; waste gas is purified through cooperative use of a first activated carbon plate and a second activated carbon plate,effective purification treatment is achieved, the air emission quality is improved, particles in the waste gas can be effectively removed, waste gas molecules are destroyed and purified, the effect is good, and the application range is wide.

Owner:人与自然环保生物科技(南京)有限公司

Refractory material mixing device

InactiveCN111530360AAchieving mixing and stirringWell mixedTransportation and packagingRotary stirring mixersElectric machineRefractory

The invention discloses a refractory material mixing device, and relates to the field of material mixing. Aiming at problems that existing mixing devices for refractory materials are mostly complex instructure, and cannot fully mix materials; the quality of processed materials is further influenced and the workload of workers increases and the devices are inconvenient to use and low in practicability, and the like, a technical scheme is provided, wherein the mixing device comprises a first stirring tank, a connecting block is welded to the left side of the first stirring tank, a double-shaftmotor is fixedly connected to the face, away from the first stirring tank, of the connecting block, a rotating shaft is fixedly connected to an output shaft of the double-shaft motor, and a second bevel gear and a first belt wheel are welded to the end, away from the double-shaft motor, of the rotating shaft. The refractory material mixing device is simple in structure, novel in design, capable offully mixing refractory materials, capable of improving the refractory material processing quality and reducing the labor amount of workers, easy to use, high in practicability and suitable for widepopularization.

Owner:长兴县中泰耐火材料有限公司

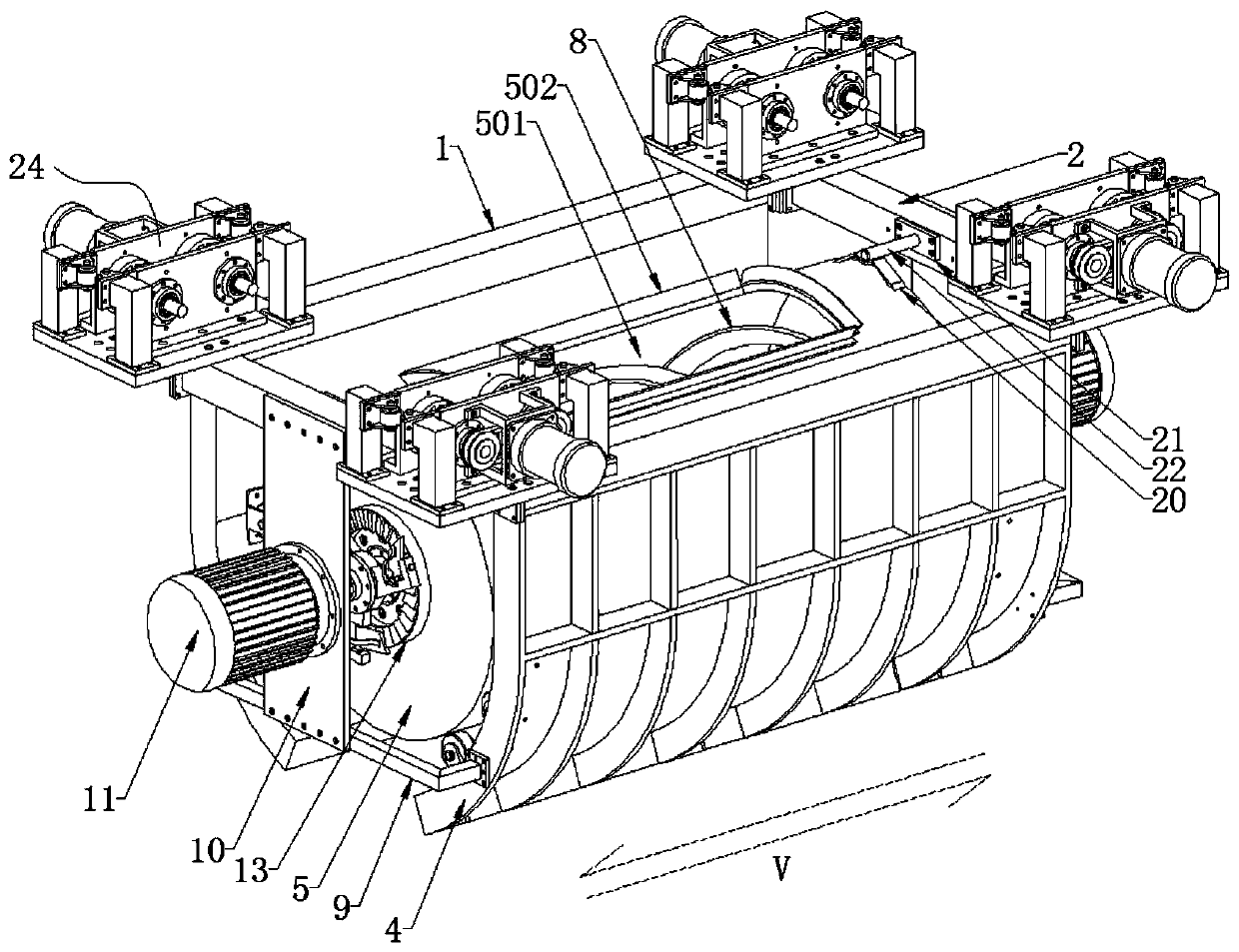

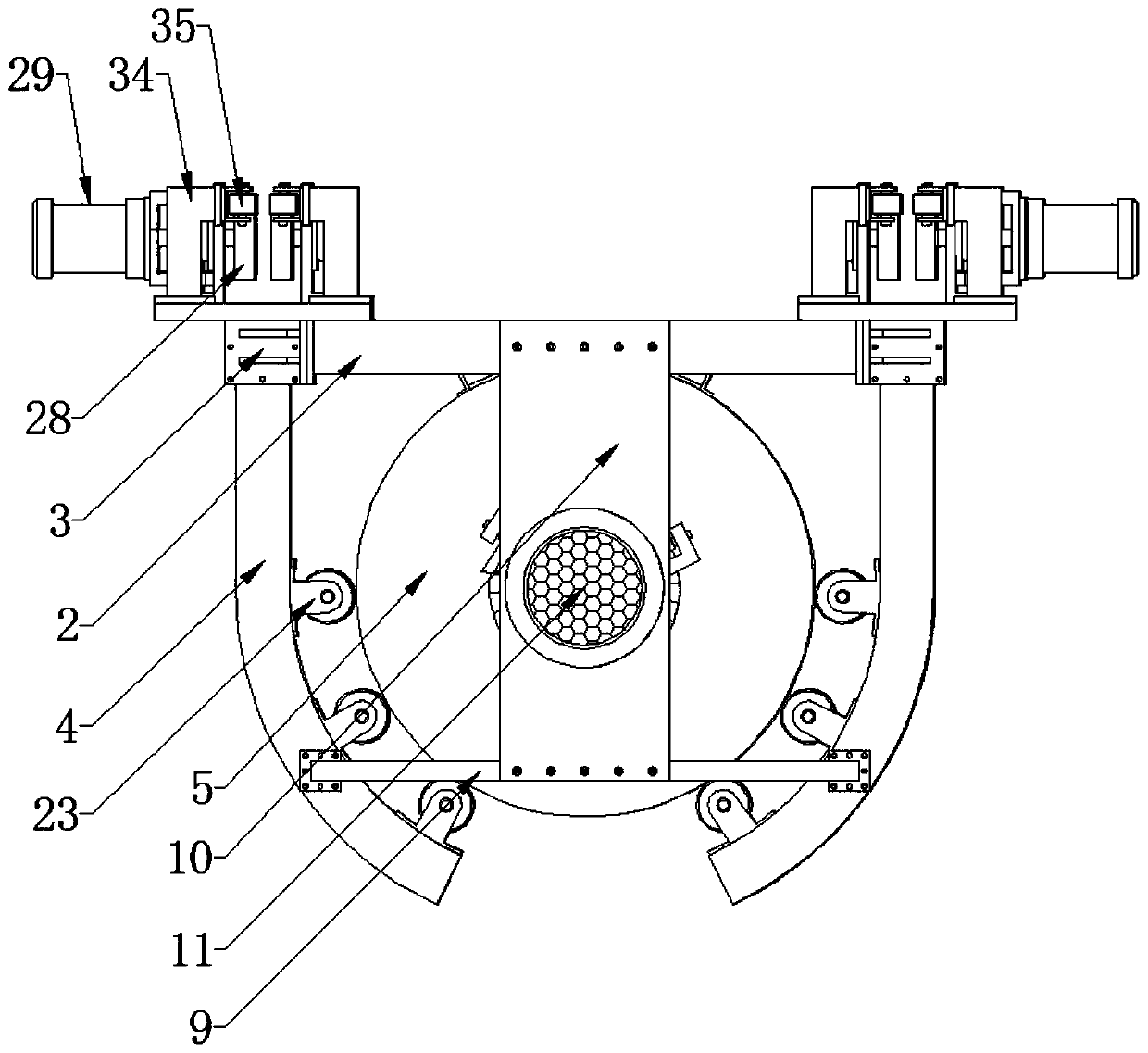

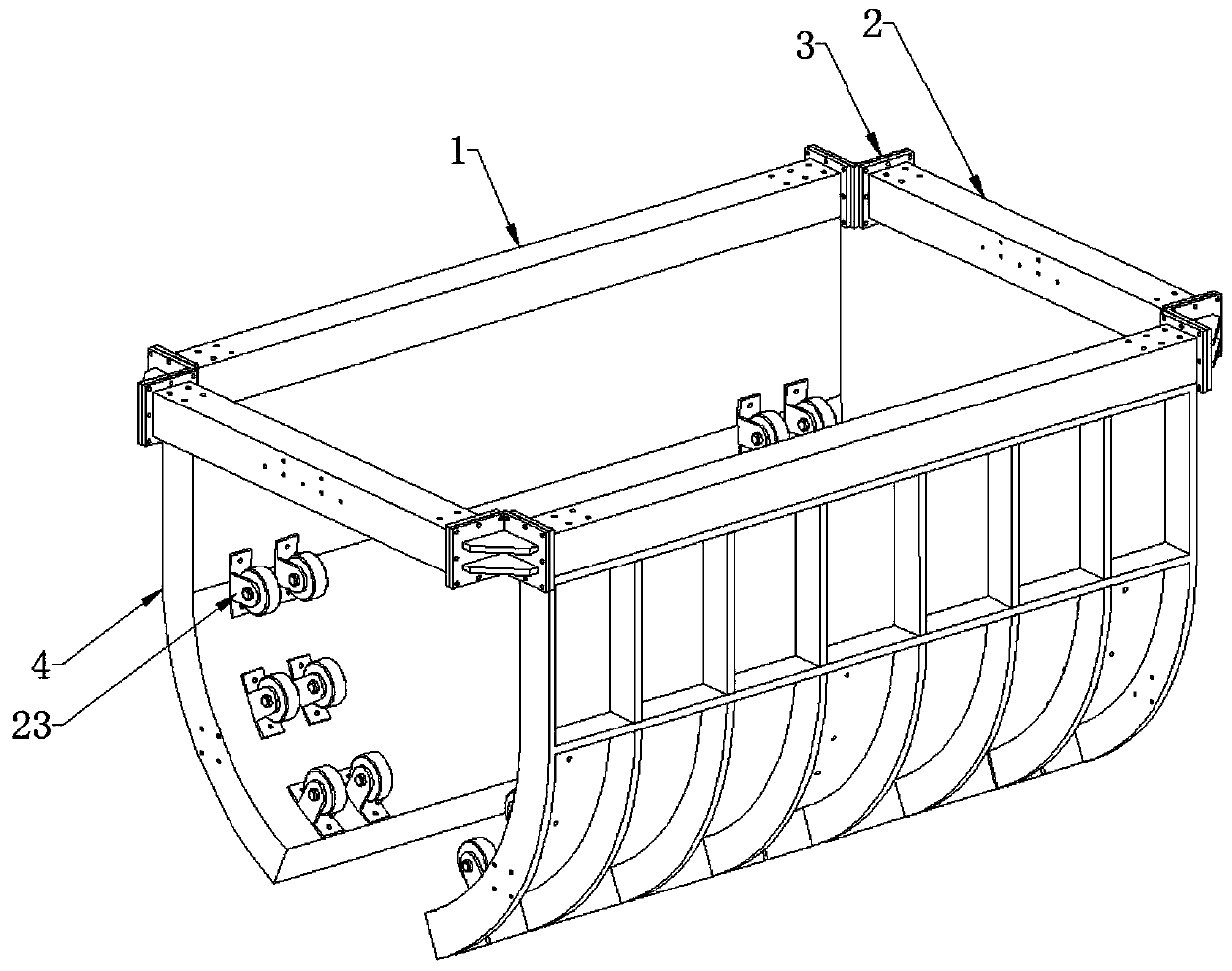

Mixture conveyor for concrete transportation

ActiveCN110774446AAchieve dumpingReasonable structureDischarging apparatusFeeding arrangmentsBLENDER/MIXERStructural engineering

The invention discloses a mixture conveyor for concrete transportation, and relates to the technical field of transportation equipment. The mixture conveyor for concrete transportation includes firstinstallation tubes, second installation tubes, striker plates, a mixing mechanism, turnover mechanisms and a moving mechanism. The two first installation tubes are arranged and distributed in front and rear orientations. The two second installation tubes are arranged and distributed in left and right orientations. The two first installation tubes and the two second installation tubes form a rectangle and are connected through an L-shaped connecting plate. The two striker plates are arranged and the striker plates are in a J shape. The two striker plates are symmetrically distributed and installed on the lower end faces of the first installation tubes. The mixing mechanism is arranged between the two striker plates and is used for mixing and stirring sand, stone, water and cement, and avoiding arranging a mixer outside independently. The turnover mechanisms are arranged at the front and rear sides of the mixing mechanism and are used for the overturn of the mixing mechanism to pour outthe mixed concrete. The moving mechanism is arranged over the connecting plate and used for moving the mixing mechanism so as to move the mixing mechanism to the position over the specified position.

Owner:CCCC SHEC FOURTH ENG

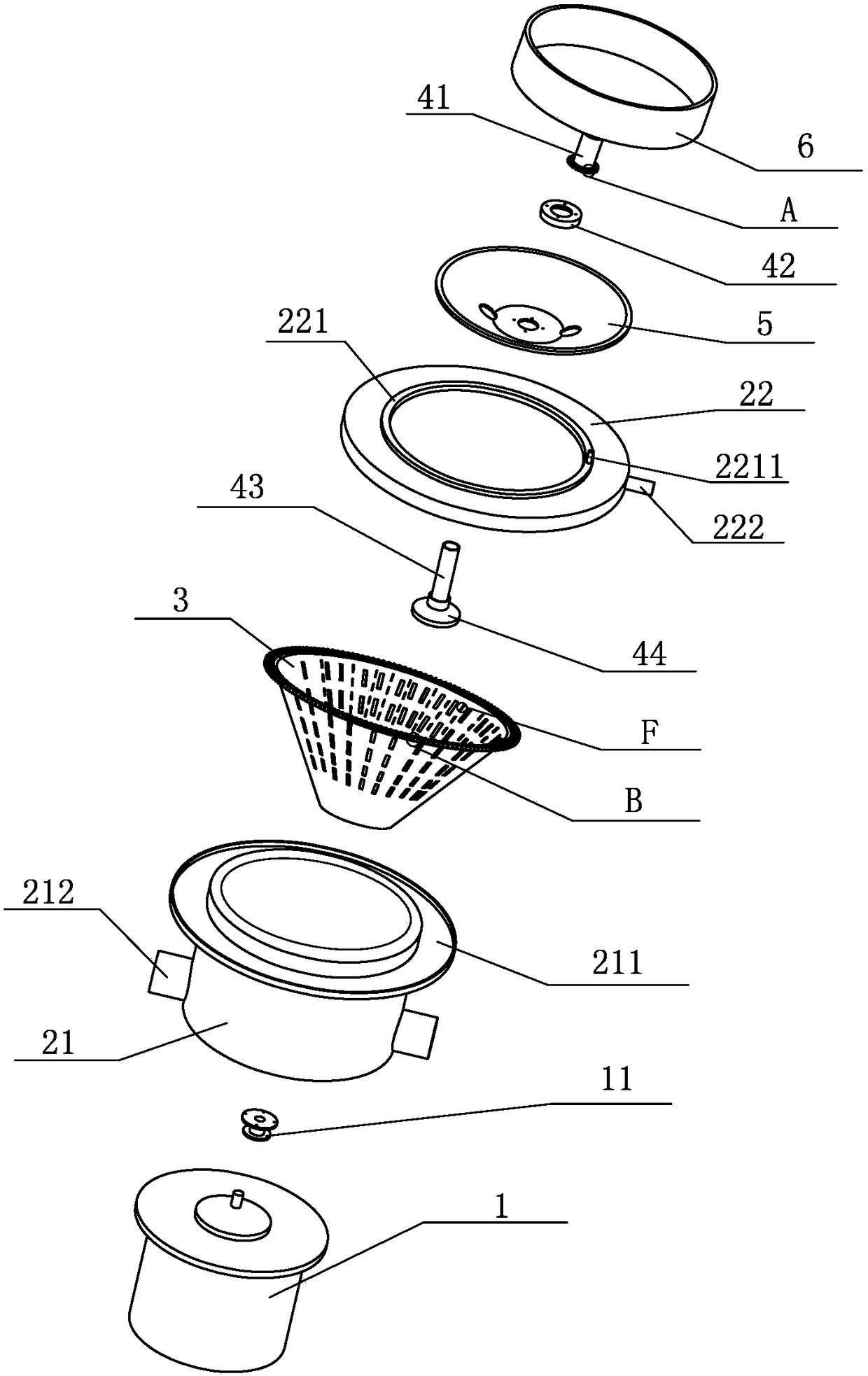

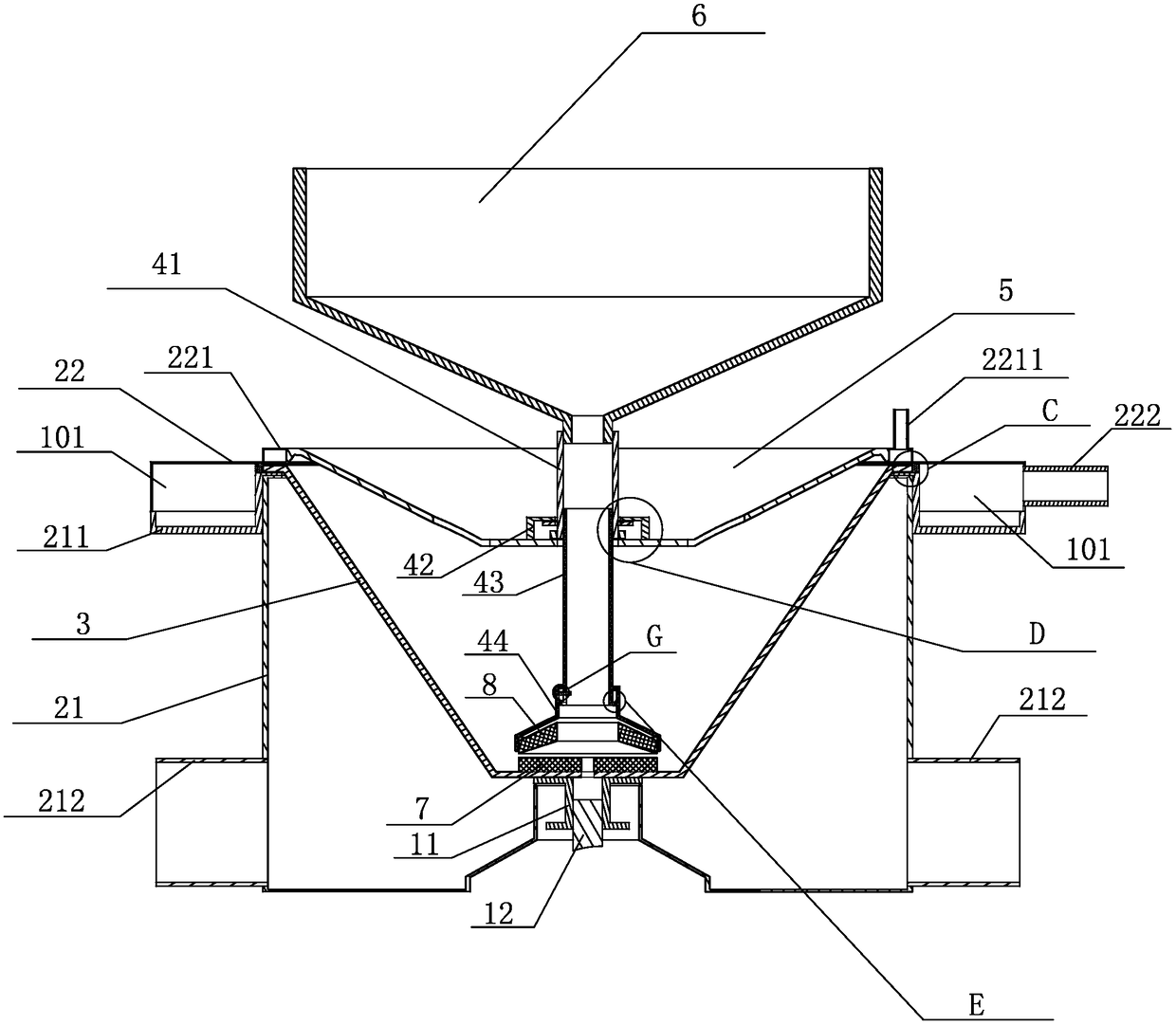

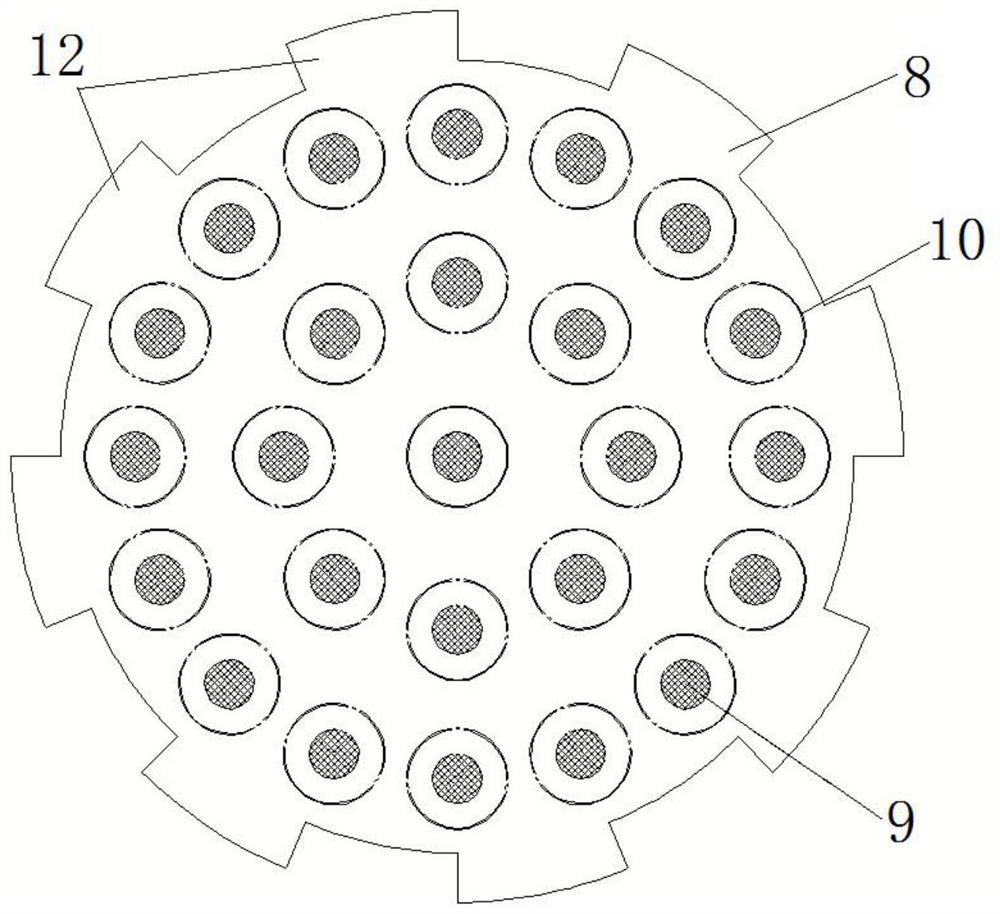

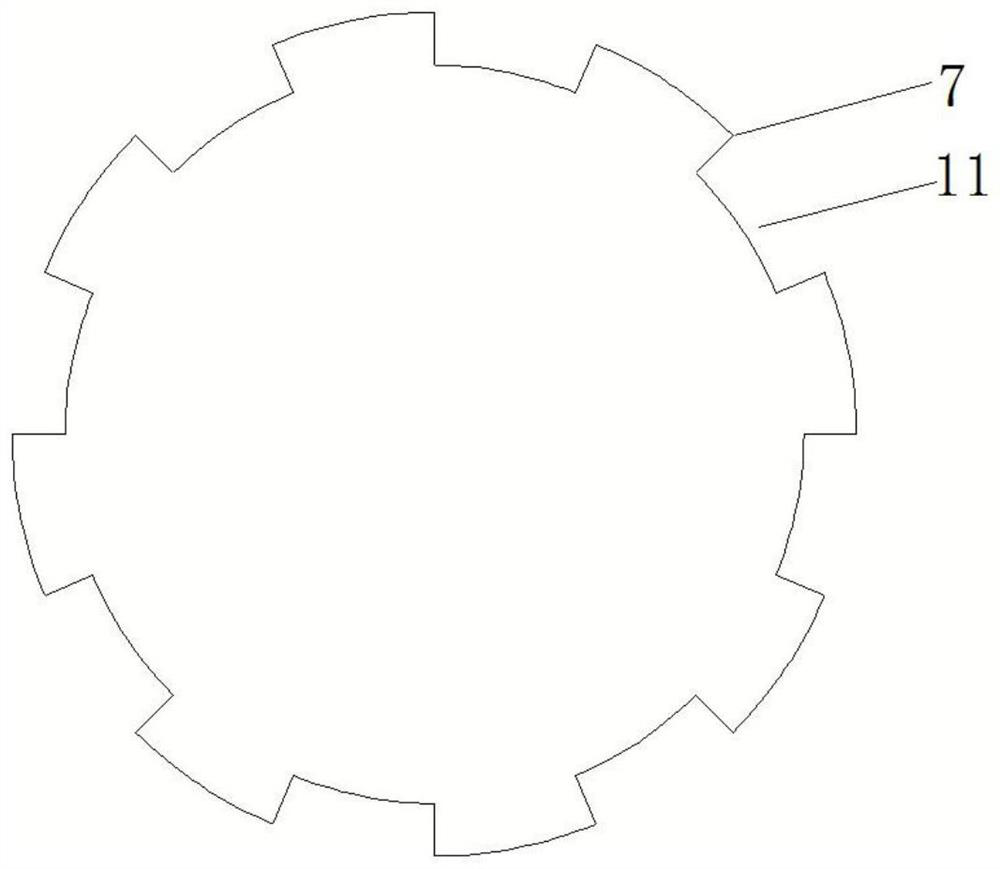

Automatic soybean milk maker integrating stir and residue separation

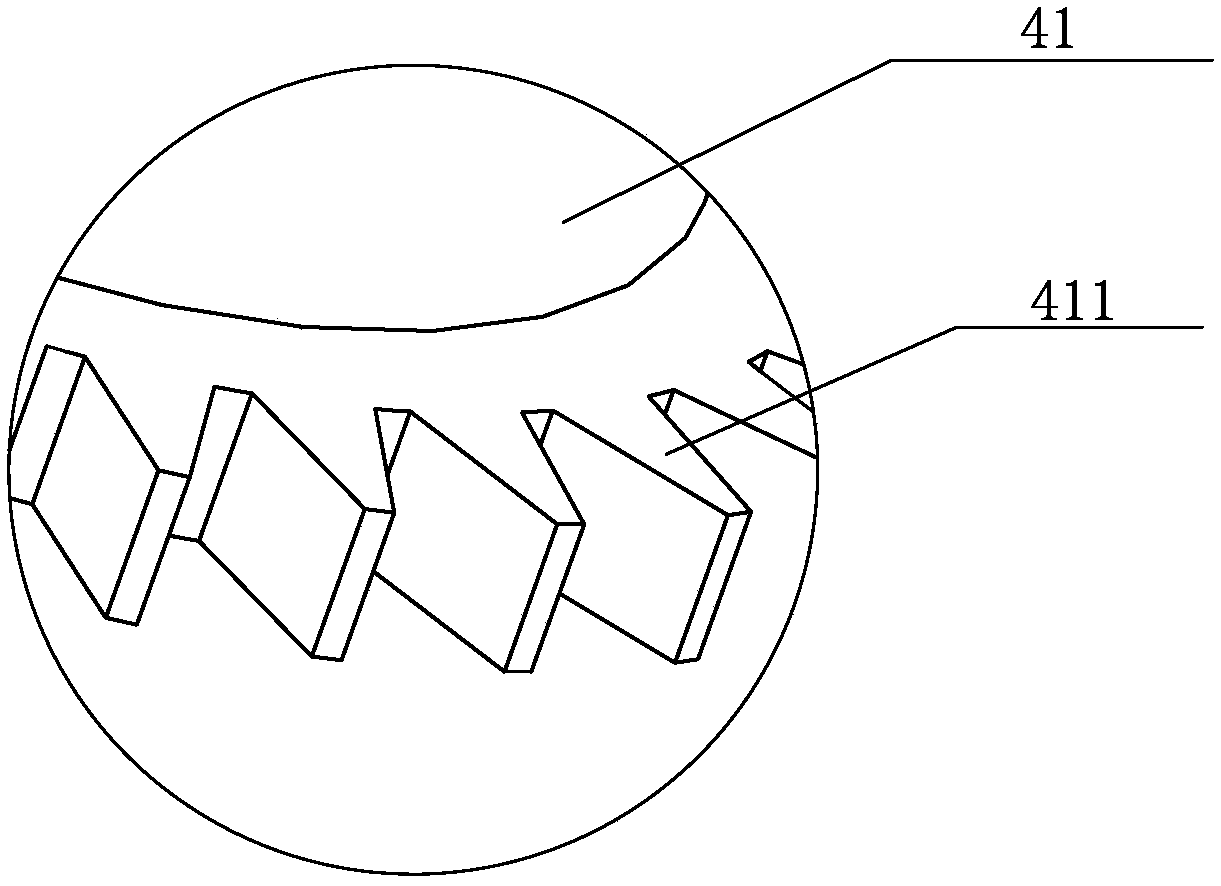

PendingCN108579975AIncrease grindAchieving mixing and stirringCentrifugesGrain treatmentsEngineeringSoybean protein

The invention provides an automatic soybean milk maker integrating stir and residue separation. The automatic soybean milk maker integrating stir and residue separation comprises a motor, a soybean milk and residue separation shell, a transmission body, a centrifugal separation screen, a moving grinding piece, a static grinding piece, a hopper and an adjustment mechanism. The soybean milk and residue separation shell is provided with an annular residue body vibration stirring grinding chamber and an annular water distribution chamber. A plurality of stirring teeth which are evenly distributedin the circumferential direction of an outer circular ring are arranged on the outer side face of the outer circular ring of the centrifugal separation screen. A plurality of isolation plates corresponding to the stirring teeth one to one are arranged on the upper plane of the outer circular ring. A plurality of countersinks which are evenly distributed in the circumferential direction of the outer circular ring are arranged on the lower plane of the outer circular ring. In the automatic soybean milk maker integrating stir and residue separation, because a residue body generated after the first time of grinding directly enters the annular residue body vibration mixing grinding chamber, and it can be directly achieved that the residue body and water are mixed again and the residue body is ground through stir of the stirring teeth in the annular residue body vibration mixing grinding chamber, manpower is saved, the extraction rate of soybean protein is increased at the same time, and theyield of bean products is increased then.

Owner:张余超

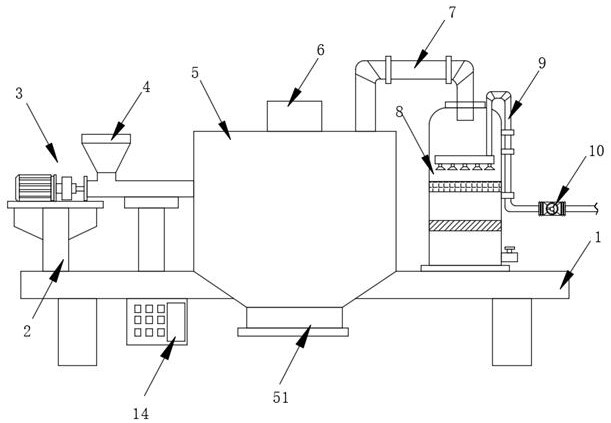

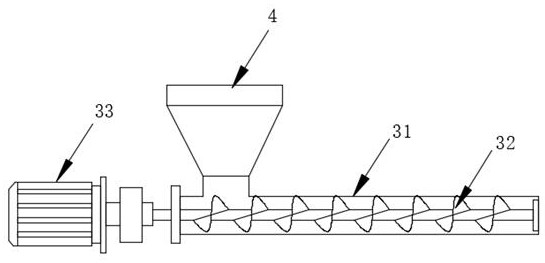

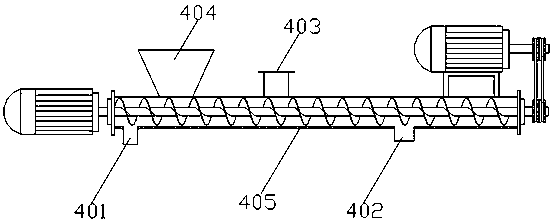

Compound feed machining and feeding mechanism

InactiveCN108851146AAchieving mixing and stirringRealize quantitative dischargeFeeding-stuffGrain treatmentsPulp and paper industry

The invention discloses a compound feed machining and feeding mechanism. The mechanism comprises a mechanism body and a discharging hopper. The discharging hopper is arranged at the bottom of the mechanism body. A clamping groove is formed in the discharging hopper, the mechanism body is movably clamped to the clamping groove, the top of the mechanism body is provided with a motor and a feeding inlet, a stock bin is arranged inside the mechanism body, a rotating shaft is arranged at the bottom of the motor, the rotating shaft extends into the stock bin, a stirring rod is fixedly arranged on the rotating shaft, a protrusion is fixedly arranged at the bottom end of the rotating shaft, a mixed bin is arranged at the bottom of the stock bin, a discharging outlet is formed in the top of the mixed bin, a baffle is arranged at the bottom of the discharging outlet, the baffle is sleeved with a connecting rod, a stirring mechanism is arranged on the connecting rod, and an embedded groove is formed in the top end of the connecting rod. The rotating shaft and the connecting rod are movably clamped through the protrusion and the embedded groove, mixed stirring of feed and breaking of caked feed can be achieved, the baffle can be driven to move up and down conveniently, and quantified feed discharging can be achieved.

Owner:ANHUI GAOLAOZHUANG ECOLOGICAL AGRI TECH CO LTD

Automatic liquor processing machine

PendingCN110669603AImprove processing efficiencyThe structure of the device is reasonableAlcoholic beverage preparationRadiationElectric machineryProcess engineering

The invention belongs to the technical field of liquor processing, and particularly relates to an automatic liquor processing machine. The automatic liquor processing machine comprises a shell, a storage cylinder is fixedly connected to the top of the shell, a second groove is formed in the side surface of the inner wall of the storage cylinder, and telescopic assemblies are fixedly connected to the top and the bottom of the inner wall of the second groove. According to the automatic liquor processing machine, by arranging a feeding pipe and a spray head, feeding is carried out conveniently according to using needs, and materials are dropped to a measuring cup by opening a corresponding number of solenoid valves for quantitative transferring to achieve the purpose of quantitative feeding;the device uses the storage cylinder, the feeding pipe, the spray head, a first motor, a conveyor belt and the measuring cup, the purpose of automatic feeding during the processing of maotai-flavor liquor is achieved, labor and effort are saved, and the processing efficiency is greatly improved; the purpose of sterilizing, disinfecting, filtering, and mixing of the materials is achieved by arranging a filter screen, stirring leaves and ultraviolet lamps; and the whole device is reasonable in structure, convenient to operate and high in practicability.

Owner:石门壶瓶山酒业有限公司

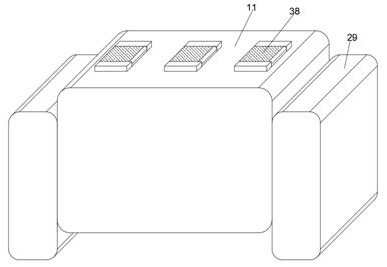

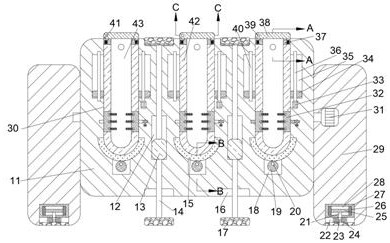

Safety detection system for content of food preservative

InactiveCN114217029ASpeed up the fallWell mixedPreparing sample for investigationTesting foodProcess engineeringAqueous solution

The invention discloses a food preservative content safety detection system which comprises a main machine body, three working cavities with the same size and upward openings are formed in the main machine body, working test tubes capable of moving up and down are arranged in the working cavities, and mixing cavities with upward openings are formed in the working test tubes and used for detecting the content of food preservatives. Through vibration of the working test tube, a food sample in the sample test tube is promoted to completely fall downwards, subsequent food preservative detection is further facilitated, the detection accuracy is improved, meanwhile, in the mixing process of the sample and an aqueous solution, through rotation of the movable sliding block, the sample can be mixed with the aqueous solution, and the detection efficiency is improved. Meanwhile, the elastic plate continues to input vibration into the working test tube, mixing of the solution and the food sample is promoted, impurities in the to-be-detected solution are more uniform, and then the accuracy of subsequent preservative detection is improved.

Owner:许建孝

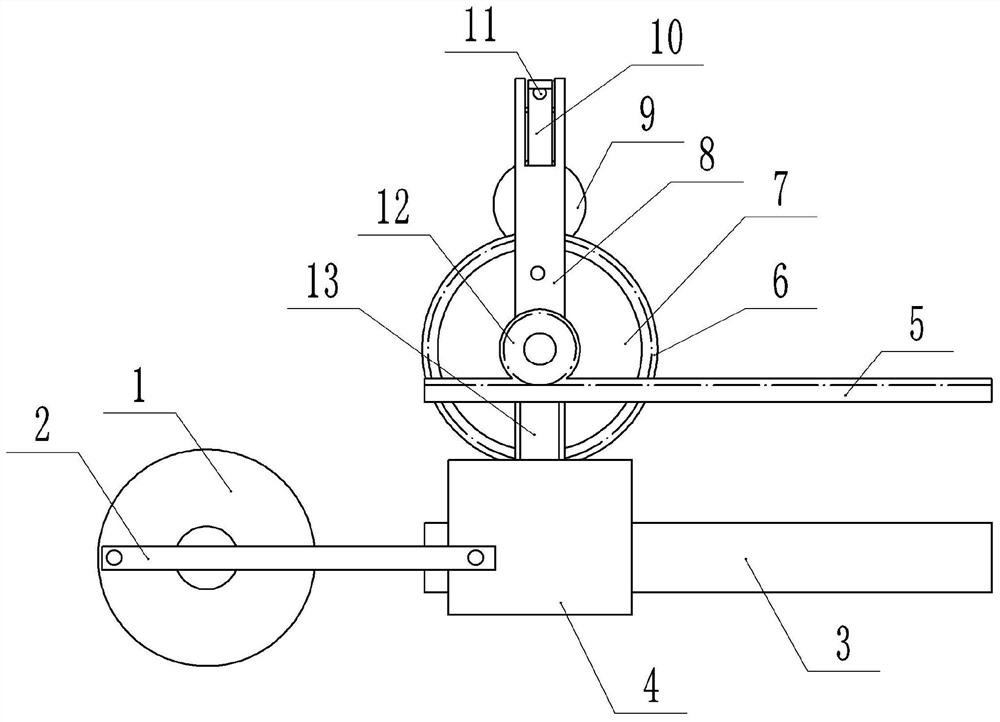

Accumulated-snow removing device high in cleaning ability

The invention discloses an accumulated-snow removing device high in cleaning ability. The accumulated-snow removing device comprises a rectangular hollow shell and is characterized in that support wheels are mounted at the bottom of the rectangular hollow shell, a turbine mounting space is arranged at the inner top end of the center of the rectangular hollow shell, a raw material mixing space located right below the turbine mounting space is arranged inside the rectangular hollow shell, and a main exhaust hole communicated with the bottom-end center of the raw material mixing space is arrangedinside the rectangular hollow shell. The accumulated-snow removing device has the advantages that by effectively utilizing one motor, raw material mixing and outputting are achieved while gas drivingis achieved, and multipurpose is achieved; in addition, the device is provided with a gas flow discharge and control mechanism, gas pressure during gas discharge can be effectively controlled, accumulated snow on a road surface can be blown away, salt water is utilized to remove residual accumulated snow and ice on the road surface, and the device is high in removing ability and high in practicality.

Owner:刘晓莉

Concrete pouring device for preventing concrete segregation and using method

InactiveCN112776176AAchieving mixing and stirringImprove bearing strengthDischarging apparatusCement mixing apparatusArchitectural engineeringStructural engineering

The invention discloses a concrete pouring device for preventing concrete segregation and a using method. The device comprises a box body, wherein stirring devices are symmetrically arranged on one side of the inner wall of the box body; each stirring device comprises a connecting shaft; each connecting shaft is arranged in a round hole in one side of the inner wall of the box body; an anti-segregation device is arranged below one side of the inner wall of the box body; the anti-segregation device comprises a mounting plate; one side of the mounting plate is connected with the inner wall of the box body; a booster pump is arranged on one side of the lower surface of the inner wall of the box body; a discharging port is formed in a shell of the booster pump and connected with a jet orifice through a pipeline; and a movable lifting device is arranged on the outer wall of the jet orifice. According to the concrete pouring device for preventing concrete segregation, in the concrete processing and pouring construction process, concrete segregation can be prevented, so that the effects of improving the construction quality and the bearing strength of concrete are achieved, and economic losses caused by potential safety hazards can be effectively avoided.

Owner:JIANGXI UNIV OF TECH

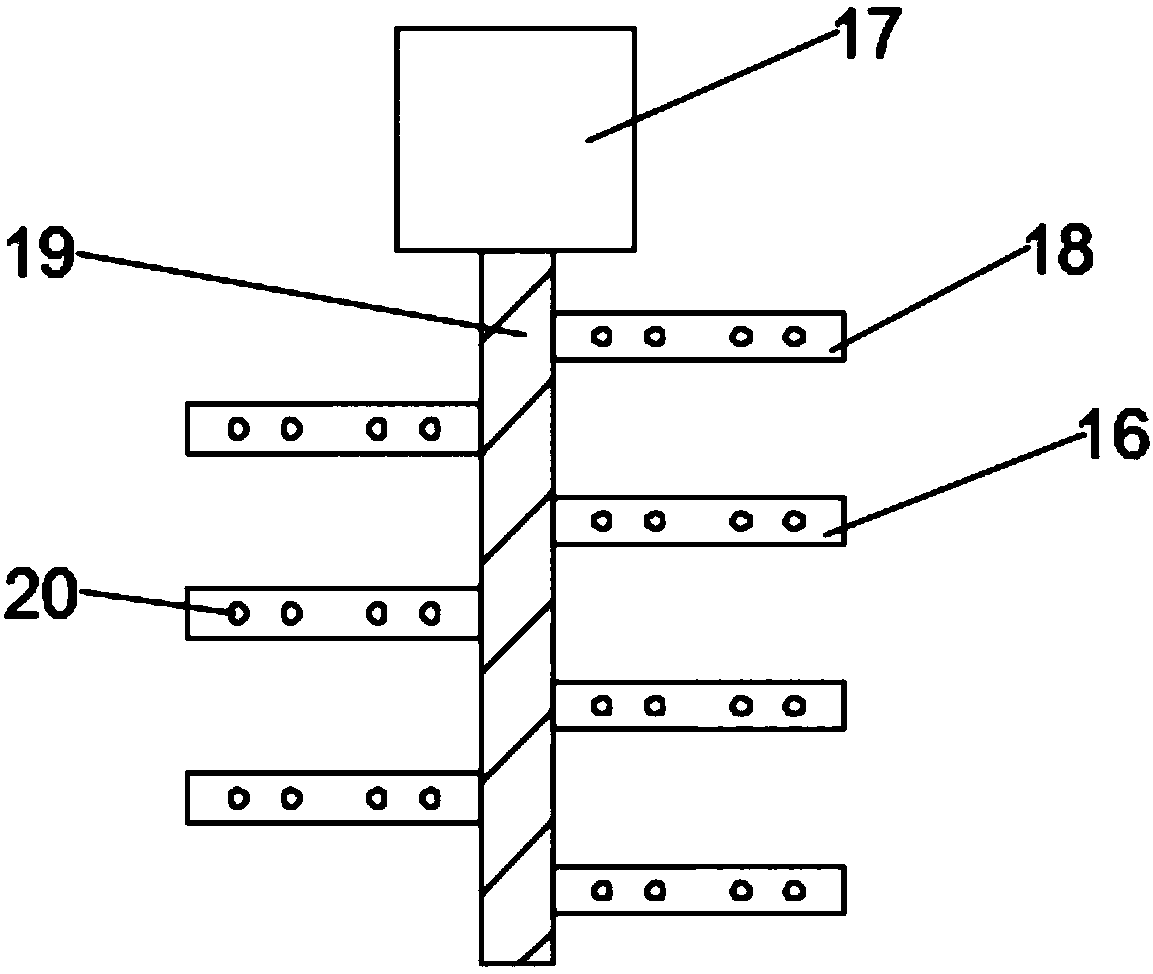

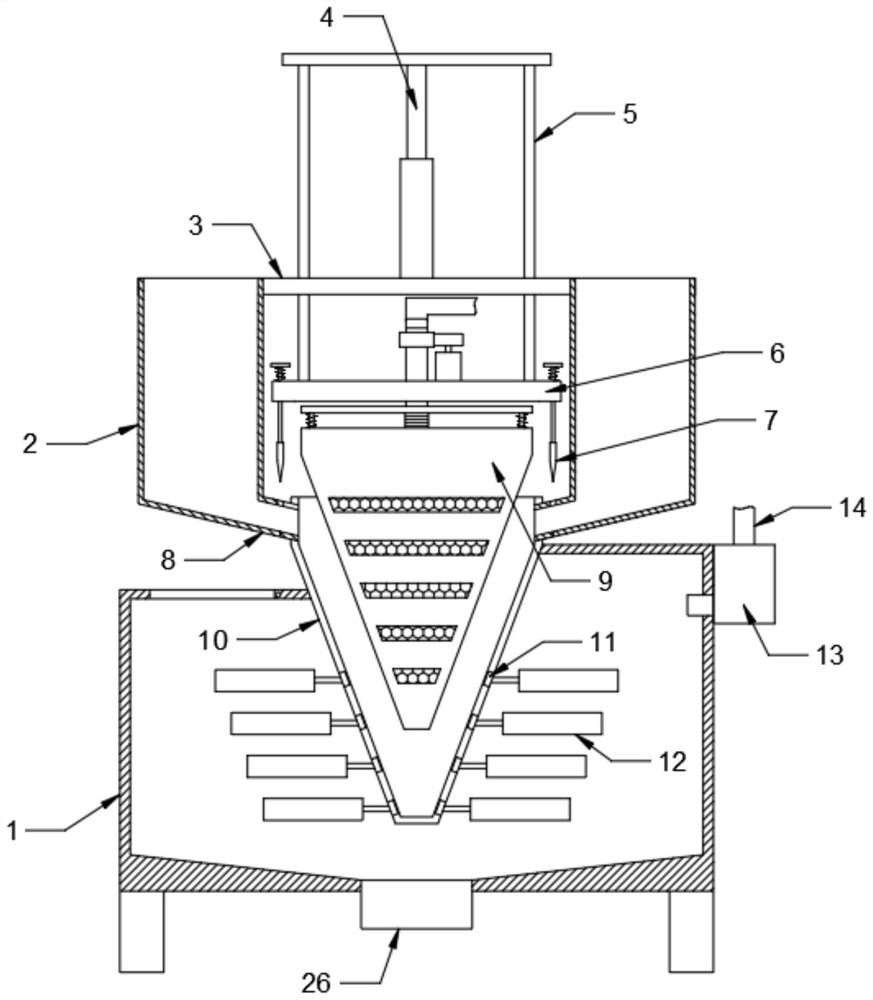

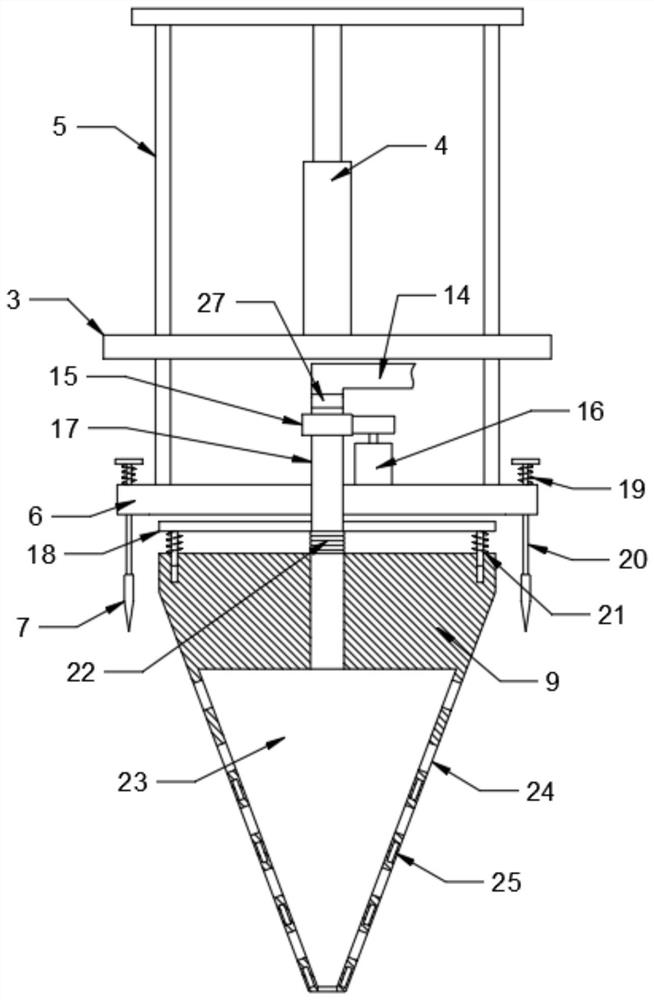

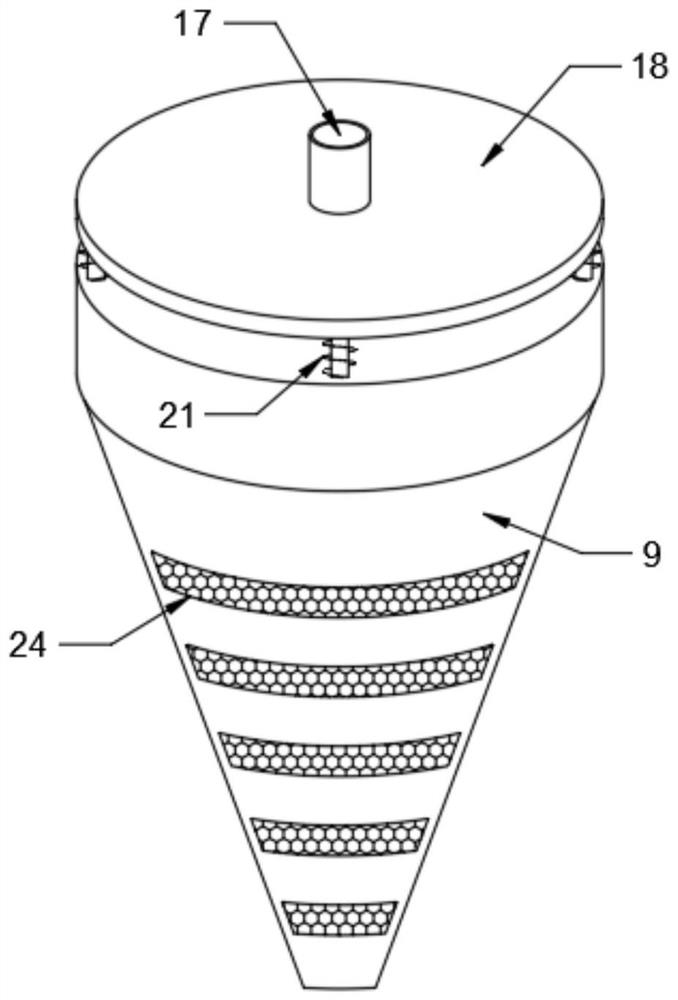

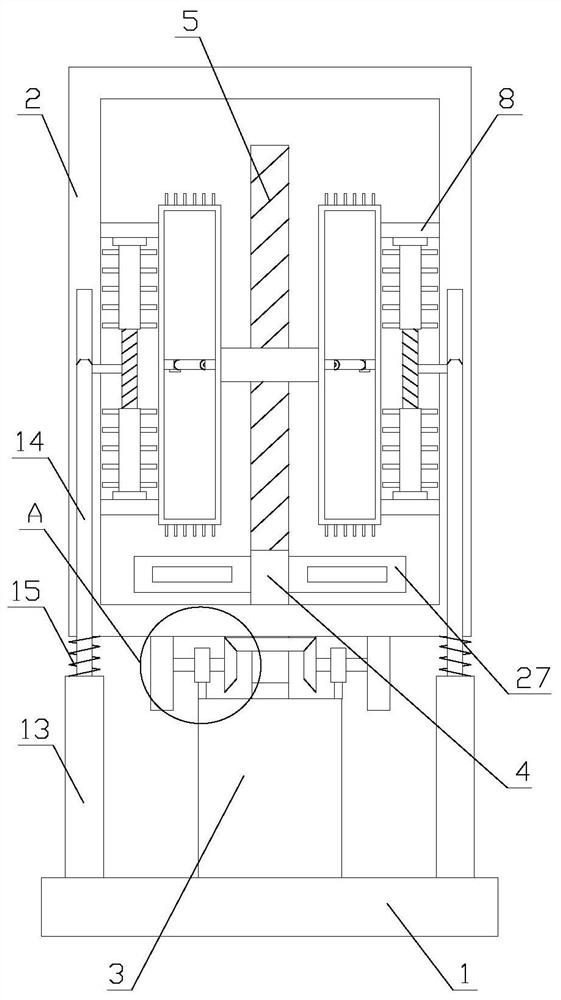

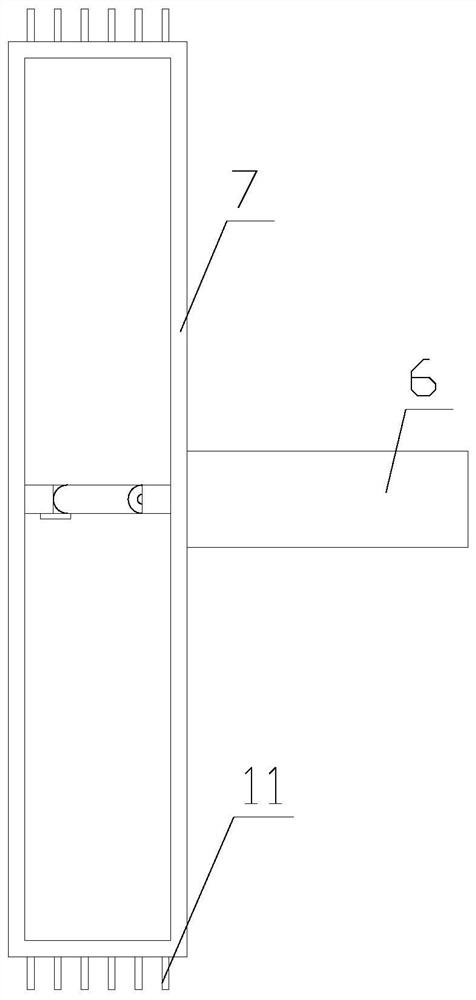

Ingredient grinding device for water-based building coating production

ActiveCN114146756AAchieve grindingImprove grinding effectTransportation and packagingMixersArchitectural engineeringStructural engineering

The ingredient grinding device for water-based building coating production comprises a stirring tank, a conical grinding barrel extending into the stirring tank is installed on the stirring tank, a plurality of ingredient barrels are fixedly installed in the circumferential direction of a barrel opening of the conical grinding barrel, and discharging channels communicating with the barrel opening of the conical grinding barrel are arranged at the bottoms of the ingredient barrels; a top plate is fixedly connected among barrel openings of the multiple batching barrels, a mounting plate capable of moving up and down is mounted below the top plate, a rotatable conical grinding head is elastically mounted at the bottom of the mounting plate, and the conical grinding head is matched with the conical grinding barrel; a plurality of material blocking plates are elastically installed in the circumferential direction of the installation plate and move up and down along with the installation plate to enter or leave the discharging channel, and opening and closing are achieved. According to the device, the automatic discharging and grinding process of various ingredients can be achieved, powder with the consistent particle size can be sucked into the stirring tank after grinding, stirring is conducted at the same time, the automation degree is high, and efficiency is high.

Owner:广德昊宇新型材料有限公司

Stock solution stirring device

InactiveCN112999945AAchieve primary mixingAchieve secondary mixingTransportation and packagingMixer accessoriesElectric machineryEngineering

The invention relates to a stock solution stirring device which comprises a base, a fixing box, a supporting mechanism and a driving mechanism, the driving mechanism comprises a motor, a rotating rod, a first lead screw and a mixing assembly, and the supporting mechanism comprises a supporting assembly, a vibrating assembly and a stirring assembly. According to the stirring device for the stock solution, vibration stirring of a main body and primary stirring of the main body are achieved through cooperation of the restoring force of a cam and the restoring force of a spring, cross-flow stirring of the main body, secondary stirring of the main body are achieved through discharging of the bottom end of the piston barrel, and spraying of the main body is achieved through discharging of the top end of the piston barrel; mixing stirring of the main body, eg the third-grade stirring is achieved through moving of the main body to the top end of the fixing box through the piston barrel, rotating of a threaded barrel, eg the rotation of a stirring rod is realized through movement of a positioning rod, fourth-grade stirring on the main body is realized; linkage of a plurality of mechanisms is achieved through a same driving source, and the use practicability is improved.

Owner:南京鸿音工程技术有限公司

Stirring device for high-viscosity material

PendingCN111672390AAchieving mixing and stirringSimple structureRotary stirring mixersTransportation and packagingElectric machineryEngineering

The utility model discloses a stirring device for a high-viscosity material. The stirring device comprises a stirring tank and a stirrer arranged in the stirring tank, wherein the stirrer comprises adriving motor, a rotating shaft and two or more stirring paddles arranged on the rotating shaft; each stirring paddle comprises a hub fixedly connected with the rotating shaft and a plurality of blades fixed in the circumferential direction of the hub; and each blade comprises a steel pipe, a first blade and a second blade, the first blade and the second blade are welded to the two sides of the steel pipe, a plurality of air holes for introducing air are formed in the steel pipe, the air holes communicate with an air source arranged outside the stirring tank, an included angle is formed between the first blade and the second blade, and the opening direction of the included angle is upward, namely the included angle faces the driving motor, so upward axial force is generated to stir materials when the stirring paddles are driven to rotate, and axial stirring effect is further improved. The stirring device is simple in structure, low in rotating speed, sufficient in stirring and mixing,and efficient and easy to clean.

Owner:XIAN THERMAL POWER RES INST CO LTD

Plate type rubber vulcanizing device

ActiveCN112976384AAchieving mixing and stirringWell mixedHollow article cleaningPolymer scienceVulcanization

The invention relates to the field of rubber processing, in particular to a plate type rubber vulcanizing device. The plate type rubber vulcanizing device comprises a rack and a stirring tank, a stirring rod is rotationally connected to the stirring tank, one end of the stirring rod is located in the stirring tank, the other end of the stirring rod is located on the outer side of the stirring tank, and stirring blades located in the stirring tank are fixedly connected to the stirring rod. A first gear is coaxially and fixedly connected to the portion, located on the outer side of the stirring tank, of the stirring rod, a first rack is welded to the rack, the first gear is meshed with the first rack, and a transverse pushing mechanism used for driving the stirring tank to transversely move in a reciprocating mode is arranged on the rack. According to the scheme, the mixing efficiency of rubber and a vulcanizing agent is improved.

Owner:重庆市九龙橡胶制品制造有限公司

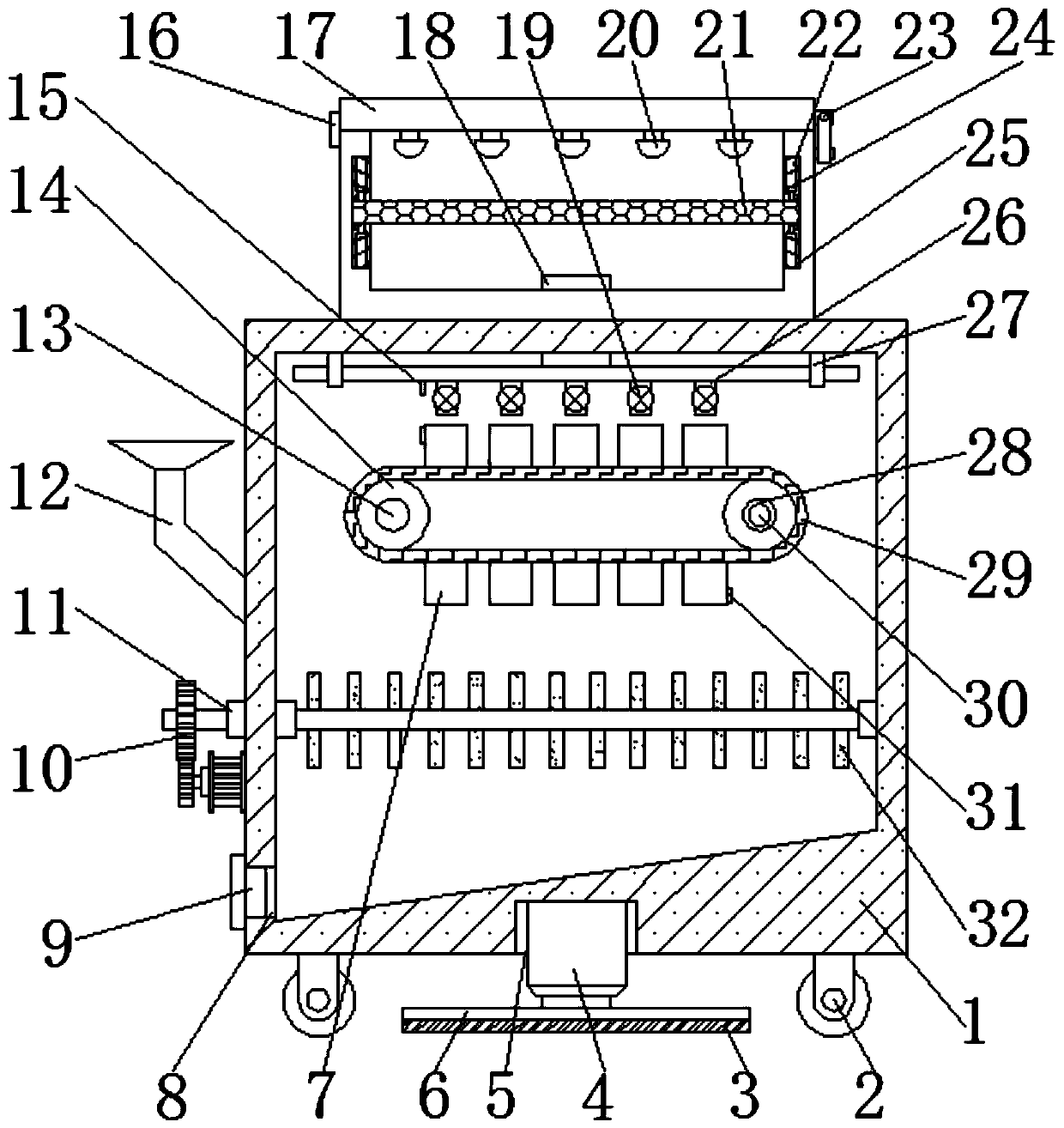

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment is composed of a machine box, a pulverizing device, a conveying device, a stirring device, a water supply device and amaterial box, wherein a material inlet is formed in the upper end surface of the machine box; the pulverizing device is arranged below the material inlet; the pulverizing device is composed of pulverizing teeth, a belt and a pulverizing motor; the conveying device is composed of a conveying shaft, a conveying belt and a conveying motor; the stirring device is arranged at the lower side of the conveying device; the stirring device is composed of a stirring motor, a stirring shaft and a stirred box; the water supply device is arranged on the upper side of the stirring device; the water supply device is composed of a water tank, a water delivery pipe, a water pump and a sprinkling nozzle; machine legs are arranged on the lower side of the machine box; and the material box is arranged on one side of the machine legs. Each device is provided with an independent power device, so the problem of shortage of power is solved, multiple functions are integrated, and the whole operating efficiencyis improved.

Owner:蔡伟锋

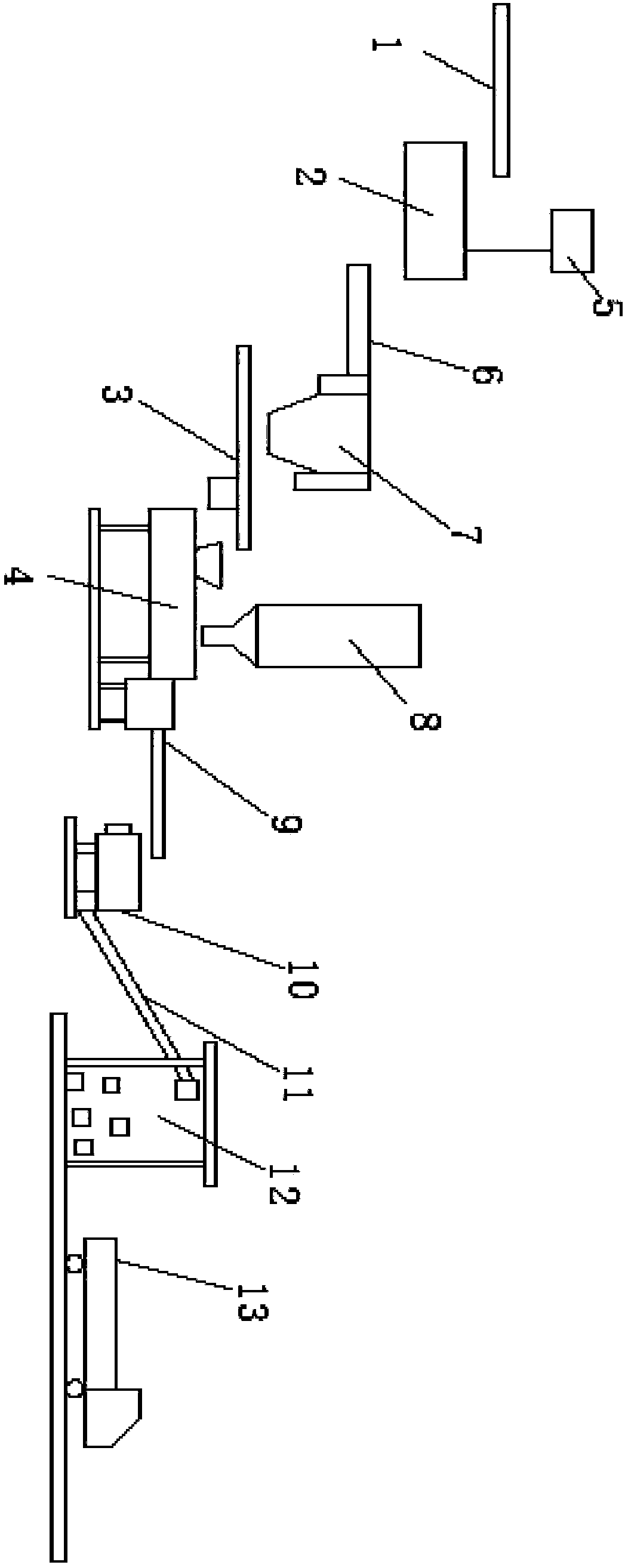

Electroplating-sludge cement curing process

InactiveCN107651892ASmooth processMeet the use requirementsDispersed particle filtrationWaste water treatment from metallurgical processElectroplatingSludge

The invention discloses an electroplating-sludge cement curing process. The electroplating-sludge cement curing process includes: firstly, delivering electroplating sludge to a dry grinding box through a conveyor belt device for dry grinding; transferring the electroplating sludge subjected to dry grinding to a storage groove through a lifting mechanism; discharging the electroplating sludge in the storage groove to a blending mixer through a metering device; adding cement, water and additives to the blending mixer through power supply equipment for blending mixing through the blending mixer;transferring a mixed mixture to a forming machine through a transferring device for forming; transporting formed cement blocks to a curing chamber through a belt conveyor for static solidification storage; finally, carrying away the cement blocks through a transport vehicle. The process is smooth, capable of achieving curing processing of the electroplating-sludge cement, environment friendly andreliable and current use requirements are met.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

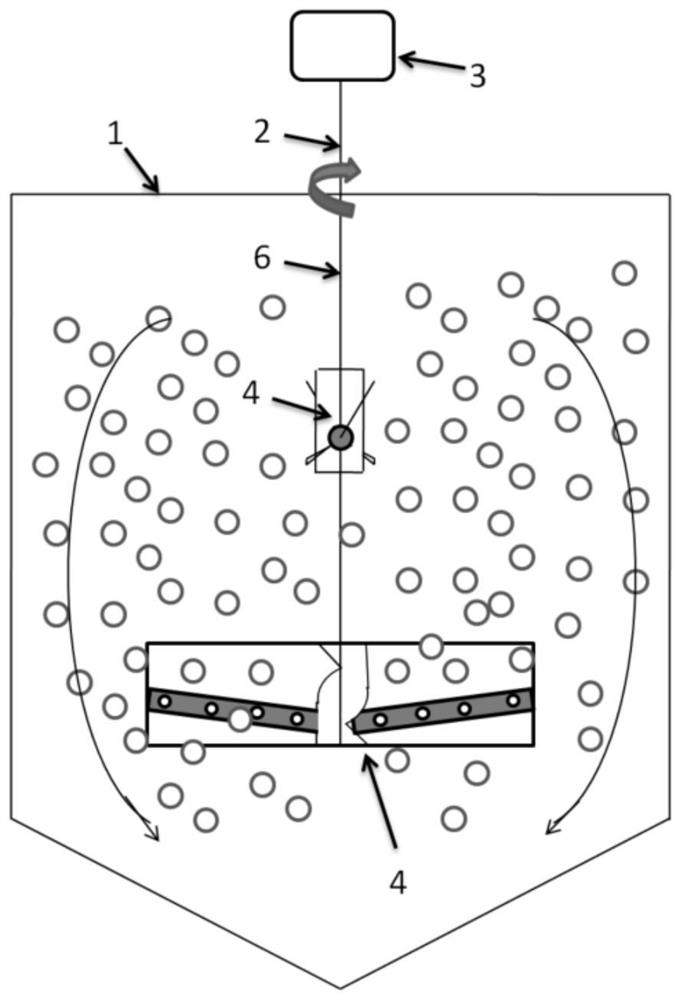

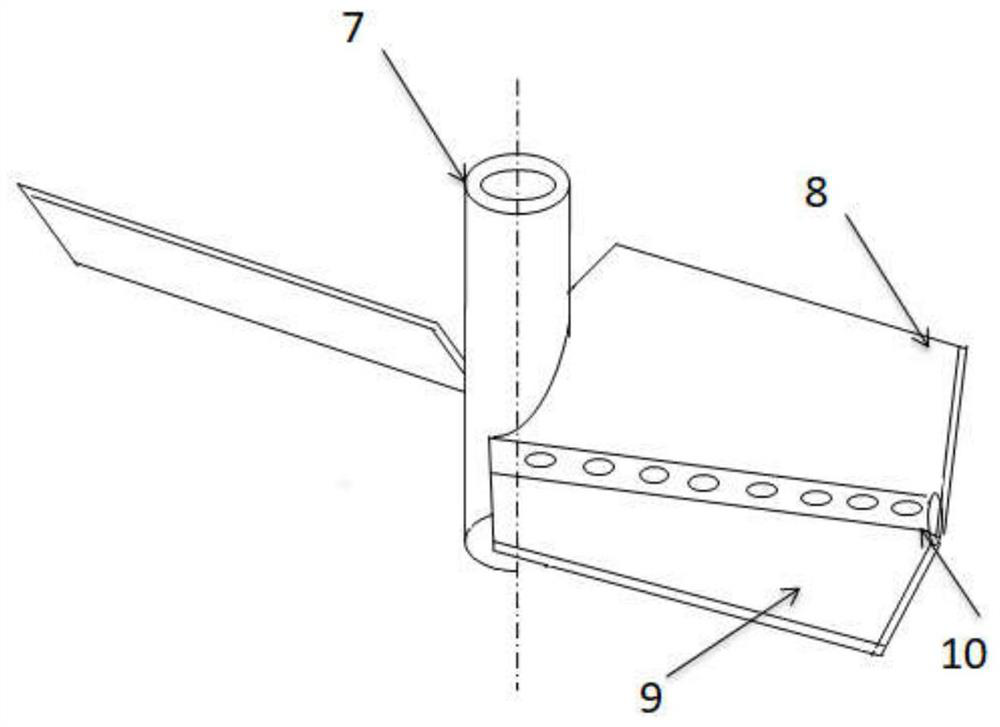

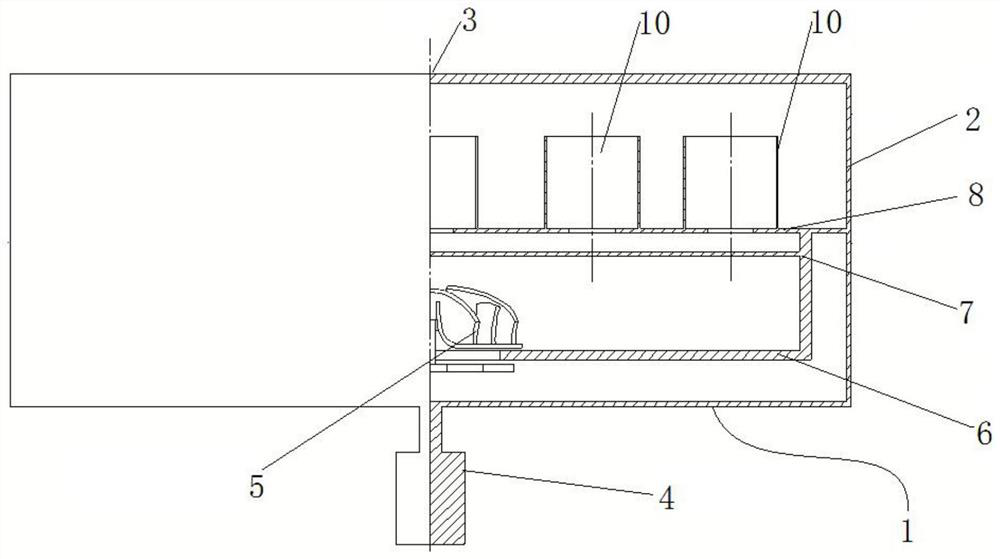

Efficient cell culture reactor and stirring system thereof

PendingCN113637585AImprove mixing efficiencyStir continuously to circulate and evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringCultured Cell Line

The invention discloses an efficient cell culture reactor and a stirring system thereof. The efficient cell culture reactor comprises a magnetic stirring mechanism and a flexible flow channel, wherein the magnetic stirring mechanism is located at the bottom of the flexible flow channel, the flexible flow channel is fixed to the barrel wall of a reaction barrel of the efficient cell culture reactor, and the magnetic stirring mechanism is arranged at the bottom of the reaction barrel; and a nutrient solution in the reaction barrel can reach culture barrels of the efficient cell culture reactor through the flexible flow channel. The stirring method of the magnetic stirring mechanism and the flexible flow channel is utilized, continuous circulation and uniform stirring of the nutrient solution needed by cell culture can be achieved, large-scale cell culture and mixing and stirring are effectively achieved, it is guaranteed that the nutrient solution is continuously supplied to cells, the mixing efficiency is high, and the efficient cell culture reactor and the stirring system thereof are particularly suitable for large-scale cell culture.

Owner:SICHUAN UNIV

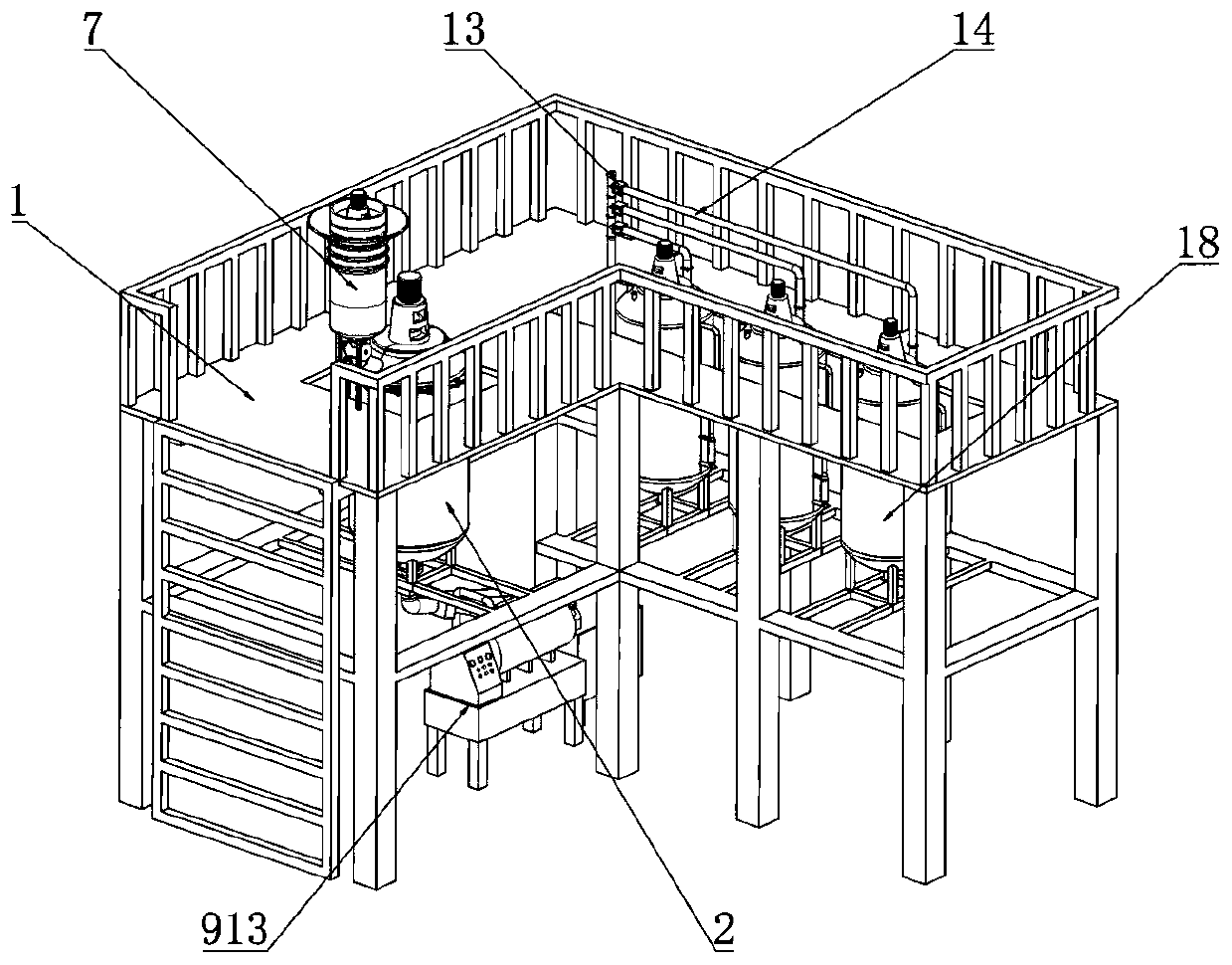

Automatic mixing and moving feeding system for novel building material production process

InactiveCN114407195AEasy accessReduce the overall heightDischarging apparatusPretreatment controlDrive wheelConstruction engineering

The invention discloses an automatic mixing and moving feeding system for a novel building material production process, and particularly relates to the technical field of building material production, the automatic mixing and moving feeding system comprises a mixing barrel, the outer side of the mixing barrel is provided with a batching bin, the top of the mixing barrel is provided with a barrel cover, and the surface of the barrel cover is movably provided with a driving wheel; a large disc wheel is installed on the central axis of the surface of the barrel cover, a driving motor is connected to the top of the large disc wheel through a shaft, a feeding table is installed below the mixing barrel, a transmission roller is arranged on the surface of the feeding table, a conveying crawler belt is installed on the right side of the front end of the feeding table, and a background is fixed to the left side of the front end of the feeding table; and a feeding barrel is arranged above the transmission roller. According to the invention, the inner and outer layer structure is adopted in the mixing barrel, the hollow discharging pipe is arranged in the middle, and the sealing ring is additionally arranged on the inner wall, in contact with the discharging pipe, of the bottom of the mixing barrel, so that leakage is prevented, and materials can be mixed in the space between the mixing barrel and the discharging pipe.

Owner:灌云县斯威特再生资源有限公司

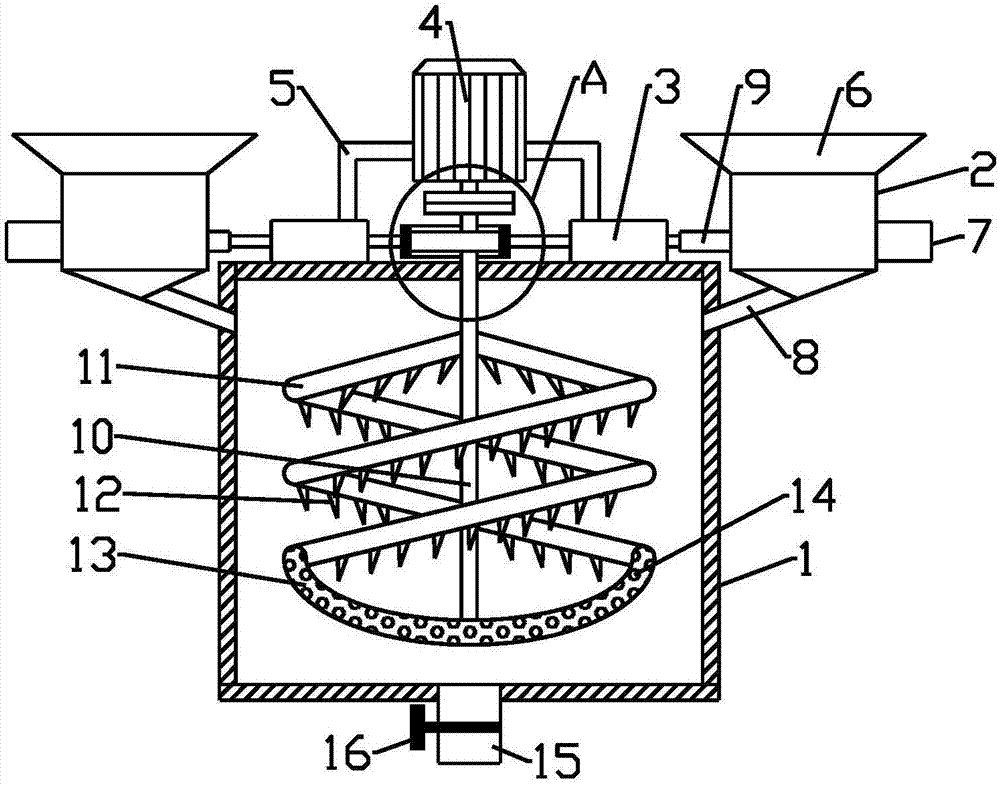

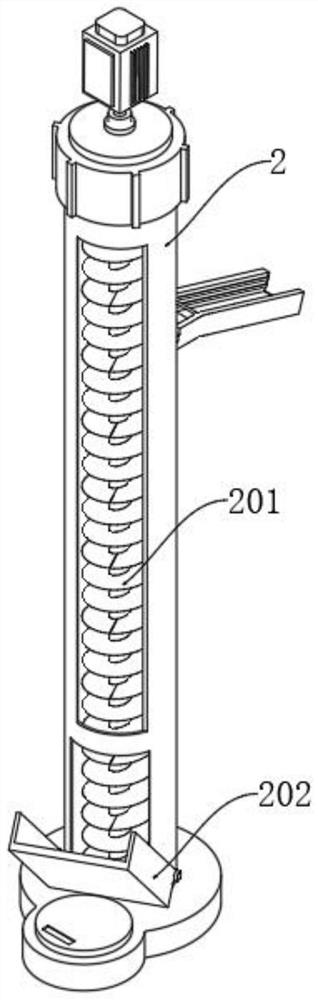

Multifunctional mixing stirring system

PendingCN109621817AAchieving mixing and stirringVolume is easy to calculateRotary stirring mixersTransportation and packagingEngineeringSmall footprint

The invention discloses a multifunctional mixing stirring system. The system comprises an elevator, a feeding hopper, a stirring chamber, a conveying mechanism bearing materials in the stirring chamber, a solvent chamber and a mixing stirring mechanism, wherein the feeding hopper and the stirring chamber are arranged at the two ends of the elevator; the solvent chamber is connected to the mixing stirring mechanism through a pipeline, the conveying mechanism is a two-way conveying mechanism, and a first discharging port and a second discharging port are respectively formed in the two ends of the conveying structure; a feeding port is formed in the upper side surface of the conveying mechanism and connected with the stirring chamber, the first discharging port is connected to a mixing stirring device, and the second discharging port is connected with the feeding hopper. The multifunctional mixing stirring system is simple in structure, capable of achieving circulating mixing of powder materials and high in mixing degree; conveying and stirring systems and other systems only need a small motor to achieve the uniform mixing effect, and the energy-saving effect is ensured; the automation degree is high, and self-cleaning of a mixing system can be achieved; the small mixing system is small in occupied area, mixing and discharging are synchronous, and the production efficiency is improved.

Owner:李籽贤

Production equipment capable of guaranteeing quality of donkey-hide gelatin

InactiveCN108816073AEnable recyclingReasonable designRotary stirring mixersTransportation and packagingThermal insulationElectric heating

The invention discloses production equipment capable of guaranteeing quality of donkey-hide gelatin. The production equipment comprises support frames, a support base, a stirring box and an electric heating cavity, wherein the bottoms of the support frames are welded on two sides of the upper surface of the support base, the stirring box is arranged above the support base, the support frames are fixedly welded on two sides of the stirring box, and the stirring box comprises a thermal insulation layer and a stirring cavity from outside to inside sequentially; a feeding port is formed in the upper side of the left side wall of the stirring box and connected with the stirring cavity; the electric heating cavity is fixedly mounted on the right side of the upper surface of the support base, themiddle of the upper surface of the electric heating cavity is connected with an air suction pipe. The production equipment is reasonable in design and can sufficiently and irregularly stir raw materials, can sufficiently mix the raw materials, guarantees the quality of the raw materials, also can guarantee the proper stirring temperature in the stirring process and realize the purpose of disinfection and sterilization and is time-saving, labor-saving and high in working efficiency.

Owner:湖南图强科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com