Automatic calorimeter for caloric analysis of sample

A calorimeter and calorific value technology, applied in the thermal development of materials, chemical instruments and methods, dissolution and other directions, can solve the problems of inconsistent oxygen bomb volume, affecting the test accuracy, affecting the constant volume accuracy, etc., to ensure the accuracy of test analysis, High precision of test analysis and guaranteed effect of constant volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

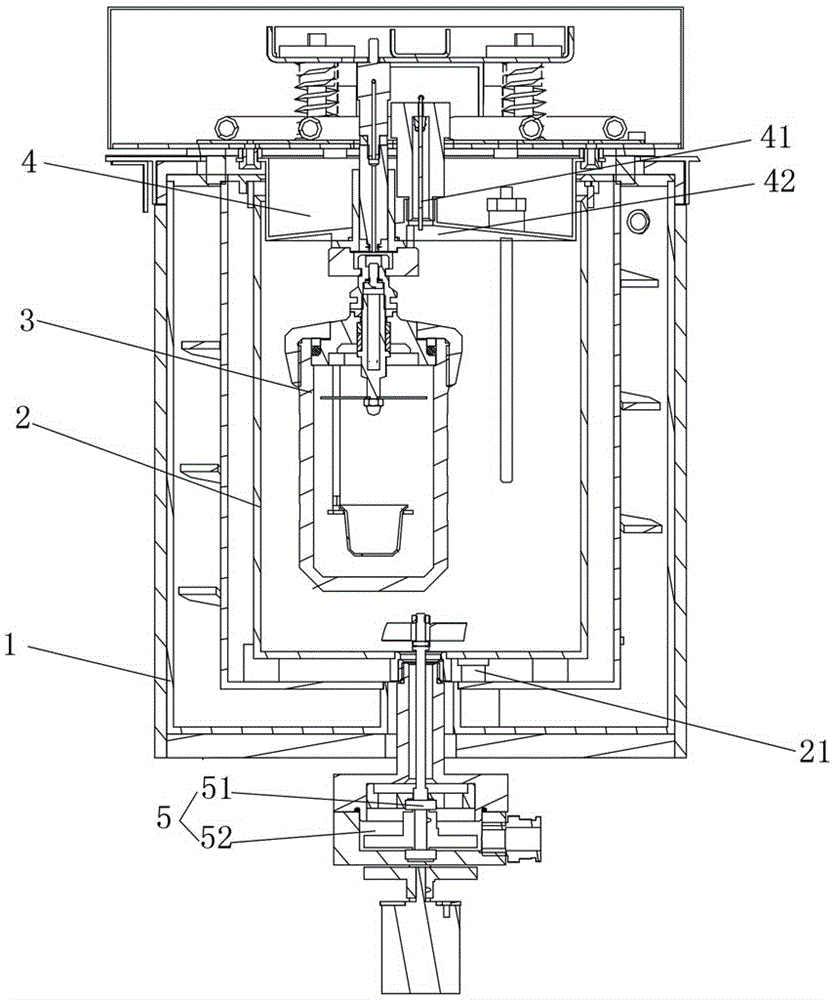

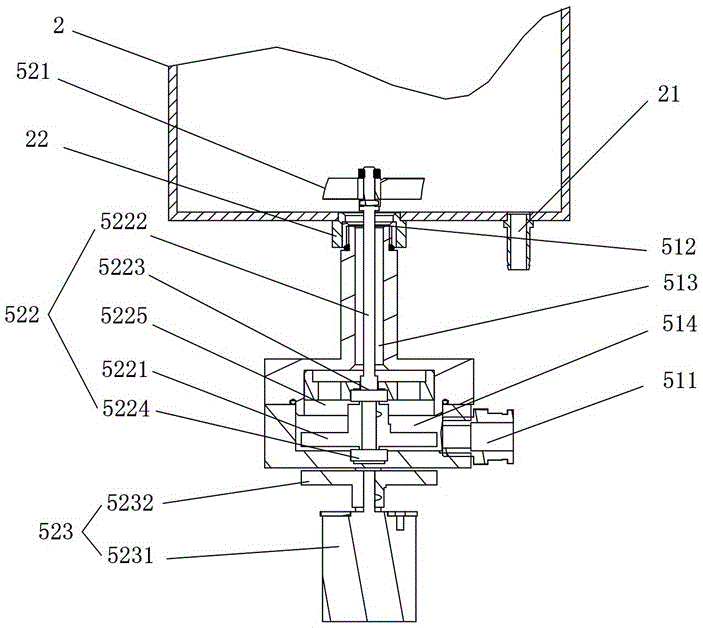

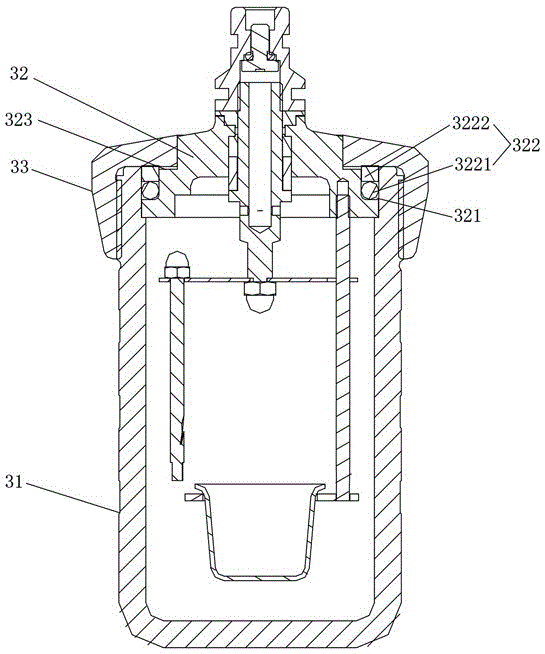

[0035] like Figure 1 to Figure 3 As shown, the present invention provides an automatic calorimeter for analyzing the calorific value of samples, comprising an outer barrel 1, an inner barrel 2, and an oxygen bomb 3, the oxygen bomb 3 is arranged in the inner barrel 2, and the inner barrel 2 is arranged in the outer barrel 1, The outer side of the outer barrel 1 is provided with a water supply stirring mechanism 5 for supplying and stirring water into the inner barrel 2. The water supply stirring mechanism 5 includes a water passage chamber 51 and a magnetic stirring assembly 52. One end of the water passage chamber 51 is provided with a water inlet 511 for It communicates with external water supply equipment, and the other end of the water passage chamber 51 is provided with a water outlet 512 for communicating with the inner barrel 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com