Automatic moxa stick rolling machine

A moxa stick, automatic technology, applied in the field of automatic moxa stick rolling machine, can solve the problems of restricting the development and growth of factories and enterprises, inaccurate weight of moxa sticks, low production efficiency, etc., and achieve automatic mass production, remarkable practicability, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

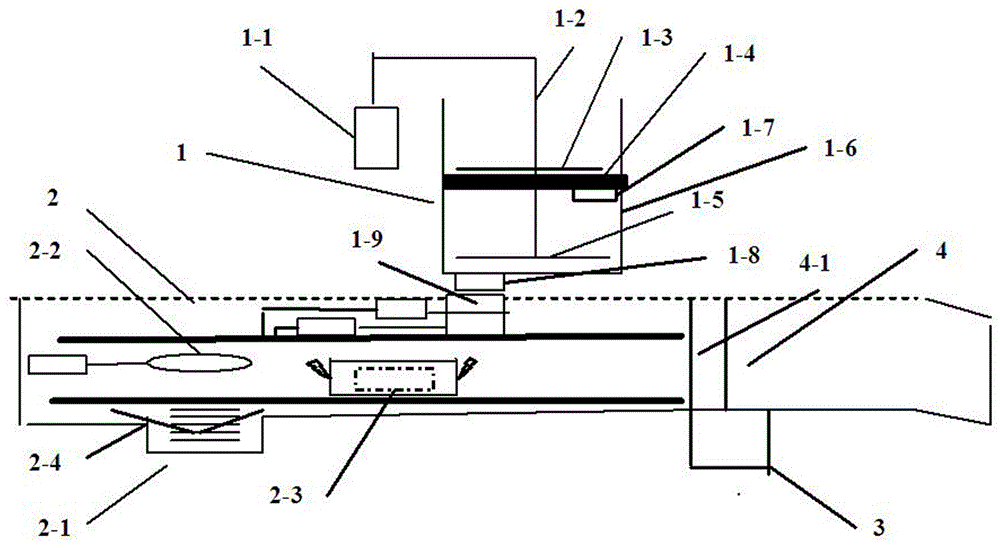

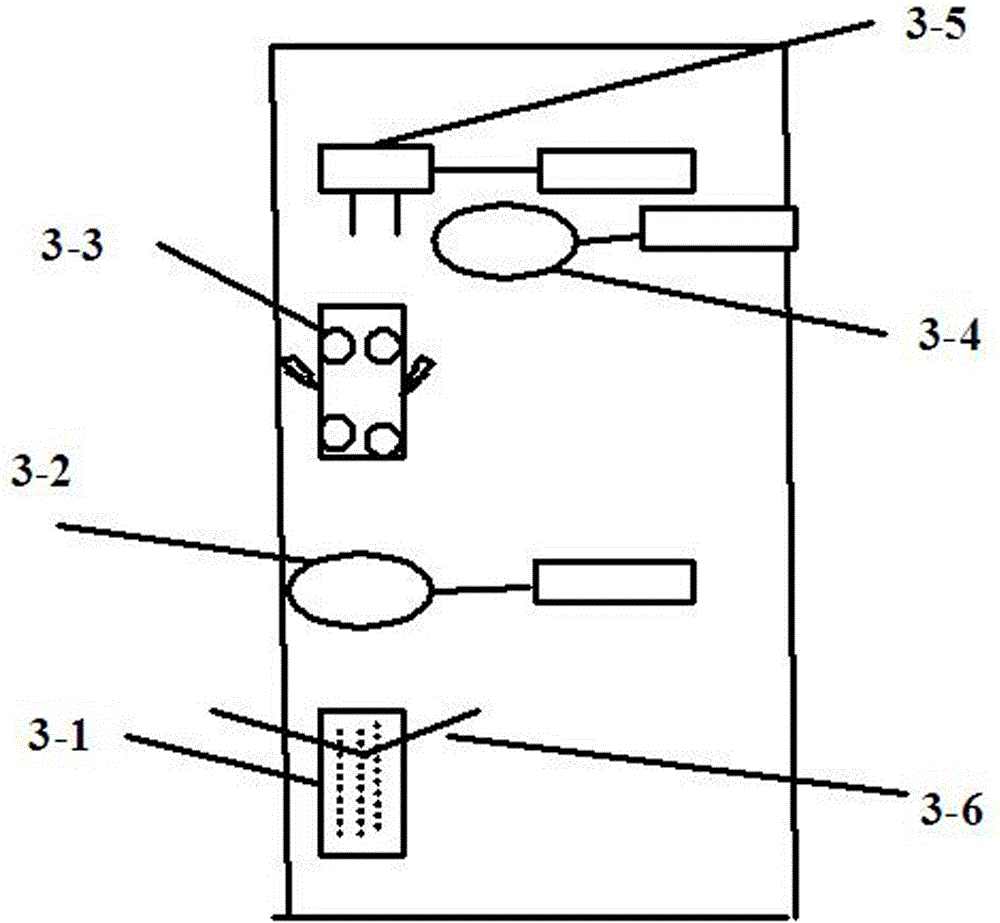

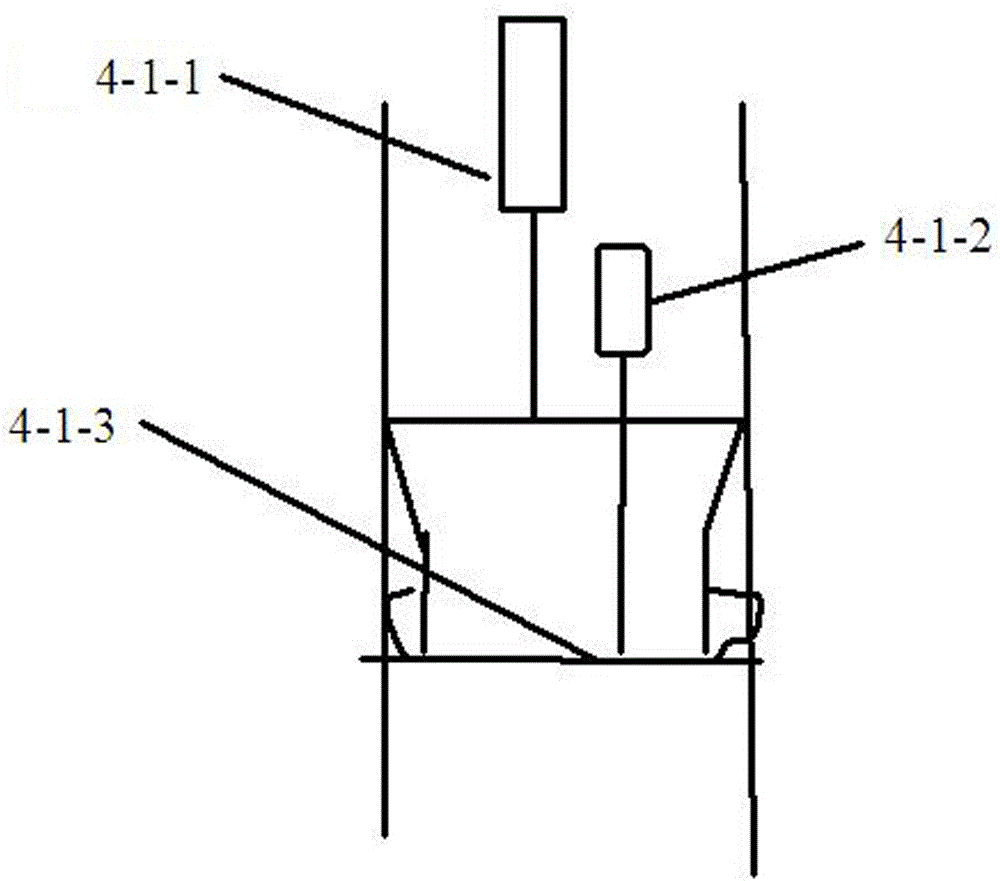

[0019] see figure 1 It is a schematic diagram of the structure of the present invention. The present invention proposes an automatic moxa stick rolling machine, which is characterized in that it includes a cylindrical metering and feeding mechanism 1 arranged in sequence, and an outer wrapping paper conveying mechanism. Mechanism 3, inner packaging paper conveying mechanism 2, moxa stick forming mechanism 4; the cylindrical metering and feeding mechanism 1 includes a metering mechanism and a feeding mechanism, and the metering mechanism includes a cylindrical cylinder body 1-6, a stirring shaft 1 -2, upper scraper 1-3, lower scraper 1-5, partition 1-4, motor 1-1, sensor, feeding device, the bottom 1-6 of the cylinder is provided with a rectangular blanking chute 1-8, the upper end of the stirring shaft 1-2 is connected to the sprocket, the middle is connected to the upper scraper 1-3, and the bottom is connected to the lower scraper 1-5, and the sprocket is connected to the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com