Slightly expansive cement grouting material

A pouring material and micro-expansion technology, which is applied in the field of micro-expansion cement pouring material, can solve the problem of uncontrollable gas generation at ambient temperature, etc., and achieve the effects of easy control of expansion, good fluidity and homogeneity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

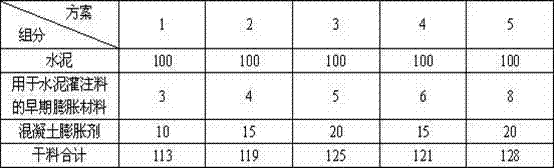

[0017] According to the ratio of raw materials in Table 1, a series of micro-expansion cement pouring materials can be prepared respectively.

[0018] Table 1 Formula of micro-expansion cement pouring material (mass ratio, unit: part)

[0019]

[0020] The preparation method is that according to the material formula in Table 1, each component is mixed evenly, and the material of this patent series can be obtained.

[0021] Beneficial effect

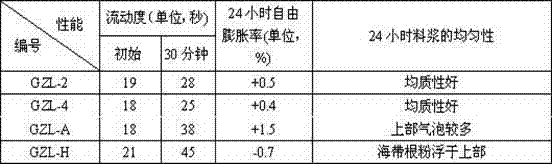

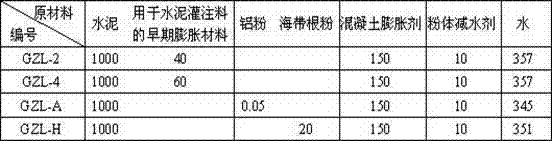

[0022] Generally, polycarboxylate powder water reducer is used in cement pouring materials to improve fluidity. Using this material, two kinds of micro-expansion cement pouring materials were prepared according to the schemes "2" and "4" in Table 1. , and then according to the mass ratio water: dry material ratio of 0.3, add water and stir to make cement pouring slurry (respectively denoted as GZL-2 and GZL-4), in order to compare the traditional method, aluminum powder and untreated The treated same kind of kelp root powder was us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com