Automatic digging baijiu preparation machine

A grain wine machine and automatic technology, applied in the field of automatic digging grain wine machine, can solve the problems of difficult work, high labor intensity, low production efficiency, etc., and achieve the effects of accurate material location, high work efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

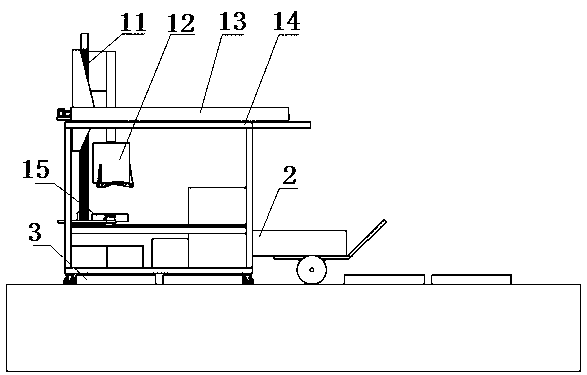

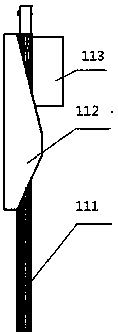

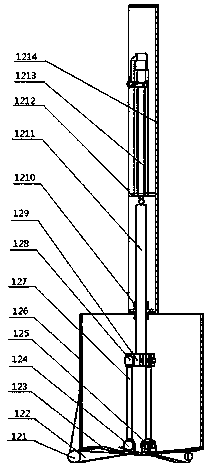

[0028] see Figure 1 to Figure 7 As shown, the automatic digging wine making machine of the present invention includes a bucket lifting device 11 for controlling the strength and depth of the digging cylinder, a bucket device 12 for precisely controlling the opening and closing angle of the digging claws, and a bucket device 12 for setting the unloading angle. The translation device 13 for the material position, the mobile car 14 for providing control, power and other device installation, the material trolley 2 for taking materials, and the material receiving device 15 for preventing the material from the bucket from being scattered on the ground. The translation device 13 adopts Fixed point, positioning movement, accurate position of excavated materials, accurate control of digging cylinder force and depth of dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com