Compaction device preventing odor emission for solid waste treatment

A garbage disposal and compaction device technology, which is applied in grain processing, presses, solid waste removal, etc., can solve the problems of inconvenient garbage placement, different volumes, and inconvenient quick removal, etc., to achieve safe and convenient use, reduce pollution, Guarantee the effect of water filtration and recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

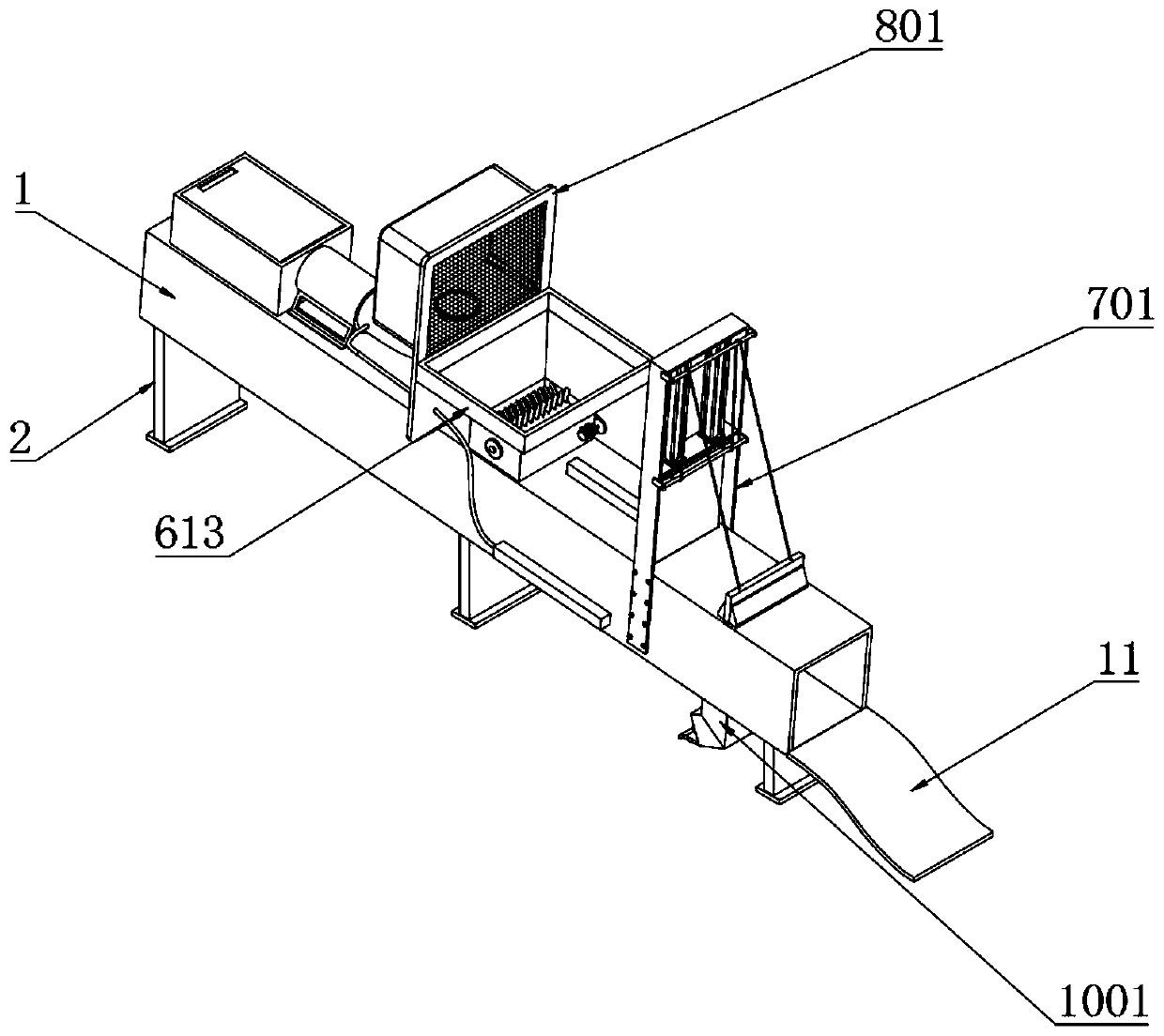

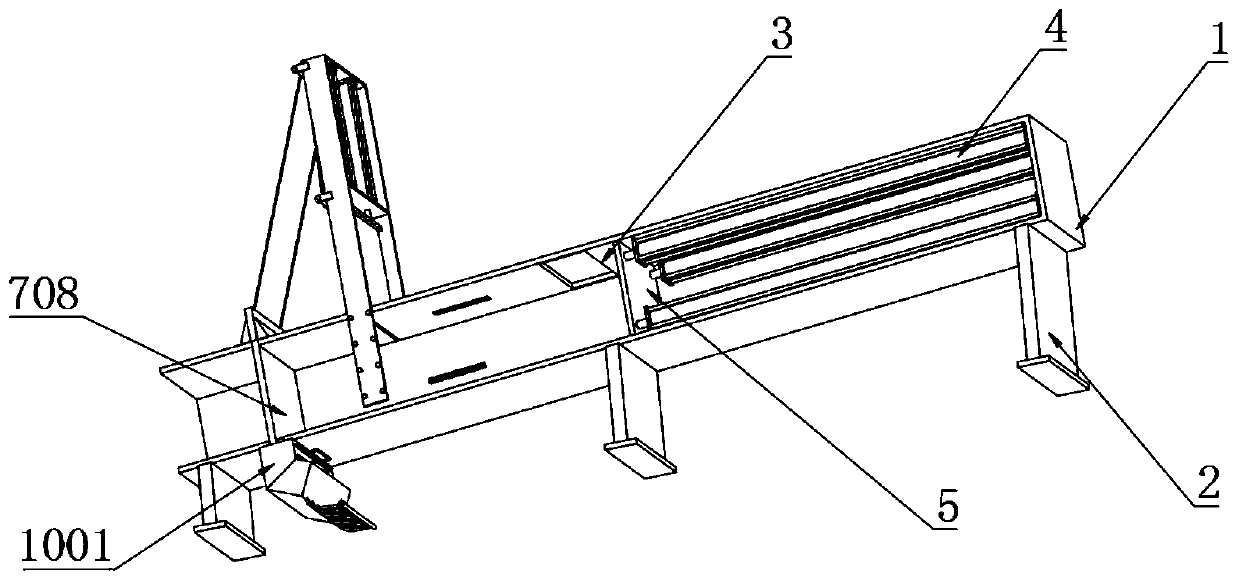

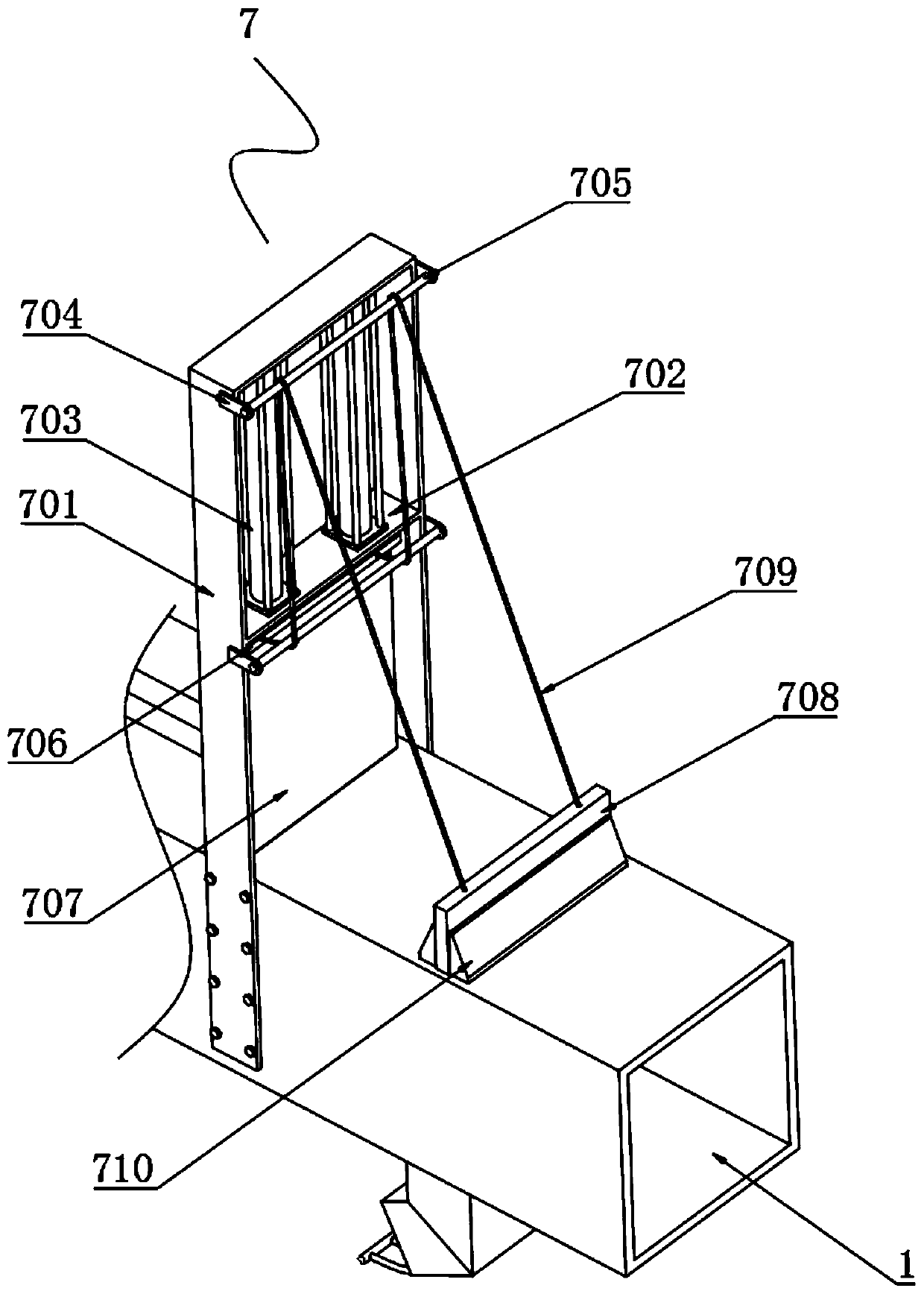

[0057] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a compacting device for solid waste treatment that prevents odor from emitting, including a compacting cylinder 1, which is installed on the ground through a support frame 2, and the middle part of the top of the compacting cylinder 1 is There is a feed port 3 through it, and a compaction hydraulic cylinder 4 is installed at each corner of one end of the compaction cylinder 1. The ends of the hydraulic rods of the four compaction hydraulic cylinders 4 are welded with a compaction plate 5 and a support frame 2. There are three and the height ratio is three to two to one. The highest support frame 2 is located under the compaction hydraulic cylinder 4, and the bottom end of the compaction cylinder 1 located at the lowest support frame 2 is welded with a guide plate 11 to ensure that after being cut The solid waste block can slide out stably.

[0058] The other end of the compactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com