A capacitor forming machine

A molding machine and capacitor technology, applied in the field of capacitor molding machines, can solve the problems of cost, difficulty in quality assurance, and the inability of capacitors to be inserted into circuit boards, so as to reduce costs, improve efficiency, and improve product consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

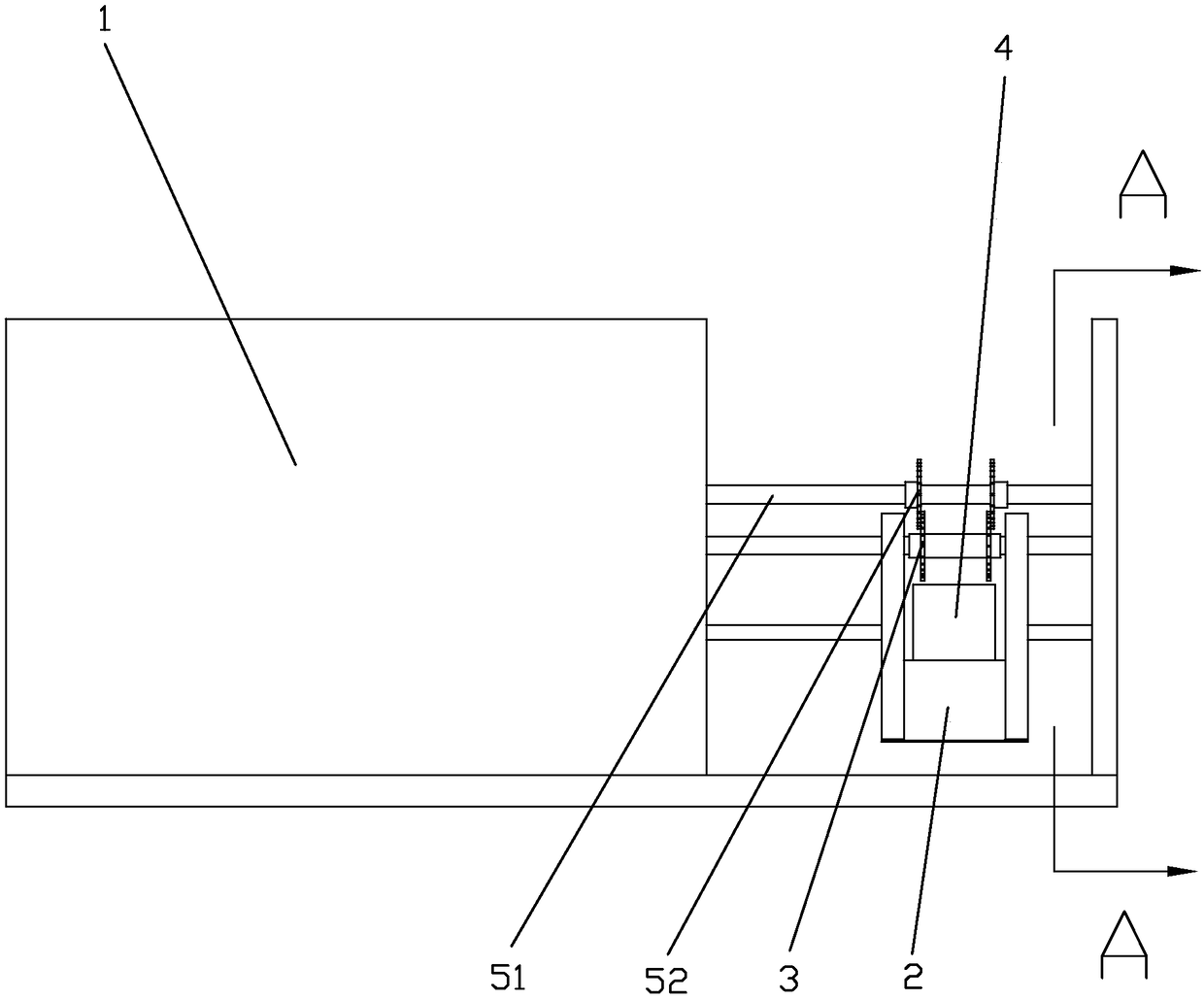

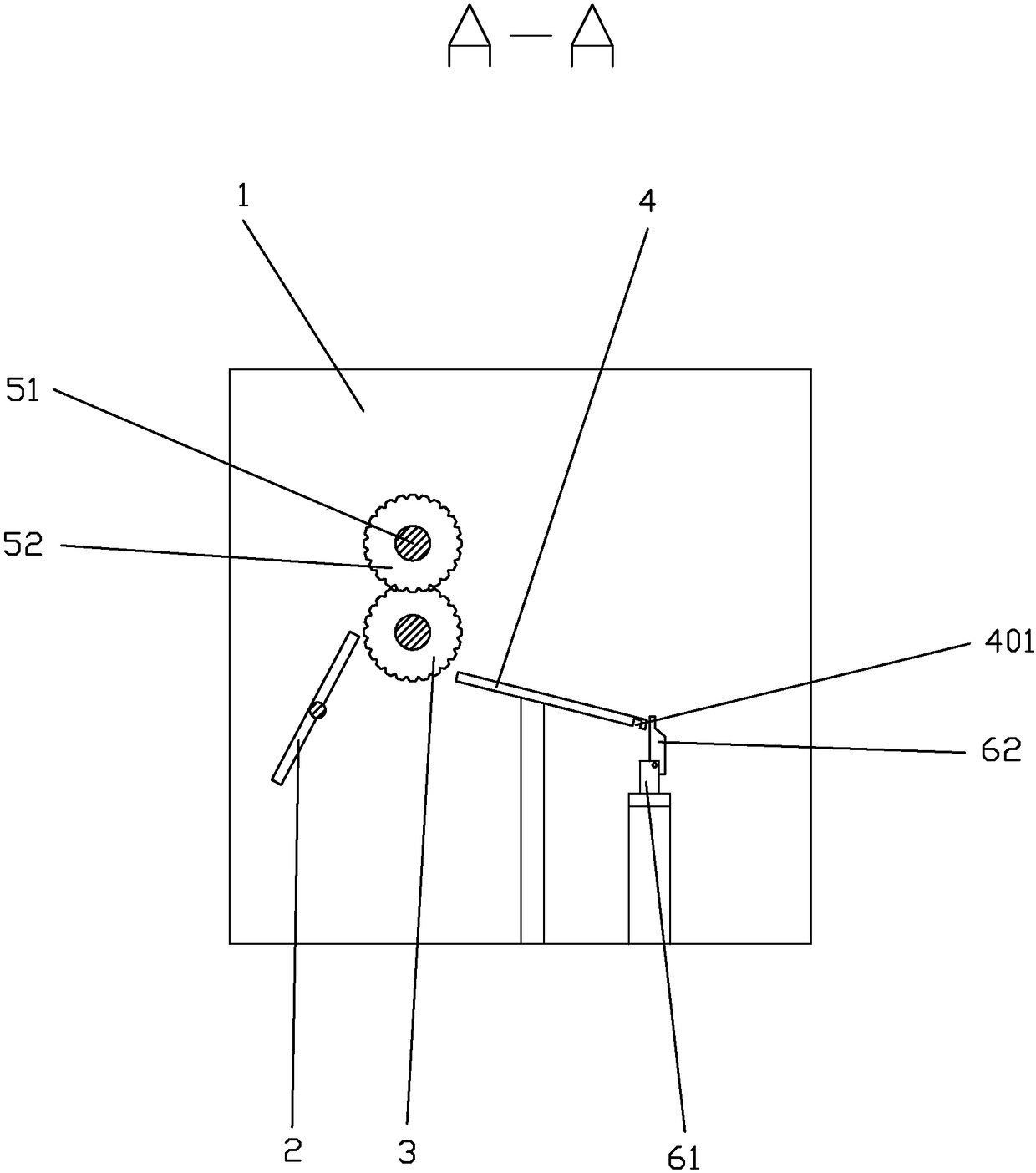

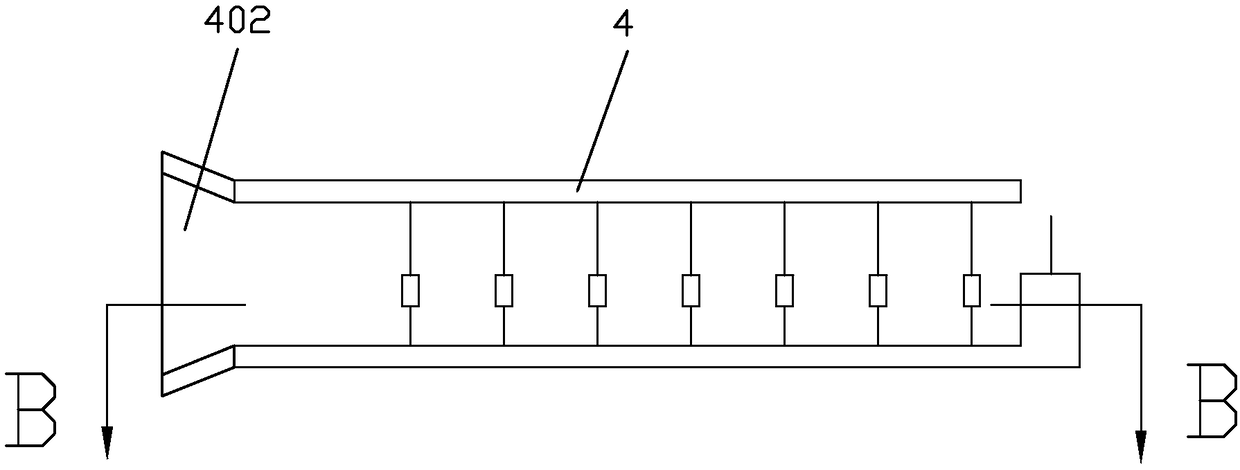

[0019] refer to Figure 1~Figure 4 , a capacitor forming machine, including a main machine 1, a conveying guide rail 2, a cutter device, a first conveying gear 3, a rear conveying guide rail 4 and a bending forming device, the rear end of the conveying guide rail 2 is close to the first conveying gear 3 , the conveying guide rail 2 is provided with a slot consistent with the width of the capacitor row, the tooth pitch of the first conveying gear 3 is consistent with the interval of the capacitor in the capacitor row, the cutter device includes a rotating shaft 51 and is installed on the rotating shaft 51 Two shearing gears 52, the two shearing gears 52 separate the two sides of the first conveying gear 3 and close to the first conveying gear 3, the size of the shearing gear 52 and the first conveying gear 3, the number of teeth The same and rotate in different directions, the shearing gear 52 is tangent to the dedendum circle of the first conveying gear 3; the rear conveying g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com