Fully-automatic mixed-color brick face material stirring station

A fully automatic, mixing station technology, used in mixing plants, mixer accessories, mixers, etc., can solve the problems of cumbersome manufacturing steps, block production and preparation of mixed-color floor tiles, and no research and development of manufacturing processes, and achieve a complete manufacturing process. Automatic, simple and flexible setup, efficient preparation of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

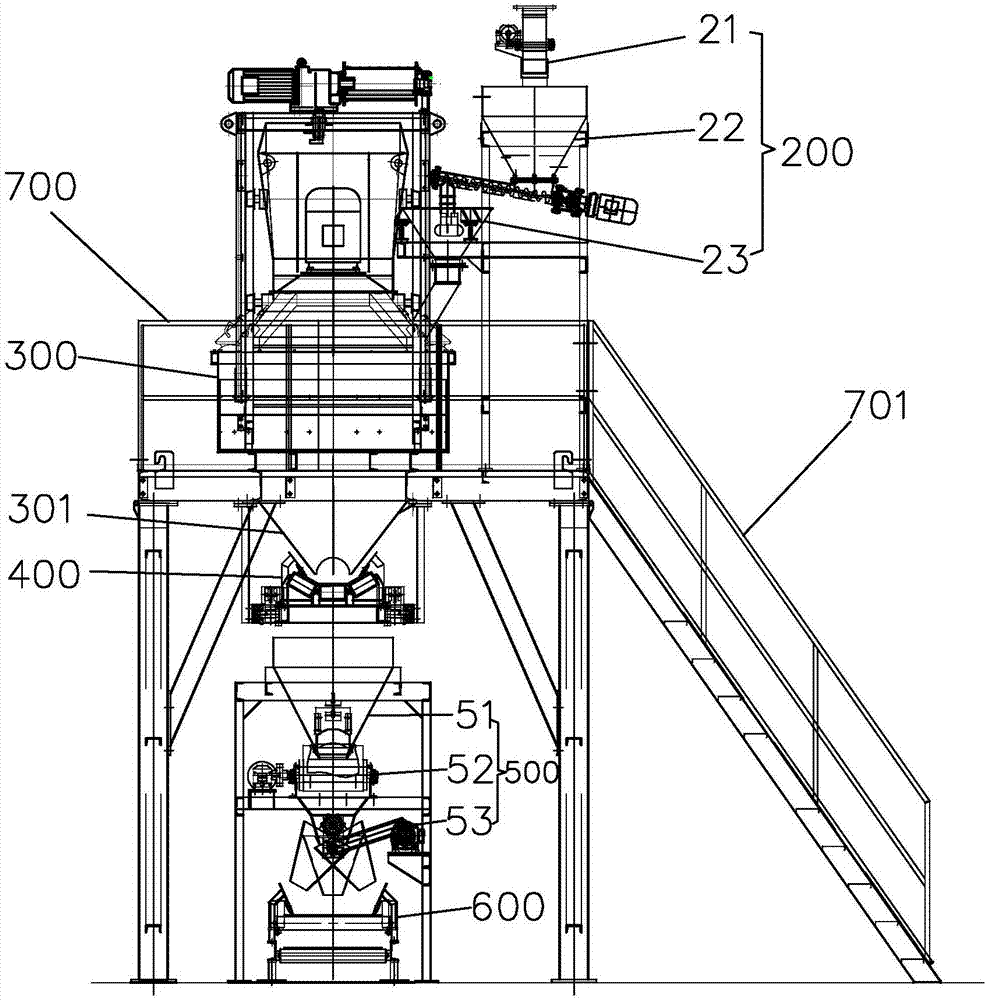

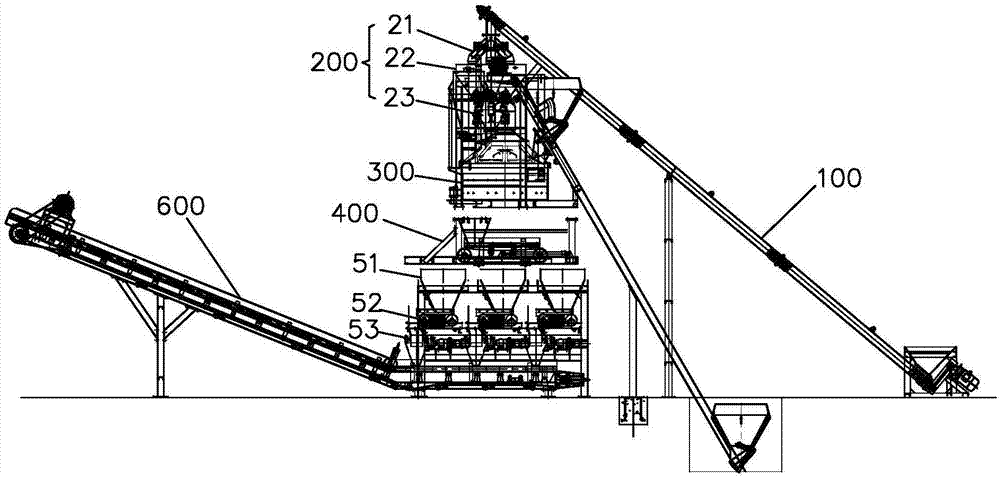

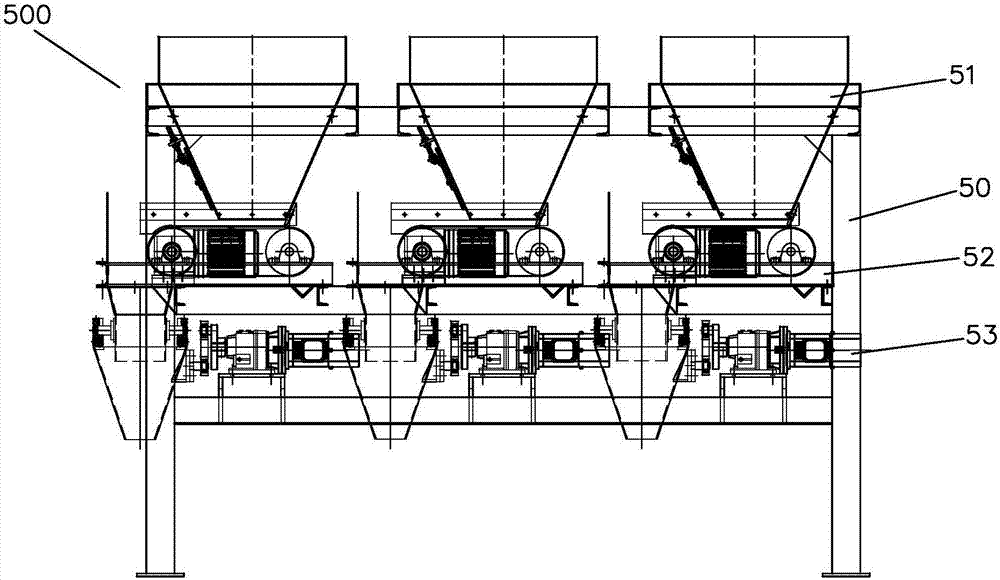

[0093] This case involves a fully automatic mixed color brick fabric mixing station, such as Figure 1-2 As shown, it mainly includes a toner storage and micro metering device 200, a fabric mixing tank device 300, an automatic material distributing device 400, a mixed-color fabric distributing machine 500 and a mixed-color fabric bending belt conveyor 600 arranged up and down in sequence. The toner storage and micrometering device 200 is also connected to a toner conveying device 100 for supplying toner.

[0094] The mixing station is also equipped with a fabric mixing platform 700 that is erected on the periphery of each device and plays a certain role in connecting and supporting the high-level equipment. Help climbing ladder 701.

[0095] The toner storage and micro-metering device 200 includes a digital channel feeding assembly 21 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com