Automatic pouring PU (Polyurethane) earplug manufacturing device

A technology for manufacturing devices and earplugs, applied in the field of automatic perfusion PU earplug manufacturing devices, can solve the problems of low production efficiency, high production cost, waste of A material, etc., and achieve the effect of saving labor materials, high degree of automation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

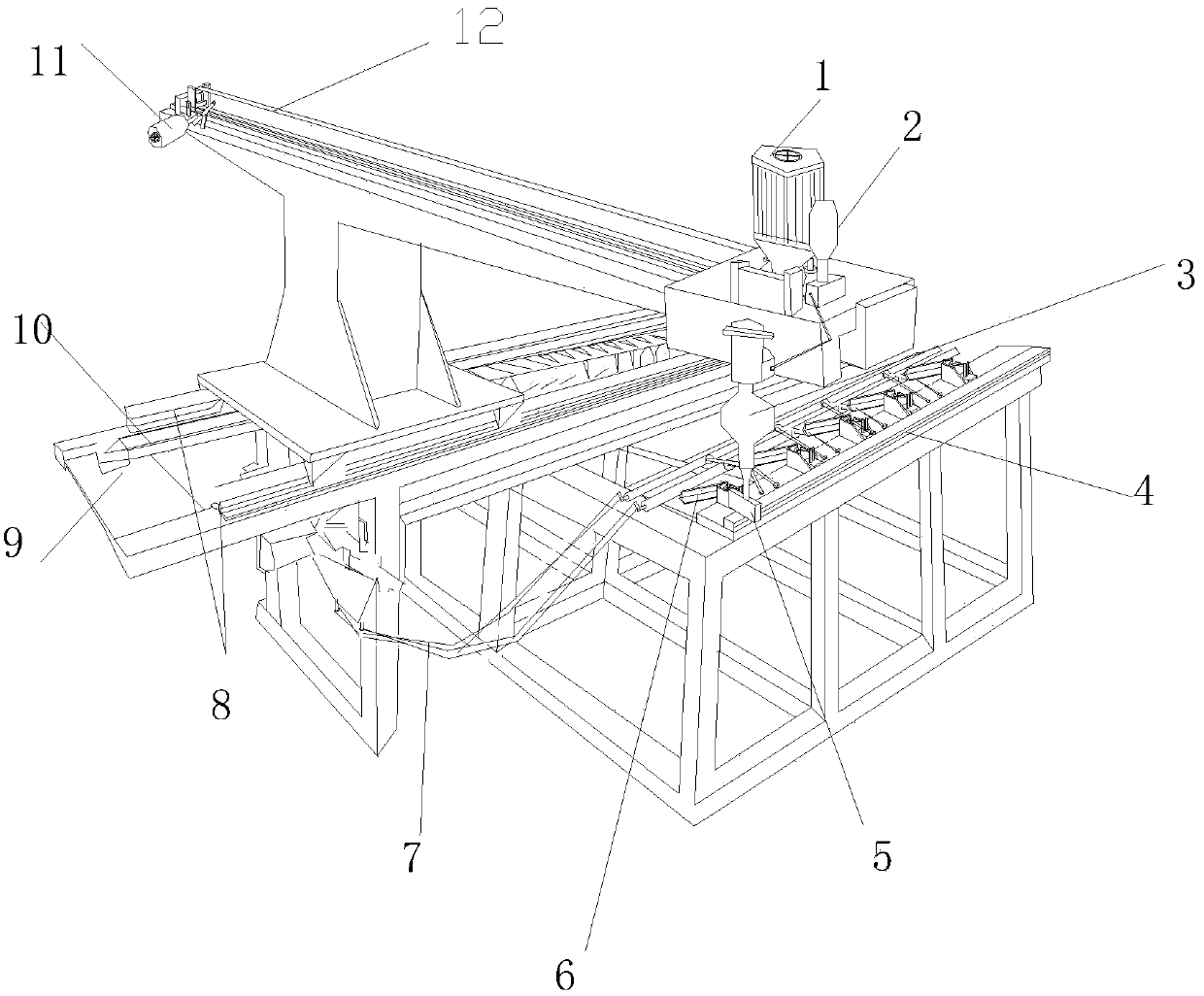

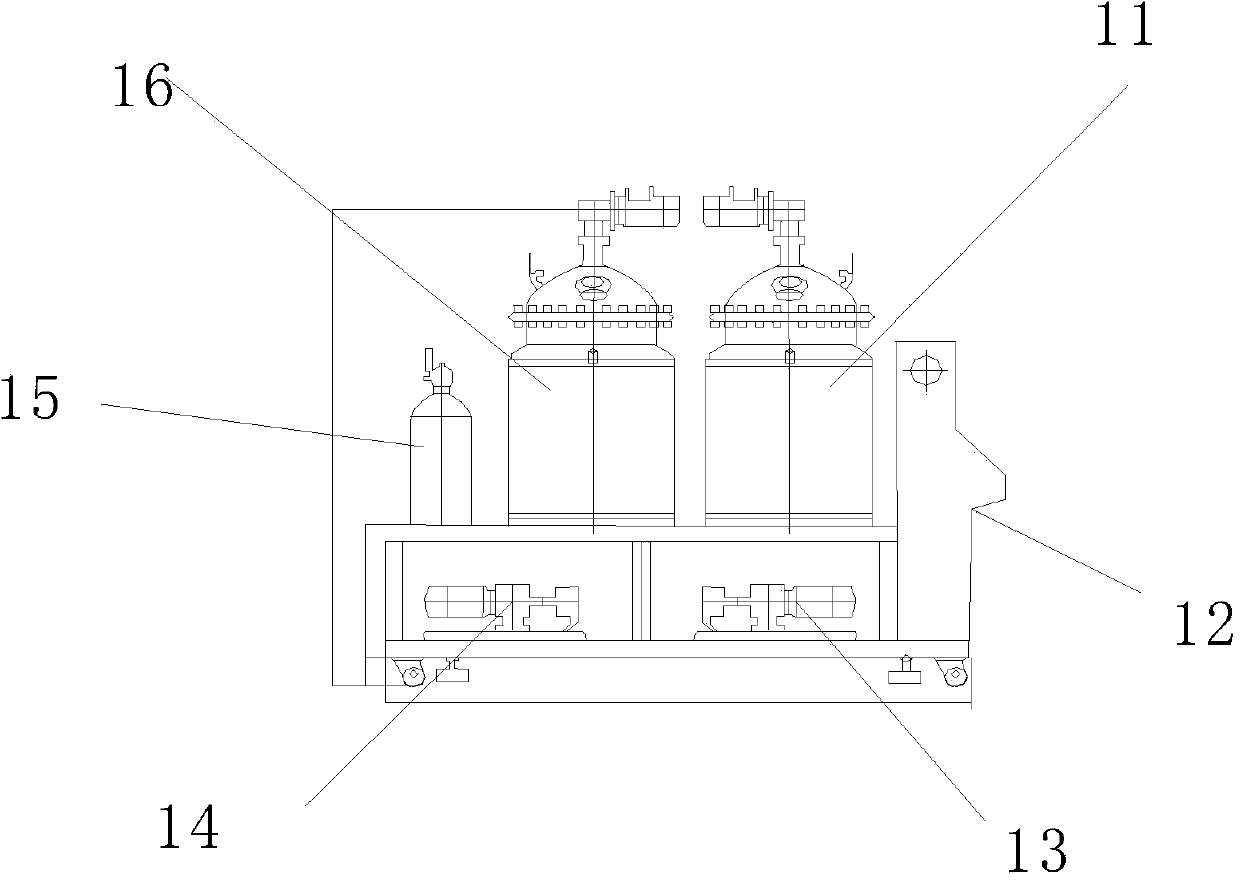

[0011] refer to figure 1 , figure 2 Shown; design a kind of automatic perfusion PU earplug manufacturing device, be provided with frame, be provided with X-axis guide rail 8 and X-axis driving mechanism 10 on described frame, be provided with a cantilever that can move along guide rail on X-axis guide rail 8 , the cantilever is provided with a Y-axis guide rail 12 and a Y-axis drive mechanism 11, an automatic color matching device 2 that can move along the guide rail is provided on the Y-axis guide rail 12, and an earplug mold fixing seat 4 and an automatic line change are provided at one end of the frame. The mold opening and clamping device 6 is provided with a plurality of earplug molds at intervals on the fixed seat 4, and a double-pipe water heating circulation device 7 for heating each earplug mold is also provided on one side of the frame.

[0012] The automatic color matching device 2 includes a mixing motor 1, a high-speed mixing head 3 driven by the mixing motor 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com