Patents

Literature

78results about How to "Consistent volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

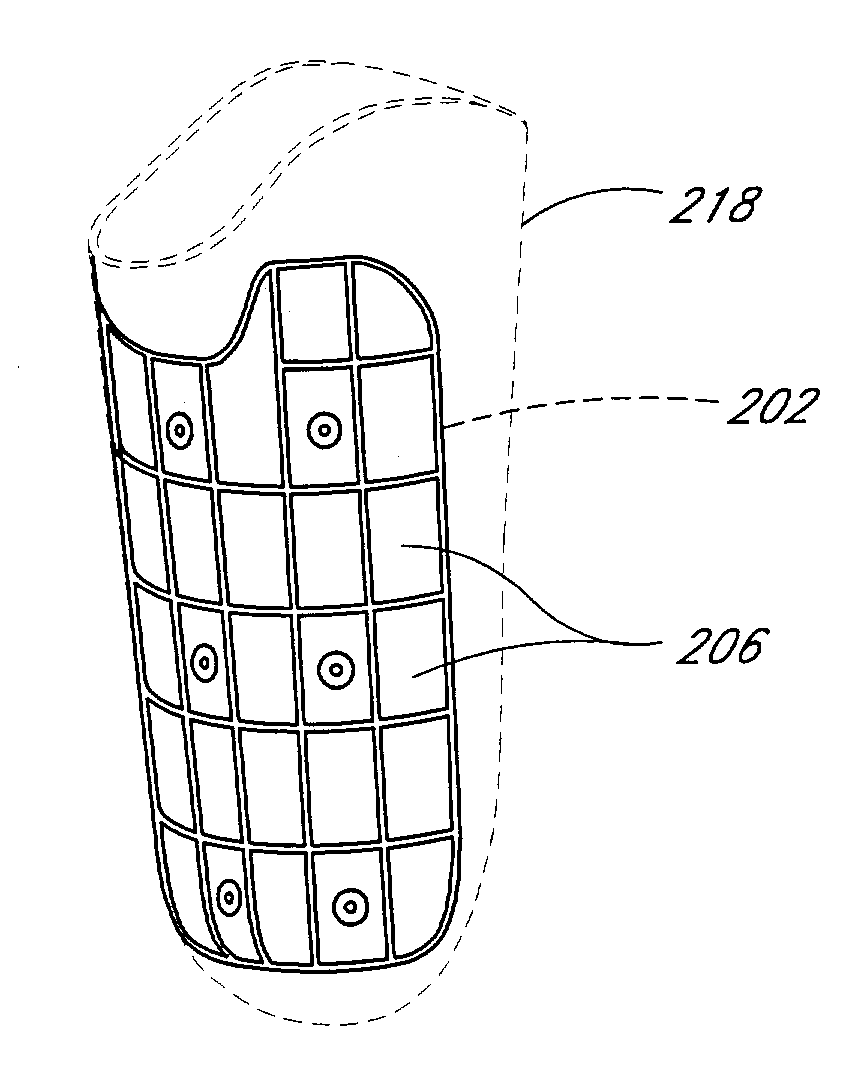

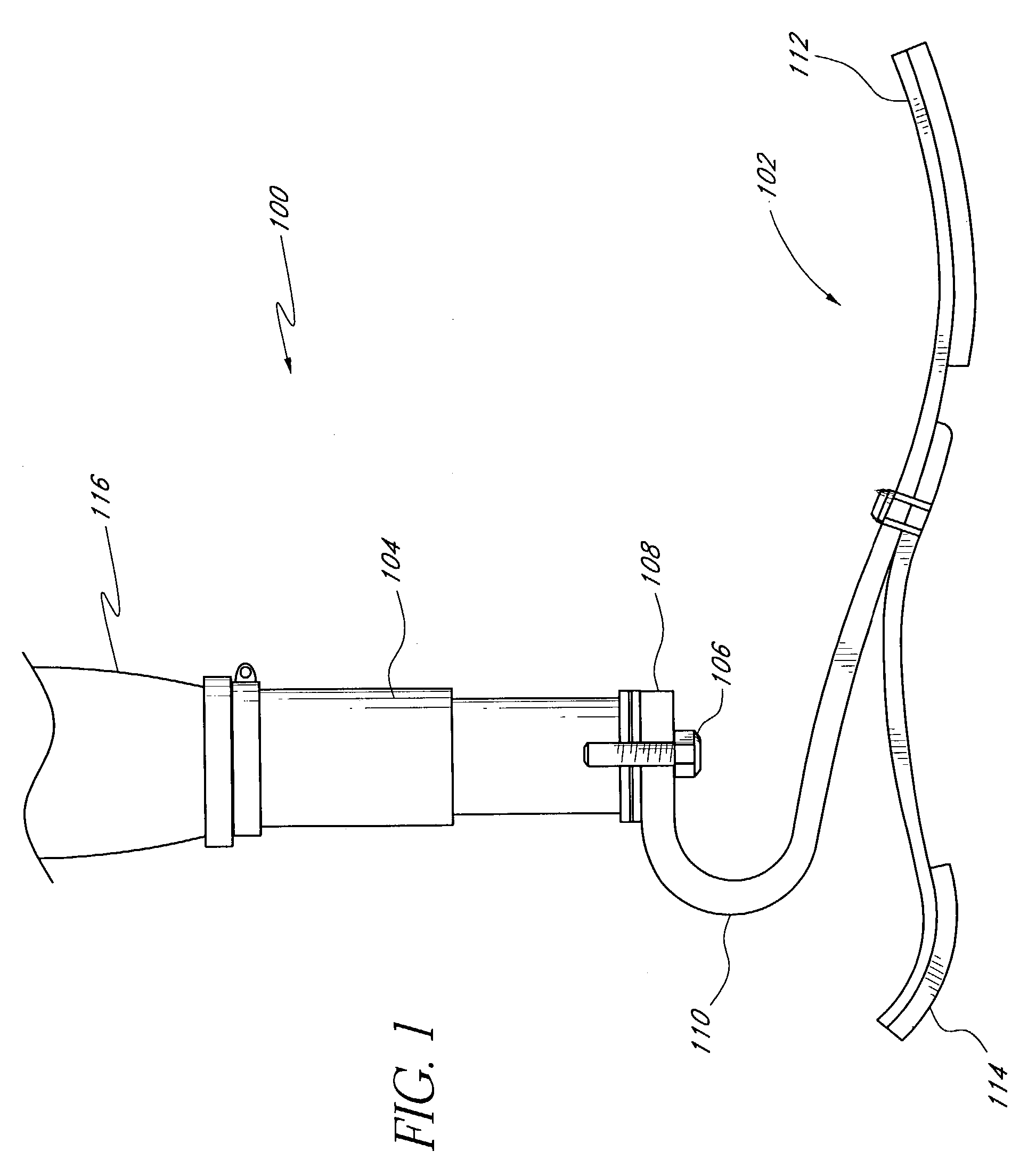

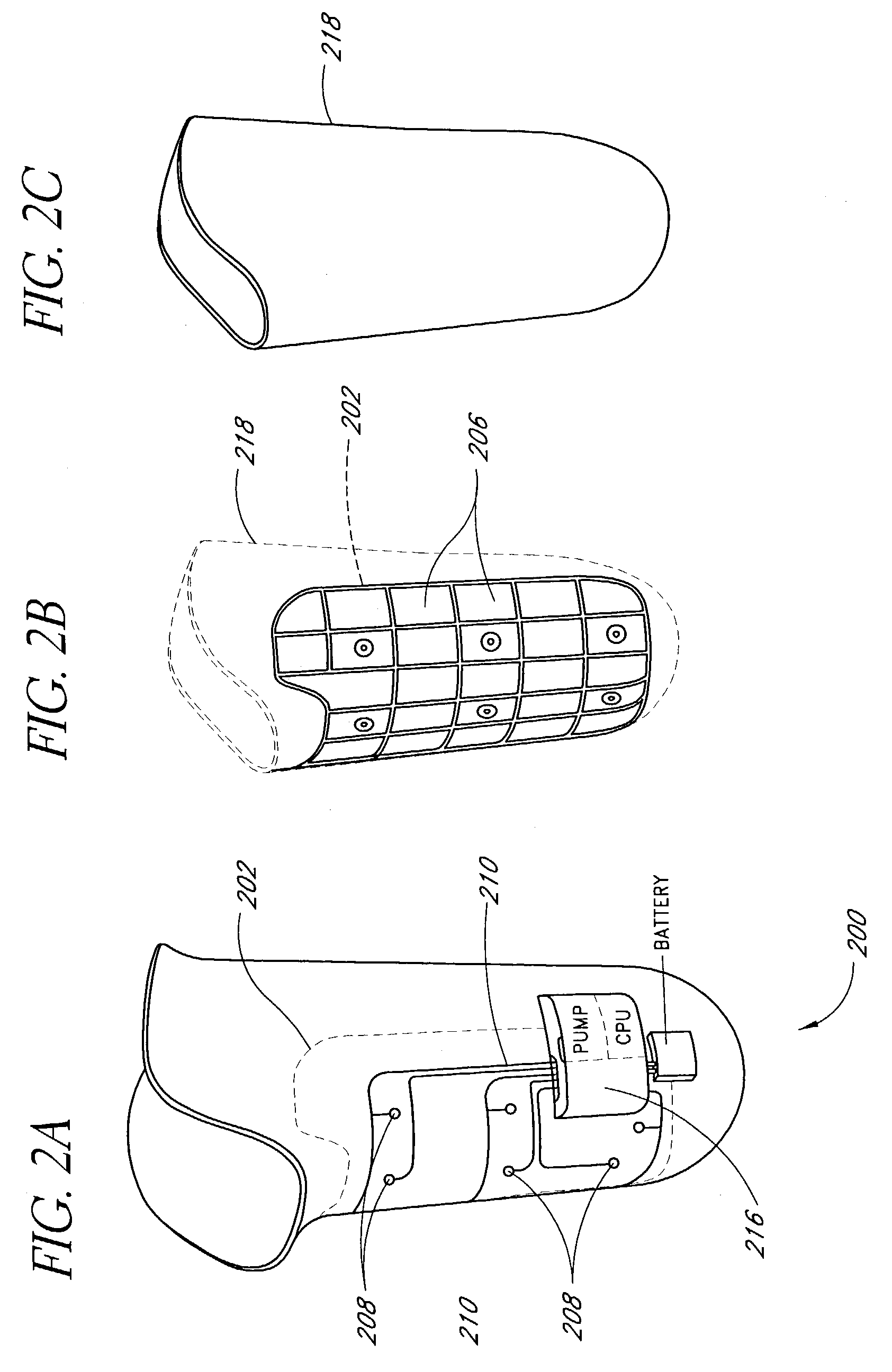

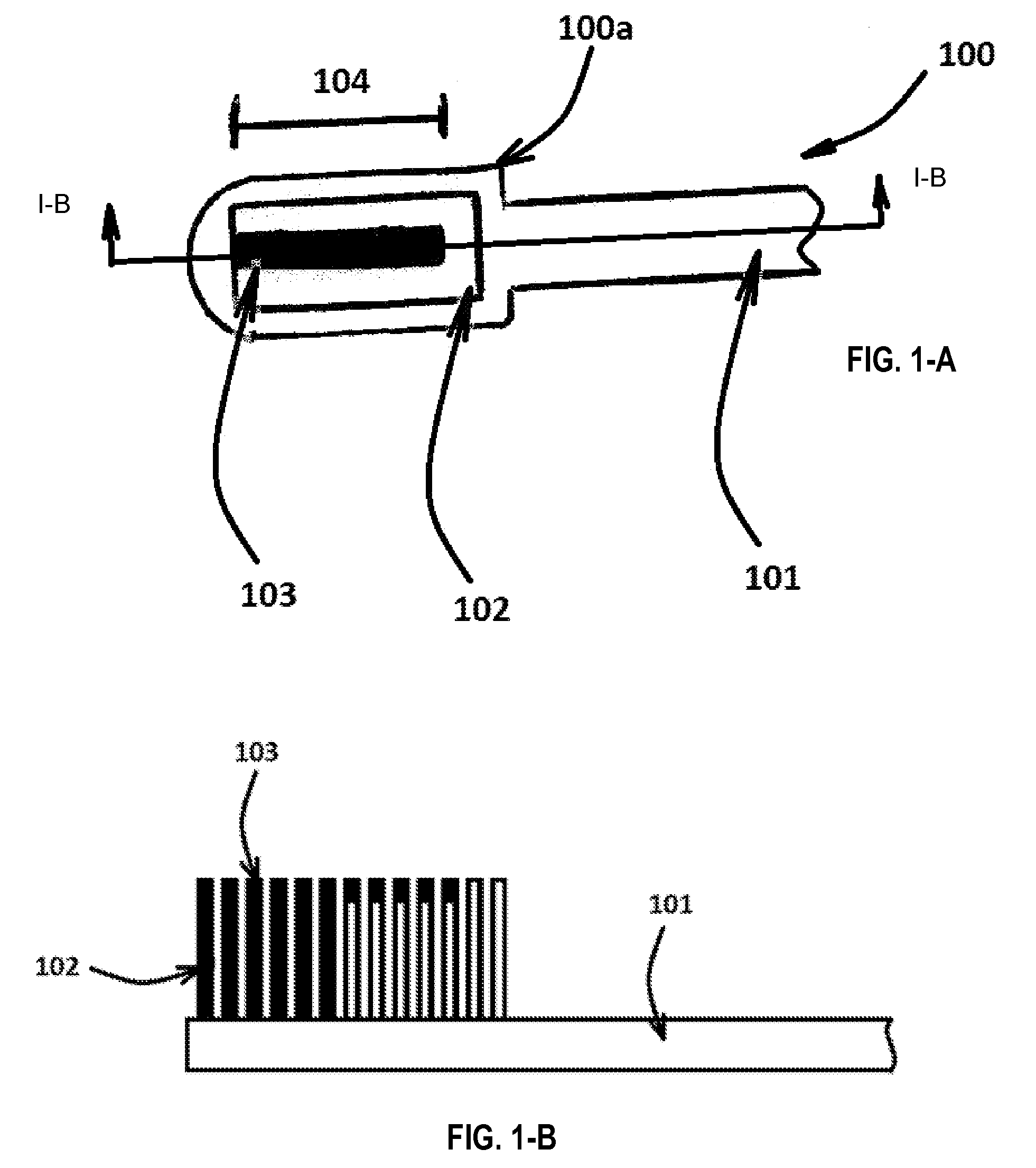

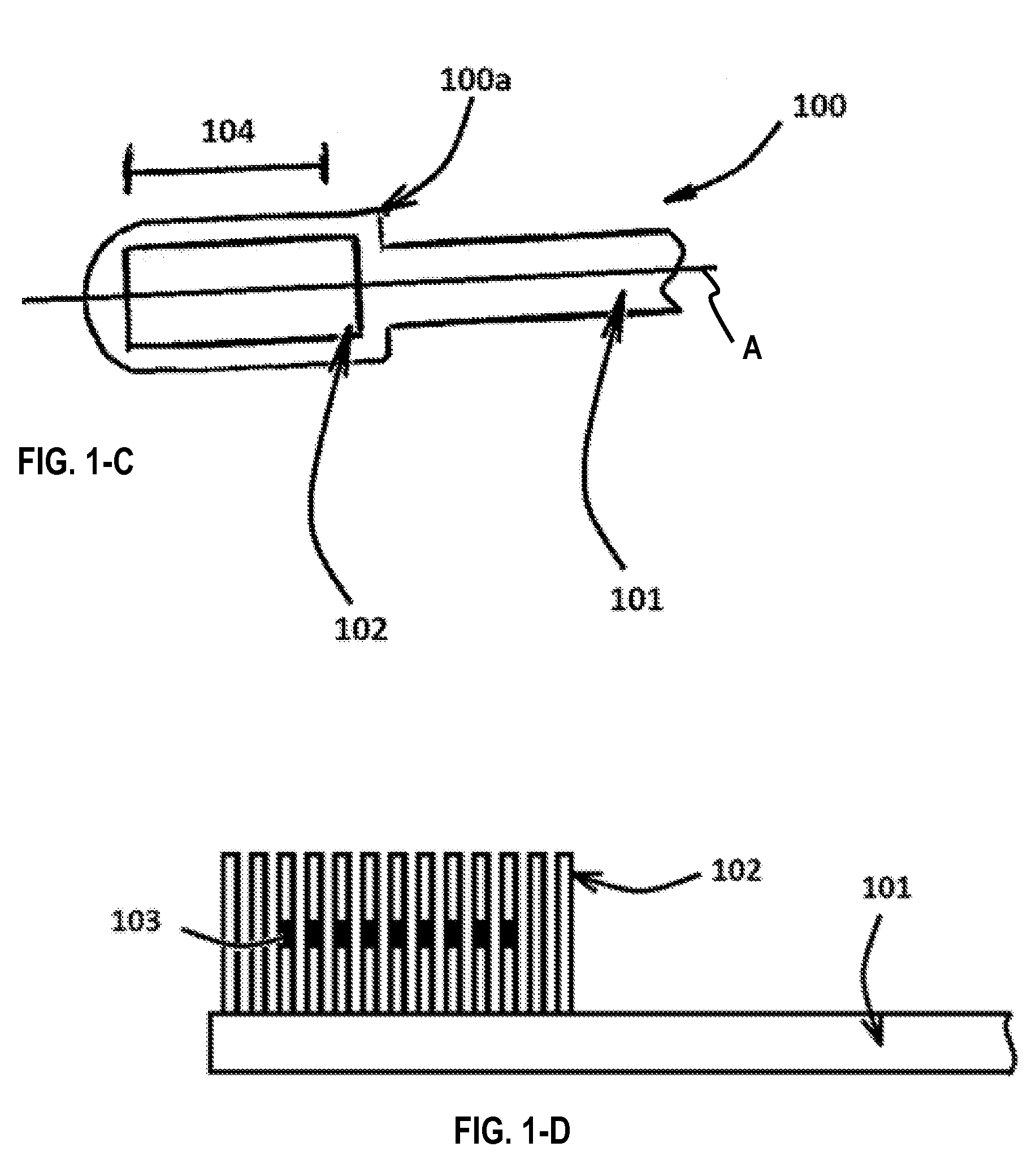

Socket insert having a bladder system

A prosthetic device having a socket with an insert having a bladder system for monitoring and compensating for volume fluctuations in a residual limb is provided. A plurality of bladders are preferably provided, in one embodiment, substantially only on a posterior portion of the socket. The bladders may be organized into zones, with the zones being inflatable to differing pressures depending on volume fluctuations in a residual limb. Pressure sensors may be provided for each bladder or for each zone, and flow regulators may be provided to control fluid flow into or out of the bladders or zones of bladders based on readings from the pressure sensors to control volume within the insert. Alternatively, bladders can be manually inflated depending on an amputee's needs.

Owner:PHILLIPS VAN L

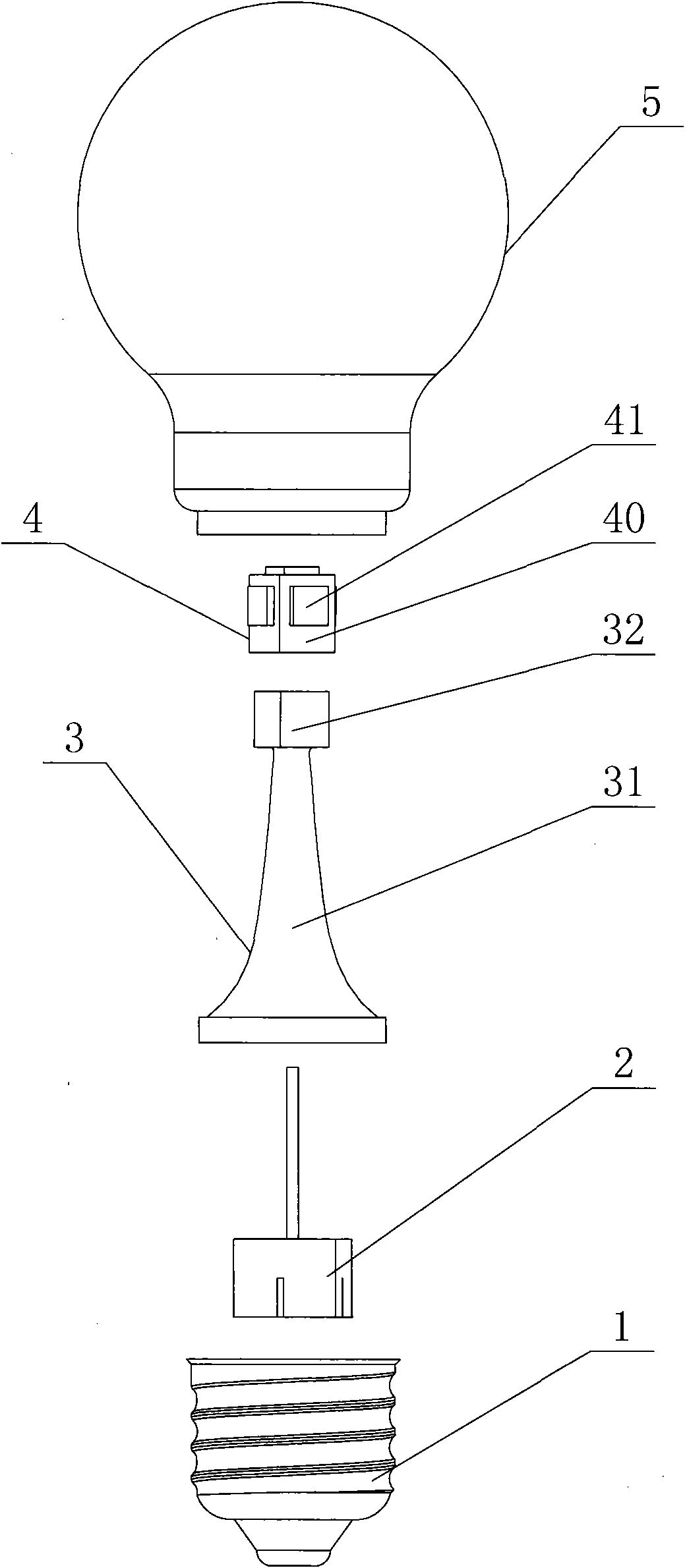

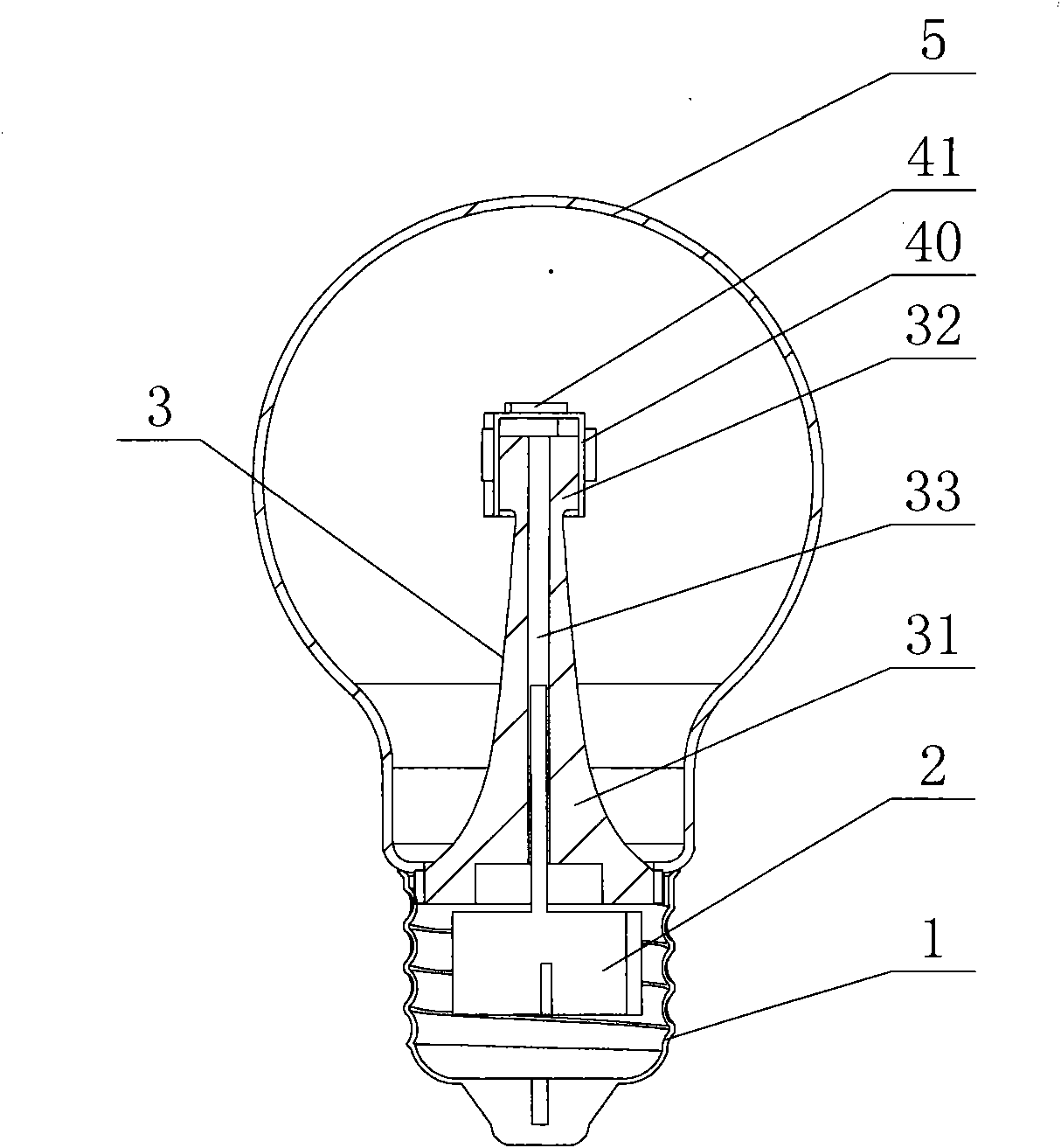

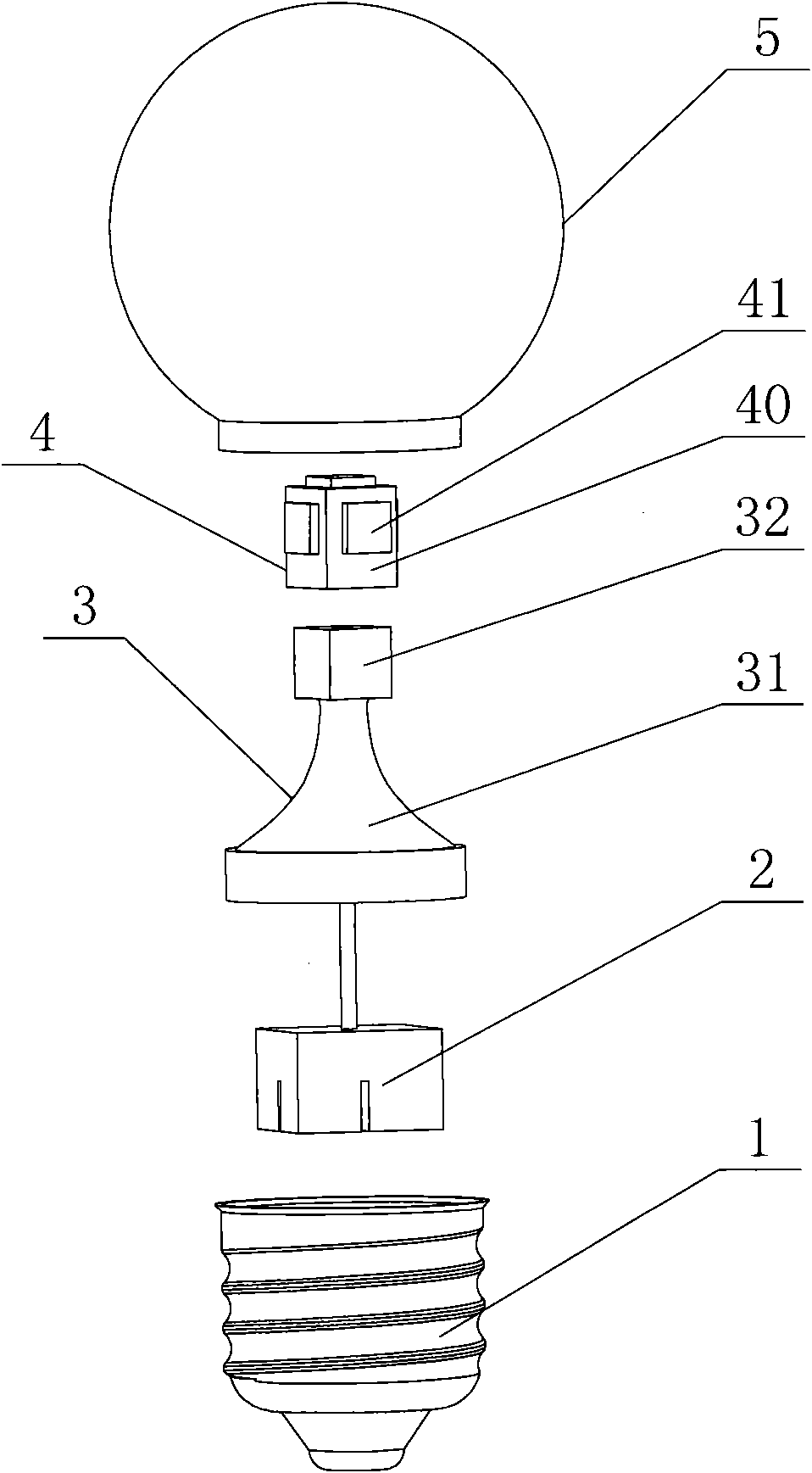

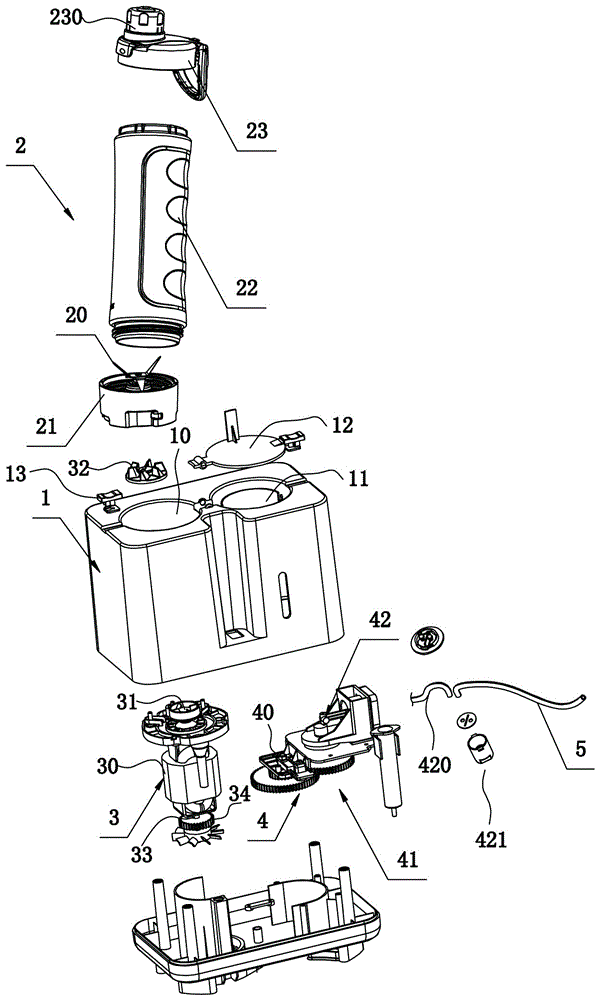

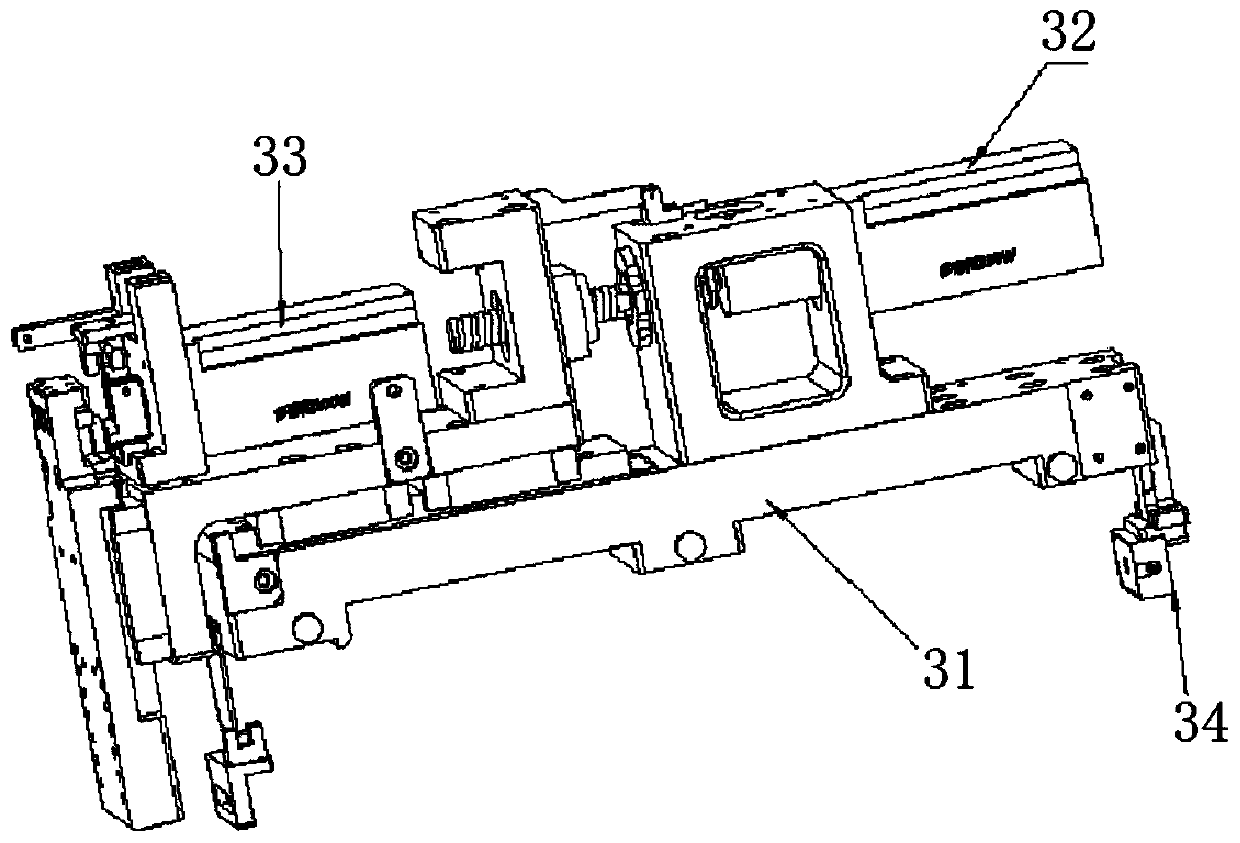

LED bulb

InactiveCN101598272ADoesn't look obtrusiveObtrusive appearancePoint-like light sourceElectric circuit arrangementsBus-holderLight head

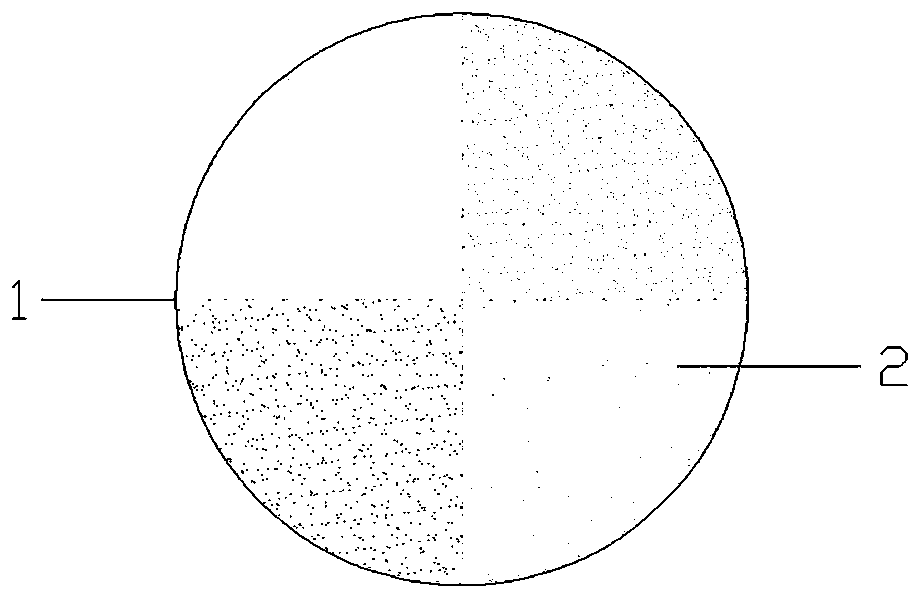

The invention discloses an LED bulb, which has good light transmitting performance and has the same light emitting mode, volume and shape as common incandescent light bulbs. The LED bulb comprises a bulb holder (1), a driving circuit component (2), a light source support (3), an LED light source (4) and a bulb case (5), wherein the light source support (3) comprises a pedestal (31) and a polyhedron (32) and is made of metal; the internal axial center of the pedestal (31) is provided with a wire hole (33); the polyhedron (32) is positioned on the top of the pedestal (31); the lower part of the pedestal (31) and the inner wall of the bulb holder (1) are contacted tightly for heat conduction; the LED light source (4) comprises heat dissipating baseplates (40) and LED chips (41) positioned on the heat dissipating baseplates (40); the heat dissipating baseplates (40) are directly fixed on each surface of the polyhedron (32) in the circumferential direction, and the LED chips (41) give out light in all directions by taking surfaces of the polyhedron (32) in the circumferential direction as the reference surfaces; and the driving circuit component (2) is electrically connected with the bulb holder (1) and the LED light source (4) through leads.

Owner:SMALUX ELECTRICAL MFG

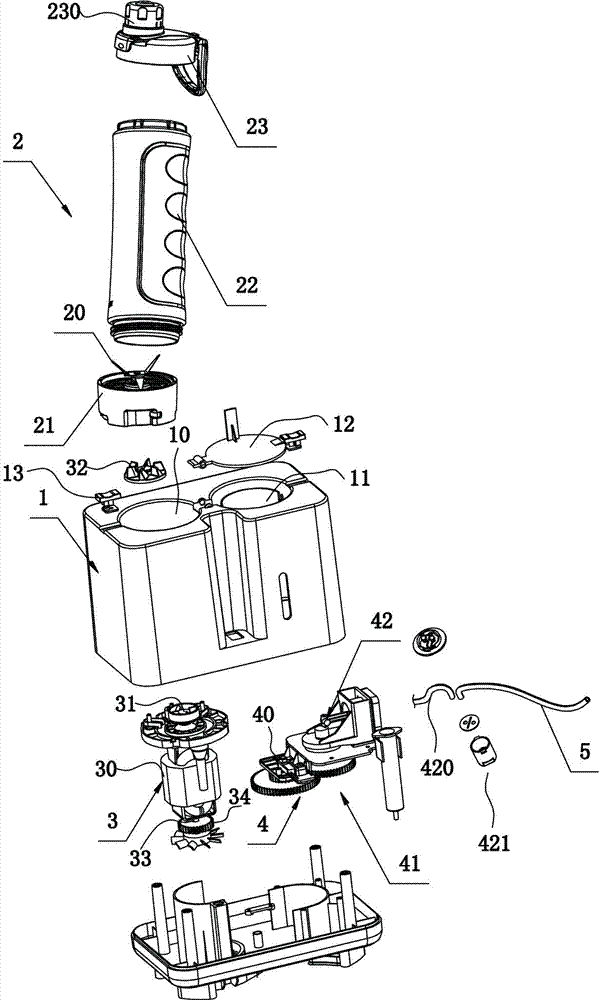

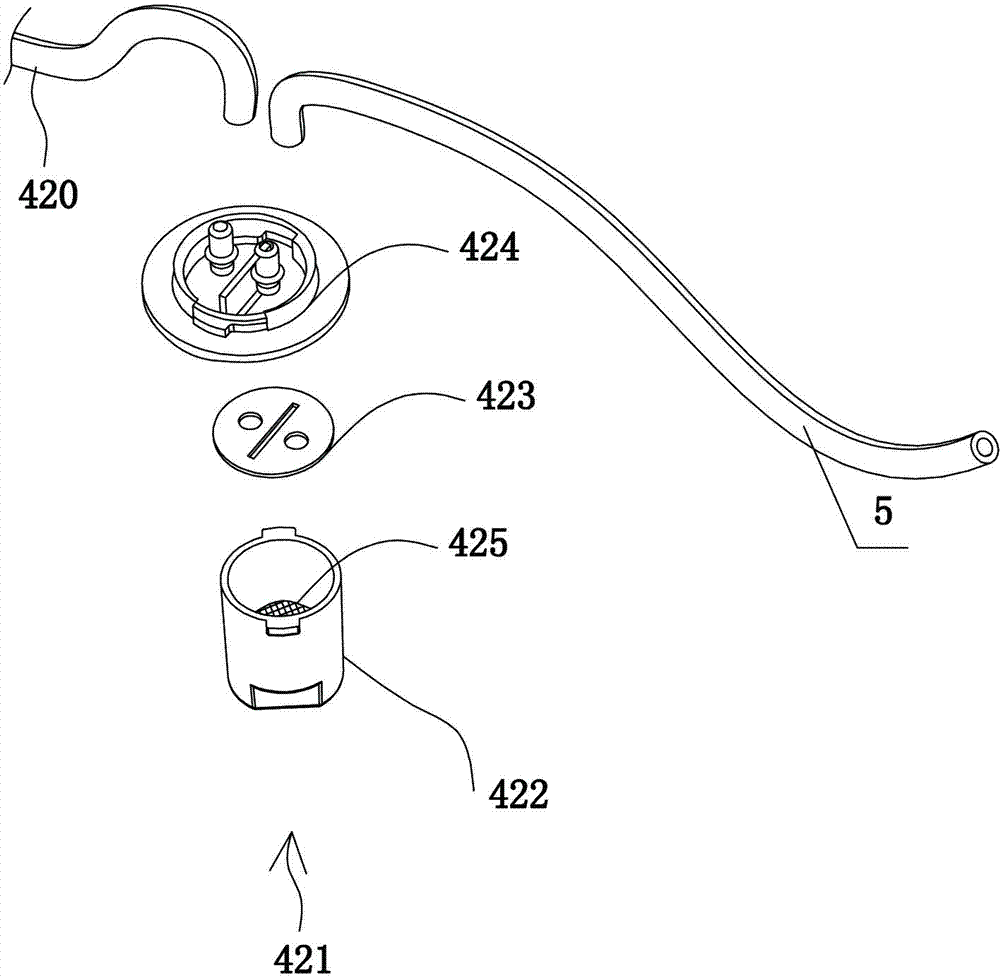

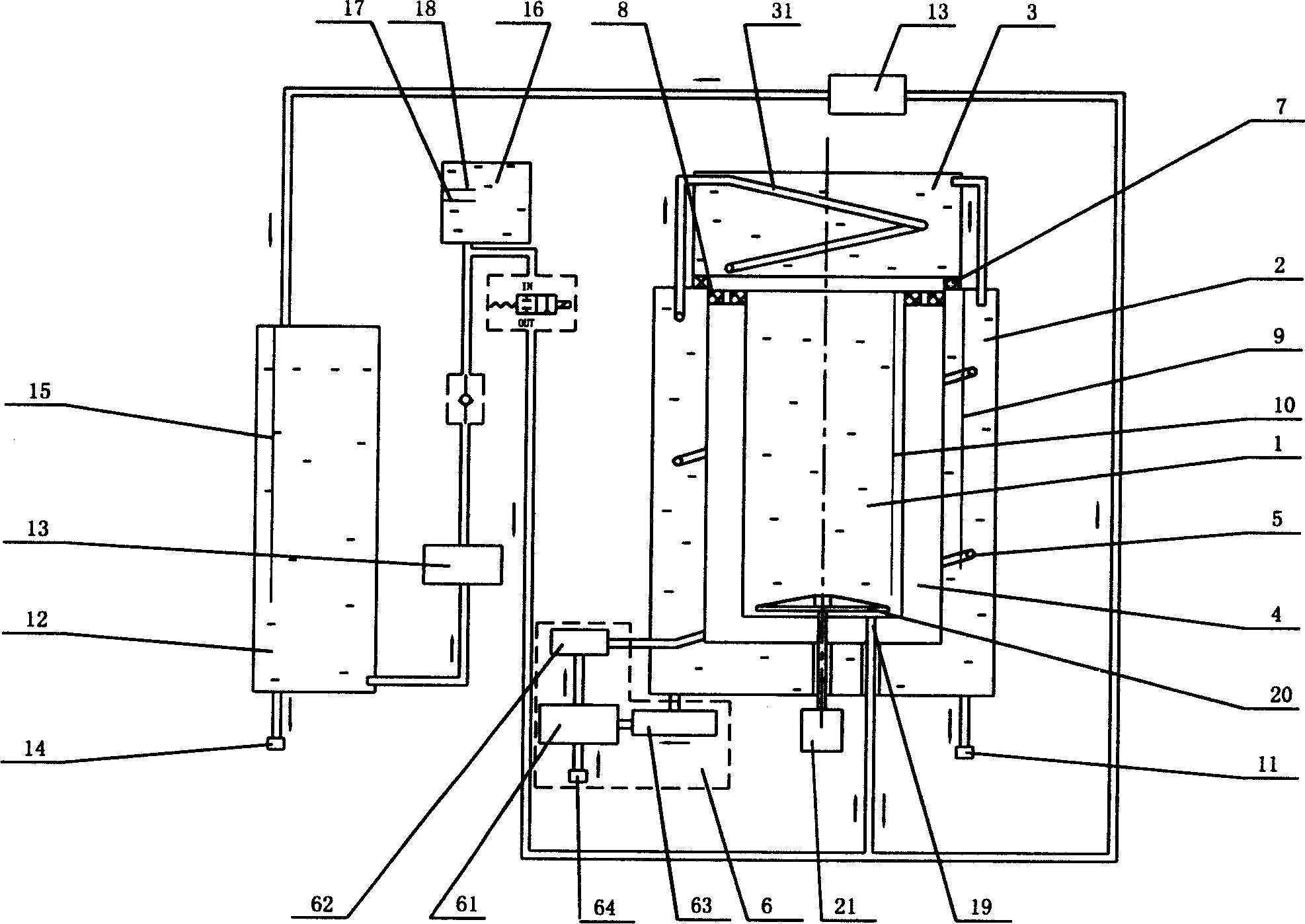

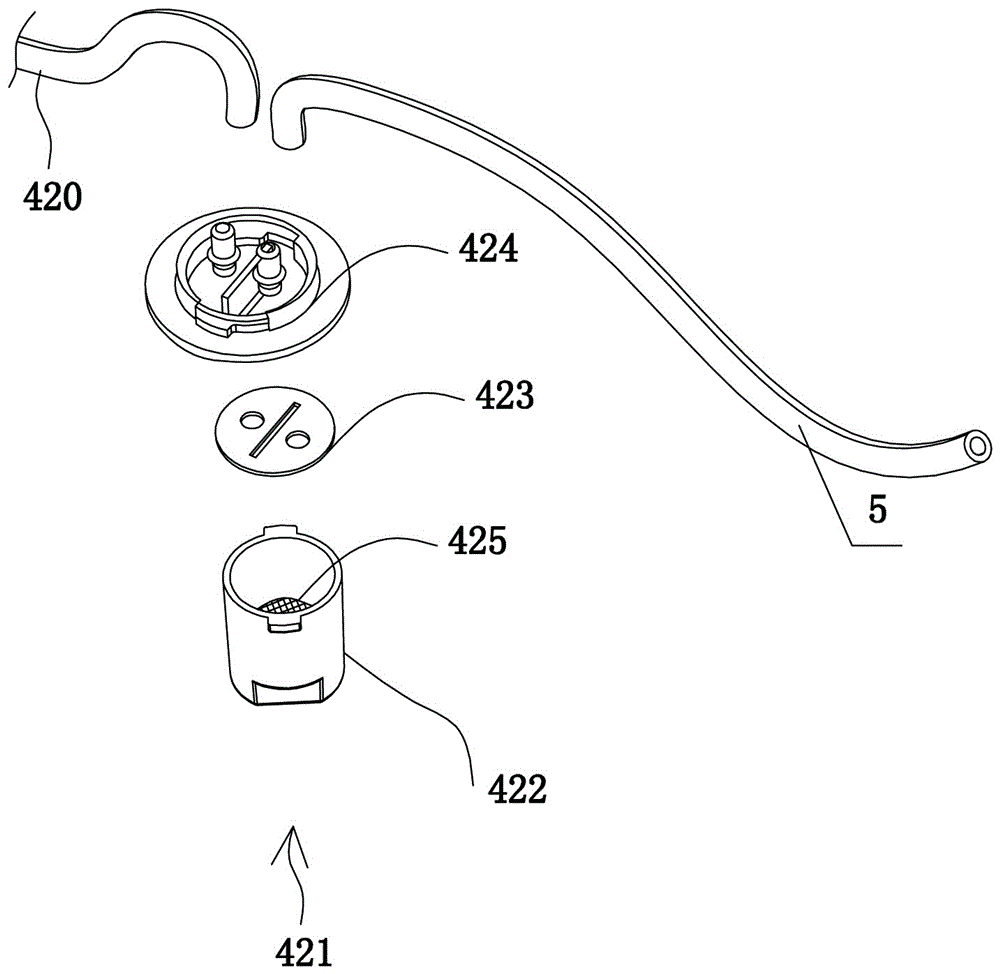

Food processor/juicer of improved structure

A food processor / juicer of an improved structure comprises a fixed base, a cup assembly, a driving assembly and a vacuum pump assembly. The cup assembly comprises a cup holder, a cup wall and a cup cover; the driving assembly comprises a driving motor, a first output shaft, a clutch and a second output shaft, and a first variable gear is arranged on the second output shaft; the vacuum pump assembly comprises a base frame, a speed change unit and a compression unit, the fixed base is provided with an opening, the compression unit is provided with an air extraction opening, the air extraction opening is connected with one end of a telescopic hose, the cup cover is provided with an air extraction hole, and the other end of the telescopic hose penetrates through the opening, then extends to the cup cover and is connected with the air extraction hole. The food processor / juicer is compact in integrated structure and convenient for a user to operate and carry, manufacturing cost is reduced, occupation on the inner space of the fixed base is reduced, and therefore the size and weight of the fixed base are substantially kept identical with those of an existing frequently-used juicer.

Owner:厦门乐时及物智能科技有限公司

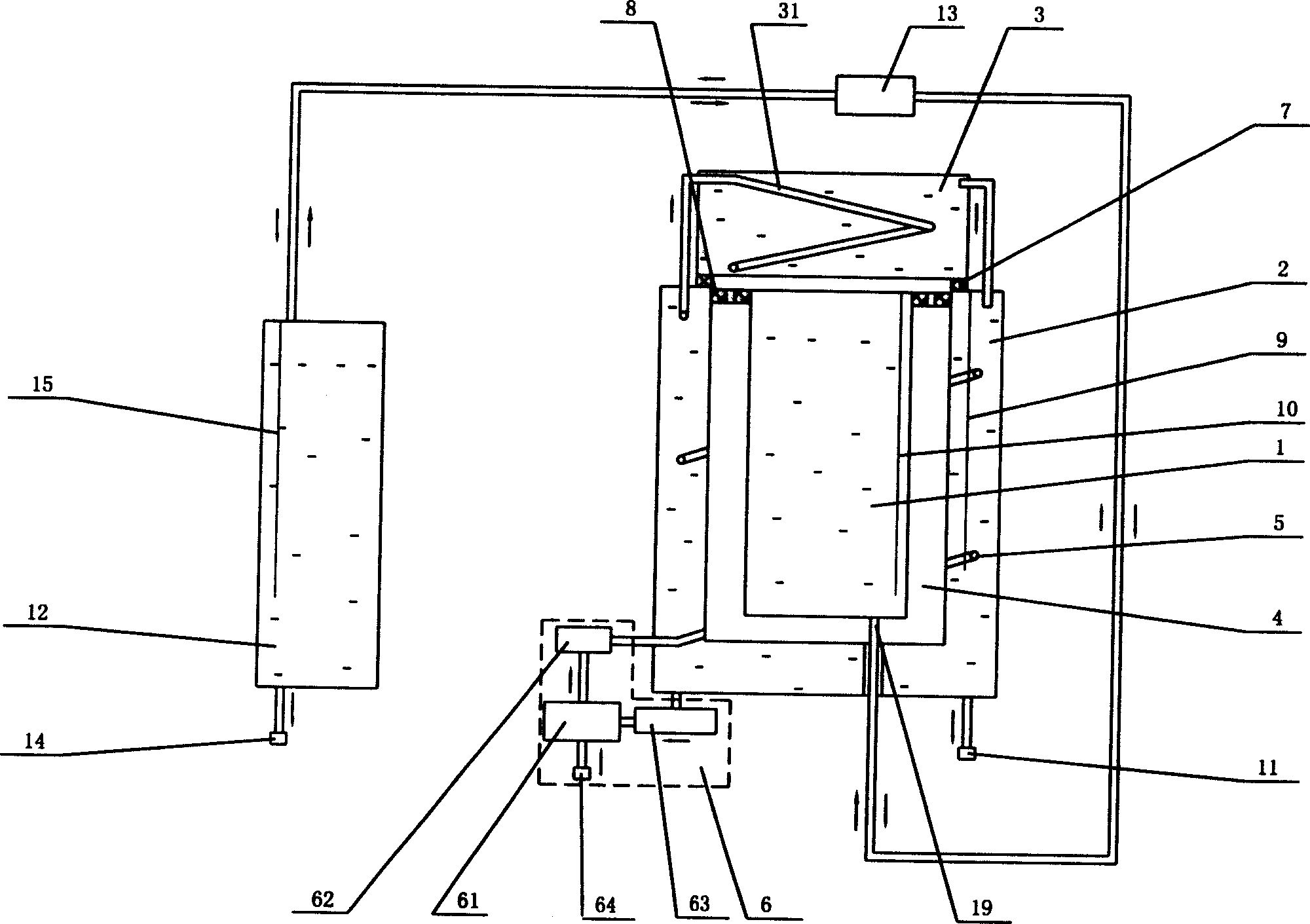

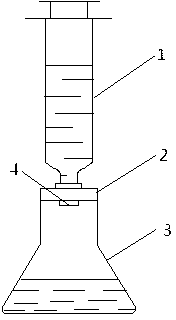

Bilayer type peripherical isothermal temperature setting calorimeter

ActiveCN1719214AImprove the mixing effectConsistent temperatureCalorimeterEngineeringWater temperature

The present invention discloses a double-layer circumferential isothermal constant temperature calorimeter. It includes internal barrel, external barrel, stand-by barrel and barrel lid placed on the top portion of internal barrel and external barrel. Said invention also provides their assembling mode and working principle of said calorimeter.

Owner:HUNAN SUNDY SCI & TECH DEV

A structurally improved food cooking machine/juice machine

A food processor / juicer of an improved structure comprises a fixed base, a cup assembly, a driving assembly and a vacuum pump assembly. The cup assembly comprises a cup holder, a cup wall and a cup cover; the driving assembly comprises a driving motor, a first output shaft, a clutch and a second output shaft, and a first variable gear is arranged on the second output shaft; the vacuum pump assembly comprises a base frame, a speed change unit and a compression unit, the fixed base is provided with an opening, the compression unit is provided with an air extraction opening, the air extraction opening is connected with one end of a telescopic hose, the cup cover is provided with an air extraction hole, and the other end of the telescopic hose penetrates through the opening, then extends to the cup cover and is connected with the air extraction hole. The food processor / juicer is compact in integrated structure and convenient for a user to operate and carry, manufacturing cost is reduced, occupation on the inner space of the fixed base is reduced, and therefore the size and weight of the fixed base are substantially kept identical with those of an existing frequently-used juicer.

Owner:XIAMEN MYLUX INTELLIGENT TECH CO LTD

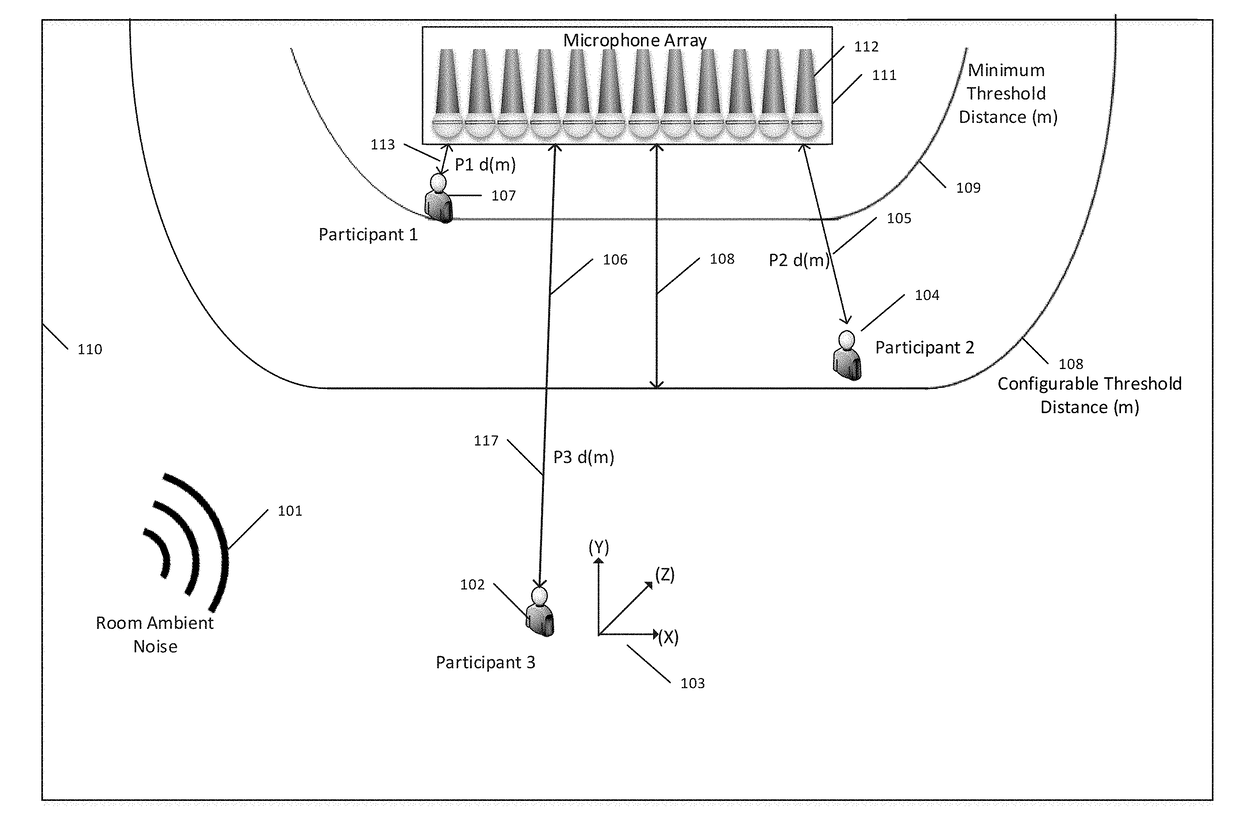

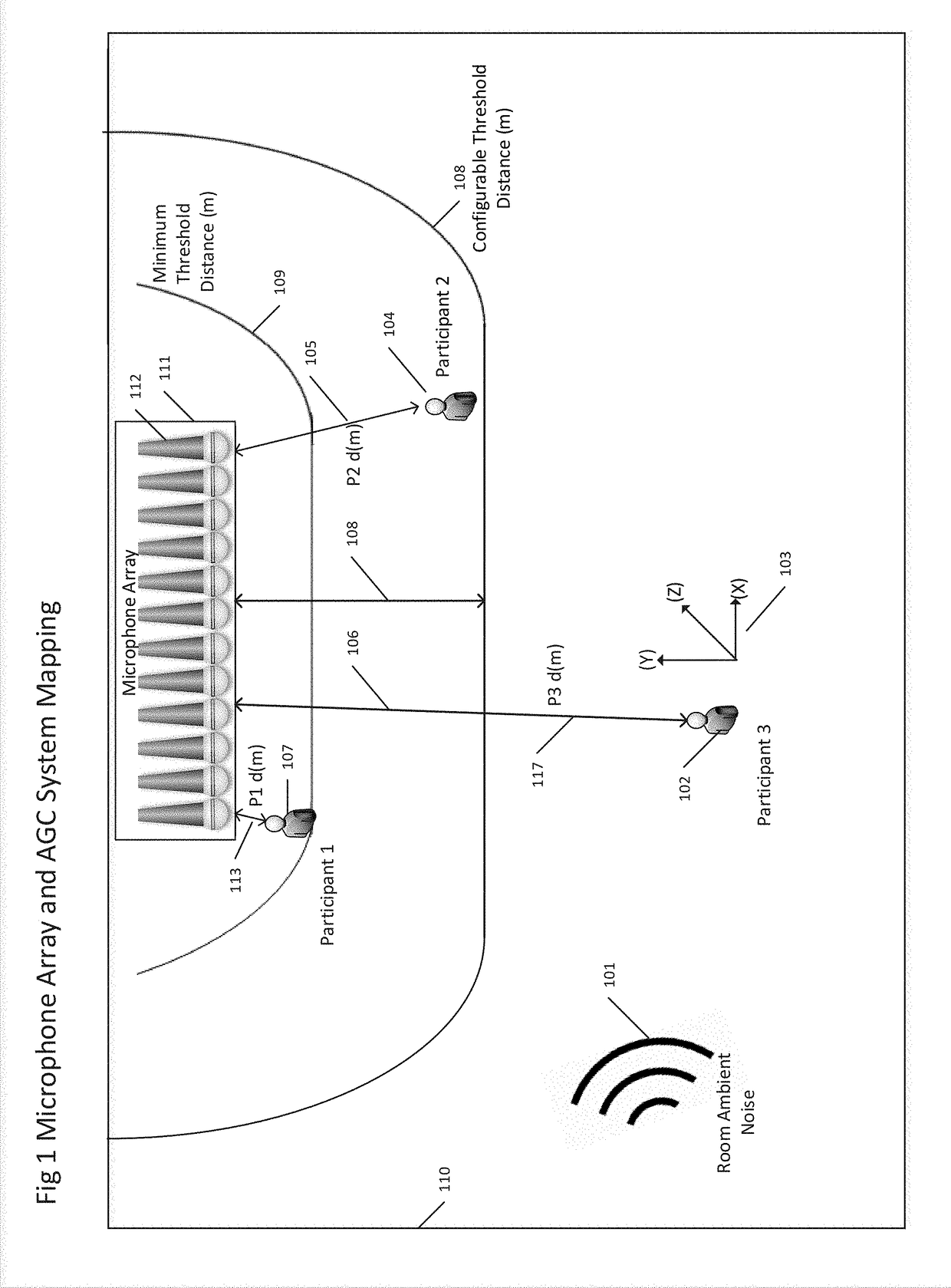

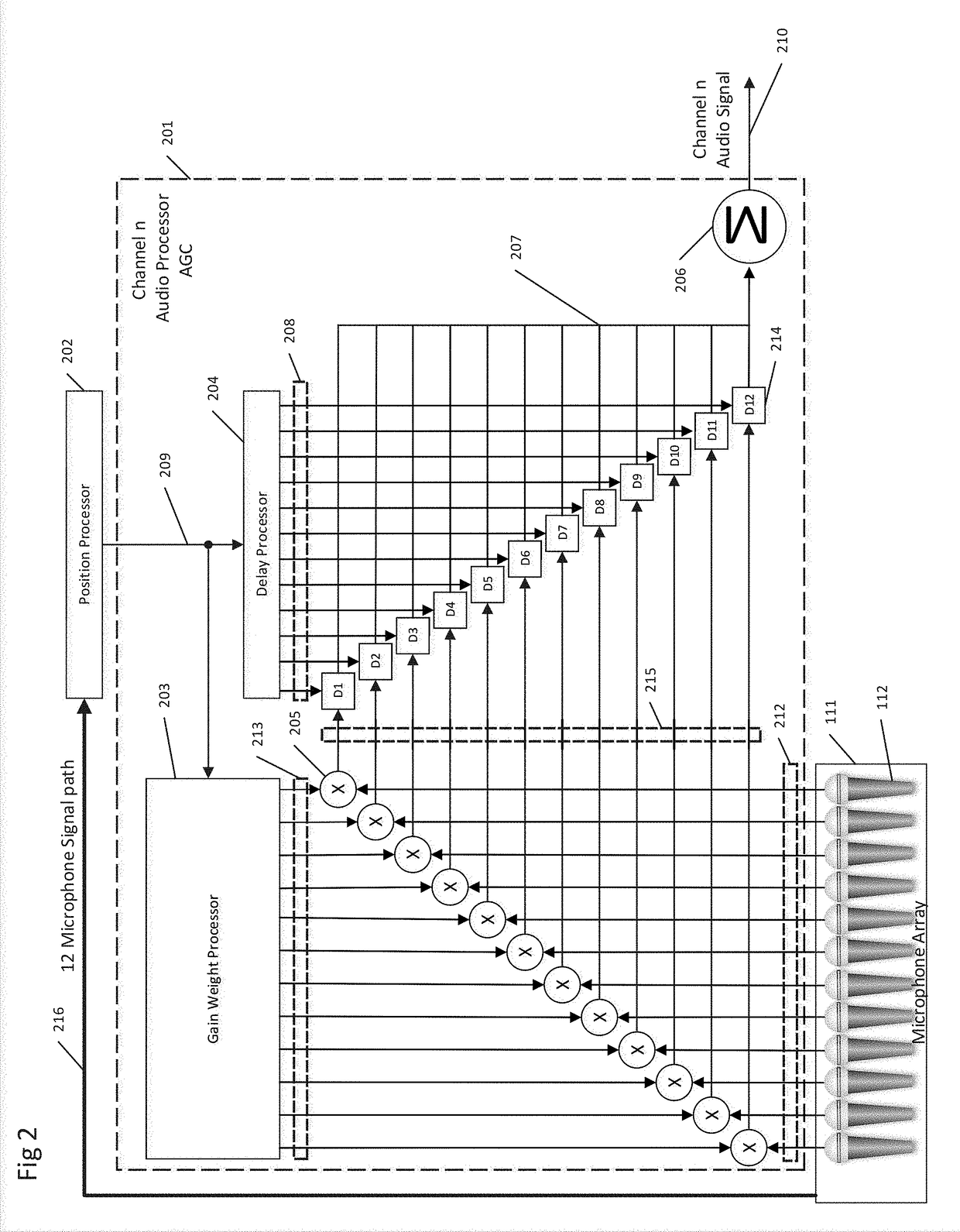

Method, apparatus and computer-readable media utilizing positional information to derive agc output parameters

ActiveUS20180074782A1Stable background sound levelConsistent sound levelMicrophonesSignal processingSound source locationSound sources

Method and apparatus for automatic gain control utilizing sound source position information in a shared space having a plurality of microphones and a plurality of sound sources. Sound signals are received from the microphones. One or more processors locate position information corresponding to each of the sound sources. The processor(s) determine the distance to each of the sound sources from each of the microphones. The processor(s) define a predetermined gain weight adjustment for each of the microphones. The processor(s) apply the defined weight adjustments to the microphones to achieve a consistent volume of the desired plurality of sound sources. The processor(s) maintain a consistent ambient sound level regardless of the position of the sound sources and the applied gain weight adjustments. The processor(s) output a summed signal of the sound sources at a consistent volume with a constant ambient sound level across the plurality of sound source positions.

Owner:NUREVA INC

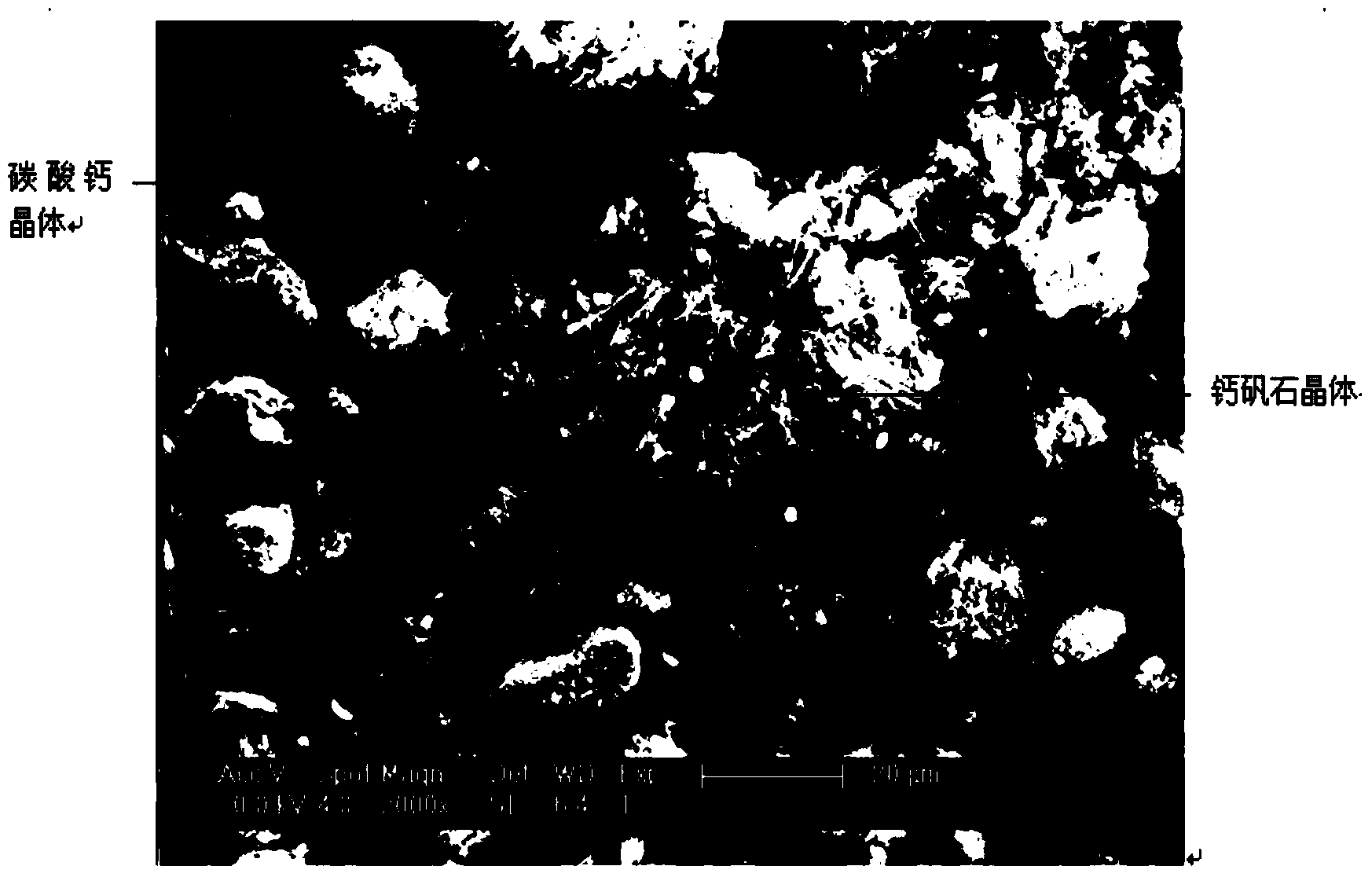

Soil curing agent based on desulfurized fly ash activity and preparation method and application thereof

InactiveCN104045293AAvoid the risk of volume instabilityRealize resource utilizationSoil preservationFluorescenceSlag

The invention discloses a soil curing agent based on desulfurized fly ash activity and a preparation method and application of the soil curing agent. The preparation method comprises the steps of performing chemical analysis or fluorescence analysis to obtain components of desulfurized fly ash and superfine slag powder characteristic substances, focusing on testing the content of sulfur trioxide in the desulfurized fly ash, and converting the content into the content of calcium sulfate; testing the content of aluminum oxide in the superfine slag powder; controlling calcium sulfate in the desulfurized fly ash and aluminum oxide in the superfine slag powder according to the classic structure 3CaO.Al2O3.3CaSO4.32H2O, of the ettringite molecule, wherein the mole ratio of calcium sulfate to aluminum oxide is no greater than 3:1; uniformly mixing the desulfurized fly ash and the superfine slag powder according to a pre-estimated ratio, and adding alkali excitant sodium hydroxide and zinc stearate, thereby preparing the novel soil curing agent. The activity of desulfurized fly ash is utilized, and meanwhile, the problem that the volume of the desulfurized fly ash is not stable is solved. The curing effect of the soil curing agent is better than that of a coal ash-lime stable roadbed material and is equivalent to that of a cement stable roadbed material, and the price is only 1 / 3 to 1 / 2 of that of the cement stable roadbed material.

Owner:SOUTHEAST UNIV

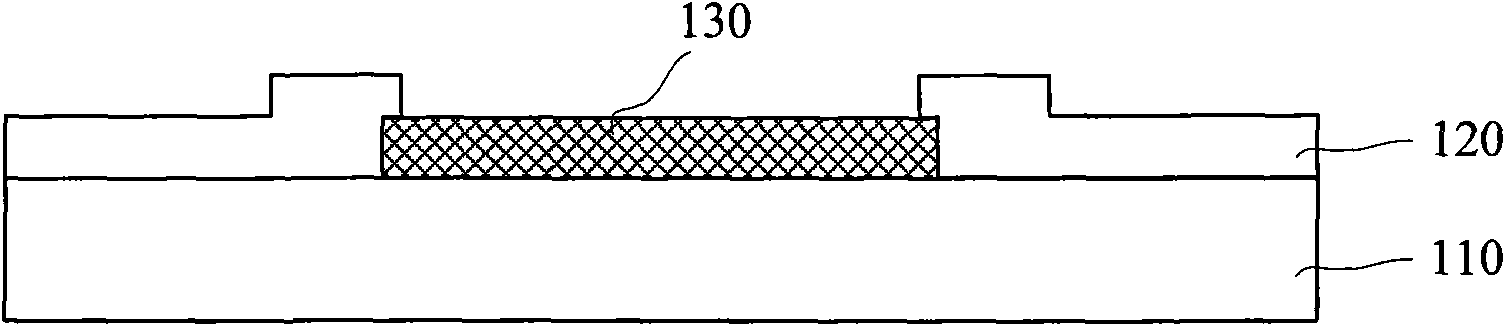

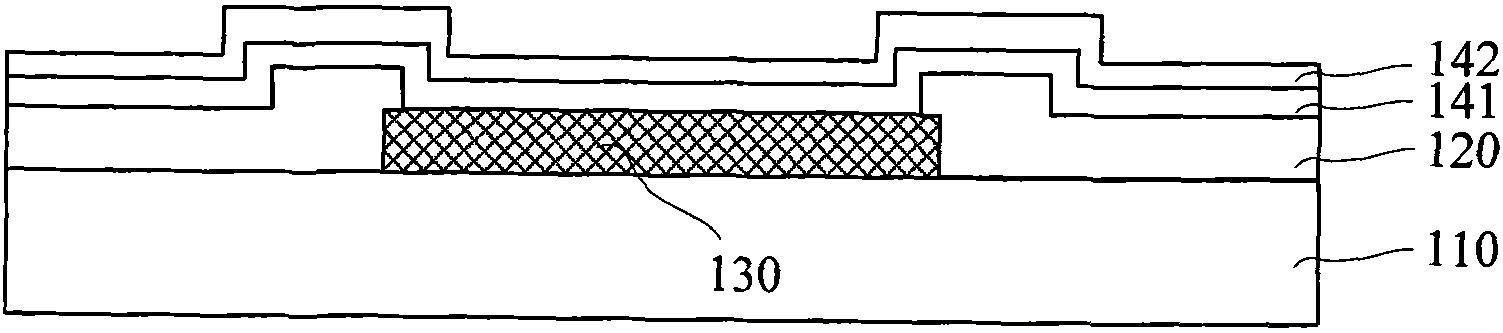

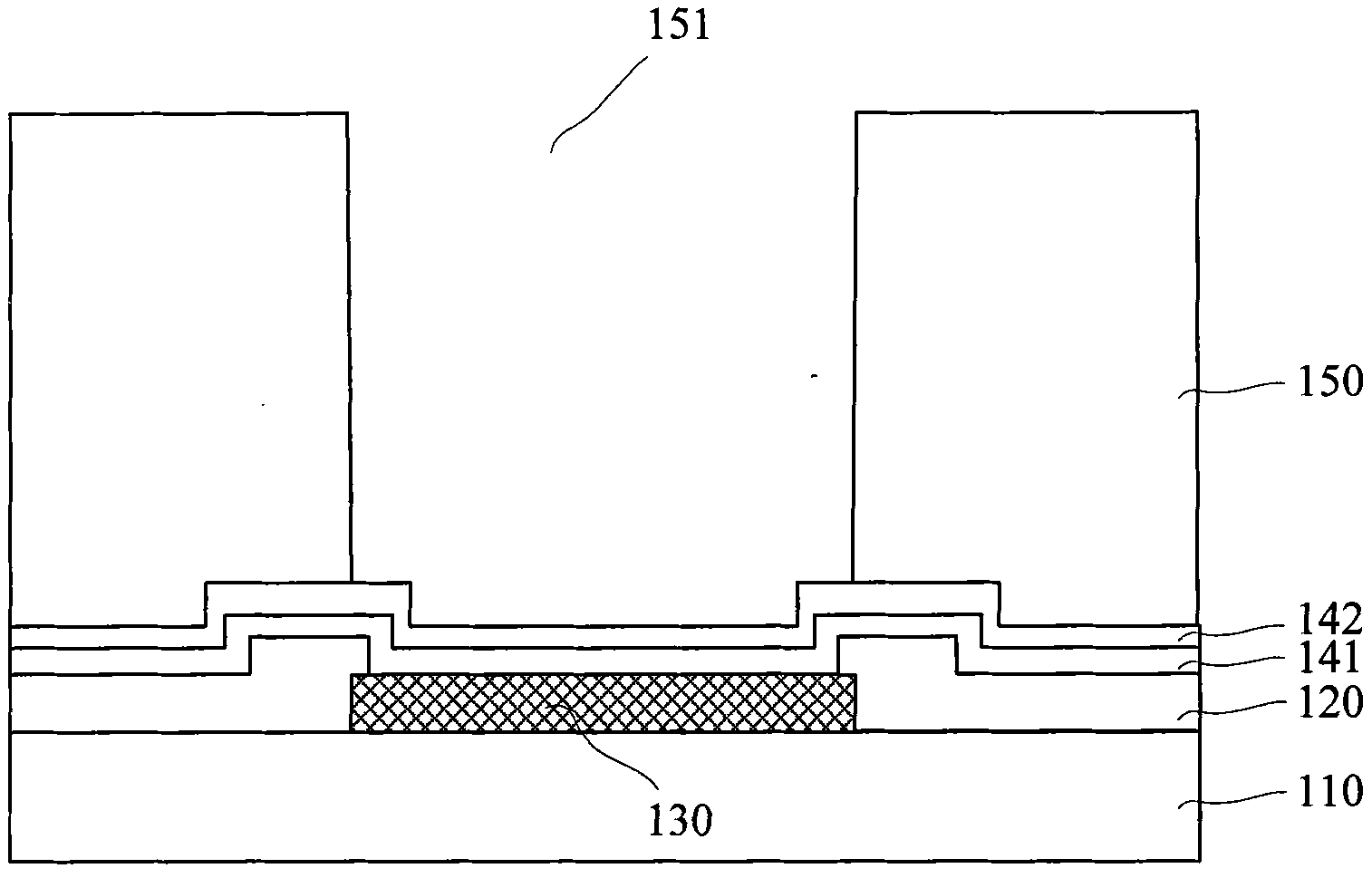

Method for manufacturing solder lug

ActiveCN101894766AHighly consistentConsistent volumeSemiconductor/solid-state device detailsSolid-state devicesMetallurgyMetal electrodes

The invention discloses a method for manufacturing a solder lug. The method comprises the following steps: providing a semiconductor substrate with a pad; forming a metal laminate on the semiconductor substrate; forming a first photoresist layer on the metal laminate, and patterning the first photoresist layer to form a first opening which is positioned above the pad and exposed from the metal laminate; forming a metal electrode in the first opening; flattening the first photoresist layer and the surface of the metal electrode; forming a second photoresist layer on the first photoresist layer and the surface of the metal electrode, and patterning the second photoresist layer to form a second opening which is exposed from the metal electrode; forming a solder layer in the second opening; removing the first photoresist layer, the second photoresist layer and the metal laminate which is not covered by the metal electrode; and refluxing the solder layer to form bumps. In the method, high quality solder lug with accordant height and volume can be formed, and the yield of semiconductor devices can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

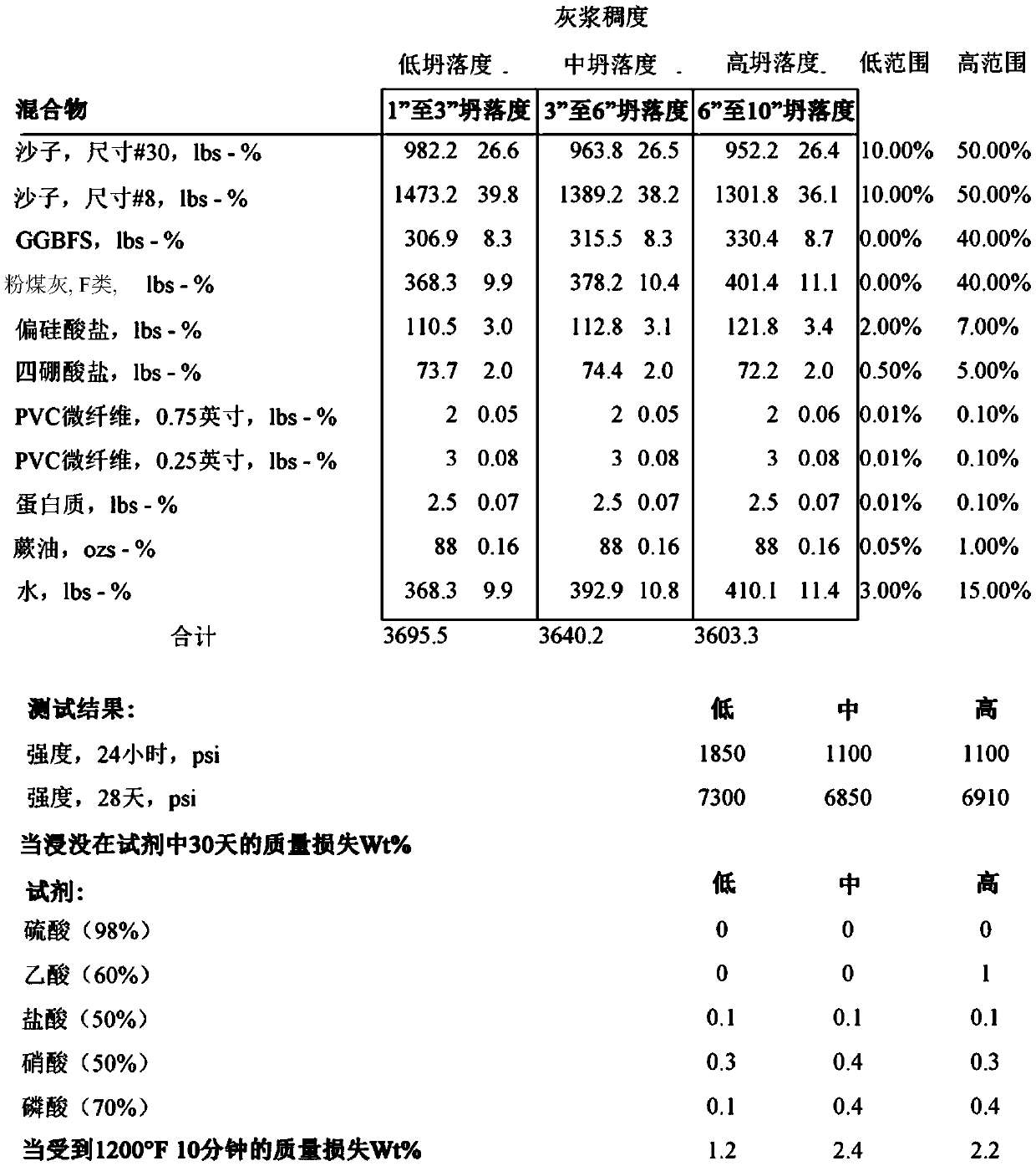

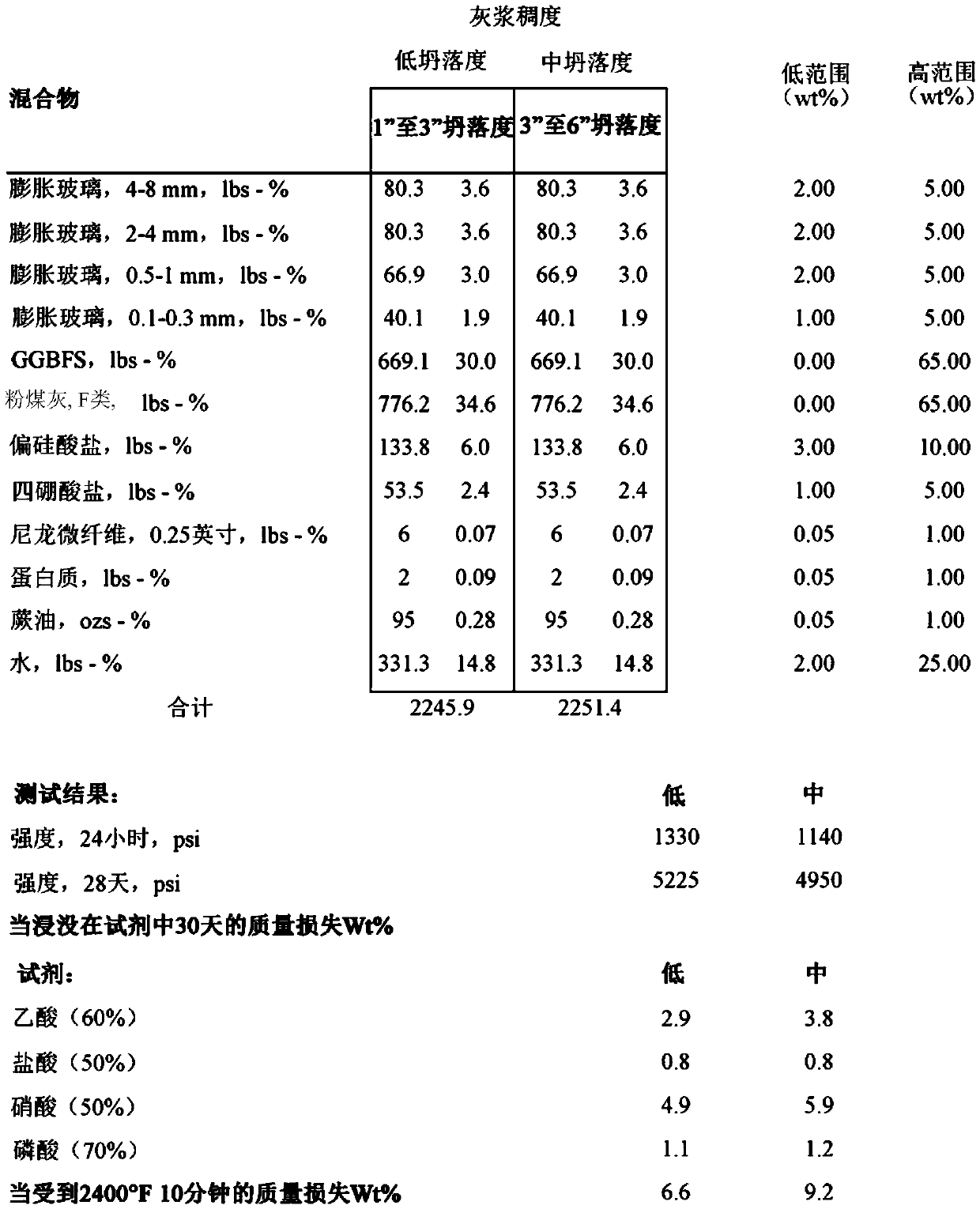

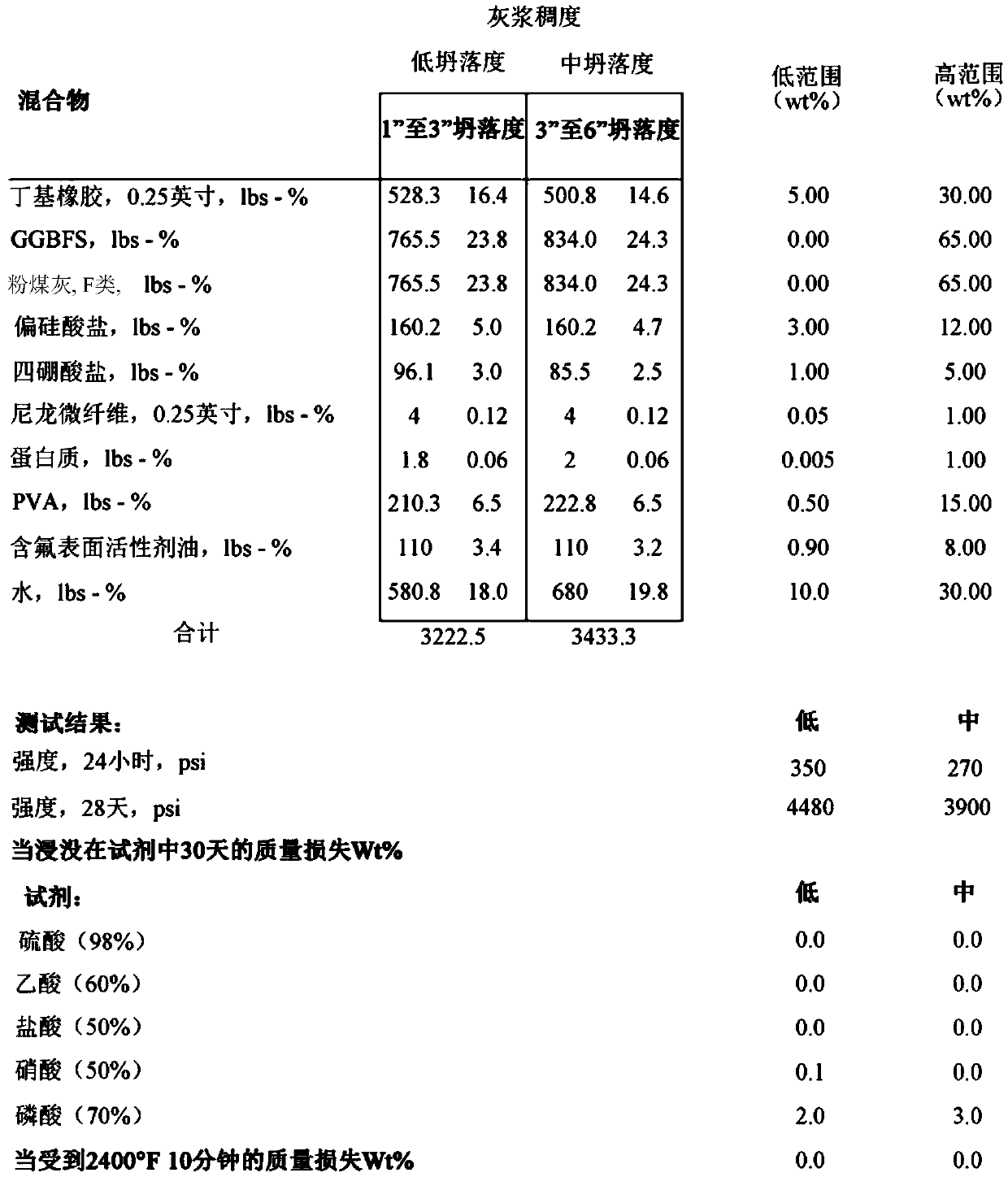

Cold fusion concrete

ActiveCN109790072AReduce water contentReduced sticky/tacky propertiesSolid waste managementCement productionSlagKaolin clay

A cold fusion concrete formulation including a mixture of water, silicon based mineral aggregates acting as a filler material; sodium or potassium metasilicate / pentahydrate acting as an activator; waste from steel production including Granulated Ground Blast Slag acting as a cementitious ingredient; high calcium or low calcium waste from coal combustion (fly ash or bottom ash) acting as a cementitious ingredient; sodium tetraborate, sodium citrate dihydrate, citric acid, or boric acid acting as set-time retarders; strengthening agents including including calcium, potassium, magnesium, sodium,or aluminum hydroxides; attapulgite, kaolin, red, or other fine grained, high alumino silicate containing clay, for increasing the silicon and alumino-silicate concentration and associated strength; aprotein or synthetic protein material to form a weak covalent bond with the hydroxides and silicates, for the purpose of maintaining a consistent volume during the curing process; and a pollinated fern oil to reduce water content of the mixture and decrease viscosity.

Owner:GEOPOLYMER SOLUTIONS LLC

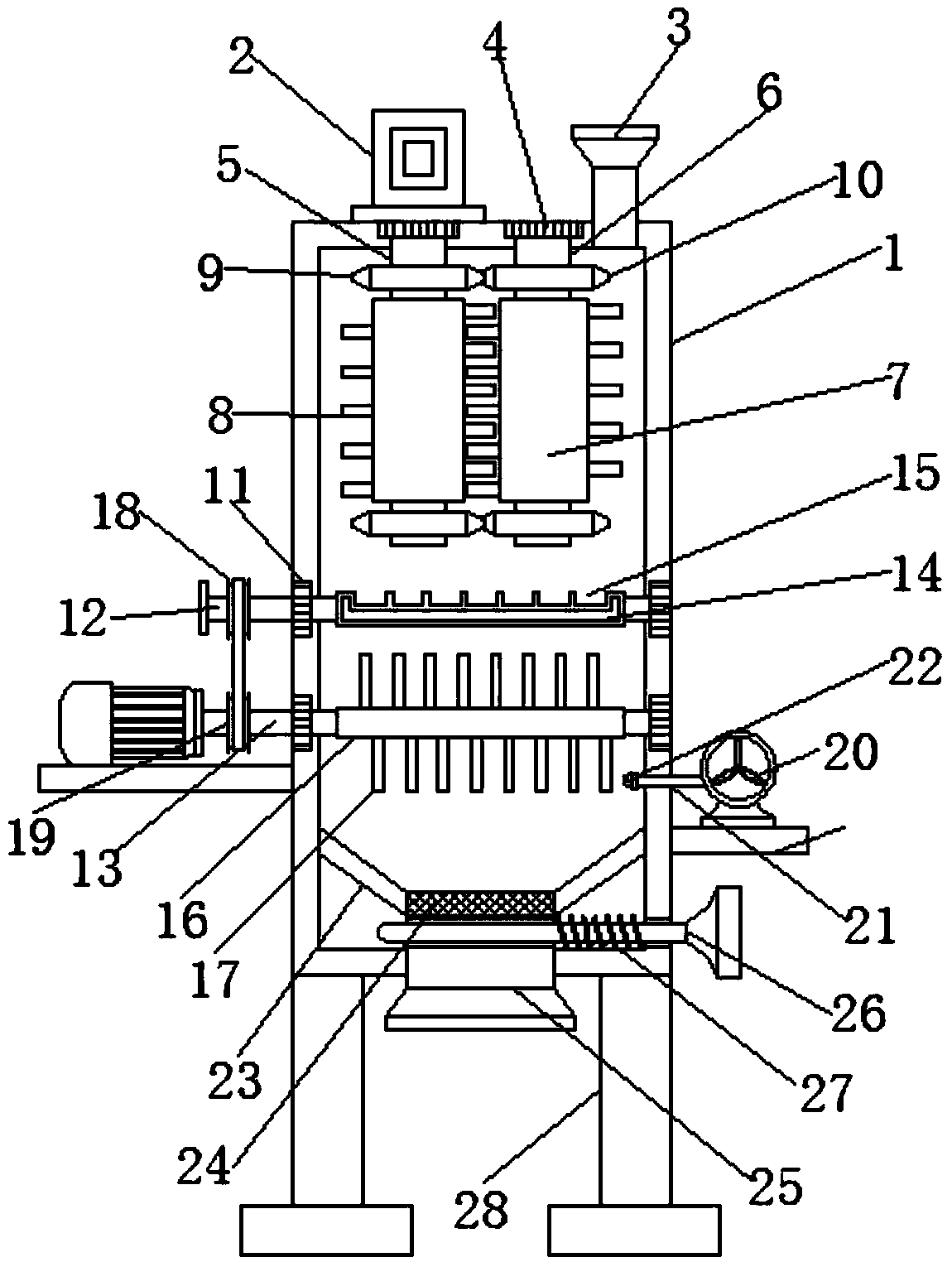

Multiple mixing device for powder coating used for plastic product

InactiveCN108993296AImprove stirring efficiencyLabor intensiveTransportation and packagingMixer accessoriesEngineeringPowder coating

The invention discloses a multiple mixing device for powder coatings used for a plastic product. The multiple-mixing device comprises a mixing box and a motor, wherein the upper surface of the mixingbox is fixedly connected with a feeding hopper; the top part of the inner wall of the mixing box is fixedly connected with two first bearings; the inner walls of two first bearings are respectively and fixedly connected with a driving shaft and a linkage shaft; and the outer walls of the driving shaft and the linkage shaft are respectively connected with a mashing rod. The multiple mixing device for the powder coatings used for the plastic product provided by the invention has the following advantages: through arrangement of the driving shaft, the linkage shaft and mashing rods, the powder coatings can be subjected to primary stirring, and the powder coatings with different volumes are subjected to crushing treatment, so the volumes of the powder coatings are consistent, and the stirring efficiency of the powder coatings is improved; through arrangement of a blanking tray, a stirring rod and stirring blades, secondary mixing of the powder coatings can be realized; and the blanking traycontrols the blanking amount of the powder coatings, so excessive blanking amount of the powder coatings to affect the mixing effect of the mixing box is avoided.

Owner:蒙城县虹升塑粉有限公司

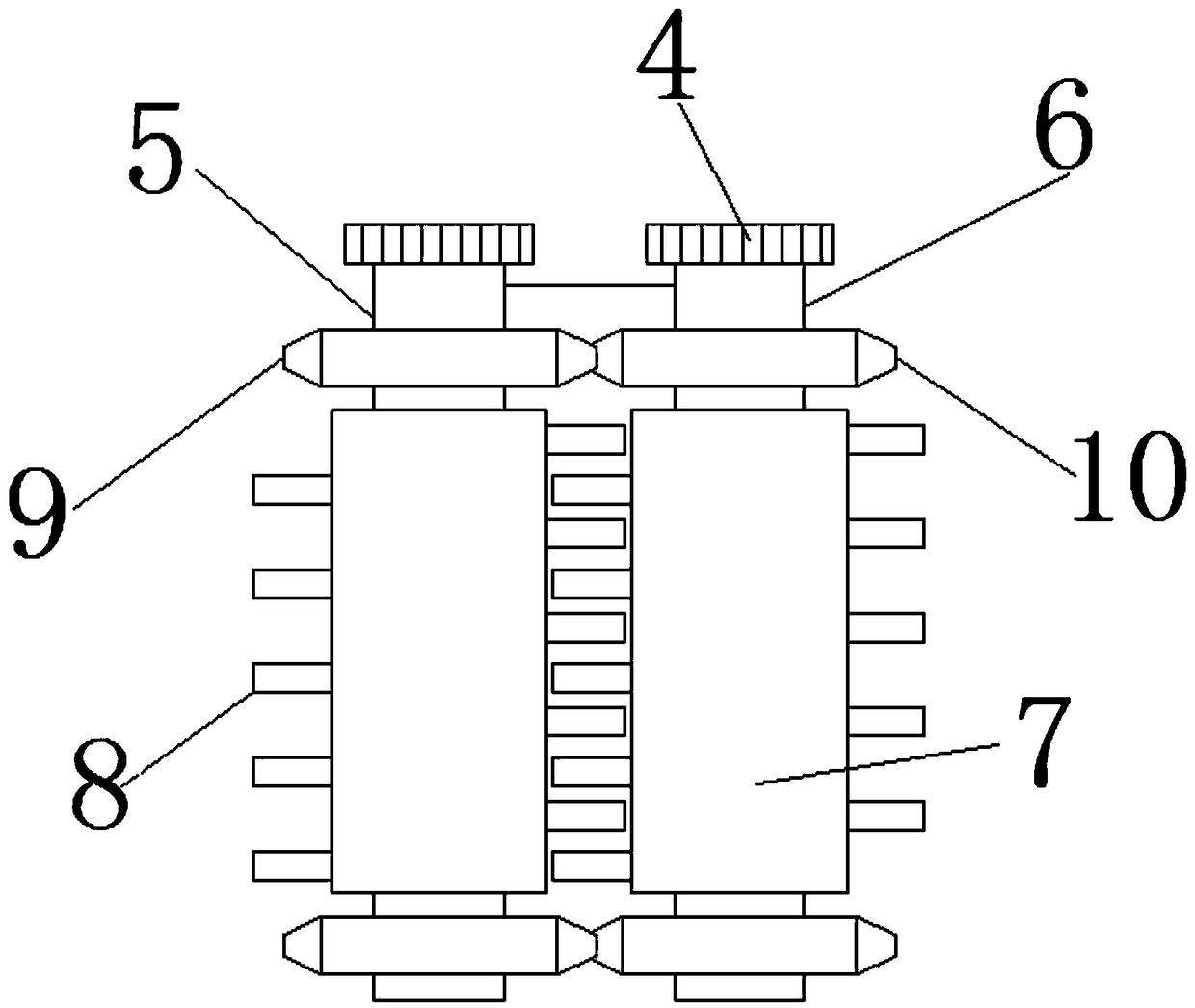

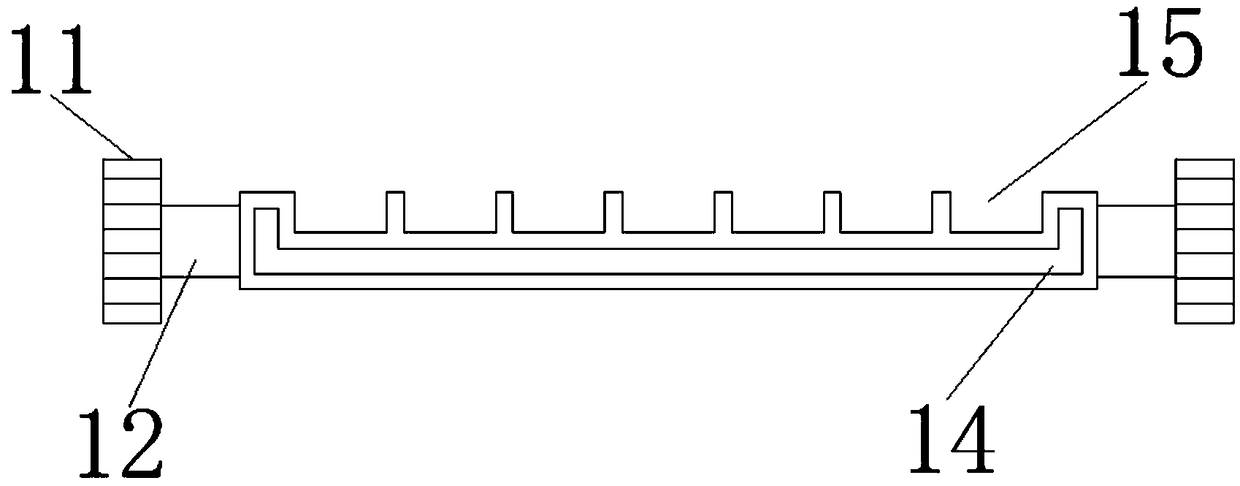

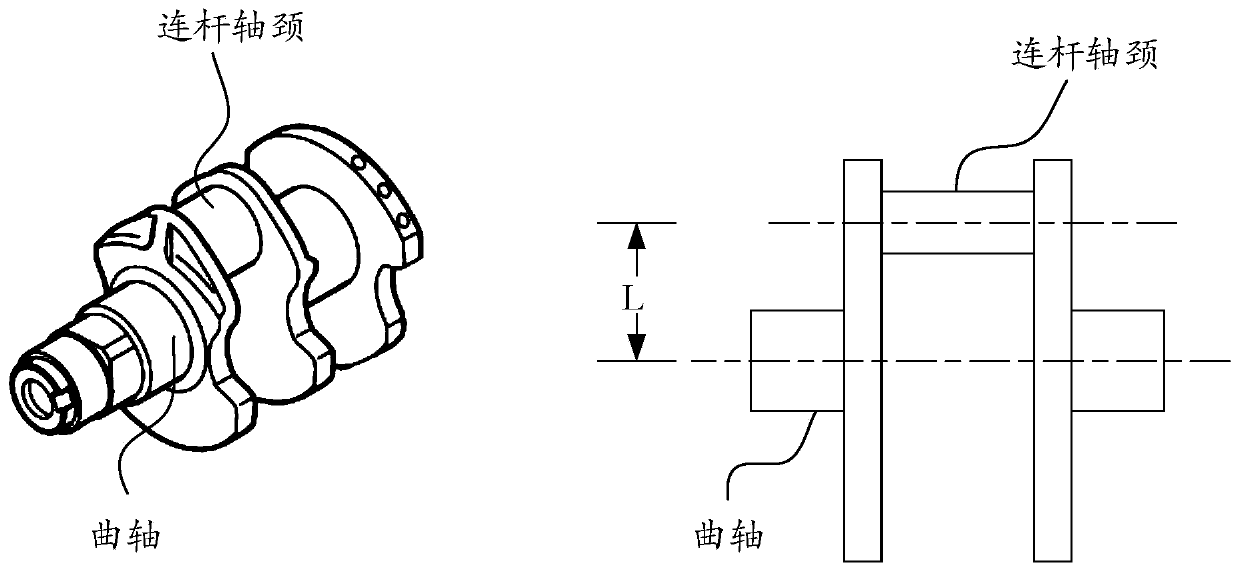

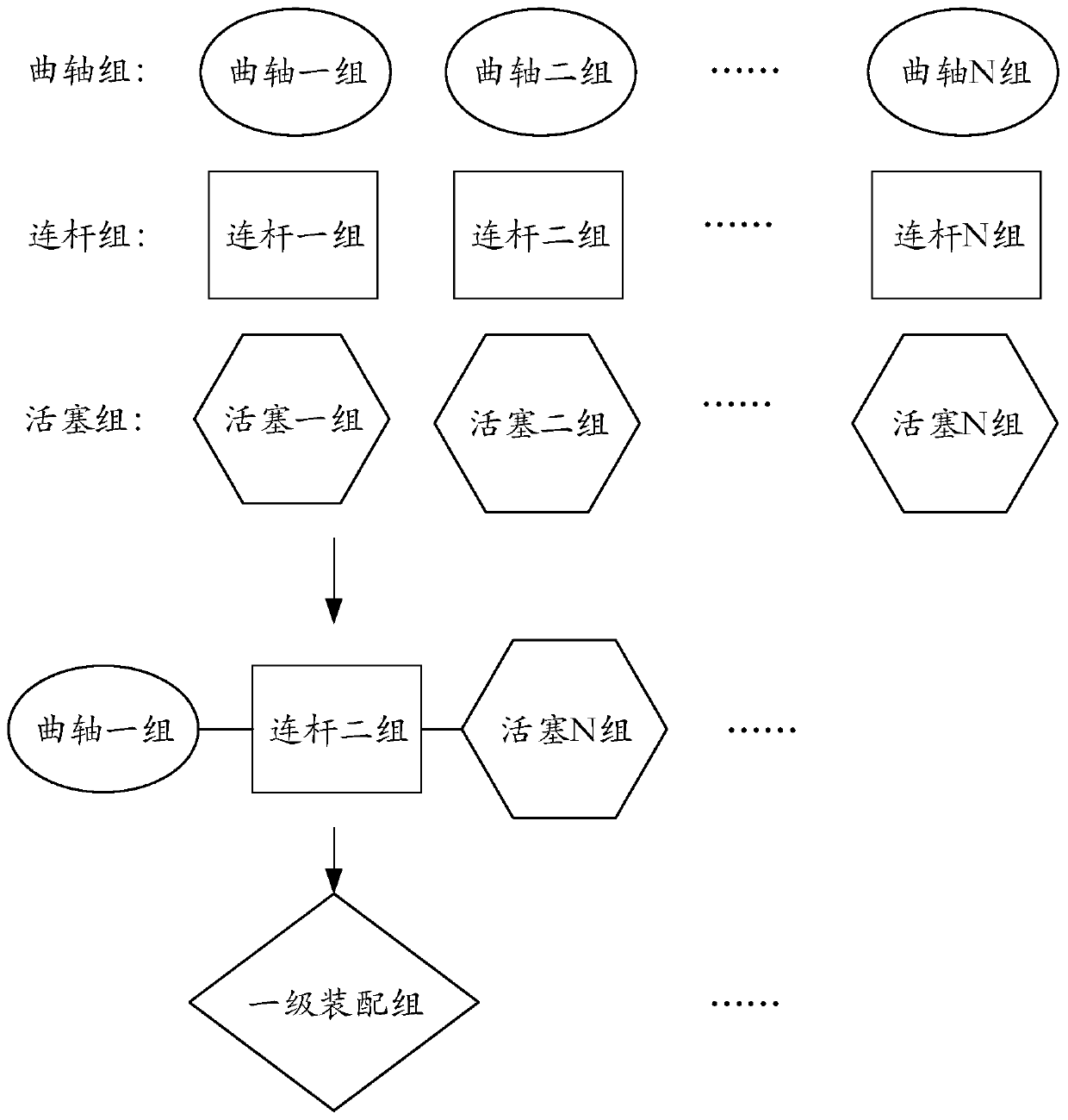

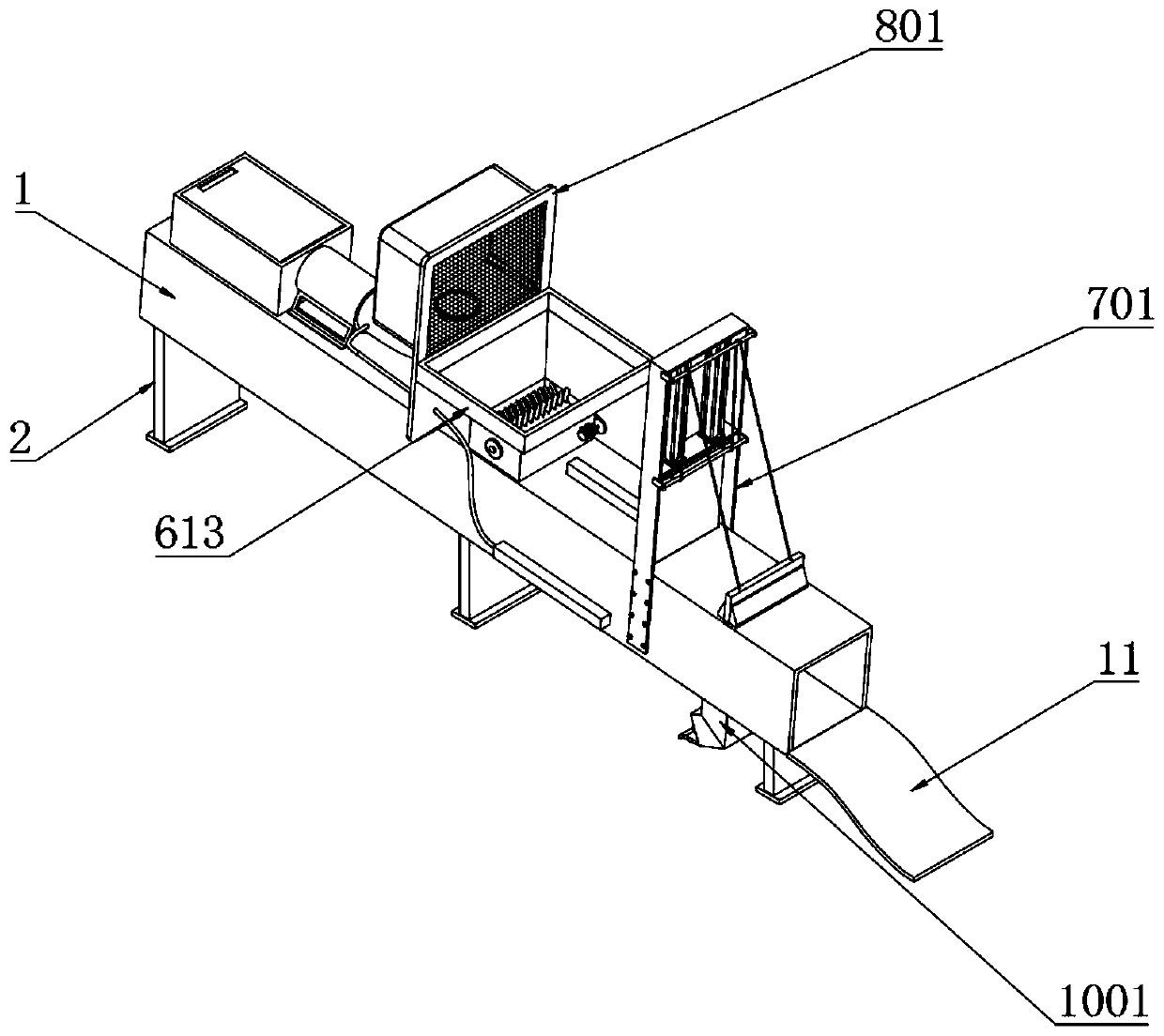

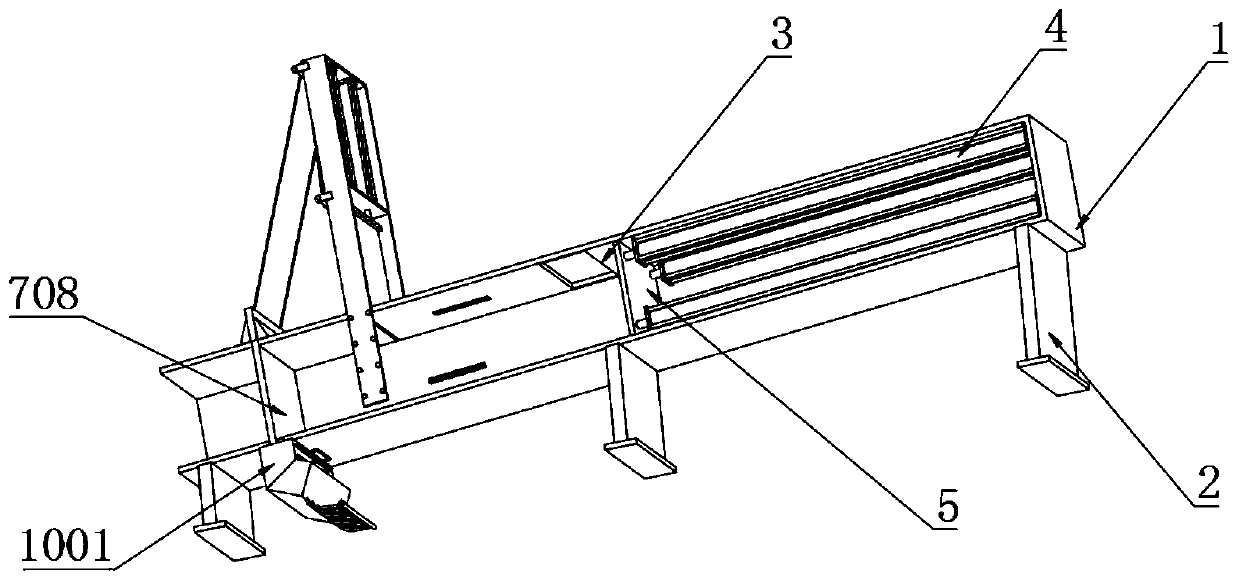

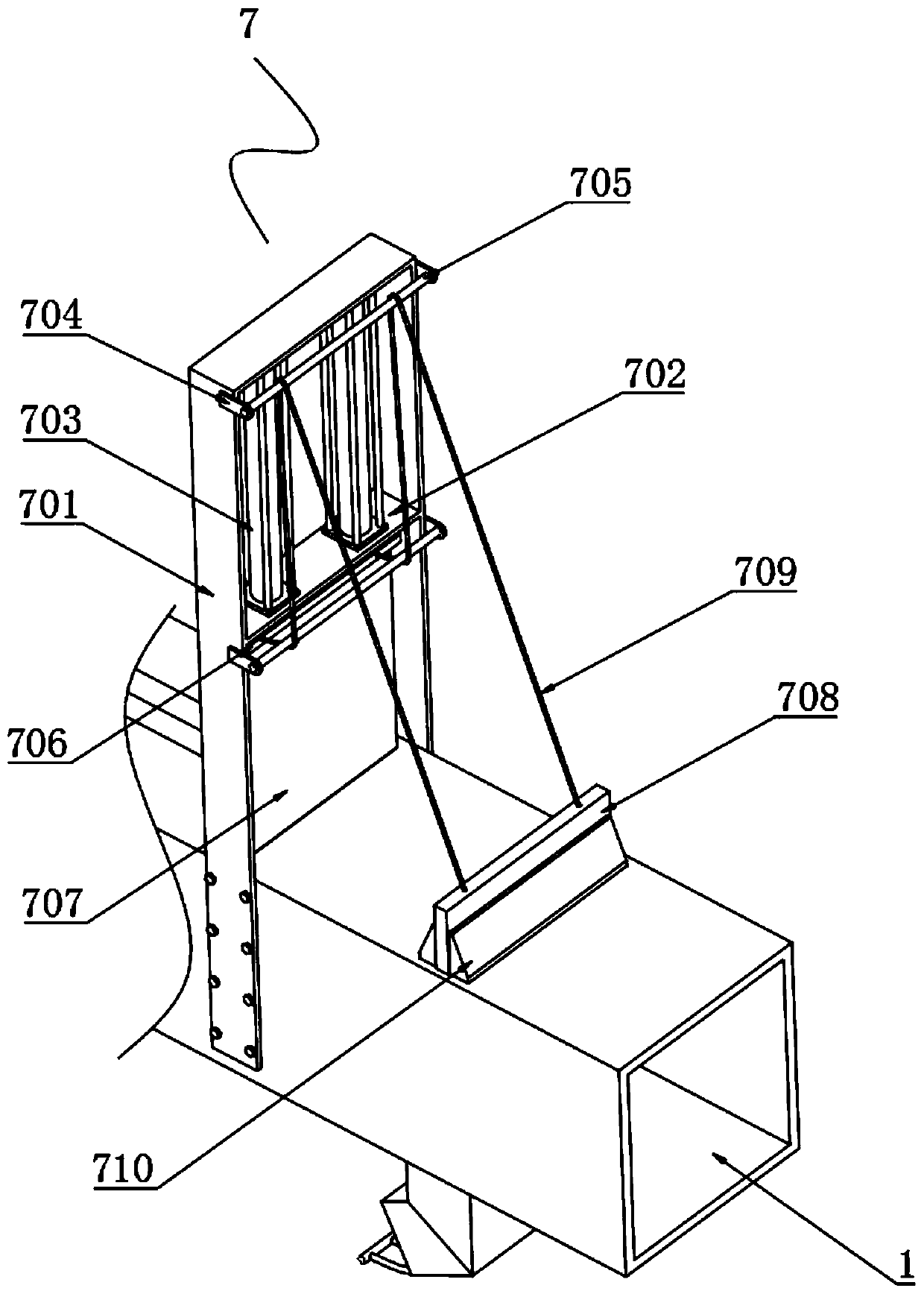

Engine assembling method

InactiveCN109909742AEliminate Tolerance StackupConsistent volumeAssembly machinesMachines/enginesCombustion chamberCylinder block

The invention discloses an engine assembling method. The engine assembling method comprises the steps that a swing diameter tolerance of a crankshaft connecting rod journal is acquired as a crankshafttolerance; a connecting rod length tolerance is acquired as a connecting rod tolerance; the tolerance of the distance of a piston from a pin hole to the top is acquired as a piston tolerance; crankshafts, connecting rods and pistons are chosen to compose a plurality of first grade assembly groups, and in the first grade assembly groups, the sum of the crankshaft tolerance, the connecting rod tolerance and the piston tolerance is less than a first preset value. The engine assembling method eliminates tolerance superposition so as to guarantee the volumes of various combustion chambers to be precisely consistent, and vibration and abrasion are reduced; the total weight of the assemblies of cylinders is enabled to tend to be consistent, and the consistency of the volumes of the combustion chambers is further guaranteed; the operation of the crankshafts, the connecting rods, the pistons and cylinder bodies are smooth, and the non-smooth operation of the piston caused by the error of a certain assembly is avoided; and the problems of the volume change and sealing of the combustion chambers caused by cylinder mats are solved. Furthermore, by reducing the accessories of the cylinder mats, the engine is simpler and more stable.

Owner:于桂超

Compaction device preventing odor emission for solid waste treatment

ActiveCN110624668AEasy to useConsistent volumeSolid waste disposalDirt cleaningHydraulic cylinderEngineering

The invention discloses a compaction device preventing odor emission for solid waste treatment. The device comprises a compaction cylinder, wherein the compaction cylinder is mounted on the ground through a support frame, the end parts of hydraulic rods of four compaction hydraulic cylinders are in welded connection with a compaction plate, a hydraulic rod of a cutting hydraulic cylinder penetrates through a middle plate and is provided with a connecting plate, a cutting knife plate is clamped at the bottom of the connecting plate, the top end of a baffle is fixedly connected with a traction rope, and limiting stop blocks are welded at the positions, corresponding to the two sides of the baffle, of the top end of the compaction cylinder. According to the compaction device, cutting of a compacted waste solid material is completed through a cutting mechanism, so that the compacted discharged solid waste is consistent in size, stable and regular placement into a transport vehicle is facilitated, the stability of the solid waste in a transportation process is improved, and meanwhile, the baffle is driven by the traction rope to move up and down, the purpose of quick cutting and quick discharging after cutting is achieved, and the compacted solid waste is more easily taken out.

Owner:山东环沃环保科技有限公司 +1

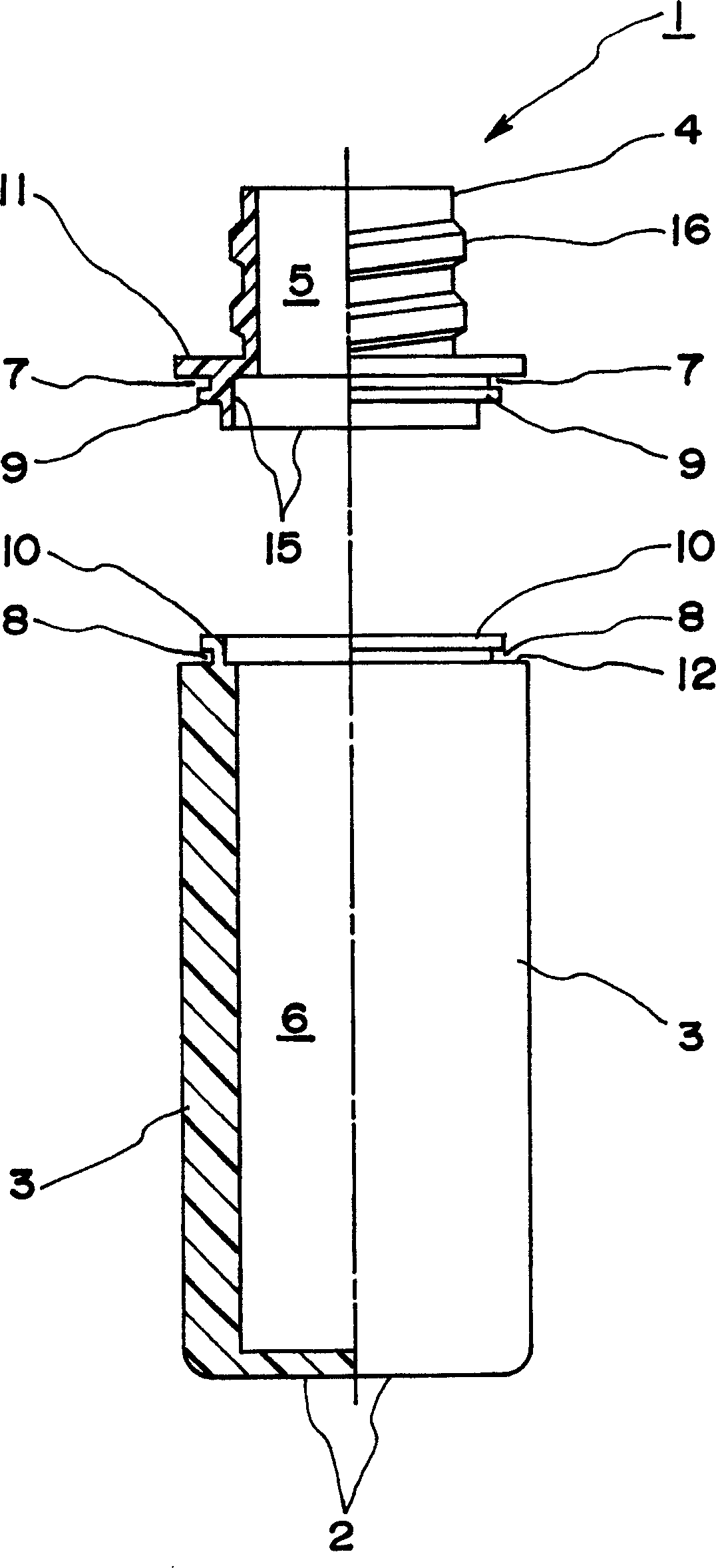

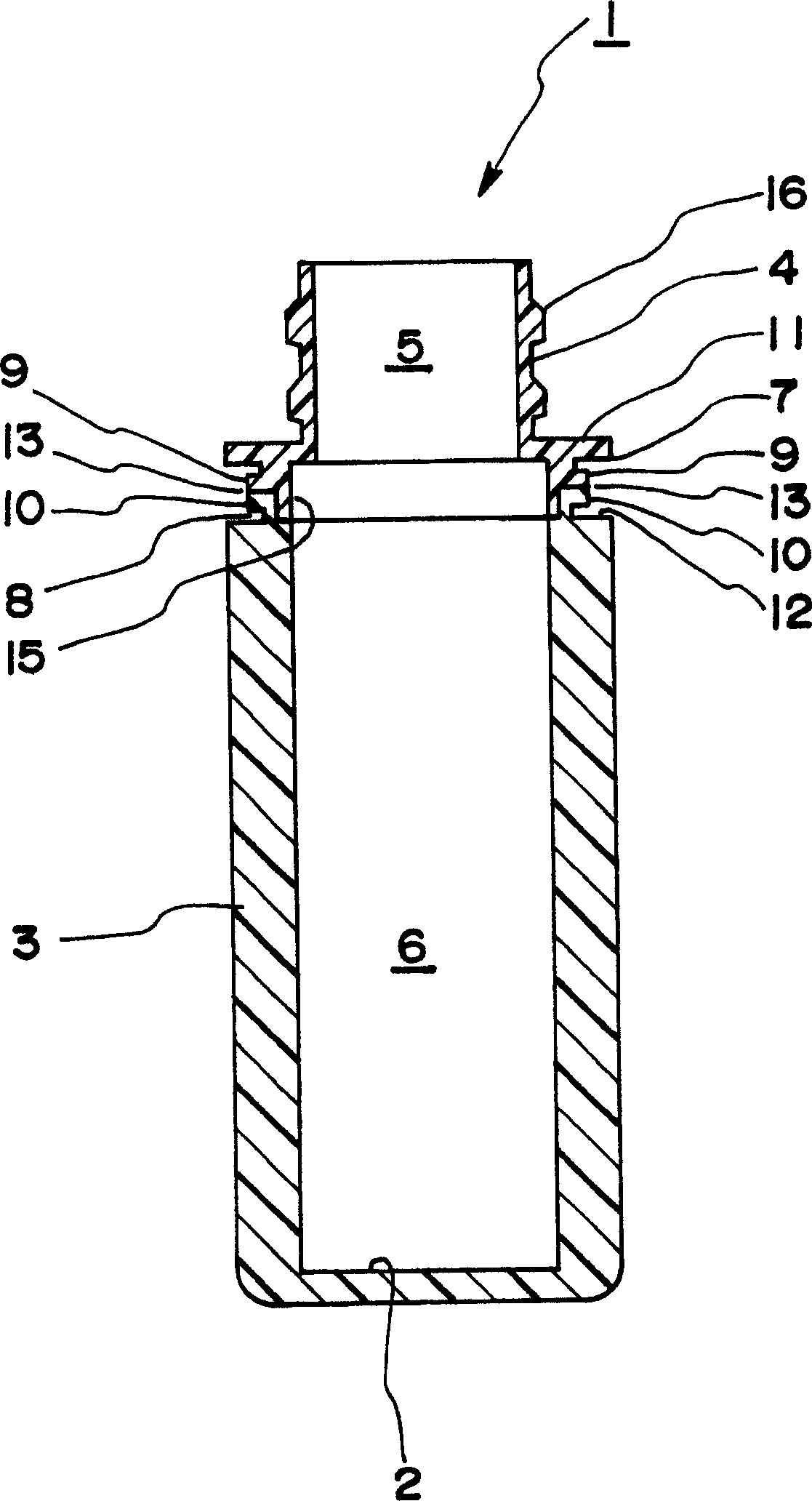

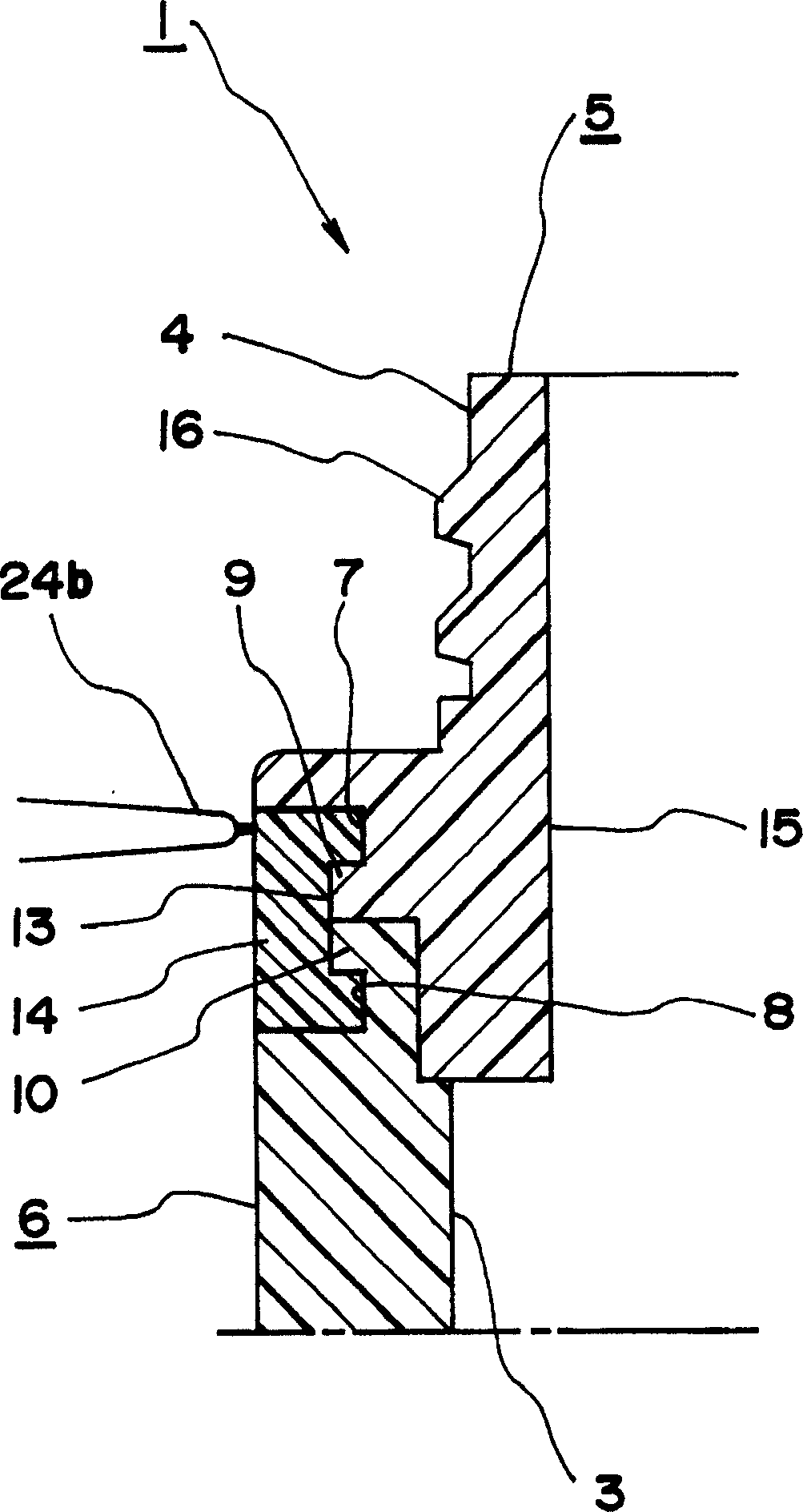

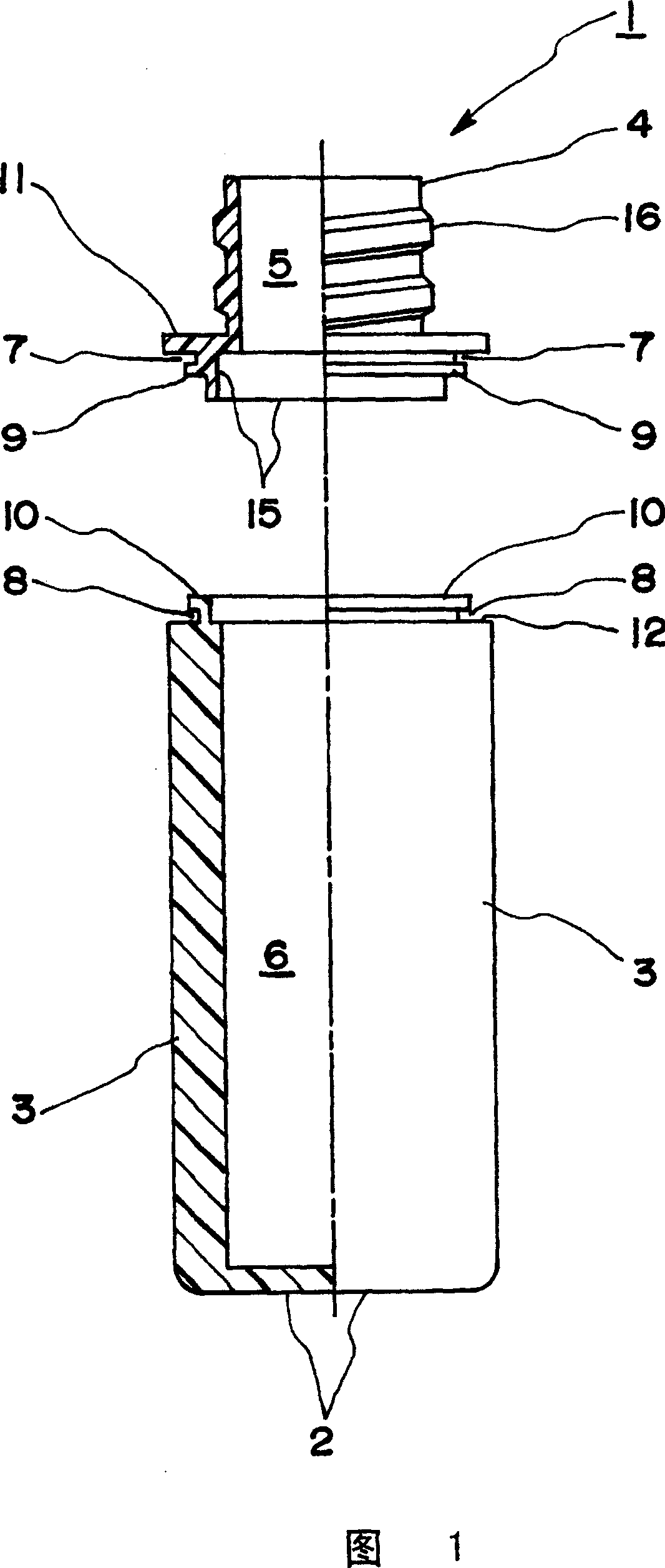

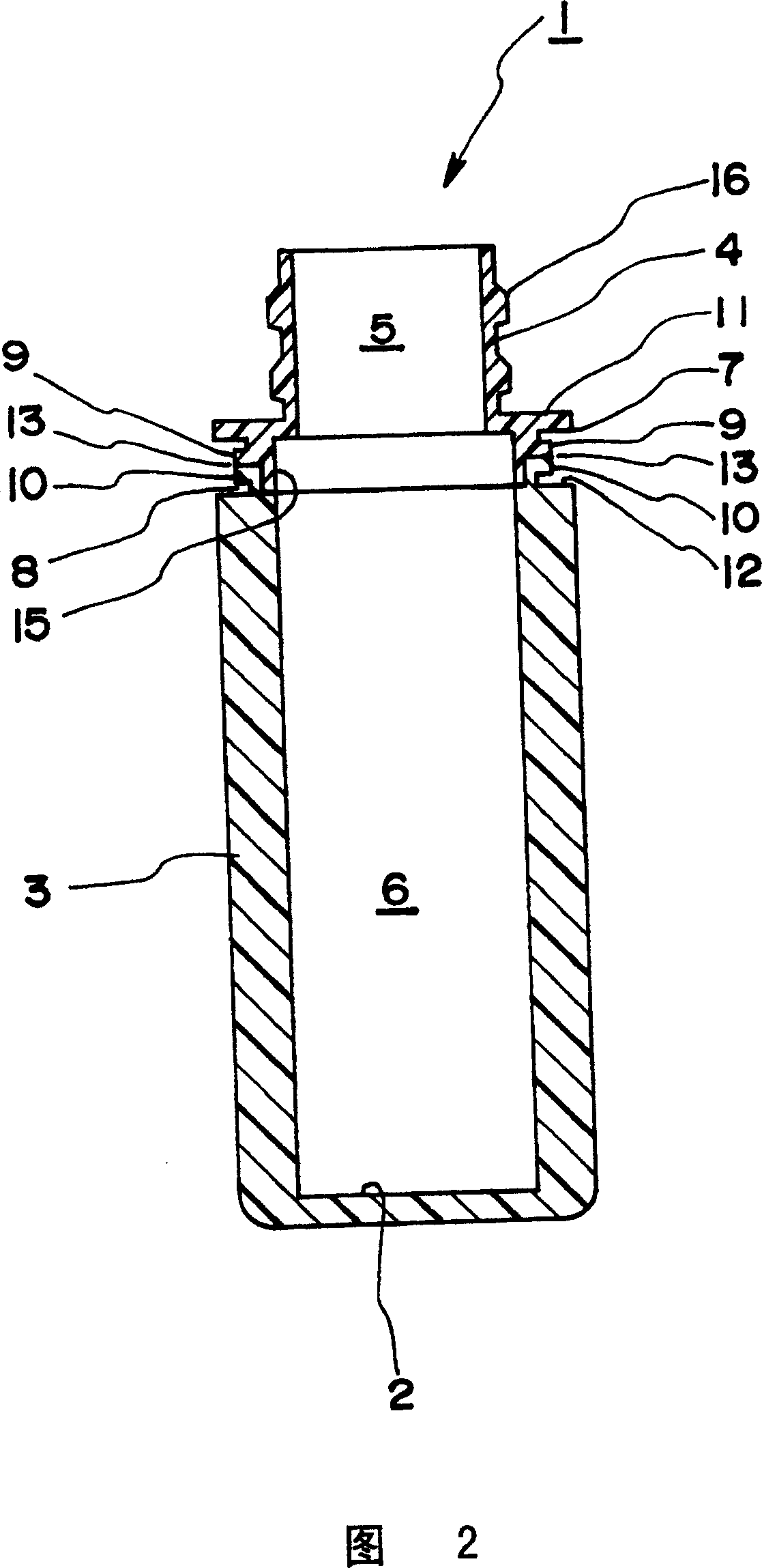

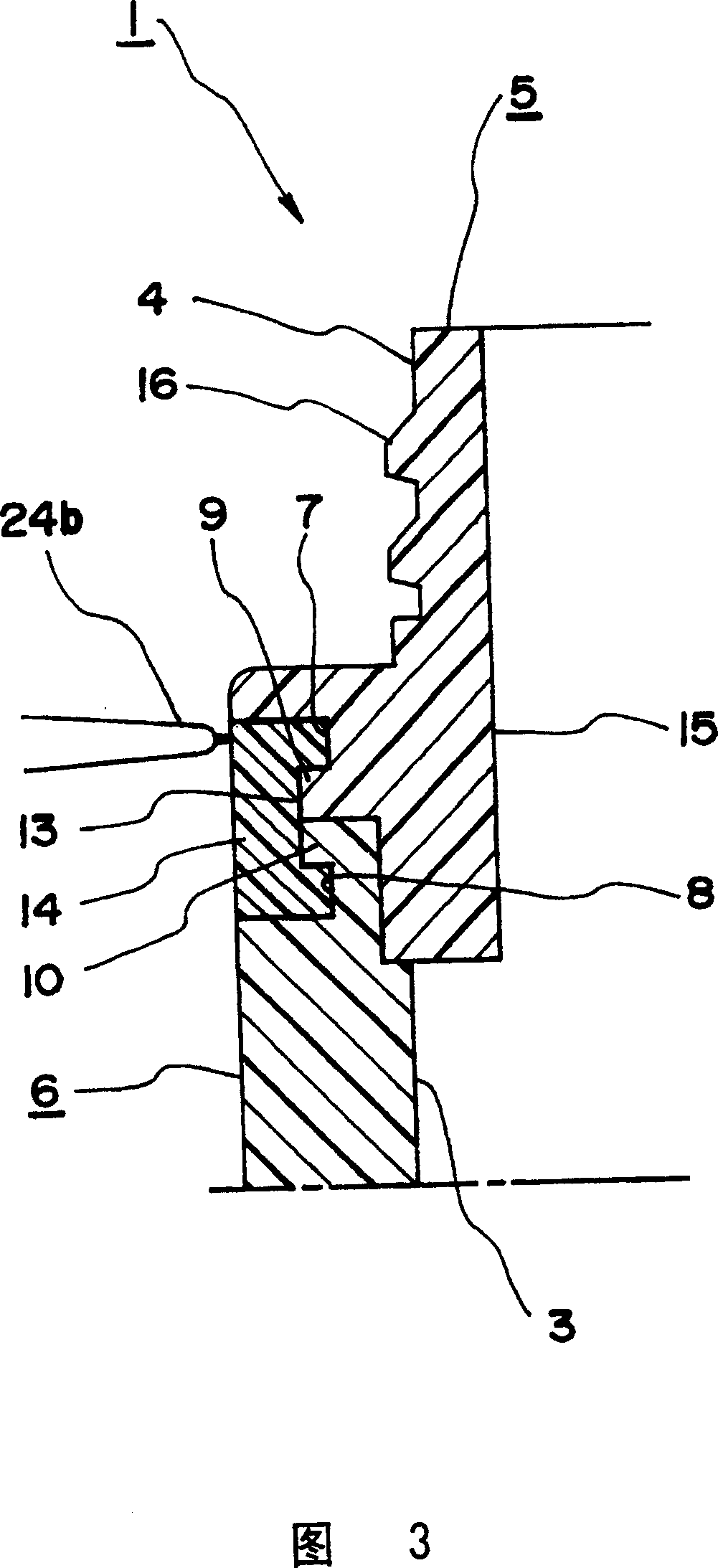

Bottle container made of resin and method for manufacturing the same

InactiveCN1541903AHigh quality visual impressionConsistent volumeBottlesDomestic articlesEngineeringBottle

The present invention provides a bottle container made of resin, which comprises a cylindrical barrel with a bottom and a cylindrical neck portion with a diameter smaller than that of the barrel,said bottle container further comprising an upper part and a lower part divided into two parts by dividing at an upper end or a lower end of the barrel, and under the condition that the upper part and the lower part are connected with each other, said two parts are integrated by a cover member for liquid-tightly covering connecting surfaces of said two parts to shield the connecting surfaces from outside and to integrate the two parts with each other.

Owner:YAITA SEISAKUSHOKK

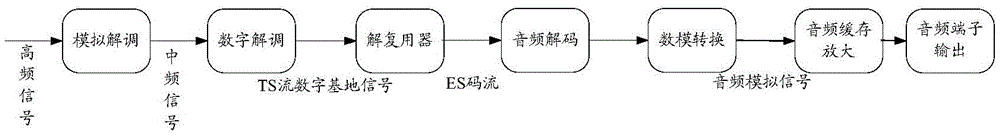

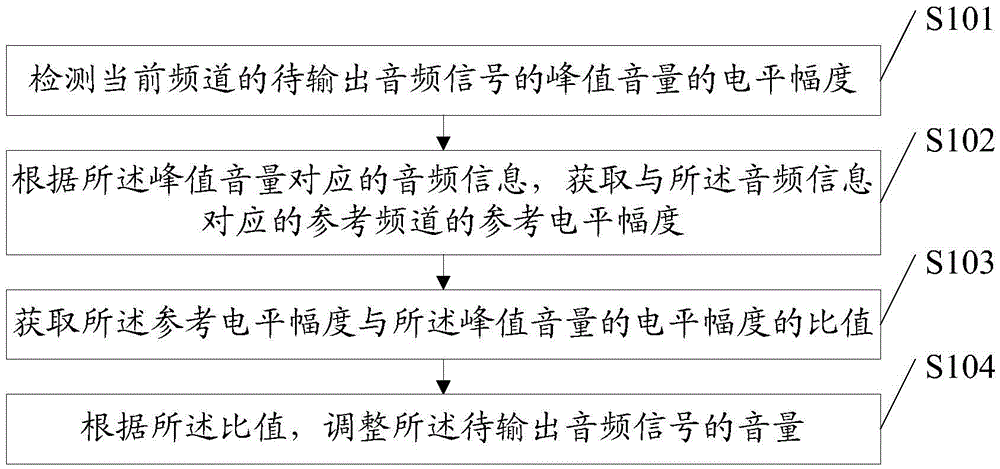

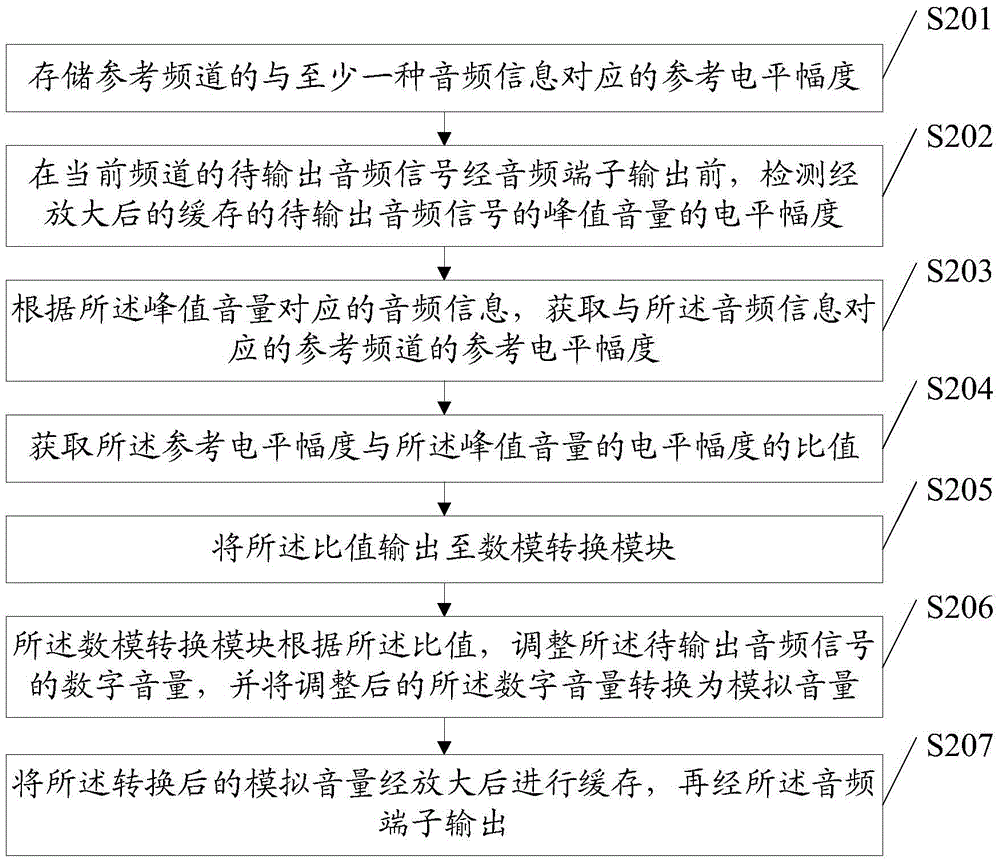

Method of adjusting television program volume and apparatus thereof, and digital television receiving terminal

ActiveCN105611203ANo auditory discomfortNot cause discomfortTelevision system detailsColor television detailsCurrent channelPeak value

A method of adjusting a television program volume and an apparatus thereof, and a digital television receiving terminal are disclosed. In an embodiment of the invention, through detecting a level amplitude of a peak value volume of an audio signal to be output of a current channel, according to audio information corresponding to the peak value volume, a reference level amplitude of a reference channel corresponding to the audio information is acquired and a specific value of the reference level amplitude and the level amplitude of the peak value volume is acquired too. According to the specific value, a volume of the audio signal to be output is adjusted so that the volume of the audio signal to be output corresponding to each channel of each audio information is consistent with a volume corresponding to the audio information of the reference channel. Volumes output by the channels of the digital television receiving terminal are consistent so that audience hearing discomfort caused by a too loud volume or a too small volume output by the different channels of the digital television receiving terminal is not generated.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

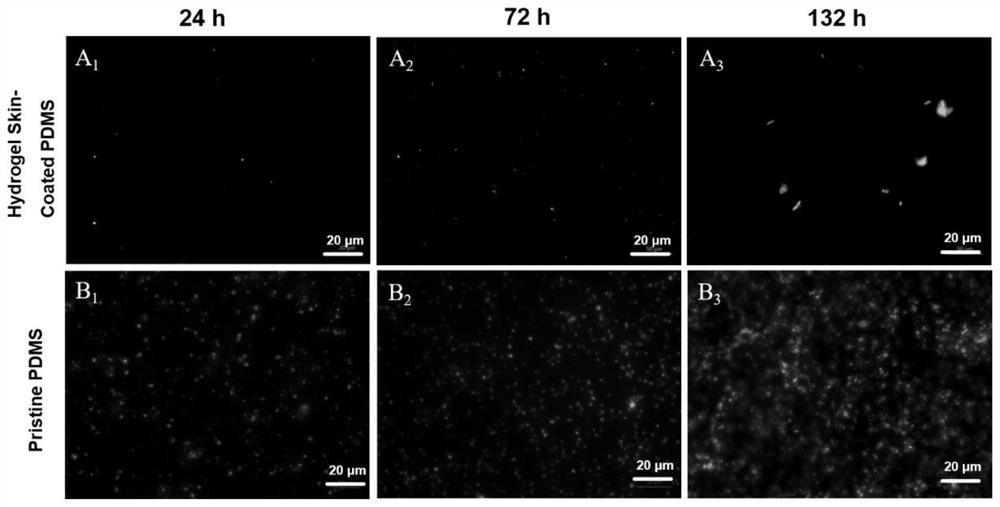

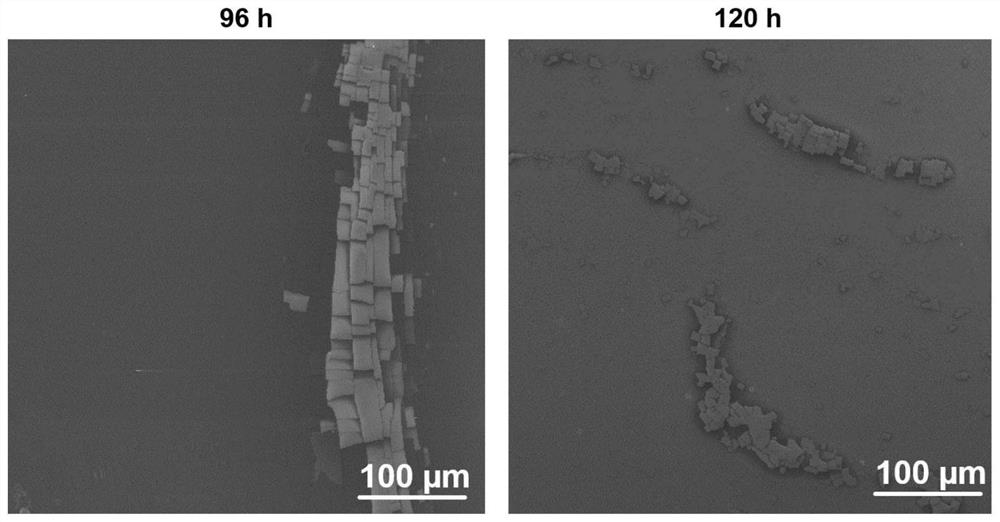

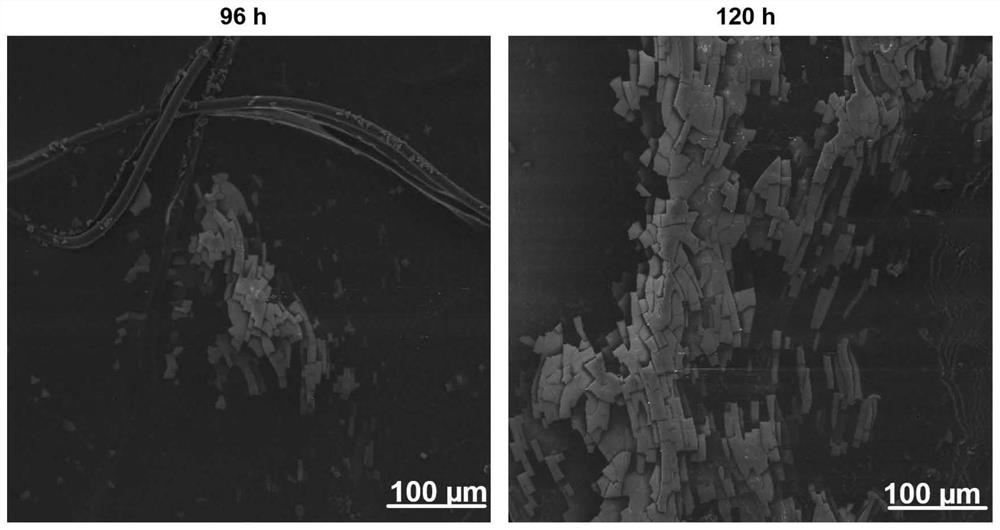

Antifouling zwitterionic hydrogel coating with bacterial responsiveness and preparation method of zwitterionic hydrogel coating

The invention relates to the technical field of polymer hydrogel, in particular to an antifouling zwitterionic hydrogel coating with bacterial responsiveness and a preparation method thereof. The hydrogel coating contains hyaluronic acid, wherein the hydrogel coating is a zwitterionic polymer, and the molecular chain of the polymer has anionic and cationic groups at the same time. The preparation method disclosed by the invention is simple, efficient and environment-friendly; interface interpenetration firm combination is formed between the hydrogel coating and a polymer substrate, a certain binding force and a low friction coefficient are achieved, and the coating is degraded and falls off under the condition that bacteria secrete hyaluronidase, so the effect of resisting bacterial adhesion is achieved; and the antifouling zwitterionic hydrogel coating can be stored in deionized water for a long time, has excellent hydrophilicity, bending resistance and friction resistance, and has wide application prospects in the field of biomedical surface materials, especially in the aspect of serving as a medical catheter surface coating and the like.

Owner:ZHEJIANG UNIV OF TECH

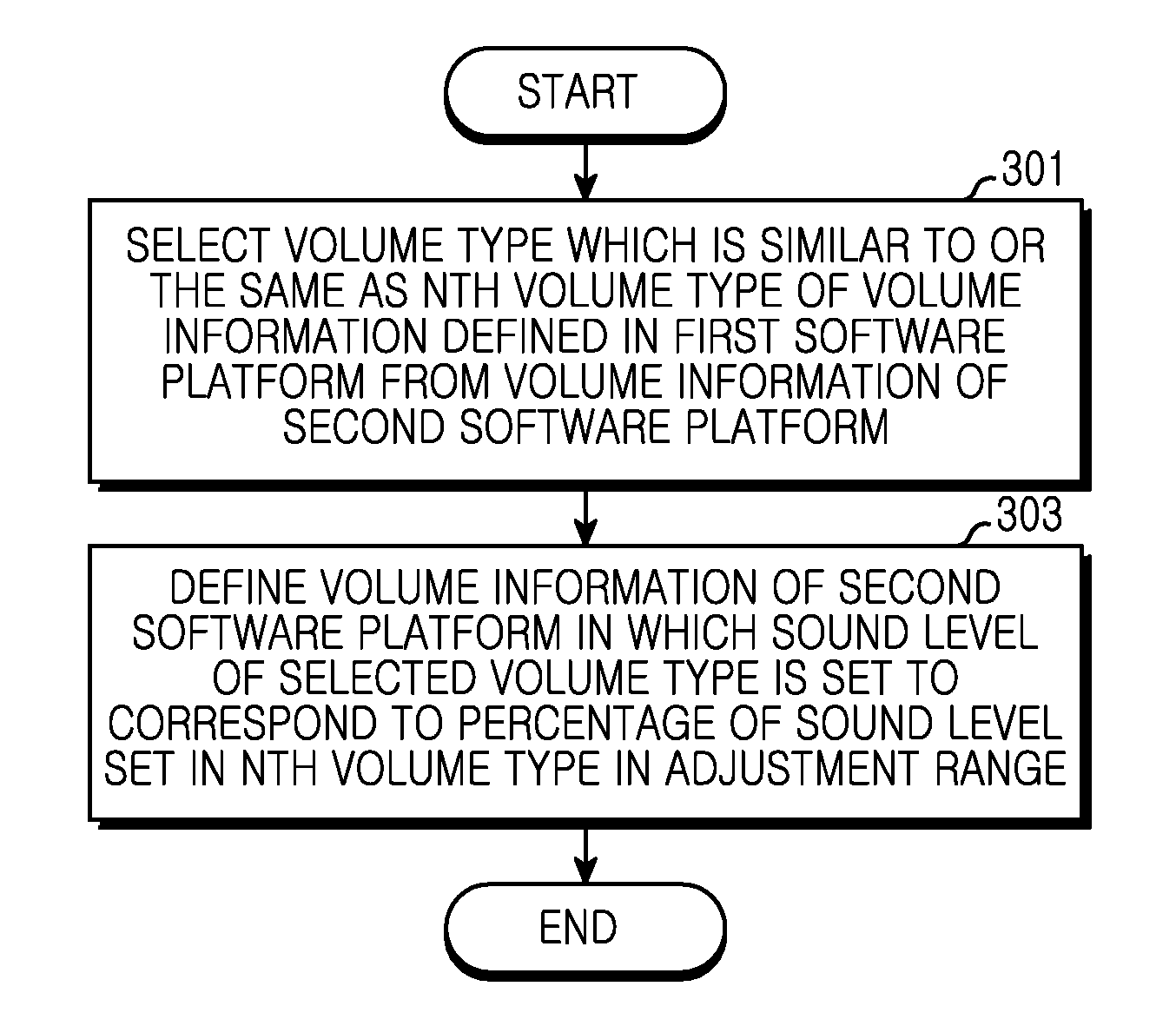

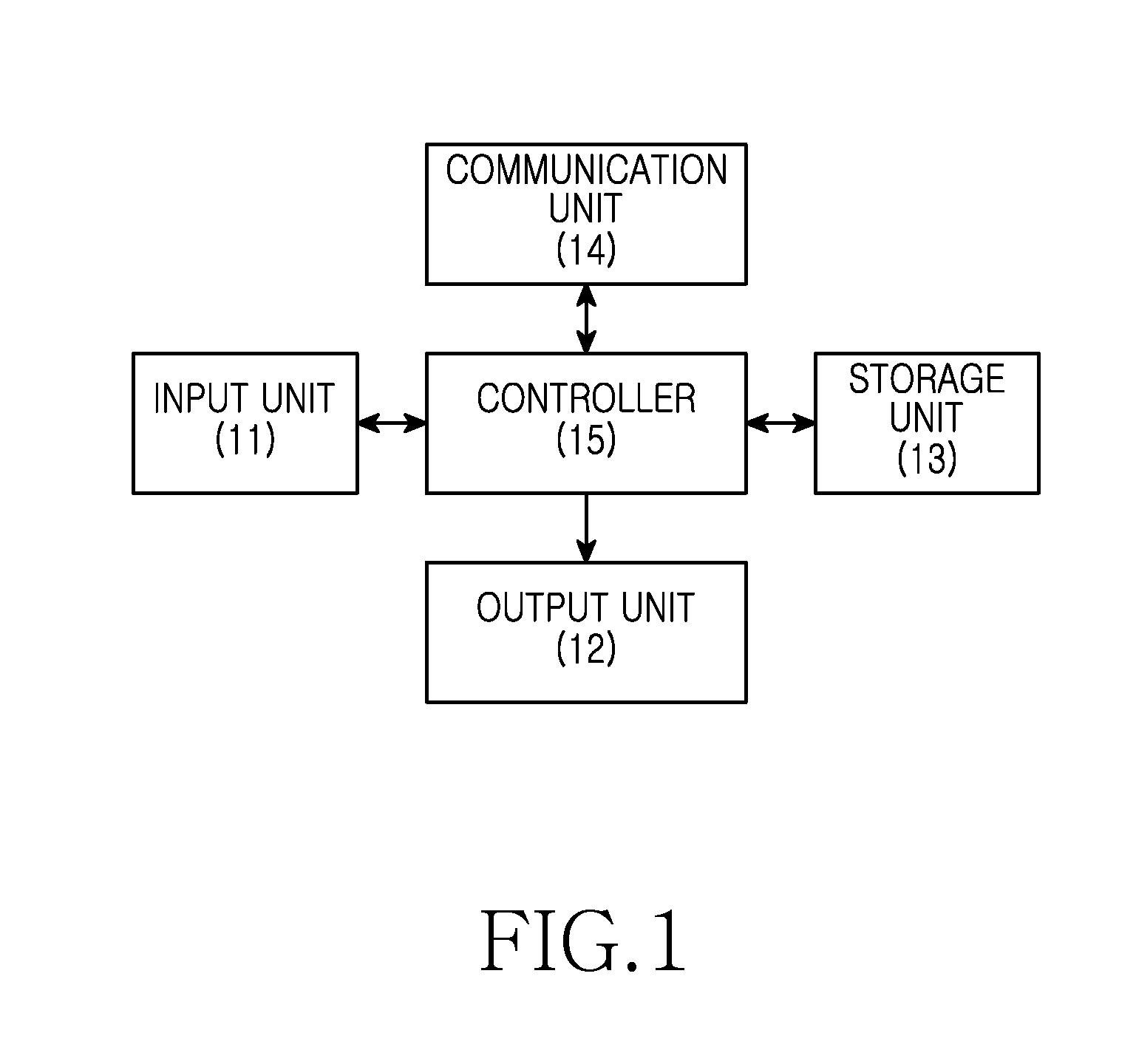

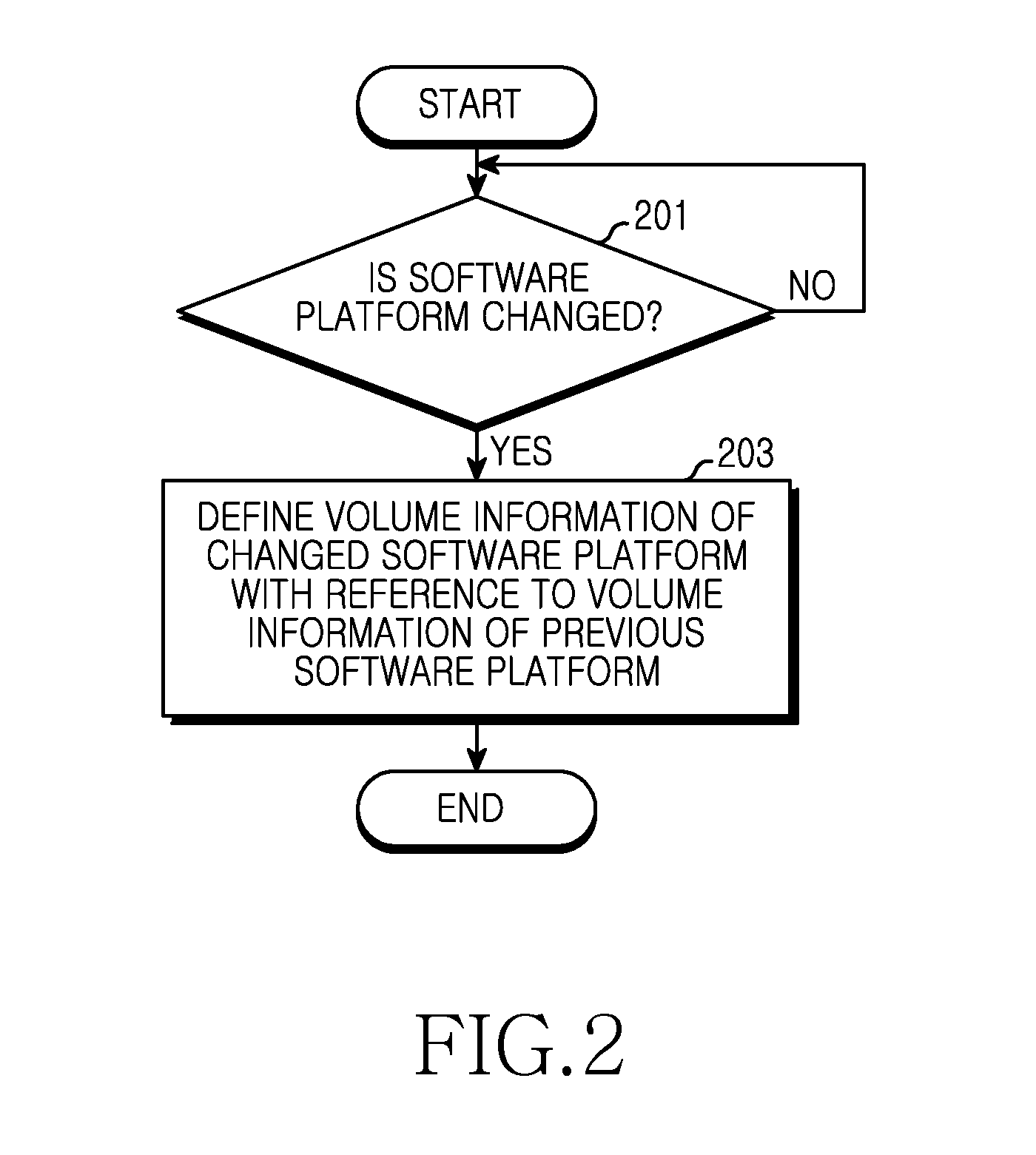

Method and apparatus for synchronizing information between platforms in a portable terminal based on a multi-software platform

A method of synchronizing information between platforms in a portable terminal based on a multi-software platform is provided. The method includes verifying that a first software platform is changed to a second software platform; and if the first software platform is changed to the second software platform, defining volume information of the changed second software platform with reference to volume information of the first software platform.

Owner:SAMSUNG ELECTRONICS CO LTD

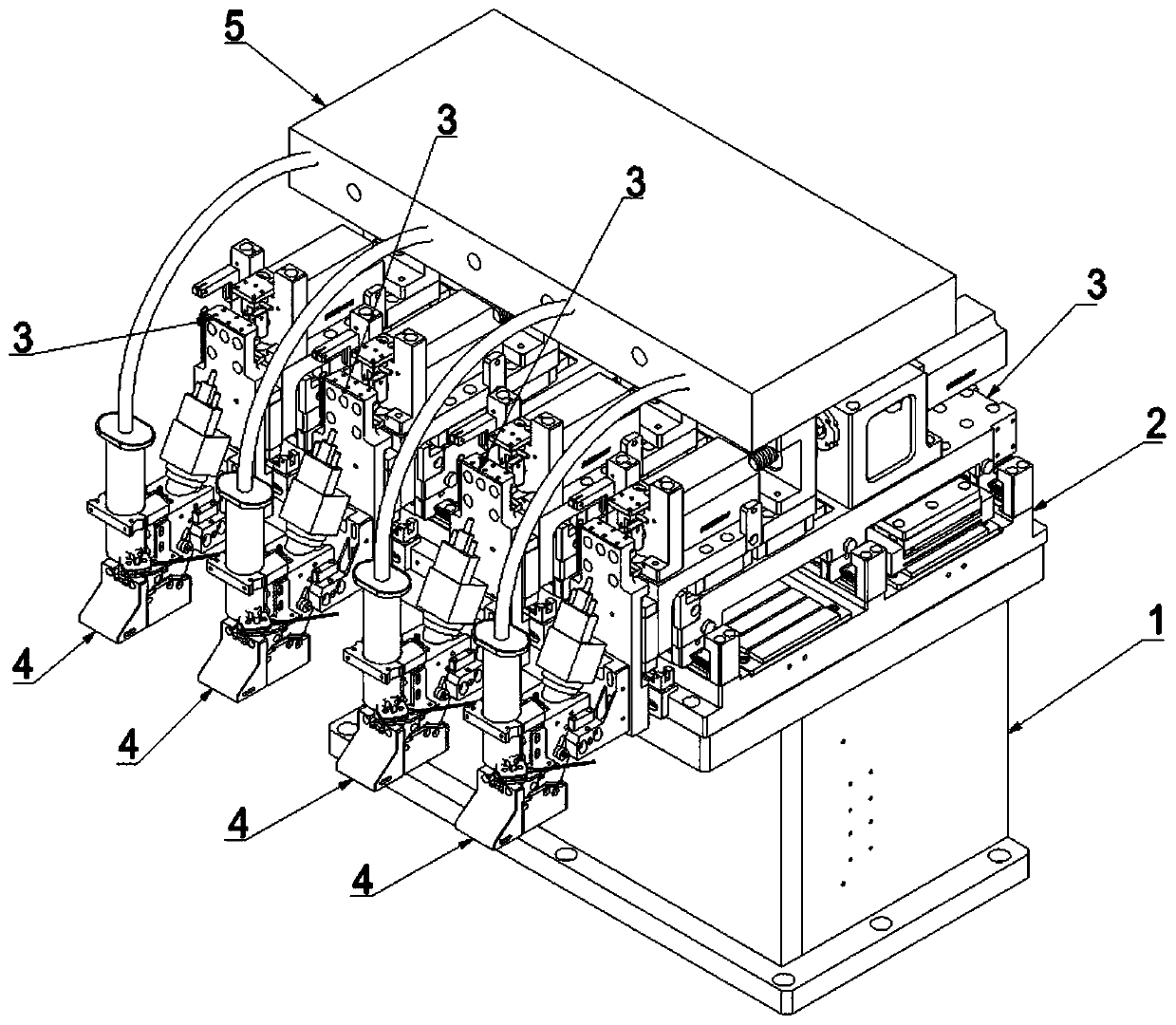

Pneumatic type multi-glue-barrel dispensing mechanism and dispensing method thereof

ActiveCN110947583AHigh movement precisionFeature ConcentrationLiquid surface applicatorsCoatingsRobot handDrive by wire

The invention discloses a pneumatic type multi-glue-barrel dispensing mechanism and a dispensing method thereof. The mechanism comprises a stand column platform, a linear drive assembly, multiple dispensing units, multiple dispensing mechanical hands and a dispensing control box. The linear drive assembly which is transversely arranged is laid flat on the stand column platform. The multiple dispensing units which independently move leftwards and rightwards are arranged on the linear drive assembly. Each dispensing mechanical hand capable of being regulated up and down is arranged at the frontend of the corresponding dispensing unit. Glue barrels on the dispensing mechanical hands are connected with the dispensing control box through gas pipes. The multiple dispensing mechanical hands in the pneumatic type multi-glue-barrel dispensing mechanism can conduct dispensing on a support while doing multidimensional independent movement in the X direction, the Y direction and the Z direction,contact assemblies of the dispensing mechanical hands transmit electrical signals through closing and opening of upper contacts and lower contacts, the relative height of dispensing heads is confirmedthrough the electrical signals, the pressure in the glue barrels can be regulated through the dispensing control box, glue discharged from the dispensing heads can keep consistent micro glue sizes and shapes, and the dispensing speed and precision are remarkably increased.

Owner:SHENZHEN XINYICHANG TECH CO LTD

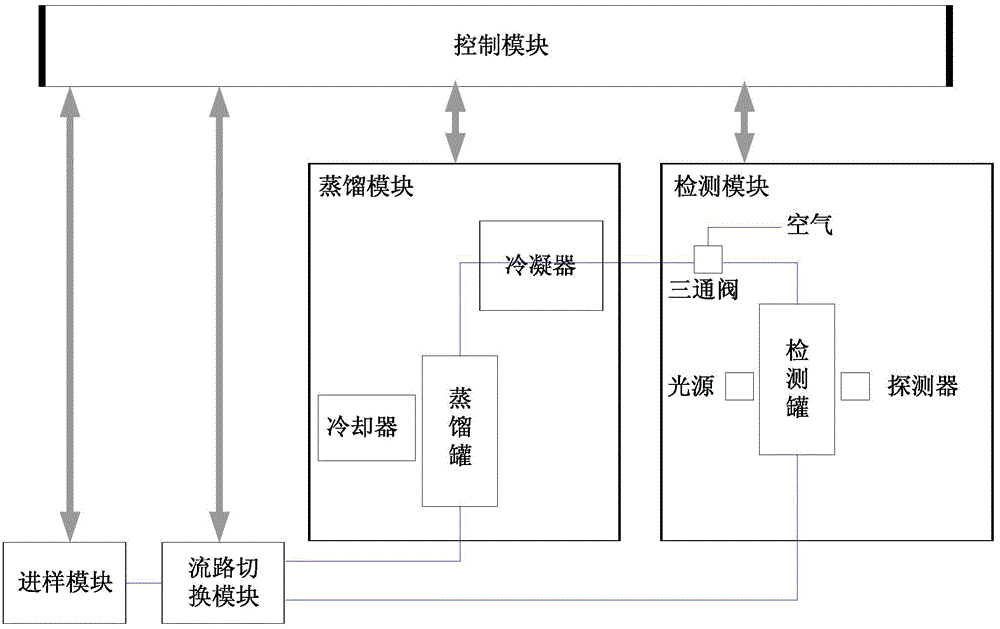

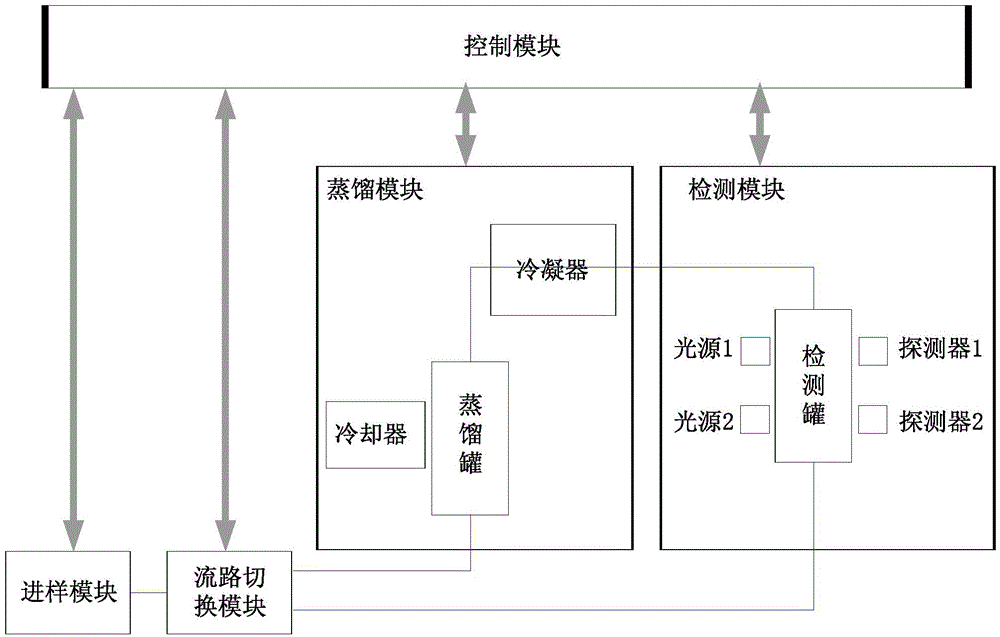

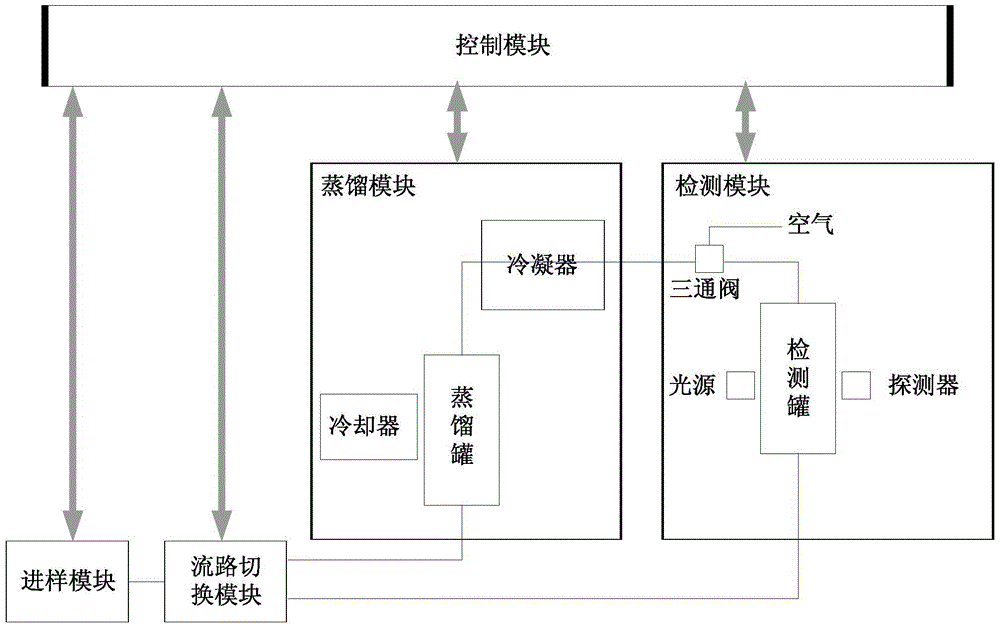

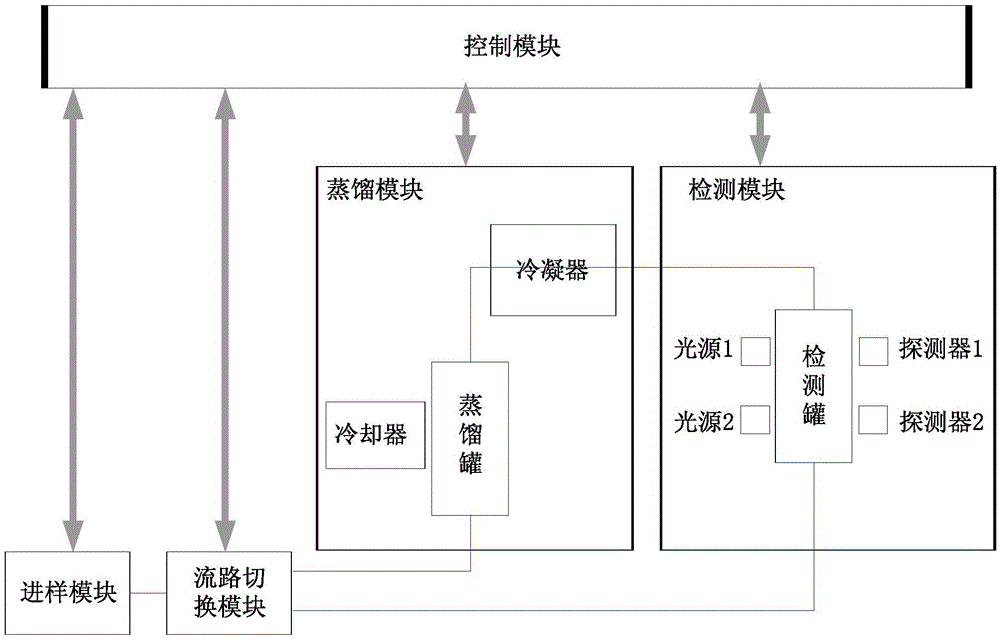

Online water quality detection and analysis device and method

The invention relates to an online water quality analysis device which comprises a control module, a sample injection module and a flow path switching module. The online water quality analysis device further comprises a distillation module and a detection module, wherein the distillation module comprises a distillation pot, a cooler, a condenser and a condensation pipeline; an anti-bumping pipe is arranged in the distillation pot; the outlet of the condensation pipeline stretches into a fraction tank and is in non-sealed connection with the fraction tank; the detection module comprises a fraction tank, a light source and a detector; the fraction tank is used for receiving the distilled distillate and serves as a color developing tank and a detection tank; the light source and the detector are used for judging the distillation end point and fixing the volume of the distillate. The invention also discloses an online water quality analysis method. The device disclosed by the invention has the advantages of simple structure, high degree of automation, high reliability and the like.

Owner:FOCUSED PHOTONICS

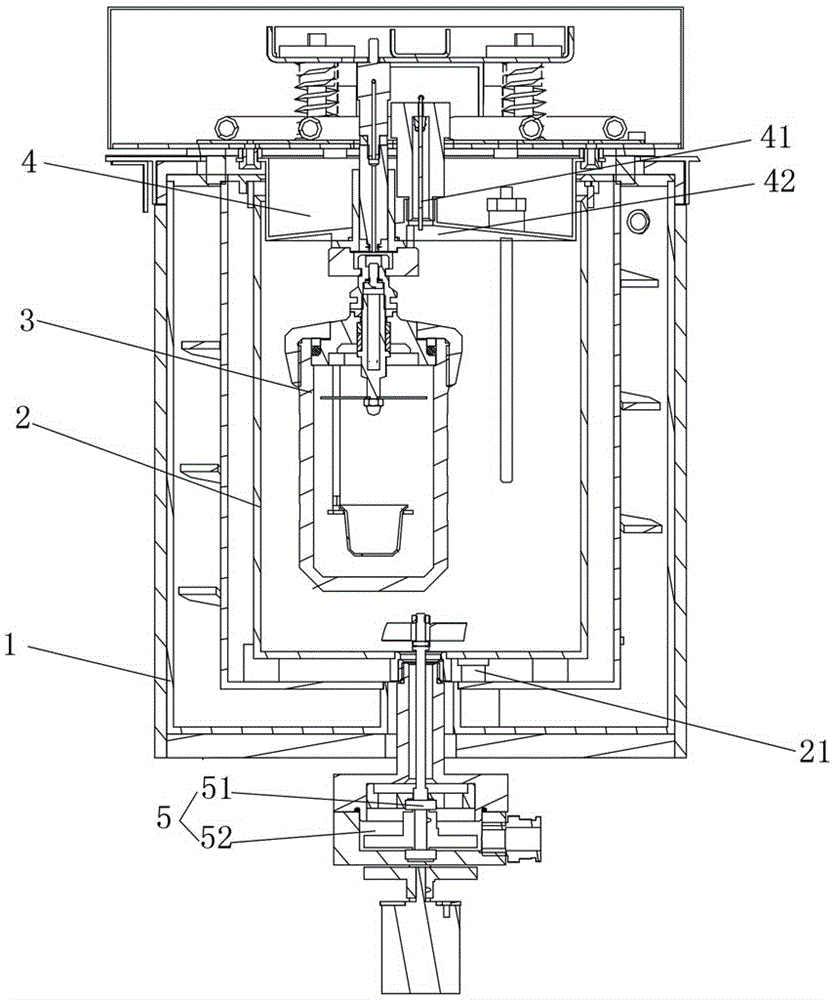

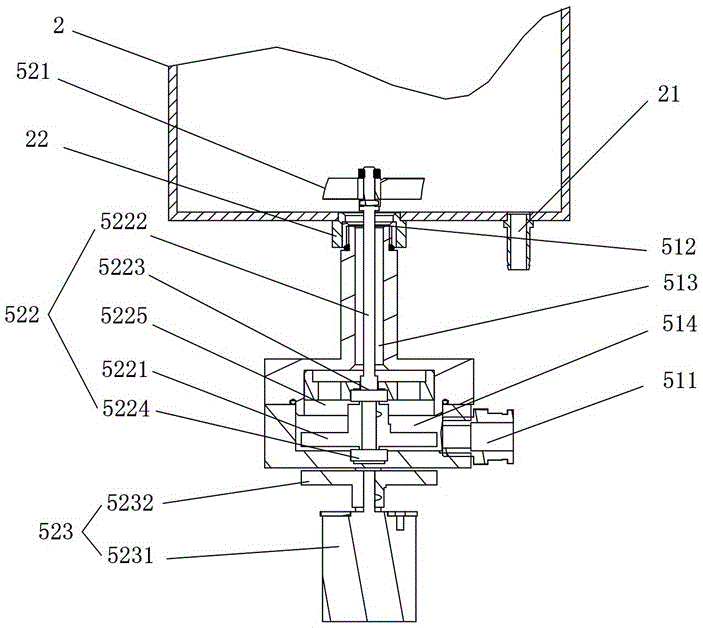

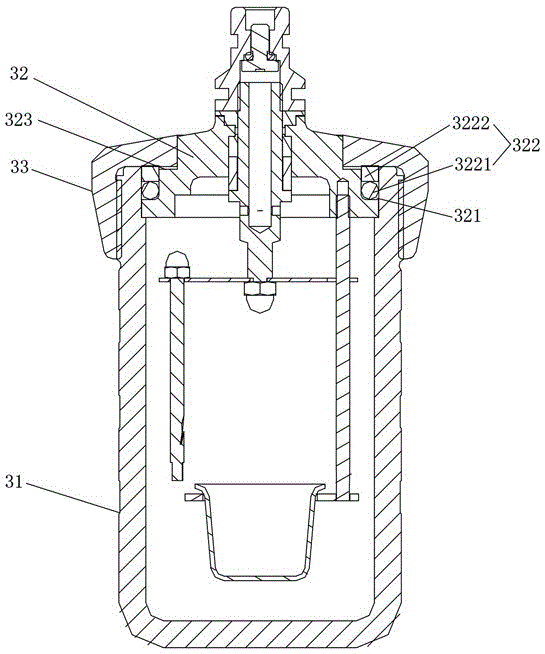

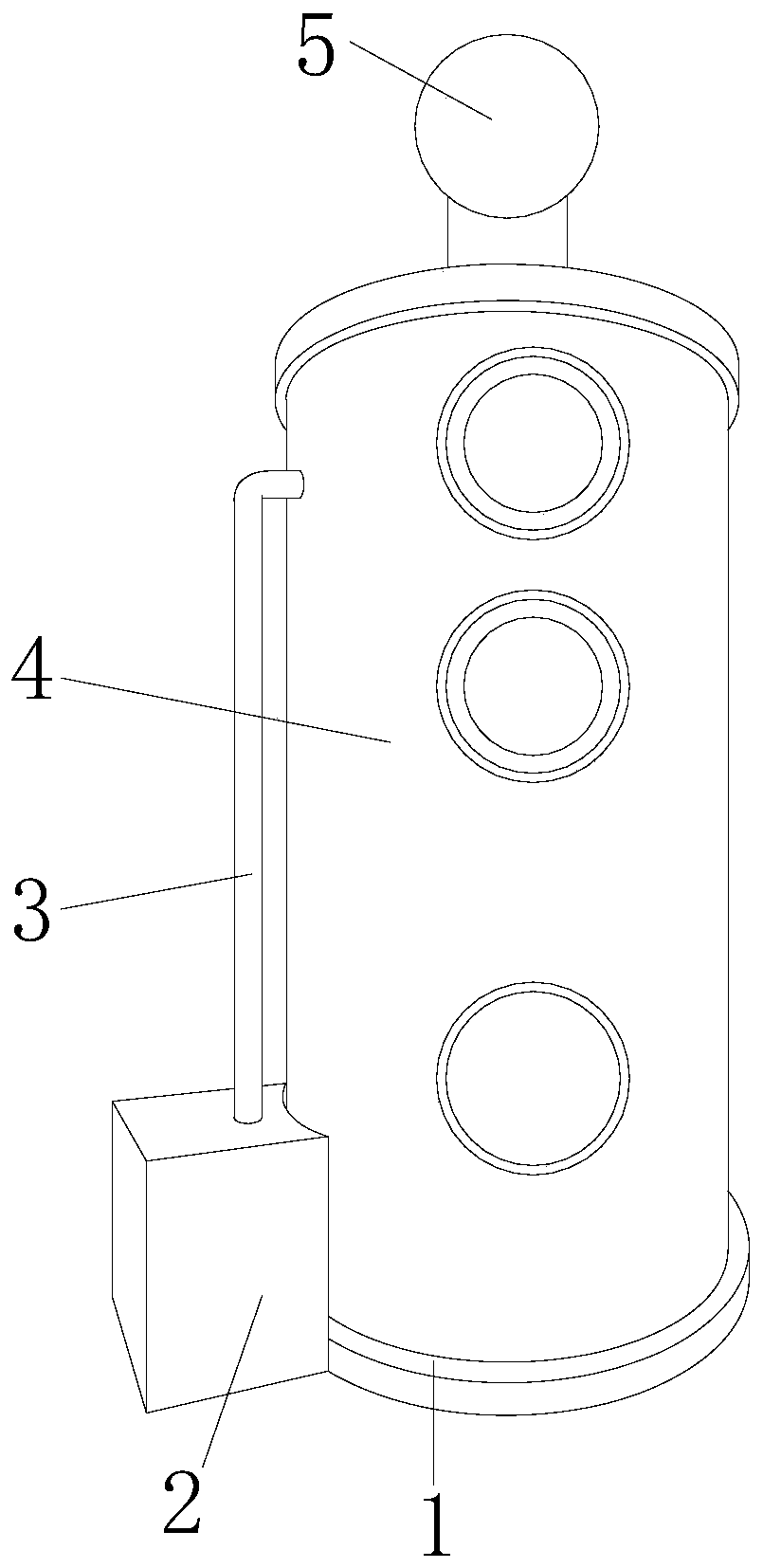

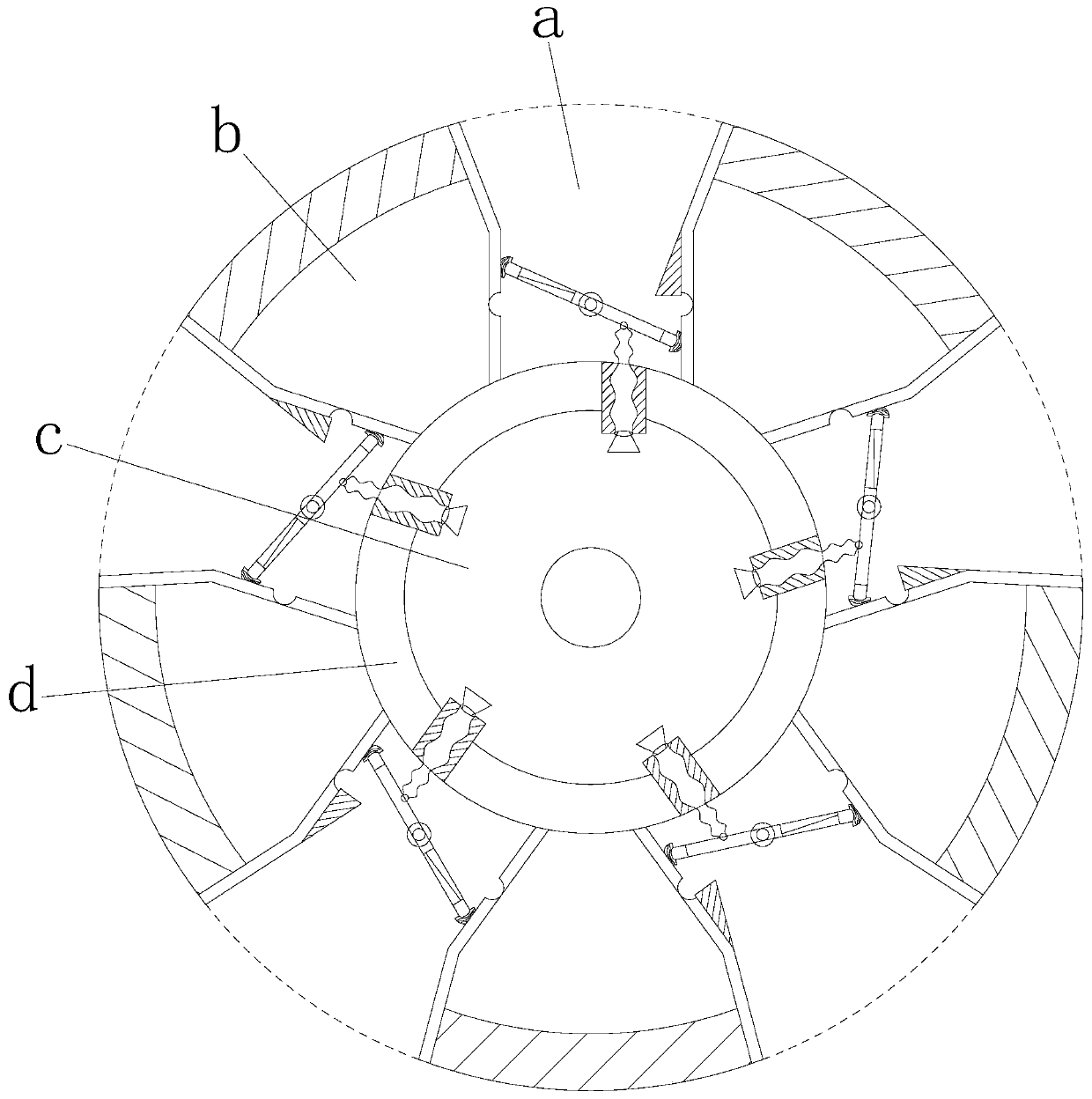

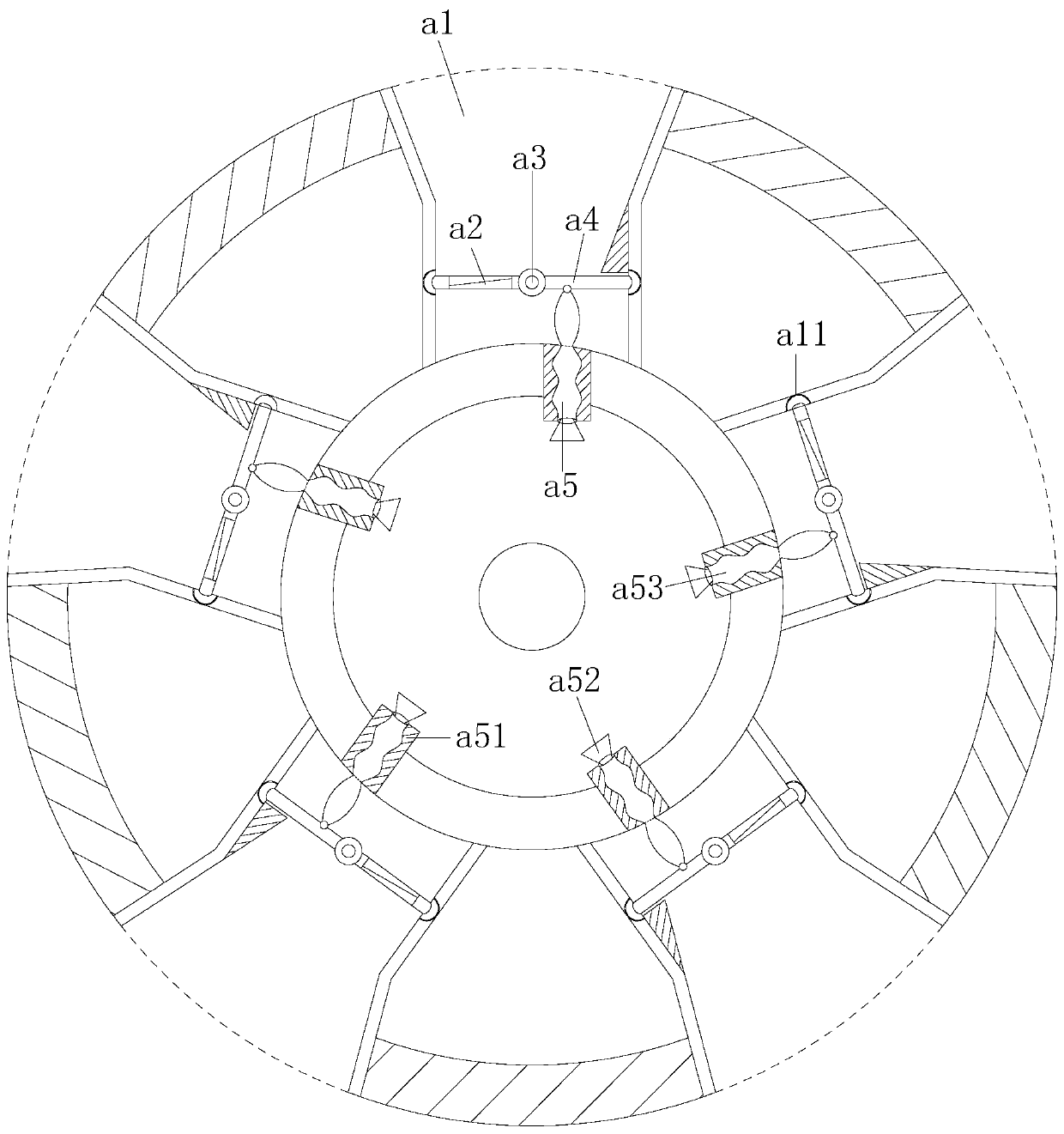

Automatic calorimeter for caloric analysis of sample

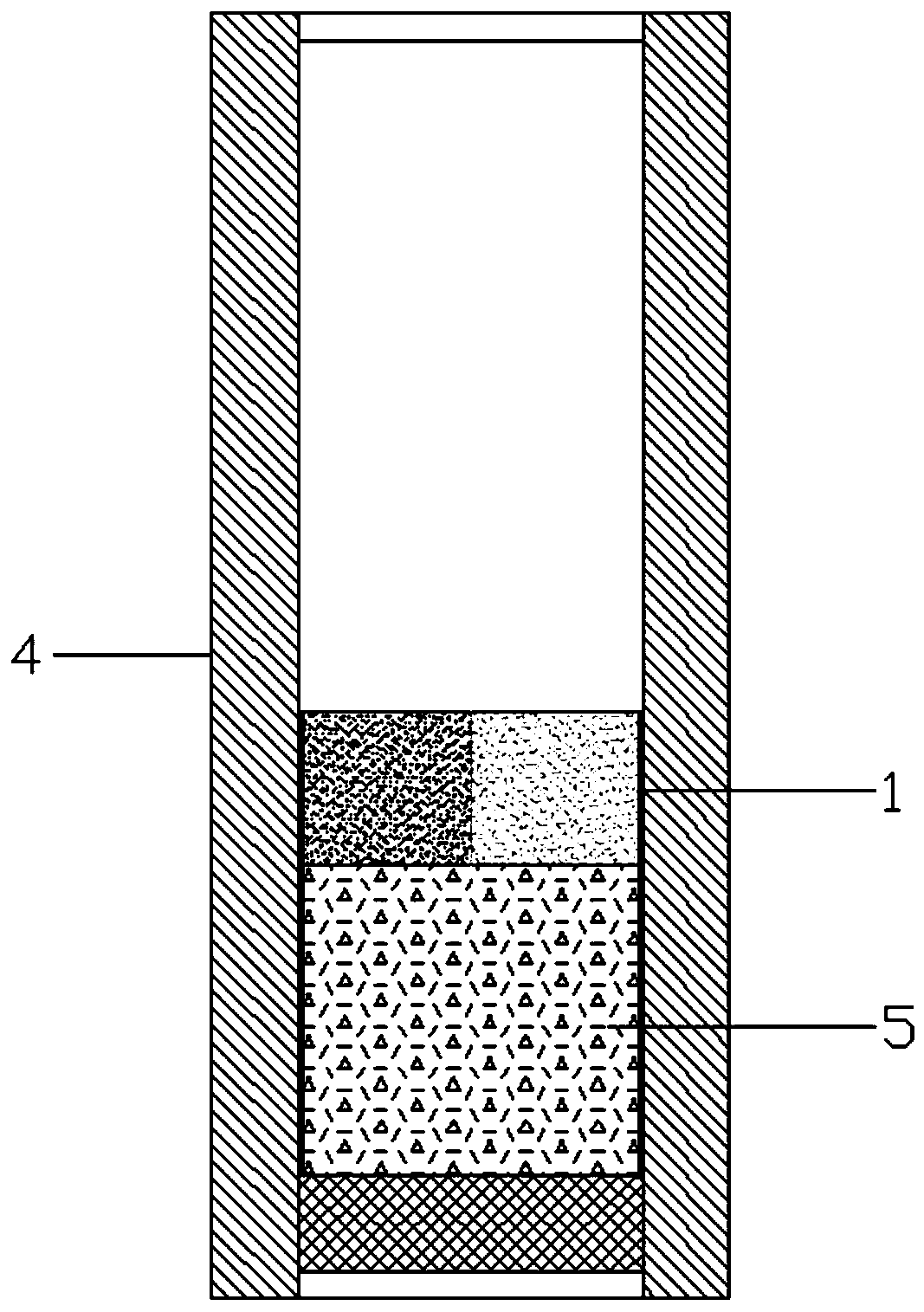

ActiveCN105973933AHighly integratedHigh test analysis precisionTransportation and packagingMaterial heat developmentOxygenCalorimeter

The invention discloses an automatic calorimeter for caloric analysis of a sample, comprising an outer barrel, an inner barrel and an oxygen bomb; the oxygen bomb is disposed in the inner barrel which is arranged in the outer barrel, a water supply stirring mechanism is arranged outside the outer barrel for supplying water to the inner barrel and stirring, the water supply stirring mechanism comprises a water supply chamber and a magnetic stirring assembly, one end of the water supply chamber is provided with a water inlet for communication with an external water supply apparatus, and the other end of the water supply chamber is provided with a water outlet for communicating with the inner barrel to supply water; the magnetic stirring assembly comprises stirring blades arranged in the inner barrel, a magnetic transmission part arranged in the water supply chamber and a magnetic drive part arranged outside the water supply chamber, the magnetic drive part cooperates with the magnetic transmission part to drive the magnetic transmission part to rotate, and the magnetic transmission part cooperates with the stirring blades to drive the stirring blades to move in sync for stirring. The calorimeter of the invention has the advantages of simple and compact structure, good stirring effect, high volume fixing precision and high test and analysis precision.

Owner:HUNAN SUNDY SCI & TECH DEV

Environmental protection air pollution detection and treatment equipmen

InactiveCN111442956AConsistent gas volumeConsistent volumeWithdrawing sample devicesGas analyser construction detailsEnvironmental engineeringAirbag

The invention discloses an environmental protection air pollution detection and treatment equipment, and its structure includes a fixed seat, a connecting seat, an external connecting pipe, a detection cavity, and a collection device. The fixed seat is fixedly connected with the connecting seat, the connecting seat is provided with the external connecting pipe, the other end of the external connecting pipe is fixed in the detection cavity, the external connecting pipe is connected with the detection cavity, the detection cavity is provided with a collection device, and the collection device iscommunicated with the detection cavity. The beneficial effects of the present invention are as follows: by entering the gas in the atmosphere into the inlet cavity, and entering the concentration cavity through the air inlet channel and the communication port, after the gas in the concentration cavity is filled, the airbag is filled through the interface, after the airbag is expanded, the plate body is pushed upward to realize the closing of the inlet cavity; at the same time, the external pressure source is turned off, because the space in the concentration cavity is fixed, so as to achievea constant sample volume, thereby improving the accuracy of the detection value of air pollution and facilitating the adoption of corresponding measures for prevention.

Owner:钱秀丽

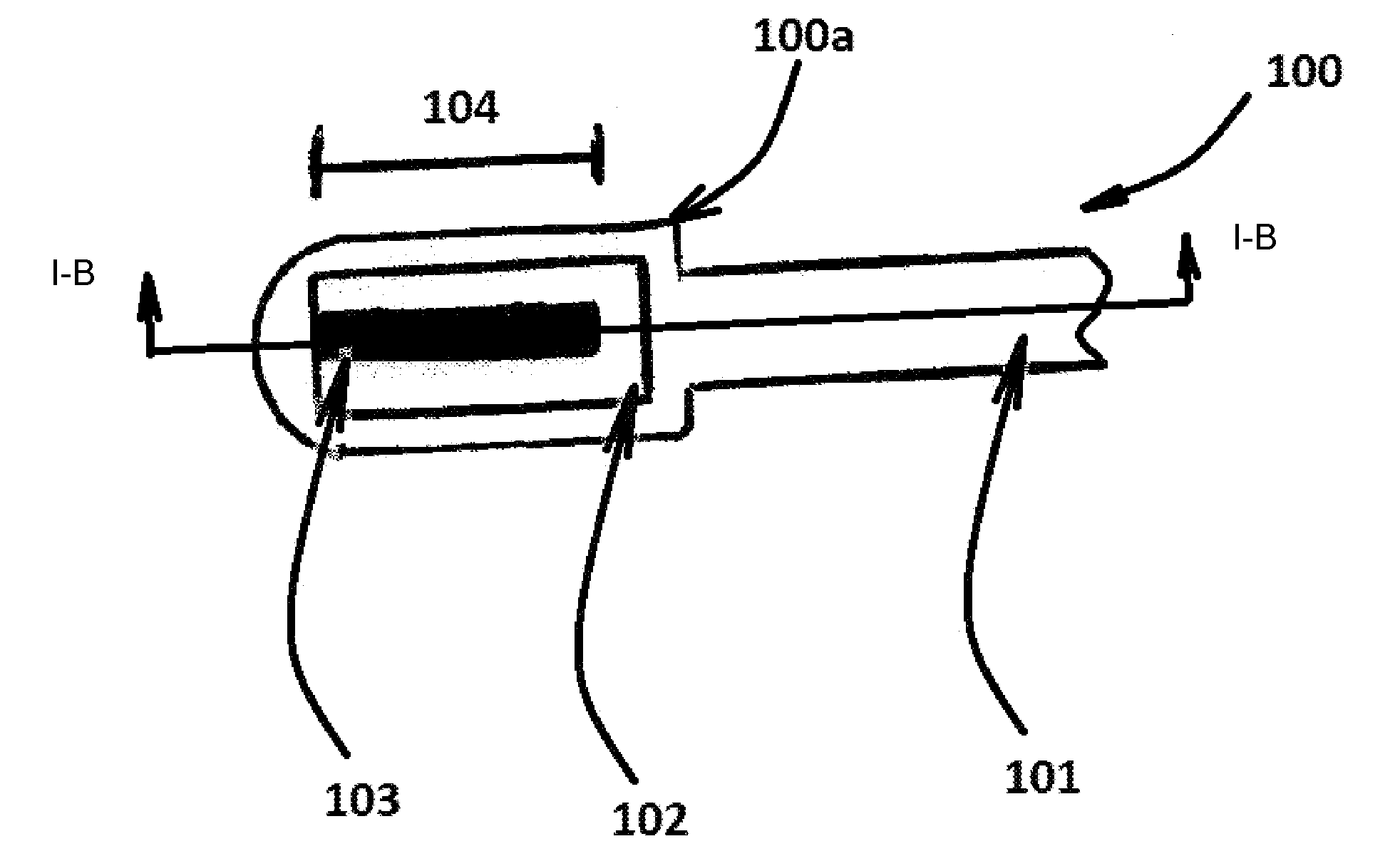

Toothbrush/toothpaste fluoride dosing toothbrush, system and method

A toothbrush, system and method for use of same are provided to enable a user to deliver a consistent volume of toothpaste to deliver a correct dosage of fluoride to children to avoid fluorosis. It is particularly advantageous to employ the toothbrush which indicates a predetermined length of toothpaste to be applied matched to a dispenser having an orifice of a predetermined diameter so the diameter of the toothpaste applied to the predetermined length results in the correct fluoride dosage.

Owner:DAVIS JOHN J

Detection method and device for residue in sample

ActiveCN103234966ASuspension stabilityAvoid cumbersome stepsMaterial analysis by observing effect on chemical indicatorEngineeringGas generator

The invention discloses a dangling titration device used for gas detection and a detection method used for detection by utilizing the device. The dangling titration device comprises an indicating liquid memory and a gas generator, wherein an opening used for hanging drops of indicating liquid is arranged at the tail end of the indicating liquid memory; the gas generator is in a sealed connection with the tail end of the indicating liquid memory; and the opening is formed in the gas generator. The dangling titration method is adopted, and the device specially used for dangling titration is provided, therefore, the drops of the indicating liquid directly react with gas generated by the sample, tedious steps that gas is absorbed by utilizing liquid and then titration is carried out in normal operation are avoided, operations are simplified, the detection time is shortened, and error caused by influence of environment on workers during detection with the titration method is avoided in the on-the-spot operation process.

Owner:GANSU CHEEZHENG TIBETAN MEDICINE CO LTD

Bottle container made of resin and method for manufacturing the same

The present invention provides a bottle container made of resin, which comprises a cylindrical barrel with a bottom and a cylindrical neck portion with a diameter smaller than that of the barrel,said bottle container further comprising an upper part and a lower part divided into two parts by dividing at an upper end or a lower end of the barrel, and under the condition that the upper part and the lower part are connected with each other, said two parts are integrated by a cover member for liquid-tightly covering connecting surfaces of said two parts to shield the connecting surfaces from outside and to integrate the two parts with each other.

Owner:YAITA SEISAKUSHOKK

A water quality online detection and analysis device and method

The invention relates to an online water quality analysis device which comprises a control module, a sample injection module and a flow path switching module. The online water quality analysis device further comprises a distillation module and a detection module, wherein the distillation module comprises a distillation pot, a cooler, a condenser and a condensation pipeline; an anti-bumping pipe is arranged in the distillation pot; the outlet of the condensation pipeline stretches into a fraction tank and is in non-sealed connection with the fraction tank; the detection module comprises a fraction tank, a light source and a detector; the fraction tank is used for receiving the distilled distillate and serves as a color developing tank and a detection tank; the light source and the detector are used for judging the distillation end point and fixing the volume of the distillate. The invention also discloses an online water quality analysis method. The device disclosed by the invention has the advantages of simple structure, high degree of automation, high reliability and the like.

Owner:FOCUSED PHOTONICS

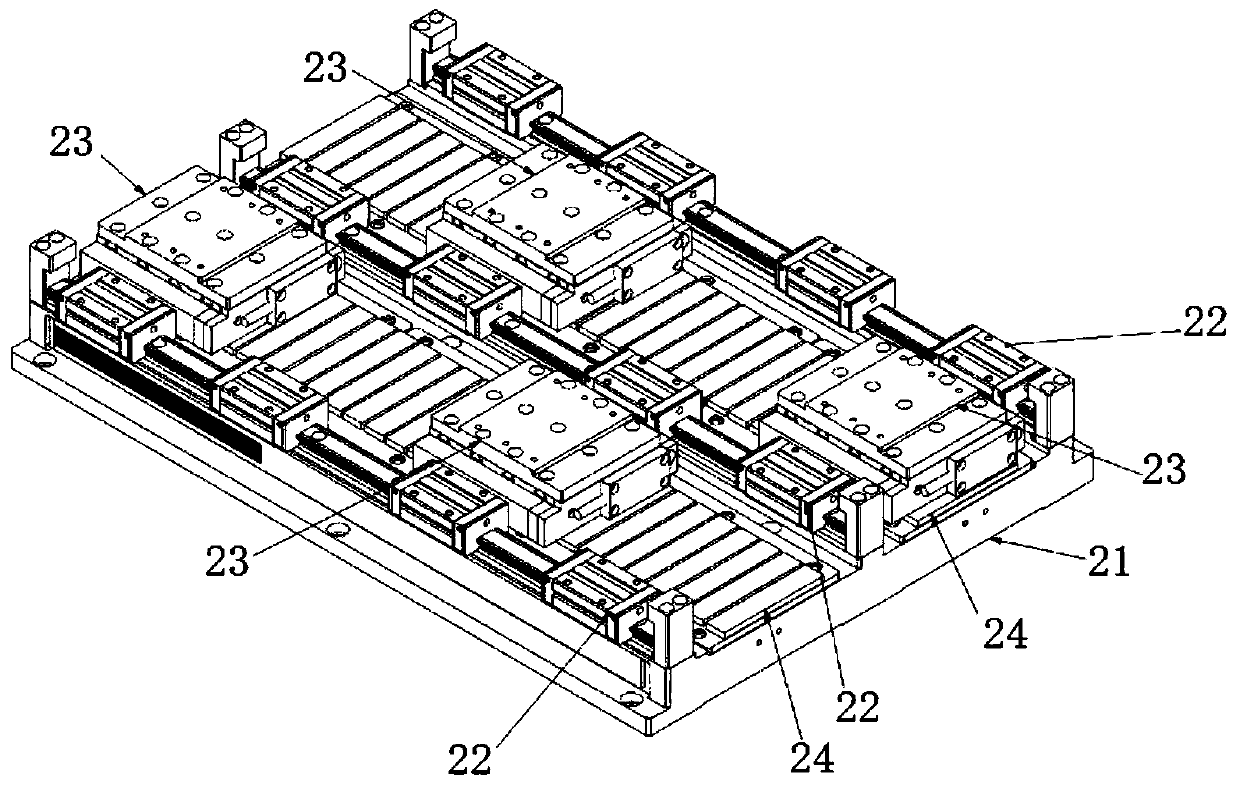

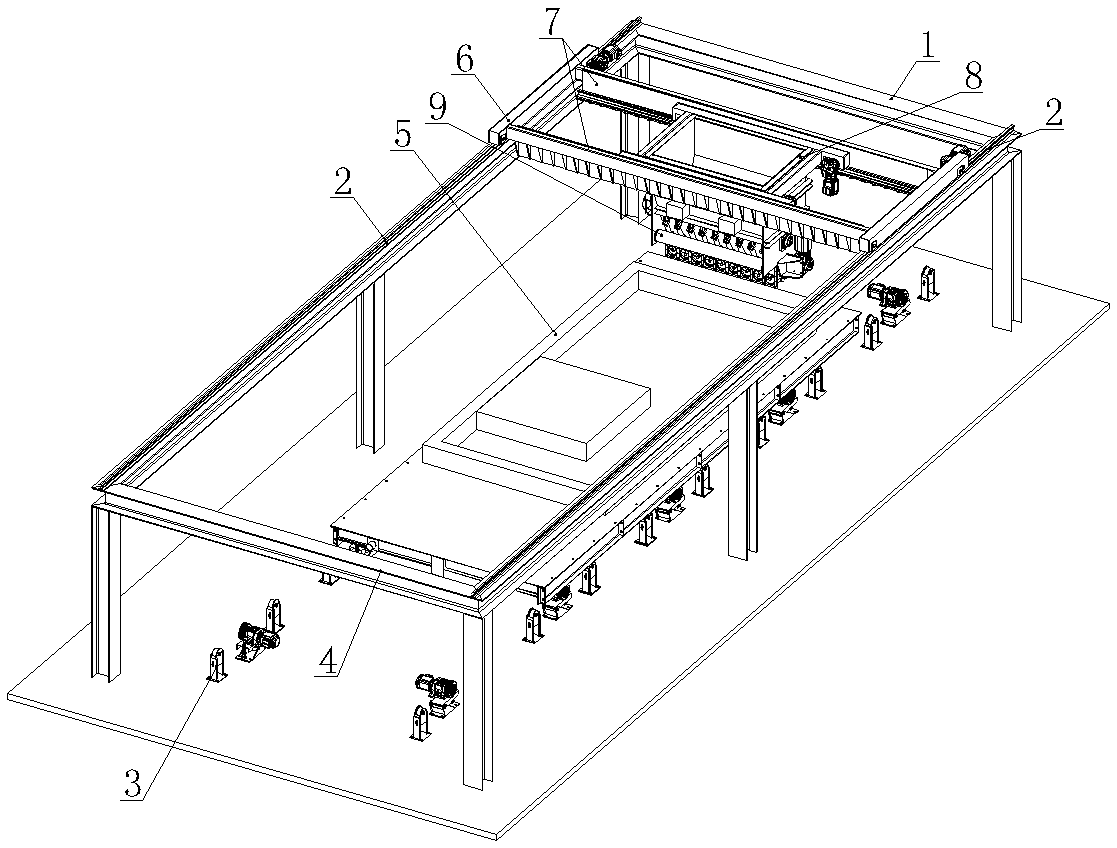

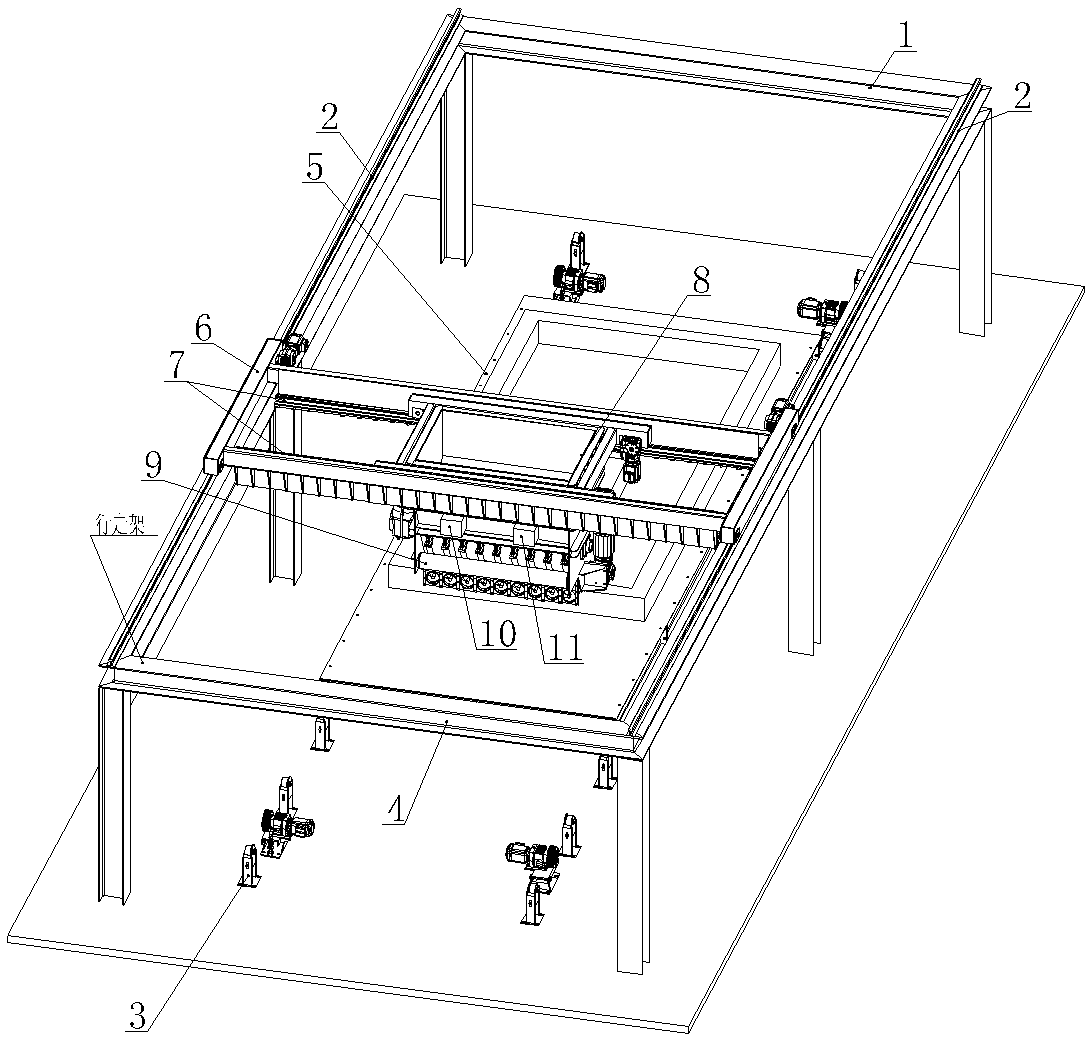

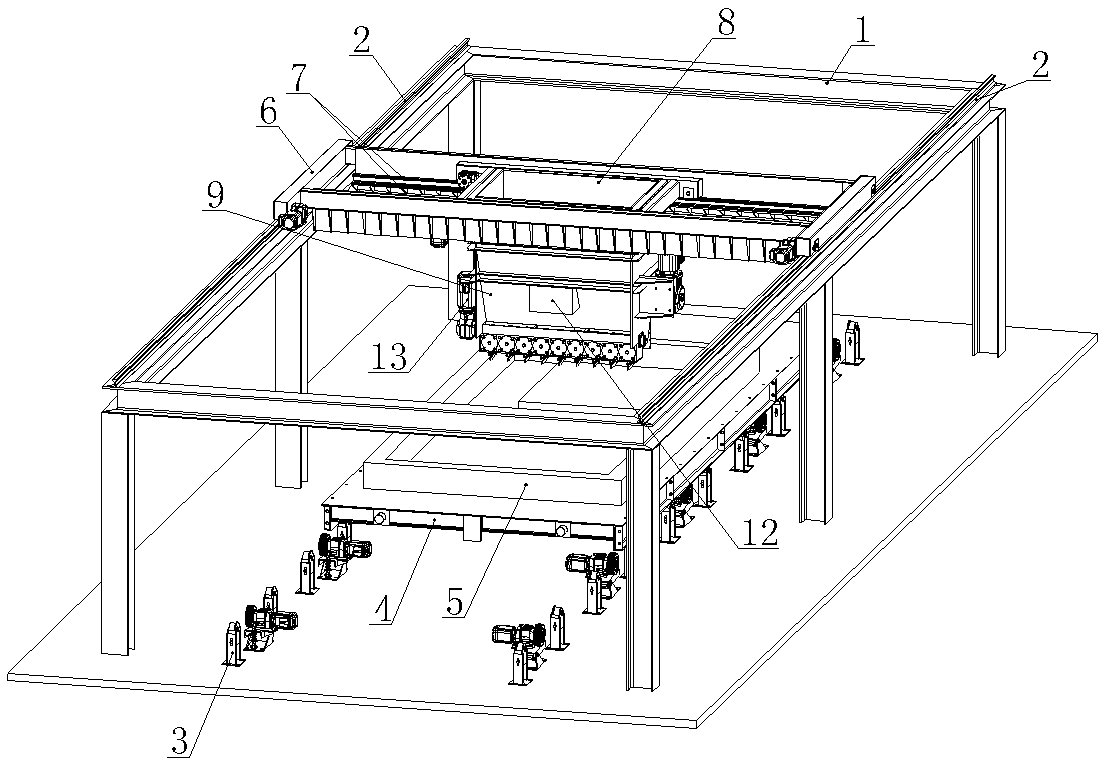

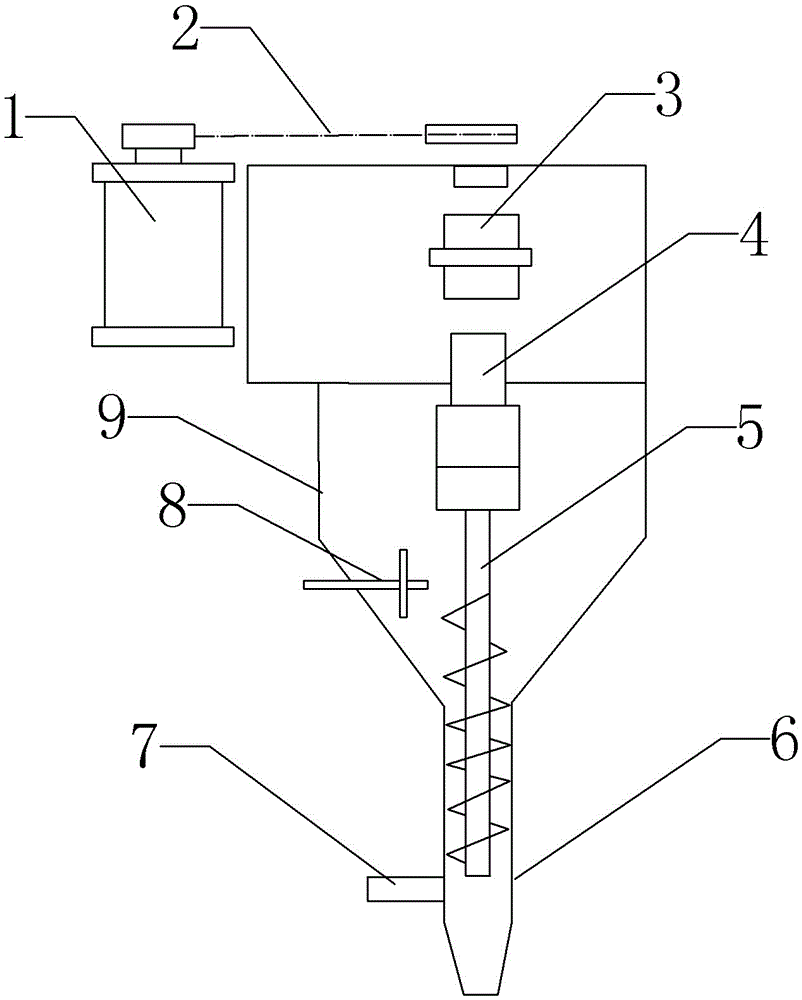

Concrete PC component distribution equipment

PendingCN111113657AConsistent volumePrecision FabricFeeding arrangmentsAuxillary shaping apparatusAcquisition apparatusElectric machinery

The invention discloses concrete PC component distribution equipment. The concrete PC component distributing equipment is characterized in that a distribution frame is provided with a distribution cart moving longitudinally, the distribution cart is provided with a distribution trolley moving transversely, the lower portion of the distribution trolley is fixedly provided with a spiral distributionmachine driven by a distribution motor to distribute materials, the spiral distribution machine is fixedly provided with an image acquisition device, the image acquisition device is in transmission connection with a programmable computer, and the programmable computer receives image information of a mold from the image acquisition device before material distribution; and the programmable computeris used for comparing with pre-stored image information to obtain the material distribution rotating speed of the material distribution motor under the corresponding image according to the volume ofthe die cavity, and controlling the material distribution motor to rotate and distribute materials according to the material distribution rotating speed. According to the concrete PC component distribution equipment, the specific mold is accurately identified through the camera equipment, the material distribution rotating speed needed by the mold is accurately obtained, the size of material distribution is consistent with the size of a mold cavity, accurate material distribution is achieved, and the problem that material distribution of material distribution equipment is not uniform or accurate enough is solved.

Owner:河南致远住工科技有限公司

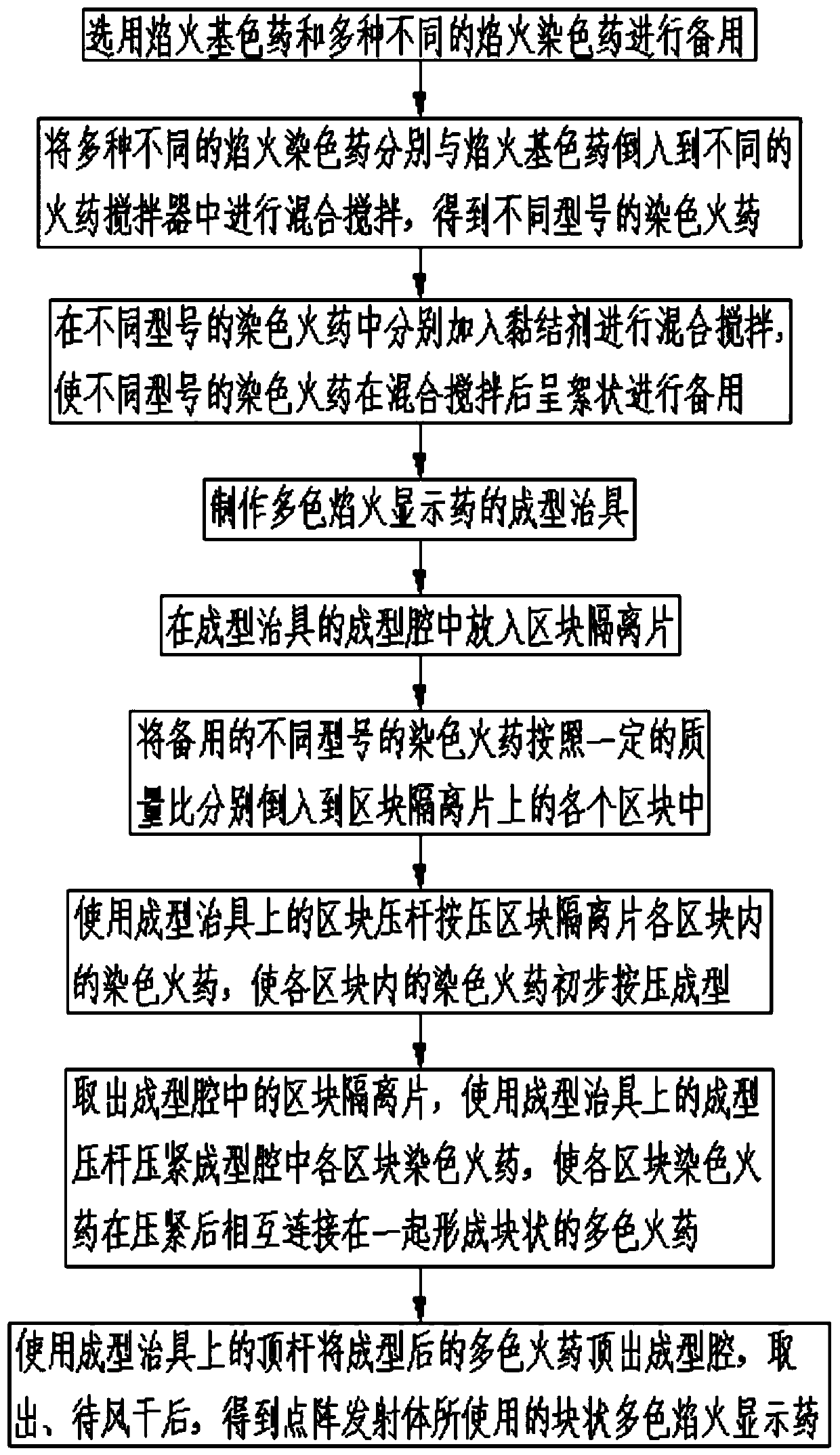

Multi-color firework display powder of image-text firework lattice launcher and preparation method of multi-color firework display powder

The invention discloses multi-color firework display powder of an image-text firework lattice launcher and a preparation method of the multi-color firework display powder. The powder and the method comprises the multi-color firework display powder which is used for being arranged on inner firework propellant powder of the lattice launcher, and the multi-color firework display powder is provided with multiple of areas for setting of flames with different colors, wherein each of the areas is made of firework primary color powder and firework dye powder, and the firework dye powder used in each area can generate the flames with different colors during combustion. According to the powder and the method, the multiple different dye powder are pressed through a forming jig to form the multi-colorfirework display powder, so that the process is simple, manufacturing is convenient, and the batch production can be carried out through the jig; and the size and mass ratio of the produced multi-color firework display powder are basically consistent, so that the time when the multi-color firework display powder is launched to a high altitude for being set off is consistent when the multi-color firework display powder is used in an image-text firework lattice structural body.

Owner:征茂德

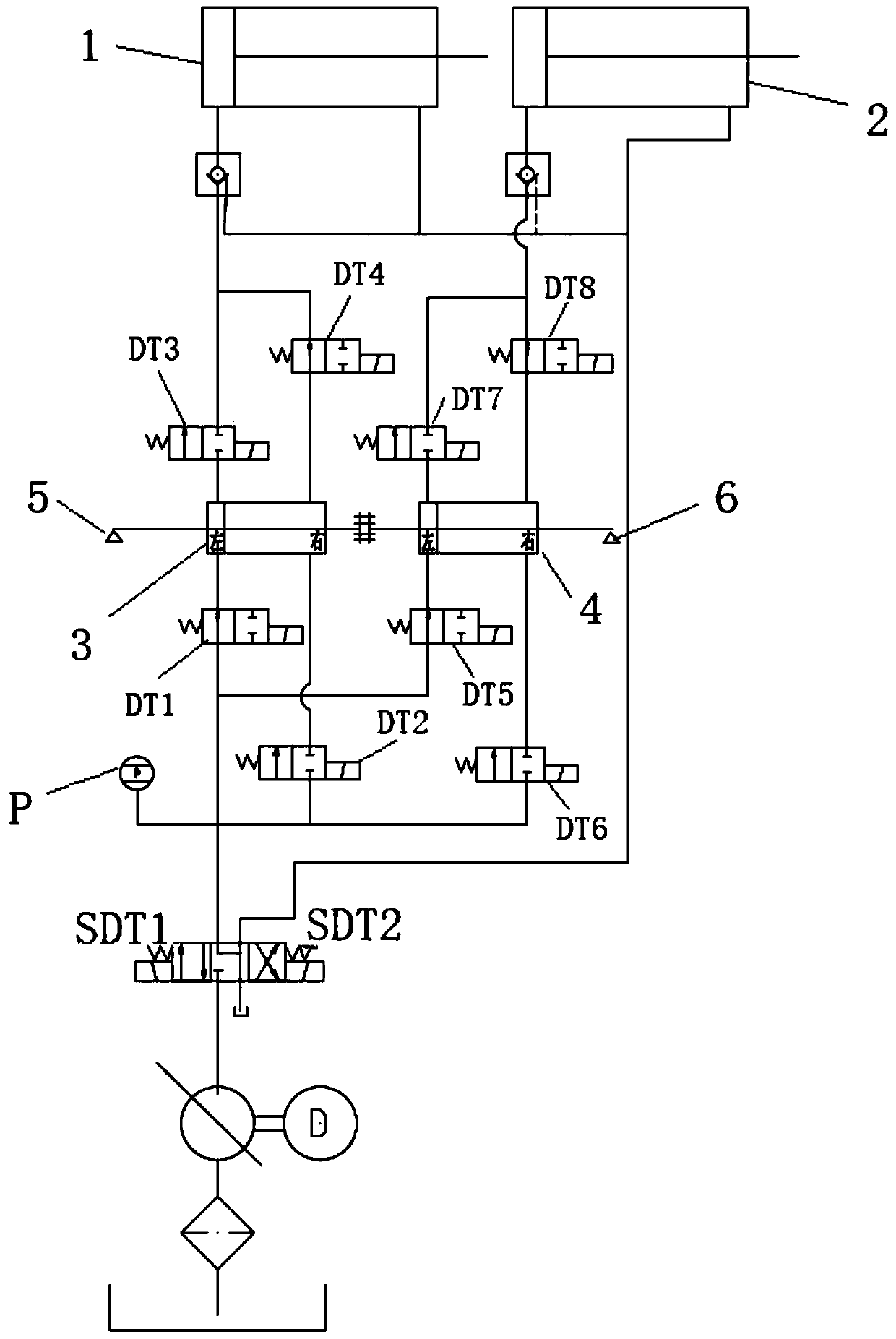

Rigid high-precision hydraulic synchronous device

ActiveCN109779991AHigh synchronization accuracyImprove reliabilityServomotorsHydraulic cylinderFuel tank

The invention relates to a rigid high-precision hydraulic synchronous device. The lower portions of a left cavity and a right cavity of a first synchronous cylinder are connected with one end of a first control valve group. The other end of the first control valve group is connected with a pressure gauge and the output end of the high-pressure oil tank. The output end of the high-pressure oil tankis provided with an electromagnetic reversing valve. The lower portions of a left cavity and a right cavity of a second synchronous cylinder are both connected with one end of a second control valvegroup. The other end of the second control valve group is connected with the pressure gauge and the output end of the high-pressure oil tank. The upper portions of the left cavity and the right cavityof the first synchronous cylinder are both connected with one end of the third control valve group. The other end of the third control valve group is connected with the left cavity of a first hydraulic cylinder through a hydraulic pipeline. The upper portions of the left cavity and the right cavity of the second synchronous cylinder are connected with one end of a fourth control valve group. Theother end of the fourth control valve group is connected with the left cavity of a second hydraulic cylinder through a hydraulic pipeline. The right cavity of the first hydraulic cylinder and the right cavity of the second hydraulic cylinder are connected in parallel through a hydraulic pipeline and then are connected with the output end of the high-pressure oil tank through an electromagnetic reversing valve. The rigid high-precision hydraulic synchronous device can rigidly guarantee that the hydraulic cylinders needing adjustment synchronously act.

Owner:煤科(北京)检测技术有限公司

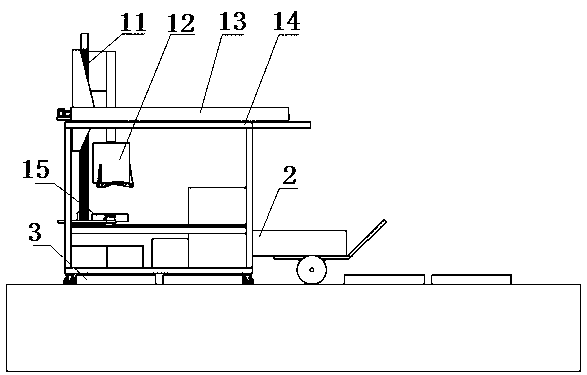

Automatic digging baijiu preparation machine

PendingCN108998329AAccurate location of excavated materialsControl the digging forceAlcoholic beverage preparationMobile vehicleEngineering

The invention relates to an automatic digging baijiu preparation machine, and belongs to the field of baijiu preparation. The automatic digging baijiu preparation machine comprises an excavator bucketelevating device used for elevating, an excavator bucket device used for material digging, a horizontal moving device used for horizontal moving of an excavator bucket, a moving vehicle used for providing control, power, and other device installation, a material trolley used for material loading, and a material receiving device used for preventing and controlling material falling; the two sides of the excavator bucket elevating device are fixedly connected with the horizontal moving device, and the front end is connected with the excavator bucket device; the horizontal moving device and the material receiving device are fixedly connected with the moving vehicle respectively. The advantages are that: the design is novel, human labor intensity is reduced greatly, the number of production people is reduced, production cost is reduced, the working efficiency is high, and the practicality is high.

Owner:长春同泽科技有限公司 +1

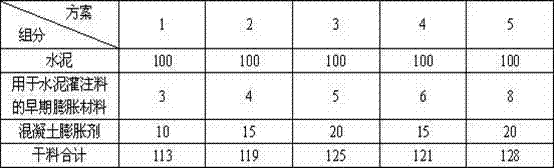

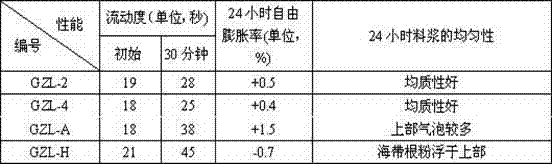

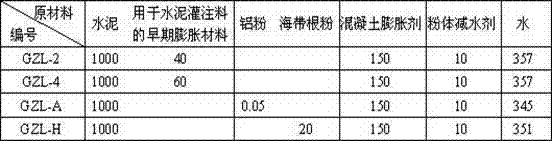

Slightly expansive cement grouting material

InactiveCN103113059AConsistent volumeThe amount of expansion is easy to controlCement groutChemistry

The invention relates to a slightly expansive cement grouting material. The slightly expansive cement grouting material consists of early expanding material of the cement grouting material, cement and a cement expansive agent. The early expanding material and the expansive agent are used for respectively offsetting early volume reducing caused by cement paste sedimentation and drying shrinkage and the long-term chemical shrinkage generated by cement continuous hydration, so that the volume stability of the cement grouting material is remarkably improved. The material has no influence to the fluidity of the cement paste, and the early expansion capacity is easily controlled, so that the cost is low, and the preparation is simple, and therefore, the slightly expansive cement grouting material is particularly applicable to engineering which has a big fluidity requirement to the cement grouting material.

Owner:TONGJI UNIV

Screw type quantitative filling device

InactiveCN105460244AEasy to cleanPracticalSolid materialPackaging machinesEngineeringMechanical engineering

The invention discloses a screw type quantitative filling device with a filling screw convenient to clean. The screw type quantitative filling device comprises a filling barrel. A vertical rotatable filling screw is arranged in the filling barrel. A filling pipe communicated with the filling barrel is arranged on the lower portion of the filling barrel. The filling screw stretches into the filling pipe. An arc-shaped through hole is formed in the side wall of the filling pipe. An opening and closing door capable of moving in the radial direction of the filling pipe is arranged in the arc-shaped through hole in a penetrating mode. A sealing ring is arranged between the opening and closing door and the arc-shaped through hole. The end face, located in the filling pipe, of the opening and closing door is a curved surface which is identical with the circumference of the filling pipe in curvature. A water passing groove capable of being communicated with the outside is formed in the upper portion of the opening and closing door. A stirring rod is further connected to the side wall of the upper portion of the filling barrel. The stirring rod stretches into the filling barrel. A water inlet hole is formed in the stirring rod. A one-way valve is arranged in the water inlet hole.

Owner:CHONGQING XIUCAI BAY FRUIT & VEGETABLE PROFESSIONAL COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com