Bottle container made of resin and method for manufacturing the same

A resin and container technology, applied in the field of manufacturing the bottle-shaped container and liquid cosmetic material bottle-shaped container, can solve the problems of cumbersome procedures, uneconomical, high material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

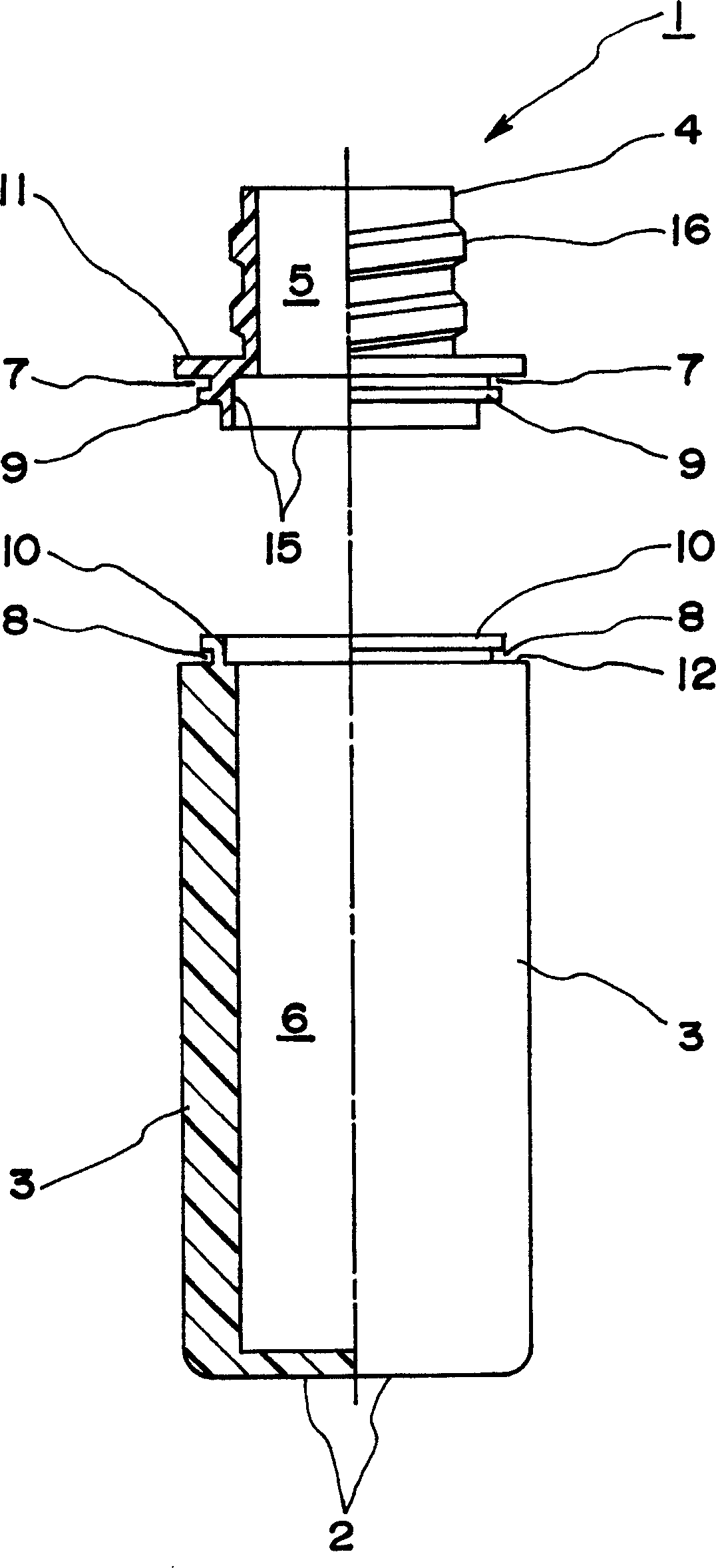

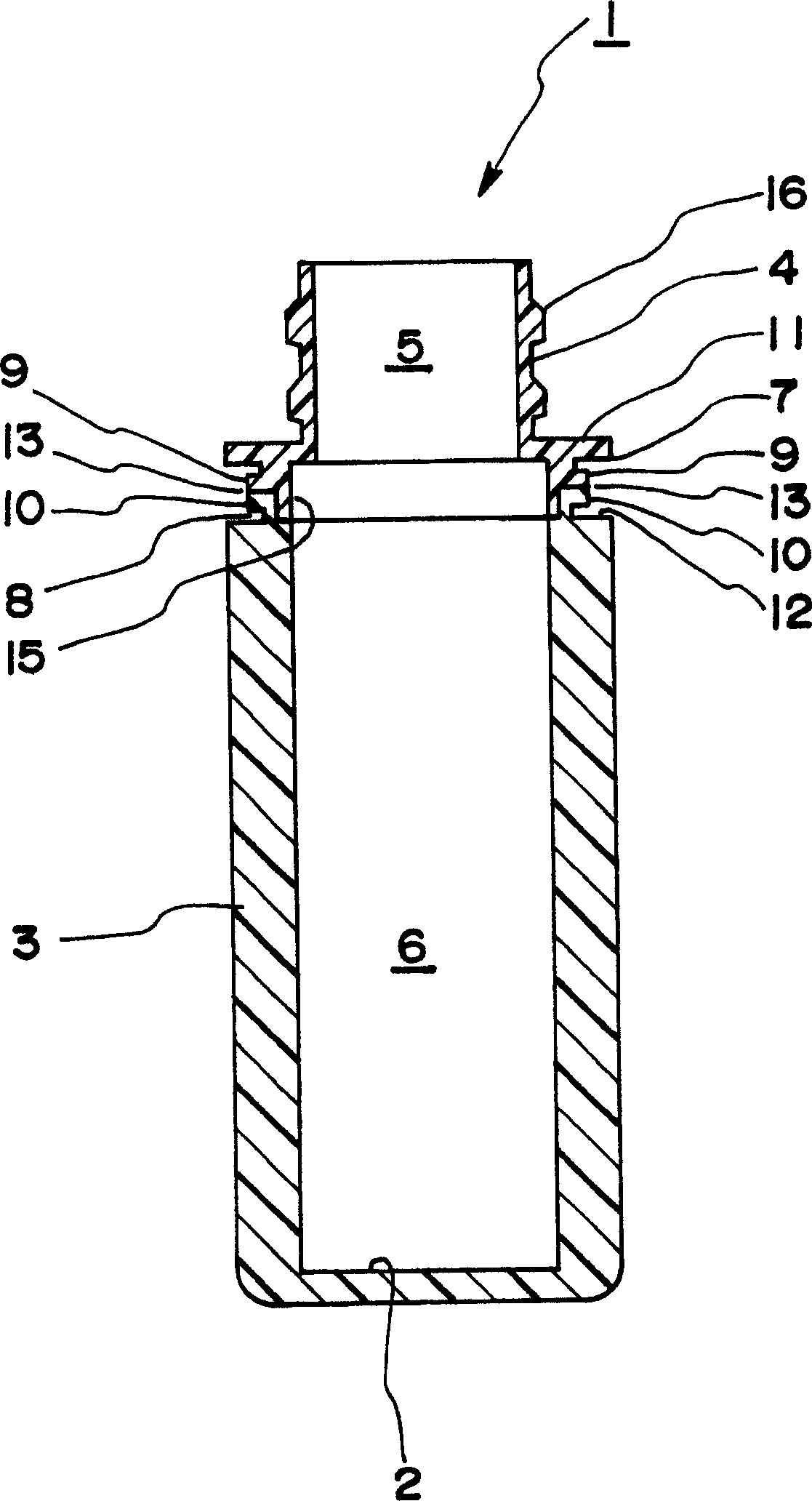

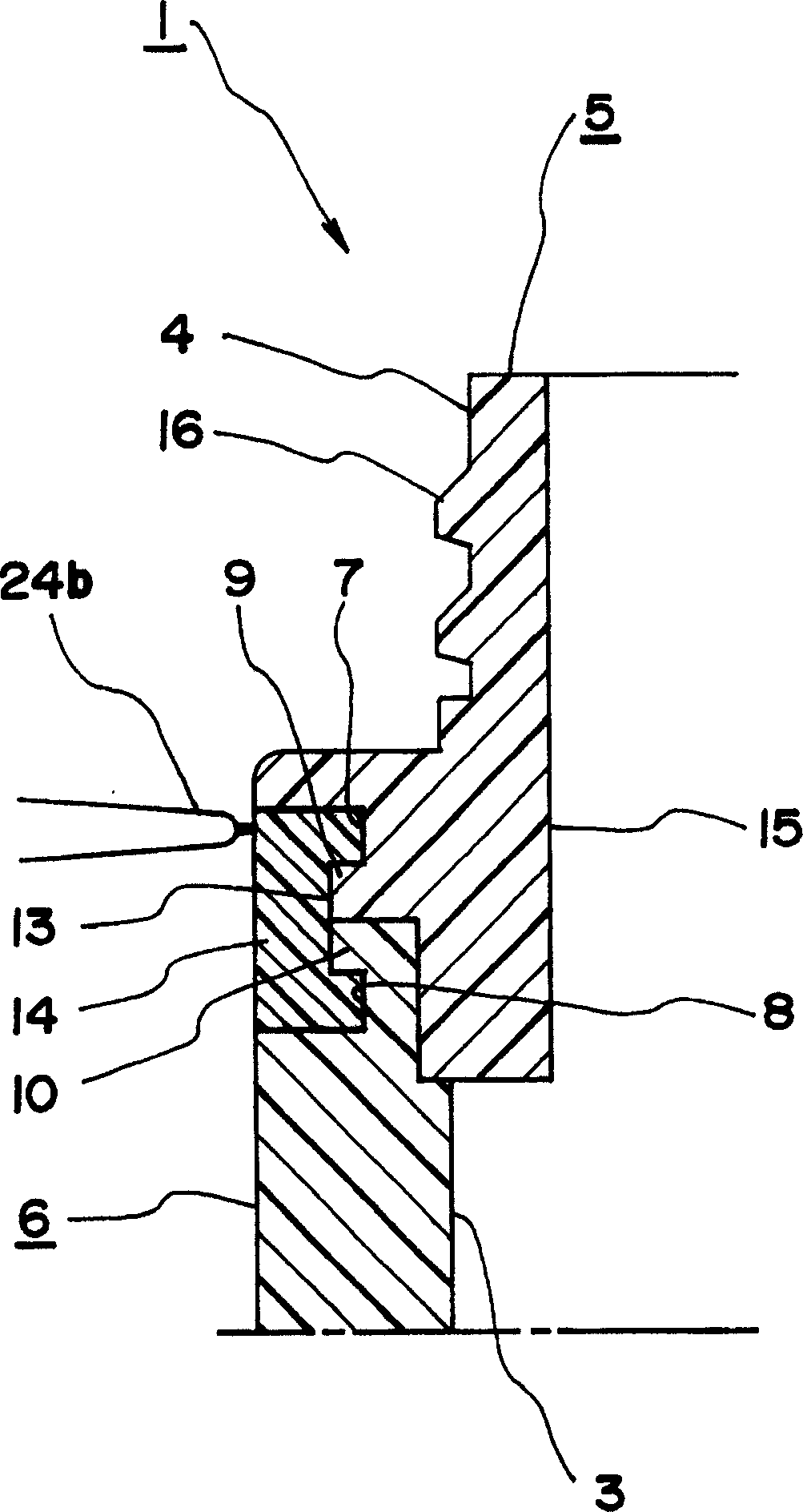

[0015] Such as figure 1 with figure 2 As shown, a bottle-shaped container 1 made of polyethylene terephthalate (hereinafter referred to as PET) includes a cylinder 3 having a bottom 2 and a cylinder neck 4 having a smaller diameter than the cylinder 3 . At the upper end of said barrel 3 , the bottle-shaped container 1 is divided vertically into two parts, an upper part 5 and a lower part 6 . Annular grooves 7 and 8 are provided on the outer peripheries of the lower end of the upper part 5 and the upper end of the lower part 6 . The annular groove 7 is composed of the lower end ring 11 of the upper part 5 and the hook-shaped ring protrusion 9 that is arranged on the lower surface of the lower end ring 11 and is bent outward. The annular groove 8 is formed by the upper end shoulder 12 of the lower part 6 and the A hook-shaped ring protrusion 10 is formed on the upper surface of the upper shoulder 12 and is bent outward. Said respective ring projections 9 and 10 form the boun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com