Full-automatic edible fungus culture material bagging machine

The invention relates to a technology for edible fungi and culture material, which is applied to a packaging machine for edible fungi culture material. It can solve the problems of single bacterial bag, low versatility and small application range, and achieve the effect of improving labor efficiency, simplifying structure and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

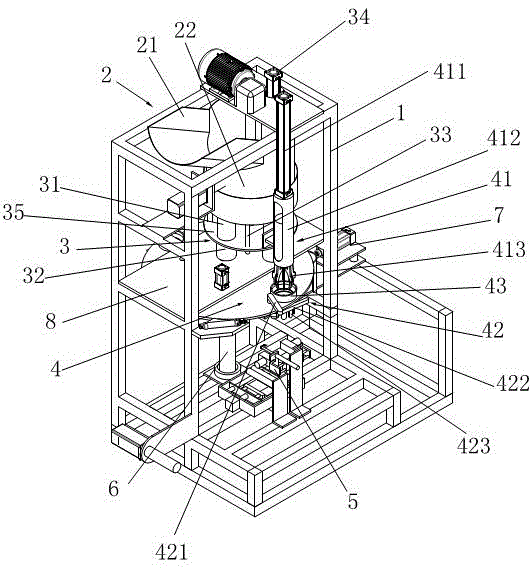

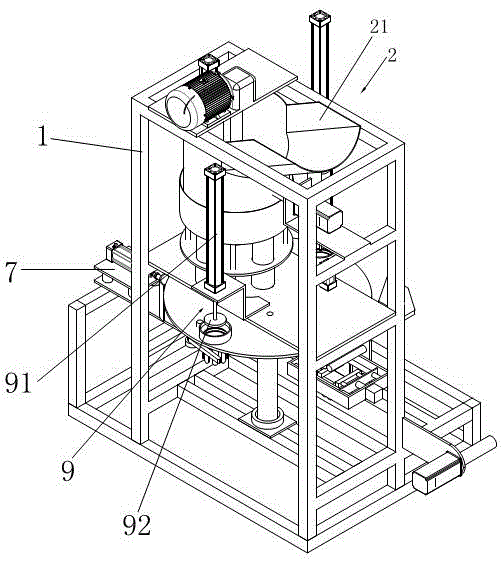

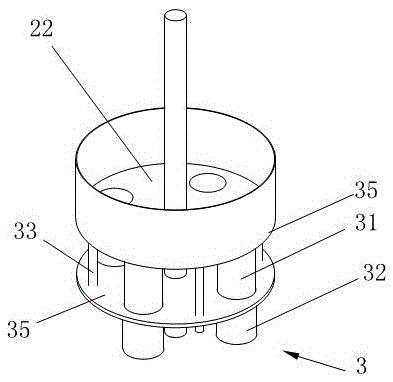

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Refer to attached Figure 1~6 , the fully automatic edible fungus compost bagging machine of the present invention includes a frame 1, wherein the frame 1 is respectively equipped with a feeding mechanism 2, a feeding mechanism 3, a station turntable 4, and a bag feeding mechanism 5 from top to bottom; The station turntable 4 can rotate around the rotating shaft 6. The station turntable 4 is respectively provided with a bag taking mechanism 41 and a bag clamping mechanism 42; barrel 31 and large loading barrel 32, the small loading barrel 31 can move up and down in the large loading barrel 32, the large and small loading barrels are respectively provided with a fixed plate 35, and a Adjustment screw 33 is arranged. The small loading barrel 31 is a long loading barrel with a small diameter, and the large loading barrel 32 is a short loading barrel wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com