Pneumatic type multi-glue-barrel dispensing mechanism and dispensing method thereof

A dispensing mechanism, pneumatic technology, applied in the coating, the device for coating liquid on the surface, etc., can solve the problem of affecting the size and thickness of the solder paste, affecting the dispensing accuracy, and inconsistent glue volume, etc., to improve the dispensing Motion accuracy, reducing space occupied area, and ensuring the effect of dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: the concrete structure of the present invention is as follows:

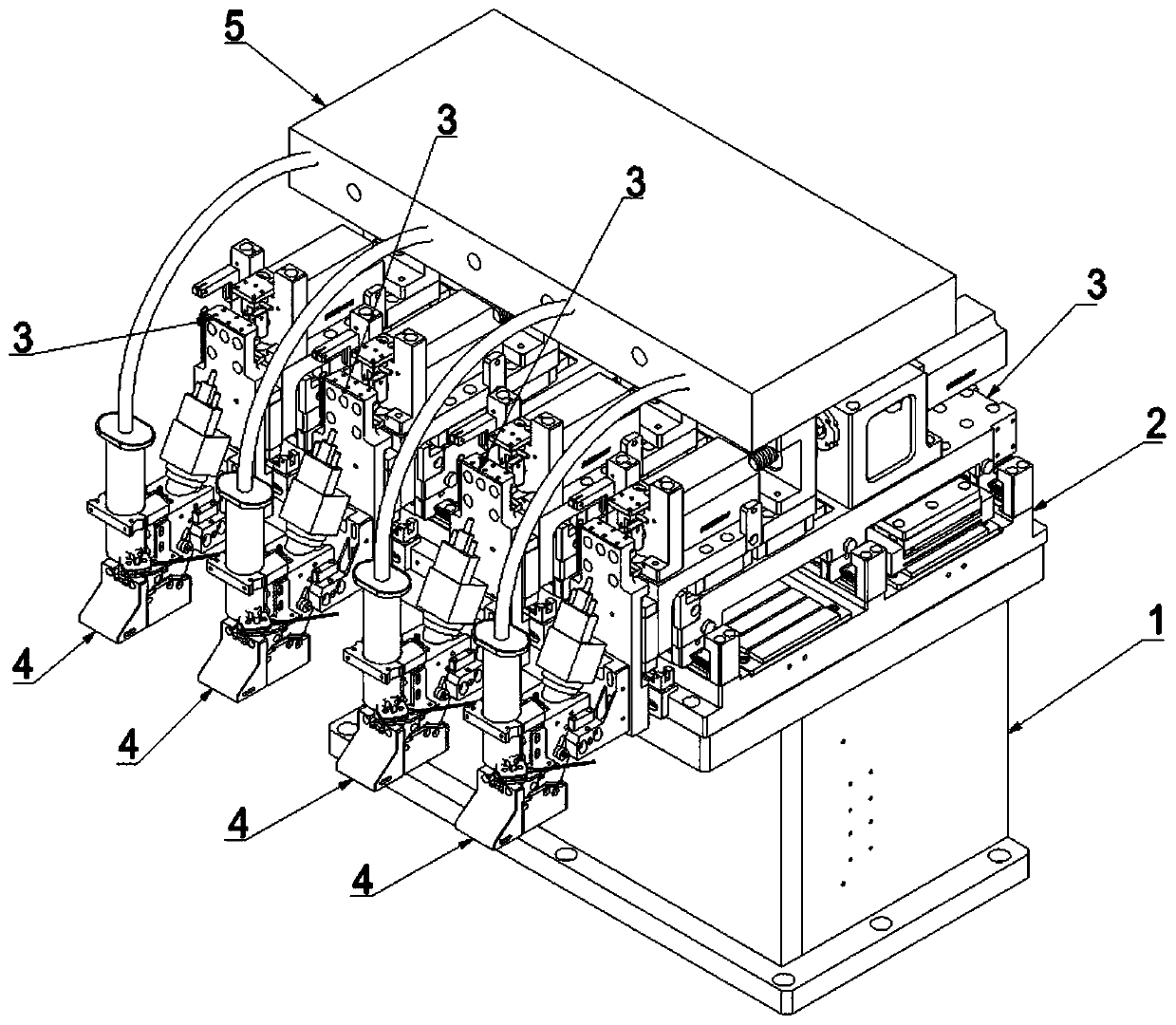

[0053] Please refer to the attached Figure 1-6 , a pneumatic multiple glue cartridge dispensing mechanism of the present invention, the dispensing mechanism includes:

[0054] Column platform 1;

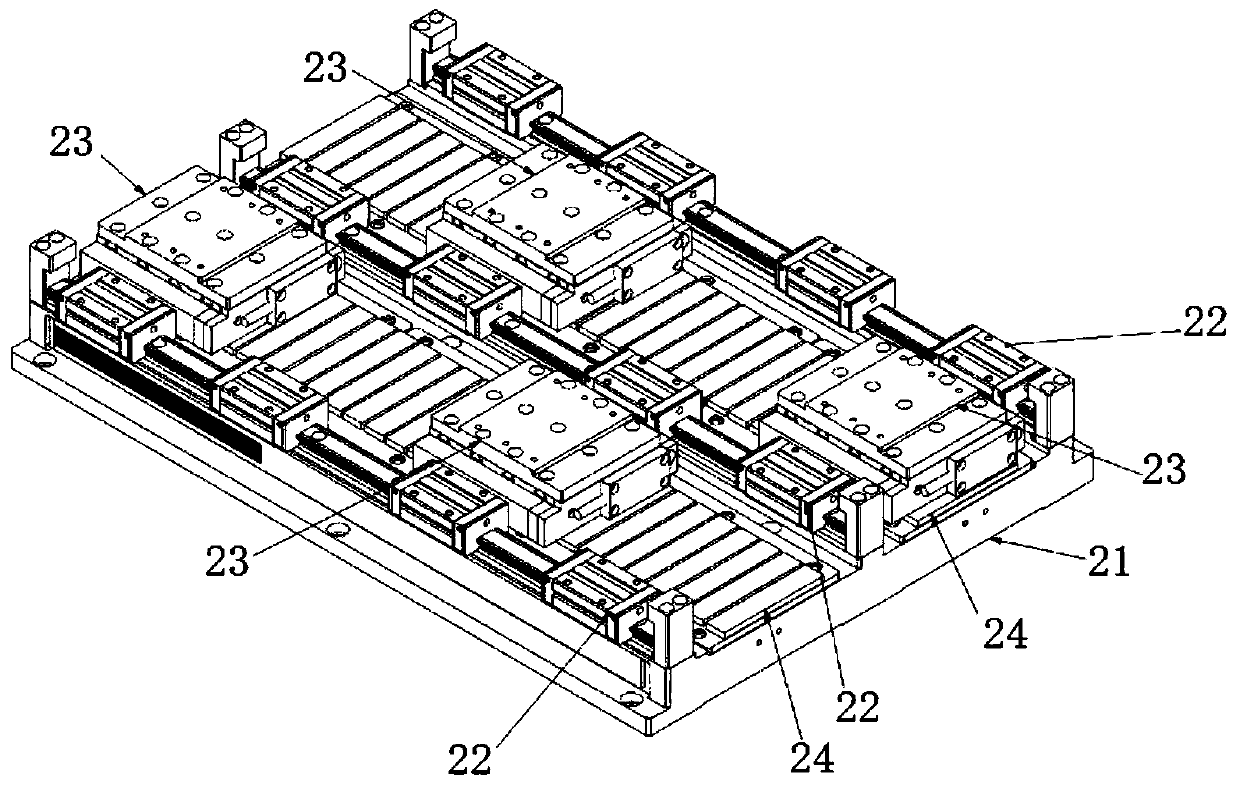

[0055] Multiple sets of linear drive components 2 installed on the top of the column platform 1 and arranged horizontally;

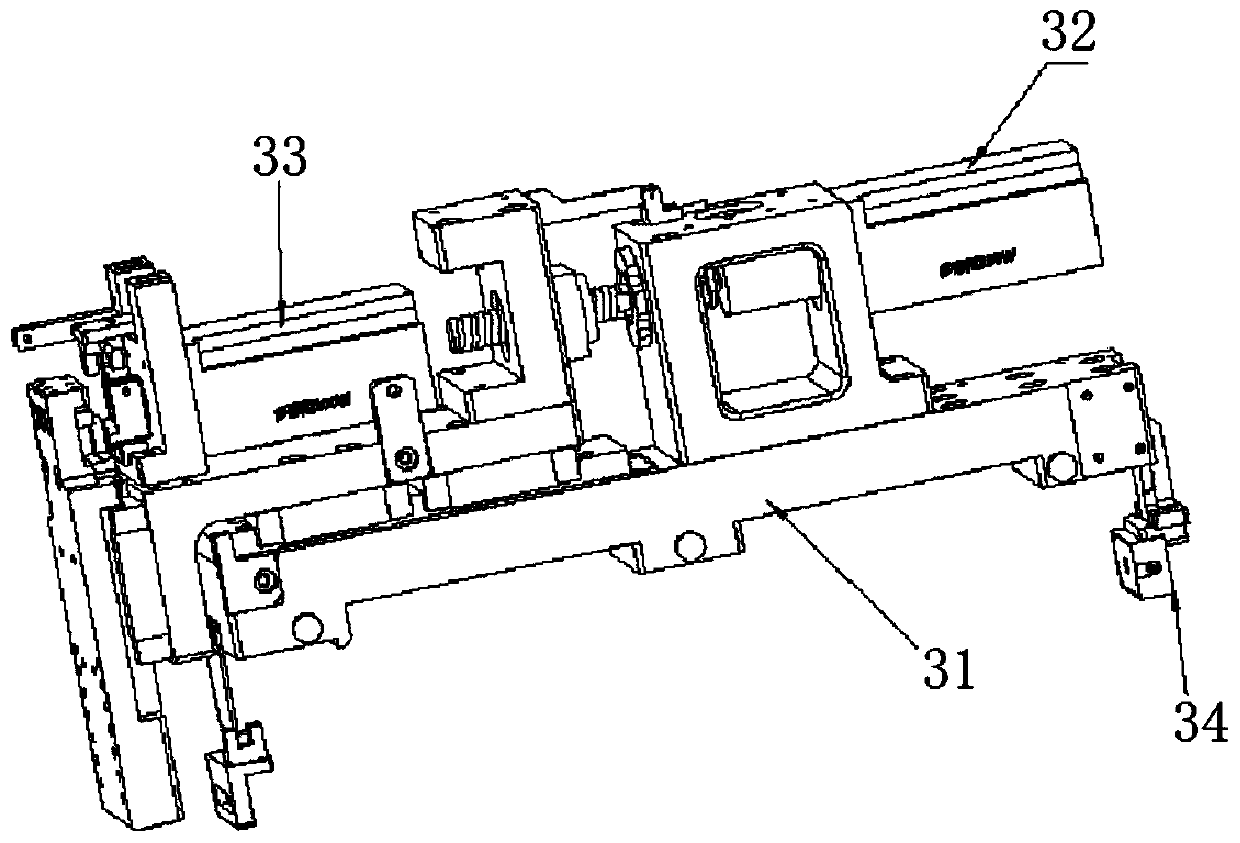

[0056] Multiple groups of dispensing units 3 are installed on the movable part of the linear drive assembly 2 and are driven by the linear drive assembly 2 to move in the X-axis;

[0057] The dispensing manipulator 4 is installed on the front end of the dispensing unit 3 and can be driven by the dispensing unit 3 to perform lifting motion and Y-axis movement. The dispensing manipulator 4 is provided with upper and lower contacts and a dispensing head , the dispensing manipulator 4 transmits electrical signals by closing and disconnecting the upper and lower contacts, and t...

Embodiment 2

[0081] A dispensing method of a pneumatic multiple glue cartridge dispensing mechanism, the method comprising the following steps:

[0082] Step 1, at first, the dispensing manipulator 4 is driven by the system of the left and right linear drive components 2 and the dispensing unit 3, so that each dispensing manipulator 4 reaches directly above the desired dispensing support;

[0083] Step 2, then, the camera lens assembly 42 in the glue dispensing manipulator 4 takes pictures of the bracket to identify, and the camera lens assembly 42 assists the system to drive the bracket to move to the collagen dispensing point;

[0084] Step 3, then, the dispensing control box 5 controls the solenoid valve to apply pressure to the rubber cartridge, and the system drives the dispensing manipulator 4 to move downward to dispens the bracket;

[0085] Step 4. Finally, the dispensing area of each dispensing manipulator 4 is determined through system programming, and multiple dispensing manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com