Concrete PC component distribution equipment

A concrete and cloth technology, applied in auxiliary forming equipment, supply device, ceramic forming machine, etc., can solve the problems of uneven cloth, insufficient uniform and accurate cloth, etc., to achieve accurate cloth, solve the problem of insufficient uniform and accurate cloth, and ensure the supply of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

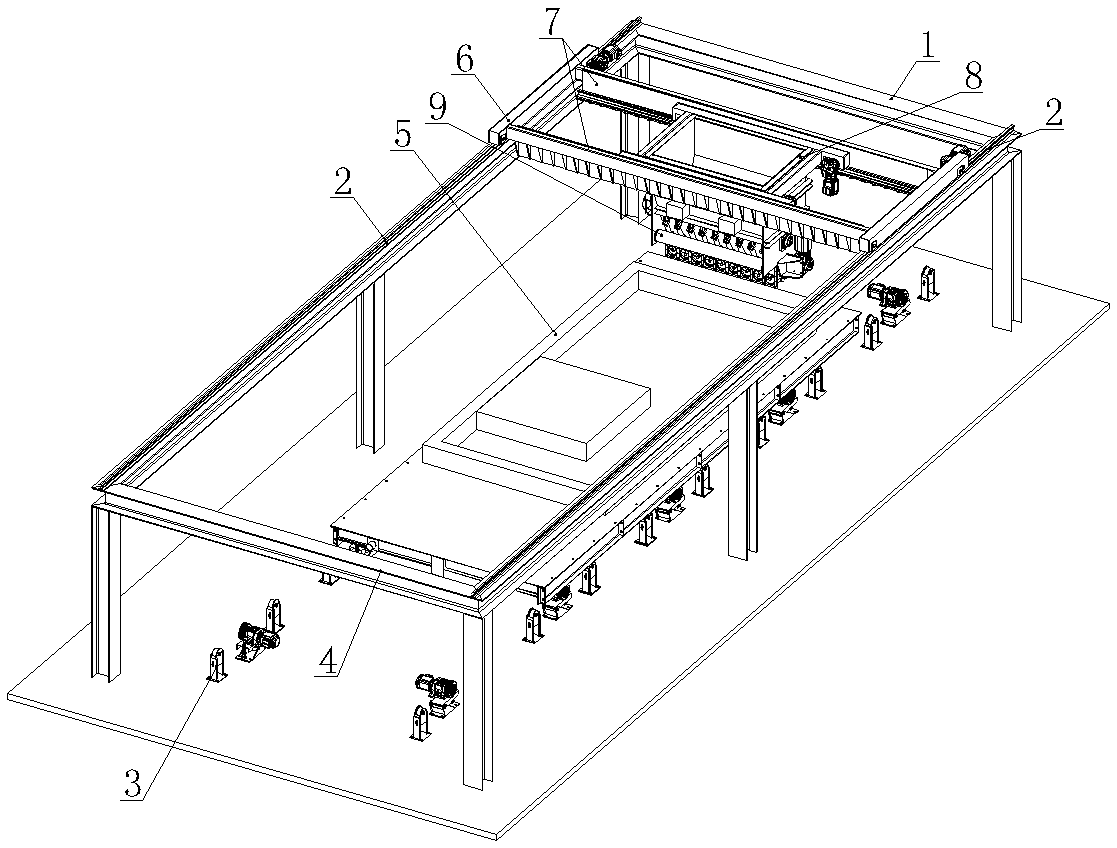

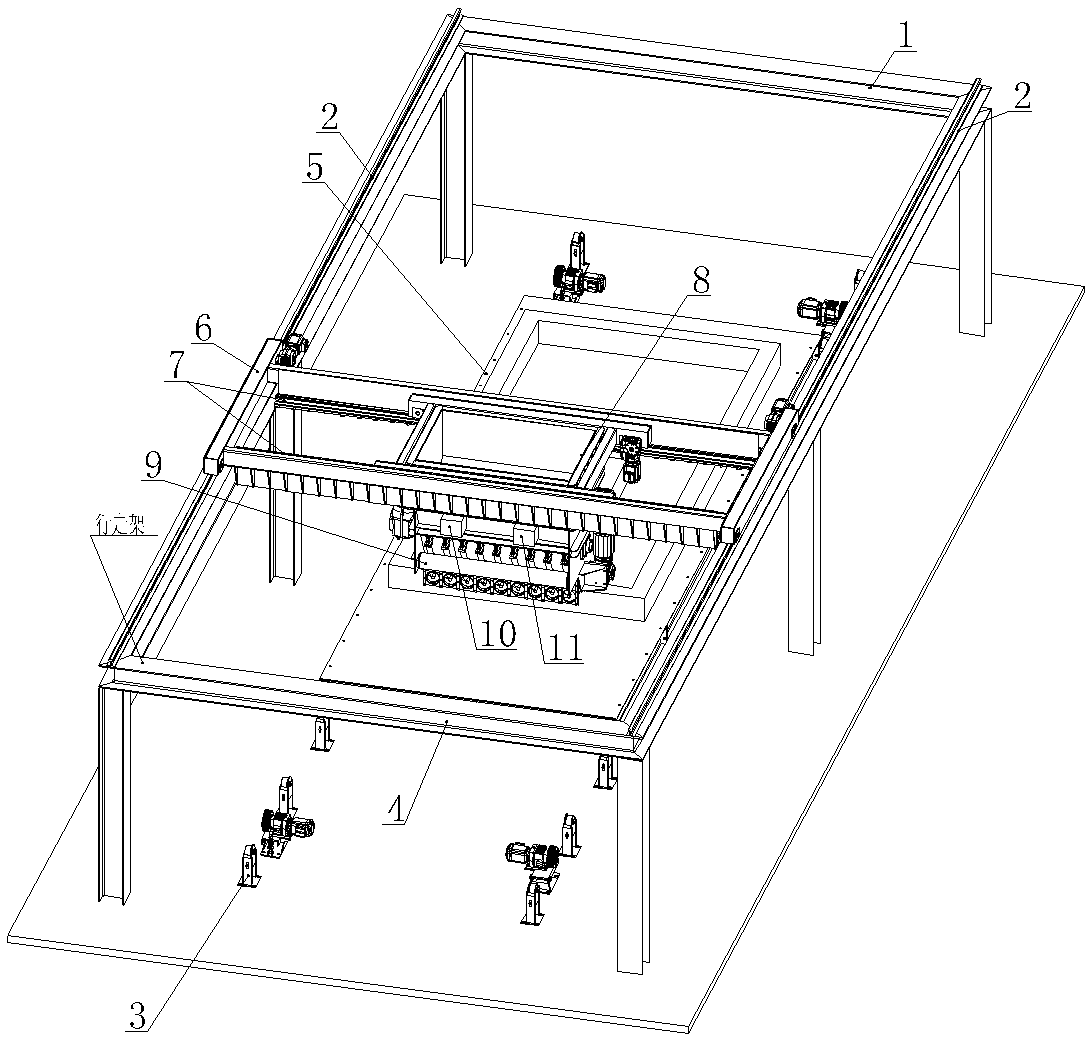

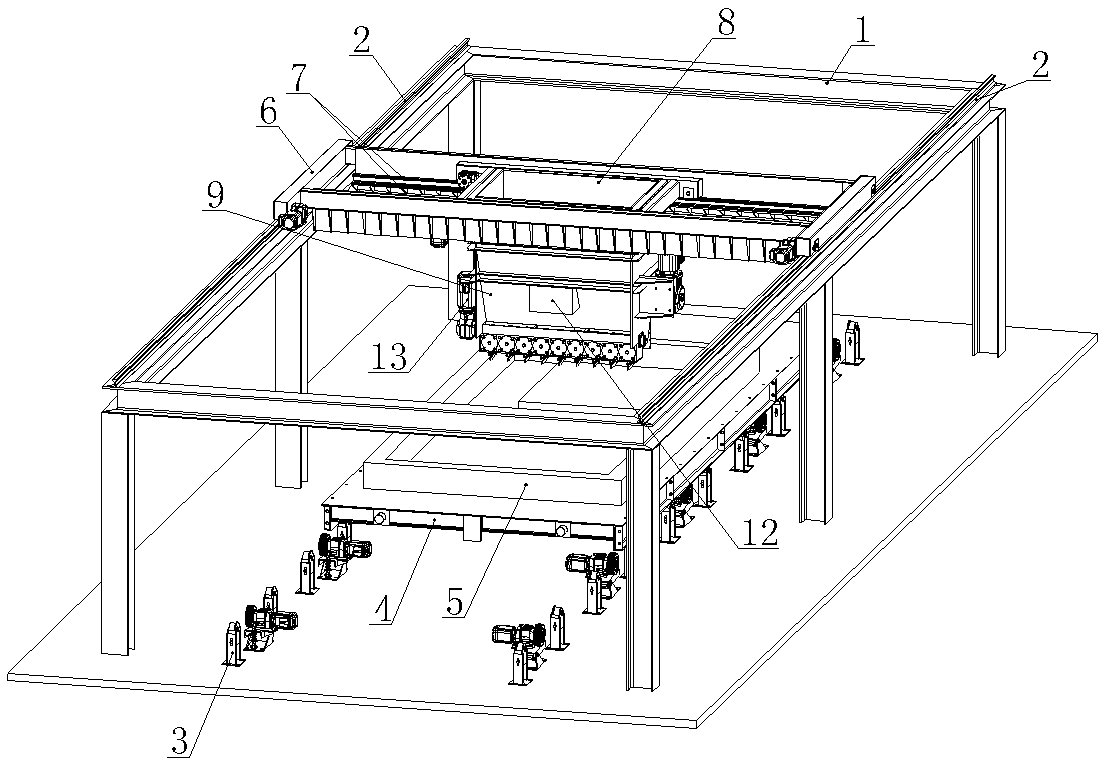

[0017] An embodiment of a concrete PC member distributing equipment, in Figure 1-Figure 5 Among them, the fabric rack 1 has two longitudinal guide rails 2, the two longitudinal guide rails 2 are parallel to each other, and are fixed on the ground foundation by columns, and two sets of parallel mold table walking wheels 3 are arranged below the two longitudinal guide rails 2. The table walking wheel 3 is located; between the two longitudinal guide rails 2, the mold table 4 is arranged on the mold table walking wheel 3, and there is a driving wheel driven by a motor every few times in the mold table walking wheels, so that the mold table 4 can Move on the mold table walking wheels, the mold table is moved on the mold table walking wheels in sequence by a plurality of mold tables, and a mold 5 is arranged on each mold table 4, and the mold 5 moves along with the mold table. Between the two longitudinal guide rails 2, there is a cloth cart 6 that moves longitudinally on the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com