Patents

Literature

37results about How to "Achieve secondary mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

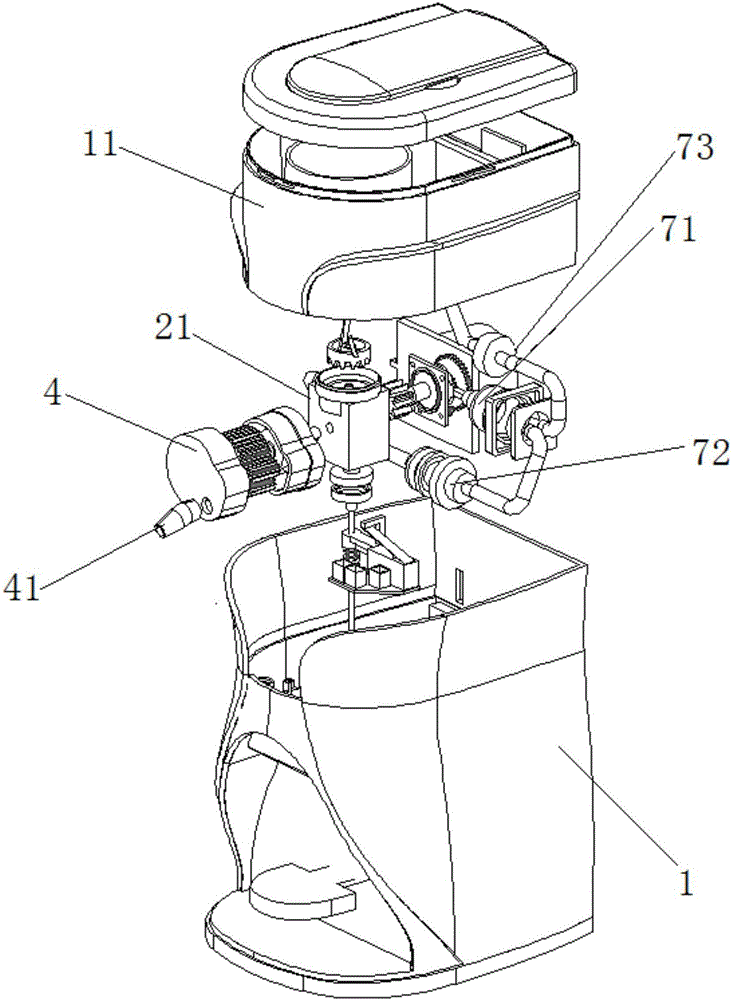

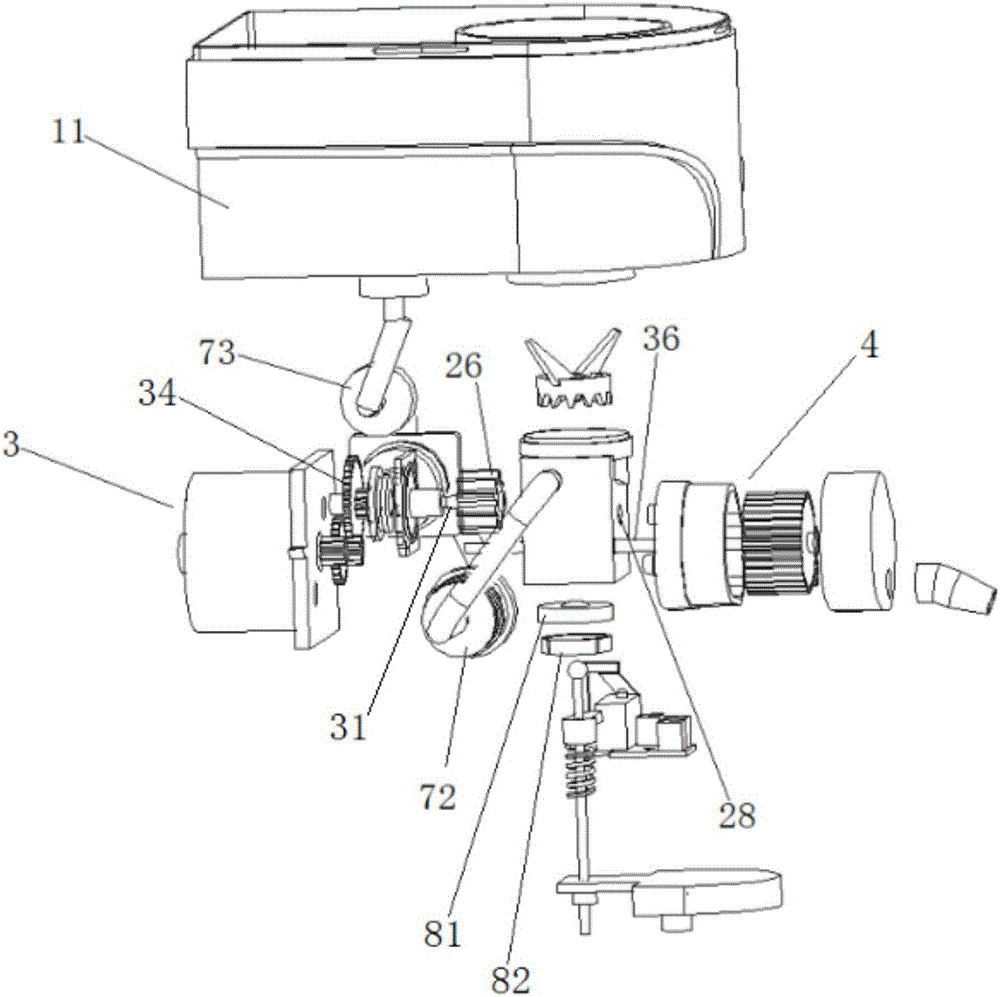

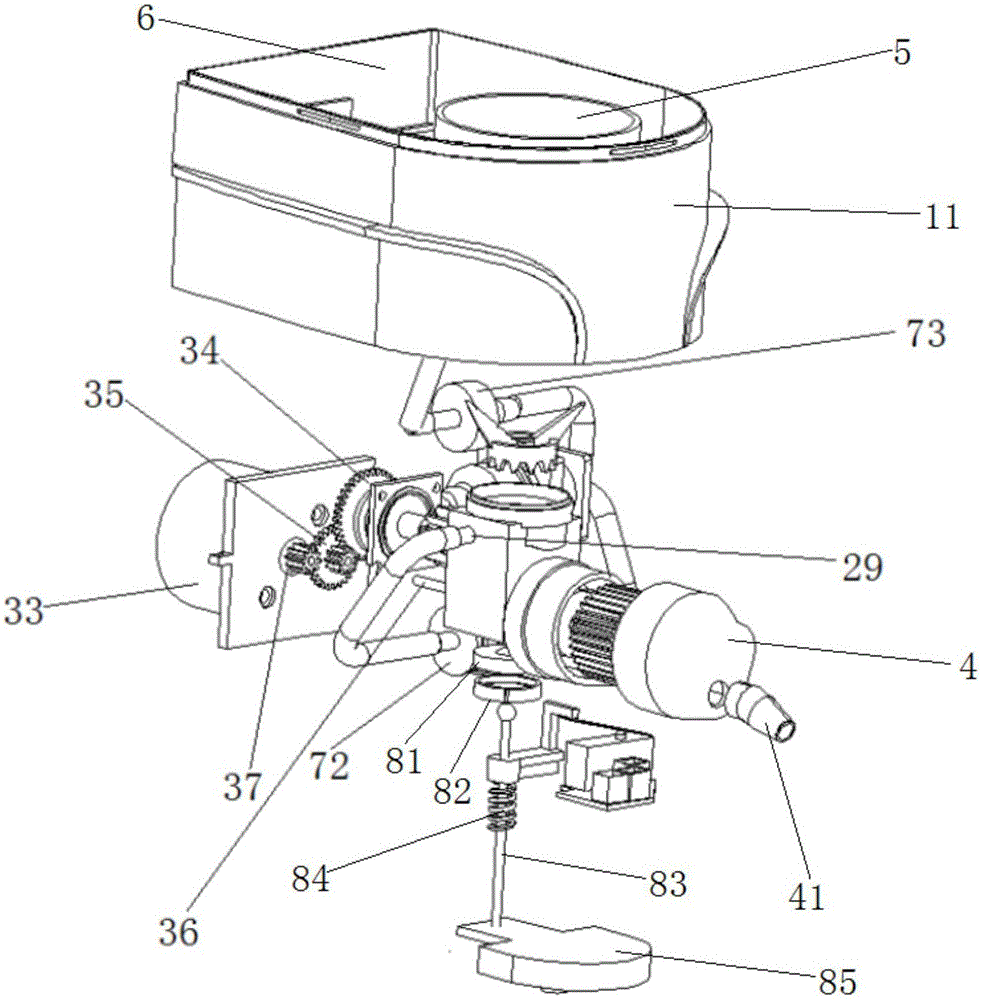

Efficient multifunctional foam soap dispenser

ActiveCN105708375AIngenious structural designSimple structural designHolders and dispensersMechanical engineeringSOAP

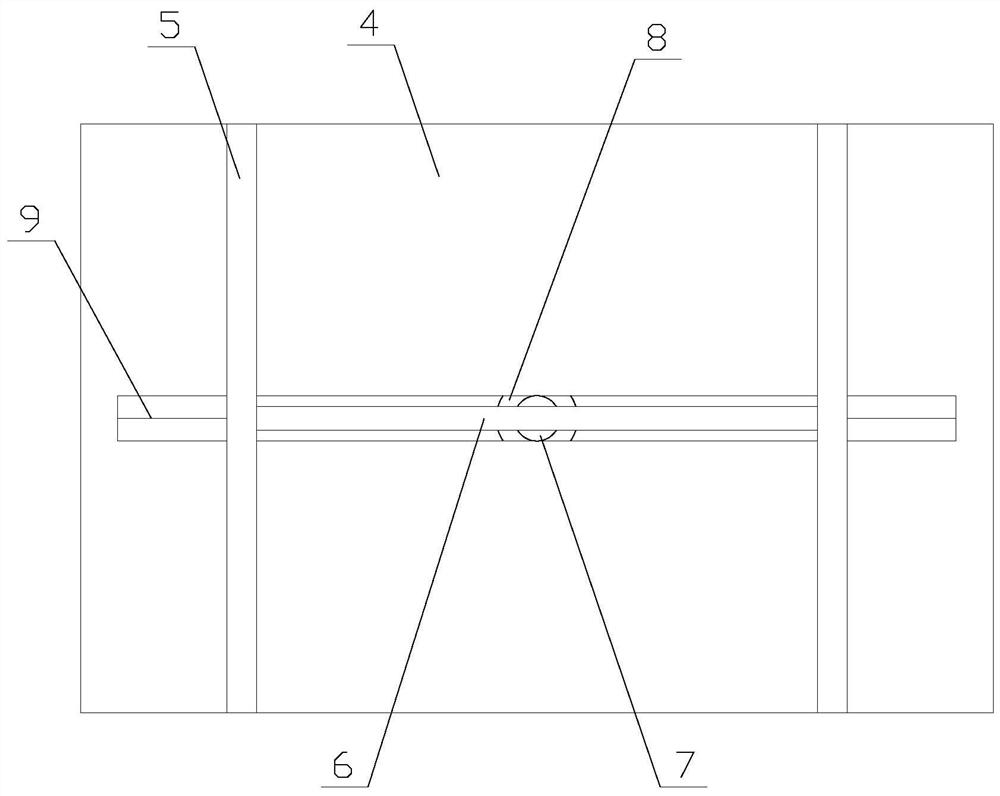

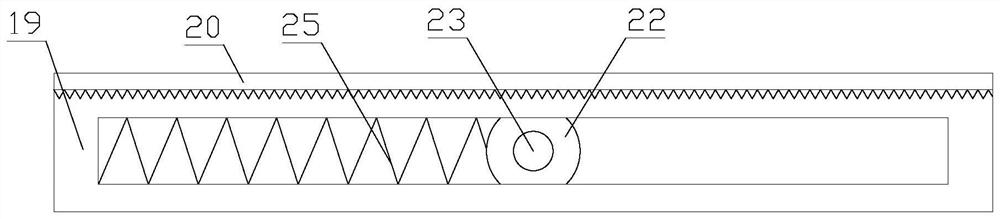

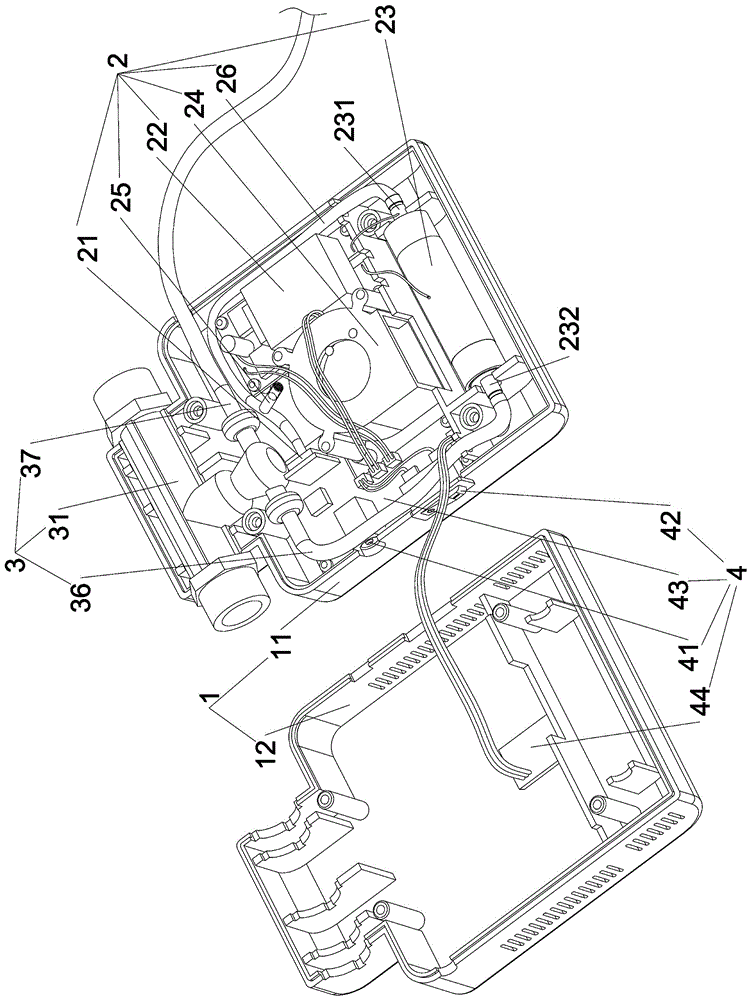

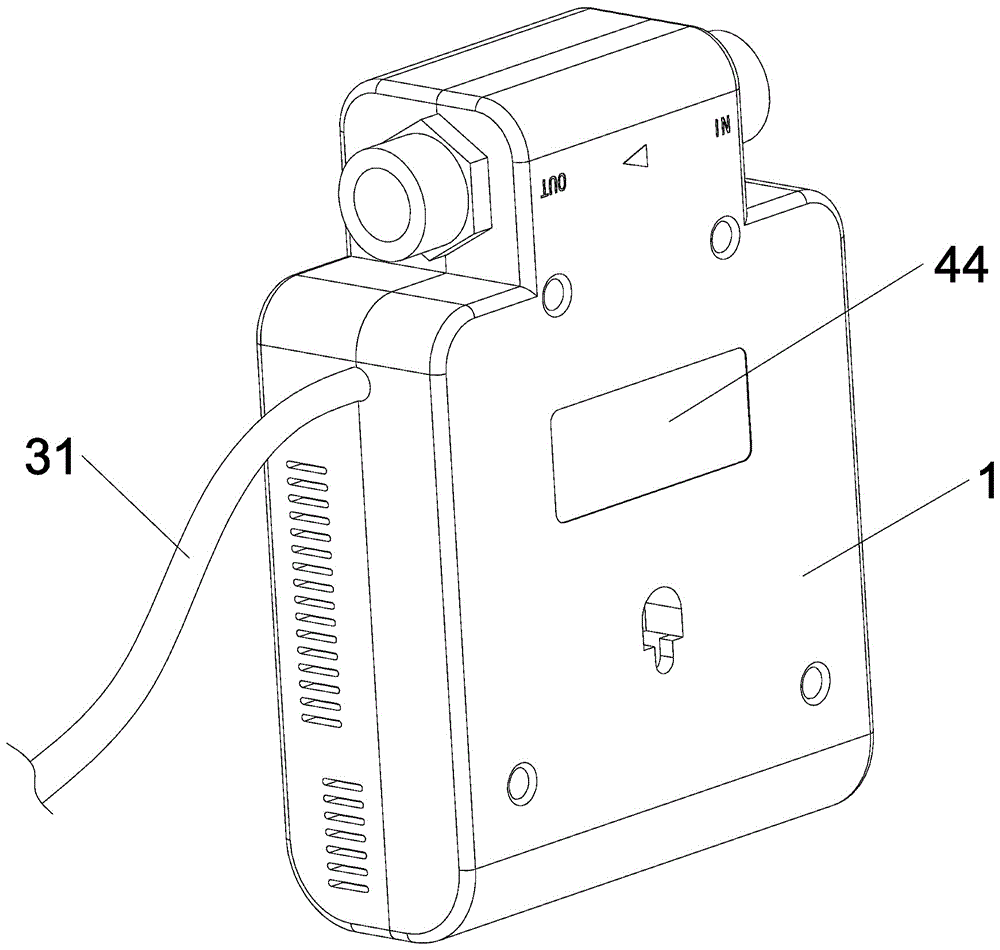

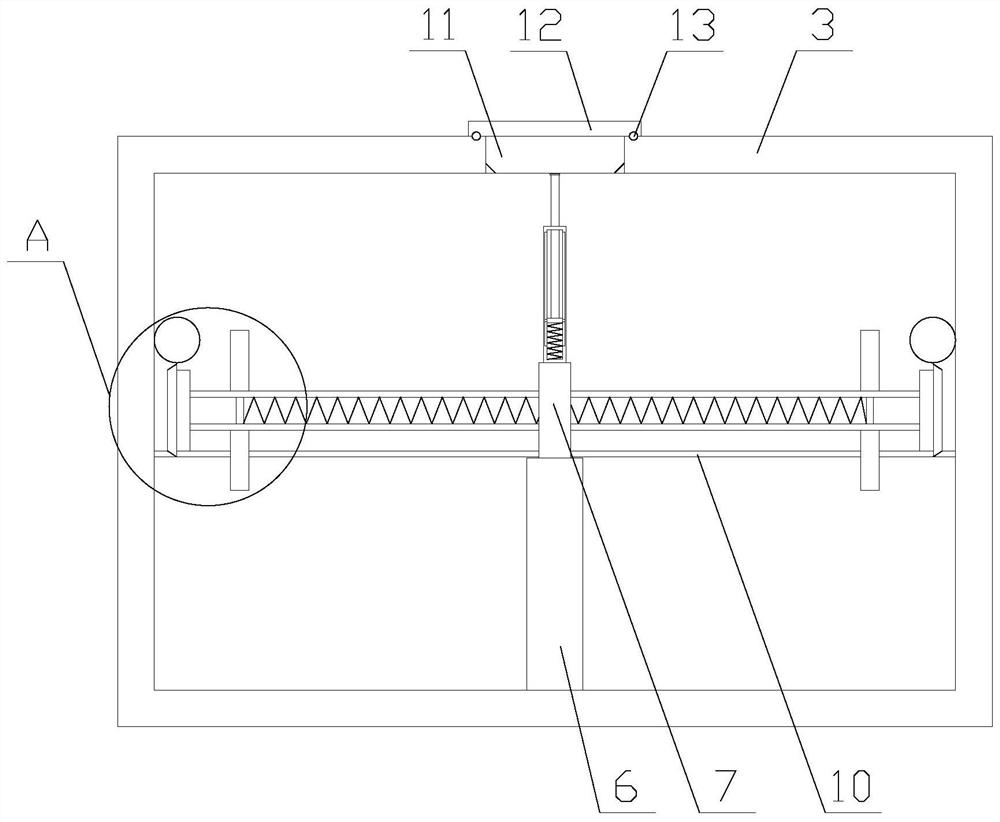

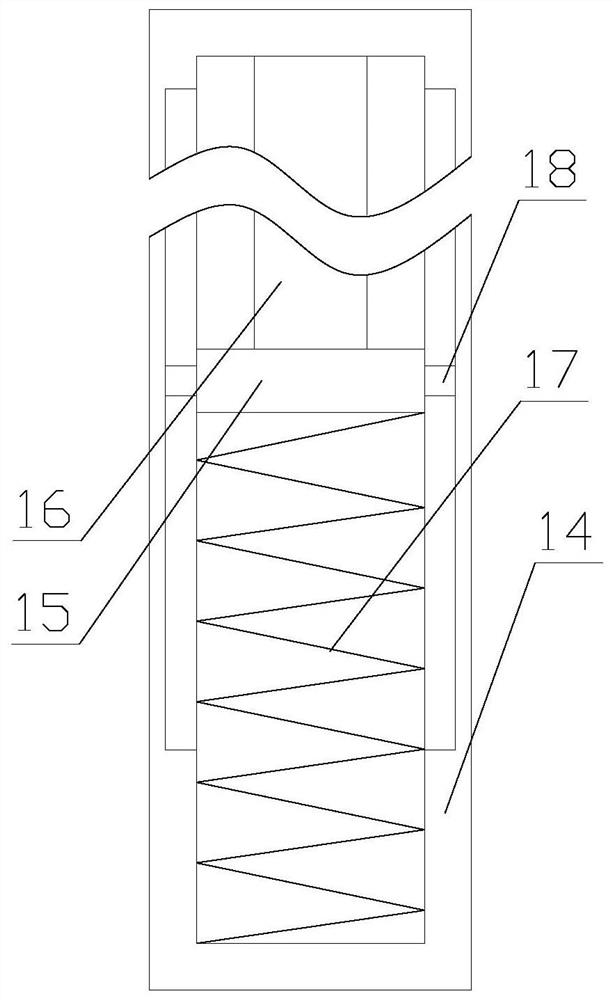

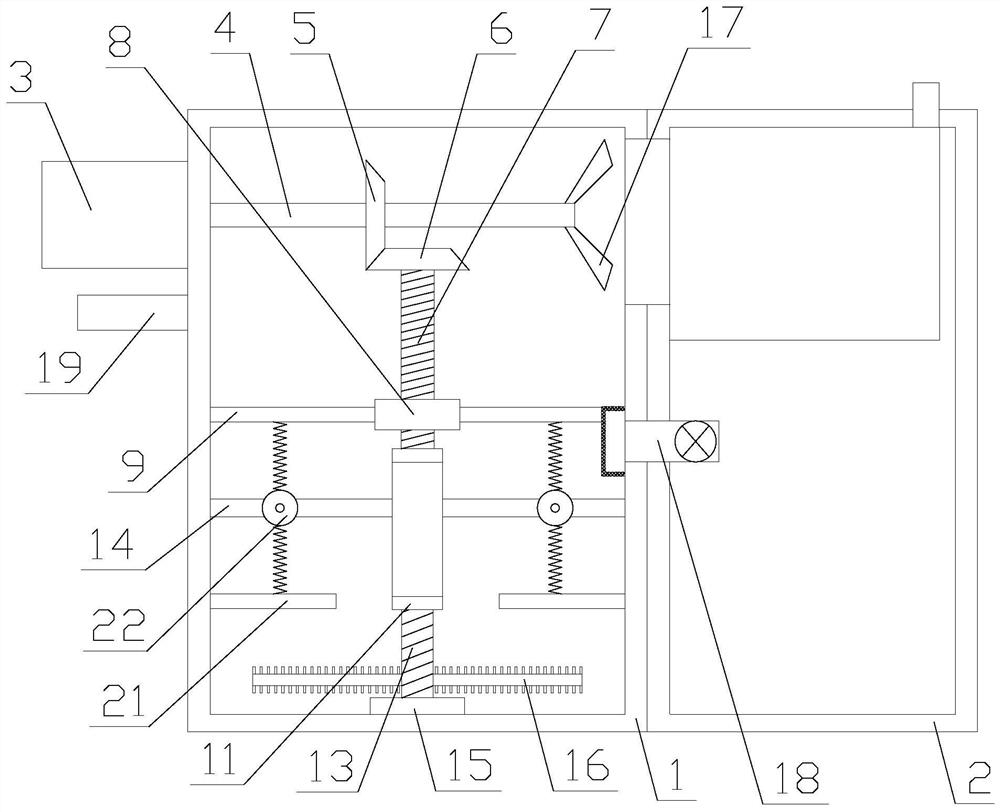

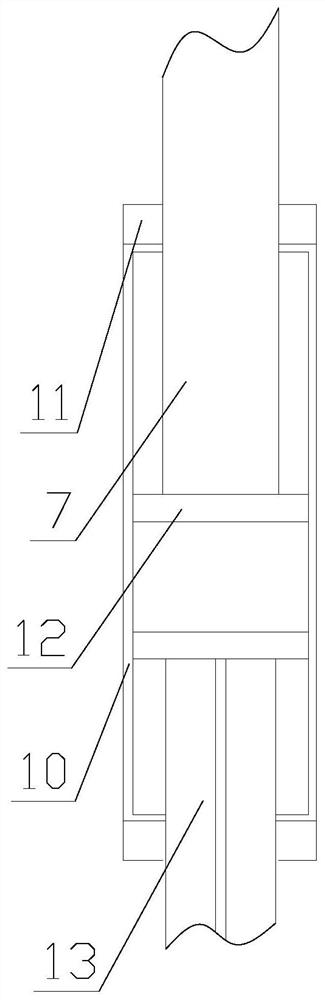

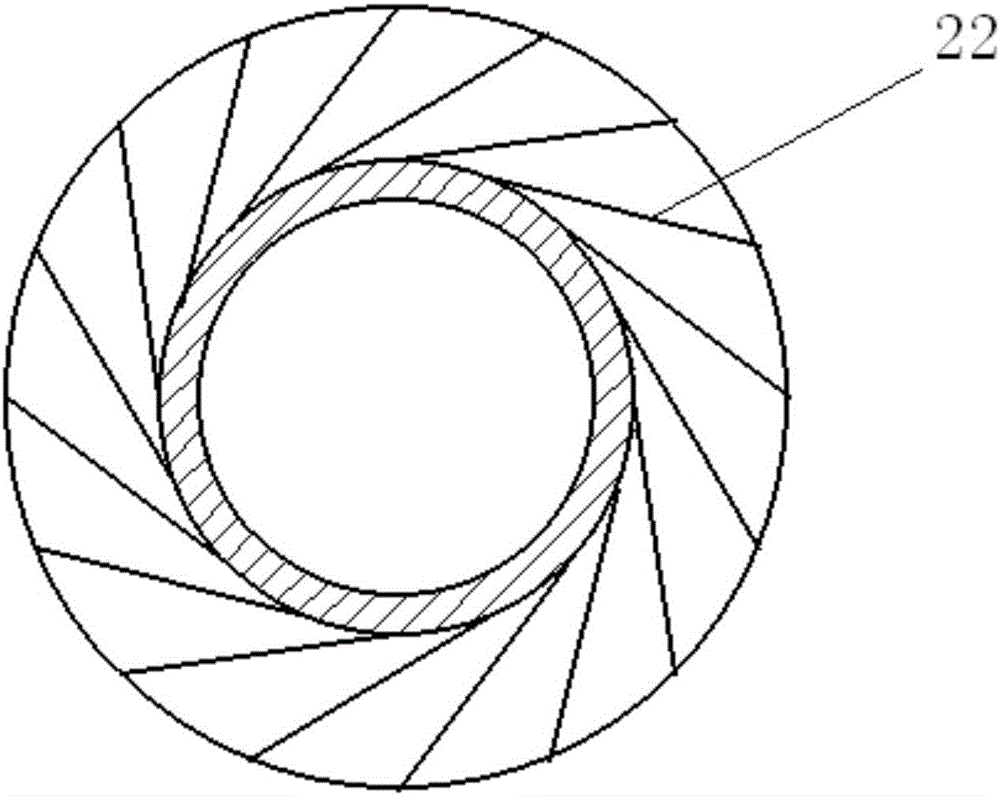

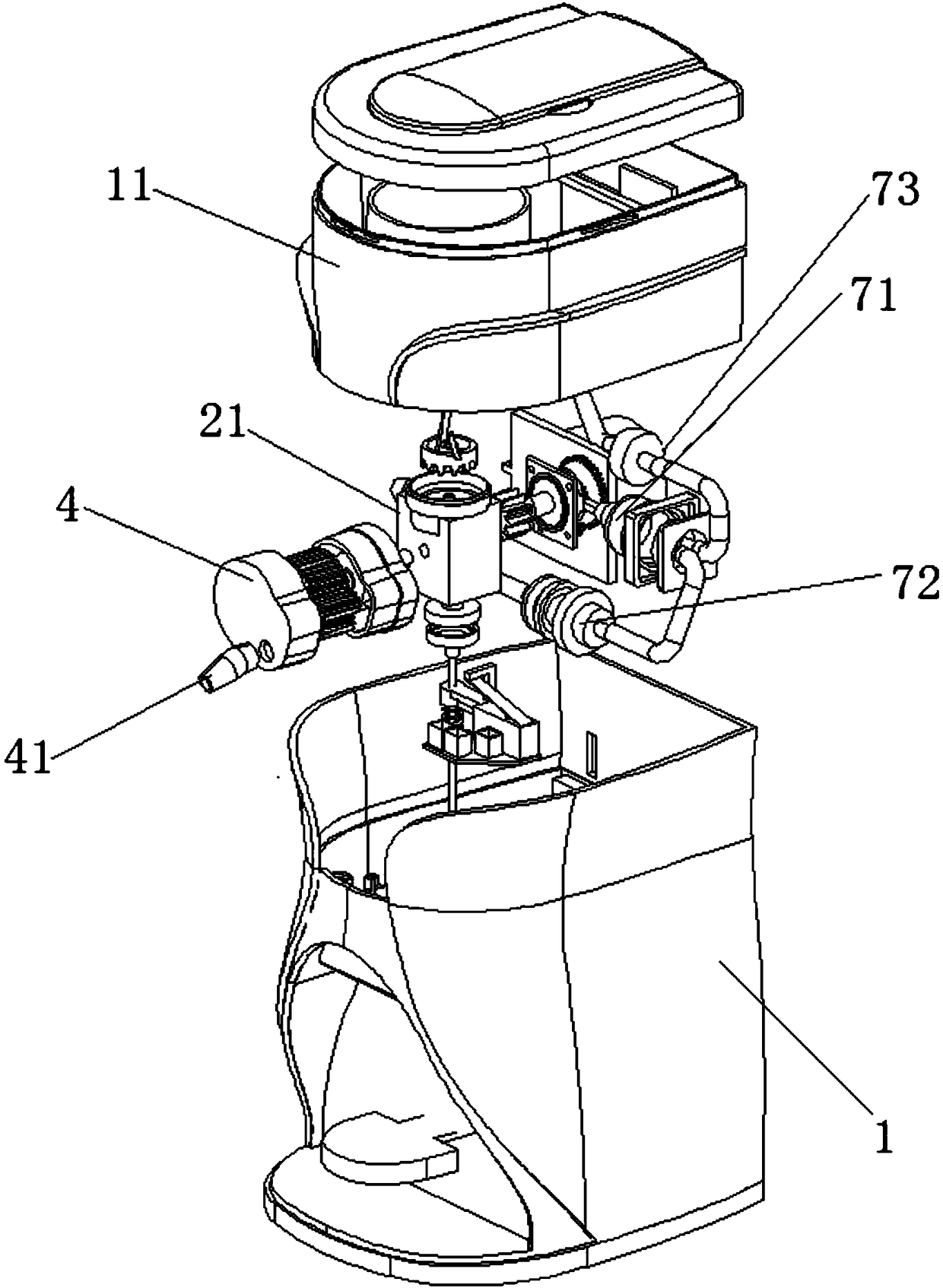

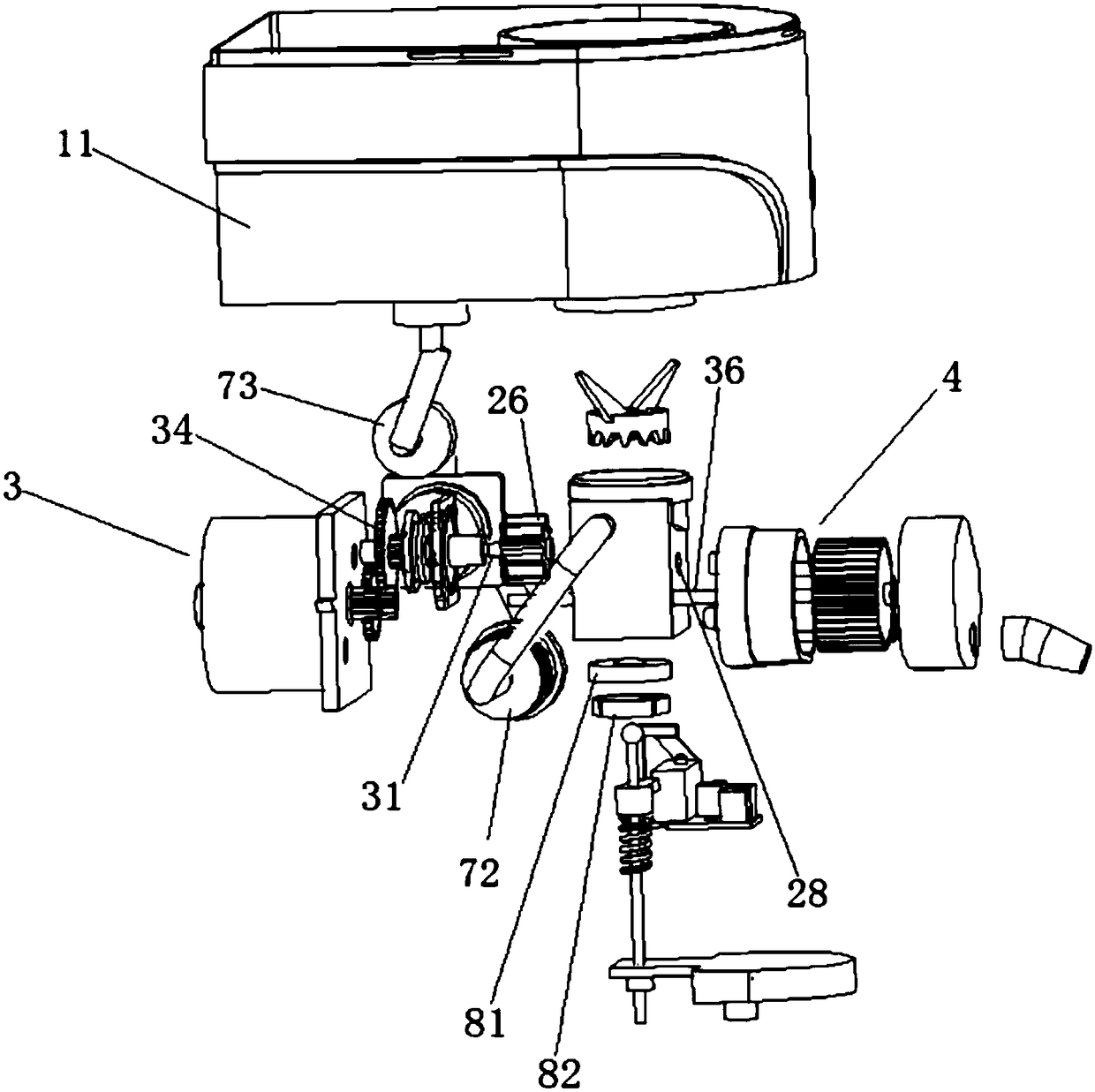

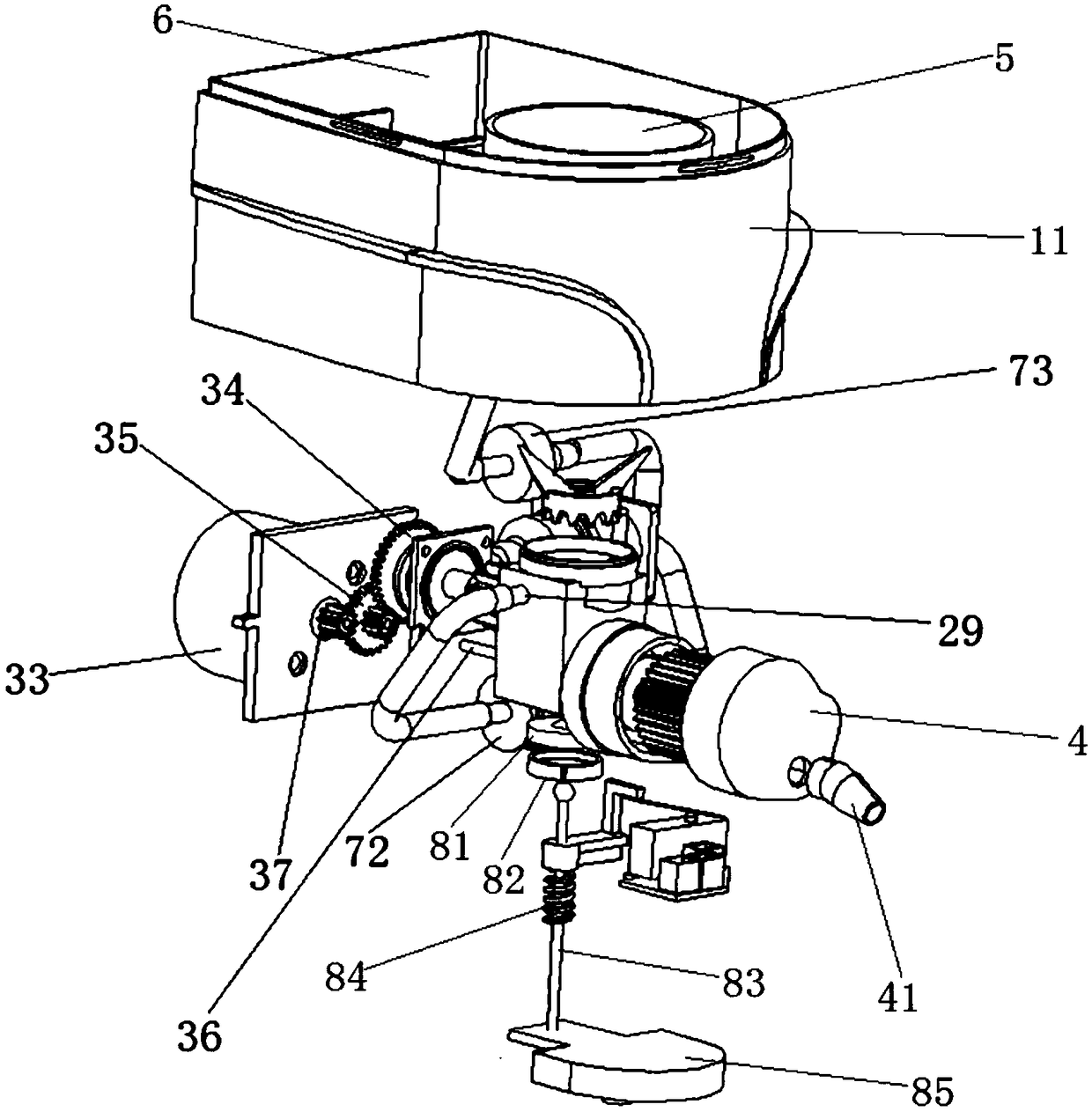

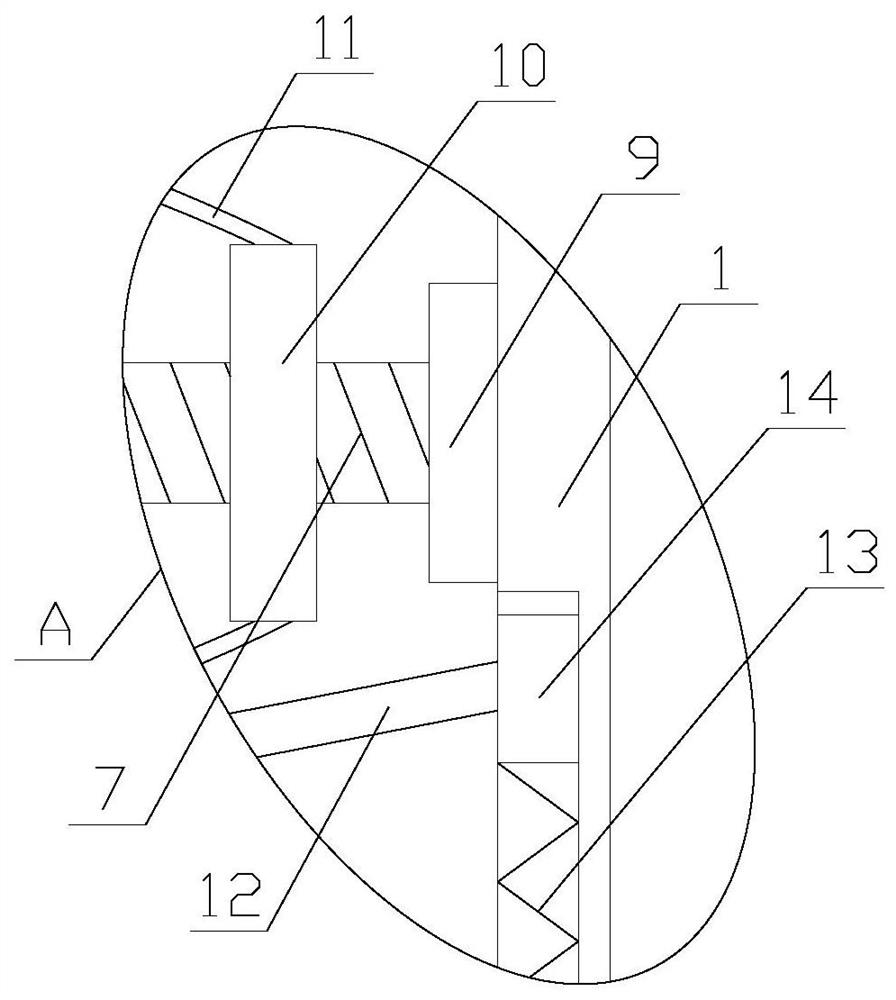

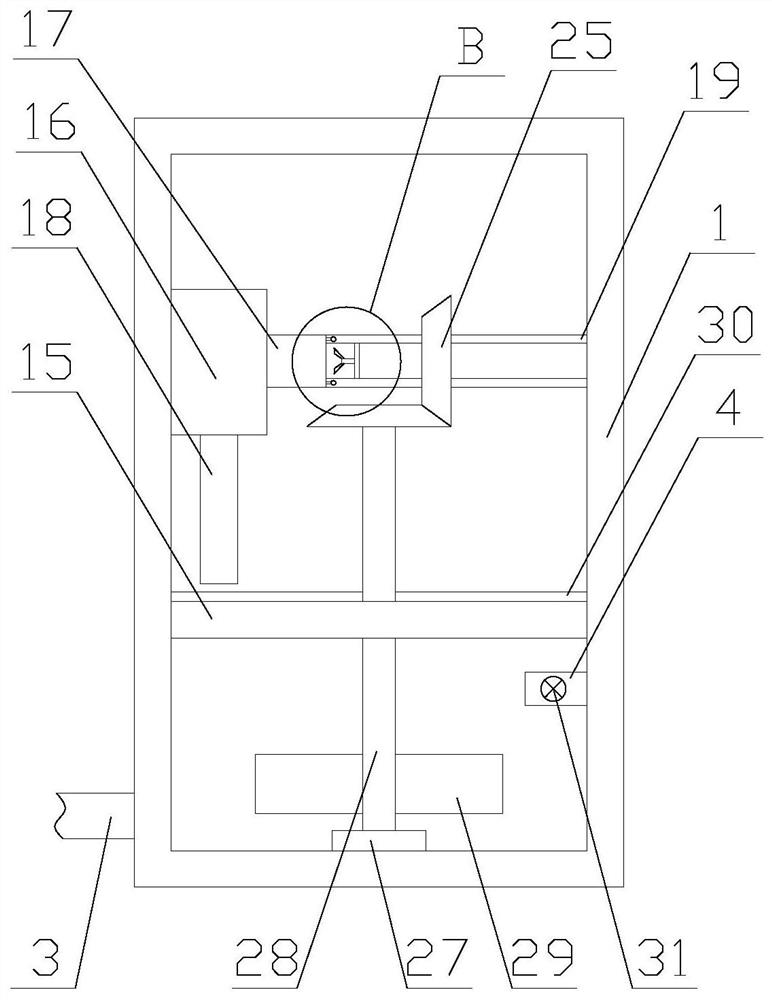

The invention discloses an efficient multifunctional foam soap dispenser. The soap dispenser comprises a shell with a soap liquid outlet, wherein a mixing-diluting-conveying device, a foaming device, a driving extraction device, a raw material cavity and a water cavity are arranged in the shell; the mixing-diluting-conveying device is connected with the foaming device, and the driving extraction device is connected with the mixing-diluting-conveying device and the foaming device and is used as the power source of the mixing-diluting-conveying device and the foaming device at the same time. The soap dispenser provided by the invention is provided with a mixing groove for realizing the proportion mixing of the water and raw materials; and meanwhile, a mixing crown and a mixing straight tooth are engaged to realize the second mixing of the raw materials; the upper part of the mixing crown is provided with stirring blades for easily scraping the raw materials to the mixing groove so that the raw material is mixed more uniformly, the raw materials can be precisely controlled, and the soap liquid outlet effect is good; furthermore, the whole soap dispenser is smart and simple in structure design, the whole soap dispenser can be controlled while only triggering a pressing plate of a trigger device, the operation is simple, the tedious process is avoided, and the working efficiency is high.

Owner:GUANGZHOU OH BUBBLE SCI & TECH CO LTD

Tap water dosing device with good stirring effect

InactiveCN113117586ARealize micro-vibrationAvoid cloggingShaking/oscillating/vibrating mixersTransportation and packagingTap waterStructural engineering

The invention relates to a tap water dosing device with a good stirring effect, the tap water dosing device comprises a water tank, a water inlet pipe, a driving mechanism and a crushing mechanism, wherein the water tank is vertically arranged, the water inlet pipe is arranged on one side of the top end of the water tank, the driving mechanism and the crushing mechanism are both arranged in the water tank, and the crushing mechanism is located above the driving mechanism; a power generation device is arranged in the water inlet pipe, the crushing mechanism comprises a feeding box and a crushing assembly, the driving mechanism comprises a driving assembly and a driven assembly, wherein the driven assembly is arranged below the crushing assembly, and the driving assembly is arranged between the crushing assembly and the driven assembly, wherein the driving assembly is connected with the driven assembly and with the crushing assembly. According to the tap water dosing device with the good stirring effect, through cooperation of the smashing mechanism and the driving mechanism, the mixing effect is improved, and the production efficiency is improved; herein, the linkage of a plurality of mechanisms is achieved through the same driving source, and the practicability is improved.

Owner:广州开就中西医医院有限公司

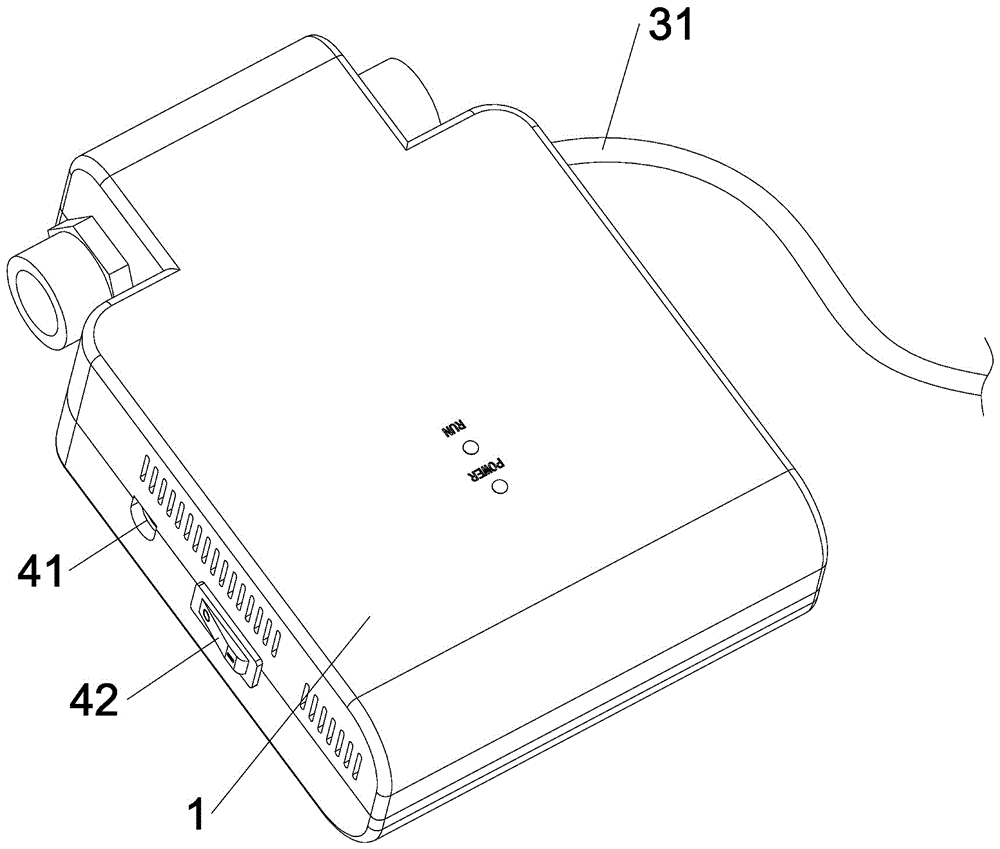

Overflowing ozone water machine

InactiveCN106582341AAchieve secondary mixingImprove mixing efficiencyFlow mixersTransportation and packagingOzone generatorEnvironmental engineering

The invention discloses an overflowing ozone water machine. The overflowing ozone water machine comprises a shell, an ozone generating device, an ozone mixing device and a power source assembly, wherein the shell, the ozone generating device, the ozone mixing device and the power supply assembly are matched. The ozone generating device comprises a negative pressure sensor, a high voltage power source, an ozone generator, an air fan and an air current-limiting filter, wherein the negative pressure sensor, the high voltage power source, the ozone generator, the air fan and the air current-limiting filter are matched. The ozone mixing device comprises a jet device, a blocking-type check valve, a first one-way check valve and a second one-way check valve, wherein the jet device, the blocking-type check valve, the first one-way check valve and the second one-way check valve are connected with the ozone generator. The overflowing ozone water machine can be installed in any required pipe, installing is convenient, and space is not occupied.

Owner:安其美(厦门)环保科技有限公司

Double-foaming foam concrete device

InactiveCN103878881ARealize continuous productionSmall bulk densityCement mixing apparatusFoam concreteFoaming agent

The invention relates to a double-foaming foam concrete device and belongs to the technical field of manufacturing devices of building materials. The double-foaming foam concrete device comprises a physical foaming system and a chemical foaming system, wherein an input pipeline of the chemical foaming system is connected to the tail end of the physical foaming system; the chemical foaming system comprises a foaming agent injecting machine, an injection pipeline, a mixer and an output pipeline, and the foaming agent injecting machine is connected to the input pipeline of the mixer connected to the physical foaming system through the injection pipeline; ultra-light foam concrete mixed by the mixer is output through the output pipeline connected to the mixer. The double-foaming foam concrete device has the beneficial effects that the physical foaming system and the chemical foaming system are integrally utilized in parallel operation, so that the remote transportation and construction of the foam concrete are realized, and the yield of the foam concrete is high; by carrying out double foaming, the ultra-light foam concrete consisting of a mass of independent and uniformly-distributed bubbles can be continuously produced, the volume density and heat conductivity coefficient of the foam concrete are low, the thermal performance of the foam concrete is very excellent, and the foam concrete is an efficient thermal insulation material.

Owner:盘锦双利建筑劳务有限公司 +2

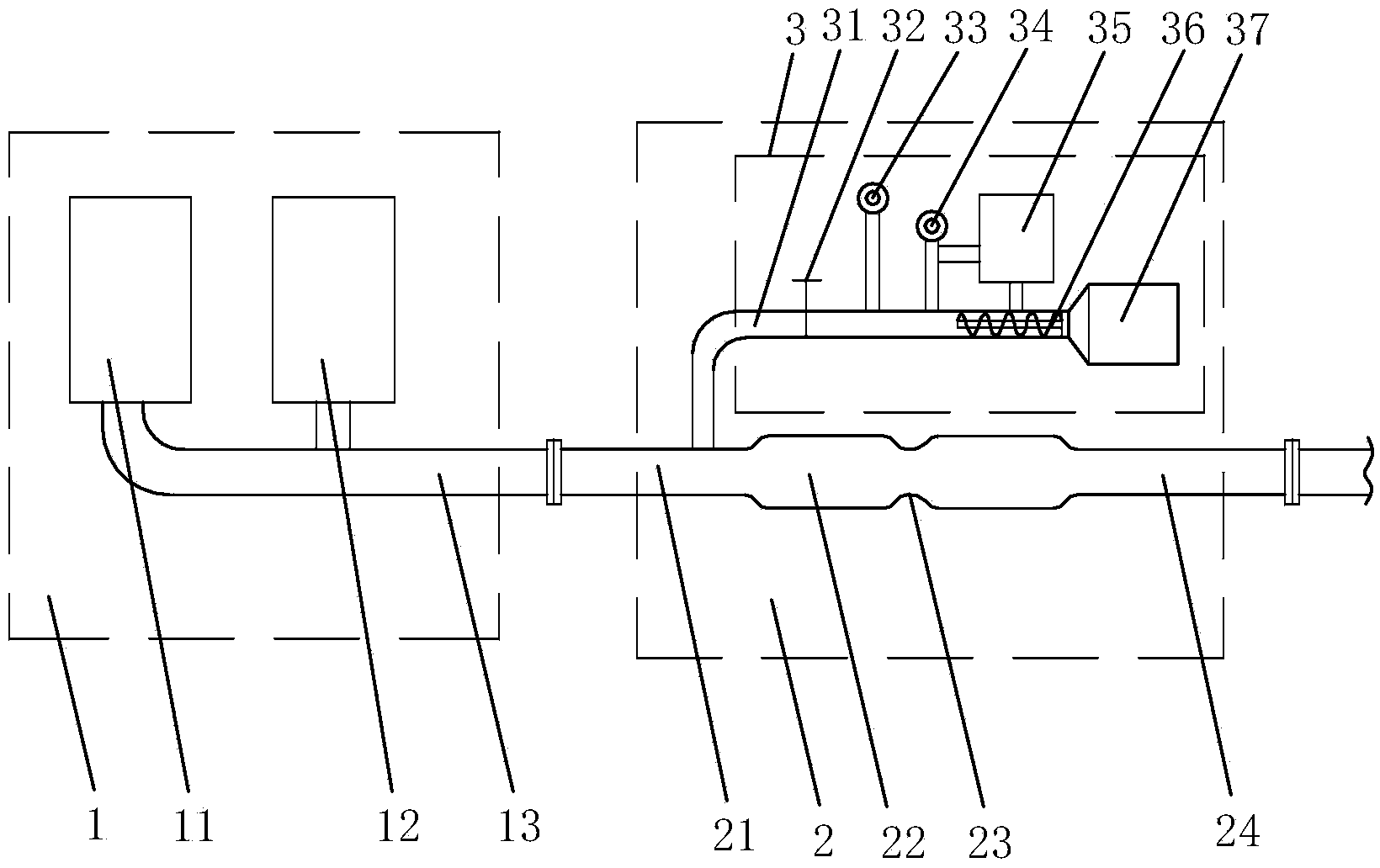

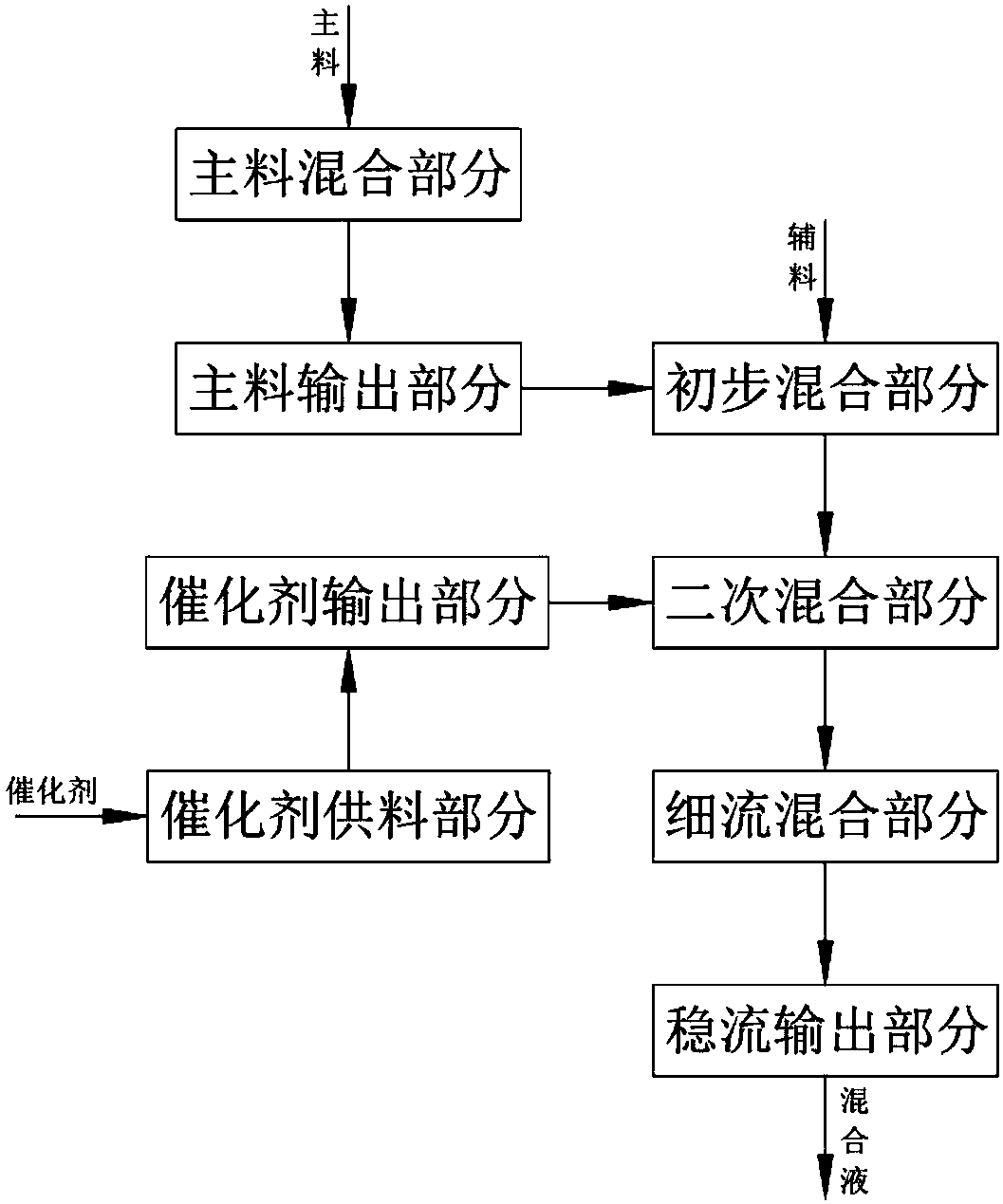

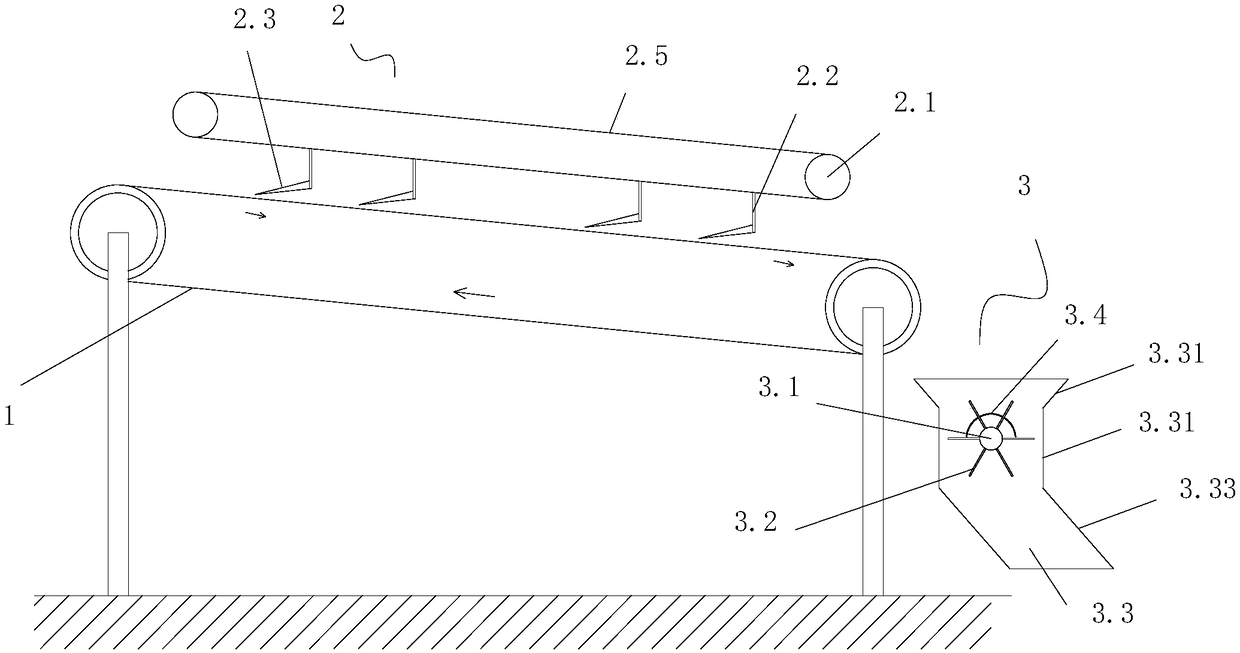

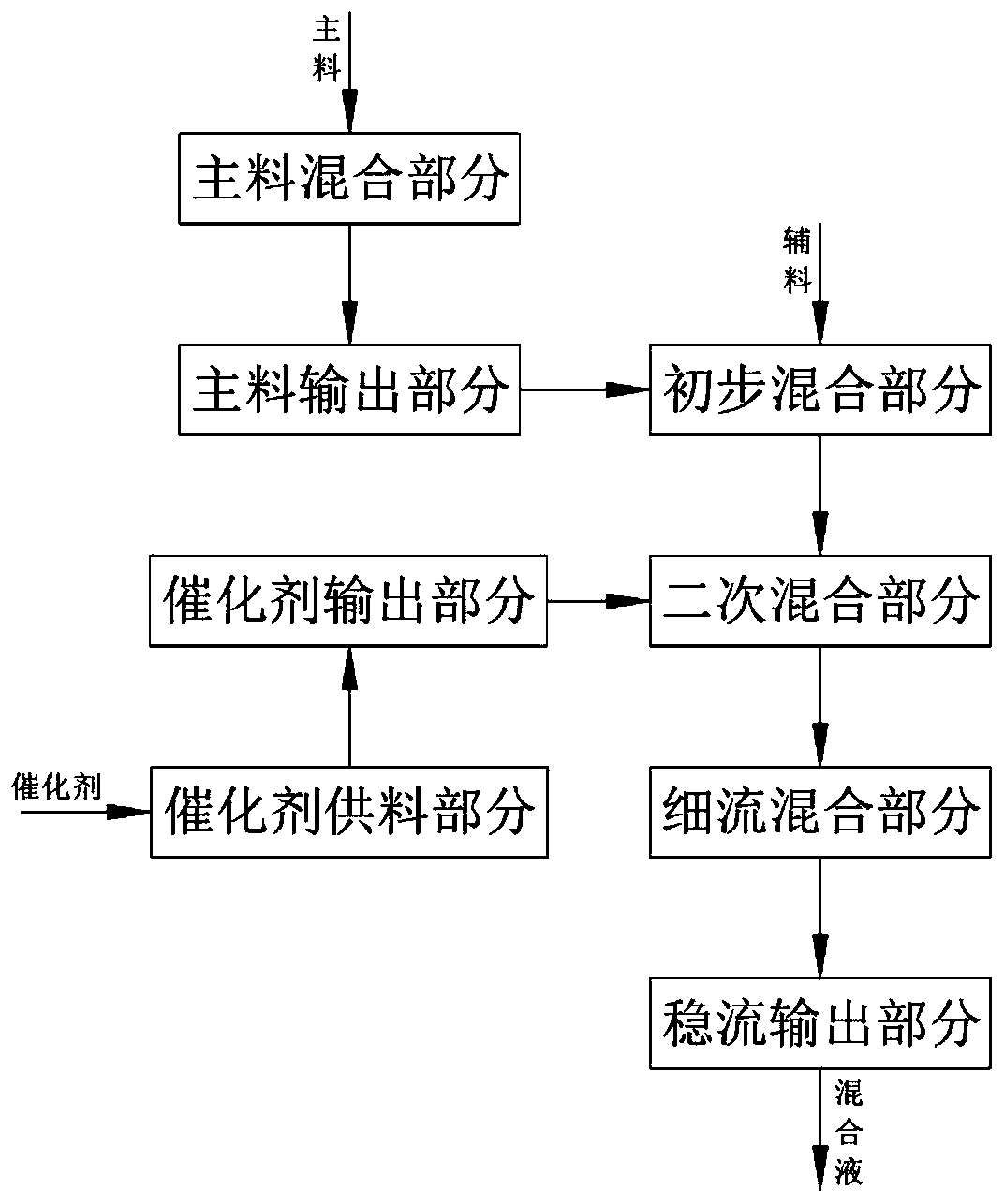

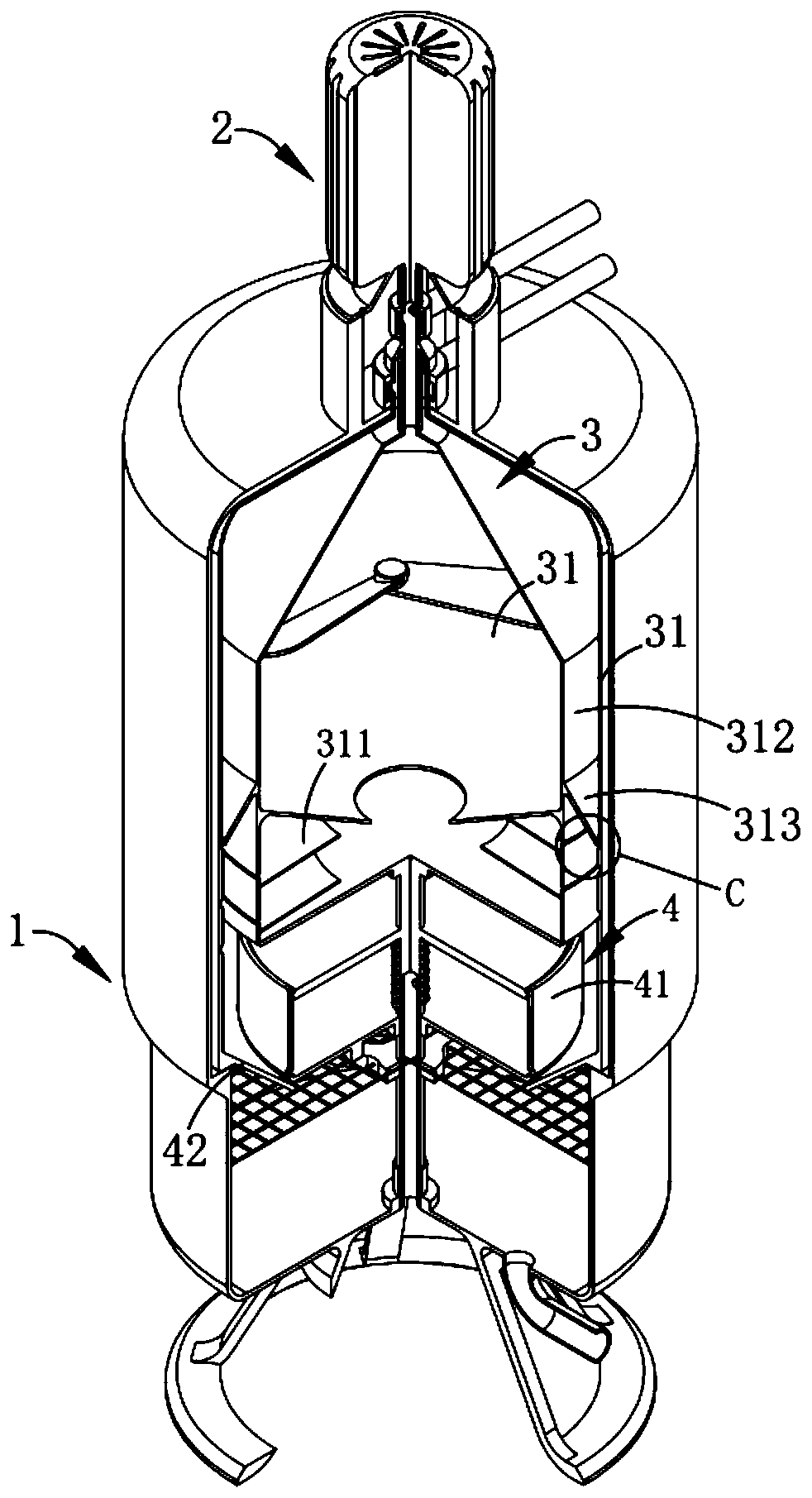

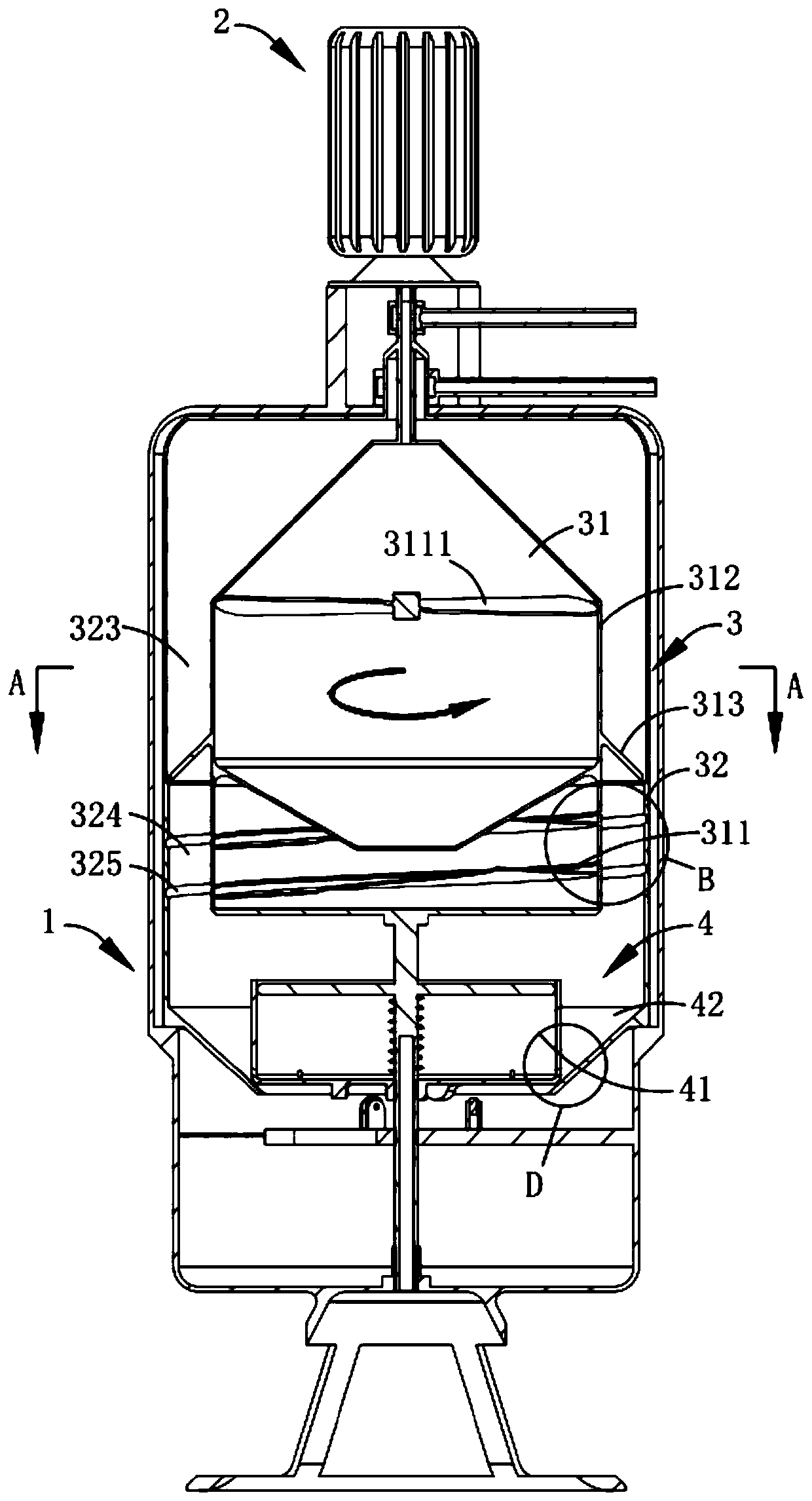

Furan resin efficient production technology

ActiveCN107825612AAchieve secondary mixingSolve the technical problems of low production efficiency and uneven mixingEngineeringCentrifugal force

The invention relates to the field of resin preparation and production, in particular to a furan resin efficient production technology. The furan resin efficient production technology comprises a mainmaterial output part, a preliminary mixing part, a secondary mixing part and a stable flow output part. A main material is conveyed by a mixing part on a main material output assembly and meanwhile ejected by a main material bin under the effect of centrifugal force, a liquid flow layer is divulged through an impact mode, preliminary mixed liquid with the main material and an auxiliary material being of an up-down overlapped structure is formed, impact is conducted through a catalyst which is ejected intermittently in a compressed mode, the main material, the auxiliary material and the catalyst flow down along the surface of a slow flow assembly after being subjected to secondary mixing, and the main material, the auxiliary material and the catalyst are output after penetrating through aflow distributing net; and the main material which is of a spiral structure is output by the mixing part and the liquid flow layer is divulged in an impact mode, the preliminary mixed liquid with themain material and the auxiliary material being overlapped up and down in a spaced mode is formed, then a flow jetting assembly is driven by a preliminary mixing mechanism to conduct secondary mixing on the catalyst in a rotary jetting mode, and the technical problems that the production efficiency is low, and mixing is not even existing in the prior art are solved.

Owner:阜阳佰恩得新材料技术有限公司

ABS engineering plastic production device

InactiveCN111844503AAchieve secondary mixingAvoid the problem of difficult to mix the ingredients wellEngineering plasticElectric machinery

The invention discloses an ABS engineering plastic production device. The device comprises a material storage barrel fixed on an extruder, a partition plate is arranged in the material storage barrel,the partition plate is used for partitioning the material storage barrel into a mixing cavity and a plurality of material storage cavities for storing raw materials, a stirring mixing assembly is provided in the mixing cavity, a cross-mixing assembly for connecting the plurality of material storage cavities with the mixing cavity is provided on the partition plate, and a material pushing screw rod driven by a first driving motor is also provided in each material storage cavity. When in use, the raw materials can be heated to specified temperatures through a heating assembly according to different fluidity of the raw materials, after the raw materials are discharged into the mixing cavity in a staggered mode through the cross-mixing assembly, preliminary rapid mixing can be completed by utilizing the fluidity of the raw materials, further, secondary mixing of the raw materials can be achieved when the stirring mixing assembly moves, and the problem that the mixing time is short, so that the raw materials are difficult to fully mix can be solved.

Owner:福州盛世凌云环保科技有限公司

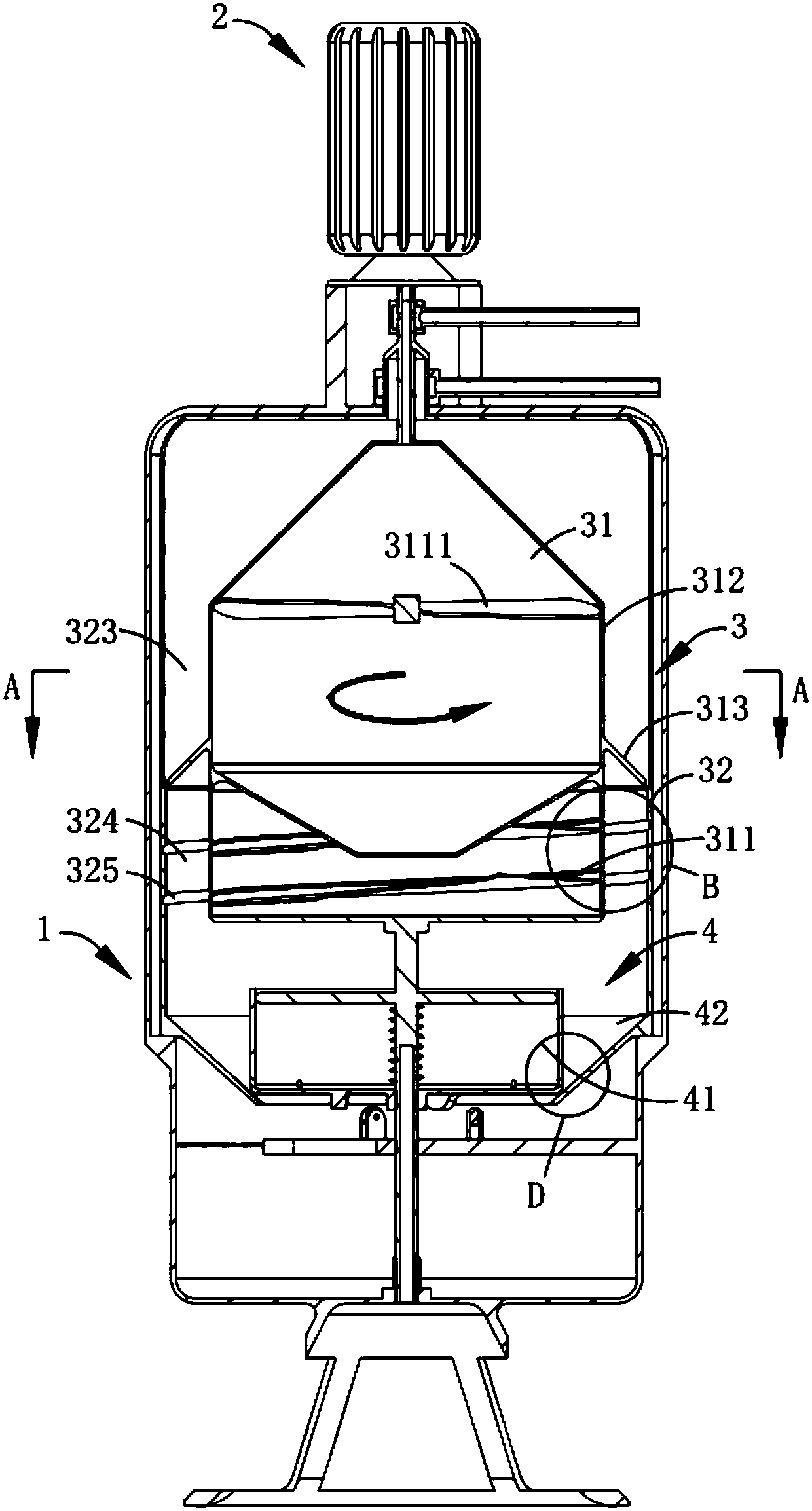

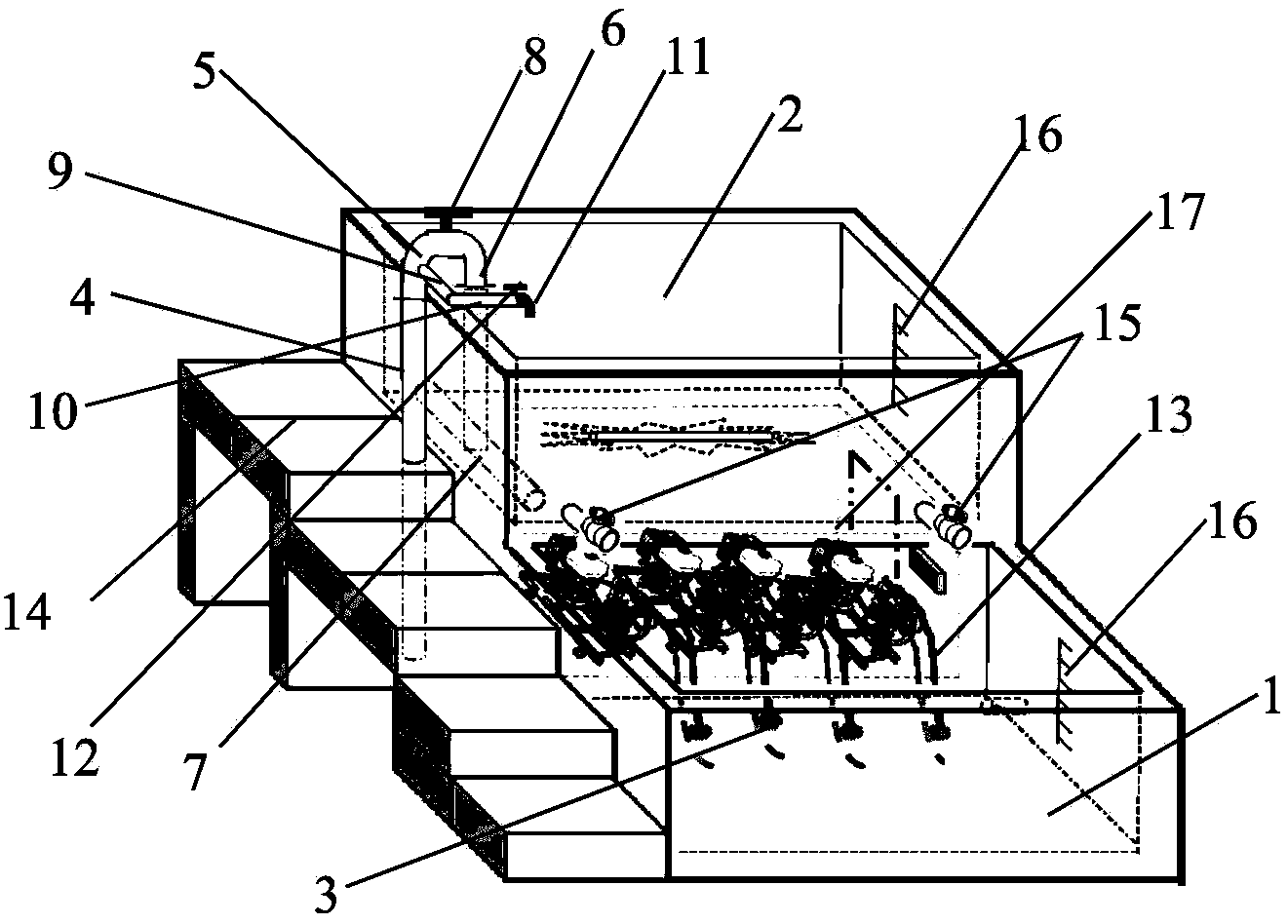

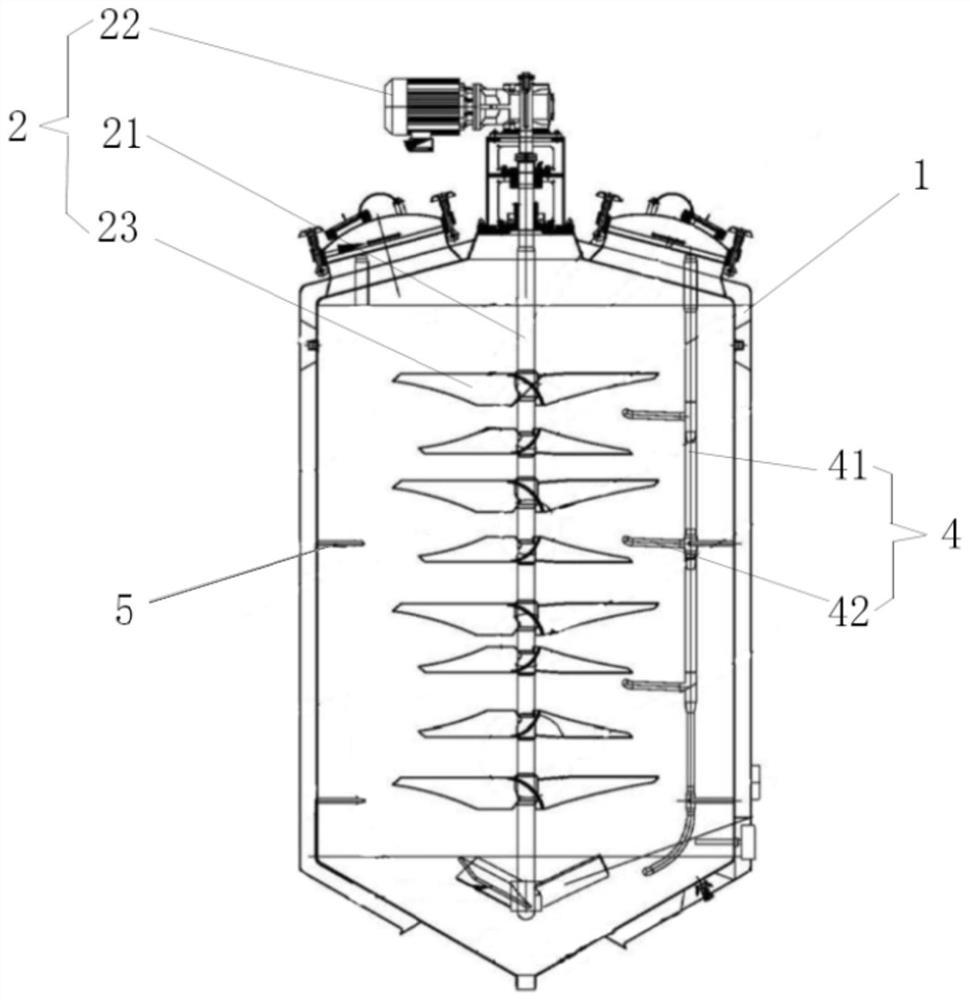

Feed stirring equipment for giant salamander

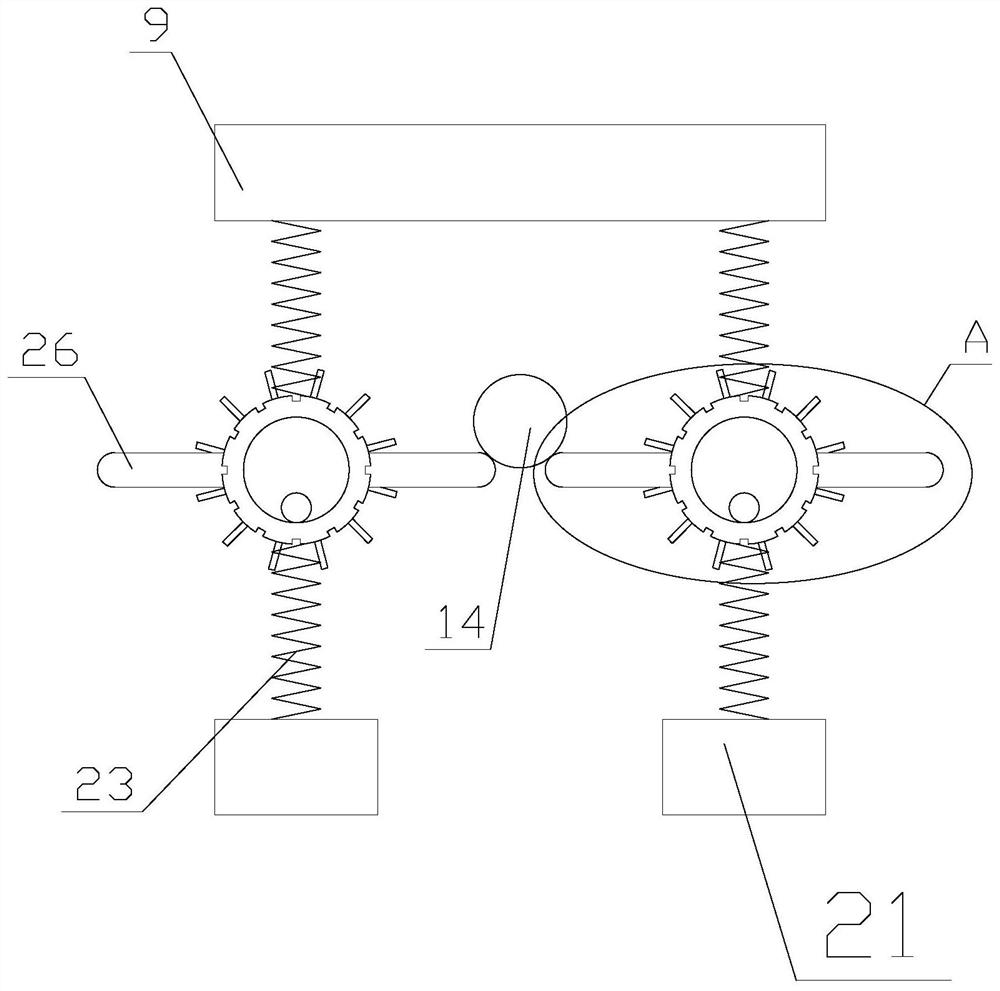

ActiveCN108704508AAchieve primary mixingAchieve secondary mixingFeeding-stuffRotary stirring mixersBiochemical engineeringGiant salamander

The invention relates to a stirring device, in particular to feed stirring equipment for giant salamander. The feed stirring equipment comprises a tank body, a connecting rod is arranged on the top ofthe tank body, a rotating shaft is vertically connected with one end of the connecting rod, a first stirring shaft is vertically connected with the other end of the connecting rod, a first sliding slot is formed in the top of the tank body, the first stirring shaft is slidably connected into the first sliding slot, a plurality of first stirring blades are arranged on the first stirring shaft, oneend of the first stirring shaft is rotationally connected with the bottom of the tank body, the other end of the first stirring shaft is positioned above the tank body, second stirring shafts are rotationally arranged around the interior the tank body, and a plurality of second stirring blades are arranged on the second stirring shafts and are intermittently meshed with the first stirring blades.The feed stirring equipment solves the problem that poor stirring effect is resulted from single rotating direction of the stirring blades in the prior art.

Owner:临沂罗开投资有限公司

Biopharmaceutical stirring device

InactiveCN113368728AAvoid separationAchieving stirringRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention relates to a biopharmaceutical stirring device, which comprises a base, a fixing rod, a fixed box, a stirring mechanism and a sealing mechanism, the stirring mechanism comprises a stirring assembly and a driving assembly, and the sealing mechanism comprises a sealing assembly and a connecting assembly. According to the biopharmaceutical stirring device, primary stirring of a main body is achieved through rotation of a connecting rod around a rotating rod, irregular movement of a stirring unit is achieved through a first spring, secondary stirring of the main body is achieved, and through cooperation of a first gear and a second gear, a connecting rod rotates along the axis of a bearing; the rotation of a collision plate is realized, the three-stage stirring of the main body is realized, the stirring effect is improved, and the sealing of the fixed box is realizedthrough the sealing mechanism, the fixed box is sealed through a sealing mechanism, people are prompted that the main body is being stirred through rotation of a circular plate, a sealing plate is limited through restoring force of a second spring, the sealing plate is prevented from being separated from the fixing box, and linkage of a plurality of mechanisms is achieved through the same driving source, and the use practicability is improved.

Owner:广州云深生物科技有限公司

Closed sewage sedimentation tank

InactiveCN112028195AAchieve secondary mixingImprove purification efficiencyTransportation and packagingMixersElectric machinerySewage treatment

The invention relates to a closed sewage sedimentation tank which comprises a main body, a box body, a purification mechanism, a driving mechanism and a stirring mechanism, the driving mechanism comprises a motor, a driving rod and a first bevel gear, and the stirring mechanism comprises a driven assembly and a stirring assembly. According to the closed sewage sedimentation tank, primary mixing ofsewage and a flocculating agent is achieved through rotation of a stirring rod, water in a sleeve is pushed out by a piston in a drawing mode while the stirring rod rotates, then the water flows outthrough a connecting hole, secondary mixing of the sewage and the flocculating agent is achieved through impact force of water flow, so that the structure is simple and use is convenient. Tertiary mixing of sewage and the flocculating agent is achieved through a shaking mechanism, so that the purification efficiency is greatly improved, meanwhile, foul smells emitted by the sewage are blown into the purification mechanism through a fan, air purification is achieved, pollution to surrounding air is prevented, repeated stirring and mixing of the sewage and the flocculating agent are achieved through the same driving source, and the sewage treatment efficiency is improved. Use practicability is improved.

Owner:李彩华

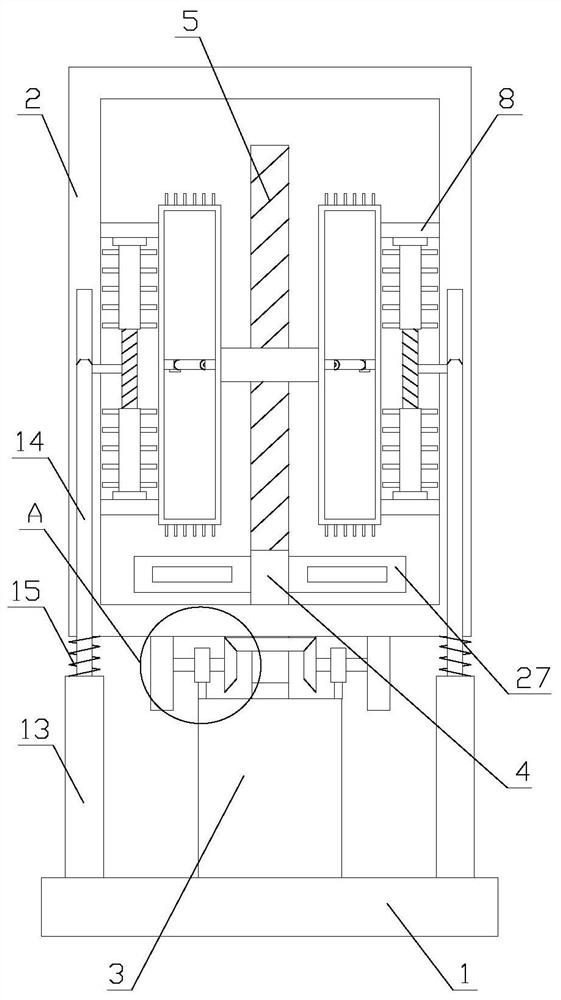

Omnibearing multifunctional mixing apparatus

InactiveCN107376696ARapid secondary mixingSecondary mixing is sufficientRotary stirring mixersTransportation and packagingEngineeringHybrid device

The invention relates to an omnibearing multifunctional mixing apparatus in the field of mixing equipment. The access doors are arranged at two sides of a mixing apparatus body, a latch is arranged below the access door, a locking device is arranged between the upper side of the access door and the mixing apparatus body, a stroke switch is arranged on the access door through cooperation, a feed inlet is arranged over the mixing apparatus body, a discharging door body is arranged below the mixing apparatus body, support bearings are respectively arranged at two sides of the mixing apparatus body, a rotor is arranged between the support bearings, a drive unit is arranged at the support bearing at any side of the mixing apparatus body through cooperation, and the drive unit is arranged by cooperating with the rotor; an auxiliary mixing device is arranged between the intermediate and the lower side of the mixing apparatus body, the auxiliary mixing device is transversely arranged at intervals, the bracing frames are arranged below the mixing apparatus body, the bracing frames are arranged at the two sides of the mixing apparatus body, the multifunctional mixing apparatus cooperates with the auxiliary mixing device with slant arrangement through the transversely arranged rotor, the materials can be rapidly mixed and stirred, and the production efficiency is increased.

Owner:任洁

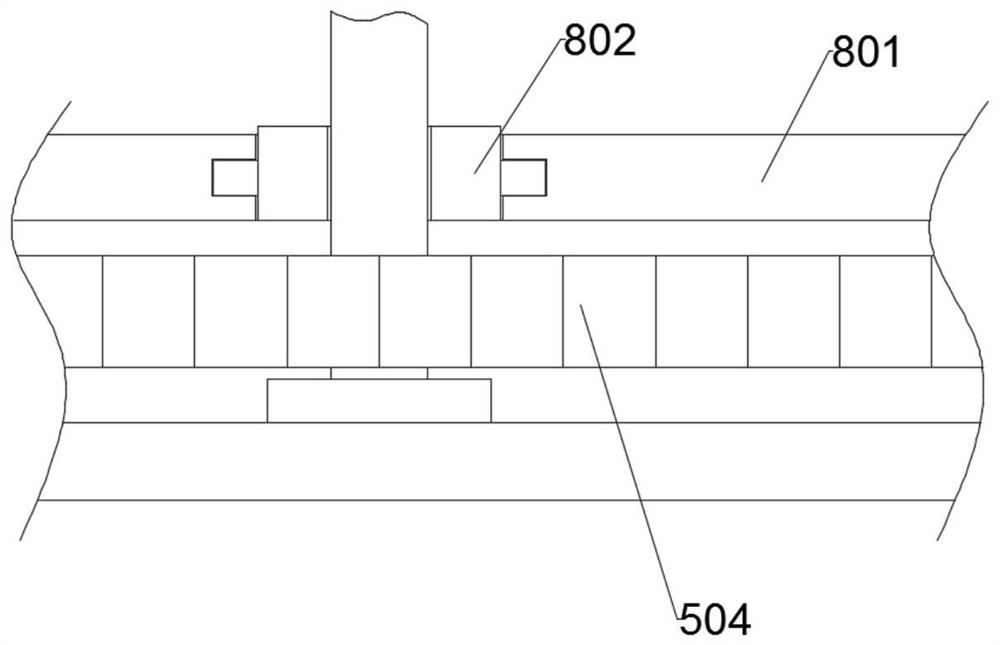

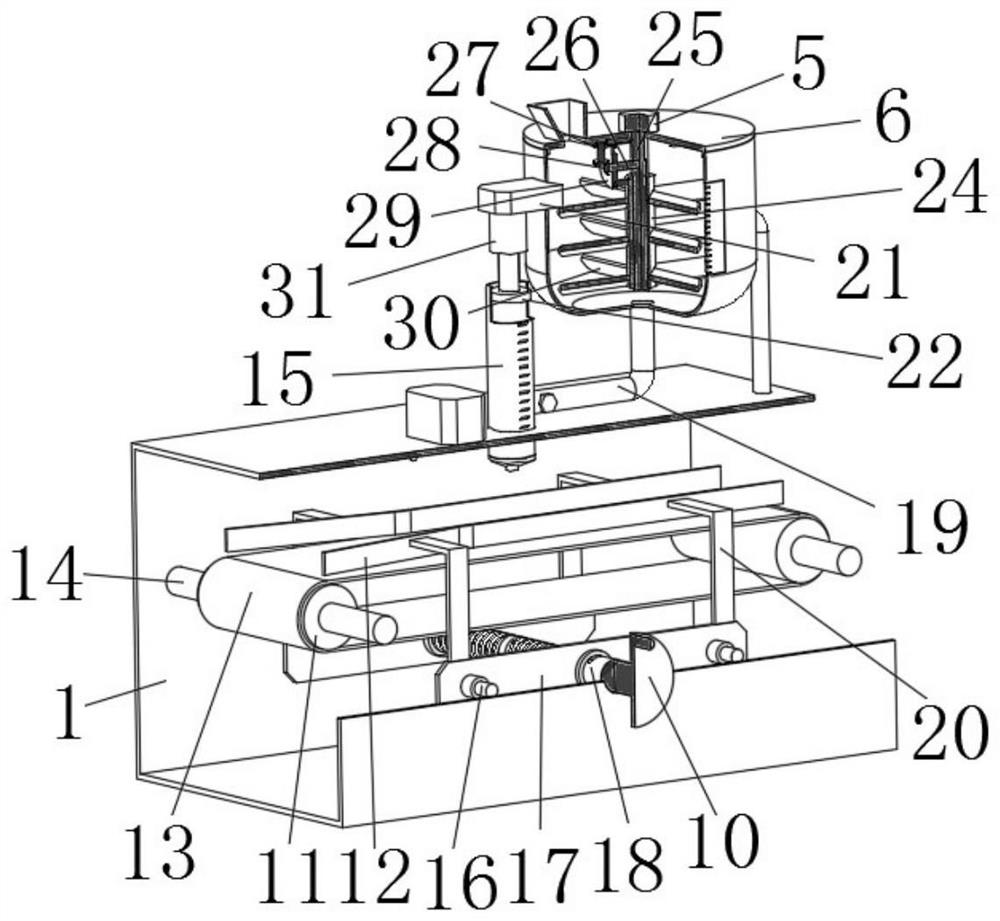

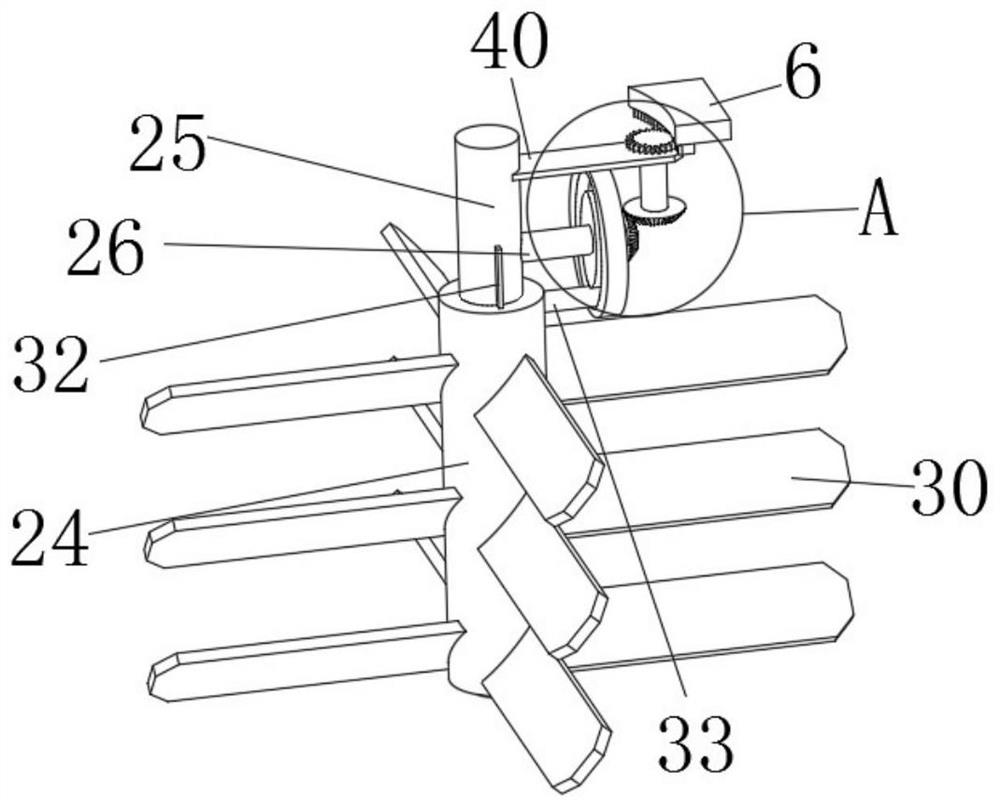

Packaging equipment capable of accurately and quantitatively packaging food with different weights

InactiveCN113978778AReasonable structureIncrease bottling speedRotary stirring mixersMixer accessoriesChemistryProcess engineering

The invention discloses packaging equipment capable of accurately and quantitatively packaging food with different weights, and relates to the technical field of food packaging equipment.The packaging equipment comprises a sterile box and a sensor fixedly connected to the top of the sterile box, and an accurate and quantitative extraction unit is installed at the top of the sterile box; and a glass bottle conveying unit and a glass bottle guiding unit are installed on the inner walls of the two sides of the sterile box, a sealing cover is fixedly connected to the top of the stirring barrel, a chili sauce stirring unit is installed in the sealing cover, and the chili sauce stirring unit is located in the stirring barrel. Chili sauce can be accurately and quantitatively extracted through the arranged accurate quantitative extraction unit, it is ensured that the chili sauce bottling amount is consistent, automatic stirring of the chili sauce can be achieved through the arranged chili sauce stirring unit, the chili sauce can be stirred more evenly, and the accuracy of the chili sauce amount in each bottle is improved; and uneven component caused by blockage in the chili sauce bottling process is avoided.

Owner:姚佳瑶

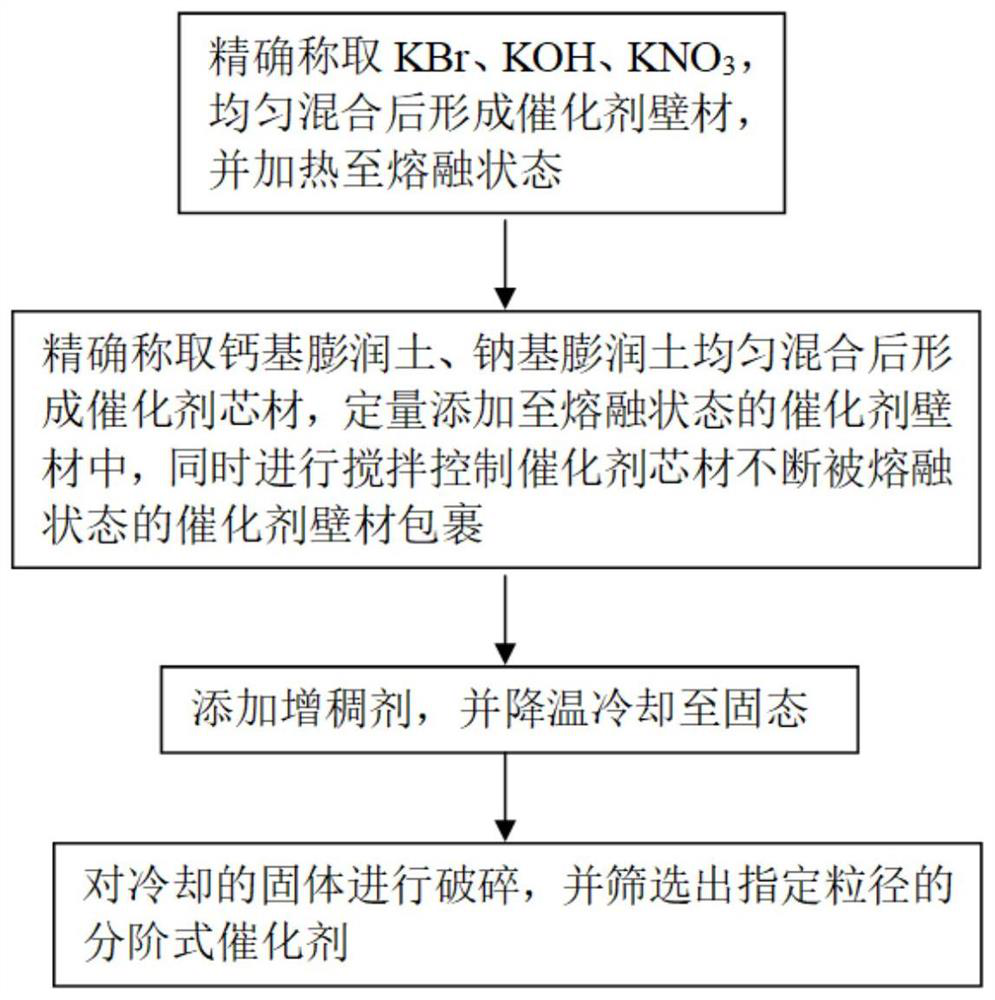

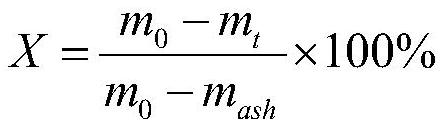

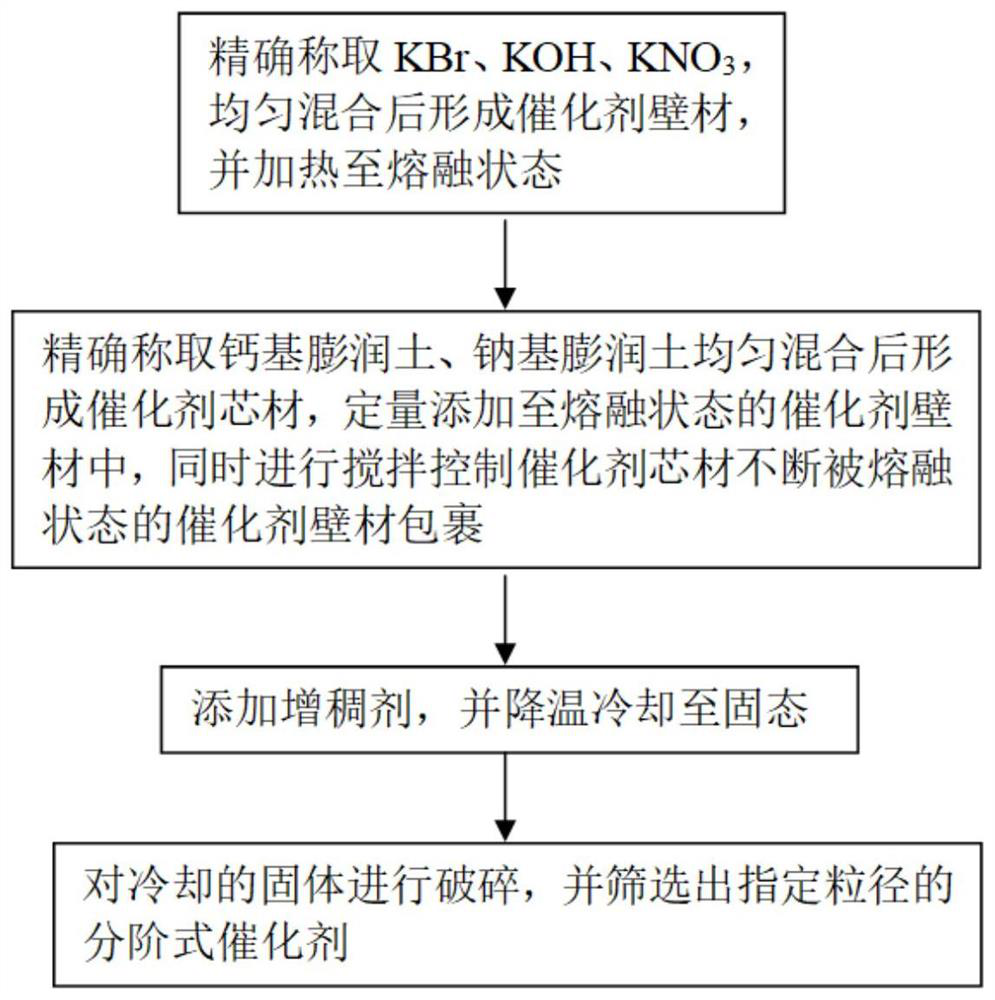

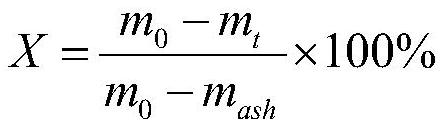

Staged catalyst for abandoned coal gasification operation in fire zone, and preparation method thereof

ActiveCN112044464ARaw materials are readily availableLow priceCatalyst activation/preparationGasification processes detailsPtru catalystSodium Bentonite

The invention discloses a staged catalyst for abandoned coal gasification operation in a fire zone, and a preparation method thereof. The staged catalyst comprises a catalyst core material and a catalyst wall material coating the catalyst core material, wherein the catalyst core material is prepared from 60-70 wt% of calcium bentonite and 30-40 wt% of sodium bentonite; and the catalyst wall material comprises, by weight, 8-10% of KBr, 30-40% of KOH and 50-60% of KNO3. The preparation raw materials of the staged catalyst for the abandoned coal gasification operation in the fire zone are simple,easy to obtain, low in price, green, safe and pollution-free, the preparation process is simple, and the staged catalyst plays a role in catalysis by the catalyst wall material and the catalyst corematerial in the earlier stage and later stage of gasification according to the temperature change in the gasification reaction process; and high-efficiency staged catalytic gasification of the fire zone abandoned coal is realized, and the fire zone abandoned coal subjected to fire area oxidation deactivation can be effectively gasified and utilized again so as to reduce waste of a large amount ofcoal resources.

Owner:CHINA UNIV OF MINING & TECH

Pesticide blending device

ActiveCN103651318ASolve for uniformitySolve efficiency problemsFlow mixersMixer accessoriesStorage poolPesticide

The invention discloses a pesticide blending device which comprises a pesticide spraying machine, a pesticide storage pool and a pesticide blending pool. The pesticide storage pool is communicated with the outside world through the pesticide spraying machine, the bottom of the pesticide storage pool is an inclined plane arranged obliquely relative to the horizontal plane, the depth of the pesticide storage pool is made to be increased gradually from one side to the other side, and the communication position of the pesticide spraying machine and the pesticide storage pool is located in one side, with the largest depth, of the pesticide storage pool. The pesticide blending pool is provided with a water filling system, and is arranged above the pesticide storage pool, and the bottom of the pesticide blending pool is communicated to the pesticide storage pool through at least one pesticide outlet pipe. The pesticide blending device solves the problems that the pesticide spraying machine is separated from a pesticide spraying system, the pesticide is blended unevenly, and blending efficiency is low, the pesticide blending device is durable, saves labor, increases efficiency, and is complete in function, easy, convenient and safe to operate.

Owner:GUANGXI JINSUI AGRICULTURE GROUP CO LTD

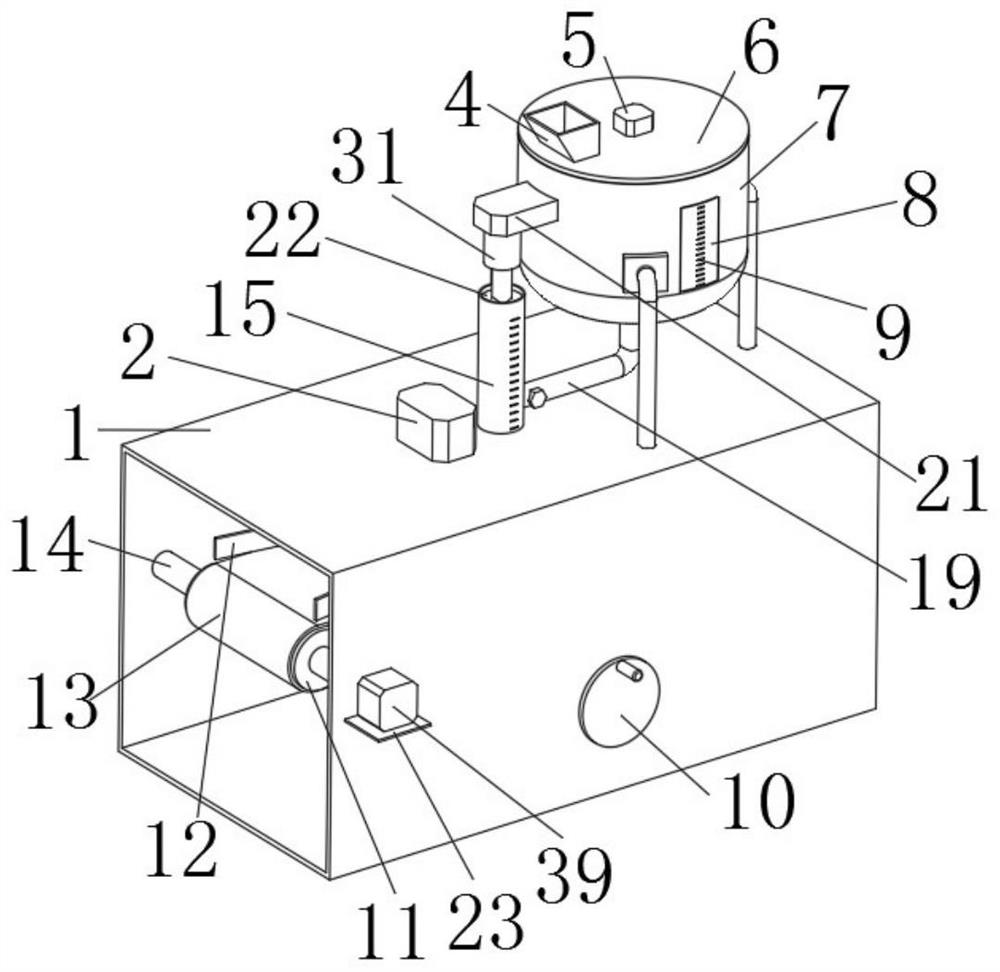

Stock solution stirring device

InactiveCN112999945AAchieve primary mixingAchieve secondary mixingTransportation and packagingMixer accessoriesElectric machineryEngineering

The invention relates to a stock solution stirring device which comprises a base, a fixing box, a supporting mechanism and a driving mechanism, the driving mechanism comprises a motor, a rotating rod, a first lead screw and a mixing assembly, and the supporting mechanism comprises a supporting assembly, a vibrating assembly and a stirring assembly. According to the stirring device for the stock solution, vibration stirring of a main body and primary stirring of the main body are achieved through cooperation of the restoring force of a cam and the restoring force of a spring, cross-flow stirring of the main body, secondary stirring of the main body are achieved through discharging of the bottom end of the piston barrel, and spraying of the main body is achieved through discharging of the top end of the piston barrel; mixing stirring of the main body, eg the third-grade stirring is achieved through moving of the main body to the top end of the fixing box through the piston barrel, rotating of a threaded barrel, eg the rotation of a stirring rod is realized through movement of a positioning rod, fourth-grade stirring on the main body is realized; linkage of a plurality of mechanisms is achieved through a same driving source, and the use practicability is improved.

Owner:南京鸿音工程技术有限公司

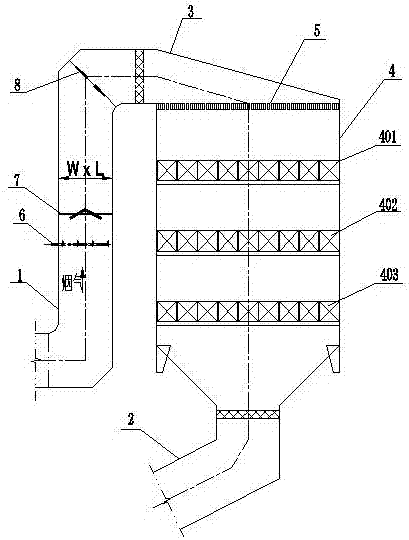

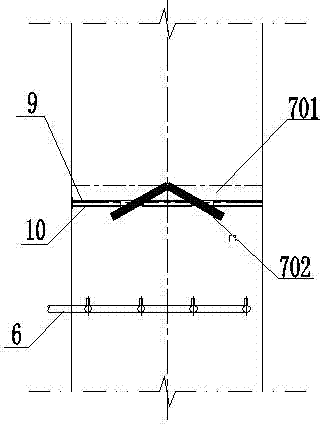

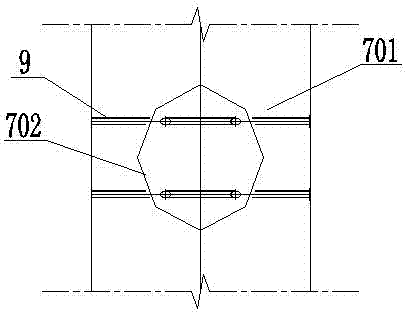

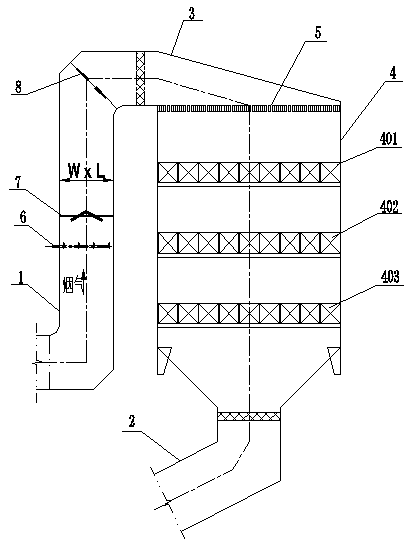

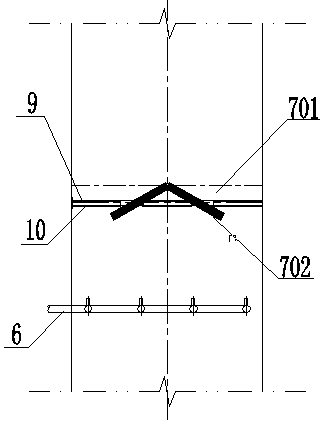

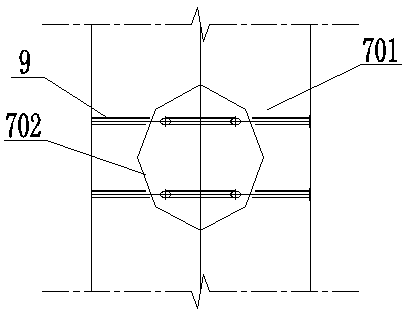

Efficient mixing system conducive to mixing denitration

ActiveCN107081058AImprove mix qualityReduce escapeGas treatmentDispersed particle separationHybrid systemSheet steel

The invention discloses an efficient mixing system conducive to mixing denitration, comprising an efficient mixing system. The efficient mixing system comprises a first-class efficient mixing device and a second-class efficient mixing device, wherein the first-class efficient mixing device comprises a plurality of first-class efficient mixing elements, each first-class efficient mixing element comprises a seamless steel pipe and a folded circular steel plate, winged edges of both sides of the folded circular steel plate simultaneously penetrate through the seamless steel pipe, and the second-class efficient mixing device comprises a plurality of second-class efficient mixing elements, each second-class efficient mixing element comprises a seamless steel pipe and a circular steel plate, the circular steel plate penetrates through the seamless steel pipe. Through an idea of thinking from the part to the whole, a flow field of the denitration is optimized, the position, type and series of installing the efficient mixing system are determined, and the mixed quality of ammonia flue gas is improved, so that the anti-interference of the denitration system to the change of an incoming flow working condition is improved, the safe and economic operation of an unit is ensured and the existing technology problems are solved.

Owner:成都融科能源环境工程有限公司

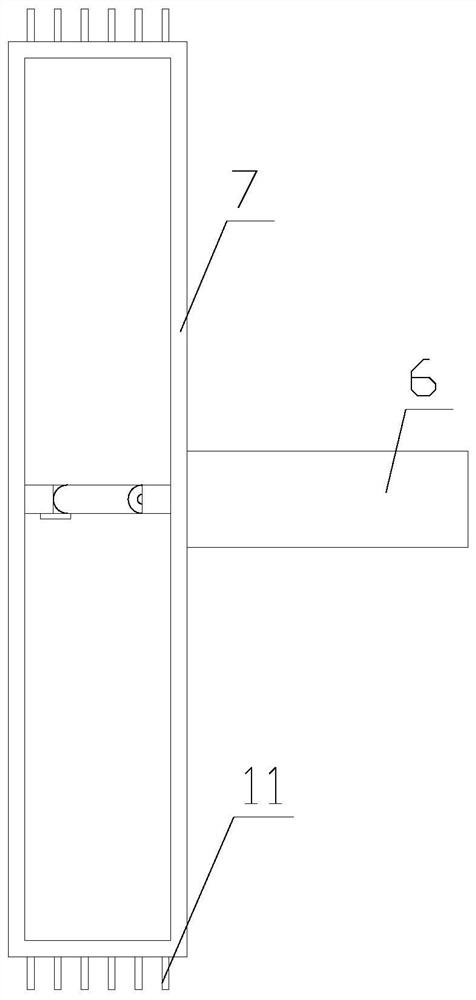

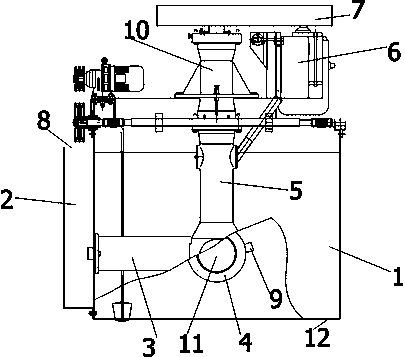

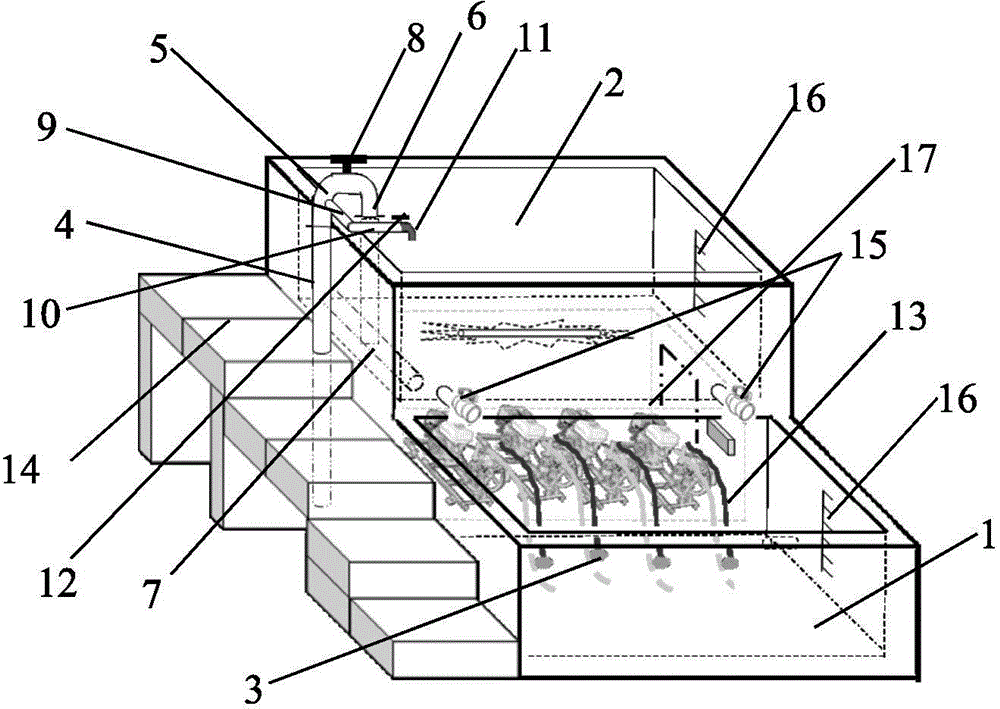

Full-hybrid mining flotation machine

InactiveCN107855224AAchieve secondary mixingInhibit productionFlotationMechanical engineeringEngineering

The invention discloses a full-hybrid mining flotation machine which comprises a base, a feeding chute, a feeding pipe, an annular bin, a stirring pipe, a fan, an air inlet, a long air port, an agentport and a scraper device. The feeding chute is designed on the lower portion of the base, provided with the long air port and connected with the feeding pipe which is connected with the annular bin,a rotating leaf is designed in the middle of the annular bin, the annular bin is provided with the agent port and connected with the stirring pipe which is connected with the fan, and the air inlet isarranged on the upper portion of the fan. The full-hybrid mining flotation machine is high in screening accuracy and production efficiency and has the advantages of simple structure, reasonable arrangement and low manufacturing cost.

Owner:杨铭坤

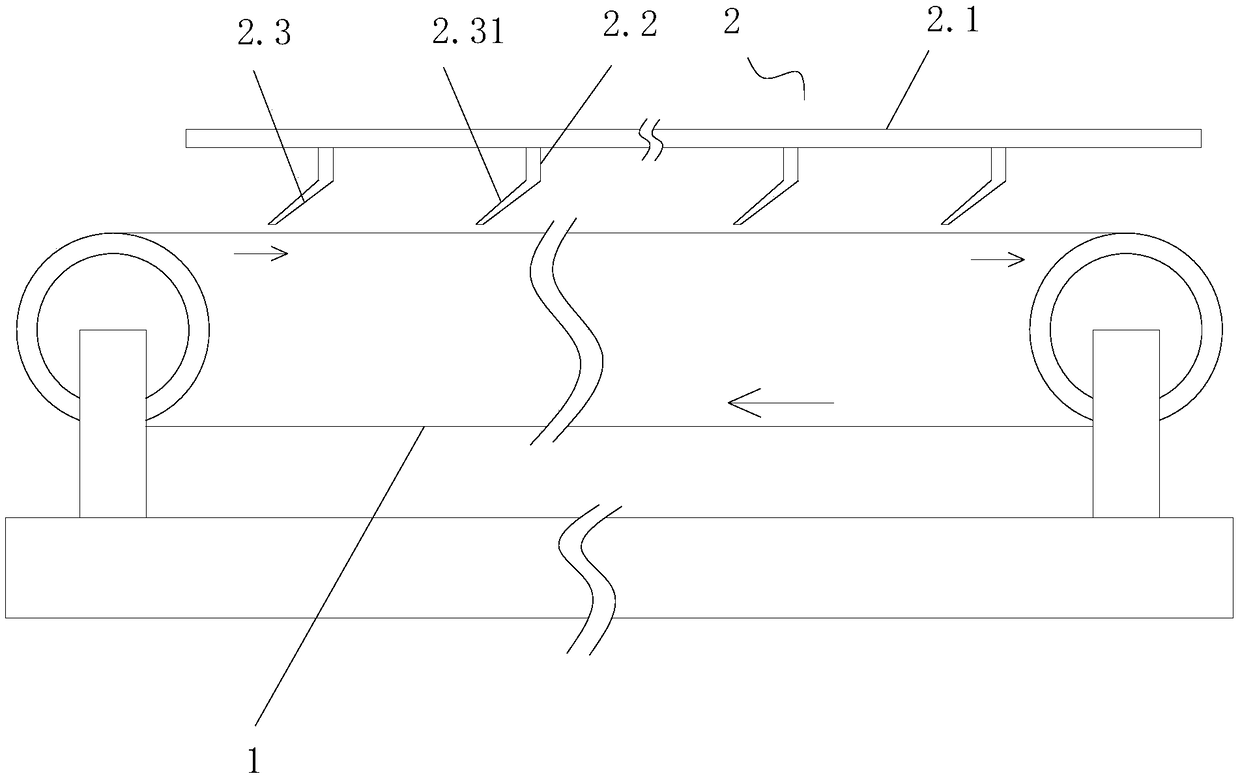

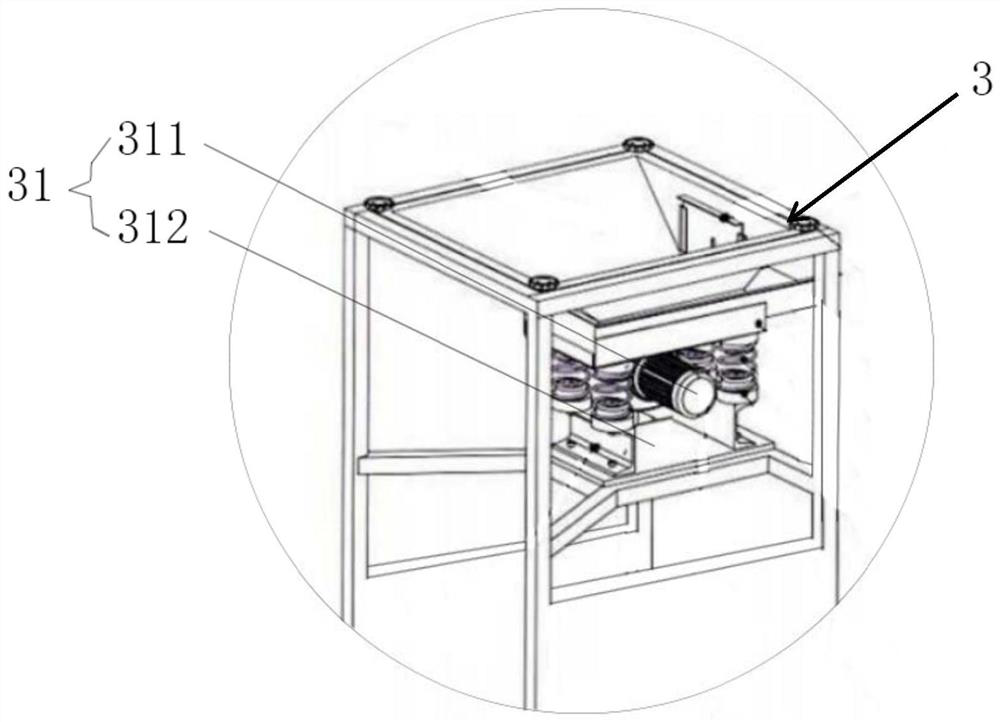

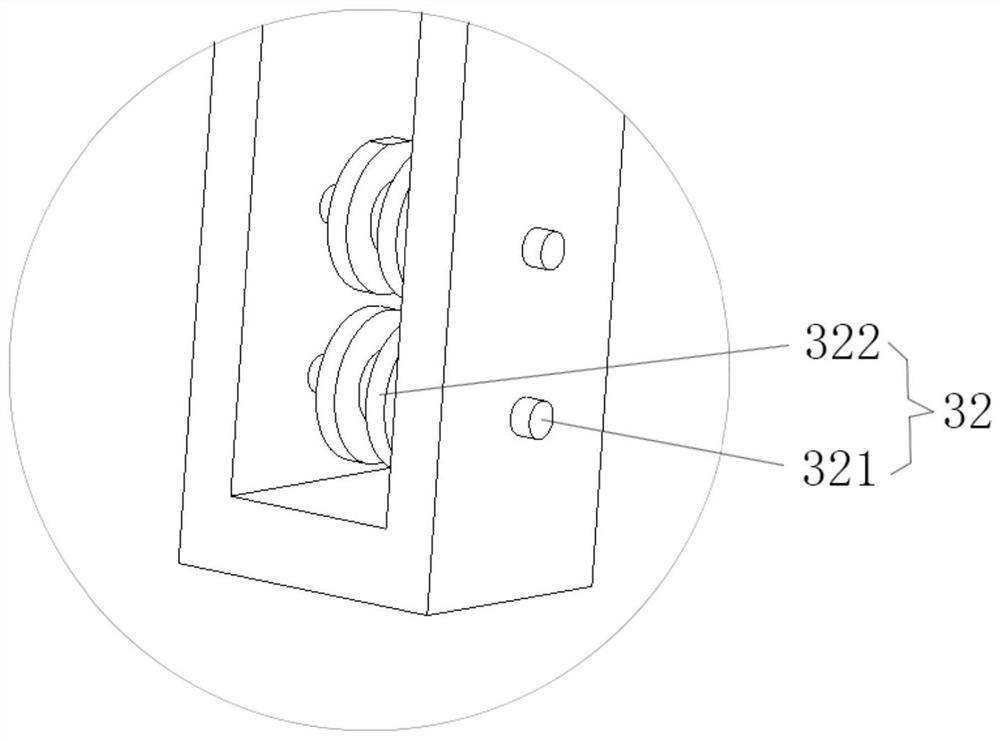

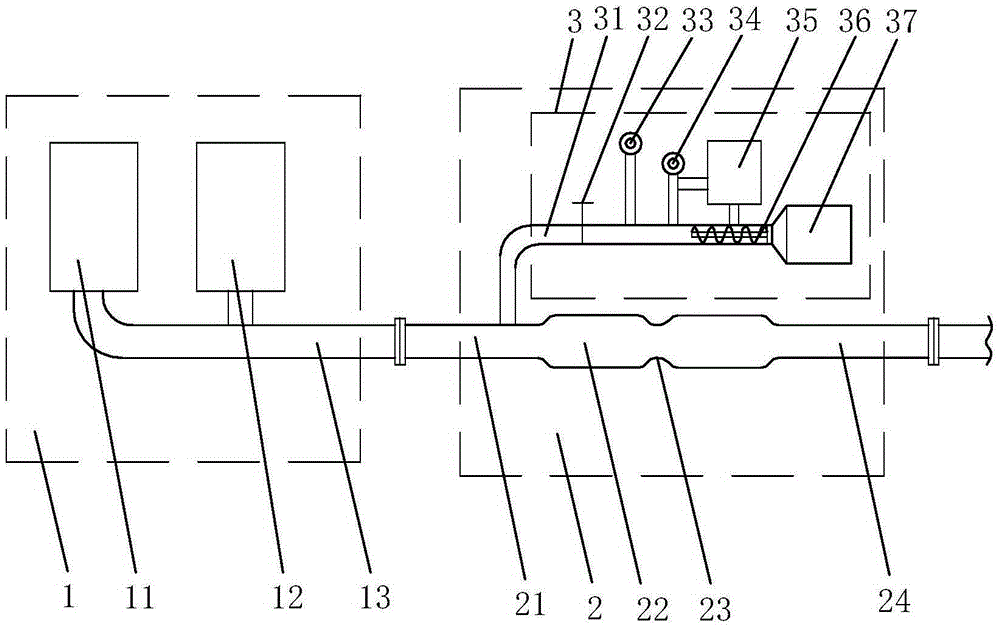

Conveying system

InactiveCN108861315AAchieve secondary mixingReduce the probability of homogeneous clusteringConveyorsMixersMixed materialsMechanical engineering

The invention discloses a conveying system which is used for conveying mixed materials. The conveying system comprises a conveying belt, and further comprises a secondary mixing assembly which comprises a support and a plurality of mixing pieces; the mixing pieces are all connected to the support through connecting pieces; the plurality of mixing pieces are arranged above the conveying belt in parallel; mixing faces are arranged on the mixing pieces, and the mixing faces and the conveying belt are obliquely arranged; and the mixing pieces are on the conveying travel of the mixed materials on the conveying belt, and part of the mixed materials move to the other end from one end of the mixing faces in the conveying process. According to the conveying system provided by the embodiment, in theconveying process of the materials, the mixing pieces ceaselessly stir the materials located at the bottom to the top, in this way, secondary mixing of the materials in the conveying process is achieved, and the probability that materials in the same category are gathered in the conveying process of the conveying belt is lowered.

Owner:宋世梅

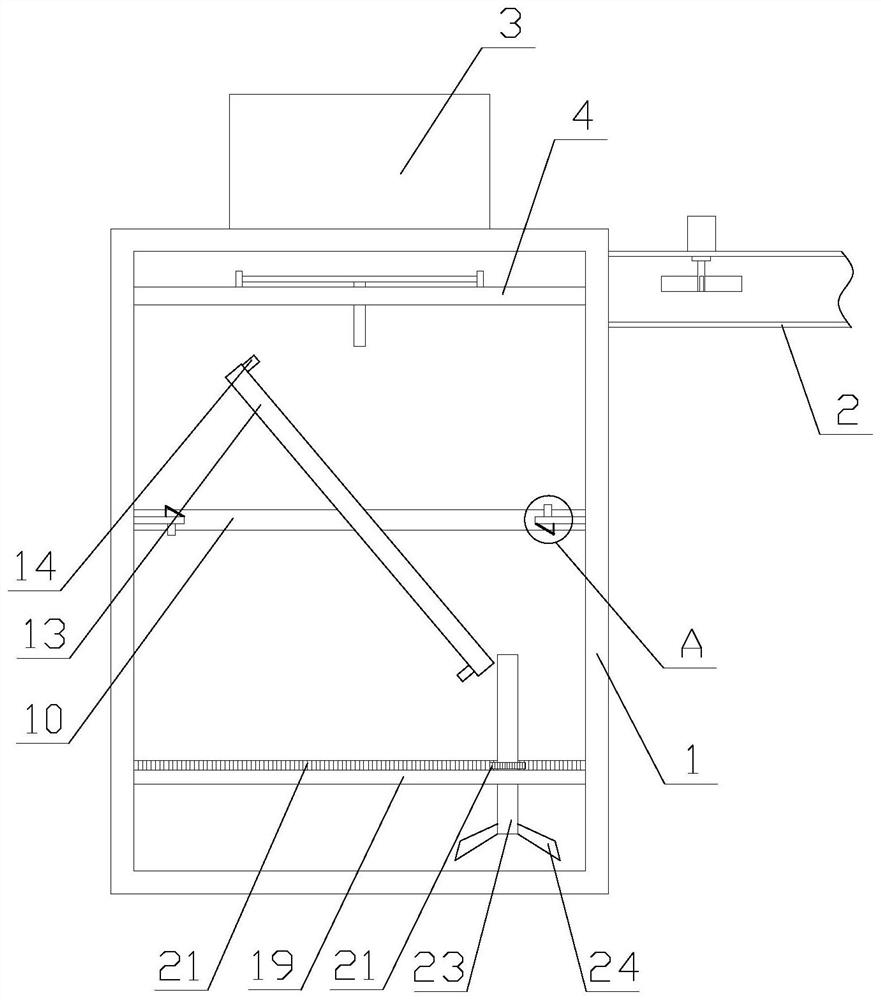

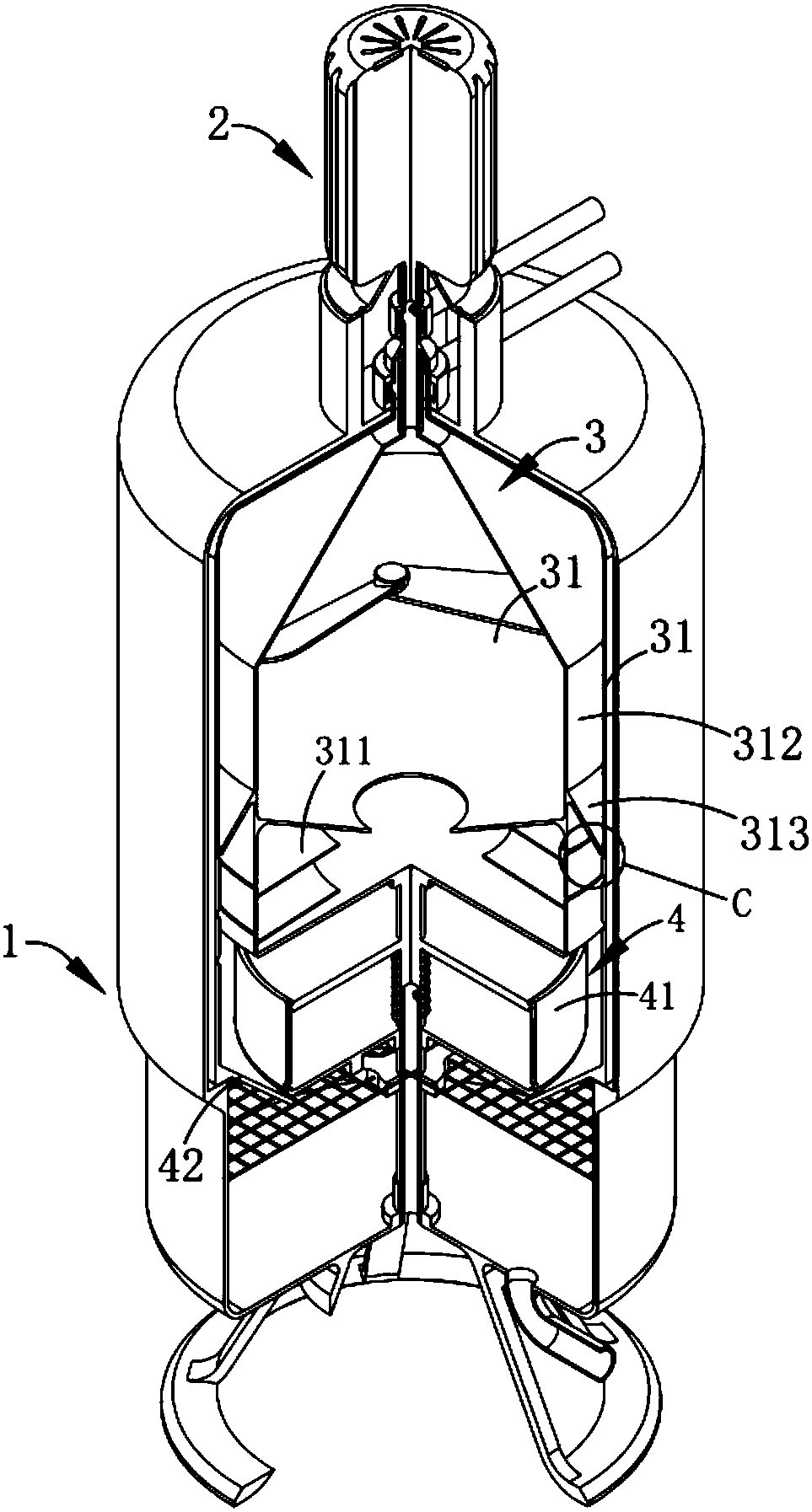

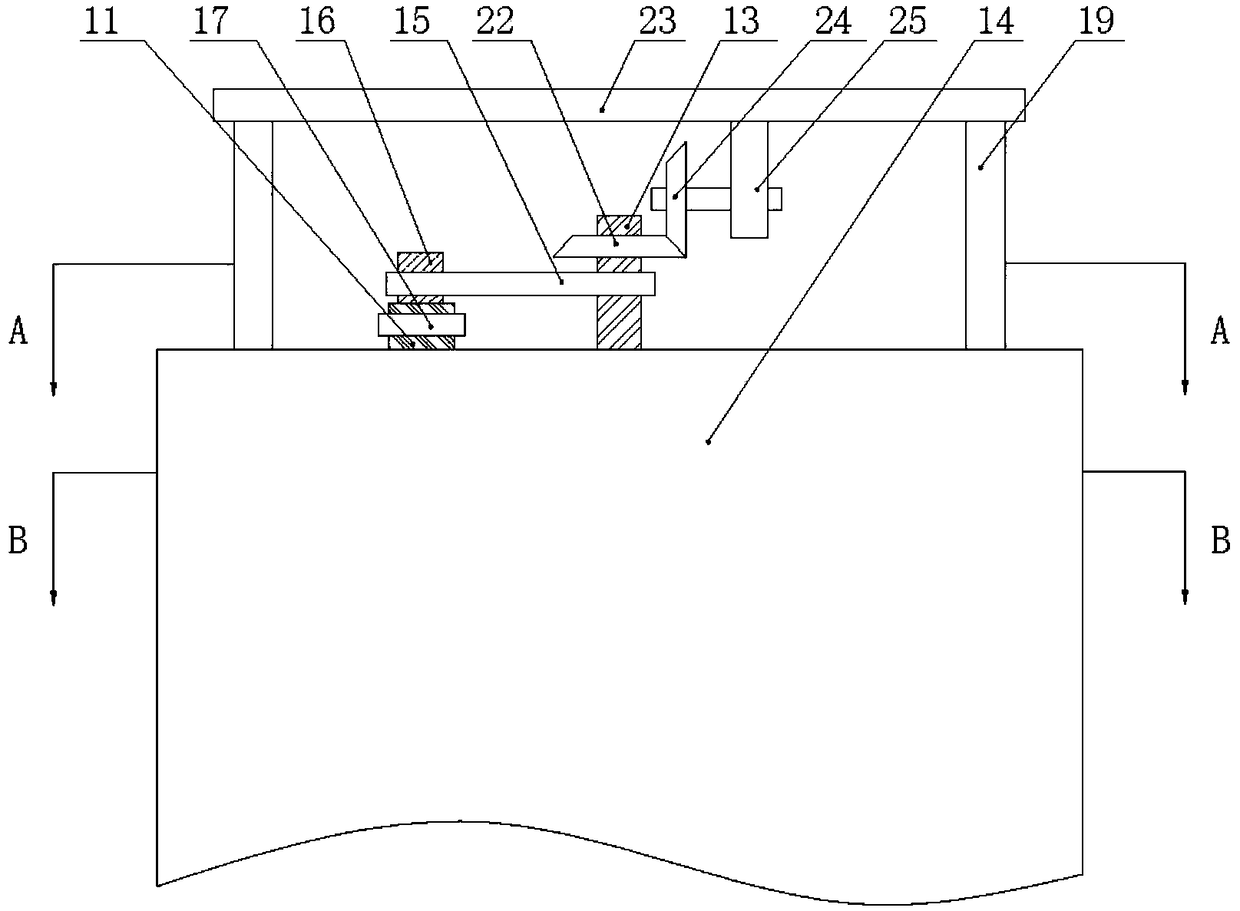

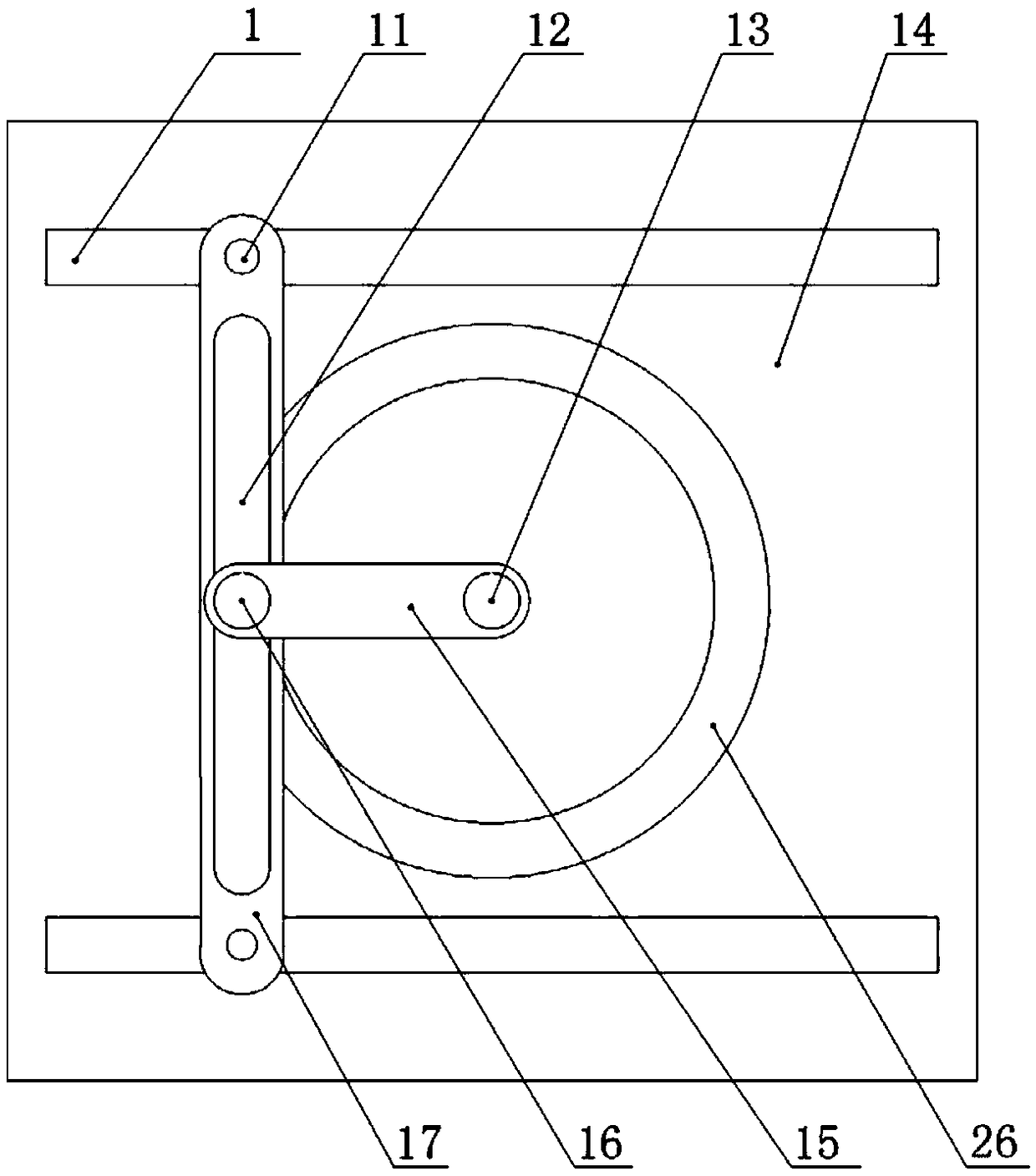

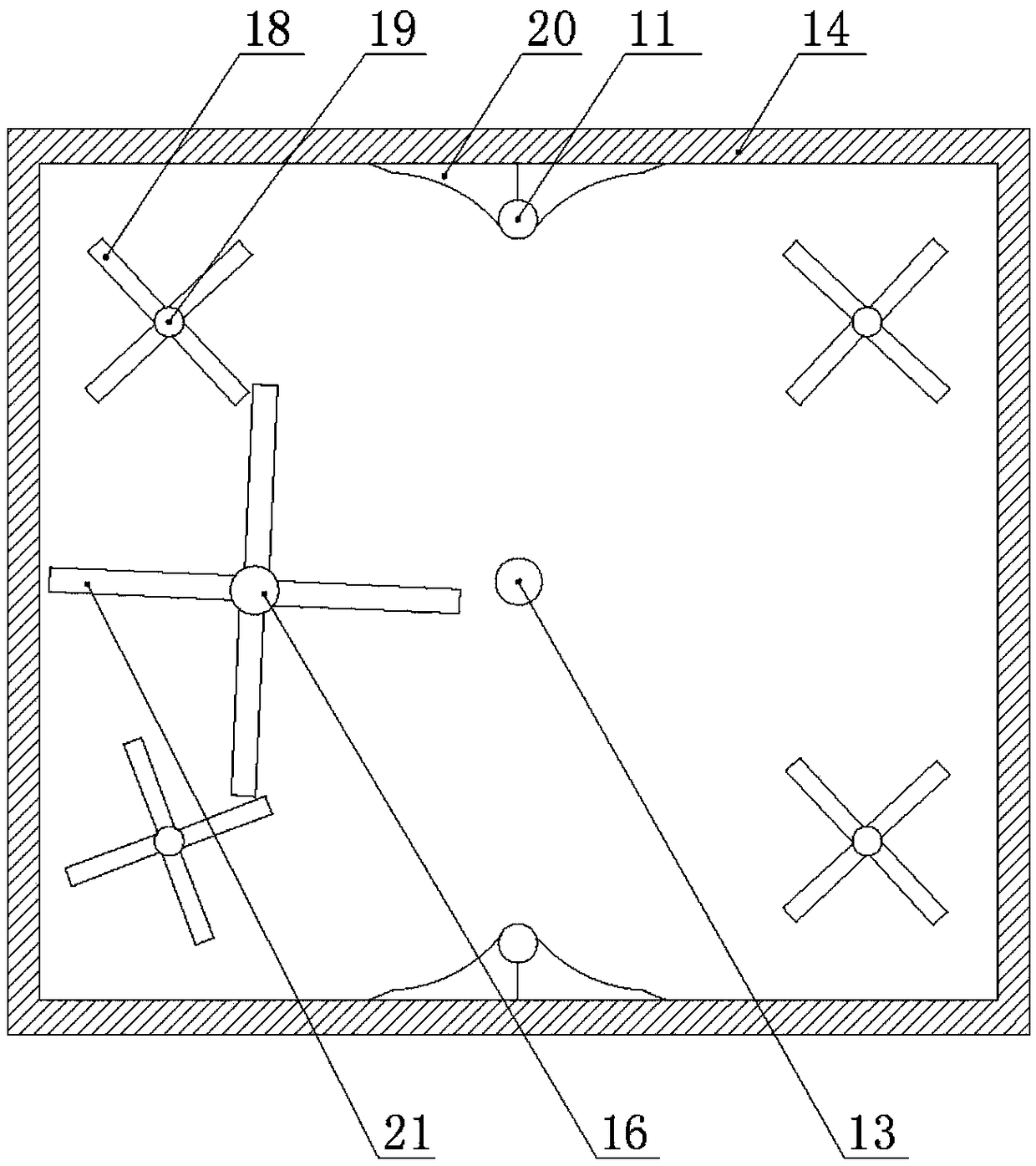

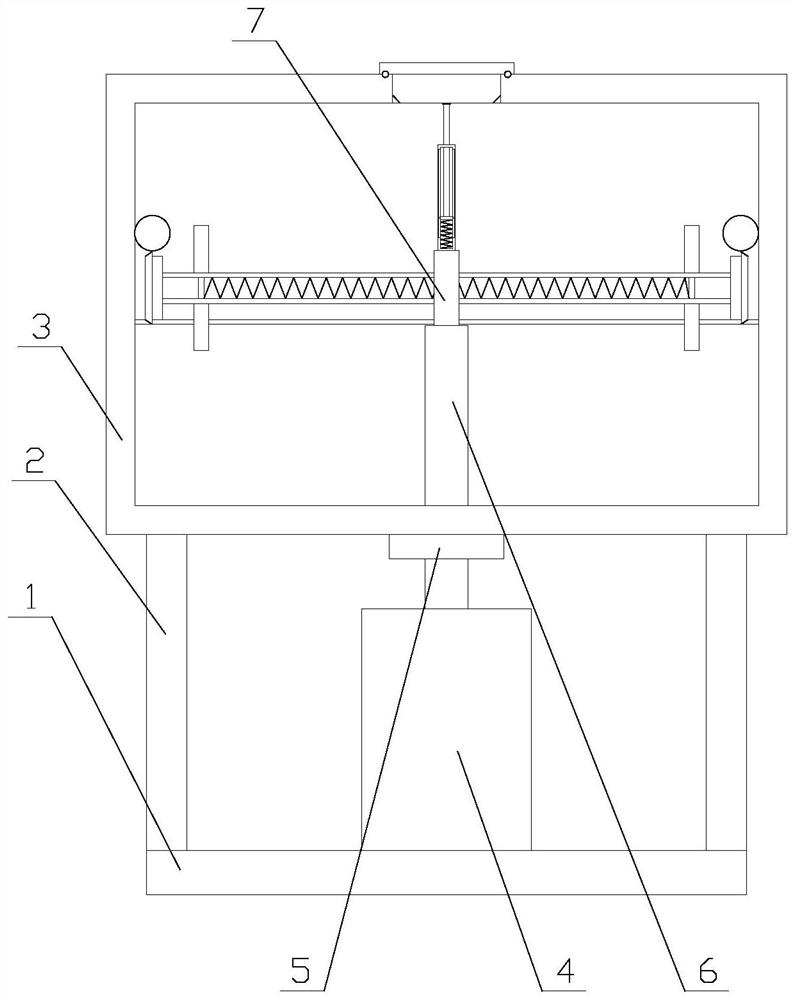

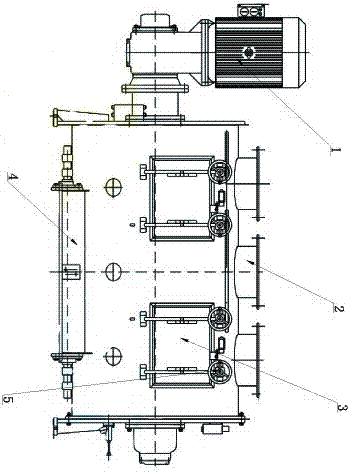

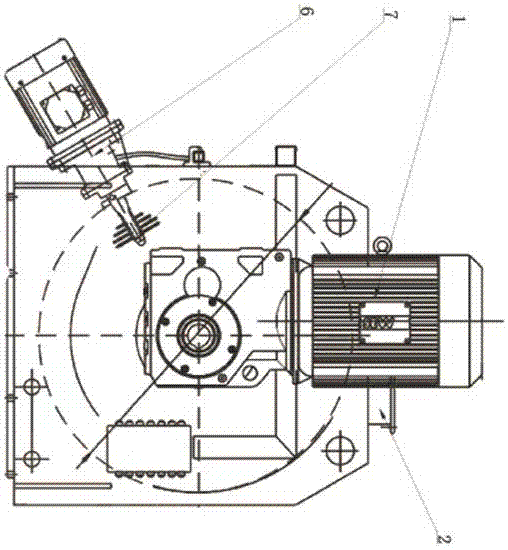

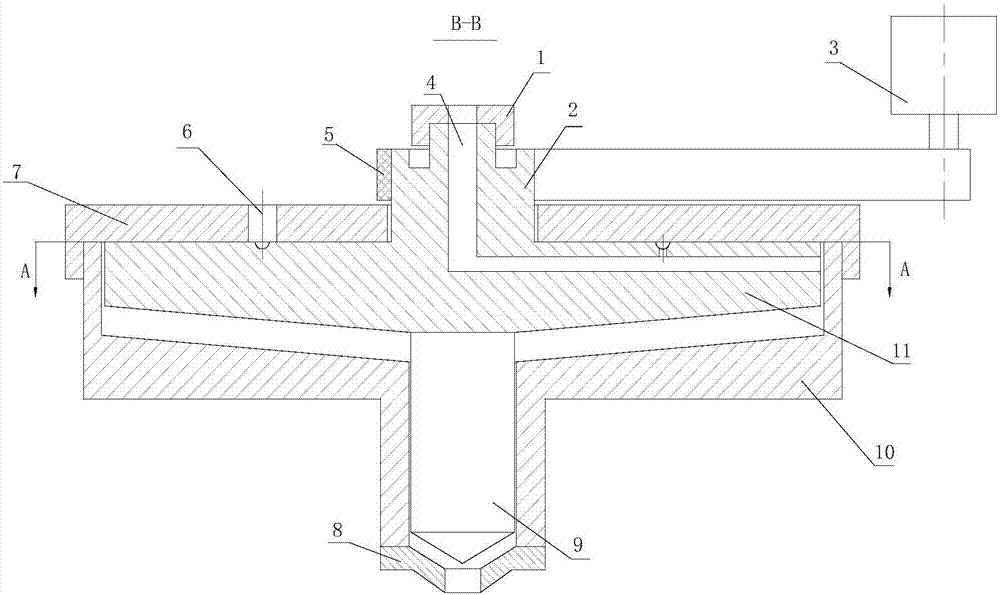

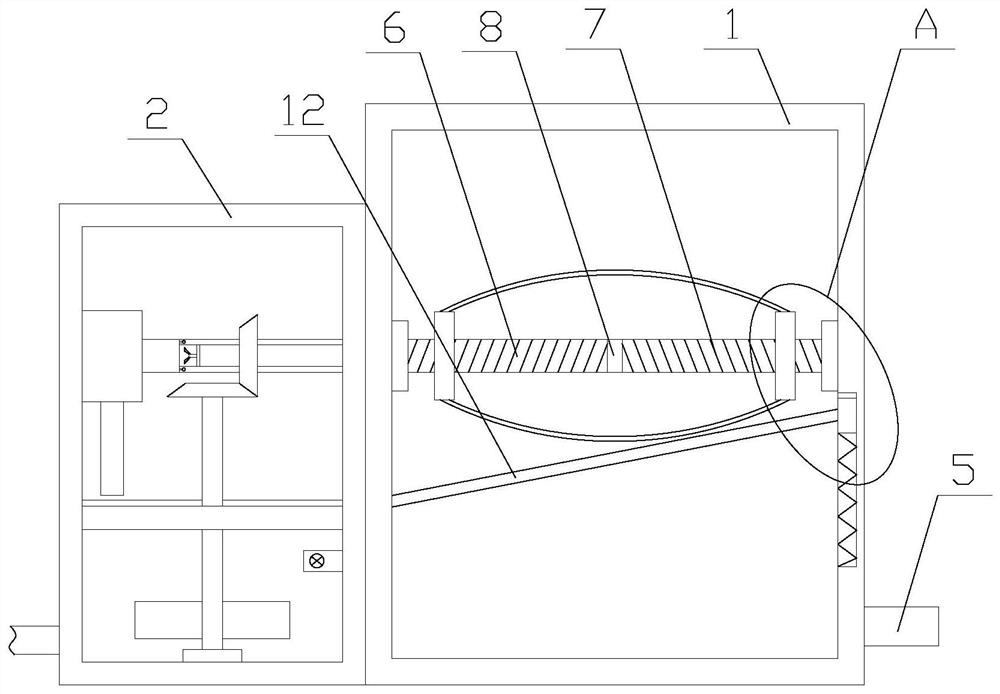

A kind of fluid mixing method and high-speed centrifugal fluid mixing device

ActiveCN105664777BWell mixedImprove mixing efficiencyTransportation and packagingMixersCircular discMicrometer

The invention relates to a fluid mixing method and a fluid mixing device, in particular to a method and a device for mixing multi-component fluids by using pulse pressure and high-speed centrifugal force. The invention proposes a high-speed centrifugal fluid mixing device, which consists of a centrifugal shear mixing disk (11) with a radial flow channel (12) and an annular flow channel (13), a barrel (10), a screw (9) , nose (8) and end cover (7) form. The transmission system is made up of frequency conversion motor (3), synchronous belt (5), synchronous belt pulley (2). Other flow channel systems consist of a rotary joint (1) leading into component A, a large hole (6) connecting the pipeline of component B, an annular flow channel (13), and a small hole through which component B enters the radial flow channel (12) (14) COMPOSITION. The invention can improve the quality and efficiency of fluid mixing, is especially suitable for the mixing of micron and nanoscale materials, and improves the dispersion quality of micronanoscale materials in the continuous phase.

Owner:QINGDAO UNIV OF SCI & TECH

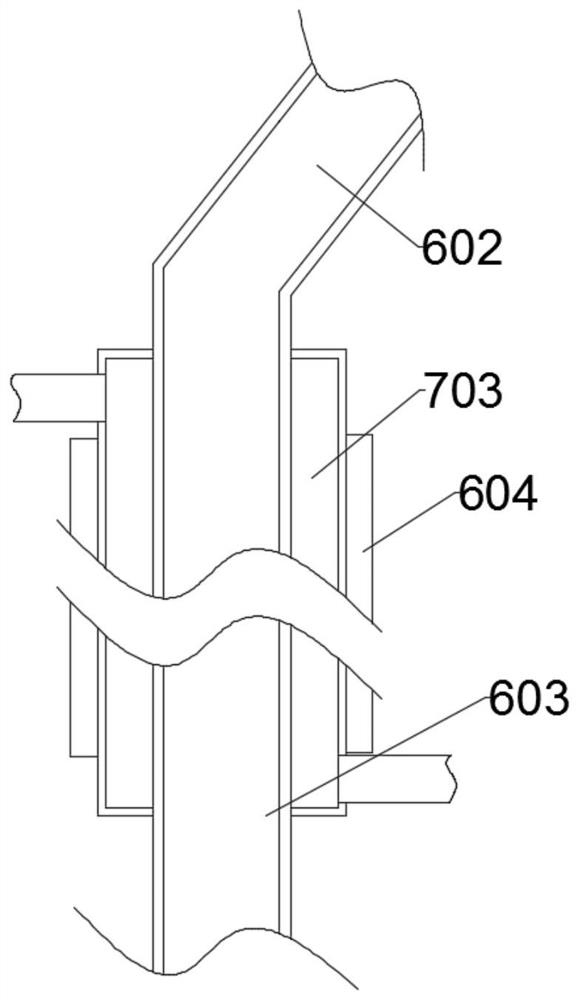

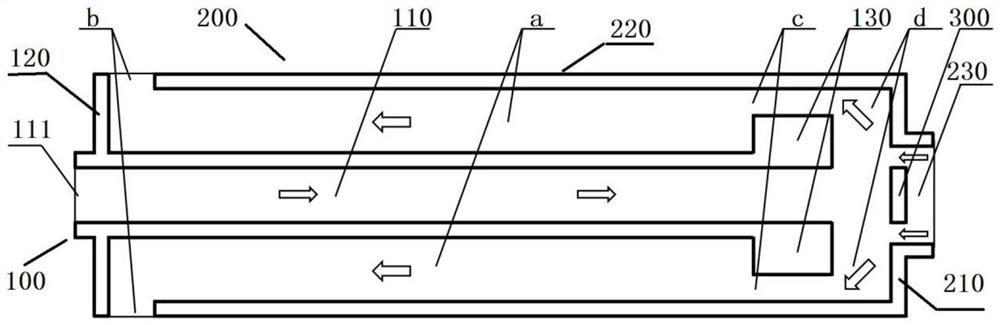

Refrigeration system and liquid dispenser thereof

ActiveCN106403406AIncrease flow rateAchieve mix uniformityFluid circulation arrangementRefrigerantEvaporator

The invention discloses a refrigeration system and a liquid dispenser thereof. The liquid dispenser comprises an inner pipe, a middle pipe and an outer pipe, wherein the chamber of the inner pipe comprises a first gradually-reducing part which is gradually reduced along the cross section from a first end to a second end of the inner pipe; a first interlayer chamber is formed between the inner wall of the middle pipe and the outer wall of the inner pipe; the first interlayer chamber comprises a second gradually-reducing part which is gradually reduced along the cross section from the first end to the second end of the first interlayer chamber; the inner pipe is provided with a liquid dispensing hole so that a refrigerant mixed through the first gradually-reducing part can enter the second gradually-reducing part via the liquid dispensing hole; the outer pipe sleeves the outer layer of the middle pipe; a second interlayer chamber is formed between the inner wall of the outer pipe and the outer wall of the middle pipe; the first end of the outer pipe is connected to the outer wall of the inner pipe through a bending plate; a liquid dispensing tray is connected between the second end of the outer pipe and the outer wall of the middle pipe. Due to the arrangement, the liquid dispenser of the refrigeration system disclosed by the invention is capable of improving the gas and liquid mixing uniformity of the liquid dispenser so as to guarantee the uniformity of the refrigerant which is dispensed into an evaporator.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

A high-efficiency multifunctional foam soap dispenser

ActiveCN105708375BIngenious structural designSimple structural designHolders and dispensersEngineeringSoap dispenser

The invention discloses an efficient multifunctional foam soap dispenser. The soap dispenser comprises a shell with a soap liquid outlet, wherein a mixing-diluting-conveying device, a foaming device, a driving extraction device, a raw material cavity and a water cavity are arranged in the shell; the mixing-diluting-conveying device is connected with the foaming device, and the driving extraction device is connected with the mixing-diluting-conveying device and the foaming device and is used as the power source of the mixing-diluting-conveying device and the foaming device at the same time. The soap dispenser provided by the invention is provided with a mixing groove for realizing the proportion mixing of the water and raw materials; and meanwhile, a mixing crown and a mixing straight tooth are engaged to realize the second mixing of the raw materials; the upper part of the mixing crown is provided with stirring blades for easily scraping the raw materials to the mixing groove so that the raw material is mixed more uniformly, the raw materials can be precisely controlled, and the soap liquid outlet effect is good; furthermore, the whole soap dispenser is smart and simple in structure design, the whole soap dispenser can be controlled while only triggering a pressing plate of a trigger device, the operation is simple, the tedious process is avoided, and the working efficiency is high.

Owner:GUANGZHOU OH BUBBLE SCI & TECH CO LTD

A step-by-step catalyst for waste coal gasification in fire areas and its preparation method

ActiveCN112044464BRaw materials are readily availableLow priceCatalyst activation/preparationGasification processes detailsPtru catalystSodium Bentonite

The invention discloses a step-by-step catalyst used for waste coal gasification in a fire area and a preparation method thereof. The step-by-step catalyst includes a catalyst core material and a catalyst wall material coated outside the catalyst core material; the catalyst core material consists of the following Composition of bentonite raw materials in weight percentage: 60-70% calcium-based bentonite, 30-40% sodium-based bentonite; catalyst wall material is 8-10% KBr, 30-40% KOH, 50-60% KNO 3 . The preparation raw materials of the hierarchical catalyst used in the waste coal gasification operation in the fire area are simple and easy to obtain, the price is cheap, green, safe and pollution-free, and the preparation process is simple. The wall material and the catalyst core material play a catalytic role in the early and late stages of gasification, realizing the efficient step-by-step catalytic gasification of the abandoned coal in the fire area, and can effectively re-gasify the abandoned coal in the fire area that has undergone oxidation deactivation in the fire area. Reduce a lot of waste of coal resources.

Owner:CHINA UNIV OF MINING & TECH

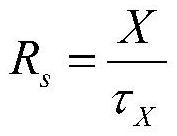

Zipper tooth, preparation method and zipper with same

InactiveCN109093930AWell mixedAchieve secondary mixingDomestic slide fastenersEngineeringHigh pressure

The invention discloses a preparation method of a plastic zipper tooth with circulating color points. Non-fusible toner and plastic colloidal particle raw materials are uniformly mixed according to aweight ratio of 1:90 to 1:110, the mixture is automatically added into a charging barrel of an injection molding machine for high-temperature melting by adopting spiral type feeding equipment and is injected into a sealed tooth mold under high pressure for solidification molding after being melted, and the plastic zipper tooth with the irregular circulating color points is obtained. The preparation method is simple, and the prepared plastic zipper tooth is full in teeth, smooth in surface and low in defect rate. The plastic zipper tooth prepared by the preparation method is made into a zipperfor being matched with ready-to-wear garments, the problem of single color of a traditional zipper is solved, and the zipper is more attractive in vision and is deeply liked by people.

Owner:德诚拉链(东莞)有限公司

A pesticide mixing device

ActiveCN103651318BSolve for uniformitySolve efficiency problemsFlow mixersMixer accessoriesStorage poolPesticide

The invention discloses a pesticide blending device which comprises a pesticide spraying machine, a pesticide storage pool and a pesticide blending pool. The pesticide storage pool is communicated with the outside world through the pesticide spraying machine, the bottom of the pesticide storage pool is an inclined plane arranged obliquely relative to the horizontal plane, the depth of the pesticide storage pool is made to be increased gradually from one side to the other side, and the communication position of the pesticide spraying machine and the pesticide storage pool is located in one side, with the largest depth, of the pesticide storage pool. The pesticide blending pool is provided with a water filling system, and is arranged above the pesticide storage pool, and the bottom of the pesticide blending pool is communicated to the pesticide storage pool through at least one pesticide outlet pipe. The pesticide blending device solves the problems that the pesticide spraying machine is separated from a pesticide spraying system, the pesticide is blended unevenly, and blending efficiency is low, the pesticide blending device is durable, saves labor, increases efficiency, and is complete in function, easy, convenient and safe to operate.

Owner:GUANGXI JINSUI AGRICULTURE GROUP CO LTD

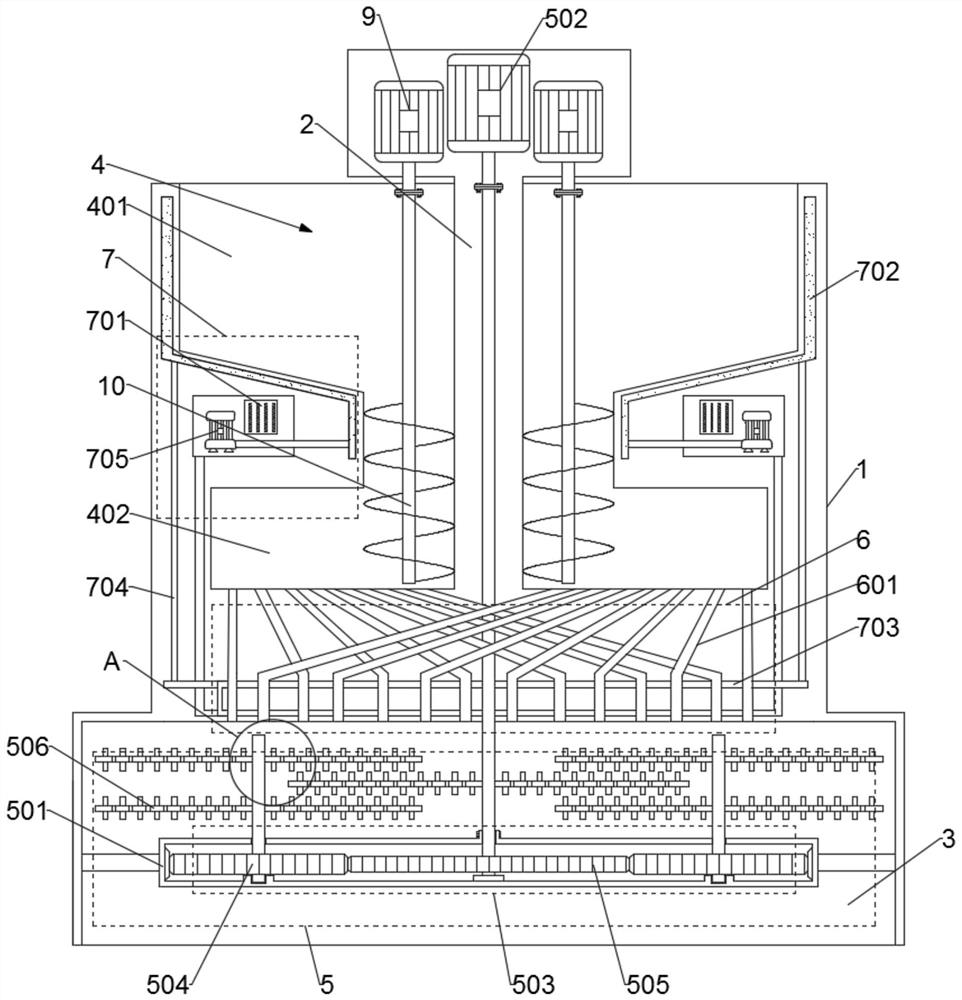

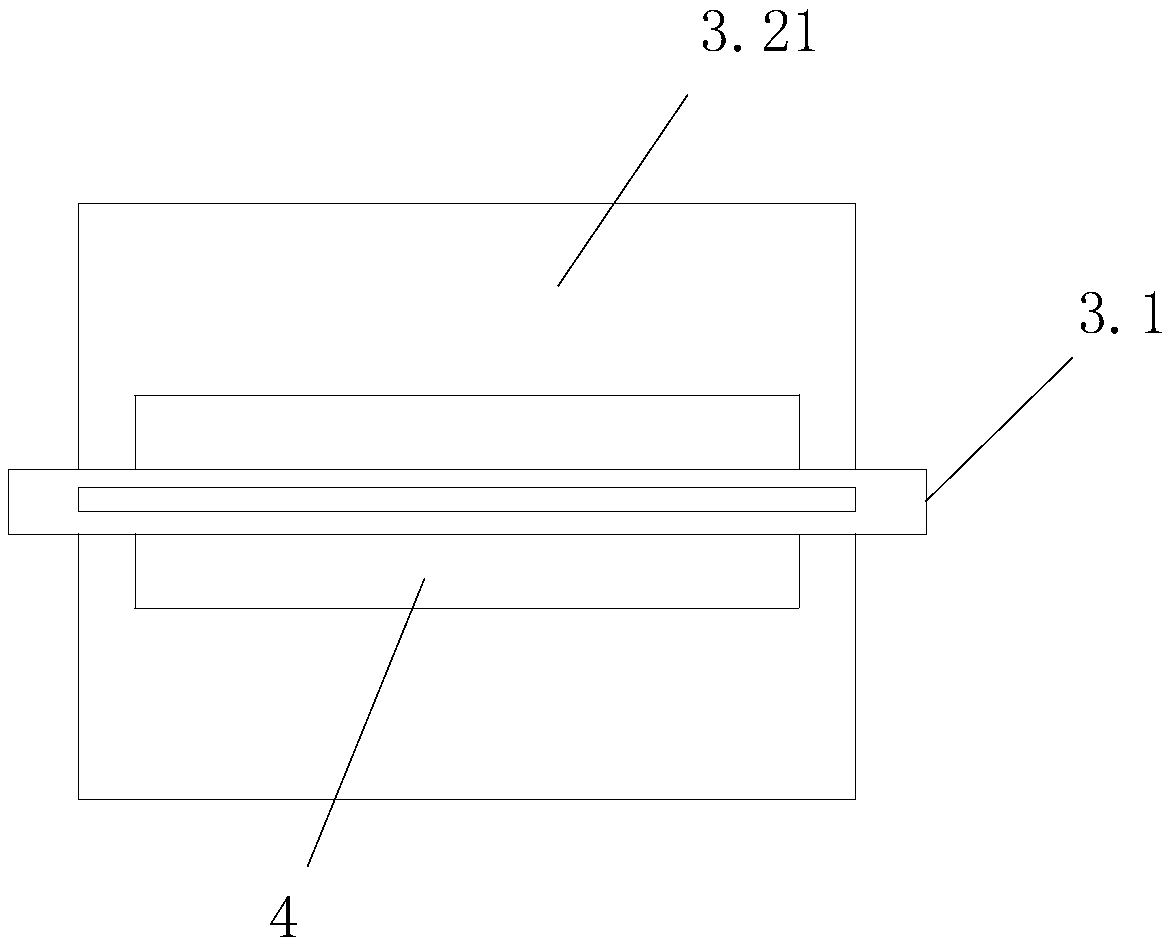

Vertical powder spraying production line

PendingCN112958346AImplement the function of mixingAchieve secondary mixingSpraying apparatusManufacturing lineIndustrial engineering

The invention provides a vertical powder spraying production line. The vertical powder spraying production line involves a spraying device and a stirring device, wherein the stirring device is used for mixing toner, the spraying device is located on the downstream of the stirring device in the toner conveying direction, the stirring device comprises a stirring container, a stirring mechanism, a track and a moving mechanism, the stirring container is used for placing the toner, the stirring mechanism is used for stirring the toner, the stirring mechanism is arranged on the stirring container, the outer contour of the track is in a circular ring shape, the central axis of the track is transversely arranged, the moving mechanism is used for driving the stirring container to move along the track, the moving mechanism is in sliding connection with the track, and the stirring container is arranged on the moving mechanism. According to the vertical powder spraying production line, the problem that a traditional coloring production line cannot mix the toner is solved, and the vertical powder spraying production line has the advantages of being simple in structure, good in toner mixing effect, easy to operate and low in production cost.

Owner:佛山市顺德区惠联模具科技有限公司

Double foam foam concrete equipment

InactiveCN103878881BRealize continuous productionSmall bulk densityCement mixing apparatusFoam concreteFoaming agent

The invention relates to a double-foaming foam concrete device and belongs to the technical field of manufacturing devices of building materials. The double-foaming foam concrete device comprises a physical foaming system and a chemical foaming system, wherein an input pipeline of the chemical foaming system is connected to the tail end of the physical foaming system; the chemical foaming system comprises a foaming agent injecting machine, an injection pipeline, a mixer and an output pipeline, and the foaming agent injecting machine is connected to the input pipeline of the mixer connected to the physical foaming system through the injection pipeline; ultra-light foam concrete mixed by the mixer is output through the output pipeline connected to the mixer. The double-foaming foam concrete device has the beneficial effects that the physical foaming system and the chemical foaming system are integrally utilized in parallel operation, so that the remote transportation and construction of the foam concrete are realized, and the yield of the foam concrete is high; by carrying out double foaming, the ultra-light foam concrete consisting of a mass of independent and uniformly-distributed bubbles can be continuously produced, the volume density and heat conductivity coefficient of the foam concrete are low, the thermal performance of the foam concrete is very excellent, and the foam concrete is an efficient thermal insulation material.

Owner:盘锦双利建筑劳务有限公司 +2

A high-efficiency mixing system that facilitates denitrification mixing

ActiveCN107081058BImprove mix qualityReduce escapeGas treatmentDispersed particle separationHybrid systemFlue gas

The invention discloses an efficient mixing system conducive to mixing denitration, comprising an efficient mixing system. The efficient mixing system comprises a first-class efficient mixing device and a second-class efficient mixing device, wherein the first-class efficient mixing device comprises a plurality of first-class efficient mixing elements, each first-class efficient mixing element comprises a seamless steel pipe and a folded circular steel plate, winged edges of both sides of the folded circular steel plate simultaneously penetrate through the seamless steel pipe, and the second-class efficient mixing device comprises a plurality of second-class efficient mixing elements, each second-class efficient mixing element comprises a seamless steel pipe and a circular steel plate, the circular steel plate penetrates through the seamless steel pipe. Through an idea of thinking from the part to the whole, a flow field of the denitration is optimized, the position, type and series of installing the efficient mixing system are determined, and the mixed quality of ammonia flue gas is improved, so that the anti-interference of the denitration system to the change of an incoming flow working condition is improved, the safe and economic operation of an unit is ensured and the existing technology problems are solved.

Owner:成都融科能源环境工程有限公司

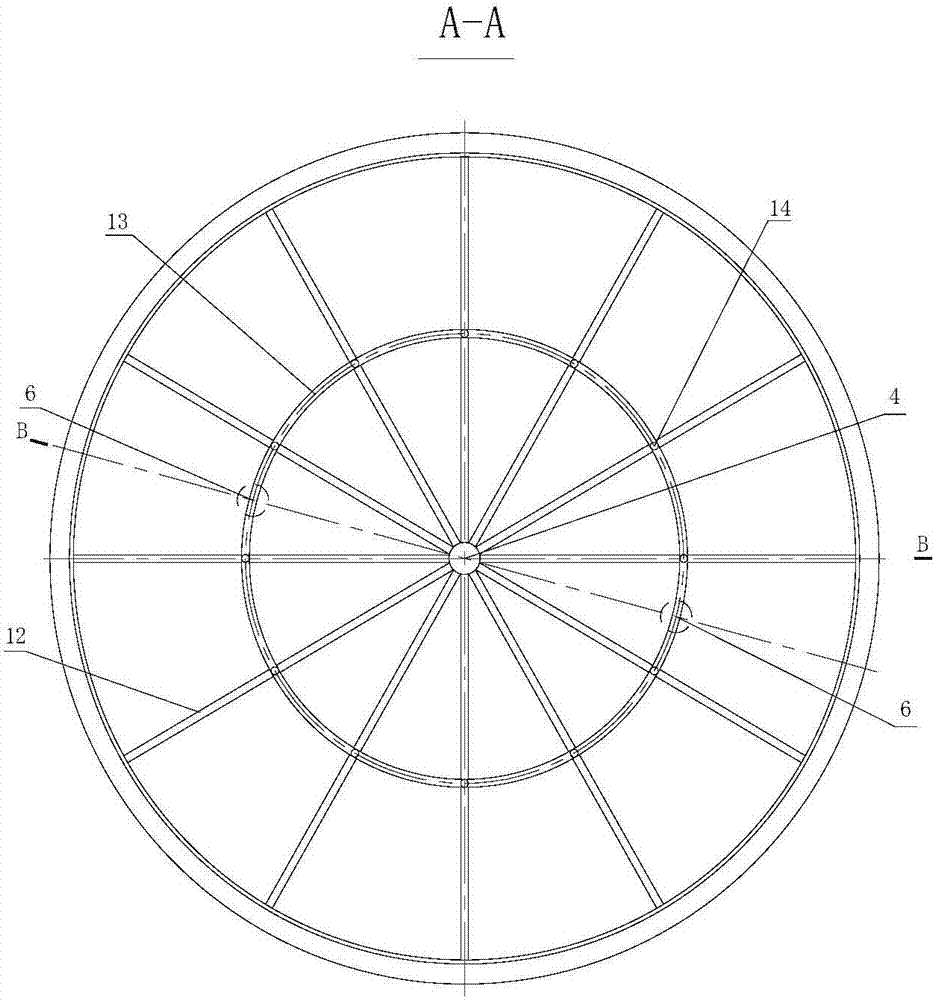

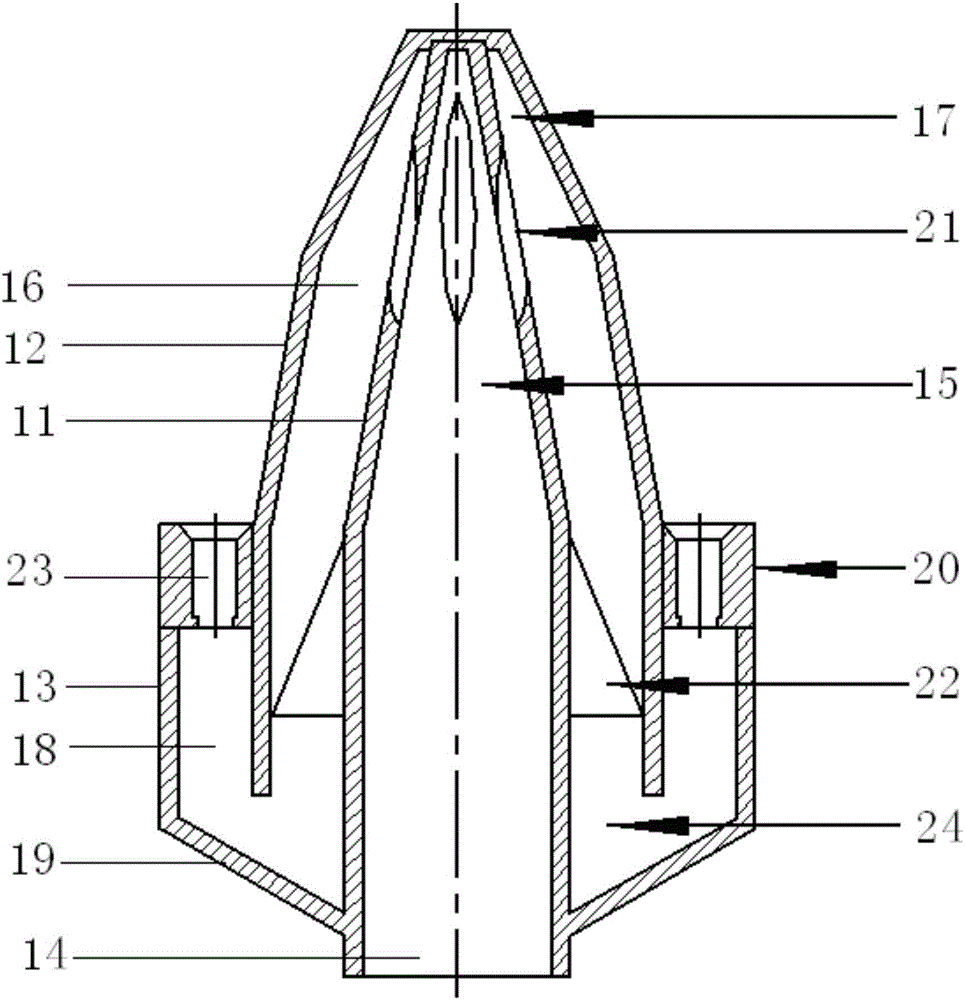

A high-temperature heat source for high-efficiency preheating of small non-premixed burners

ActiveCN113324247BEfficient outputMeet power needsIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention belongs to the technical field related to power heat sources, and discloses a high-efficiency preheating small-scale non-pre-combustor high-temperature heat source, including: an oxidant preheating channel, a shell set outside the oxidant preheating channel, and a central baffle, wherein : The oxidant preheating channel includes a hollow preheating channel and a burner arranged at one end of the hollow preheating channel, and the hollow preheating channel is used for inputting oxidant; the shell includes a shell and a baffle at the end of the shell, There is an opening in the center of the baffle, which is used to input fuel. The hollow preheating channel has one end of the burner and the gap between the baffle. The hollow preheating channel and the shell form the combustion chamber; the central baffle is set on the opening. center and fit with the opening clearance. The application can not only realize the preheating of the oxidant but also realize the effective output of the heat source. At the same time, the reverse flow of the oxidant and the fuel increases the disturbance to realize rapid and uniform mixing, which facilitates rapid combustion and meets the requirements of the power heat source.

Owner:HUAZHONG UNIV OF SCI & TECH

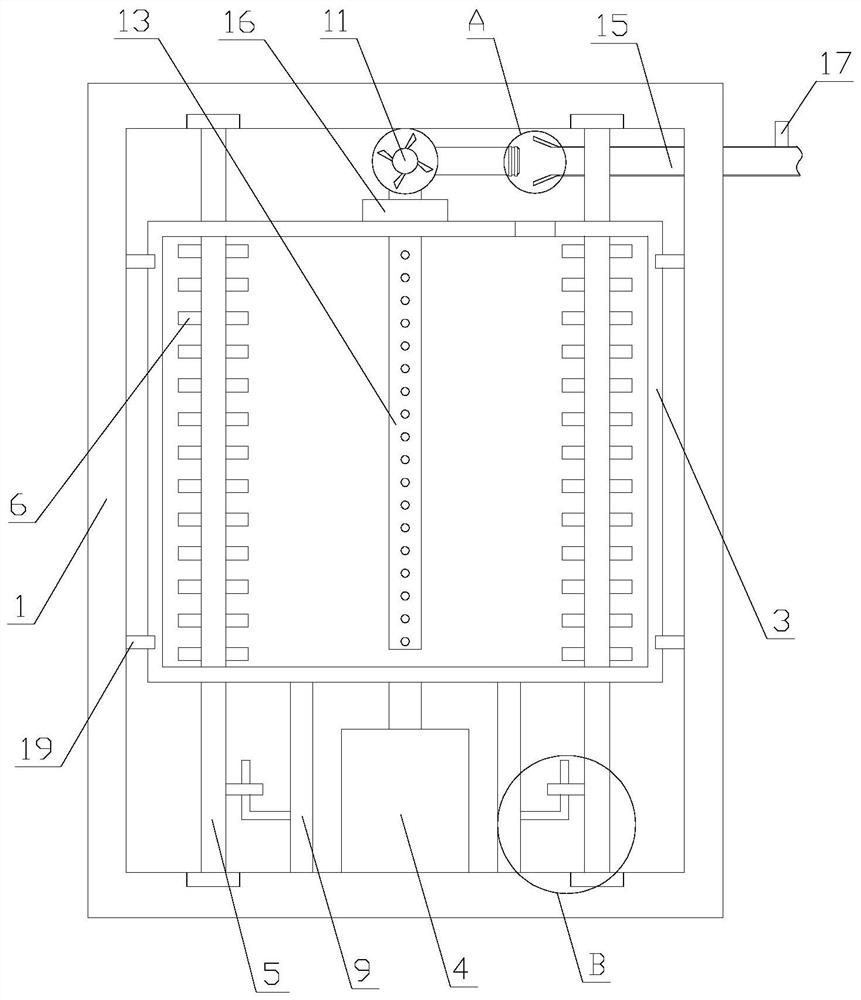

High-efficiency stirring device

InactiveCN112439353AAchieving stirringAchieve secondary mixingRotating receptacle mixersTransportation and packagingThermodynamicsElectric machinery

The invention relates to a high-efficiency stirring device which comprises a fixed box, a sliding door, a stirring mechanism and a water injection mechanism. The stirring mechanism comprises a stirring barrel, a motor and a stirring assembly. The water injection mechanism comprises a water pump, an abutting pipe, a water inlet pipe, a guide plate, a connecting pipe and a second bearing seat. According to the high-efficiency stirring device, the stirring mechanism is arranged, and the stirring barrel is driven to rotate through the motor, so that silt in the stirring barrel rotates, the silt israpidly mixed together under the action of centrifugal force, meanwhile, the stirring barrel drives a stirring rod to rotate to realize secondary stirring of the silt in the stirring barrel, and therefore the stirring efficiency is improved; and water is injected into the stirring barrel through the water injection mechanism, use is convenient, meanwhile, after water injection is finished, air blowing in the stirring barrel is achieved, tertiary stirring of silt in the stirring barrel is achieved, air draft can be conducted after after stirring is finished and the interior of the stirring barrel is cleaned, the cleanliness is improved, next-time use is facilitated, and the service life is prolonged.

Owner:魏欣菊

A kind of high-efficiency production process of furan resin

The invention relates to the field of resin preparation and production, in particular to a furan resin efficient production technology. The furan resin efficient production technology comprises a mainmaterial output part, a preliminary mixing part, a secondary mixing part and a stable flow output part. A main material is conveyed by a mixing part on a main material output assembly and meanwhile ejected by a main material bin under the effect of centrifugal force, a liquid flow layer is divulged through an impact mode, preliminary mixed liquid with the main material and an auxiliary material being of an up-down overlapped structure is formed, impact is conducted through a catalyst which is ejected intermittently in a compressed mode, the main material, the auxiliary material and the catalyst flow down along the surface of a slow flow assembly after being subjected to secondary mixing, and the main material, the auxiliary material and the catalyst are output after penetrating through aflow distributing net; and the main material which is of a spiral structure is output by the mixing part and the liquid flow layer is divulged in an impact mode, the preliminary mixed liquid with themain material and the auxiliary material being overlapped up and down in a spaced mode is formed, then a flow jetting assembly is driven by a preliminary mixing mechanism to conduct secondary mixing on the catalyst in a rotary jetting mode, and the technical problems that the production efficiency is low, and mixing is not even existing in the prior art are solved.

Owner:龙口市德兴化工有限公司

Automatic cleaning device for food processing

InactiveCN113768167AImplement filteringAchieve recyclingTransportation and packagingRotary stirring mixersProcess engineeringMechanical engineering

The invention relates to an automatic cleaning device for food processing. The automatic cleaning device comprises a fixed box, a cleaning box, a water inlet pipe, a communicating pipe, a drain pipe, a stirring mechanism and a cleaning mechanism, wherein the stirring mechanism comprises a stirring assembly and a filtering assembly, the cleaning mechanism comprises a filter screen plate, a driving assembly, a connecting assembly and a cleaning assembly, the filter screen plate is horizontally arranged in the cleaning box, the driving assembly is arranged above the filter screen plate, the connecting assembly is arranged between the driving assembly and the stirring assembly, the stirring assembly is connected with the driving assembly through the connecting assembly, and the cleaning assembly is arranged on the filter screen plate. According to the automatic cleaning device for food processing, through cooperation of the stirring mechanism and the cleaning mechanism, a main body can be cleaned for multiple times, the cleaning effect is improved, the filter screen plate is prevented from being blocked, water can be recycled, water resources are saved, linkage of multiple mechanisms is achieved through the same driving source, and the use practicability is improved.

Owner:广州市越秀区踢彤网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com