Full-automatic green bean cake former

A technology of mung bean cake and forming machine, which is applied in the directions of food forming, food preparation, food science, etc., can solve the problems of inability to realize automatic plate feeding of finished products, inability to realize automatic plate placement, poor product forming effect, etc. Consistent, consistent weight, easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

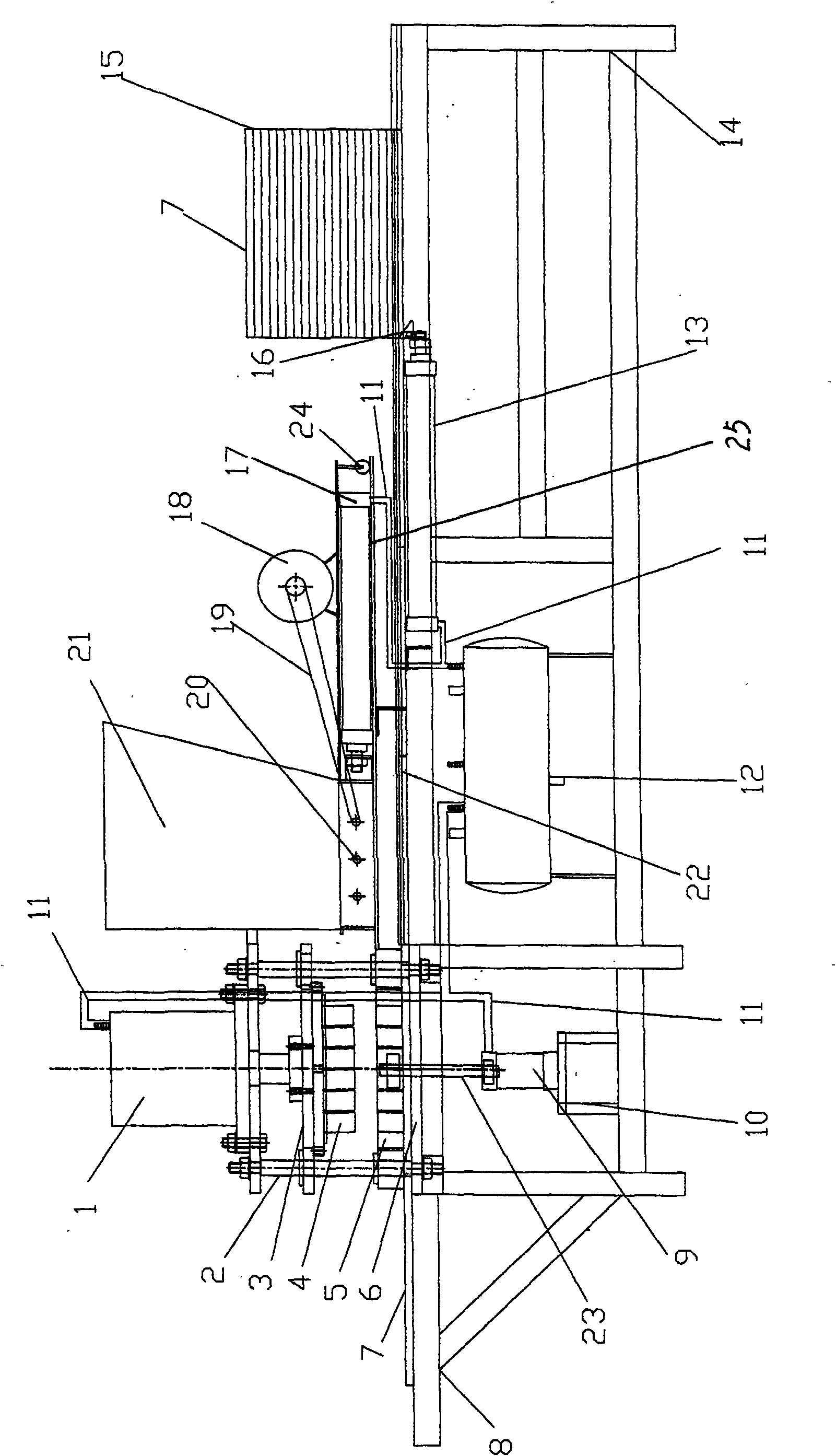

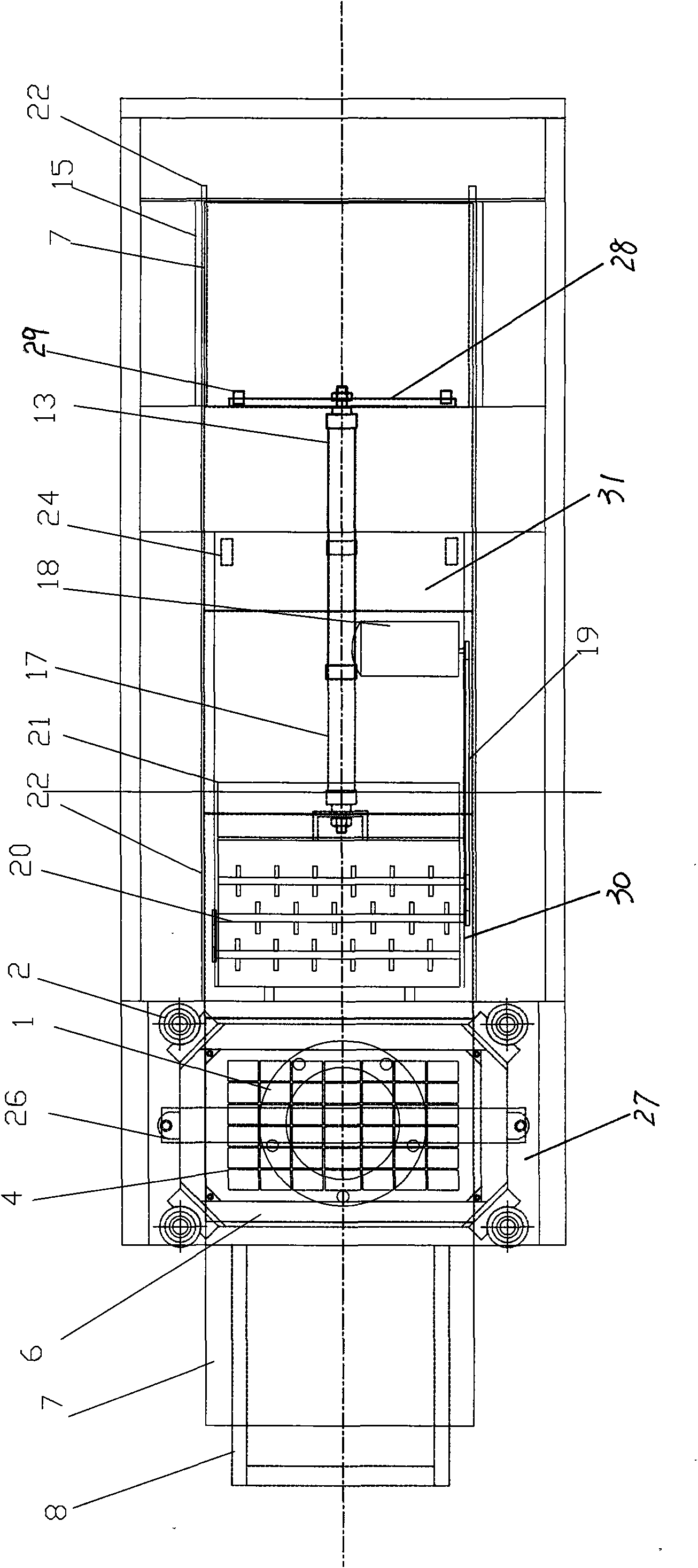

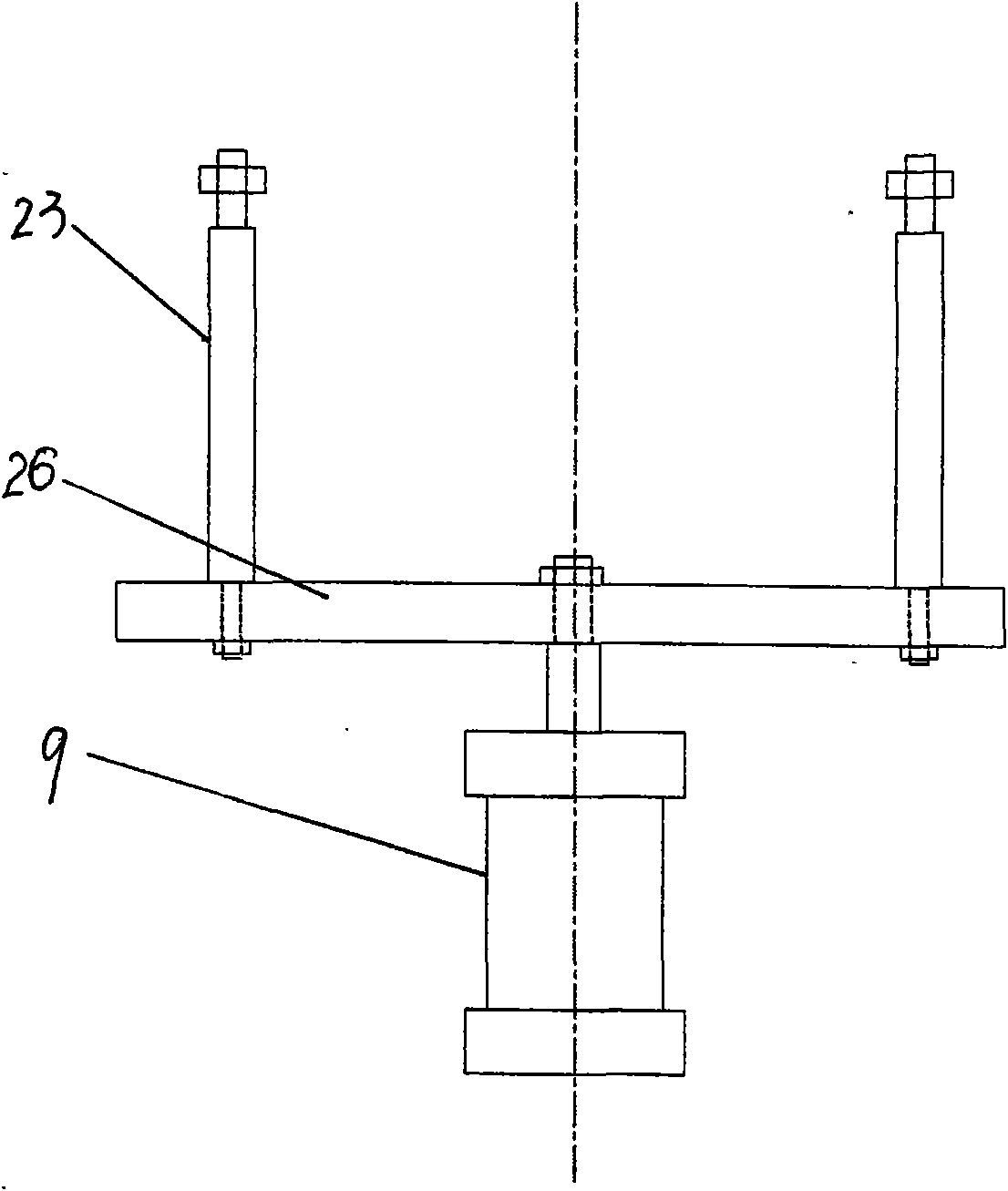

[0011] The invention is attached figure 1 , 2 As shown, the whole machine mainly includes frame 14, food hopper 21, feeding cylinder 17, lower mold 5, lower mold cylinder 9, upper mold 4, upper mold cylinder 1, pallet frame 7, pallet feeding cylinder 13, gas storage The tank 12 and the air storage tank 12 are installed and fixed under the frame 14, and are connected to the upper mold cylinder 1, the lower mold cylinder 9, the feeding cylinder 17 and the pallet delivery cylinder 13 through the air circuit 11; the upper mold 4 and the lower mold 5 are opposite Installed on the track column 2 at one end of the frame 14, the track column 2 is connected on the frame 14 through bolts; The piston rod of the cylinder 1 is connected to the upper mold fixing plate 3, which drives the upper mold 4 to slide up and down. The lower mold 5 is also installed on the track column 2 corresponding to the upper mold 4. The lower mold cylinder 9 is installed on a bracket 10 under the lower mold 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com