LED bulb

A technology of LED light bulbs and LED light sources, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., and can solve problems such as opacity, poor luminous effect, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

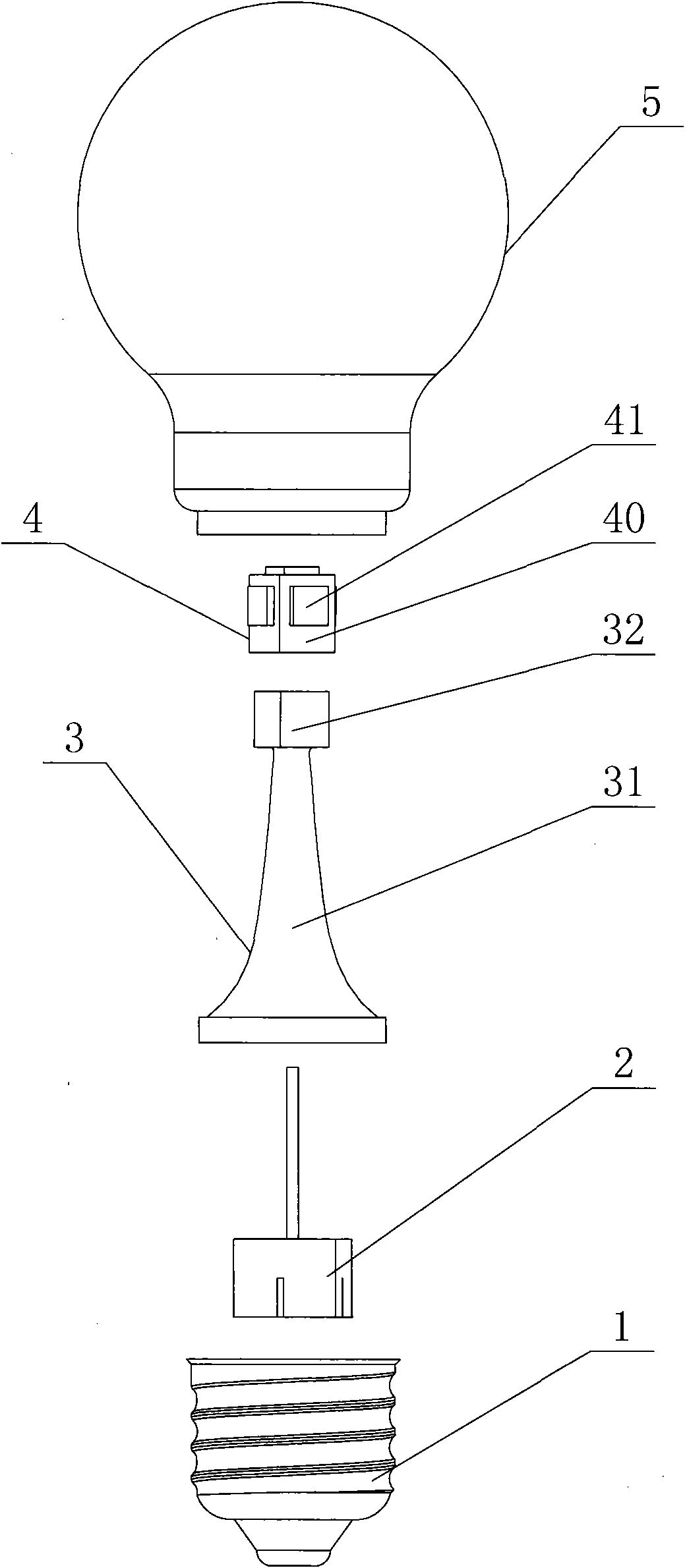

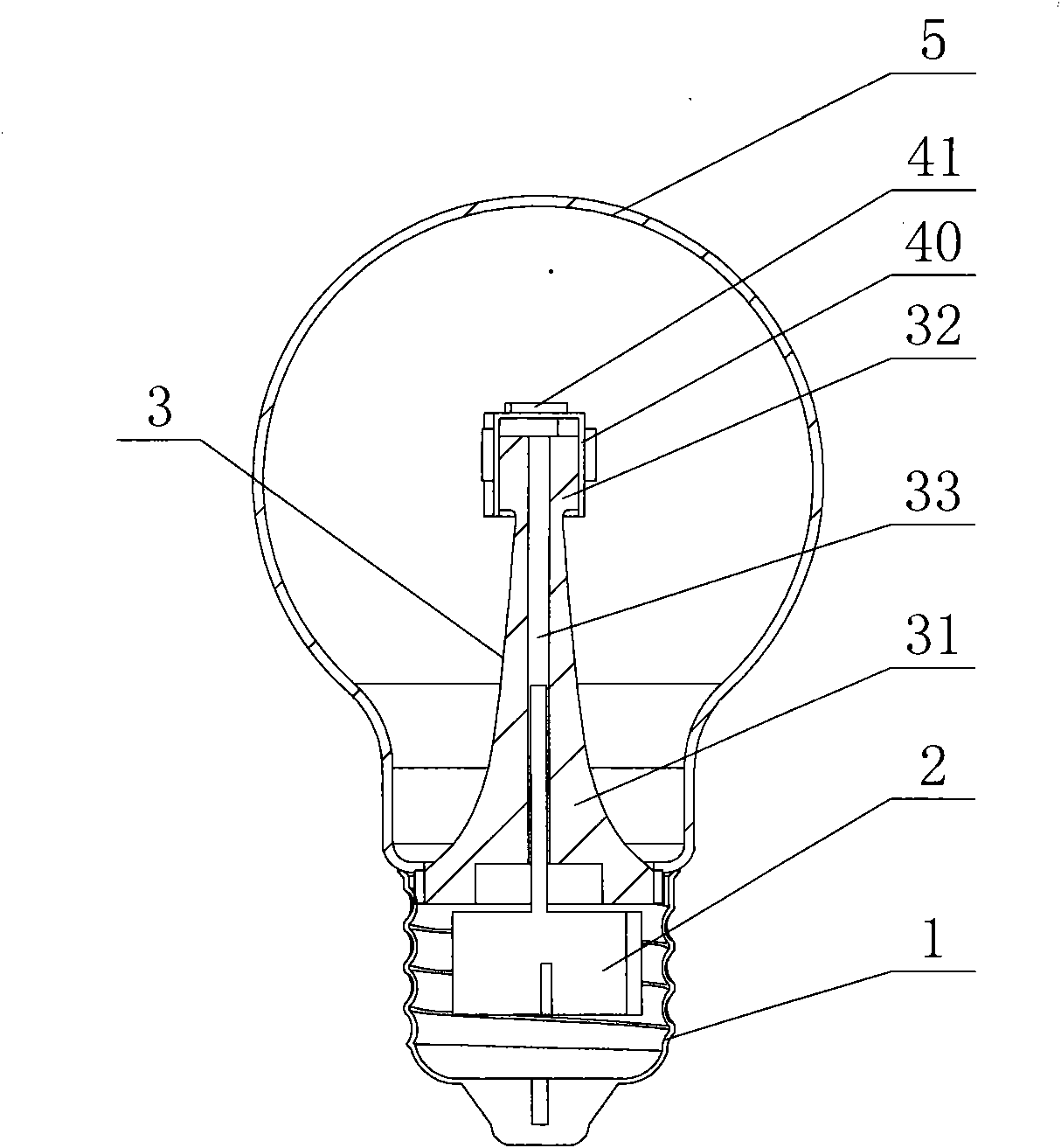

[0029] Such as figure 1 , figure 2 As shown, the LED light bulb of this embodiment includes a lamp cap 1, a drive circuit assembly 2, a light source bracket 3, an LED light source 4, and a bulb shell 5. The bulb shell 5 is pear-shaped, and the tail of the bulb shell 5 is connected to the lamp cap. 1 phase is fixedly connected, the drive circuit assembly 2 is located in the lamp holder 1, the bulb 5 surrounds the LED light source 4 and the light source bracket 3 in the inner cavity, and the model of the lamp holder 1 is E27, of course It can also be other models such as E26 or E14 or E12 or GU10 or GU5.3 or B22. The bulb shell 5 is made of plastic and has an integrated structure. Of course, it can also be made of glass. The bulb shell 5 is completely transparent. It can also be partly transparent. The light source support 3 includes a base 31 and a polyhedron 32. The light source support 3 is made of aluminum, which has a good appearance and good thermal conductivity. Of cour...

Embodiment 2

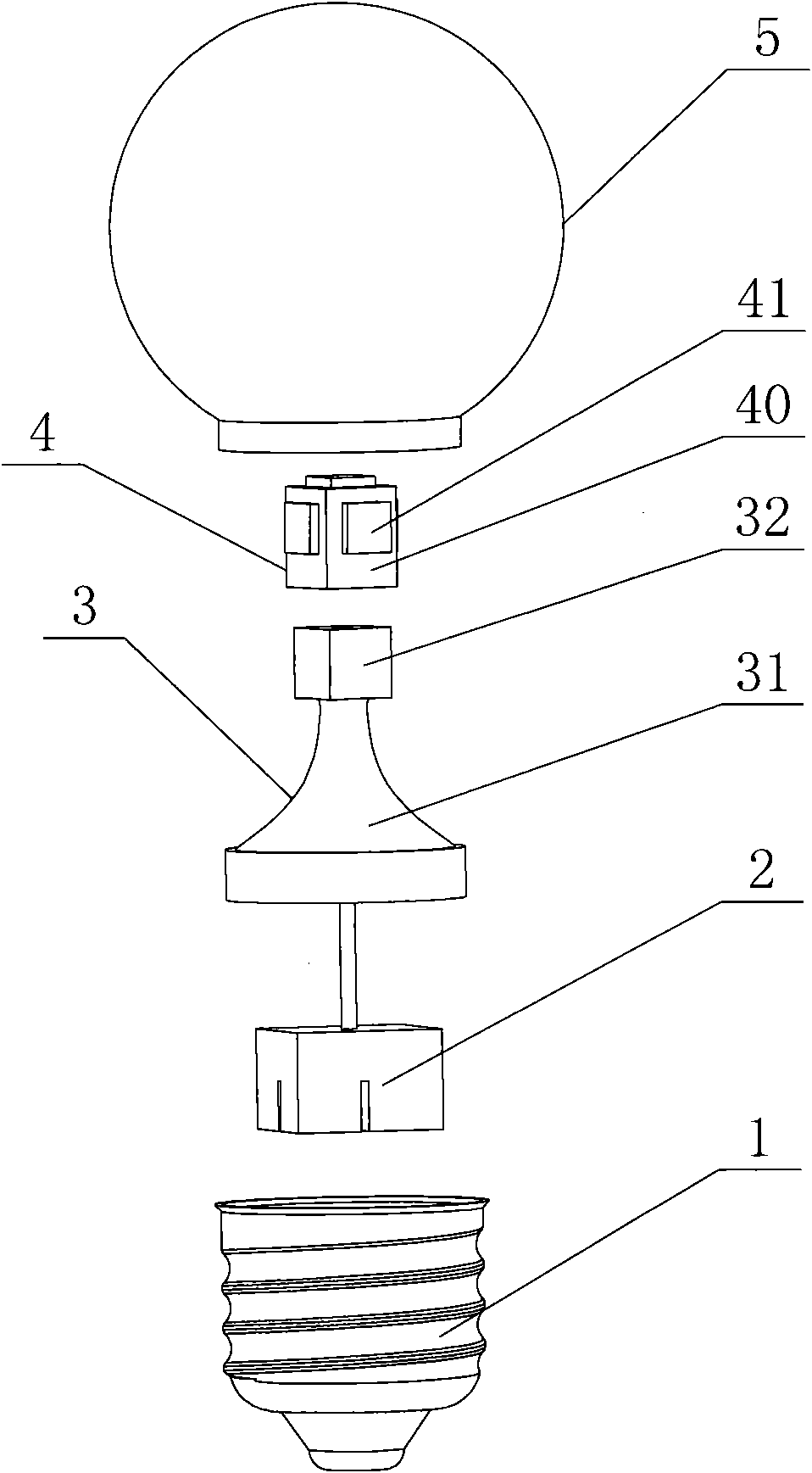

[0031] Such as image 3 , Figure 4As shown, the difference between the present embodiment and the first embodiment is that: the bulb 5 of the present embodiment is spherical and has a smaller volume, which is the same as the shape of an existing incandescent light bulb with less power.

[0032] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0034] Such as Figure 5 , Figure 6 As shown, the difference between the present embodiment and the first embodiment is that the bulb shell 5 of the present embodiment is in the shape of a candle, which is the same as the shape of the existing elongated candle light bulb.

[0035] The remaining features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com