On-site stirring, and mixing coating integrated device for coating in building industry

A mixing and mixing industry technology, applied in construction, mixers, mixer accessories, etc., can solve the problems of harmful gas generation, inability to recover harmful gas, increase the stirring speed of paint, etc., and achieve the effect of increasing the spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

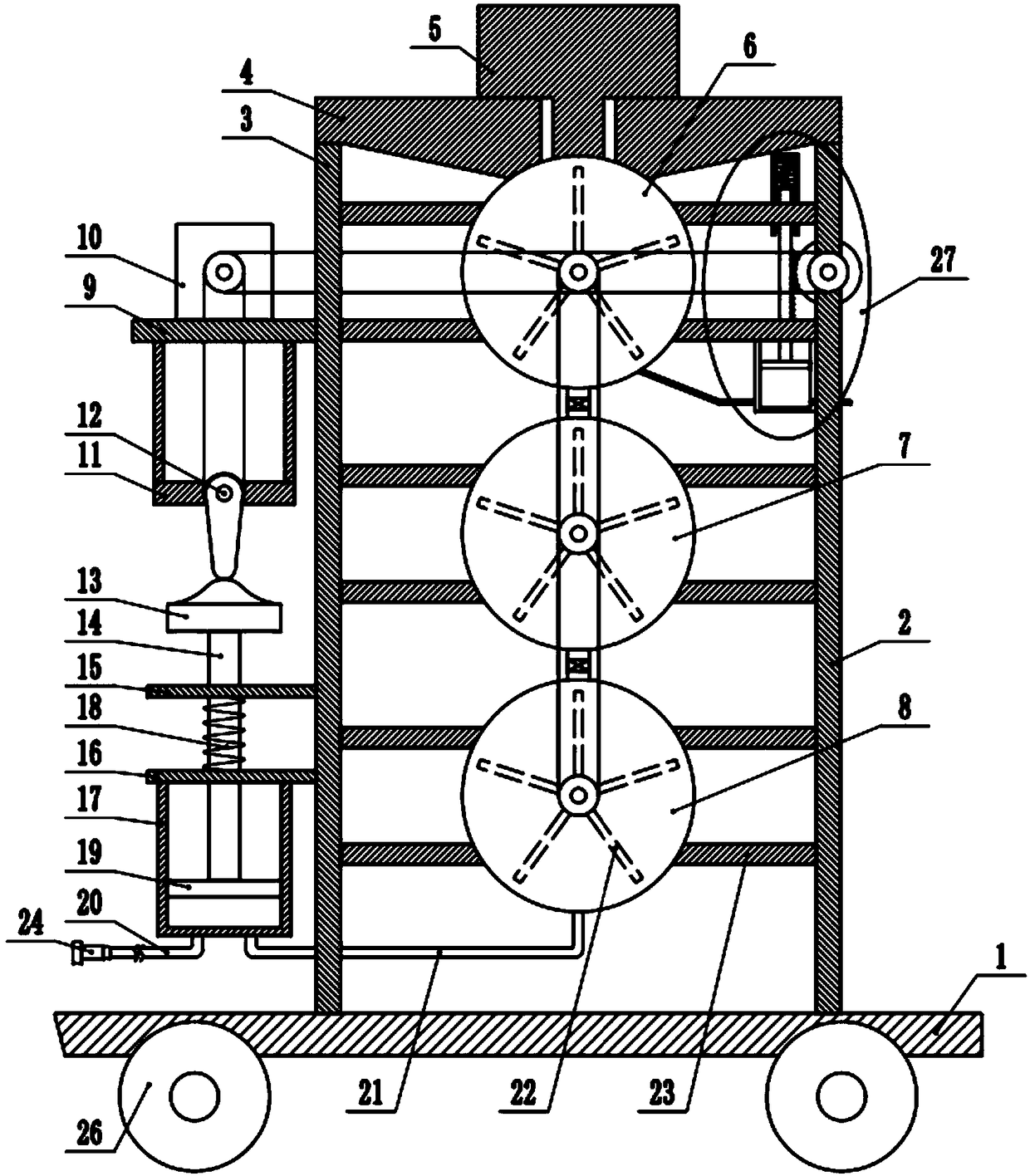

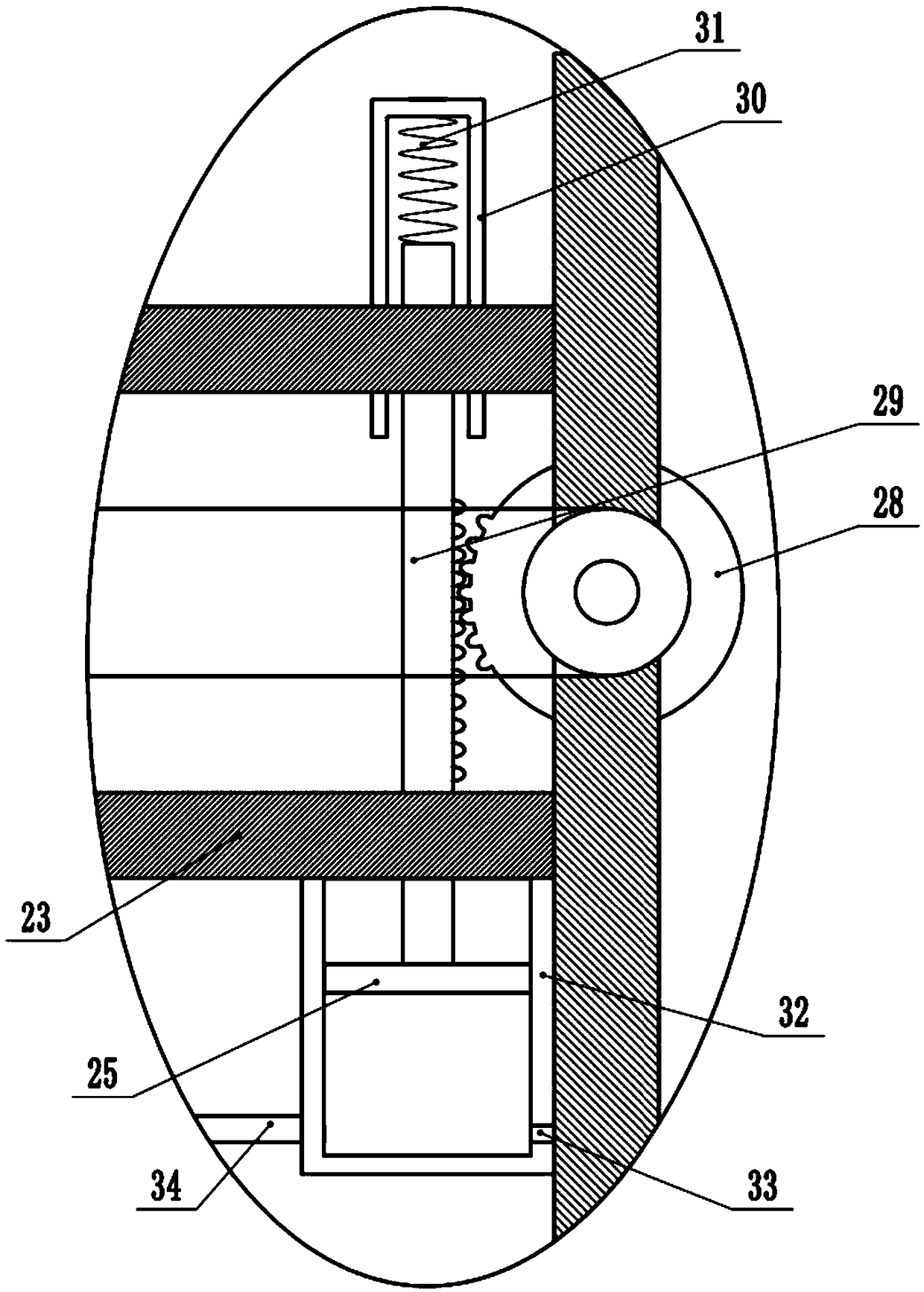

[0026] see figure 1 , an integrated device for stirring, mixing and spraying paint on site for the construction industry, comprising a bottom plate 1, the bottom end of the bottom plate 1 is rotated with a walking wheel 26, and the top of the bottom plate 1 is fixed with a first side frame 2 and a second side frame 3. A raw material mixing cylinder 6 is provided between the first side frame 2 and the second side frame 3, the top of the raw material mixing cylinder 6 is provided with a feeding mechanism, and the bottom end of the raw material mixing cylinder 6 passes through the first The feeding tube is connected to the intermediate storage tube 7, the bottom end of the intermediate storage tube 7 is connected to the finished product taking tube 8 through the second feeding tube, the second side frame 3 is fixedly connected to the first fixing plate 9, and the second side frame 3 is fixedly connected to the first fixing plate 9. A fixed plate 9 is provided with a drive motor 1...

Embodiment 2

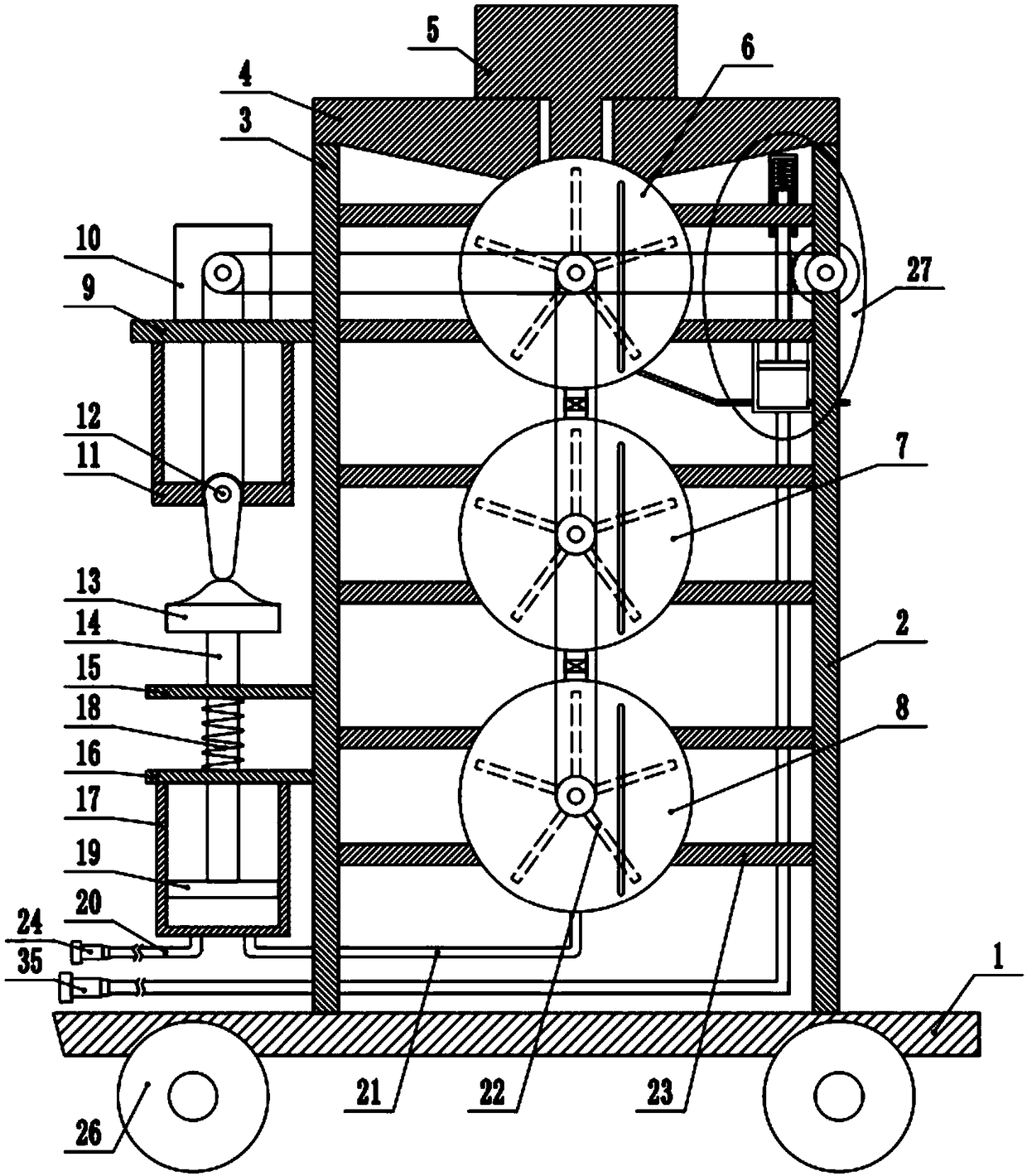

[0029] see image 3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the ends of the raw material mixing cylinder 6, the intermediate storage cylinder 7, and the finished product taking cylinder 8 are all provided with liquid level windows, and the second piston The bottom end of the cylinder 32 is fixedly connected with a negative pressure tube, and the end of the negative pressure tube is fixedly connected with a negative pressure suction head 35 .

[0030] In the implementation process of the present invention, the paint raw materials are poured in respectively through the side feed hopper 4 and the middle feed hopper 5, and then the driving motor 10 is started, and the driving motor 10 drives the raw material mixing cylinder 6 and the middle storage cylinder 7 under the action of transmission. And the stirring paddle 22 in the finished product taking cylinder 8 rotates. After the material in the raw material mixing cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com