Double-foaming foam concrete device

A technology of foam concrete and double foaming, which is applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve time-consuming and labor-intensive problems, and achieve safe pipeline transportation, excellent thermal performance, and large output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

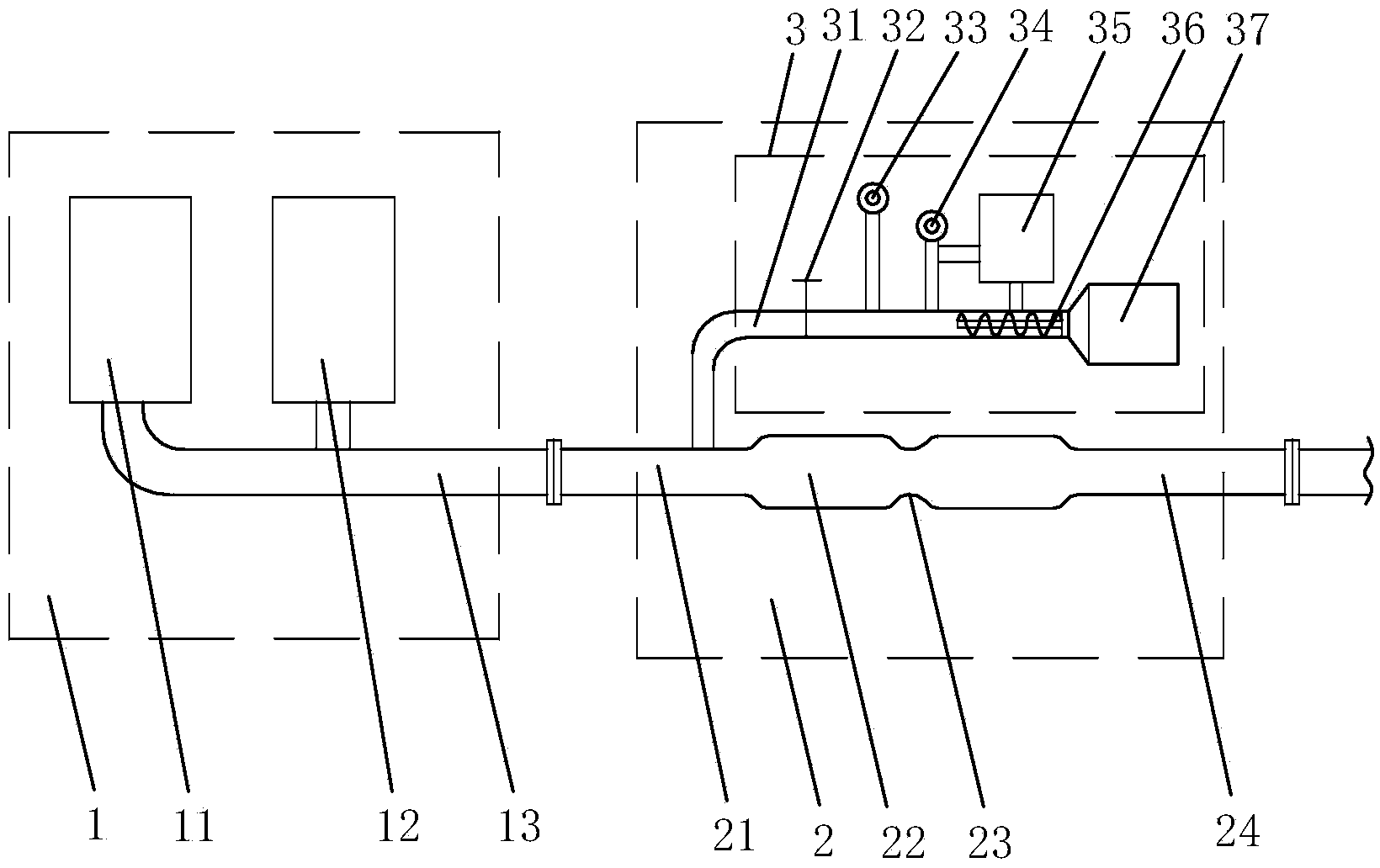

[0016] Example: such as figure 1 As shown, the present invention includes a physical foaming system 1 and a chemical foaming system 2 , the input pipeline 21 of the chemical foaming system 2 is connected to the end of the delivery pipeline 13 of the physical foaming system 1 .

[0017] The physical foaming system 1 includes a mixer 11 , a foaming machine 12 and a delivery pipeline 13 , the mixer and the foaming machine 12 are respectively connected to the delivery pipeline 13 , and the delivery pipeline 13 is connected to the chemical foaming system 2 . The structure of the physical foaming system 1 has various forms, and is not limited to the structure described in this embodiment. The physical foaming system 1 can prepare the mixture mixed with the admixtures required by the chemical foaming system 2, and use normal temperature water to prepare flowing porous concrete with a certain heat, and complete the pre-foaming process, making it possible for the continuous production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com