Packaging equipment capable of accurately and quantitatively packaging food with different weights

A quantitative packaging and packaging equipment technology, which is applied to the types of packaging items, packaging, transportation and packaging, etc., can solve the problems of high consumption of human resources, affecting the weight of bottling, and insufficient precision of the weight, so as to improve the speed and structure of bottling Reasonable and save human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

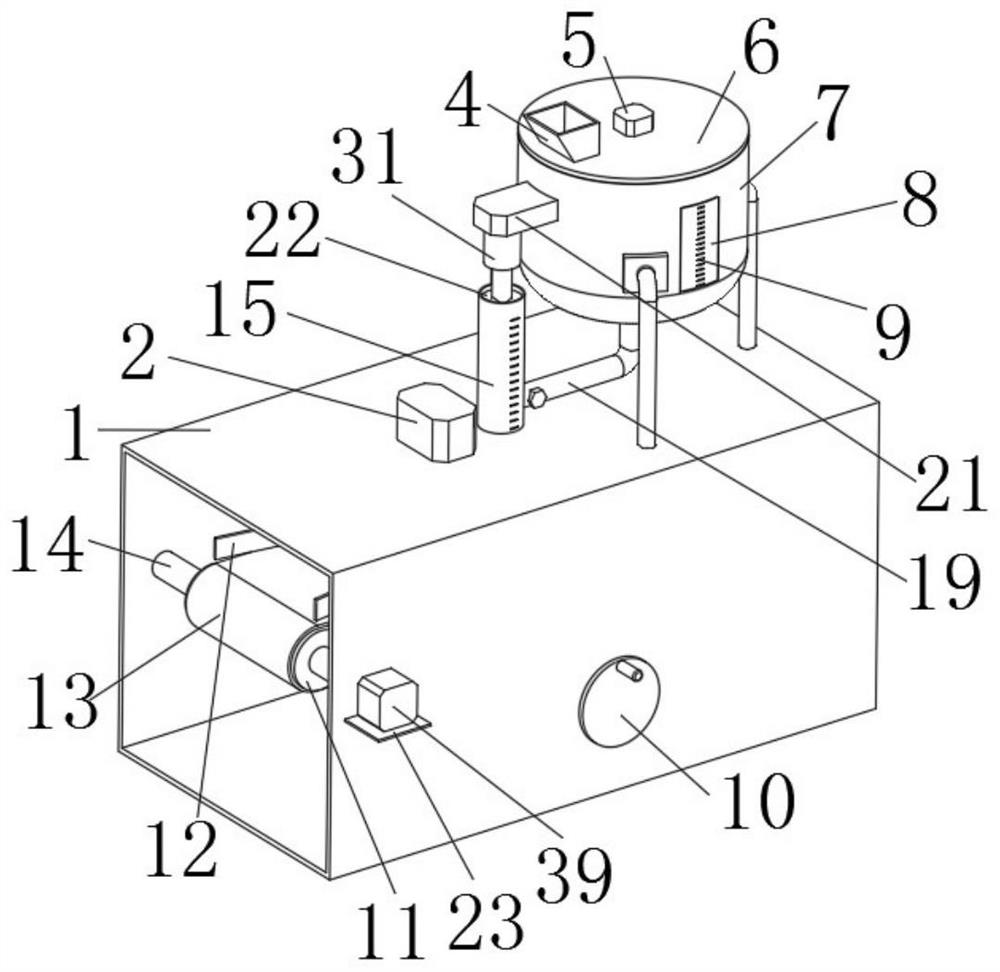

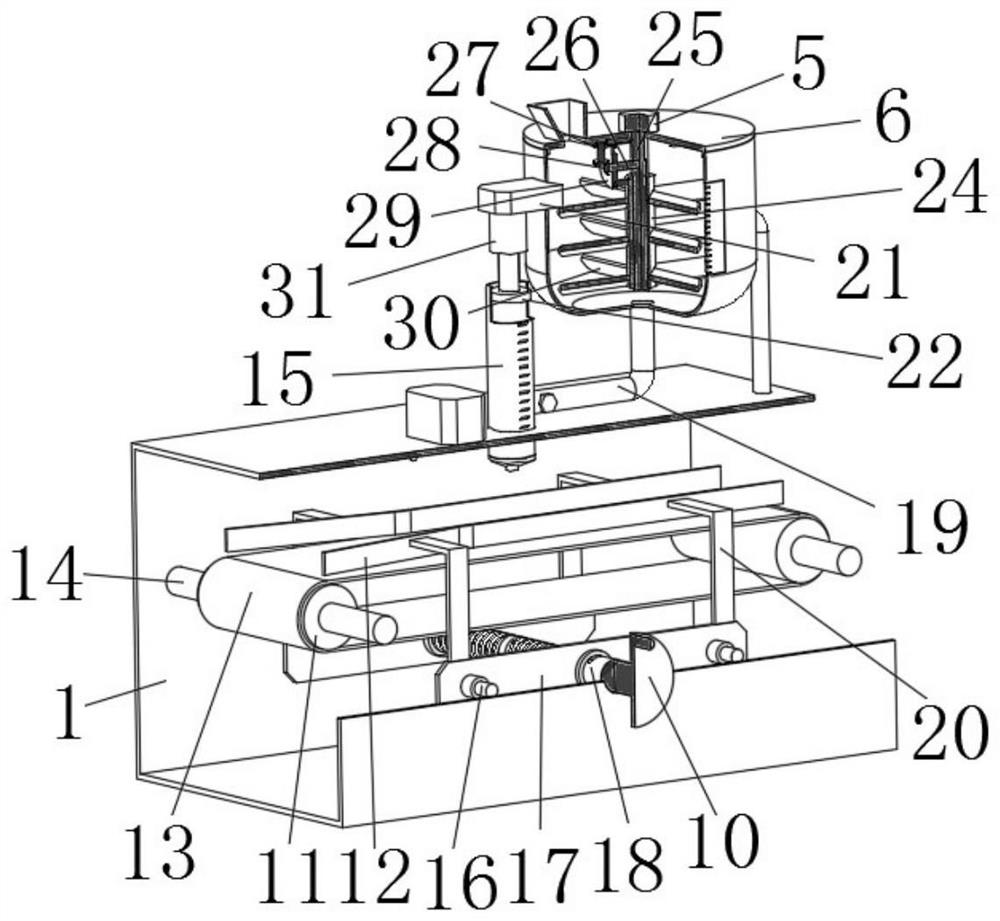

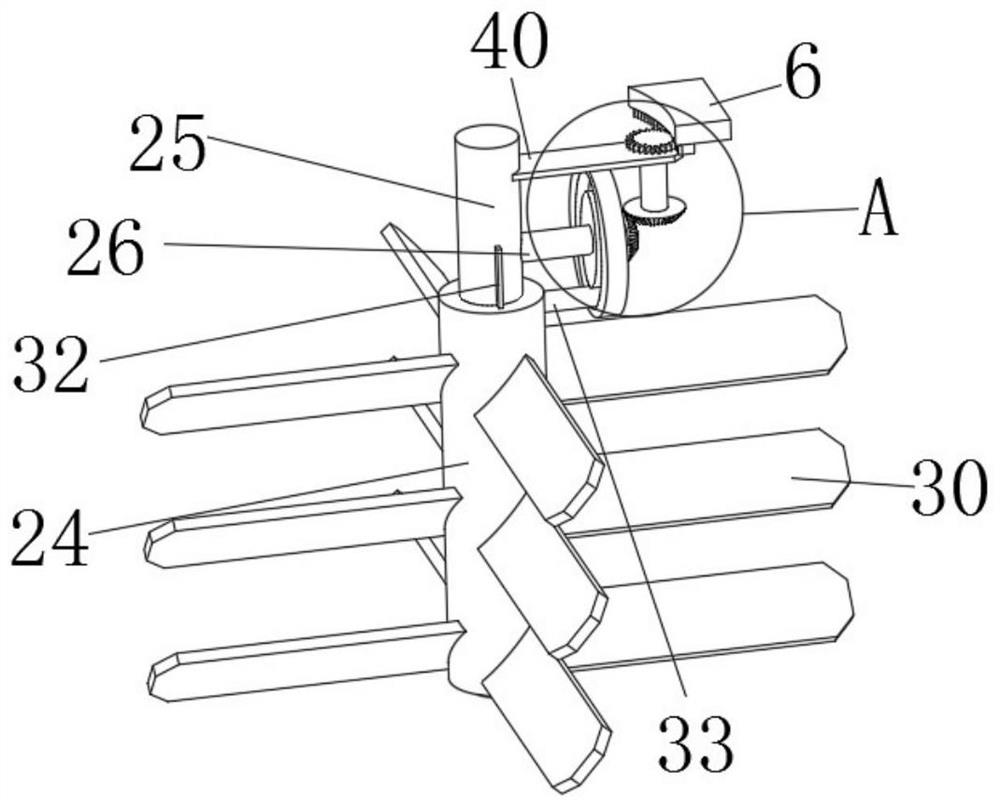

[0042] Example: Reference Figure 1-10 The shown packaging equipment can accurately and quantitatively pack food of different weights, including an aseptic box 1, a sensor 2 fixedly connected to the top of the aseptic box 1, an accurate quantitative extraction unit is installed on the top of the aseptic box 1, and the aseptic box A glass bottle transfer unit and a glass bottle guide unit are installed on the inner walls of both sides of 1. The glass bottle transfer unit is located between the glass bottle guide units. All are fixedly connected with fixed blocks, and one side of the three fixed blocks is fixedly connected with the same mixing tank 7, and the top of the mixing tank 7 is fixedly connected with a sealing cover 6, and a chili sauce stirring unit is installed on the sealing cover 6, and the chili sauce The mixing unit is located in the mixing tank 7 , and the precise quantitative measurement unit is connected with the outer wall of the mixing tank 7 .

[0043] With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com