Full-automatic fungus bag production line for edible fungi

An edible fungus and production line technology, which is applied in packaging, multiple packages, transportation and packaging, etc., can solve the problems affecting the production quality and yield of edible fungi, different tightness of manual packaging and bagging, and high labor costs, and achieve design Ingenious, low-cost, labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

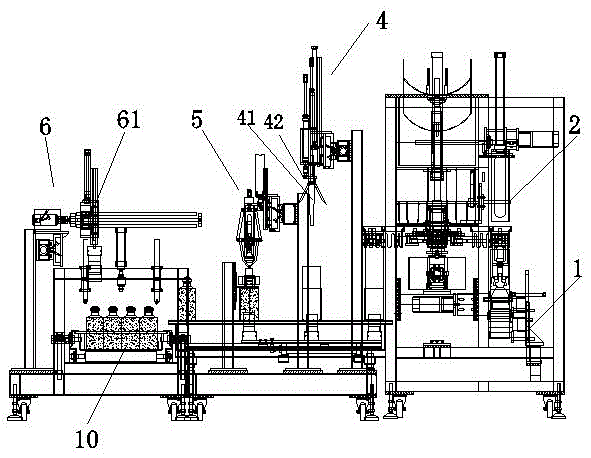

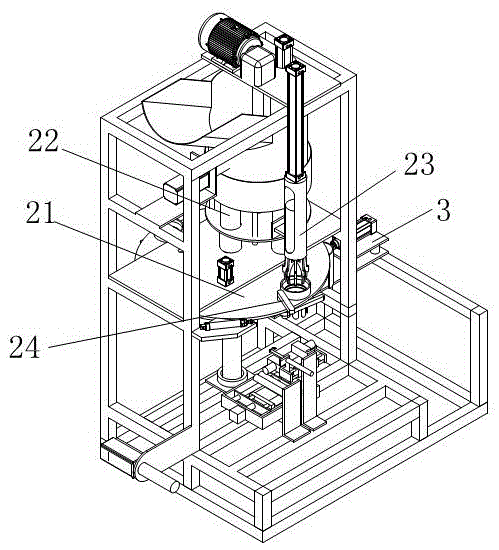

[0041] Refer to attached Figure 1~9 , this fully automatic edible fungi package production line of the present invention includes a bag feeding device 1 , a bag making device 2 , a forming device 3 , a collar device 4 , a capping device 5 and a basket loading device 6 .

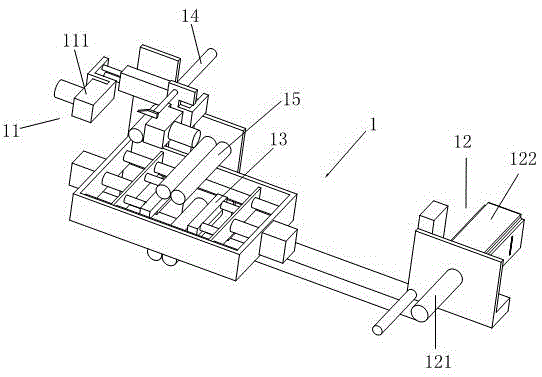

[0042] The bag feeding device 1 includes a bag opening mechanism 11 for opening the mouth of the bag, a bag releasing mechanism 12, a sealing mechanism 13 for sealing the bottom of the bag, a cutting mechanism 14 for cutting bag rolls; the sealing mechanism 13 and the cutting mechanism Guide mechanism 15 is provided between 14. The bag unwinding mechanism 12 includes a bag roll fixed shaft 121 and an unwinding motor 122 . The bag opening mechanism 11 comprises a pair of fixed blocks 111 that are arranged oppositely. Suction nozzles are also arranged on the opposite faces of the two fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com