Patents

Literature

115results about How to "Consistent weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

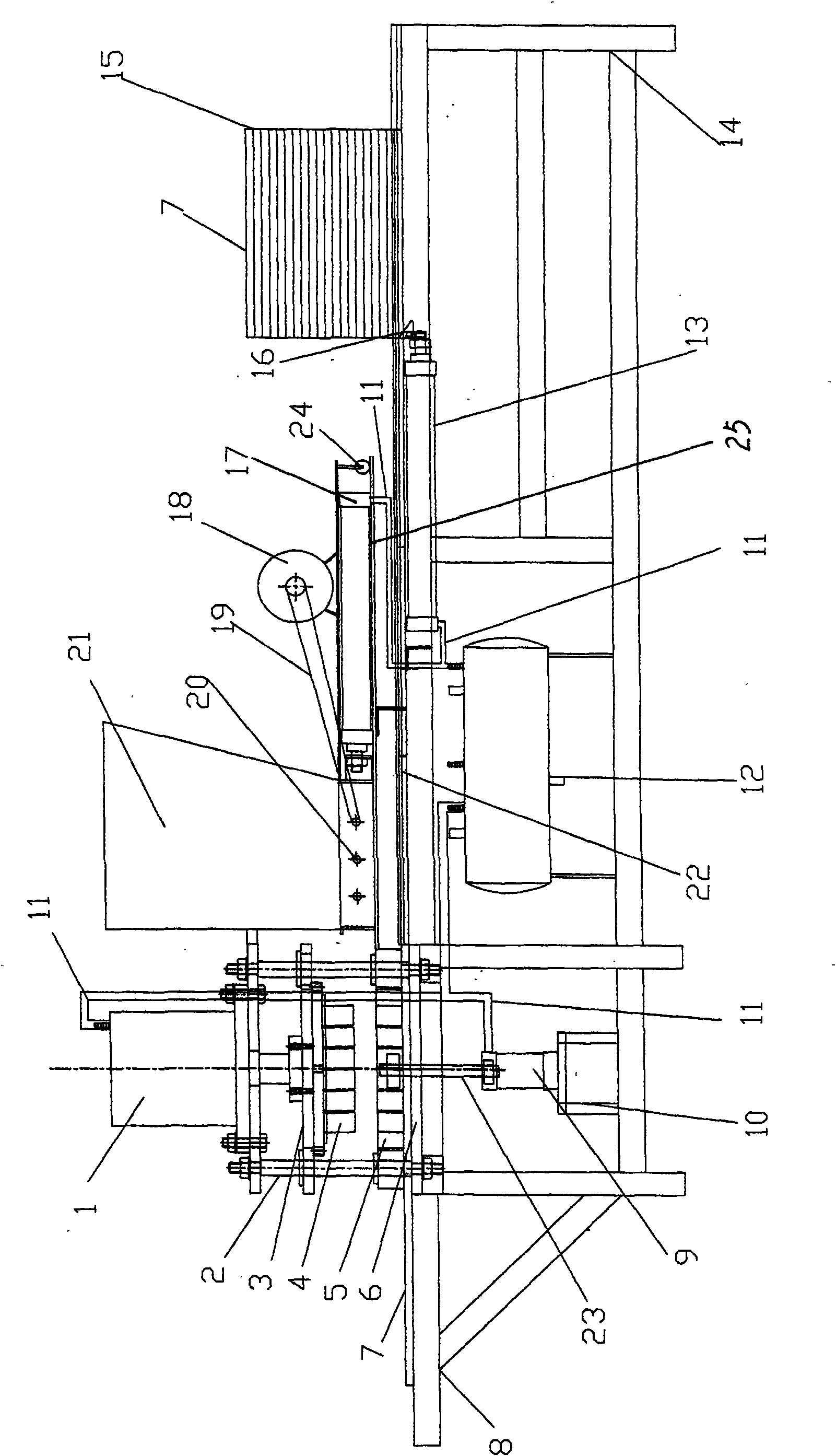

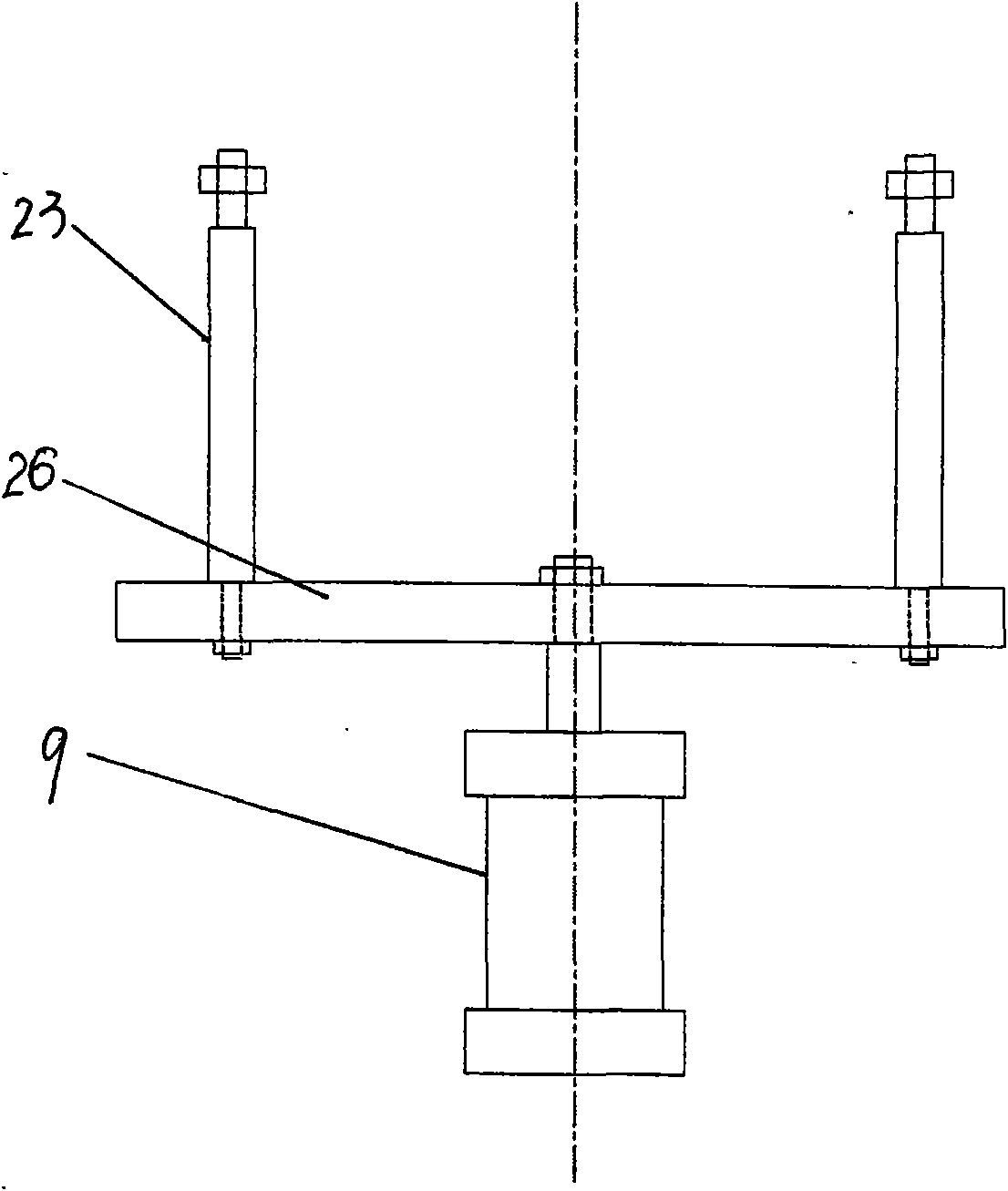

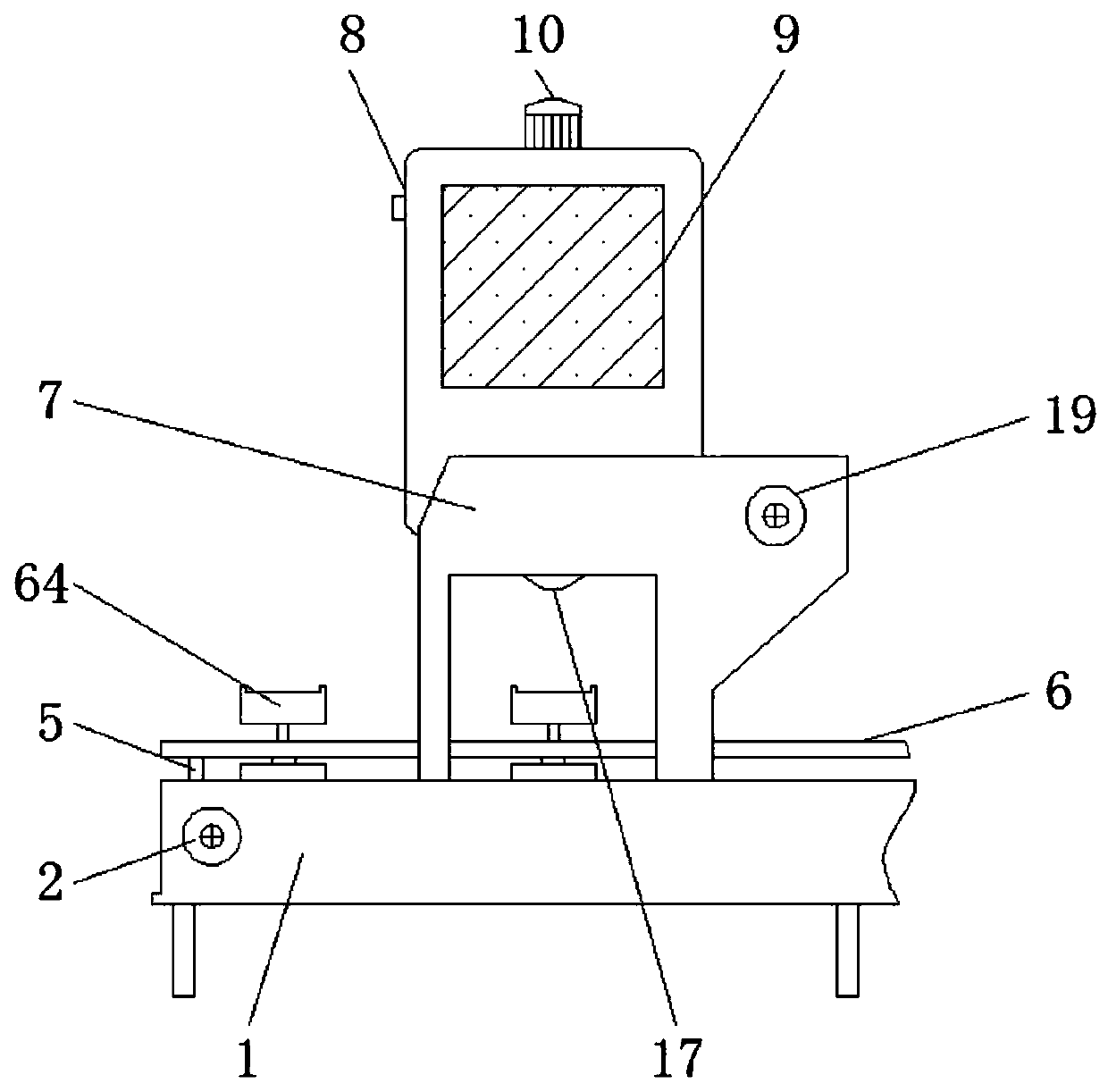

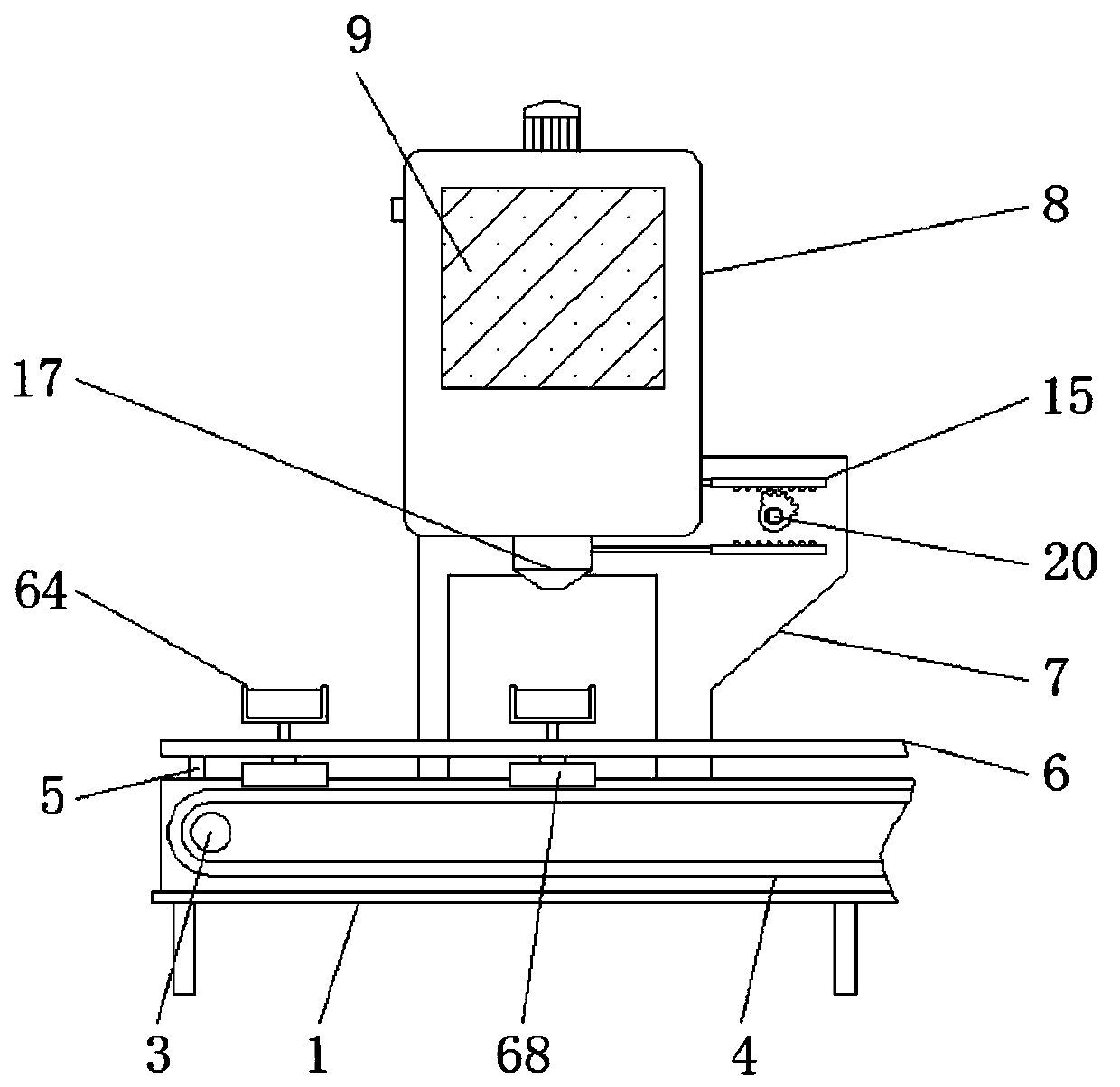

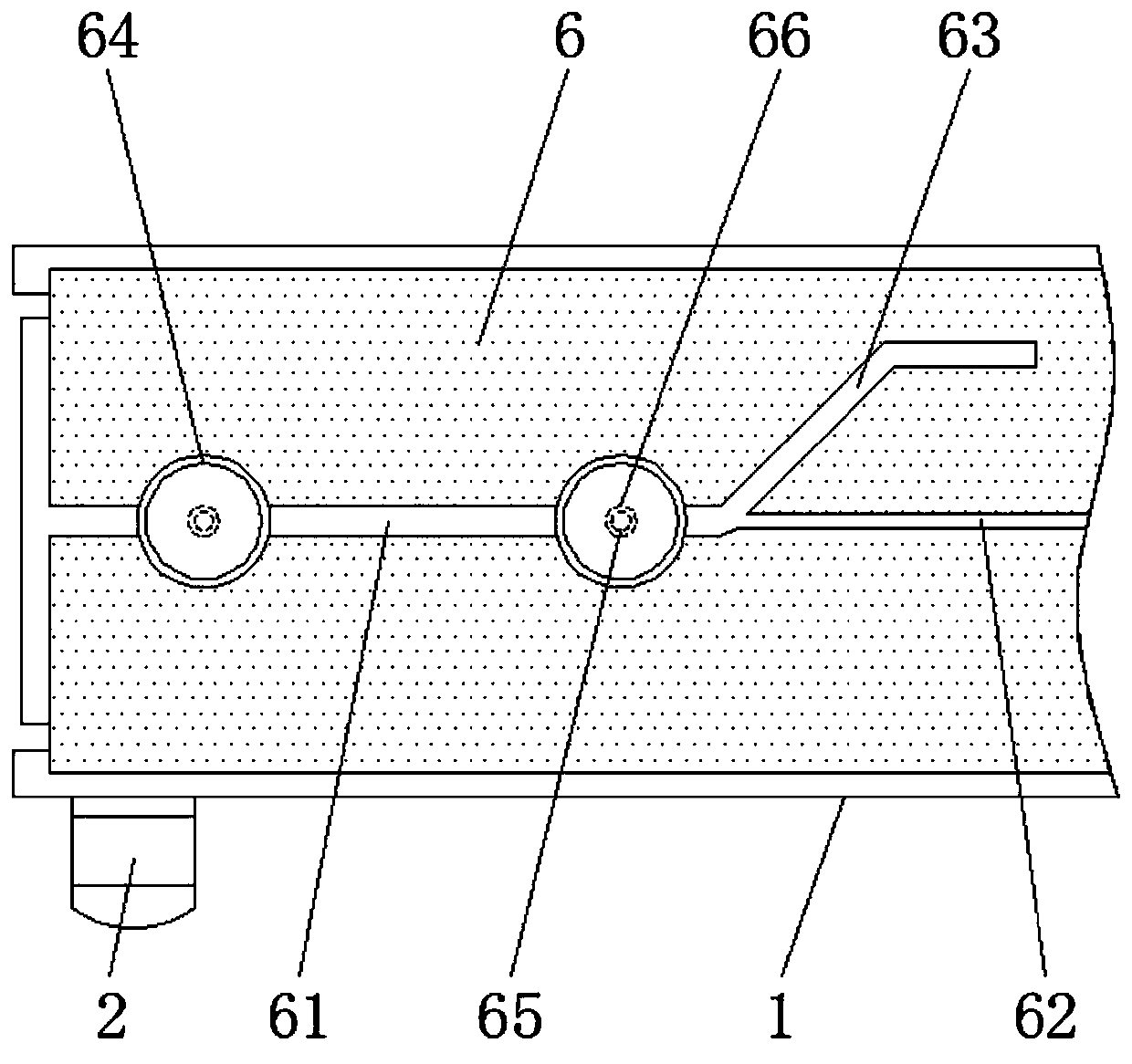

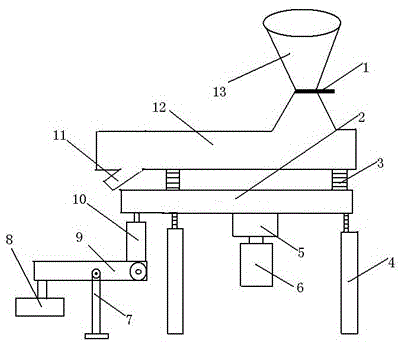

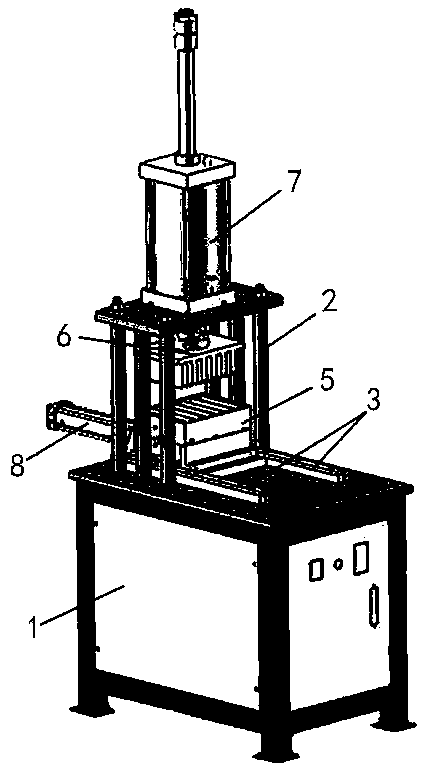

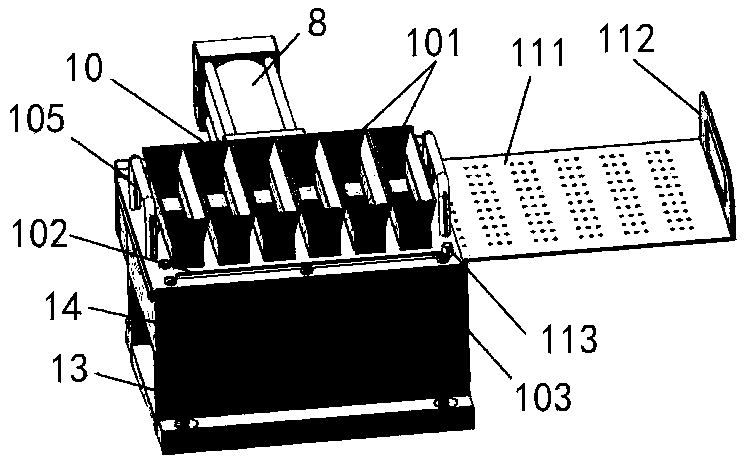

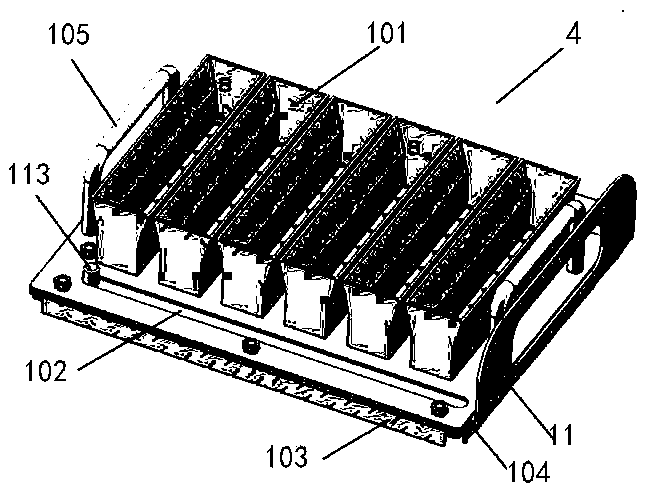

Full-automatic green bean cake former

A full-automatic green bean cake former comprises a forming system, a feeding system, a finished product delivery system, an electrical appliance system, an upper mould, and a lower mould which is relatively arranged on a track column at one end of a former frame; an upper mould cylinder and a lower mould cylinder are respectively connected with the upper mould and the lower mould; a feeding cylinder is connected with a feeding box below a food hopper; a supporting plate frame is arranged on the other end of the former frame; a supporting plate track is arranged bellowing the supporting plate frame; and a supporting plate delivery cylinder is arranged below the supporting plate frame. The former has high automation degree, can realize automatic feeding, automatic compaction, automatic mold stripping, automatic swinging plate, and automatic delivery; the maximal yield per hour of the former can reach 800kg; the finished product has good forming, consistent size, consistent thickness, consistent weight, is regular and beautiful, is convenient to pack, saves labor and time; the complete machine production only needs one person to operate; the former has a plurality of purposes, thereby forming products of powdery raw materials such as green bean cake, peanut cake, sesame cake and the like can be produced by only needing replacing the mould; and the mould is easily replaced.

Owner:商丘市福达食品机械有限公司

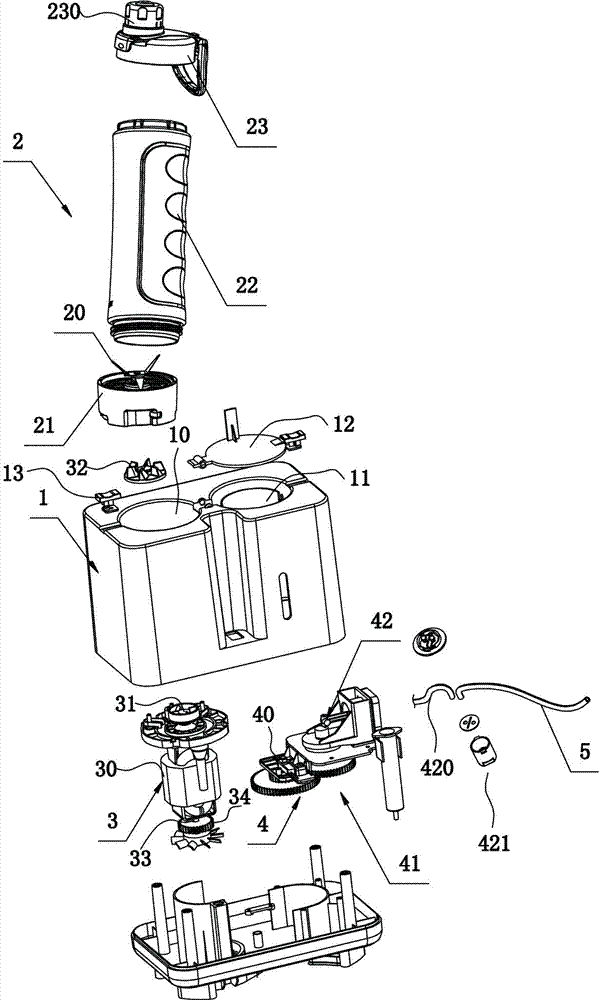

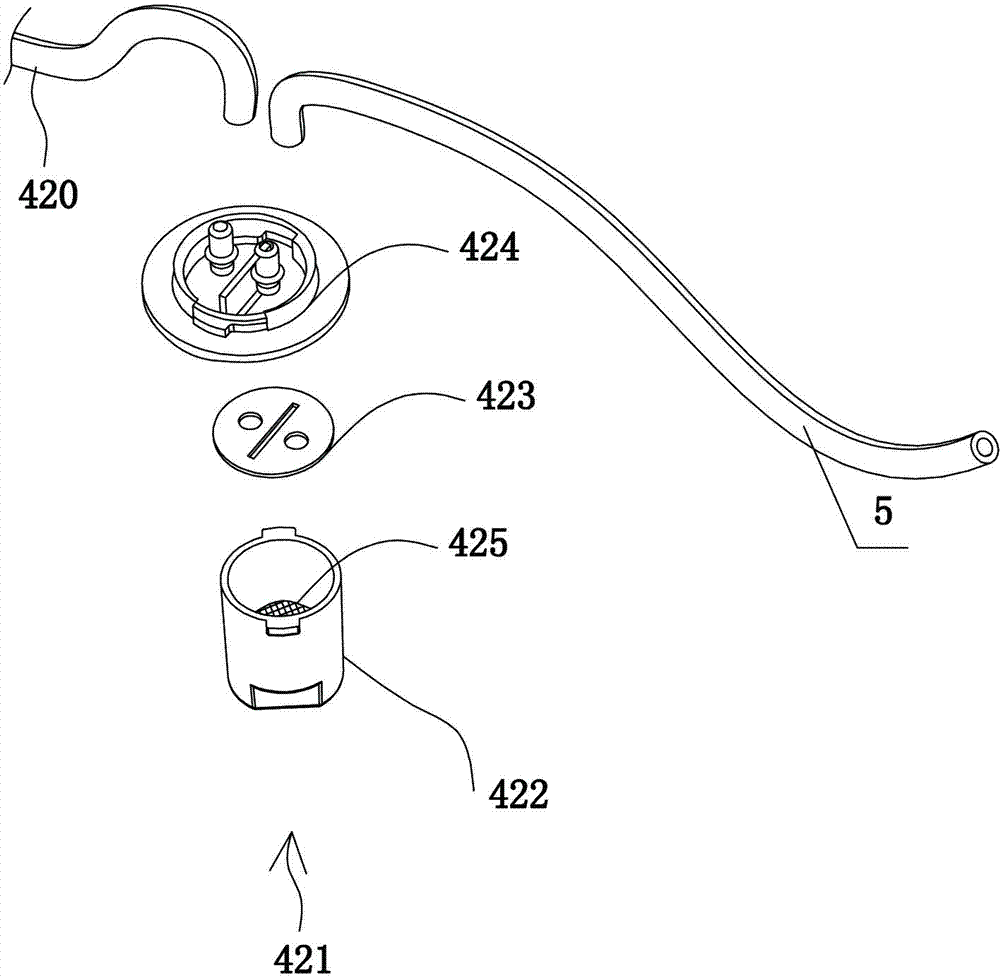

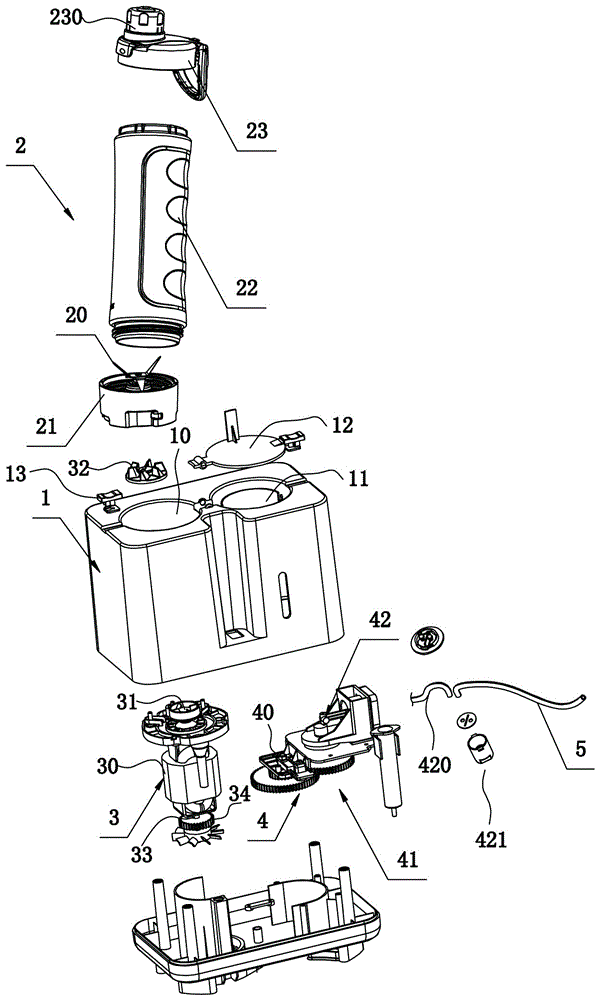

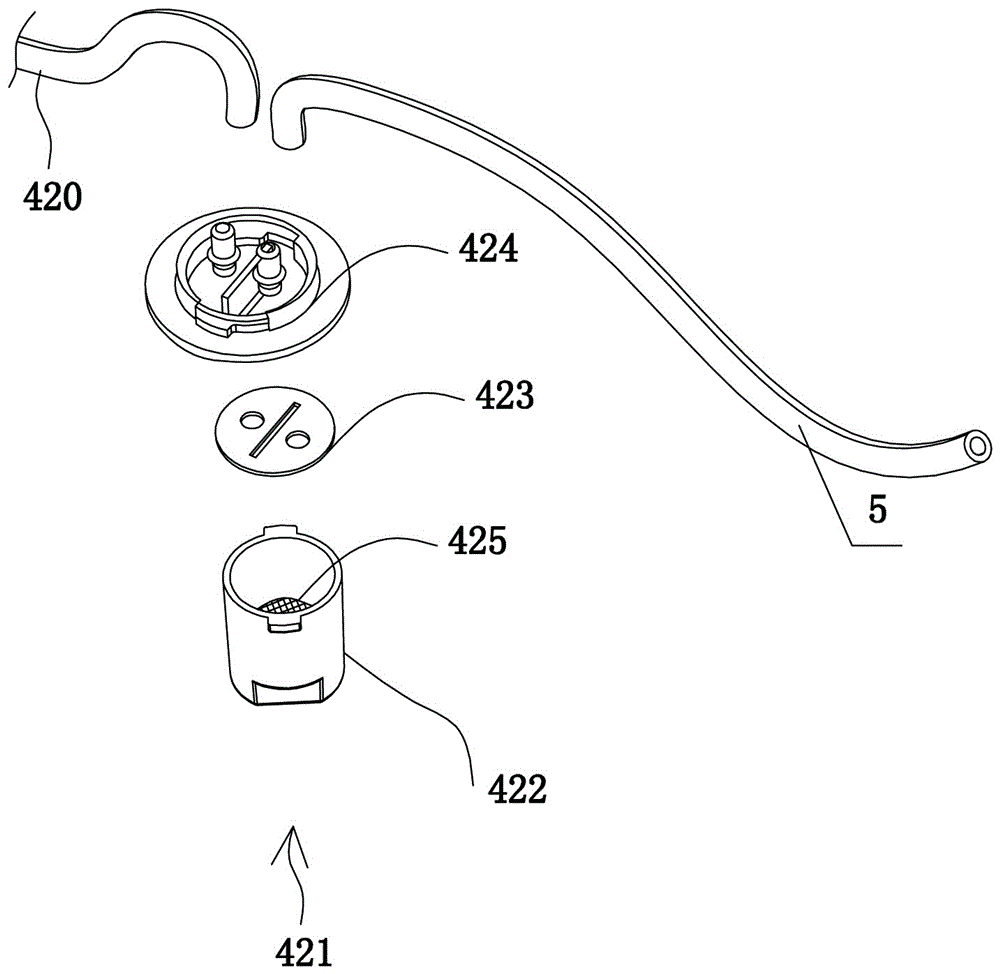

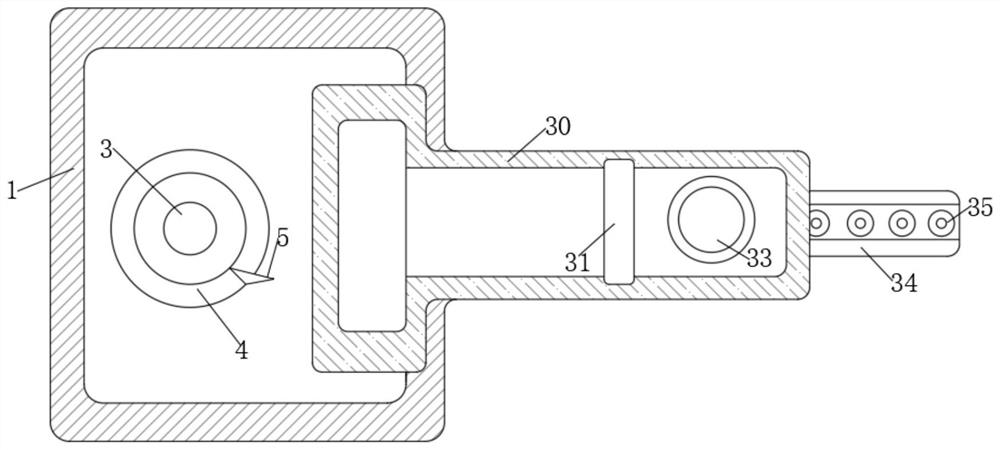

Food processor/juicer of improved structure

A food processor / juicer of an improved structure comprises a fixed base, a cup assembly, a driving assembly and a vacuum pump assembly. The cup assembly comprises a cup holder, a cup wall and a cup cover; the driving assembly comprises a driving motor, a first output shaft, a clutch and a second output shaft, and a first variable gear is arranged on the second output shaft; the vacuum pump assembly comprises a base frame, a speed change unit and a compression unit, the fixed base is provided with an opening, the compression unit is provided with an air extraction opening, the air extraction opening is connected with one end of a telescopic hose, the cup cover is provided with an air extraction hole, and the other end of the telescopic hose penetrates through the opening, then extends to the cup cover and is connected with the air extraction hole. The food processor / juicer is compact in integrated structure and convenient for a user to operate and carry, manufacturing cost is reduced, occupation on the inner space of the fixed base is reduced, and therefore the size and weight of the fixed base are substantially kept identical with those of an existing frequently-used juicer.

Owner:厦门乐时及物智能科技有限公司

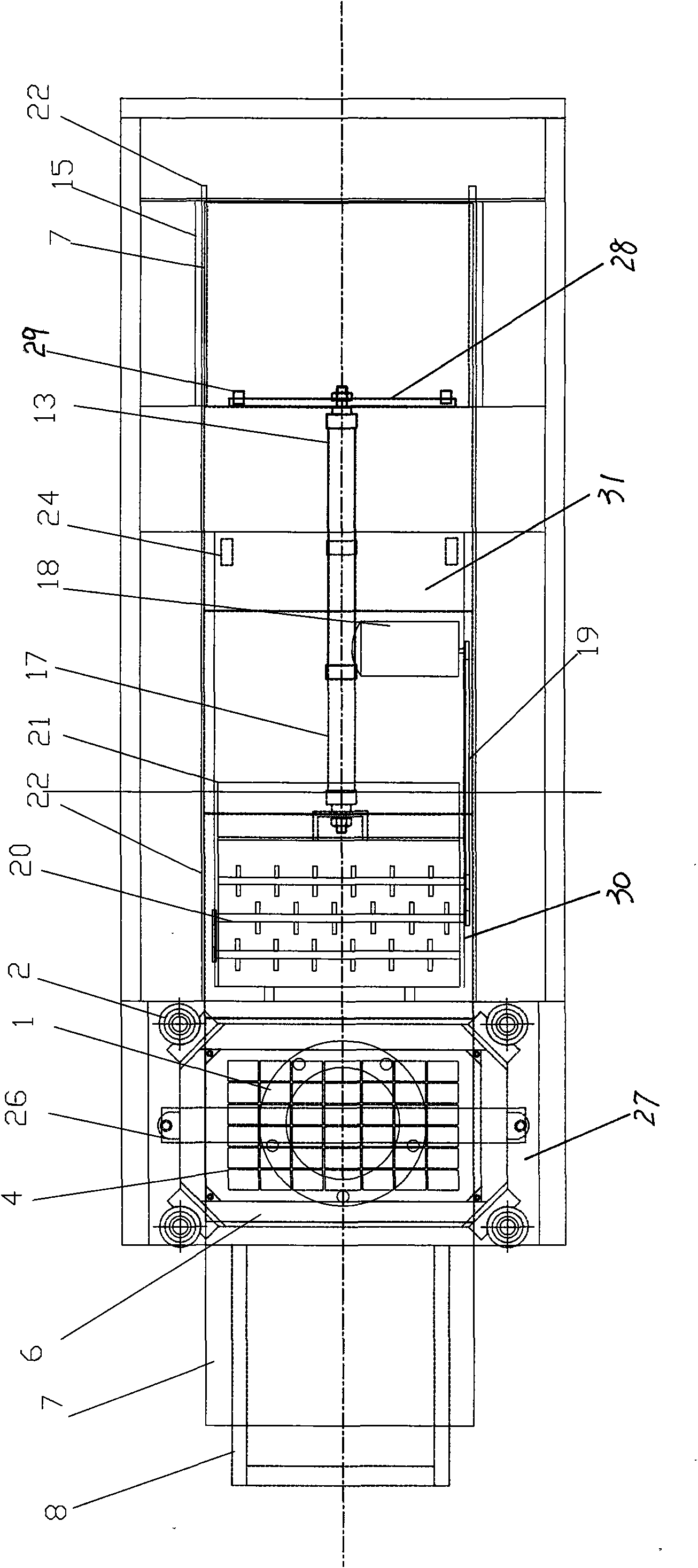

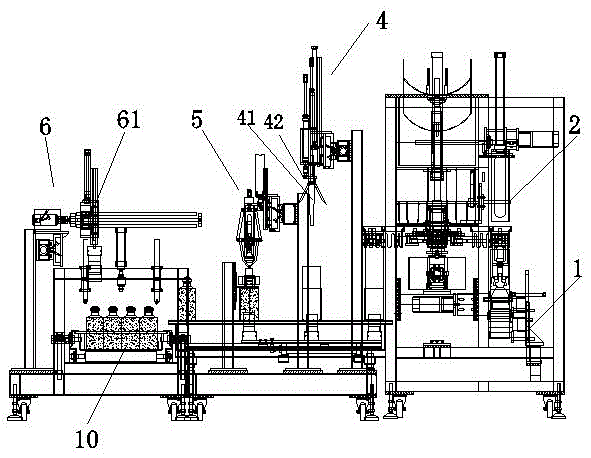

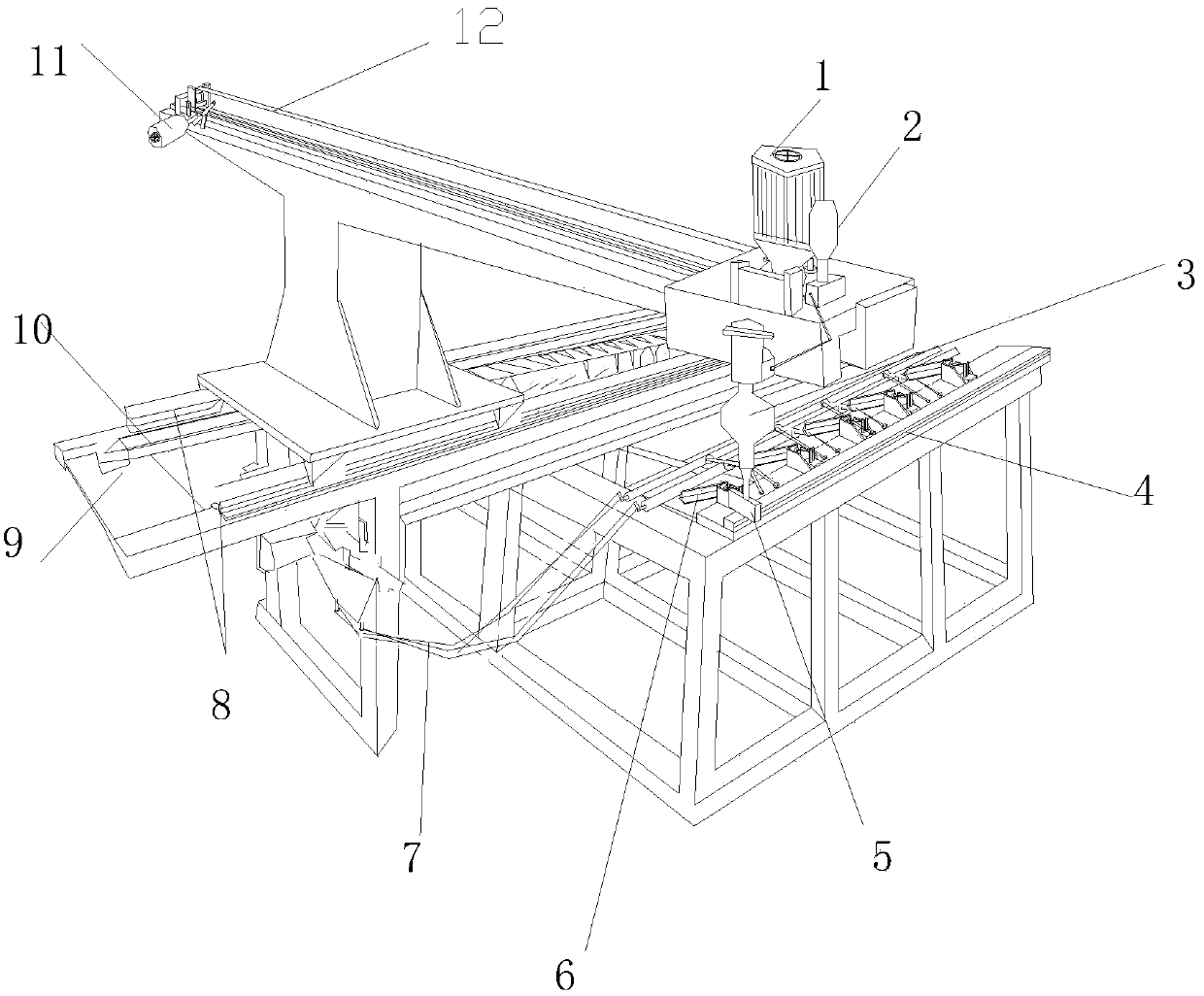

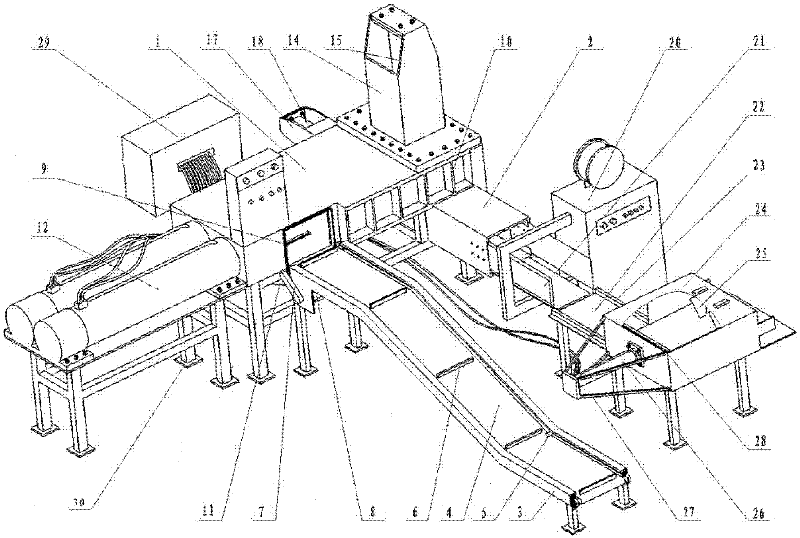

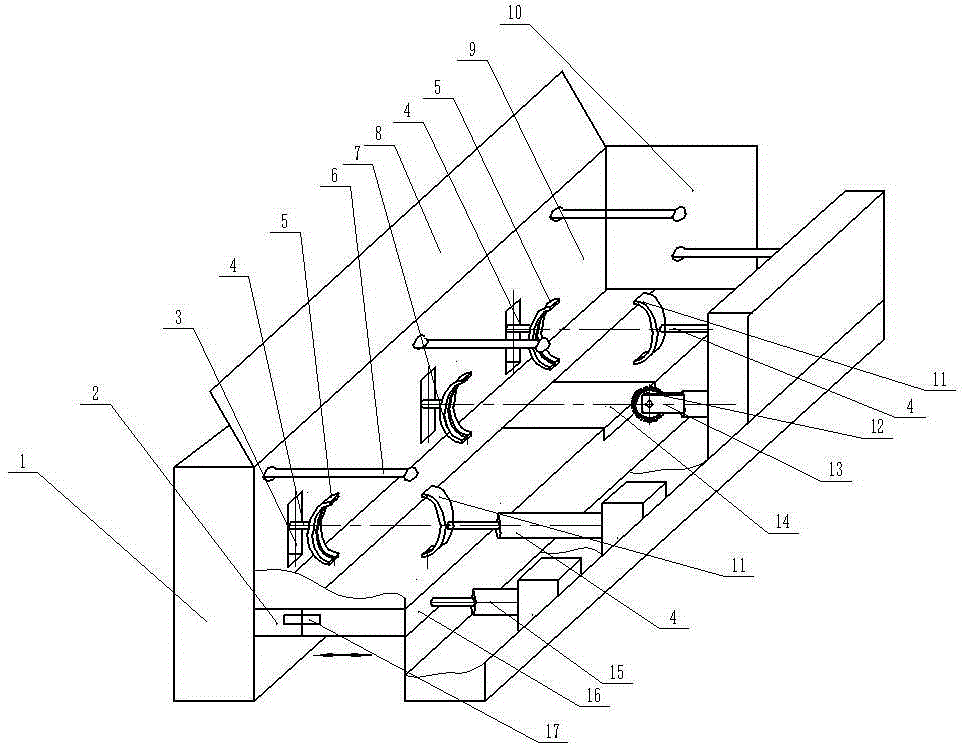

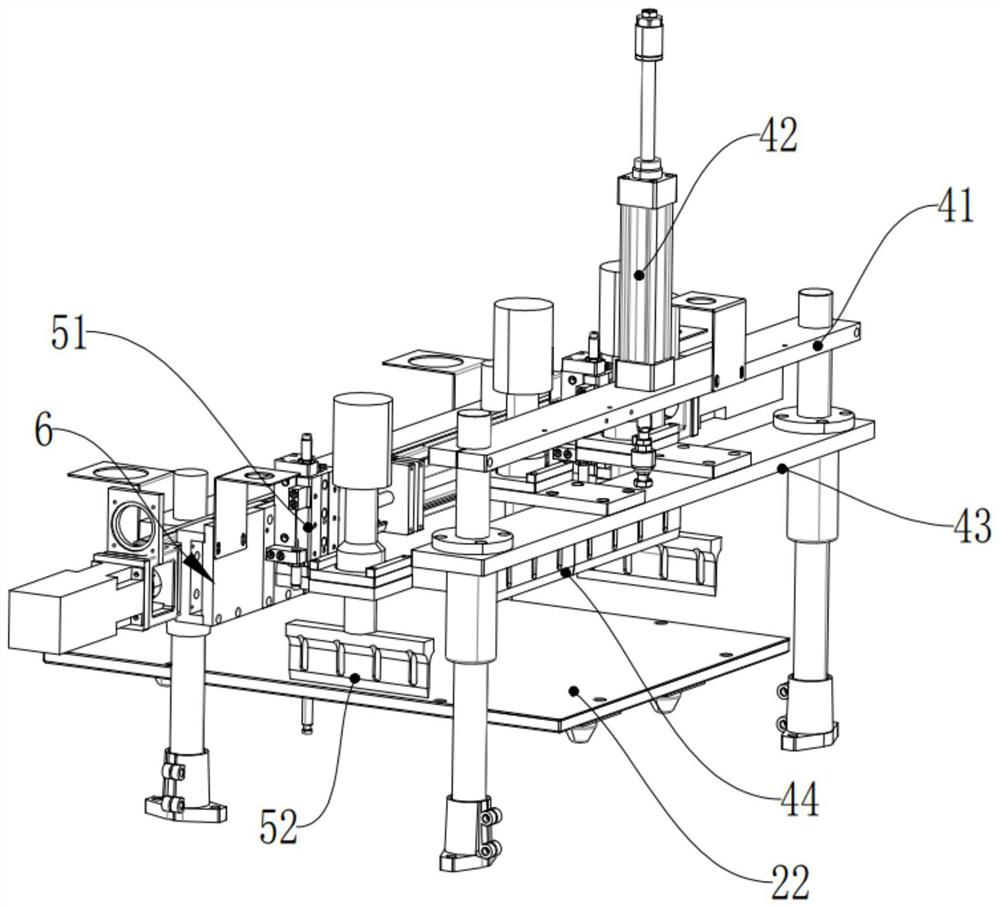

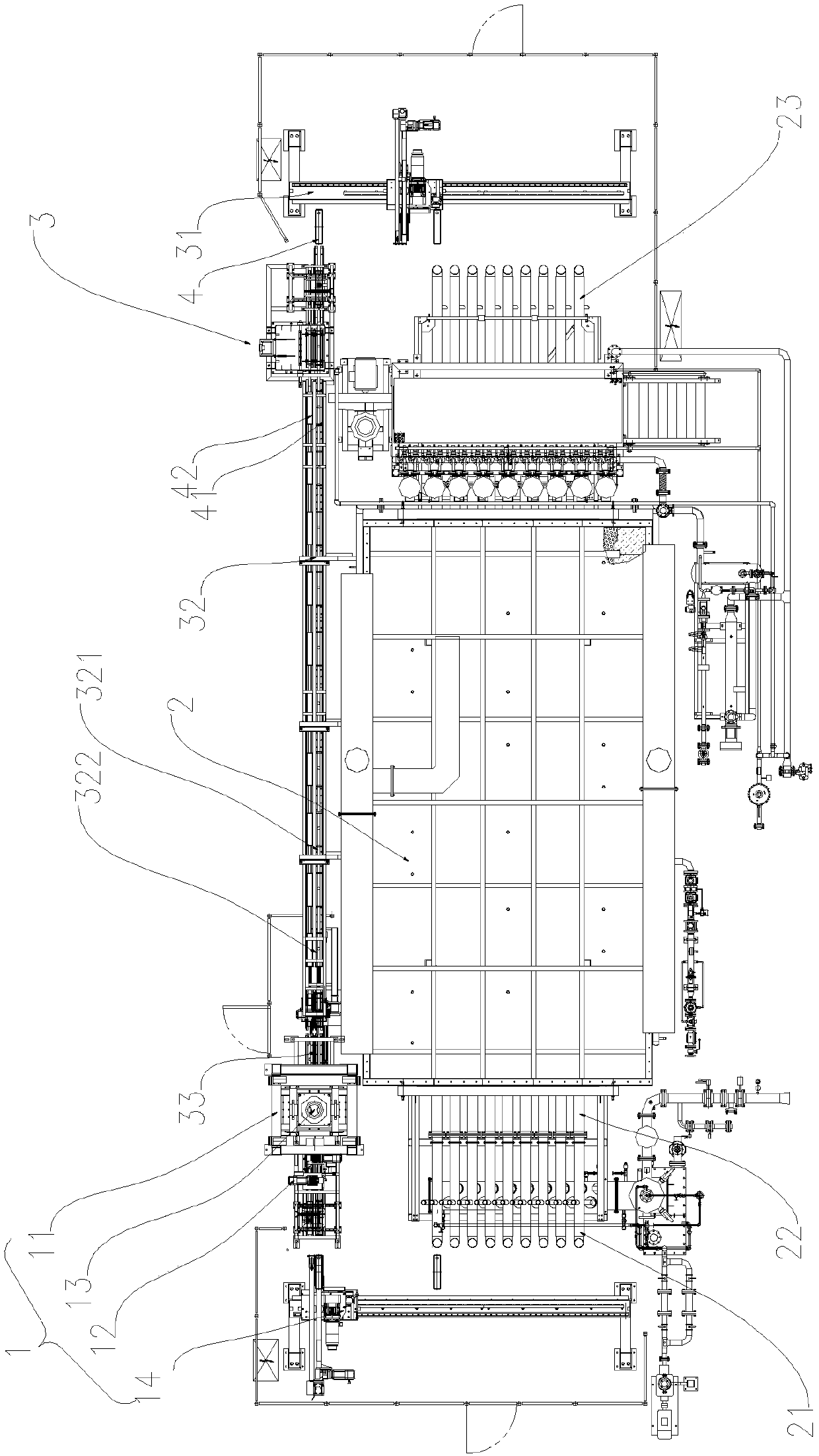

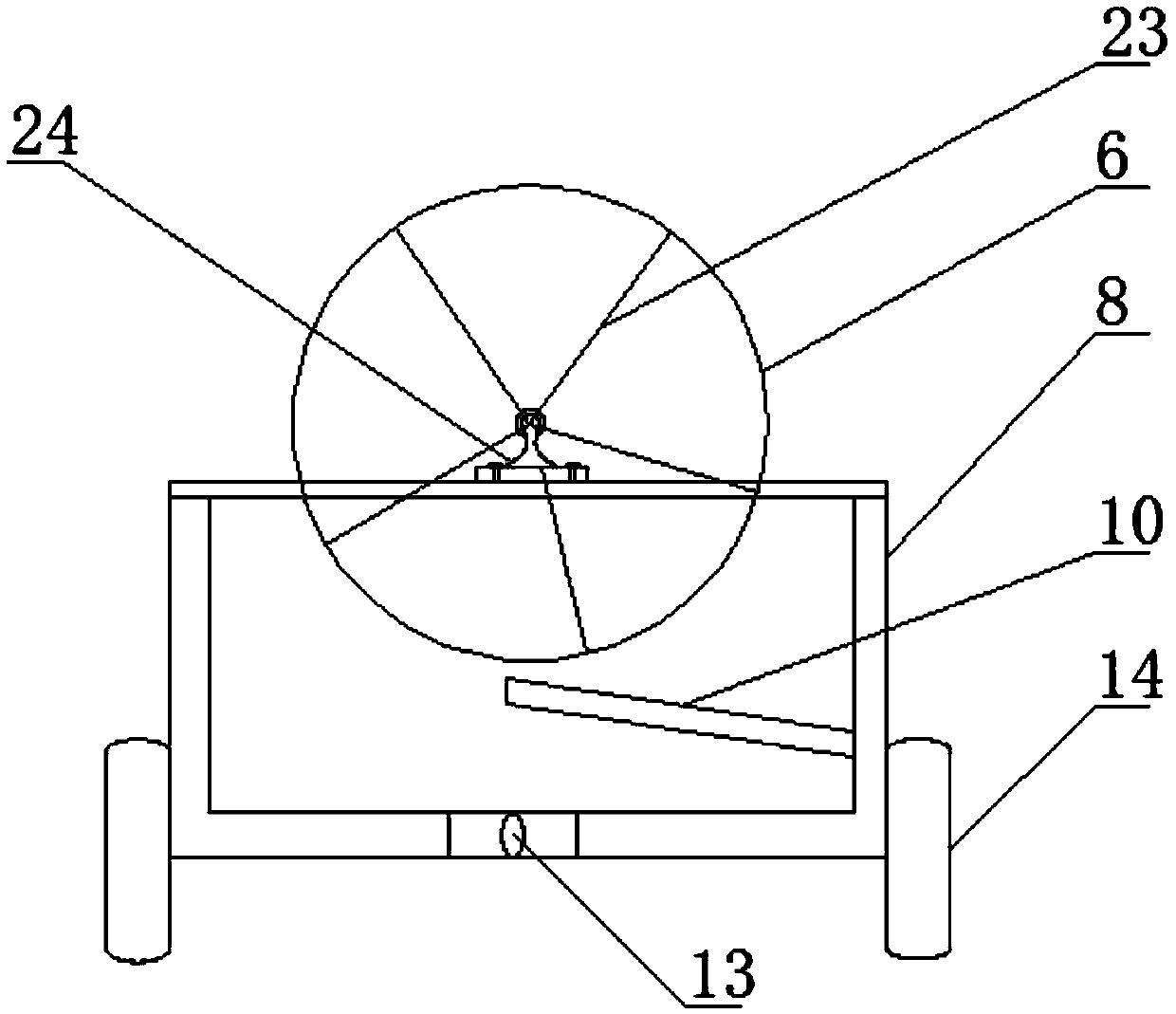

Full-automatic fungus bag production line for edible fungi

ActiveCN105564688AFully automatic production processRealize preliminary productionSuccessive articlesPulp and paper industryManufacturing line

The invention relates to a full-automatic fungus bag production line for edible fungi. The full-automatic fungus bag production line comprises a bag feeding device, a bag manufacturing device, a shaping device, a ring sleeving device, a cover pressing device and a basket loading device. According to the full-automatic fungus bag production line for the edible fungi, the full-automatic fungus bag manufacturing process can be achieved; the bag taking and fixing process is completed from bag manufacturing, bag taking and bag clamping; initial manufacturing of fungus bags is achieved through discharging, shaping and compaction; the bag opening packaging process is carried out through ring sleeving and cover pressing; and finally basket loading is carried out. Full automation is achieved, and the labor force is greatly saved; errors are not likely to be made; and in addition, the looseness degree of the fungus bags is the same, the weight of the fungus bags is the same, and therefore the production quality of the fungus bags is greatly improved.

Owner:厦门祺安达自动化设备有限公司

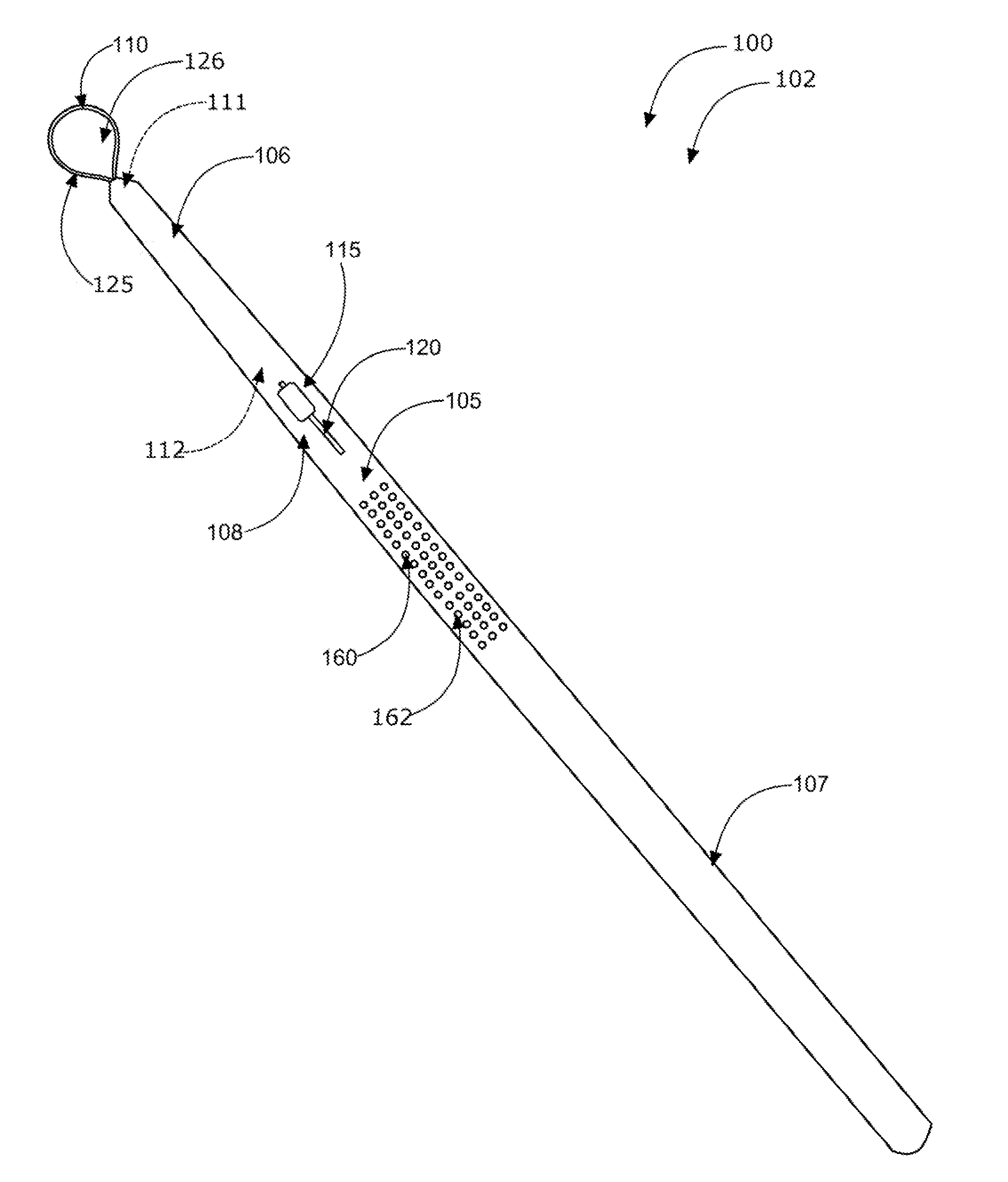

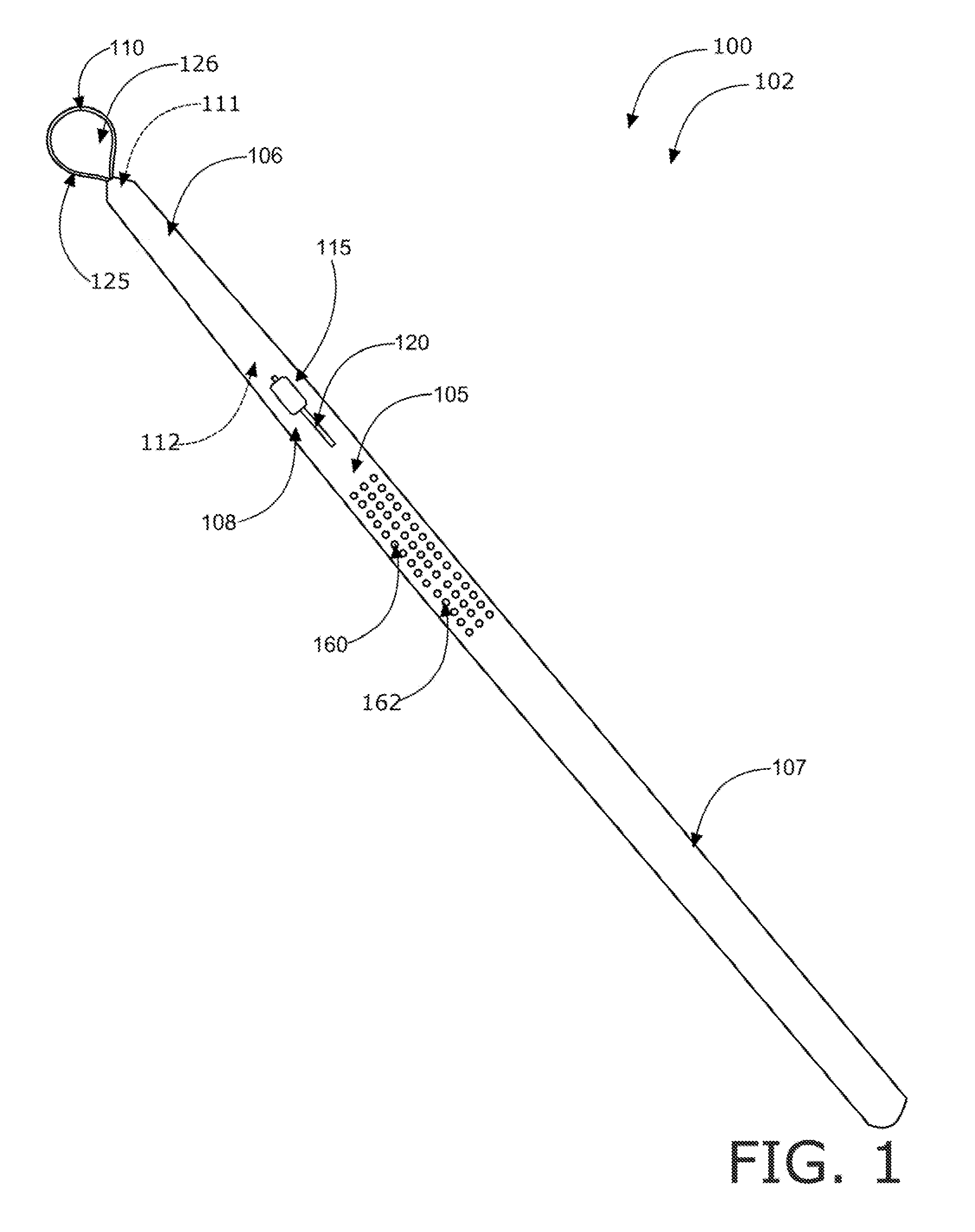

Adjustable Curette

ActiveUS20150157357A1Easy to adjustSave healthcare dollarSurgical instrument detailsExcision instrumentsCuretteEngineering

An adjustable, disposable dermal curette is structured to allow a user-practitioner to ergonomically grip a handle and manipulate an adjustable slider with a digit of their hand in order to change the diameter size of the flexible blade formed in an adjustable loop to the useful range of diameter sizes required. The user-practitioner can lock and unlock the slider in place quickly without the need to interrupt their procedure. The adjustable curette solves the problem of requiring multiple curette loop sizes for a procedure and results in improved quality of care and a savings of time and healthcare dollars.

Owner:NOVON SOLUTIONS

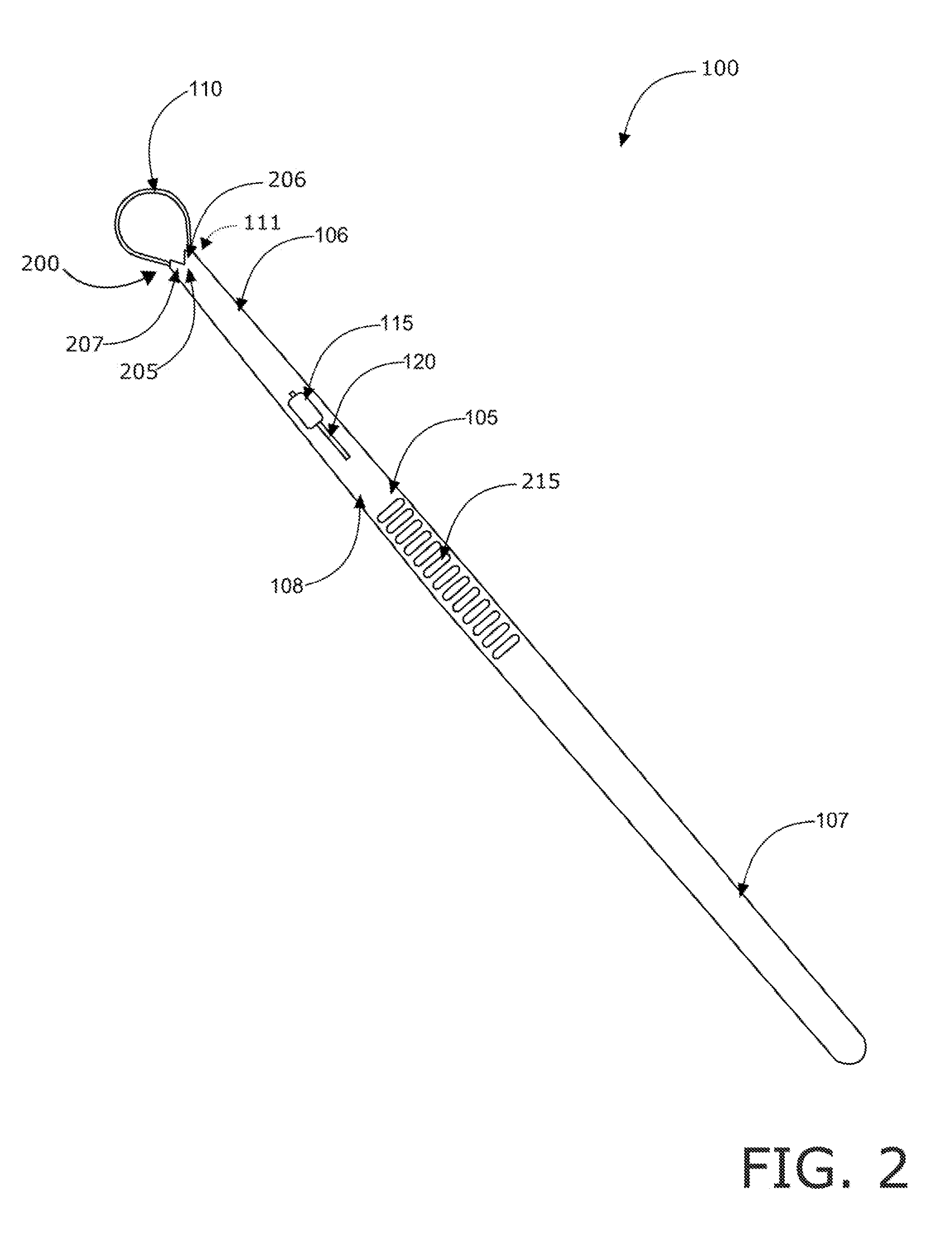

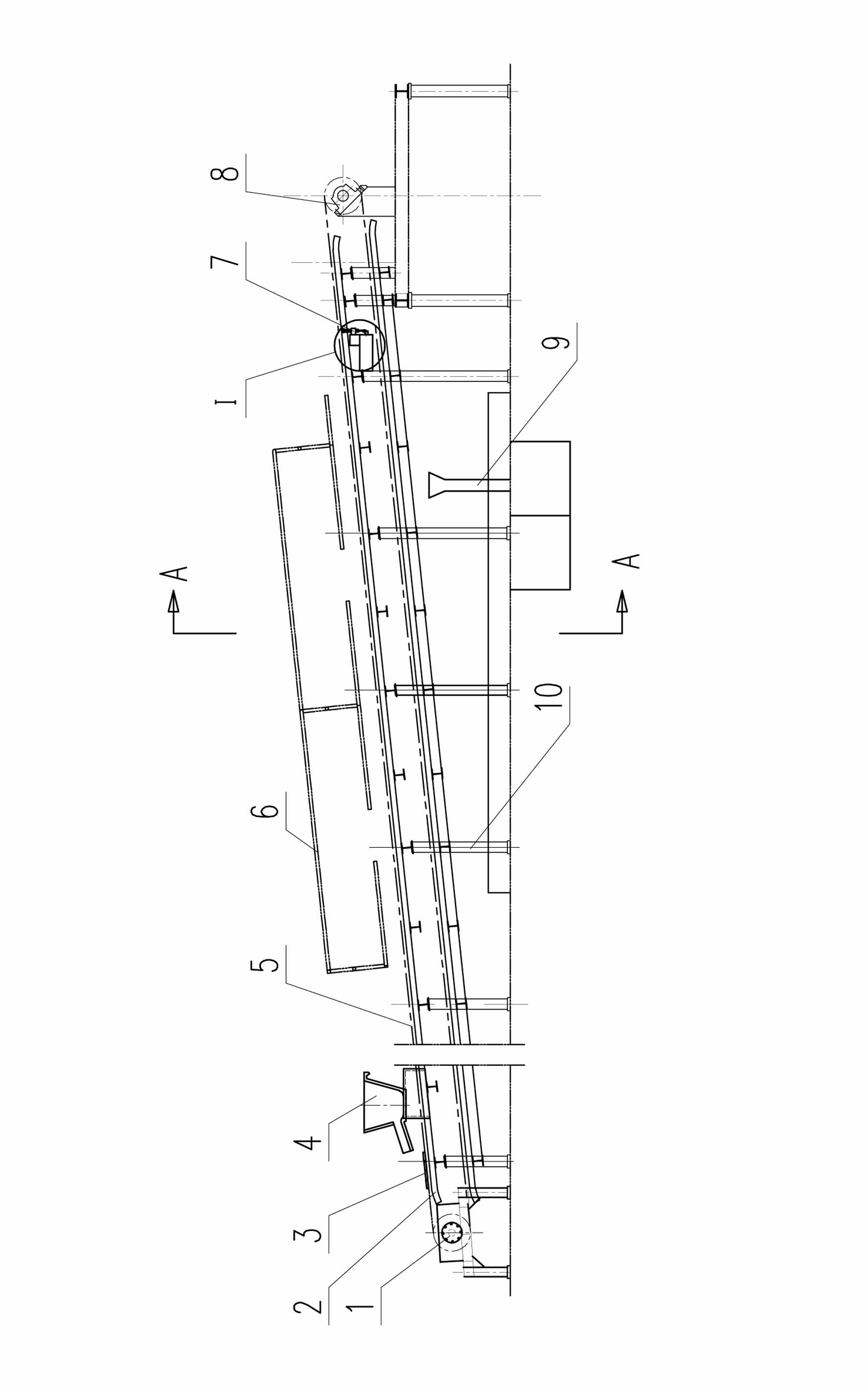

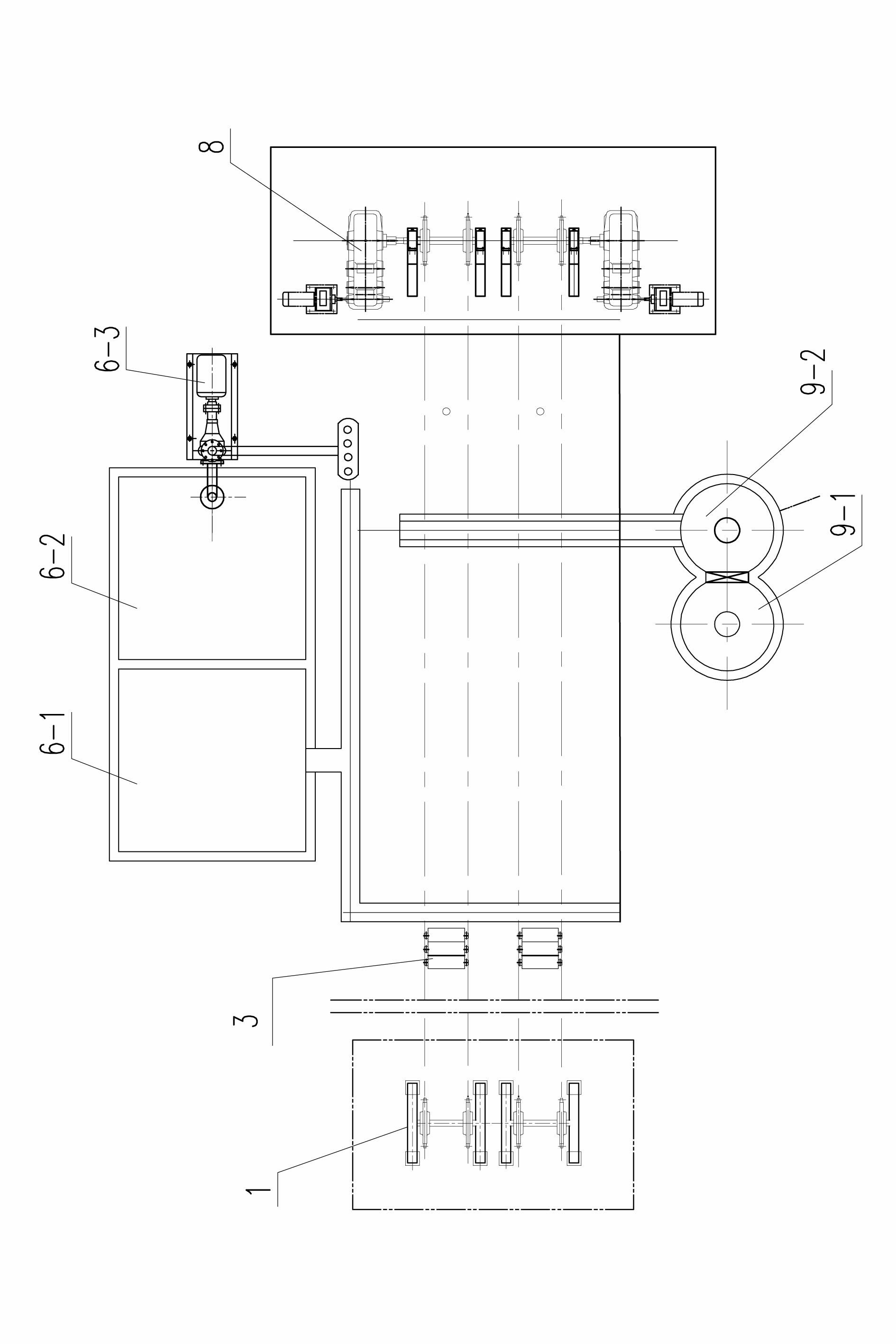

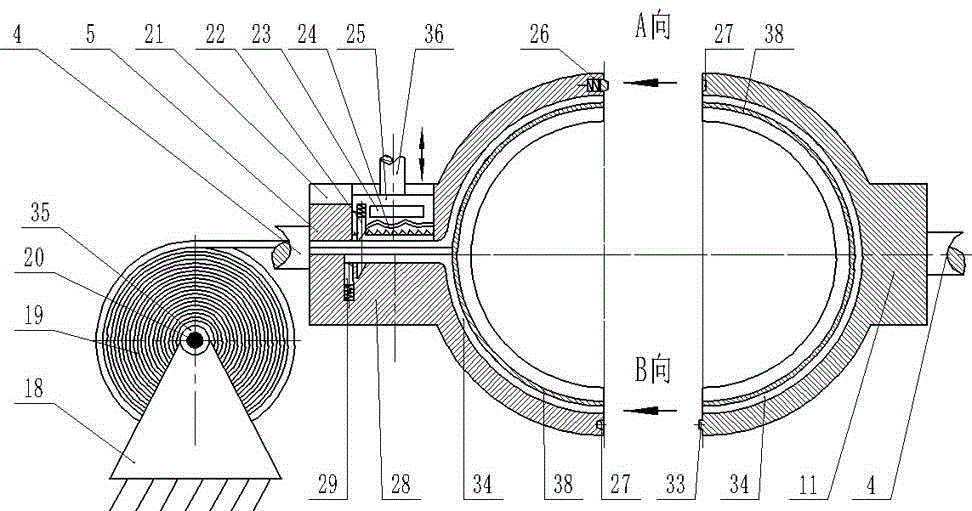

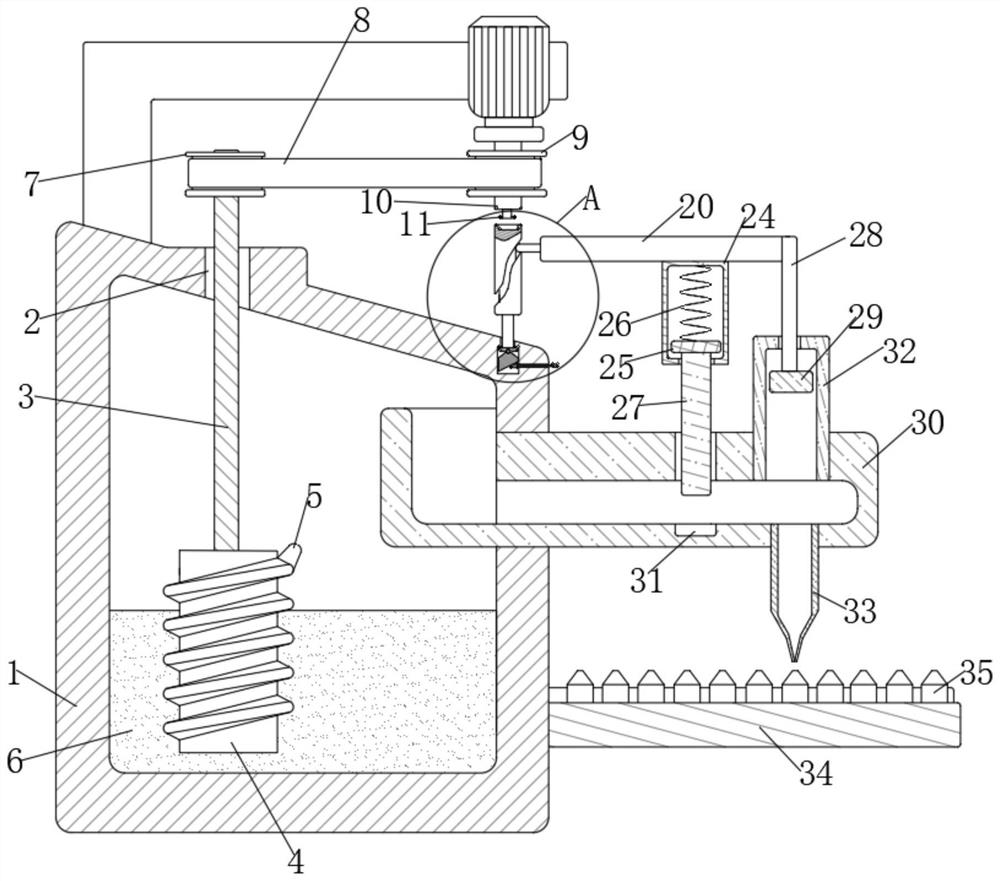

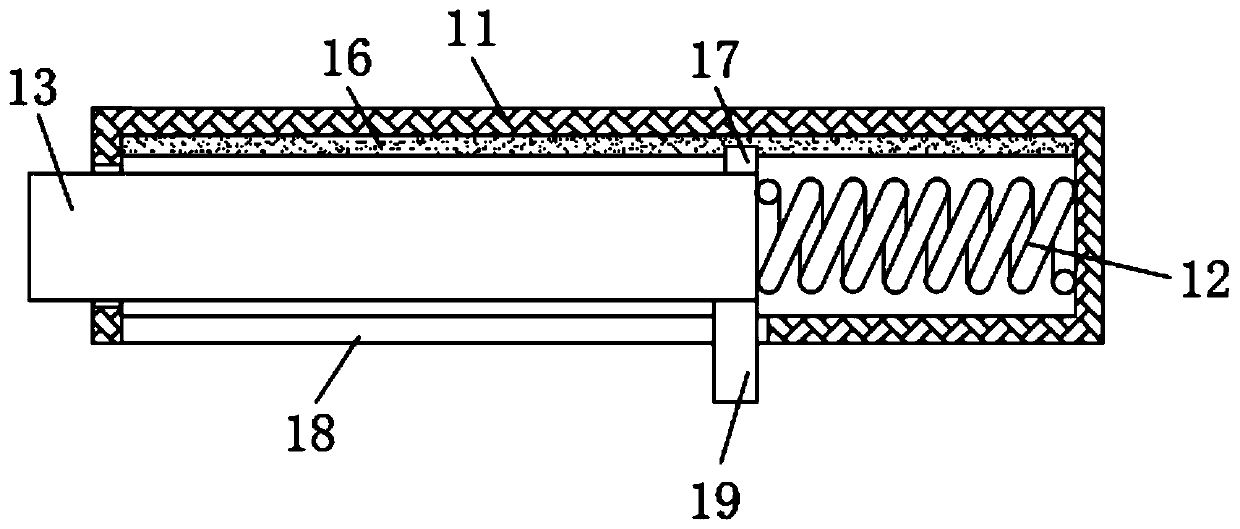

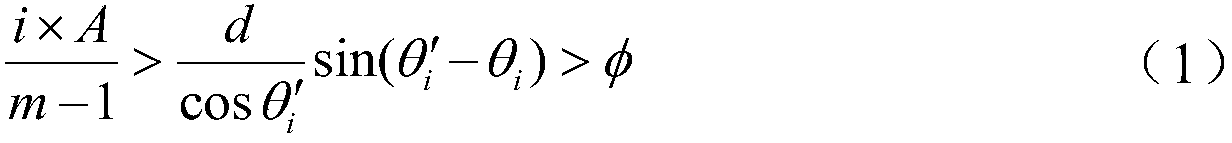

Automatic moxa stick rolling machine

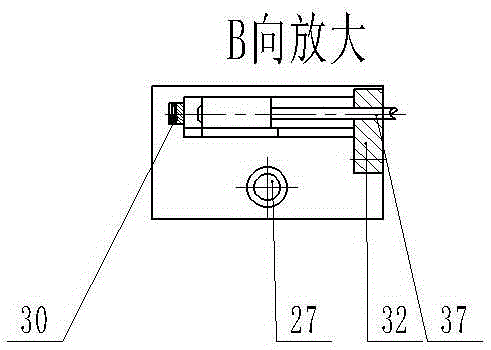

ActiveCN105919798AConsistent weightBeautiful appearanceDevices for heating/cooling reflex pointsPulp and paper industryDistance sensors

The invention provides an automatic moxa stick rolling machine. The automatic moxa stick rolling machine includes a cylindrical measurement feeding mechanism, an outer wrapping paper conveying mechanism, an inner wrapping paper conveying mechanism, and a moxa stick forming mechanism, which are arranged successively; the cylindrical measurement feeding mechanism includes a measurement mechanism and a feeding mechanism; the measurement mechanism includes a cylindrical barrel, a stirring shaft, an upper scraping plate, a lower scraping plate, a partition plate, a motor, a sensor, and a feeding device; the inner wrapping paper conveying mechanism includes an inner wrapping paper storage groove, an inner wrapping paper suction disc, an inner wrapping paper conveying disc, an air cylinder and a distance sensor; the outer wrapping paper conveying mechanism includes an outer wrapping paper storage groove, an outer wrapping paper suction disc, an air cylinder, a distance sensor, and an outer wrapping paper gluing mechanism; and the moxa stick forming mechanism includes a moxa pushing compaction device and a moxa conveying forming device. The automatic moxa stick rolling machine can continuously produce moxa sticks, can achieve automatic batch production, can save human resource, and can improve the production efficiency.

Owner:NANYANG BENCAOAI DEV

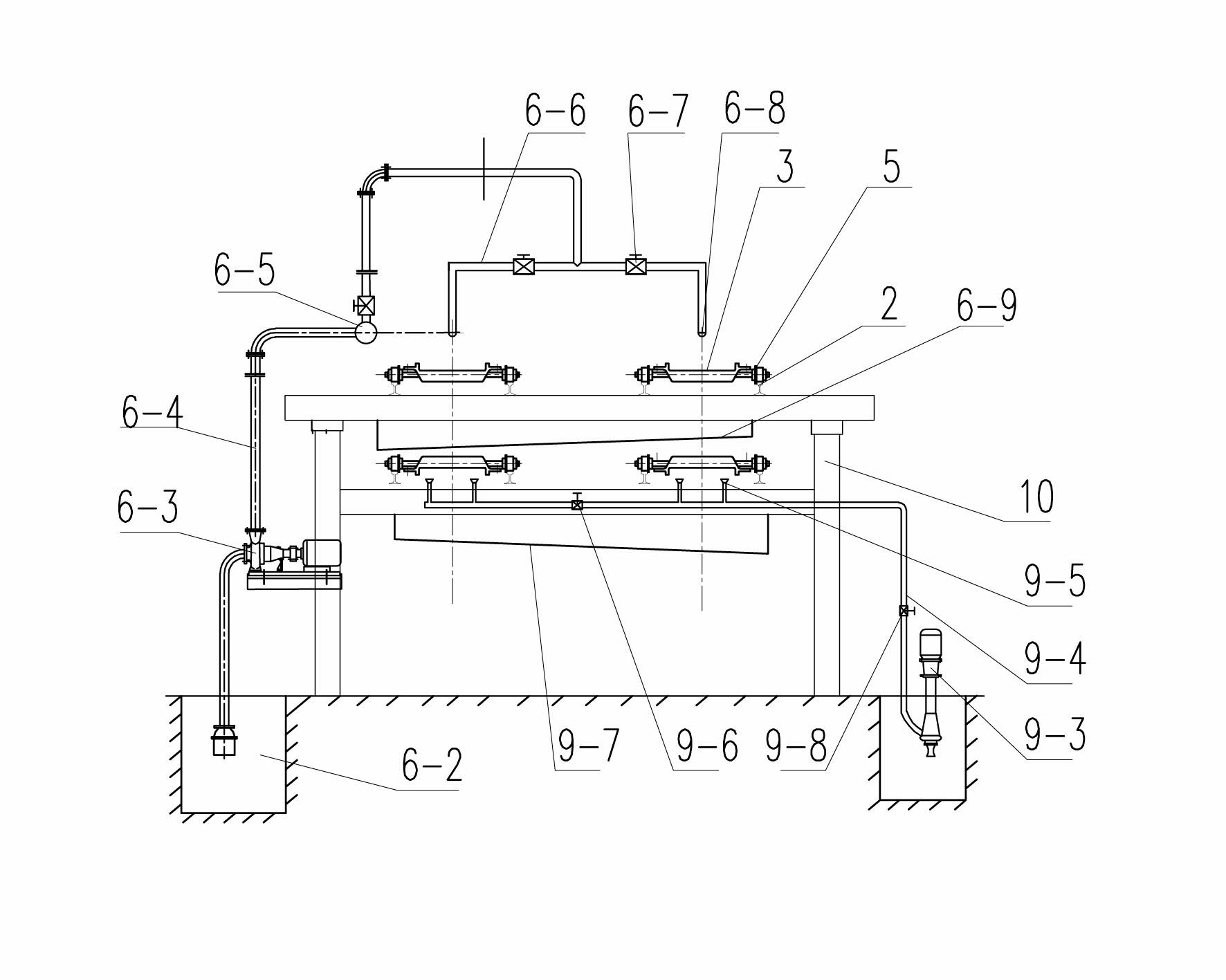

Iron alloy grain casting machine

The invention belongs to the technical field of pig casting machines for continuously producing casting pigs, and in particular relates to an iron alloy grain casting machine, which consists of a chain type slope conveyor, a grain casting die, a slurry spraying mechanism, a water cooling mechanism, a shocking device, an iron alloy liquid pouring insulation chute, a finished grain casting product receiving hopper and an electric control device, wherein the chain type slope conveyer consists of a conveyor frame, a chain inclined rail, a conveyor driving device, a conveyor tensioning and rotating device, and an annular roller chain; the slurry spraying mechanism consists of a stirring device, a slurry spraying stirring tank, a slurry spraying tank, a coating slurry sprayer and a slurry return groove; the water cooling mechanism consists of a water sedimentation tank, a water cooling tank connected with the water sedimentation tank through a water connecting pipe, a cold water sprayer and a water return groove; and the shocking device consists of a shocking bracket, a shocking driving device, an eccentric block, a fixed pin roll, a connecting rod, a reciprocating rod, a guide sleeve, a spring and a contact. The iron alloy grain casting machine completes a series of work procedures such as pouring, cooling, demolding and collecting iron alloy grains at one time and reduces labor intensity and production cost.

Owner:LIAONING DINGSHIDA METALLURGICAL EQUIP MFG +1

A structurally improved food cooking machine/juice machine

A food processor / juicer of an improved structure comprises a fixed base, a cup assembly, a driving assembly and a vacuum pump assembly. The cup assembly comprises a cup holder, a cup wall and a cup cover; the driving assembly comprises a driving motor, a first output shaft, a clutch and a second output shaft, and a first variable gear is arranged on the second output shaft; the vacuum pump assembly comprises a base frame, a speed change unit and a compression unit, the fixed base is provided with an opening, the compression unit is provided with an air extraction opening, the air extraction opening is connected with one end of a telescopic hose, the cup cover is provided with an air extraction hole, and the other end of the telescopic hose penetrates through the opening, then extends to the cup cover and is connected with the air extraction hole. The food processor / juicer is compact in integrated structure and convenient for a user to operate and carry, manufacturing cost is reduced, occupation on the inner space of the fixed base is reduced, and therefore the size and weight of the fixed base are substantially kept identical with those of an existing frequently-used juicer.

Owner:XIAMEN MYLUX INTELLIGENT TECH CO LTD

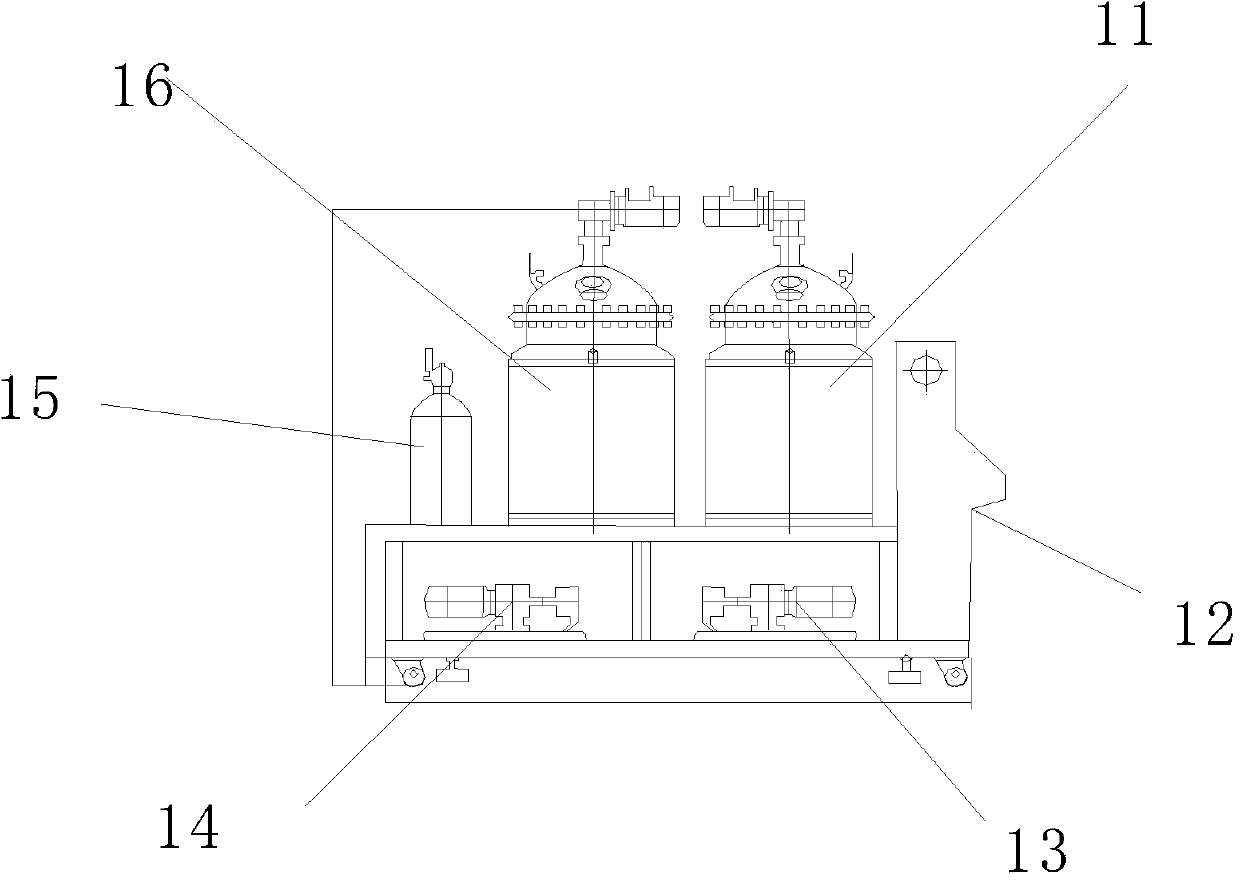

Automatic pouring PU (Polyurethane) earplug manufacturing device

The invention discloses an automatic pouring PU (Polyurethane) earplug manufacturing device. The automatic pouring PU (Polyurethane) earplug manufacturing device comprises a rack, wherein X-axis guide rails and X-axis driving mechanisms are arranged on the rack, a cantilever which can move along the guide rails is arranged on the X-axis guide rails, Y-axis guide rails and Y-axis driving mechanisms are arranged on the cantilever, an automatic color matching and injection mixing device which can move along the guide rails is arranged on the Y-axis guide rails, an earplug mold permanent seat and an automatic line feed mold opening and closing actuator are arranged at one end of the rack, multiple earplug molds are arranged on the permanent seat at intervals, and a water heating circulating device with double pipelines, which is used for heating each earplug mold, is also arranged at one side of the rack. The automatic pouring PU (Polyurethane) earplug manufacturing device has a self-timing mold opening and closing function and can be used for ensuring that products reach physical property requirements within setting time; and by adopting the automatic pouring PU (Polyurethane) earplug manufacturing device, the product quality is ensured, after mold opening, the products are separately molded, and secondary machining is not needed, so that raw materials are saved, and the efficiency is high.

Owner:玉托英

Secondary compression moulding device for bale

The invention discloses a secondary compression moulding device for a bale. The device comprises a feeding mechanism, a compression cavity, a pressure maintaining cavity, a compression mechanism, a vertical pushing mechanism, a horizontal pushing mechanism, a strapping mechanism and a cutting mechanism; the bale output end of the feeding mechanism is communicated with a feeding hole disposed on a sidewall in the length direction of the compression cavity; the pressure maintaining cavity is disposed on the lower part of the end part of the compression cavity opposite with the compression mechanism and communicated with the compression cavity; the pressure maintaining cavity extends towards one end along the width direction of the compression cavity; the top part of the end part of the compression cavity at a place corresponding to the pressure maintaining cavity is connected with the vertical pushing mechanism; the end part of the non-extending part of the compression cavity is connected with the horizontal pushing mechanism; and the extending part of the pressure maintaining cavity is orderly connected with the strapping mechanism and the cutting mechanism. The secondary compression moulding device for a bale disclosed by the invention has the advantages of being low in noise, large in compression density, high in production rate and capable of producing a secondarily-compressed bale with uniform weight and good appearance; and the square funnel-shaped design of the feeding hole of the compression cavity and the arrangement of a guide boss are good for smooth feeding for bale without blockage.

Owner:CHINA AGRI UNIV

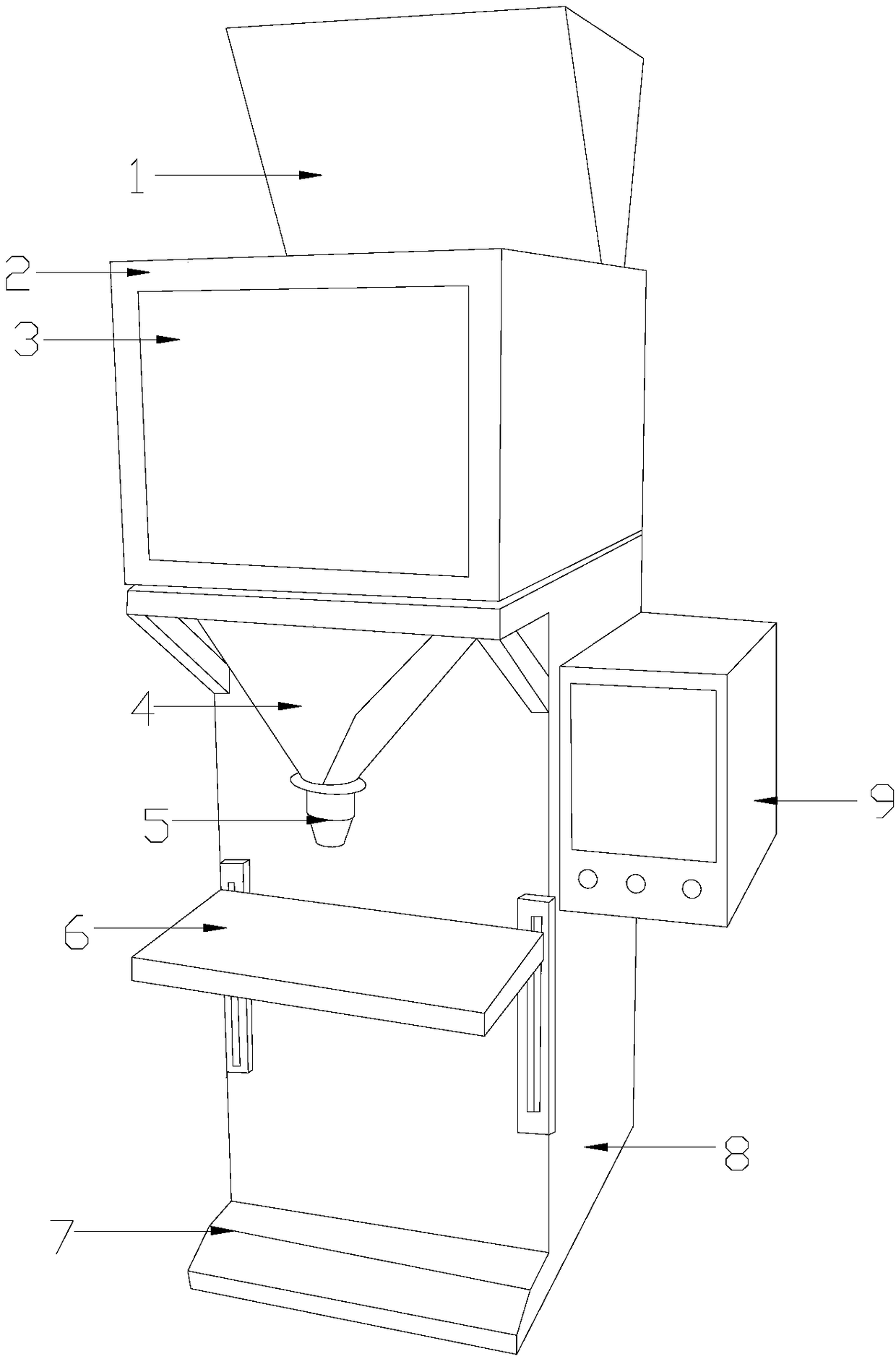

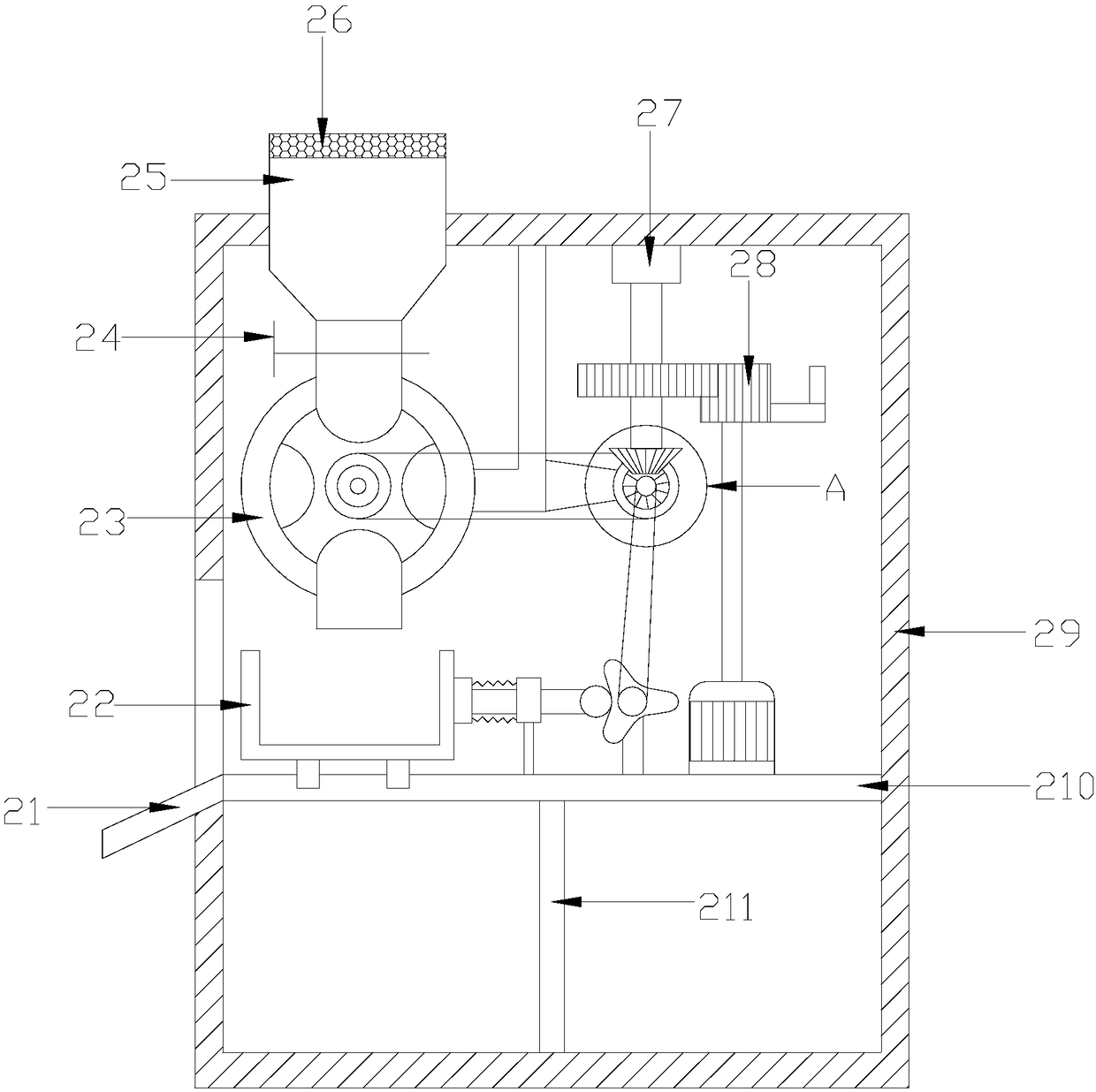

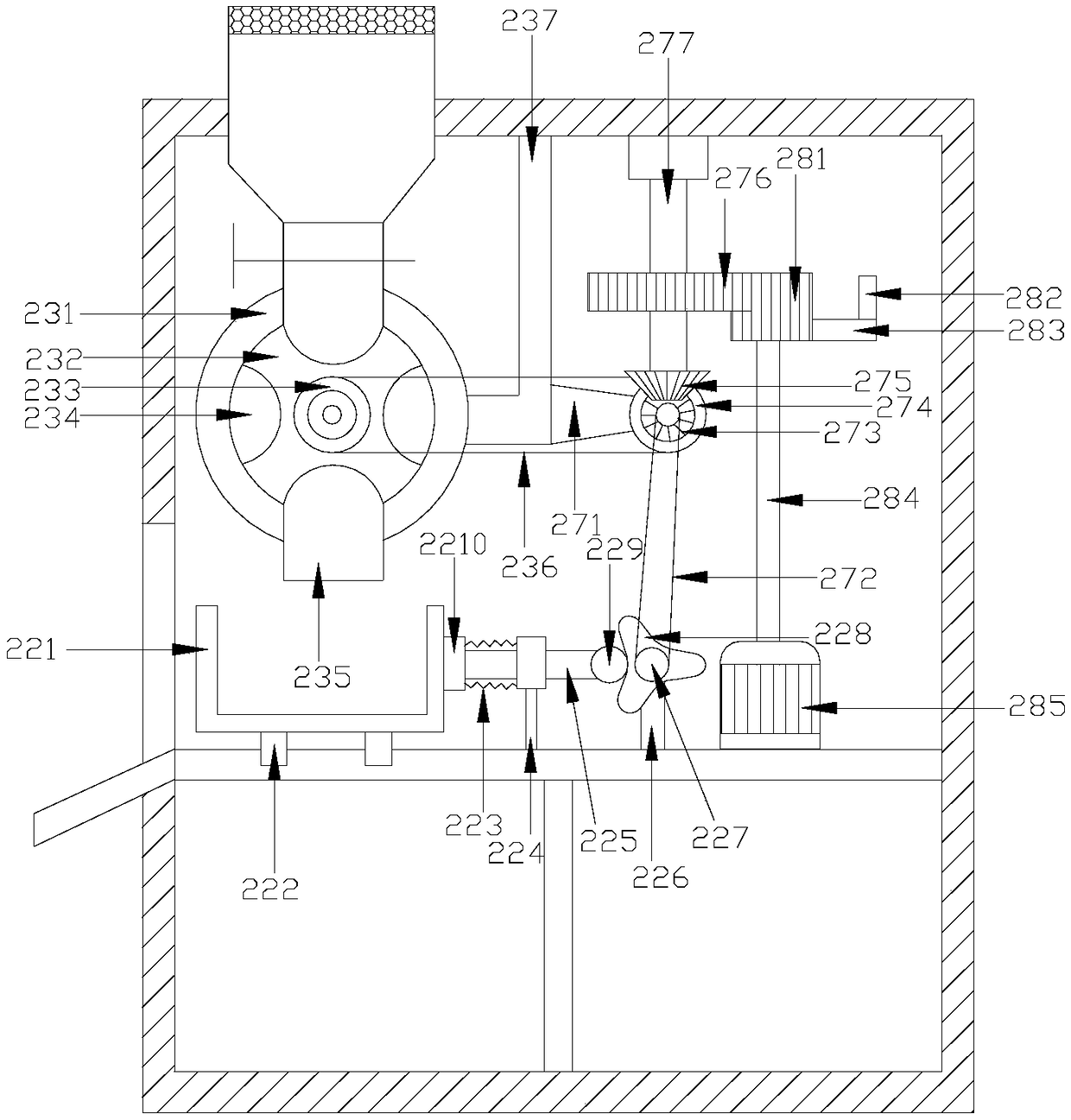

Novel feed feeding and packaging equipment

The invention discloses novel feed feeding and packaging equipment. The novel feed feeding and packaging equipment is characterized by structurally comprising a charge hopper, an automatic quantitative packaging mechanism, an observation window, a discharge hopper, a discharge pipeline, a lifting working platform, a fixed base, a working rack, and a control box body. According to the novel feed feeding and packaging equipment disclosed by the invention, a slot wheel and a pulling disc are arranged, so that the slot wheel rotates while the motor rotates one circle, and a separating wheel rotates for enabling an arc-shaped slot to intermittently move to a position below the charge hopper for collecting materials, and therefore, quantitative collecting is realized, material packaging quantitycan be controlled, weight of every pack of materials is consistent, difficult selling caused by uneven quantity of every pack is avoided, economic benefits are reduced, and daily economic benefits are guaranteed; when quantitative packaging is required, a collecting frame is placed below a discharge tube, an unloading conveying mechanism is controlled to convey from right to left; and a valve isopened for adding feed into the hopper, the feed in the charge hopper drops into the arc-shaped slot, and the motor is controlled to rotate to drive a second rotary shaft to rotate, so that a pullingdisc is driven to rotate.

Owner:HUZHOU ZHENSHUO AUTOMATION TECH CO LTD

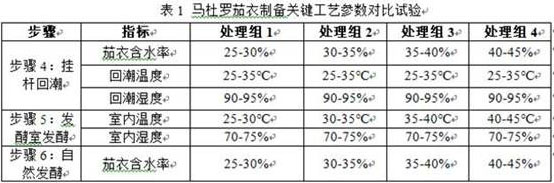

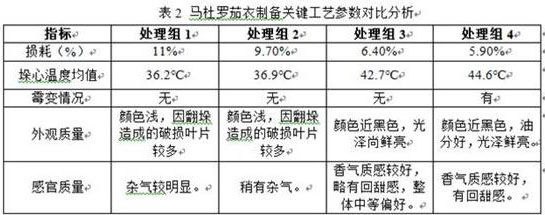

Preparation method of Maduro cigar coating

ActiveCN112515233AConsistent colorUniform colorTobacco preparationTobacco treatmentBiotechnologyEngineering

The invention discloses a preparation method of a Maduro cigar coating. The preparation method comprises the following steps: (1) selecting raw materials; (2) killing insects at low temperature; (3) soaking handles; (4) conducting moisture regaining of hanging rods; (5) fermenting in a fermentation chamber; (6) carrying out natural fermentation; (7) classifying and grading. The sizes and weights of the selected raw materials are consistent as much as possible, so that the states of coatings in the technological process are the same, and the coatings are more uniform and consistent in color inthe fermentation process of the fermentation chamber; fermentation in the fermentation chamber is combined with natural fermentation, so that the energy consumption is reduced, the fermentation time is shortened, and the tobacco quality is improved; the products after fermentation are subjected to grading treatment, so that the subsequent product screening process is shortened, meanwhile, the products with poor products are subjected to secondary fermentation in the fermentation chamber, and the utilization rate of the products is increased.

Owner:HUBEI CHINA TOBACCO IND

Method for producing bottled native ceromel

InactiveCN105831016AIntuitive original ecological shapeIntuitive traitsAnimal husbandryFood scienceBottleComb honey

The invention discloses a method for producing bottled native ceromel. The method comprises the following steps: 1, cleaning and sterilizing a ceromel bottle; 2, embedding a primer into the ceromel bottle, wherein the primer is an artificial comb foundation, a natural honeycomb or beeswax; 3, putting the ceromel bottle with the primer into a beehive; 4, guiding bees into the bottle for nesting and making honey: attracting the bees into the ceromel bottle by virtue of the primer in the step 2, and nesting and making honey on the basis of the primer; and 5, performing sealing and packaging after the ceromel obtained by honey making in the step 4 naturally matures. According to the native ceromel production method adopted in the invention, the bees can be guided into the ceromel bottle for nesting and making honey without an artificial comb foundation, which enables the finally formed ceromel finished product to be purely natural, have a primitive shape and more intuitive properties and be visible; the obtained ceromel is in a natural shape, and can meet the consumers' pursuit of natural form of honey, and the method guiding the bees into the bottle for nesting and making honey determines that the shape, size and weight of each bottle of the ceromel are basically kept consistent, and is helpful for sale of the ceromel.

Owner:周楚雄

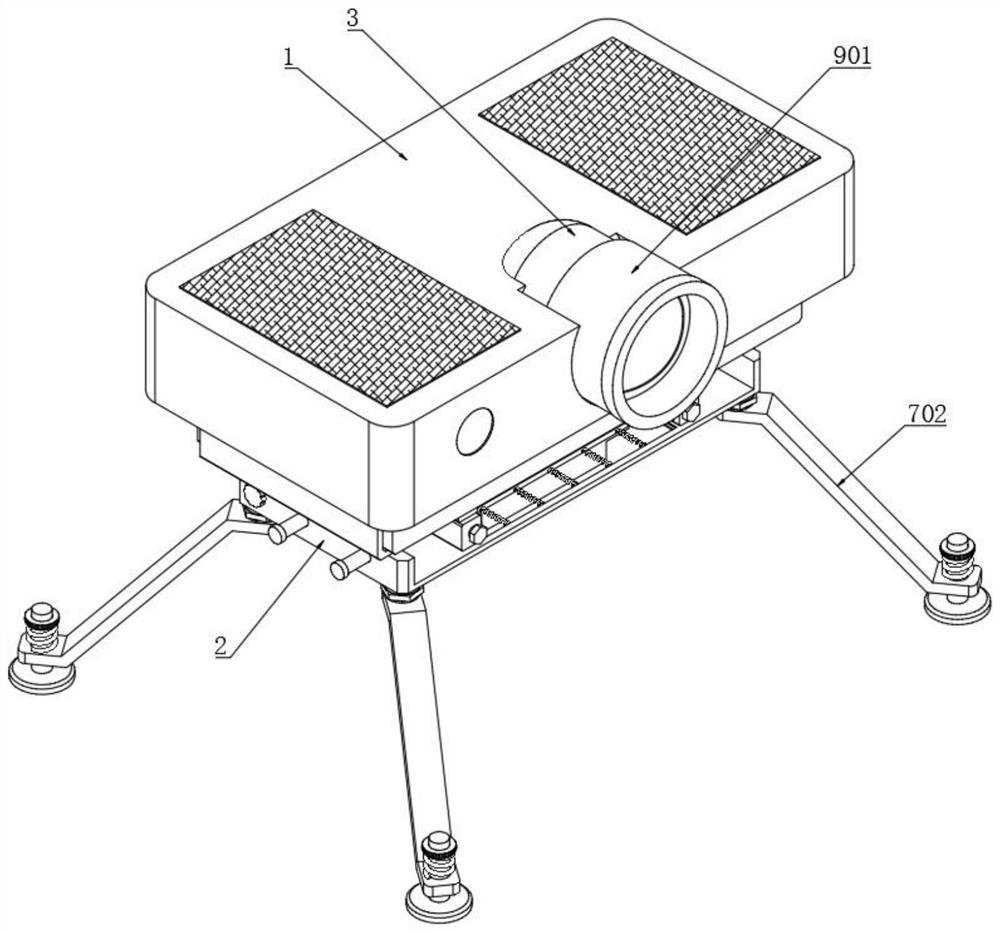

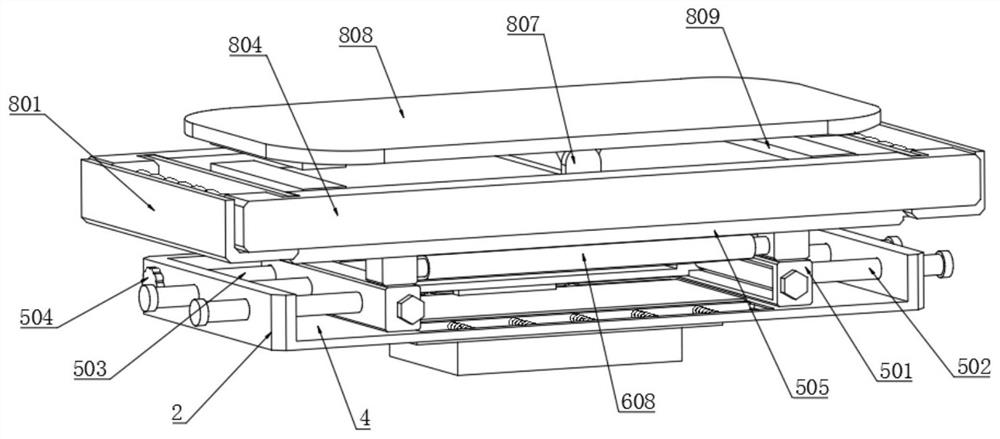

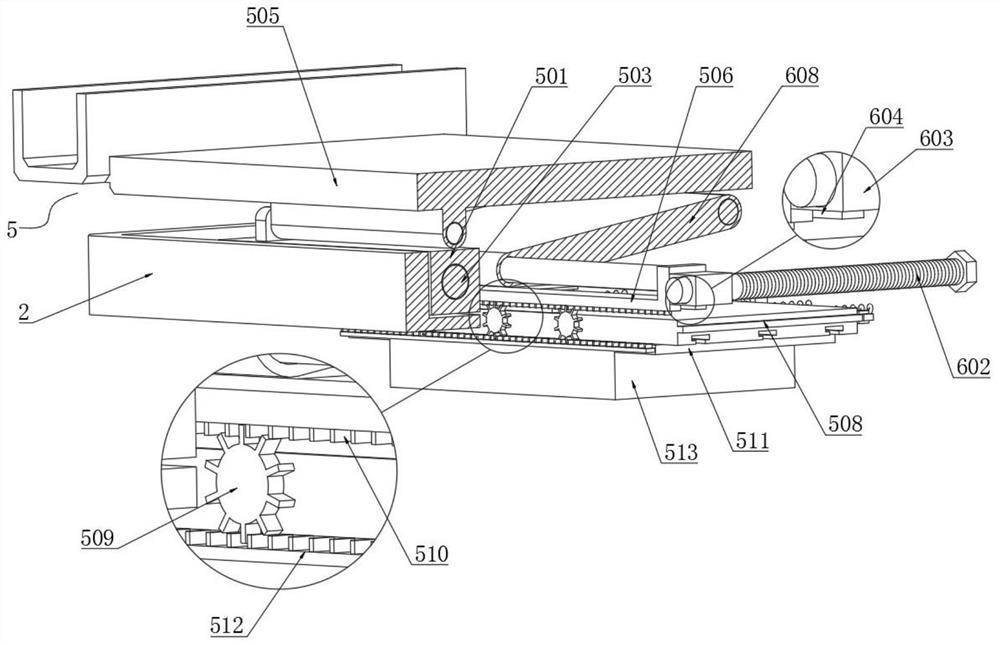

Intelligent projection system for visual communication

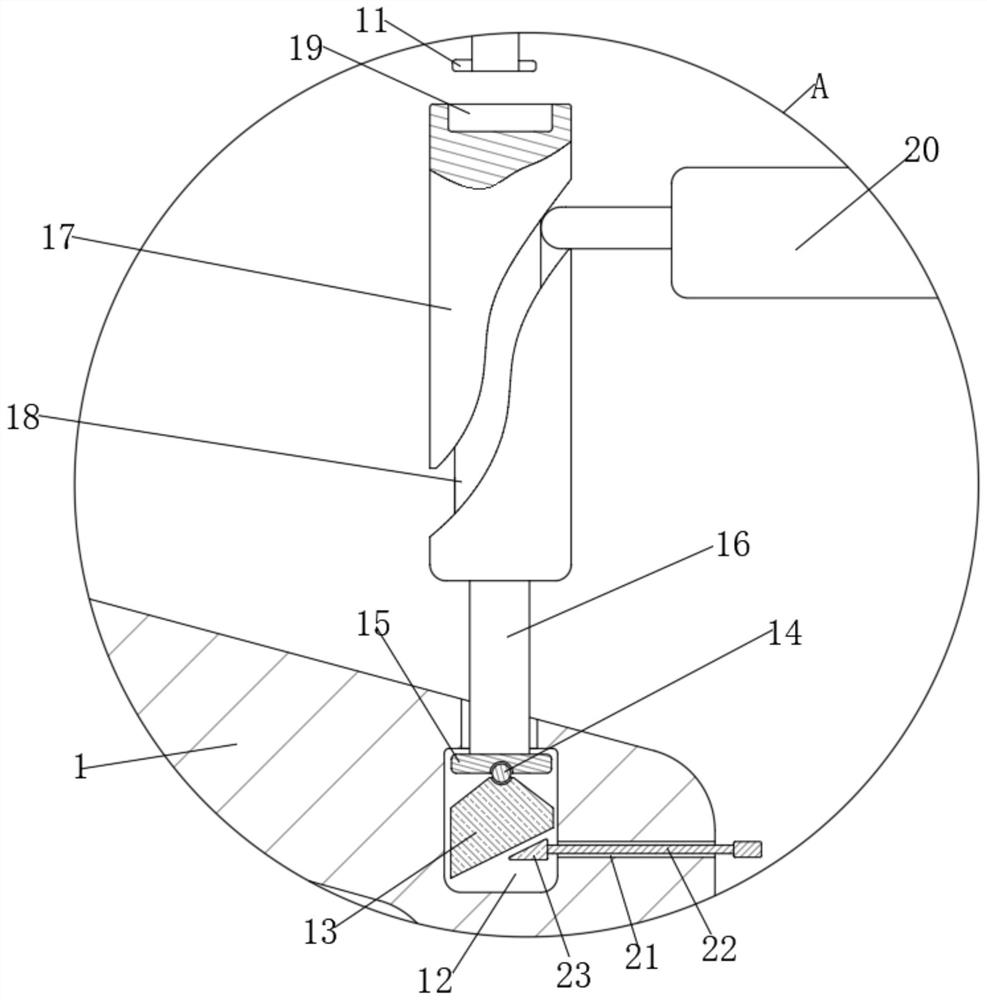

PendingCN114060675AScientific and reasonable structureEasy to useEngine sealsProjectorsGravity centerSlide plate

The invention discloses an intelligent projection system for visual communication, wherein the intelligent projection system comprises a projector and a supporting plate; one end of the projector is in threaded connection with a lens cone, a notch is formed in the top end of the supporting plate, and a position adjusting and gravity center balancing mechanism is arranged in the notch; and the position adjusting and gravity center balancing mechanism comprises a concave plate, a limiting rod, a lead screw, a rotary knob, a placing plate, a sliding plate, a groove, a movable plate, a transmission gear, a tooth bulge, a mounting plate, a rack and a counterweight plate. The structure is scientific and reasonable, and the use is safe and convenient; a position and gravity center adjusting mechanism is arranged, the lead screw is driven to rotate through the rotary knob, and the concave plate is pushed to move; and the concave plate is limited by the limiting rod, so that the concave plate slides in the notch, transverse fine adjustment is carried out on a projection picture, and the convenience of the device is improved; in addition, in the transverse fine adjustment process, the concave plate drives the sliding plate to move together, and meanwhile power is transmitted through cooperation of the transmission gear, the tooth bulge and the rack.

Owner:长春电子科技学院

Canned orange production canning device capable of ensuring weight consistency of products

The invention discloses a canned orange production canning device capable of ensuring the weight consistency of products. The canned orange production canning device comprises an outer frame, a firstmotor, a belt shaft, a conveyor belt and a device fixing plate. The first motor is mounted on the outer portion of the outer frame. A horizontal plate is arranged above the conveyor belt. A first push-pull plate is arranged on the side of a filling tank. A second push-pull plate is arranged below the first push-pull plate. The bottom end of the filling tank is connected with a discharge pipe. A special-shaped gear is mounted at the center of a horizontal shaft. A first rack is fixed to the lower end face of the first push-pull plate. Through redesign on a discharge structure, the canned orangeproduction canning device capable of ensuring the weight consistency of the products ensures the maximum consistency of the weights of finished filled cans and is higher in filling level. Moreover, the problems that a material port gets blocked due to deposition and the proportions of the contents in the cans are not uniform are solved. Meanwhile, the canned orange production canning device can conduct real-time screening on cans with non-standard weights after completion of filling.

Owner:CHANGDE HUIMEI AGRI TECH

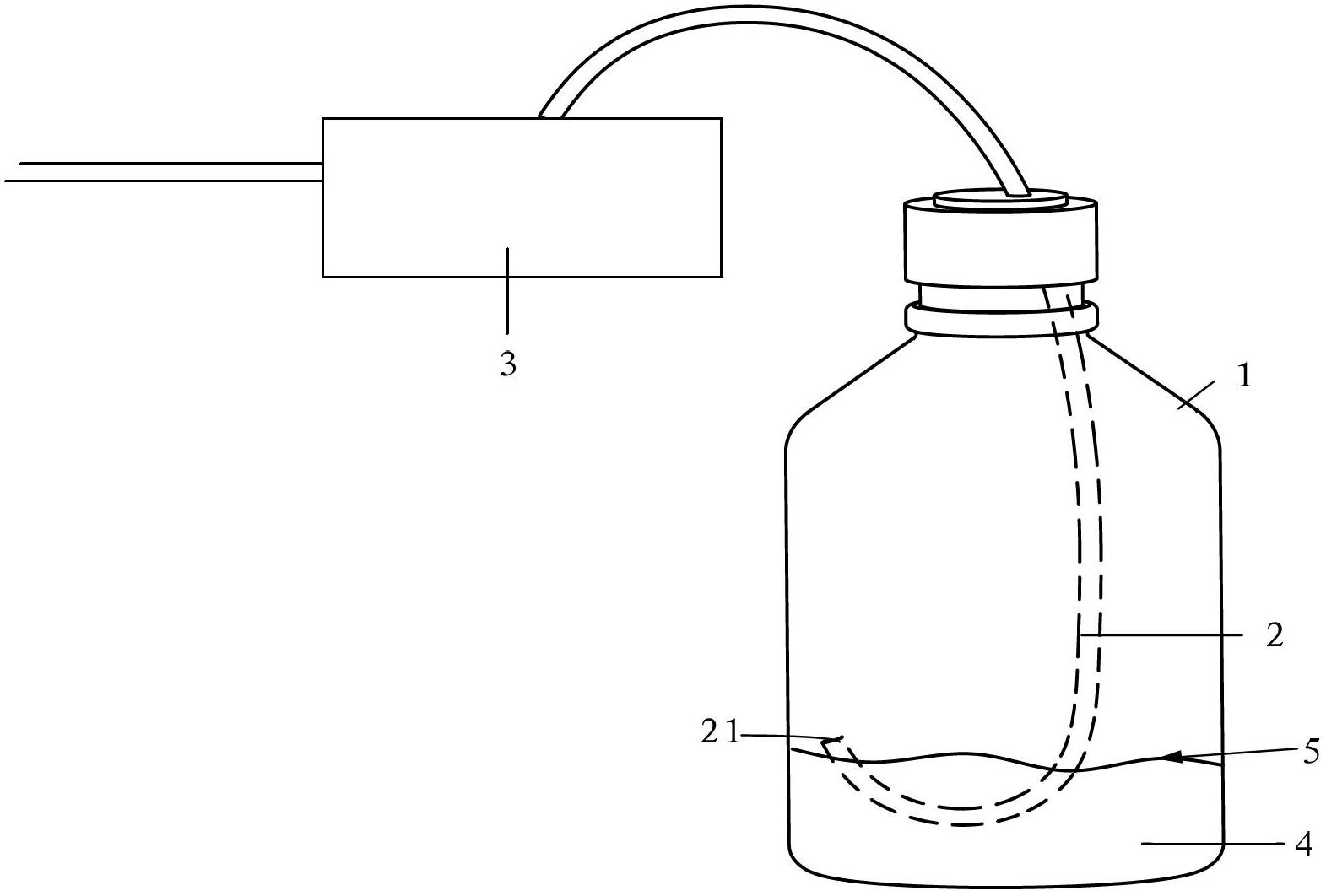

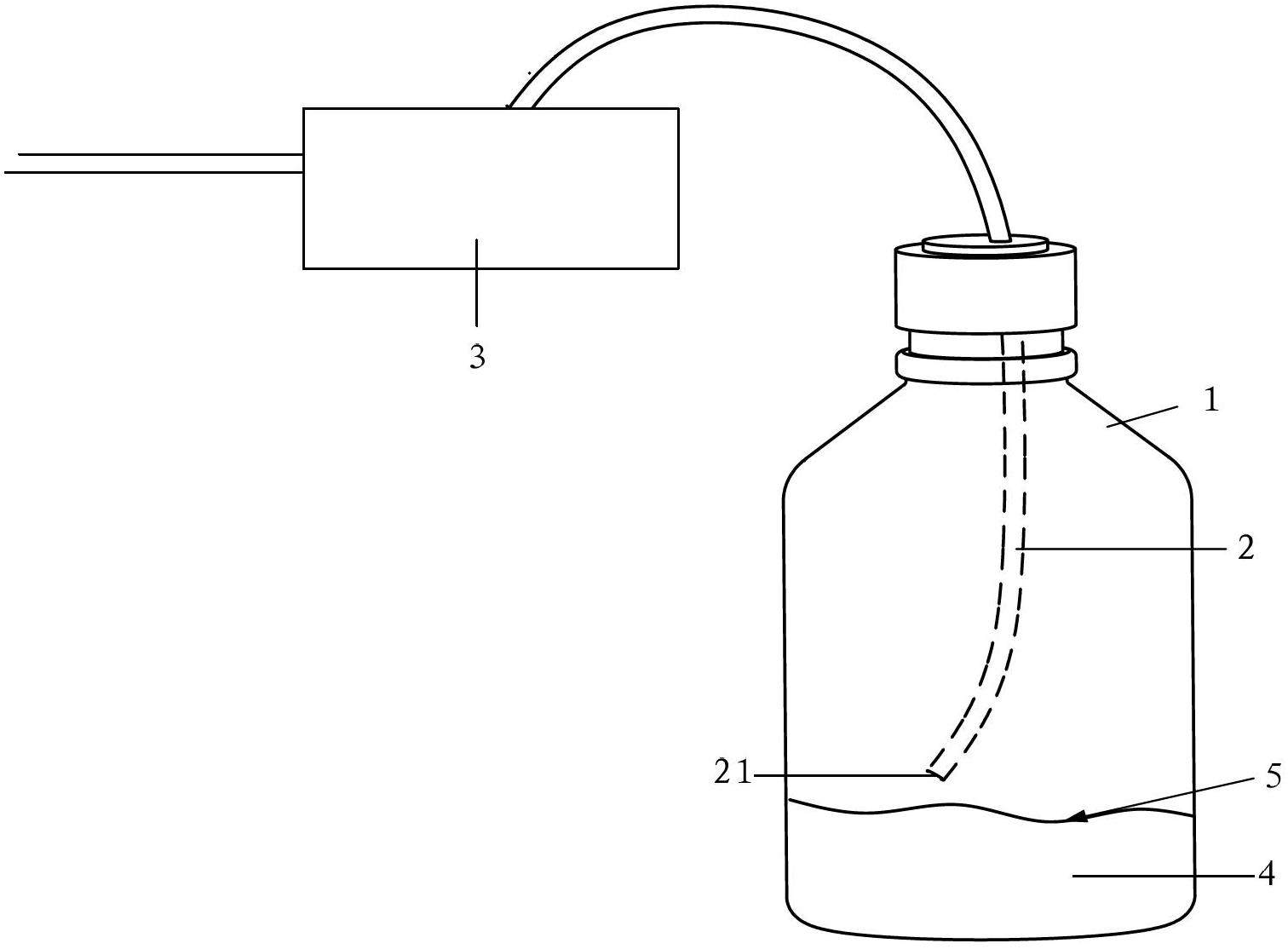

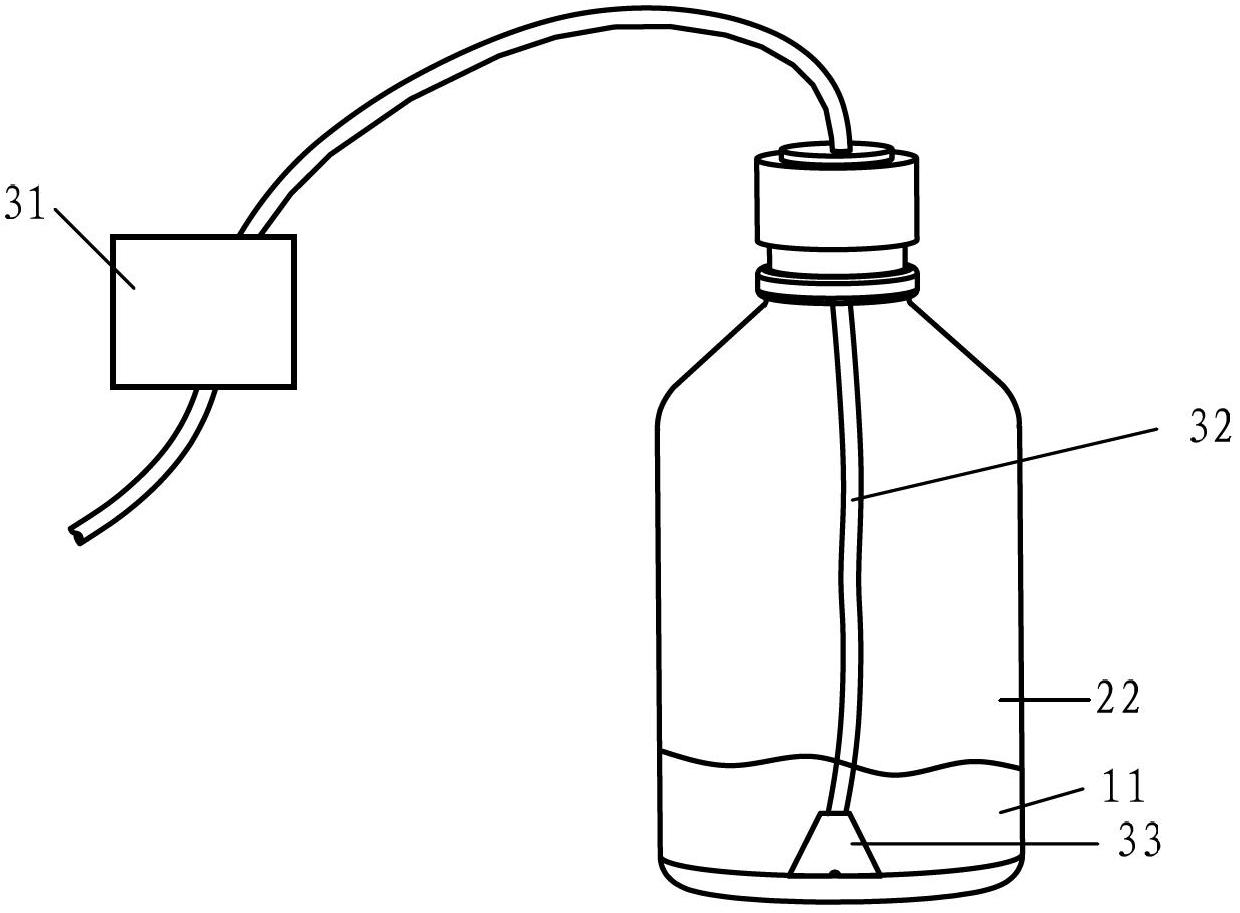

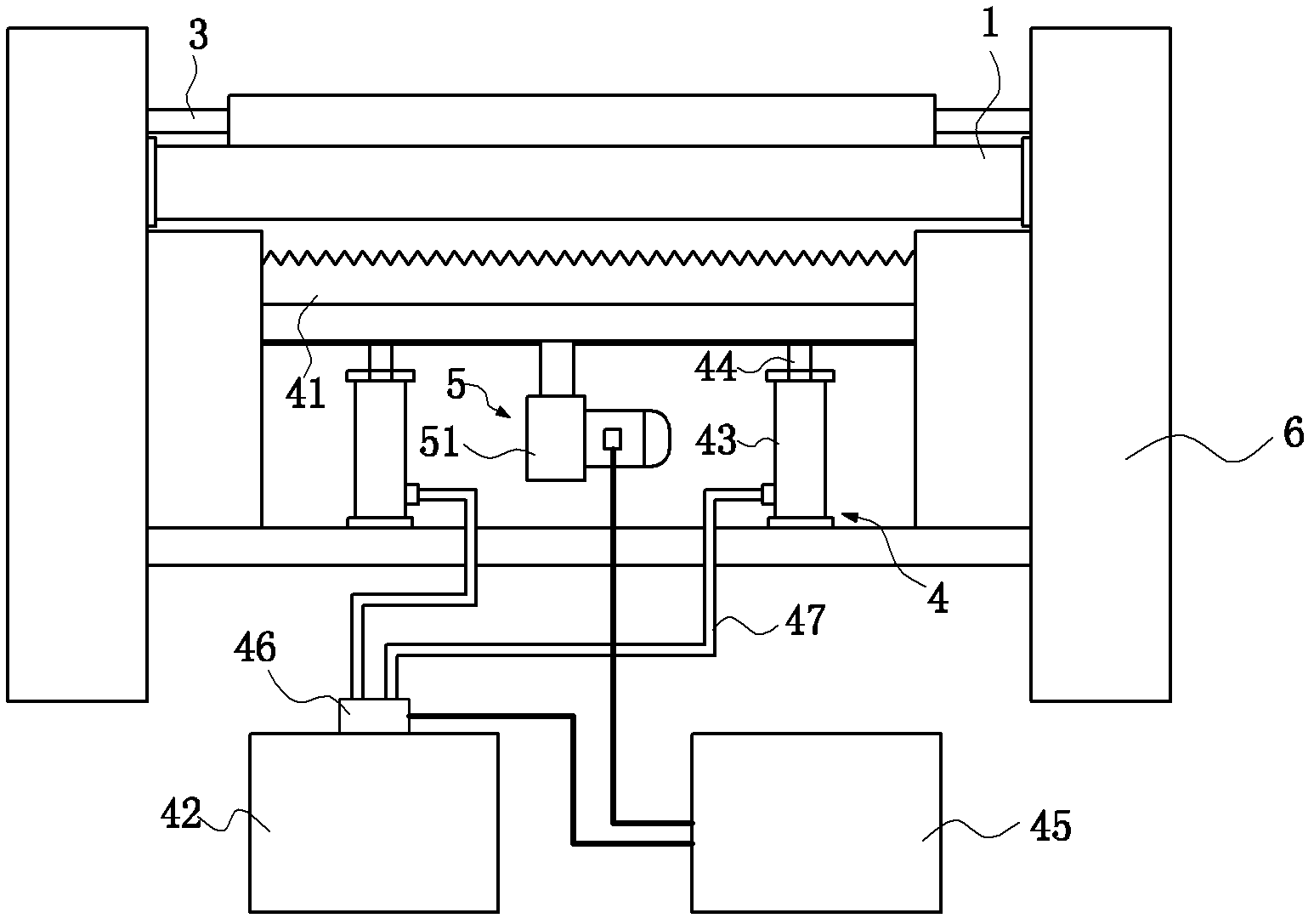

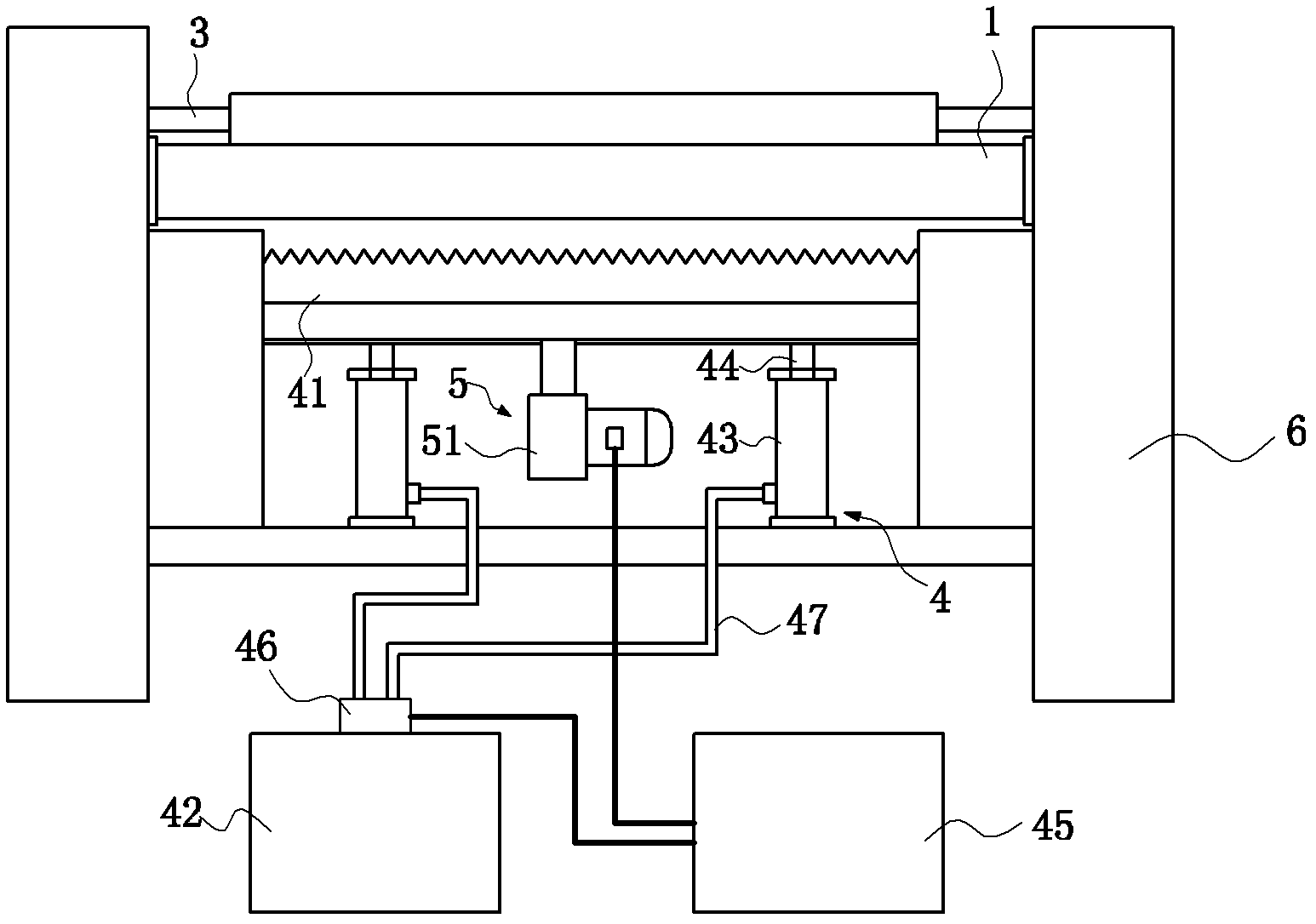

Liquid crystal suction device and liquid crystal coating equipment

InactiveCN102650774AConsistent weightAvoid inhalationLiquid surface applicatorsOptical articlesEngineeringLiquid crystal

The invention discloses a liquid crystal suction device. The device comprises a first vacuum generating unit, a flexible suction pipe and a load body, wherein the load body is arranged at one end of the flexible suction pipe; and the other end of the flexible suction pipe is connected with the first vacuum generating unit. The invention further discloses liquid crystal coating equipment. In this way, the invention can ensure that the suction end of a liquid crystal pipeline is kept below the liquid crystal level all the time so as to prevent the suction end of the liquid crystal pipeline from sucking air bubbles.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Reed combine harvester automatic wrist-cutting and bundling apparatus

InactiveCN105393698AConsistent weightImprove automatic control abilityReaper-bindersControl signalElectric machinery

The invention discloses a reed combine harvester automatic wrist-cutting and bundling apparatus comprising a reed rod collection cabin, a hydraulic driving system and an automatic bundling device. Two sides of the reed rod collection cabin are respectively provided with three pairs of hydraulic bearing rods; disc type bundling device semi-rings, semi-circular auxiliary work benches driven by piston rods and corresponding disc type cutters; and all hydraulic bearing rods, piston rods and the disc type cutters are driven by the hydraulic driving system. The automatic bundling device is a disc type bundling device. The disc type bundling device is formed by a main body, two auxiliary semi-rings, a bundling disc and a rotating shaft, wherein the rotating shaft of the bundling disc is driven by a motor and can forward and backward rotate via a control signal; a torque sensor is mounted on the rotating shaft to maintain constant torque. In the automatic bundling device, sensors, a hydraulic system, a tooth-shaped press plate, a heating device and a bundling belt cutter are employed; the bundling belt can be firmly bonded and knot-tying can be replaced; and automation can be realized.

Owner:HUNAN IND POLYTECHNIC

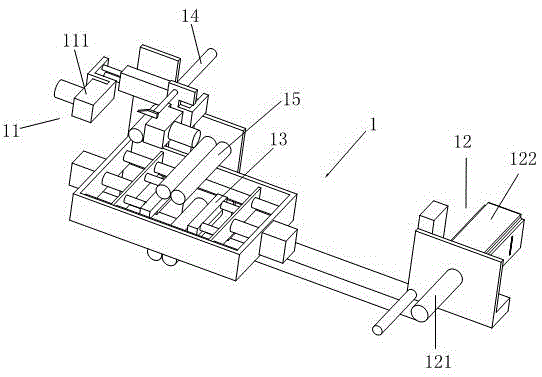

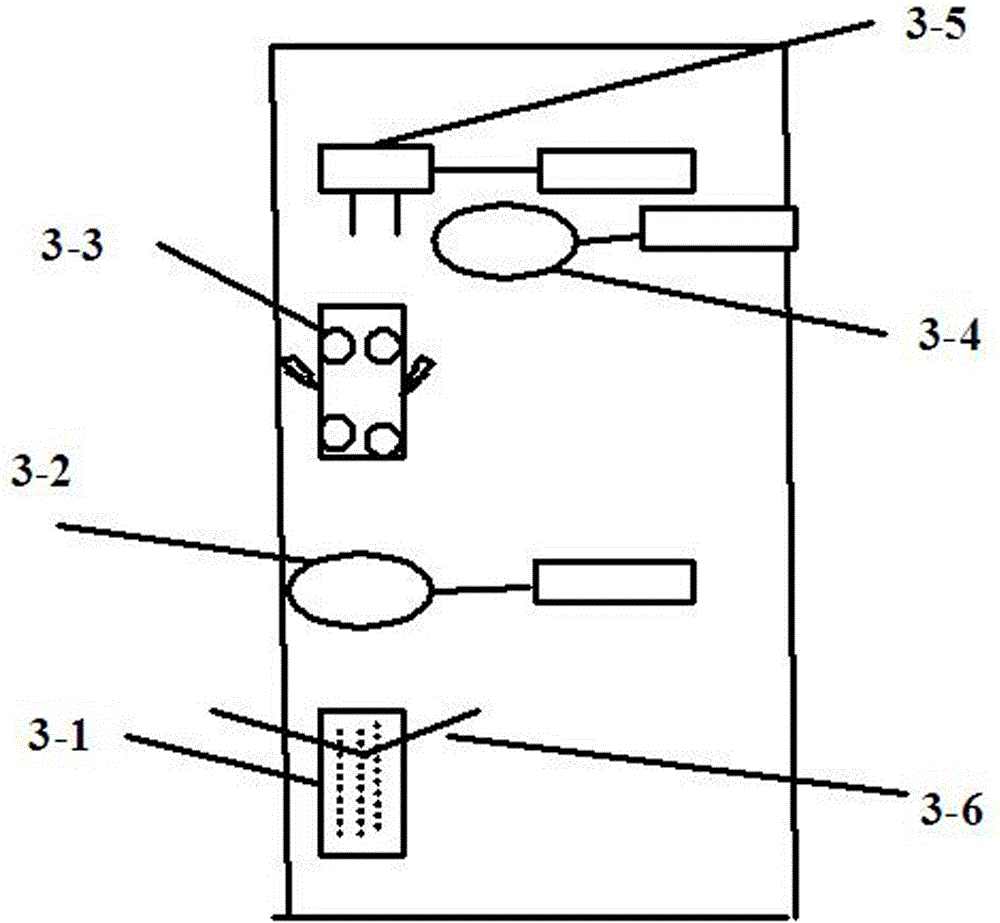

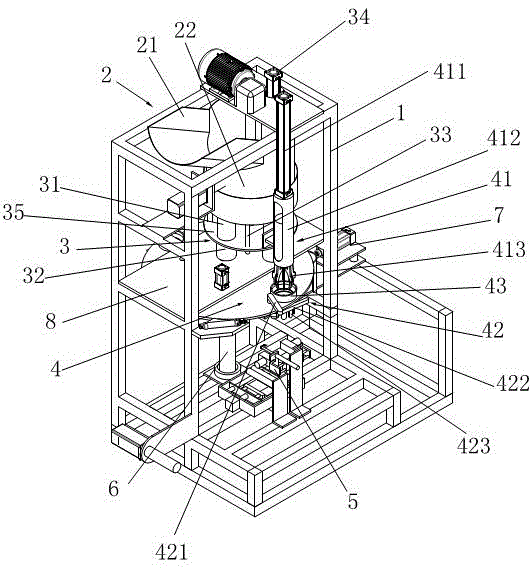

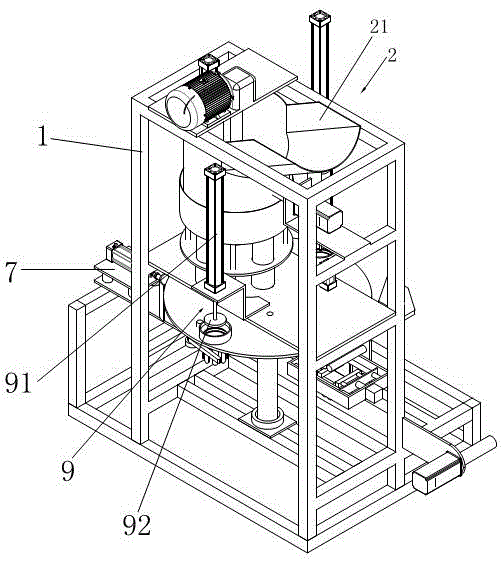

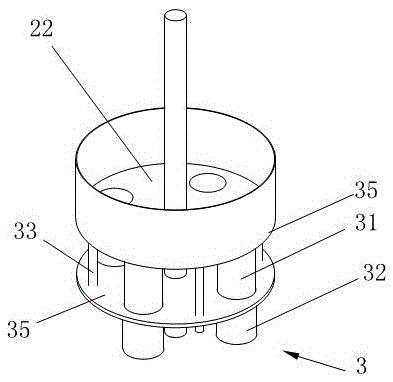

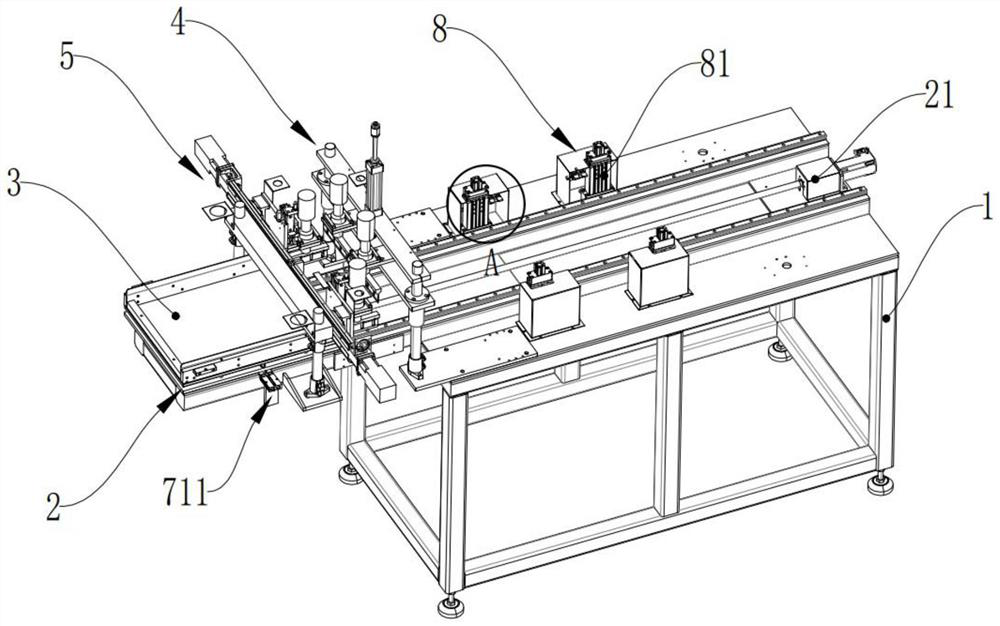

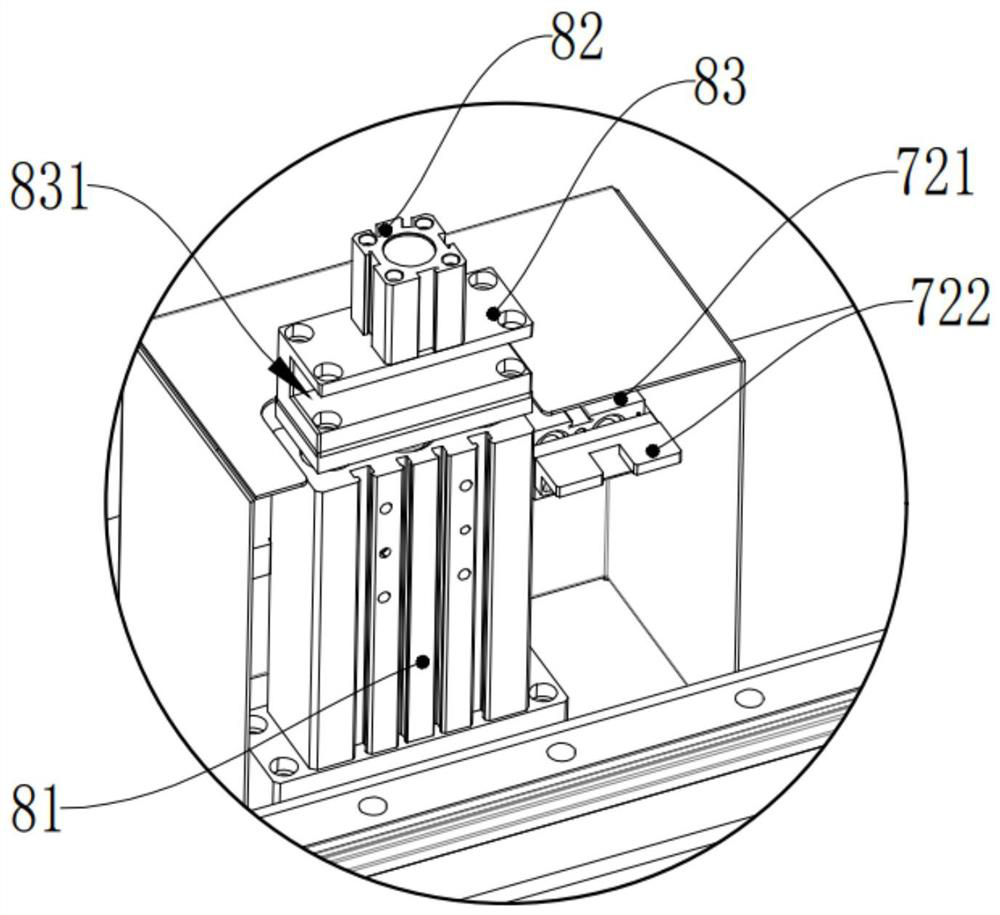

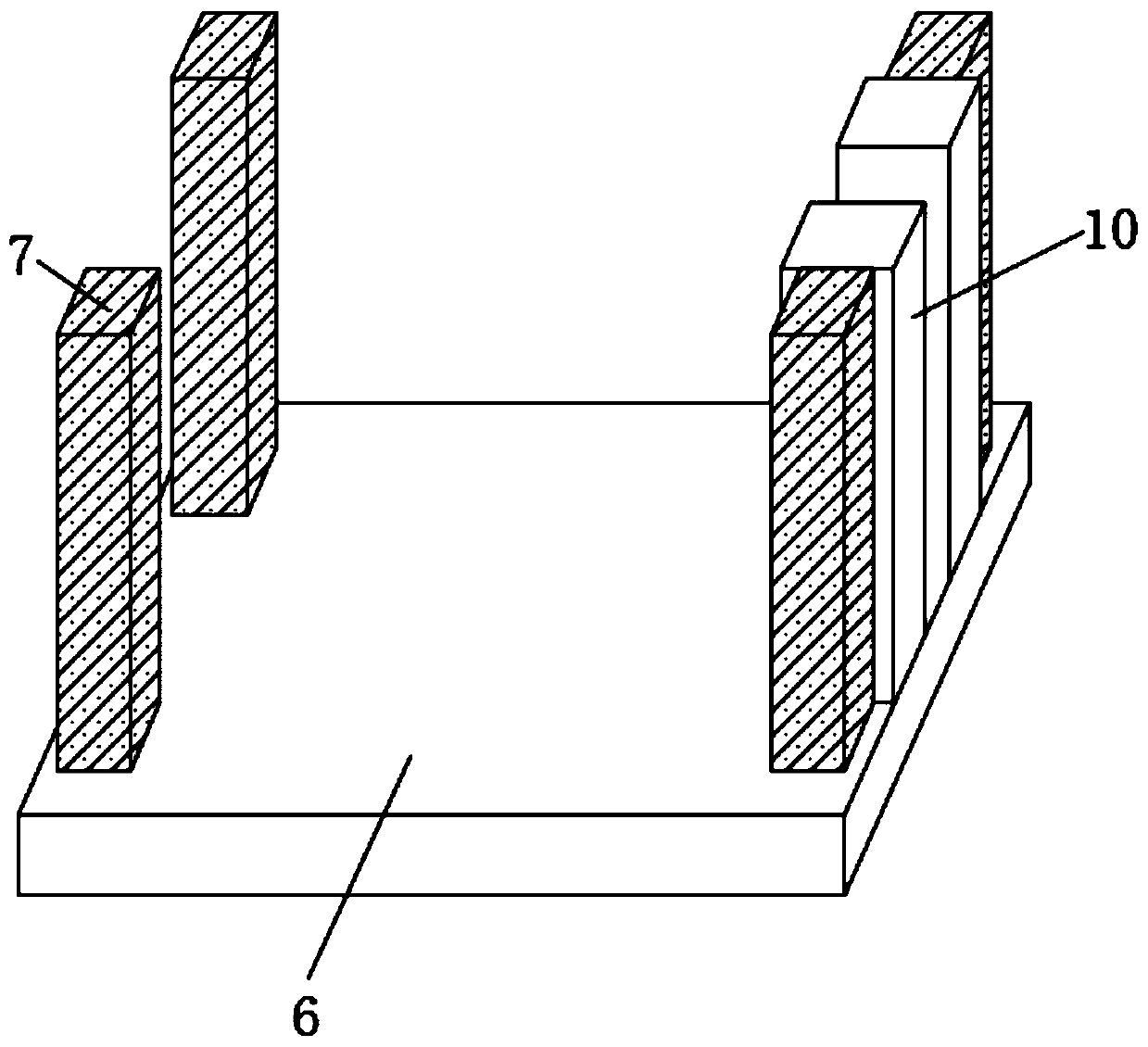

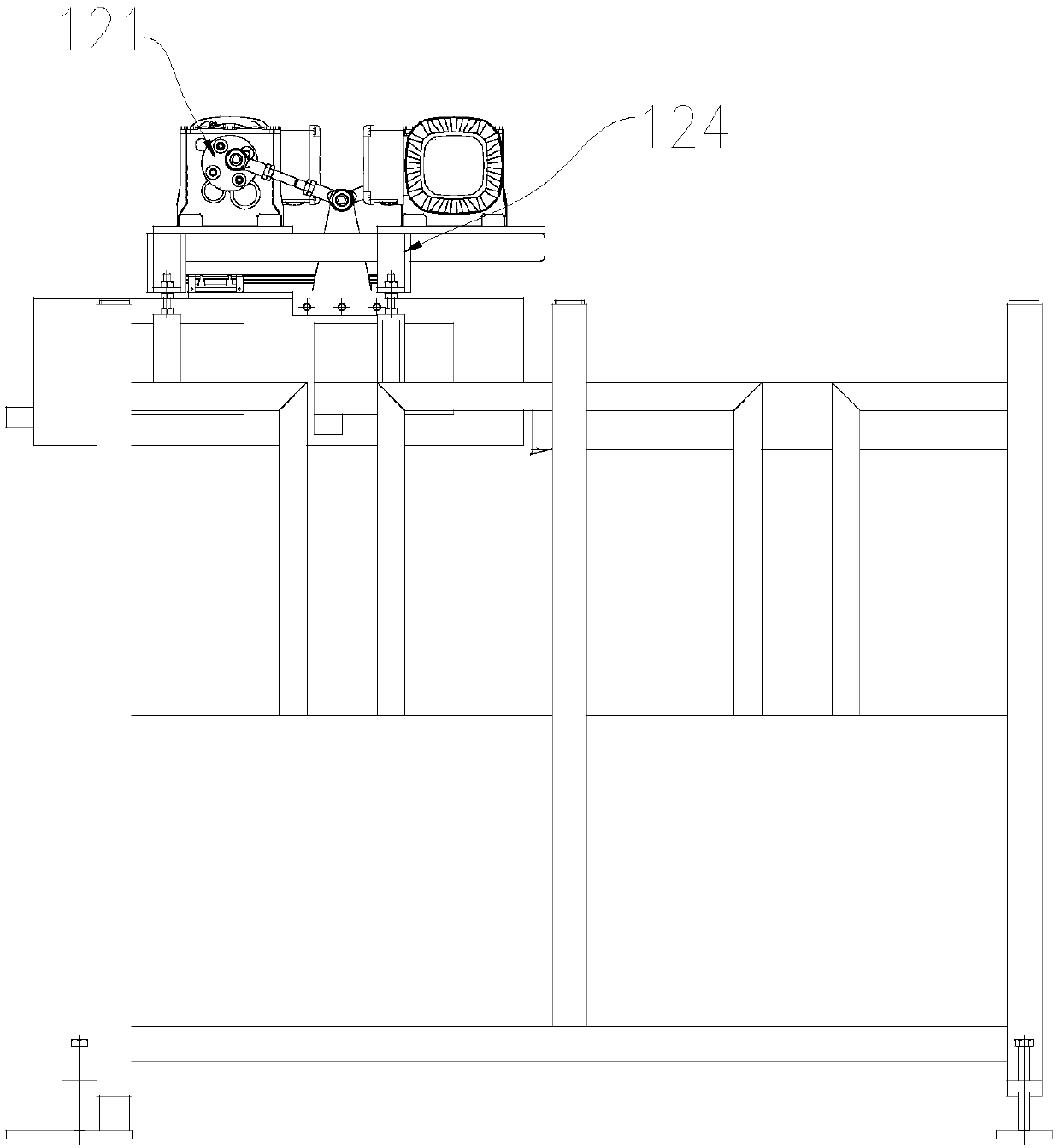

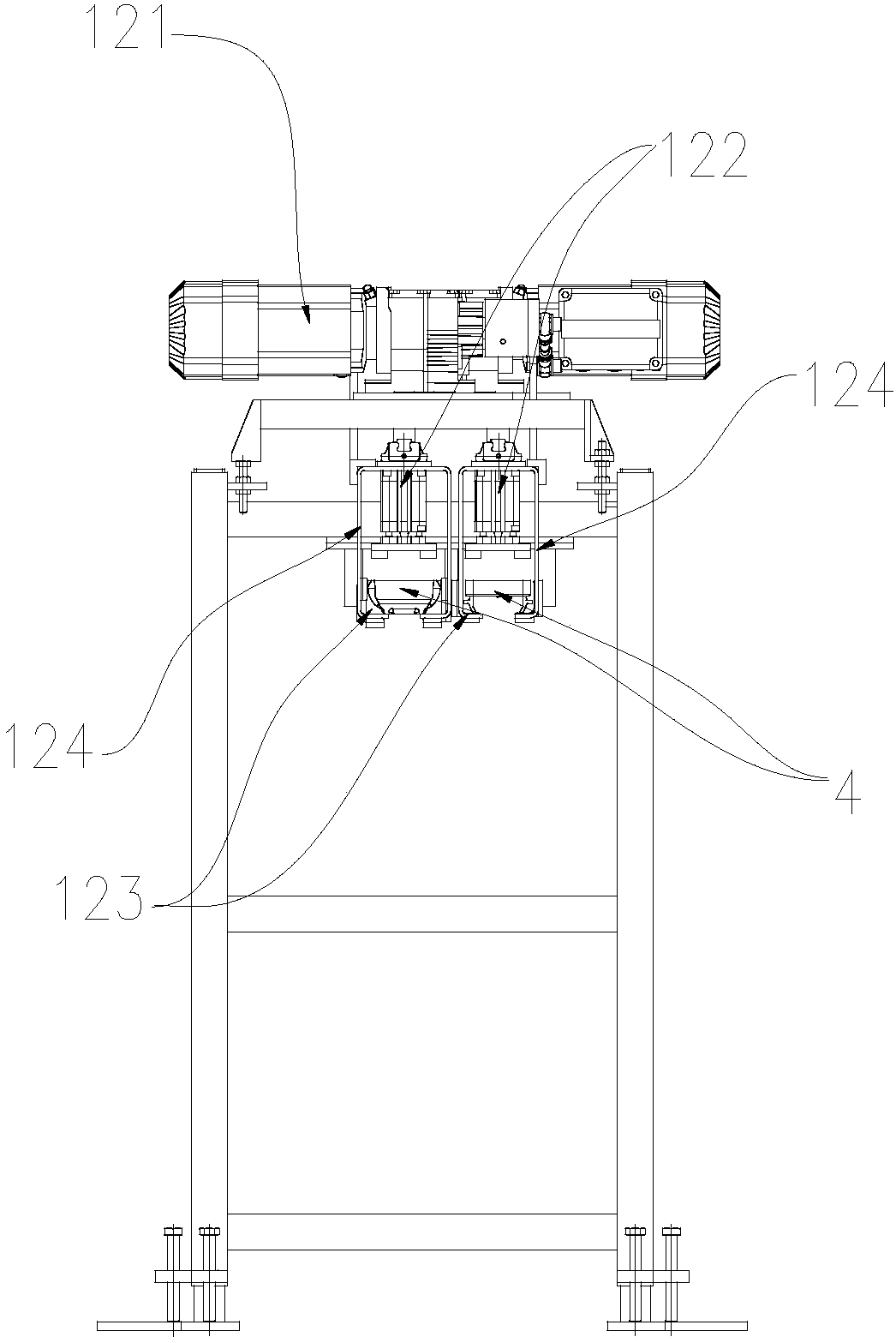

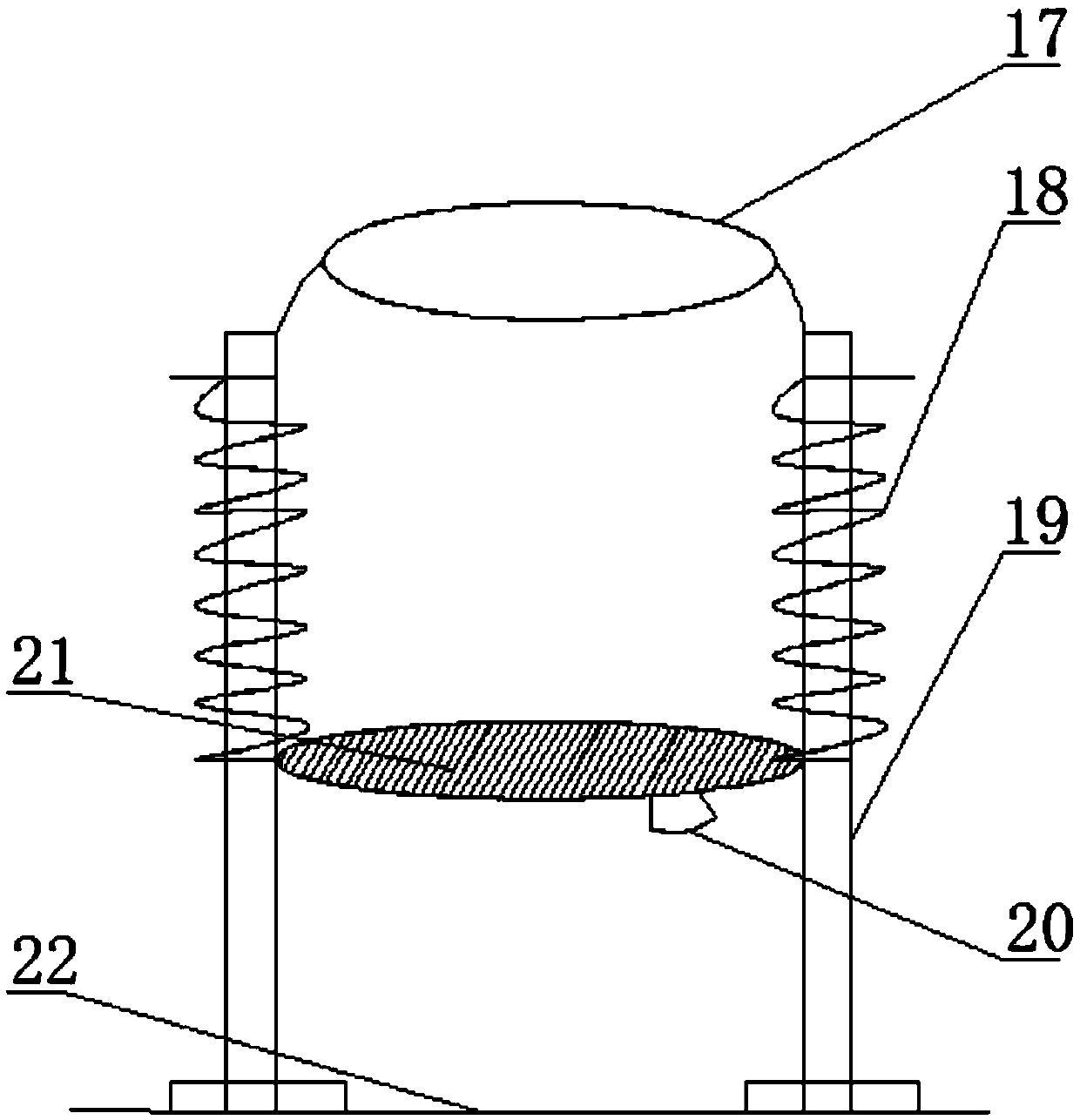

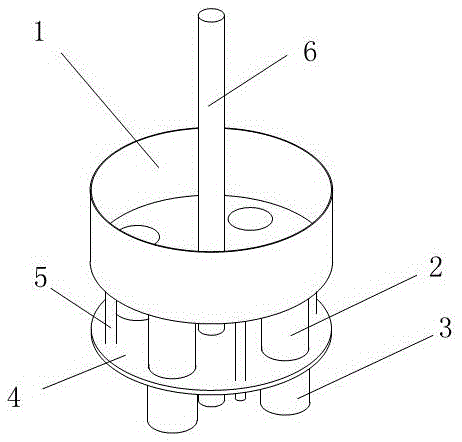

Full-automatic edible fungus culture material bagging machine

InactiveCN105557313AConsistent weightConsistent heightCultivating equipmentsMushroom cultivationEngineeringMechanical engineering

The invention relates to a full-automatic edible fungus culture material bagging machine. The bagging machine comprises a rack, and a feeding mechanism, a discharging mechanism, a station rotary disc and a bag conveying mechanism are installed on the rack from top to bottom; the station rotary disc can rotate around a rotating shaft and is provided with a bag taking mechanism and a bag clamping mechanism; the discharging mechanism comprises charging barrels and a discharging air cylinder, and each charging barrel is composed of a big charging barrel body and a small charging barrel body, wherein the small charging barrel body is sleeved with the big charging barrel body in the mode of vertically moving, fixing plates are arranged on the big charging barrel body and the small charging barrel body respectively, and adjusting screws are arranged between the two fixing plates. Manual bagging is replaced by the full-automatic edible fungus culture material bagging machine, and working efficiency is high; the full-automatic edible fungus culture material bagging machine is provided with a quantitative regulating mechanism, the requirement for producing material bags in different sizes can be met, and the manufactured fungus bags are uniform in weight and height, so that the purpose of quantitative bag manufacturing is achieved.

Owner:厦门祺安达自动化设备有限公司

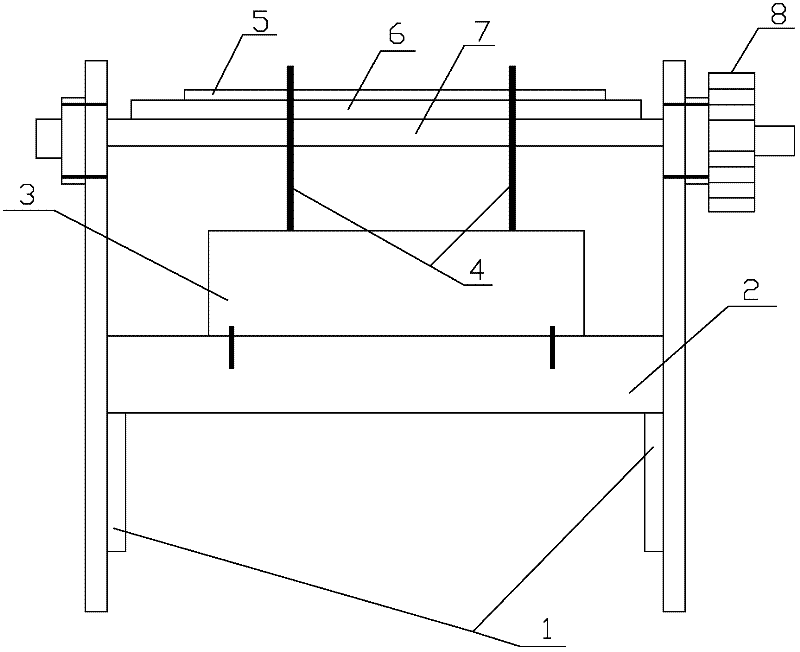

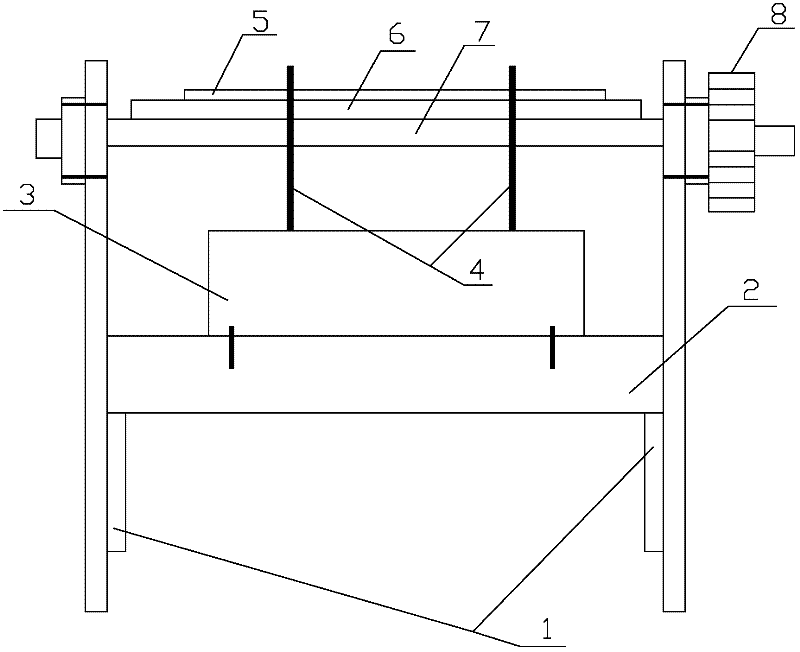

Electrically-controlled automatic screening machine

InactiveCN104443452AConsistent weightSimple processSievingScreeningControl engineeringElectrical control

The invention discloses an electrically-controlled automatic screening machine. The screening machine structurally comprises a feeding separating valve, a fine material collecting plate, vibrating springs, supporting columns, a vibration drive, a driving motor, a lever supporting rod, an electronic weighing machine, a lever, a coupling, a lump material discharging port, a vibrating screen and a feeding hopper, wherein the lump material discharging port is formed in the lower left part of the vibrating screen, the feeding hopper is installed on the upper right of the vibrating screen, the feeding separating valve is installed between the feeding hopper and the vibrating screen, the vibrating screen is connected with the fine material collecting plate through the vibrating springs, the fine material collecting plate is installed below the vibrating screen and installed on the supporting columns through the vibrating springs, and the vibration drive is installed on the lower portion of the fine material collecting plate. Because the procedures of screening, metering, packaging and the like are combined, the process is simplified, and the production efficiency is improved; besides, bags of products are uniform in weight and small in error, and metering control is accurate. Thus, the screening machine has certain application and popularization value.

Owner:HEILONGJIANG KANGGEER TECH

Plastic explosive cutting mechanism

PendingCN113200805AAvoid stickingConsistent weightExplosive working-up apparatusPlastic recyclingExplosive AgentsStructural engineering

The invention discloses a plastic explosive cutting mechanism, and belongs to the field of grenade production. The plastic explosive cutting mechanism comprises a linear moving component, an explosive carrying tray, a first punching component, a second punching component and a translation component. The first punching assembly and the translation assembly are arranged above the linear moving assembly front and back, the second punching assembly is arranged at the movable end of the translation assembly, the explosive carrying tray is detachably arranged at the movable end of the linear moving assembly, the explosive carrying tray is used for carrying plastic explosives, and a silica gel layer is laid on the explosive carrying tray; the linear driving assembly drives the explosive carrying tray to move front and back under the first punching assembly and the second punching assembly, so that the first punching assembly and the second punching assembly punch plastic explosives in the transverse direction and the longitudinal direction respectively, plastic explosive blocks with the same weight are obtained through cutting, automatic punching of the plastic explosive blocks is achieved, potential safety hazards caused by direct contact between operators and explosives are eliminated, the production safety is improved, and the labor intensity is reduced.

Owner:GUANGDONG MINGHUA MACHINERY

Cigar-like tea strip, forming device and manufacturing technique

The invention provides a cigar-like tea strip, a forming device and a manufacturing technique. The cigar-like tea strip comprises a cylindrical tea strip, one end of the cylindrical tea strip is hemispherical, the other end of the cylindrical tea strip is provided with a horizontal round face, and the cylindrical tea strip is coated with a layer of an edible material. The manufacturing technique of the cigar-like tea strip comprises the steps of (1) softening via steam, to be specific, adding dried raw tea leaves with rated weight into a steaming barrel, and softening with the leaves with steam; (2) pressing to shape, to be specific, placing the leaves softened via the steaming barrel to a position above a mold, removing a steaming barrel partition, charging the leaves evenly into a mold hole through a wooden stick, starting the mold to enter a pressing zone, automatically pressing for 250 seconds, and removing the pressed material from a mold bin obtain a semifinished tea strip; and (3) drying, to be specific, drying the shaped tea strip, and packaging the tea strip through the layer of the edible material, the tea strip being dried to the water content of less than 2 g. The tea strip herein has moderate tightness and is convenient to carry. The manufacturing technique has high efficiency.

Owner:孙洪亮

Canning quantity control assembly for cosmetic nail polish manufacturing

The invention relates to the technical field of nail polish canning, and discloses a canning quantity control assembly for cosmetic nail polish manufacturing. The canning quantity control assembly comprises a nail polish storage tank, a first round hole is formed in the upper end of the nail polish storage tank, a rotating shaft is movably inserted into the first round hole, a screw rod is fixedlyconnected to the lower end of the rotating shaft in a sleeving mode, a first belt wheel is fixedly connected to the upper portion of the outer side of the rotating shaft in a sleeving mode, the outerside of the first belt wheel is movably sleeved with a belt, and a second belt wheel is fixedly inserted into the right side of the inner part of the belt. By rotating a driving rod, the driving roddrives the belt to rotate through the second belt wheel, the belt drives the rotating shaft to rotate through the first belt wheel, the rotating shaft drives the screw rod to rotate, the screw rod ismatched with nail polish liquid through the spiral rotating direction, so that the nail polish liquid is driven upwards in a spiral mode and splashed to the upper end of the nail polish storage tank through an inclined plate, the nail polish liquid flows into a nail polish containing block along inclined face, the nail polish liquid can be homogenized in the process, and therefore the effect thatsediment in the nail polish liquid can be homogenized in the bottling process is achieved.

Owner:王威

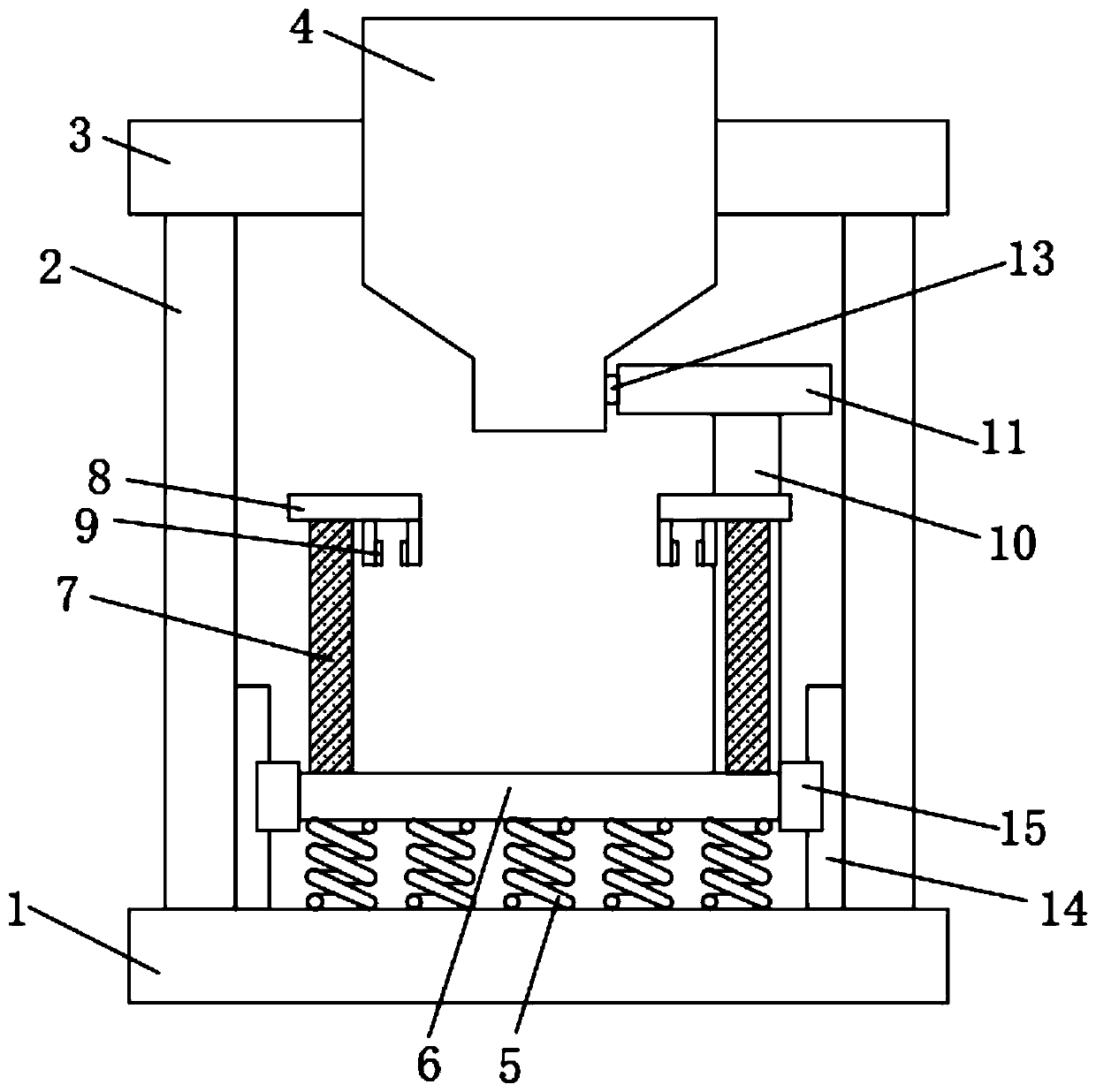

Automatic feeding weighing type metering equipment

InactiveCN110641745AConsistent weightPrevent outflowSolid materialAgricultural engineeringMechanical engineering

The invention discloses automatic feeding weighing type metering equipment and relates to the field of seed processing. The automatic feeding weighing type metering equipment comprises a base. A support is fixedly connected to the upper surface of the base. A top plate is fixedly connected to the top end of the support. A feeding hopper is installed in the middle of the top plate. First springs are fixedly connected to the upper surface of the base. A support plate is fixedly connected to the top ends of the first springs. According to the automatic feeding weighing type metering equipment, inthe bagging process, the first springs can be stressed and compressed by weight increase of packaging bags; the support plate, support rods, support columns, a fixing plate and a baffle can decline by stressing and compressing of the first springs; when the baffle declines below the feeding hopper, a second spring is no longer extruded and starts to restore shape change; the baffle can be pushedto pop up by the second spring in the restoring process of shape change, the baffle blocks below the feeding hopper, seeds are prevented from flowing out so that weight of bagging can be convenientlymetered; and thus weight of bagging can be guaranteed to be consistent.

Owner:安庆钜汇智能科技有限公司

Reduction furnace

PendingCN107560429AConsistent weightEvenly heatedFurnace typesSpecial purpose weighing apparatusMaterials science

The invention discloses a reduction furnace. The reduction furnace comprises a feeding system, a thermal reduction system, a discharging system and boats, wherein the feeding system is used for feeding to-be-reduced materials, the thermal reduction system is connected with the feeding system and used for reducing the materials, the discharging system is connected with the thermal reduction systemand used for sending out reduced materials, and the boats are used for containing the materials which move among the feeding system, the thermal reduction system and the discharging system; and the feeding system comprises a feeding device and a material weighing device, the feeding device is connected with the thermal reduction system through the material weighing device, and the material weighing device is used for controlling the weights of the materials on the boats. According to the reduction furnace, the weights of the materials which are distributed on the boats can be automatically weighed, so that the weights of the materials on all the boats are kept consistent, and the reduction efficiency of the materials is improved.

Owner:ADVANCED FOR MATERIALS & EQUIP

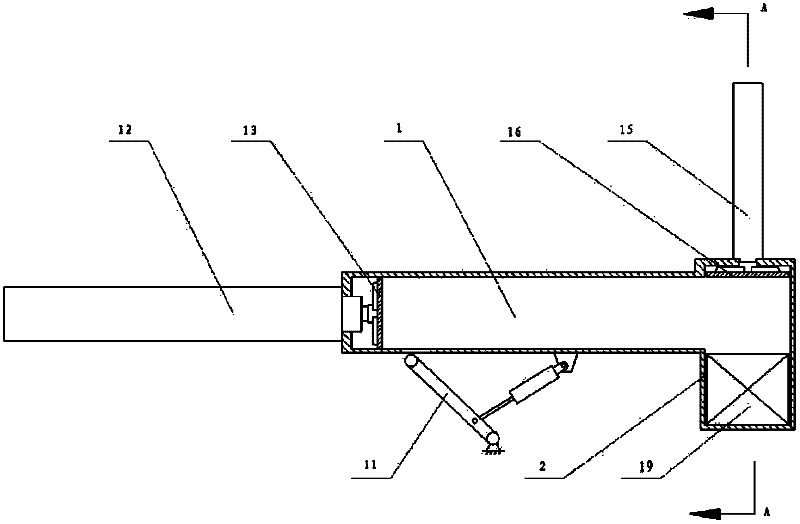

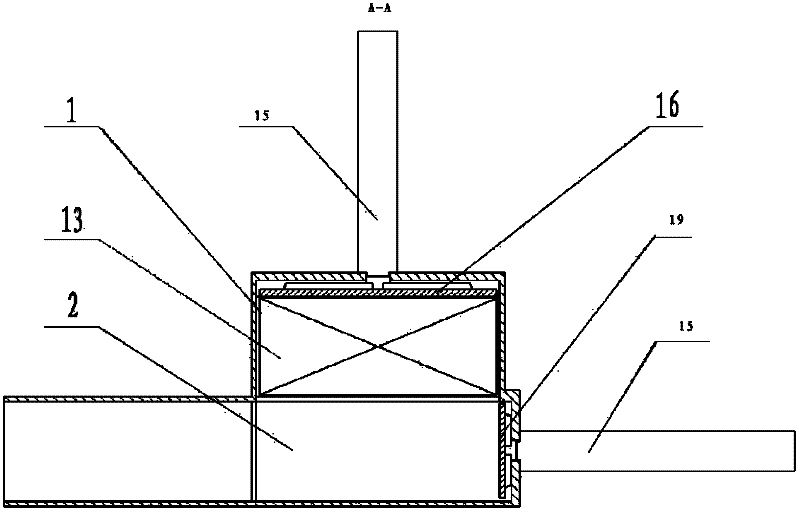

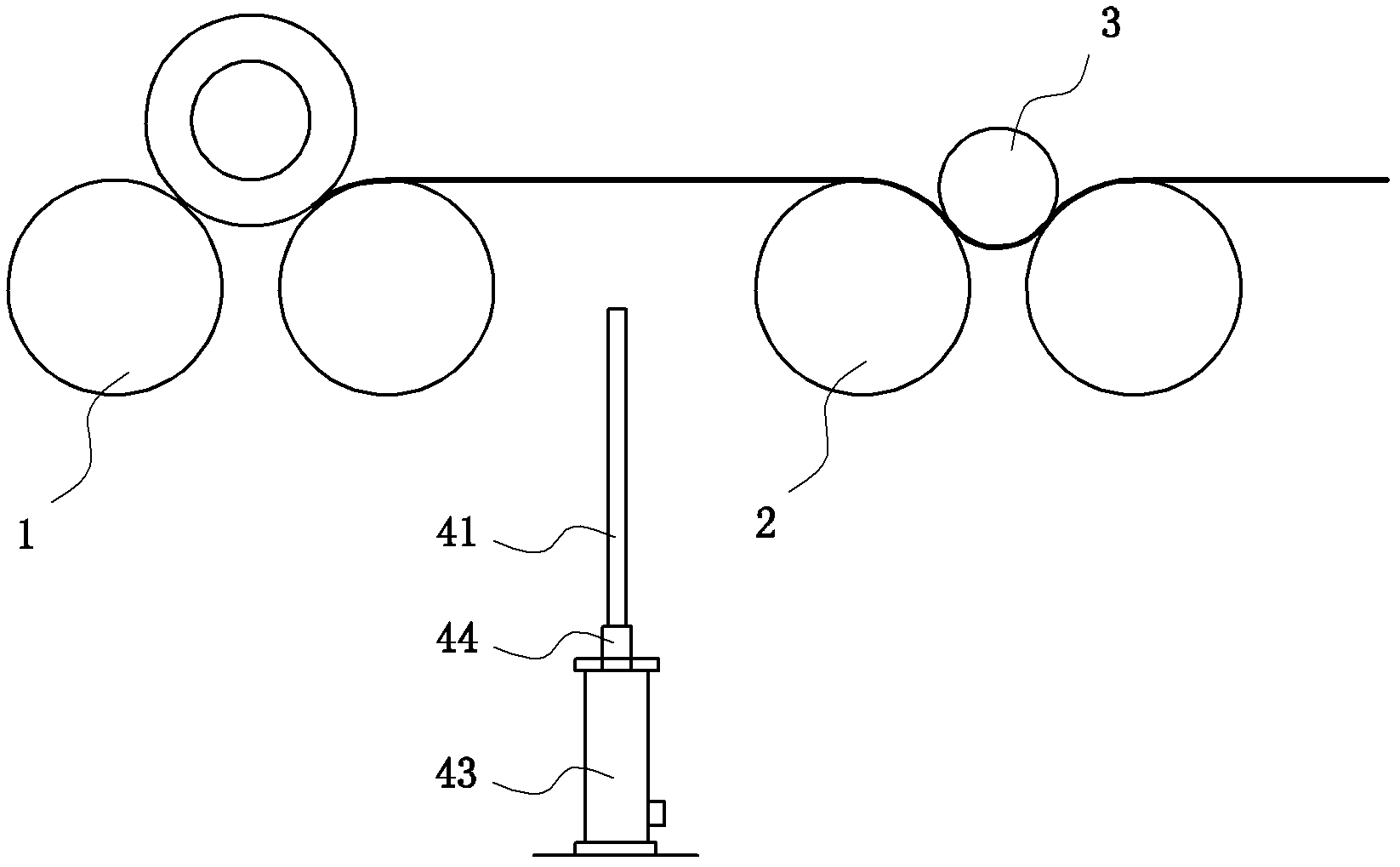

Automatic roll changing device for mulching film winding machine

InactiveCN102351110AGuaranteed accuracyHigh degree of automationWebs handlingWinding machineEngineering

The invention discloses an automatic roll changing device for a mulching film winding machine. The automatic roll changing device is arranged on a frame of the mulching film winding machine; the mulching film winding machine comprises winding roller sets respectively consisting of two matched winding rollers; each winding roller set is provided with a power device for driving the winding roller set to roll, and is provided with a mulching film winding drum which rotates together with the winding roller set and used for winding a mulching film; at least two winding roller sets are arranged; and the automatic roll changing device comprises a cutoff mechanism used for cutting off the mulching film, and a film winding mechanism used for winding the cut mulching film to the mulching film winding drum, wherein the cutoff mechanism is arranged on the frame of the mulching film winding machine, and the film winding mechanism is arranged below the cutoff mechanism. The automatic roll changing device realizes the automatic cutoff and roll changing of the mulching film, solves the technical problem which cannot be solved by technicians in the field for a long time, is structurally provided with the special cutoff mechanism and the film winding mechanism, has substantial characteristics, and has obviously improved effect.

Owner:张磊

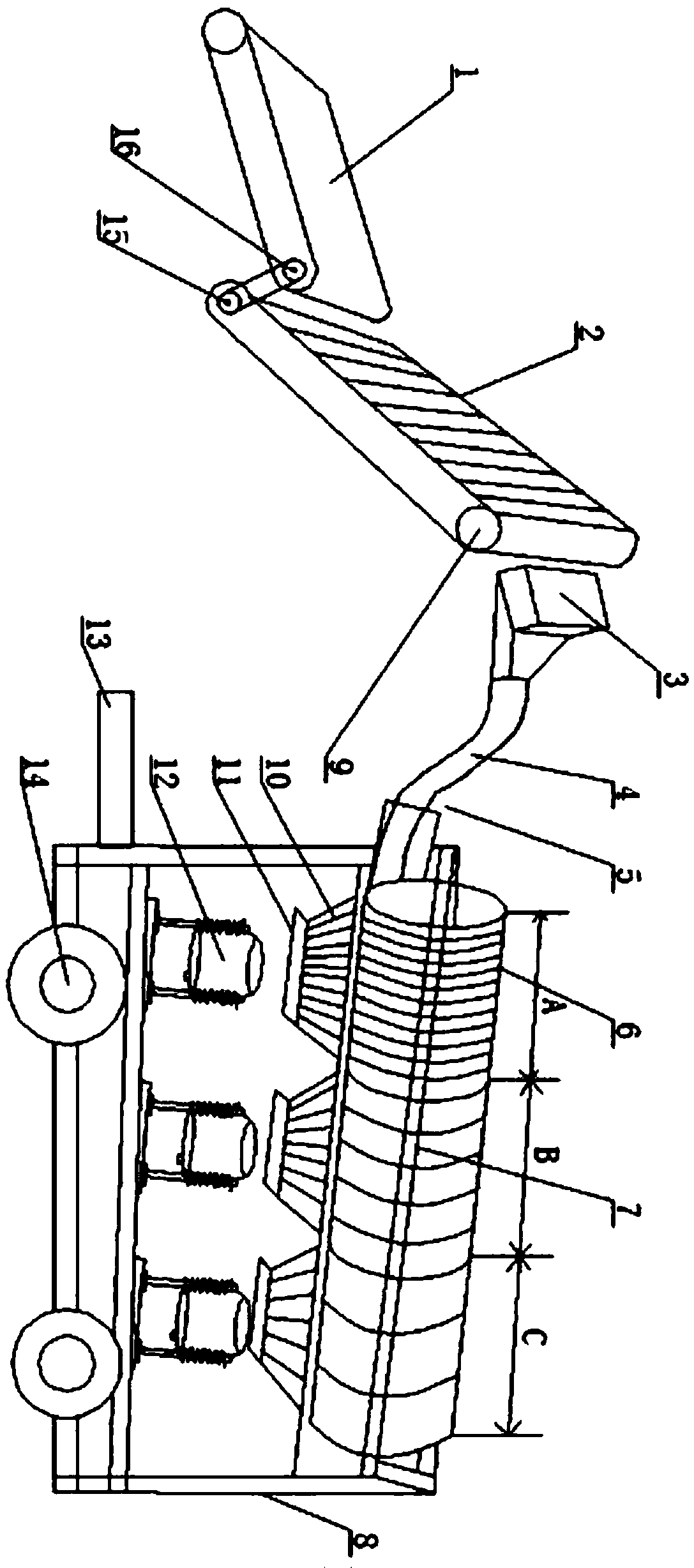

Potato classifying and bagging device

ActiveCN105363679AEasy to separateFunction increasePackaging fruits/vegetablesGradingEngineeringHollow cylinder

The invention discloses a potato classifying and bagging device. A rolling classifying screen is of a hollow cylinder structure formed by connecting annular classifying bars, the classifying bars are sequentially provided with a classifying area A, a classifying area B and a classifying area C from left to right in the order from small density to large density, and a fixed feed port is formed in higher end of the rolling classifying screen fixed to a machine frame. A lifting device is provided with an inclined transmitting scraper plate, a fixed receiving hopper is arranged at the upper end of the inclined transmitting scraper plate, the lower end of the fixed receiving hopper is connected with a receiving hose, and the receiving hose is communicated into the fixed feed port. A dropping hopper is arranged below the rolling classifying screen, and a receiving device is arranged below the end of the dropping hopper. The potato classifying and bagging device can convey, lift and automatically collect potatoes and separate the potatoes and soil, the rolling classifying screen is reliable in structure, practical and easy to operate, the potatoes and the soil can be fast separated, and the production efficiency is high.

Owner:侯文会

Automatic grid weighing device

ActiveCN102645260AConsistent weightReduce dosageOptically investigating flaws/contaminationWeighing apparatus for materials with special property/formFixed frameEngineering

The invention discloses an automatic grid weighing device and relates to the technical field of storage batteries. The automatic grid weighing device is characterized by comprising a sensor fixing frame arranged on a plate casting machine, wherein the middle of the sensor fixing frame is connected with a crossbeam; a weighing sensor is arranged on the crossbeam; the upper end of the sensor fixing frame is movably provided with a plate turning shaft; a turning plate is fixed on the plate turning shaft; a balance iron is arranged on the turning plate; and the weighing sensor is connected with the turning plate through a sheet weighing bracket. With the adoption of the automatic weighing, the manual weighing error can be reduced, the grids can be ensured to be completely weighed and are consistent in weight, the alloy amount can be reduced, and the production efficiency and quality are not affected.

Owner:TIANNENG BATTERY GRP ANHUI

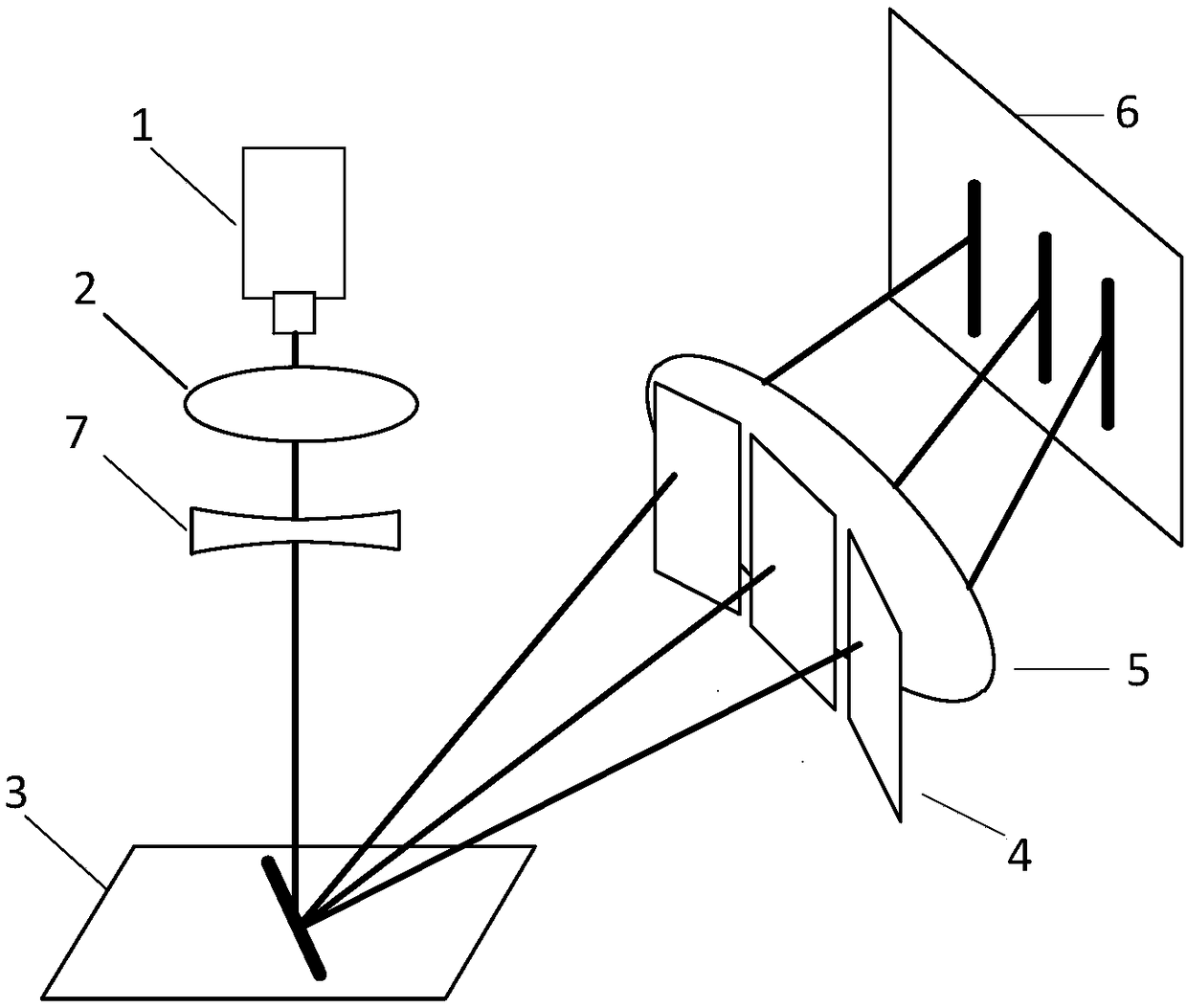

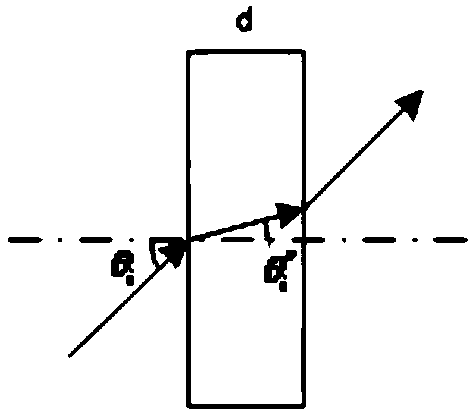

Device for suppressing speckle effect by using partial-wave surface shifting in triangular ranging linear focal imaging

InactiveCN109387852AReduce measurement uncertaintyWithout sacrificing lateral resolutionOptical rangefindersElectromagnetic wave reradiationLaser rangingMeasurement device

The invention belongs to the field of laser range finding, and discloses a device for suppressing a speckle effect by using partial-wave surface shifting in triangular ranging point linear imaging. The device comprises a transmitting unit and a receiving unit, wherein the transmitting unit comprises a laser, a focusing lens group and a cylindrical lens. A measured object is disposed below the cylindrical lens. A one-dimensional glass sheet array and a receiving lens group in the receiving unit are disposed between a photoelectric image detector and the measured object, and the scattered lightemitted by the measured object is shifted by a partial-wave surface of the one-dimensional glass sheet array to form a plurality of linear focal spot images which are received by the photoelectric image detector. The one-dimensional glass sheet array is disposed between the photoelectric image detector and the measured object, so the device can perform the shifting of the scattered light emitted by the measured object to form the plurality of linear focal spot images, and the device performs the range finding through solving a mean value, effectively reduces the measurement uncertainty in laser range finding via an averaging method, does not sacrifice the lateral resolution of a measurement device, and is better in application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

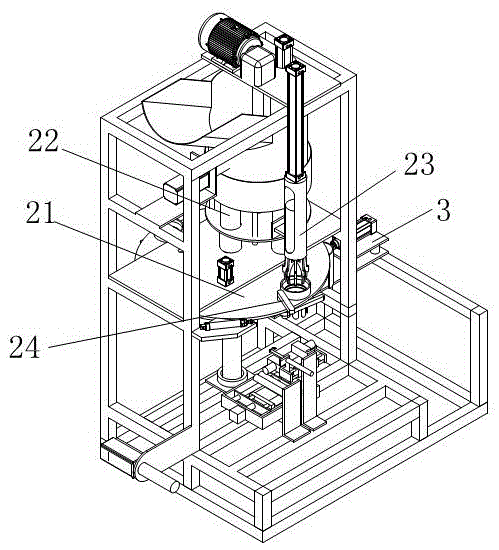

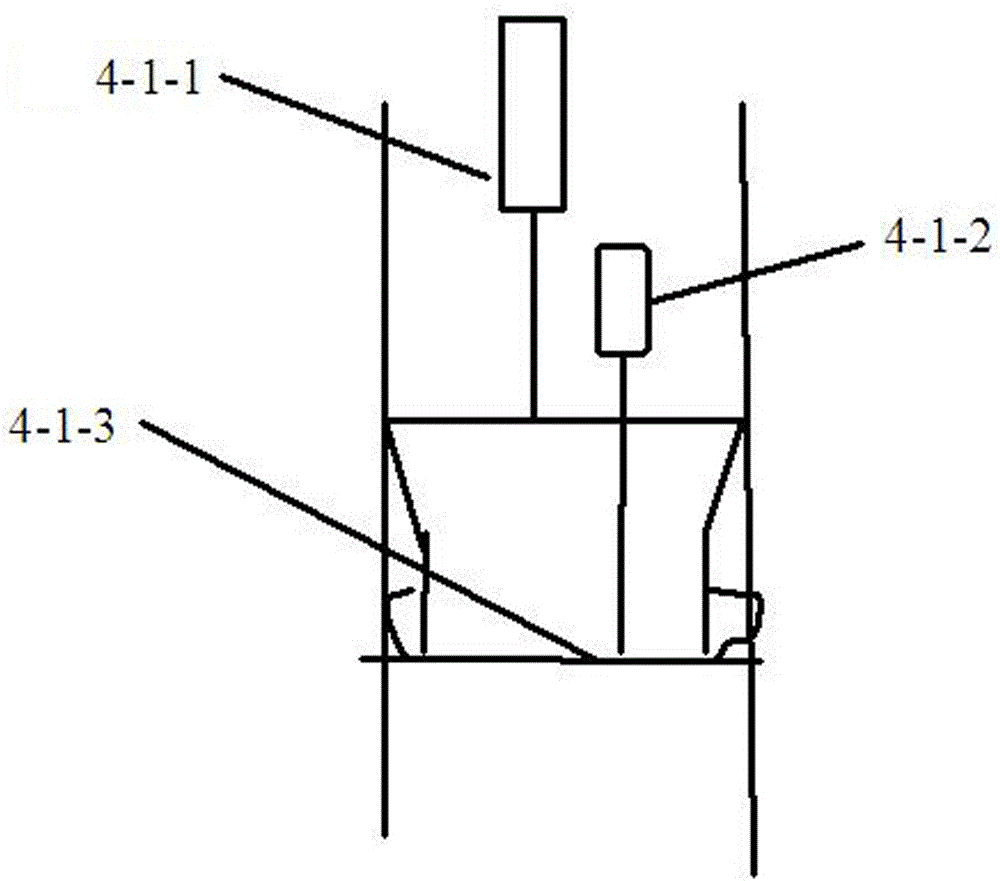

Quantitative feeding device for culture materials of edible fungi

InactiveCN105584649AImprove labor efficiencyReduce biasSolid materialCultivating equipmentsEngineeringEdible fungus

The invention relates to a quantitative feeding device for culture materials of edible fungi. The quantitative feeding device for the culture materials of edible fungi comprises a hopper disc, wherein small charge barrels are connected to the lower end of the hopper disc, and through holes communicated with the small charge barrels are arranged in the hopper disc, so that the culture materials in the hopper disc can fall into the small charge barrels; the hopper disc is coaxially connected with a fixing plate, and the fixing plate is provided with large charge barrels; and the small charge barrels sleeve in the large charge barrels in a vertically moving manner, and adjustment screws are arranged between the hopper disc and the fixing plate. The quantitative feeding device for the culture materials of edible fungi, which is disclosed by the invention, is used for replacing manual unloading and bag production, thus high working efficiency is achieved; and a quantitative adjustment mechanism is provided, adaptive to the need of producing material bags with different dimensions, and capable of keeping consistent weights and heights of fungus bags, thus the purpose of quantitative bag production is achieved.

Owner:厦门祺安达自动化设备有限公司

Kudzu root foods and processing method

InactiveCN101683151AKeep the juiceKeep the original flavorFood preparationPlant ingredientsFood flavorFood products

The invention discloses kudzu root foods with consistent sizes and uniform shapes and a processing method. The processing method comprises the following steps: preparing dewatered kudzu root decoctionpieces, getting taste absorbed and pounding the decoction pieces; molding and seasoning; and packaging. The processed kudzu root foods can be processed into cylinders or squares or cartoon shapes orthe shapes of twelve animals of Chinese signs. The invention has simple process, and processed products are not only preserved original taste and flavor of kudzu roots, but also have cool, refreshingand delicious taste. Meanwhile, the products have basically consistent weight and shapes, are convenient for being packaged and also improve the utilization rate of raw materials.

Owner:TAOJIANG SONGGE FOOD

Solid fragrance sheet and preparation method thereof

The invention relates to an aromatic substance for indoor air, in particular to a solid fragrance sheet with a sheet structure. The solid fragrance sheet is prepared by the following steps: processing eaglewood or sandalwood into powder, then adding an adhesive, producing particles with 40-80 meshes by a granulator, drying the particles, at last pressing the dried particles by a press machine. The invention also discloses a preparation method of the solid fragrance sheet. Compared with traditional eaglewood powder and sandalwood powder, the solid fragrance sheet has following advantages that: 1, the solid fragrance sheet is not easily scattered and gives off fragrance during the low temperature heating; 2, the usage process is neat and simple; 3, the solid fragrance sheet is easy to take along; 4, the solid fragrance sheet is readily identifiable according to the different molding shapes; and 5, the appearance, density and weight of the same product are same, with stale quality.

Owner:刘盛丰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com