Patents

Literature

267results about How to "Reliable settings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

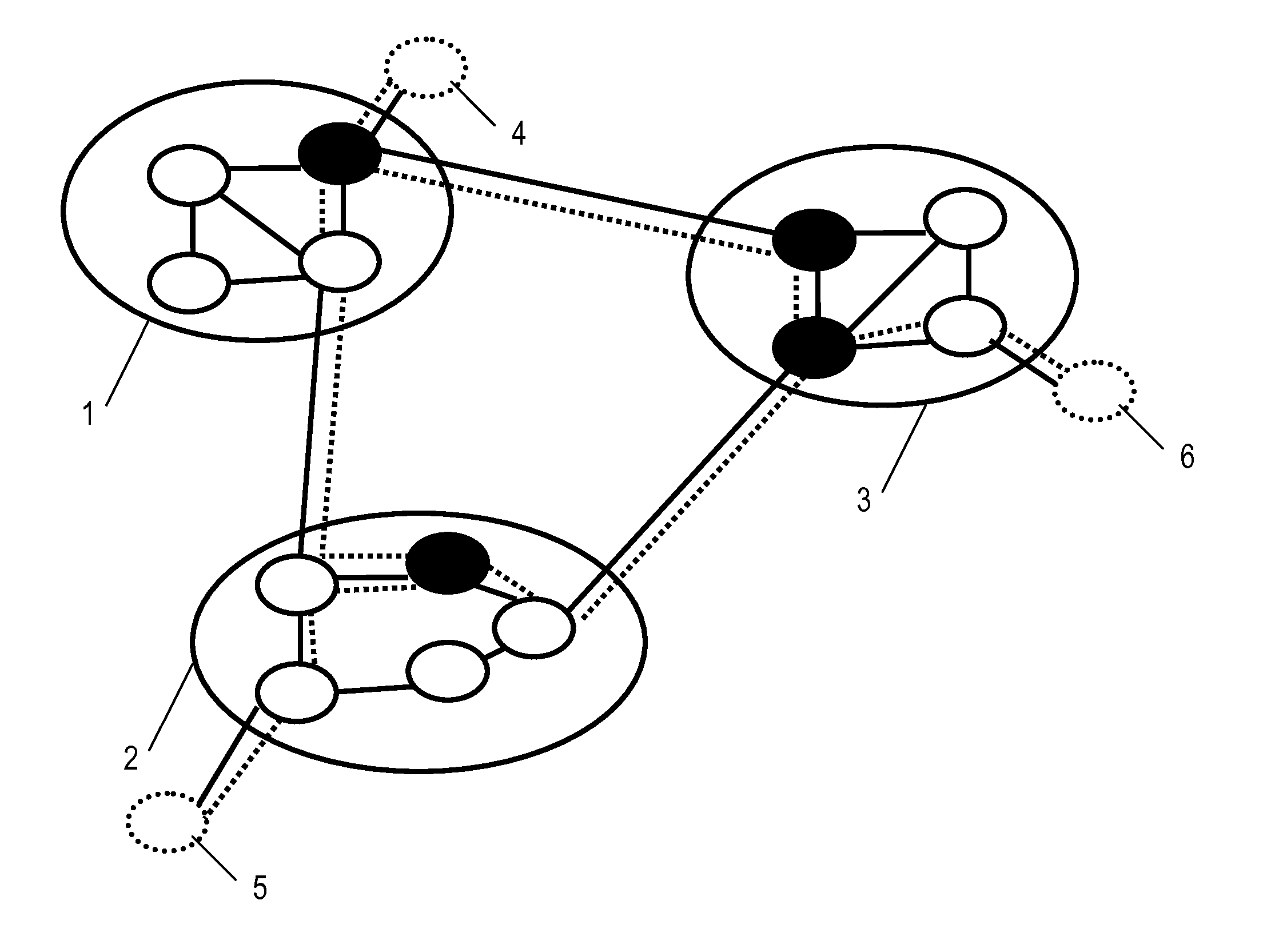

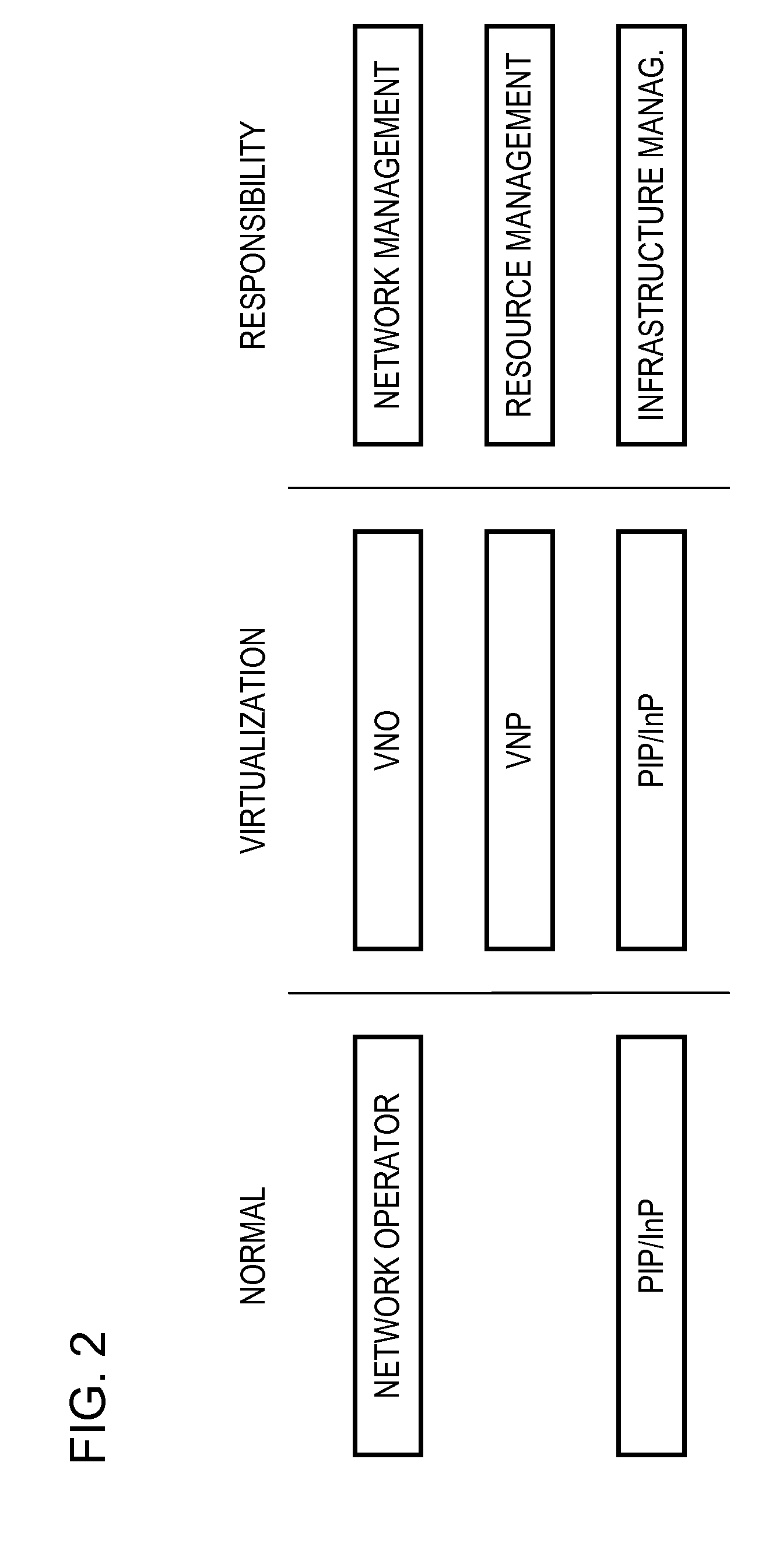

Control mechanism for reliability and availability setting in virtual networks

ActiveUS20130212285A1Improved control mechanismImprove availabilityDigital computer detailsData switching networksE infrastructureResource use

A mechanism for improving a reliability of a virtual network and resources used. At a virtual network operator level, a request for providing resources for the virtual network is sent towards an infrastructure provider level. The request includes an indication regarding a required availability and reliability level which is to be achieved by the resources of the virtual network. At an infrastructure provider level the request is processed in order to determine the required availability and reliability level, and it is checked whether the required availability and reliability level is achievable for the resources to be provided for the virtual network. A result (confirmation or denial) of the check is sent back to the virtual network operator level.

Owner:NOKIA SIEMENS NETWORKS GMBH & CO KG

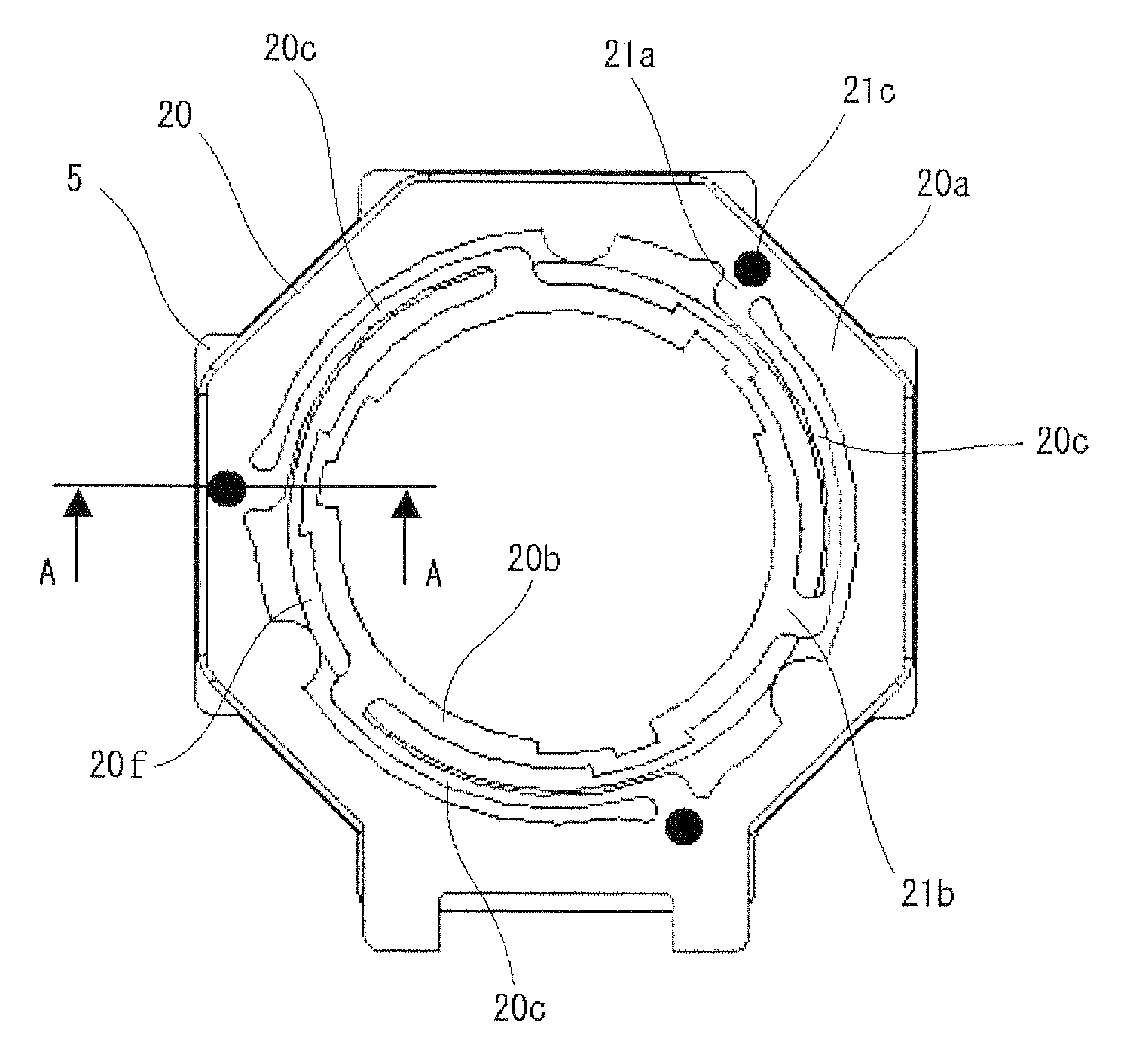

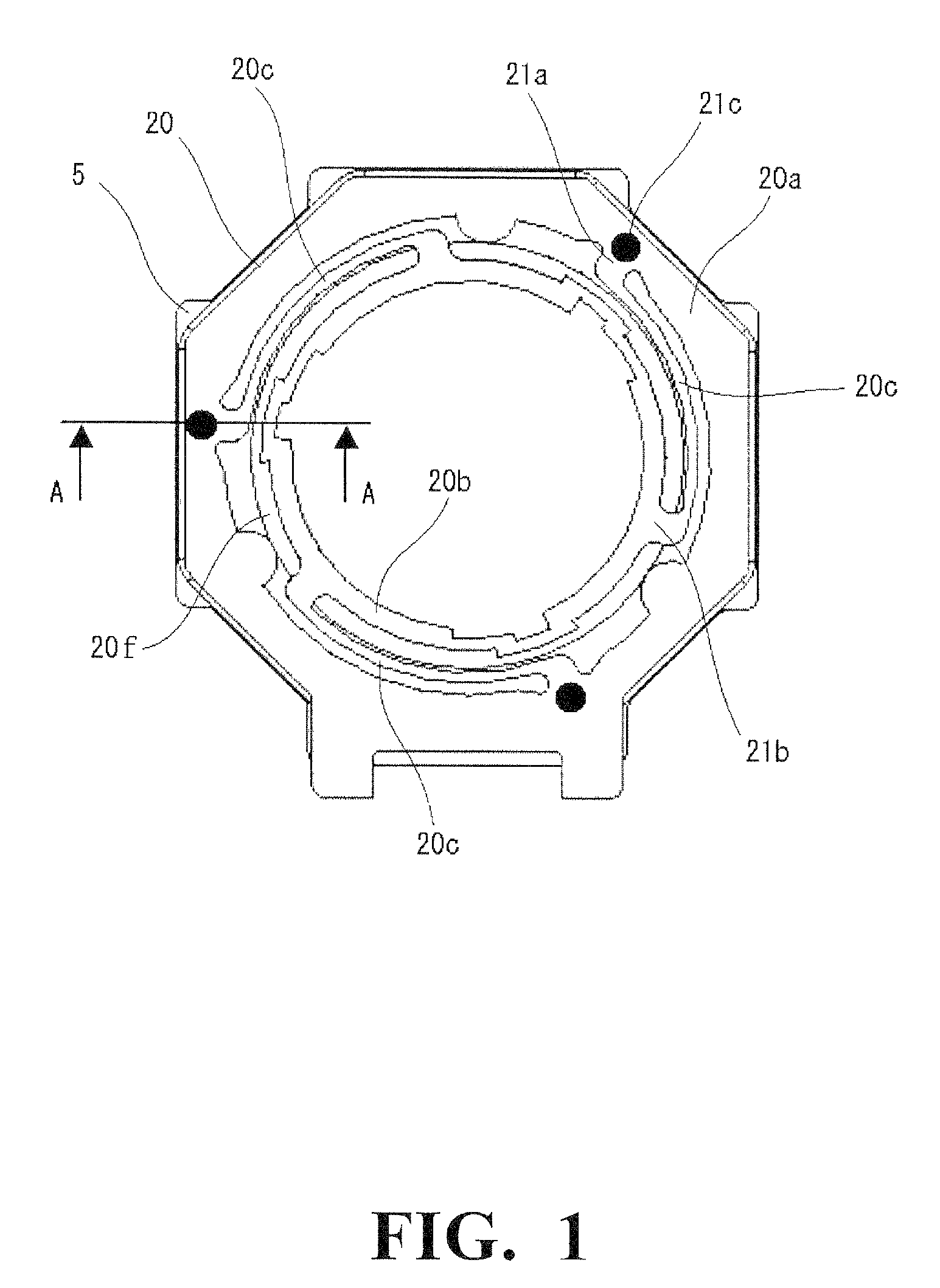

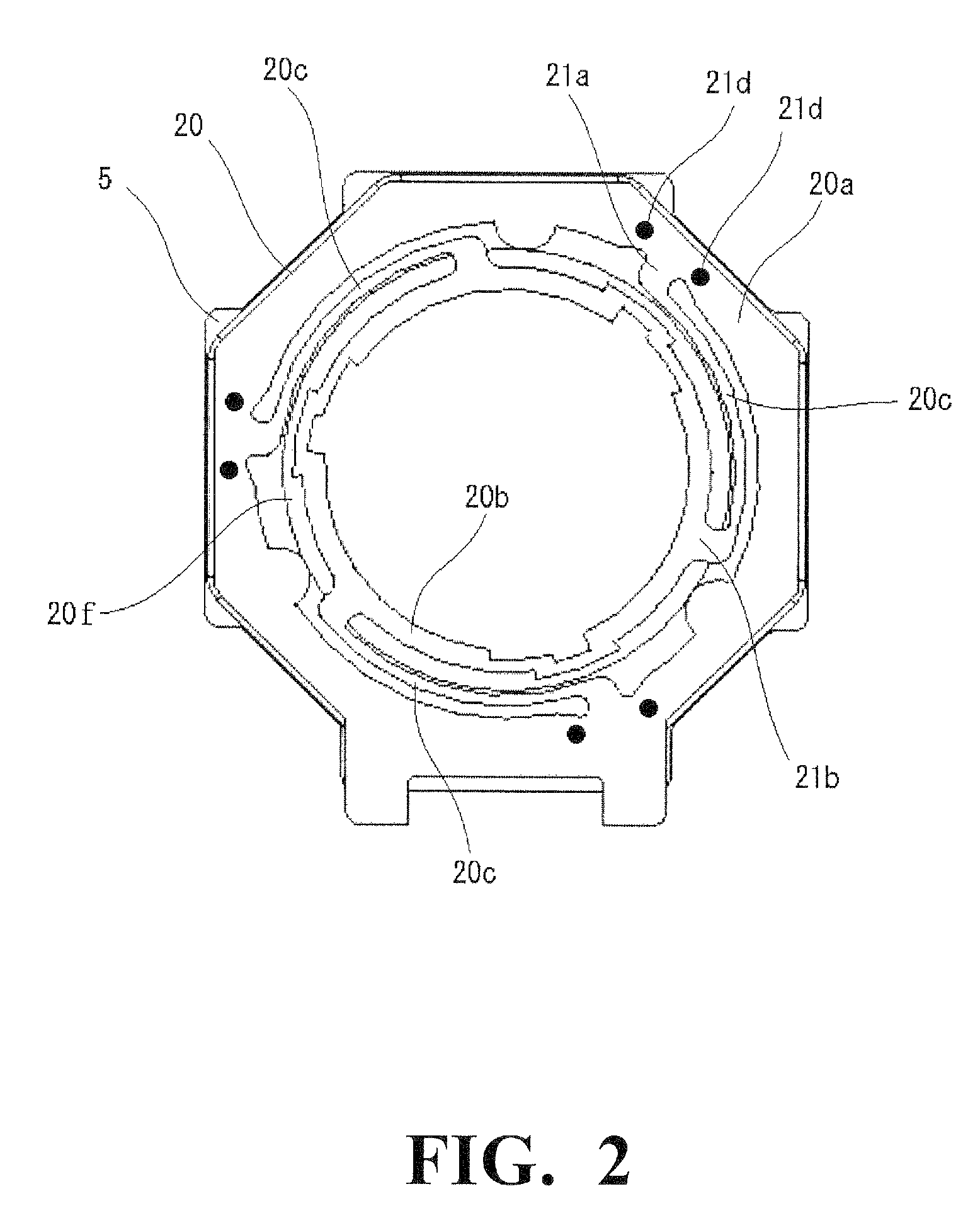

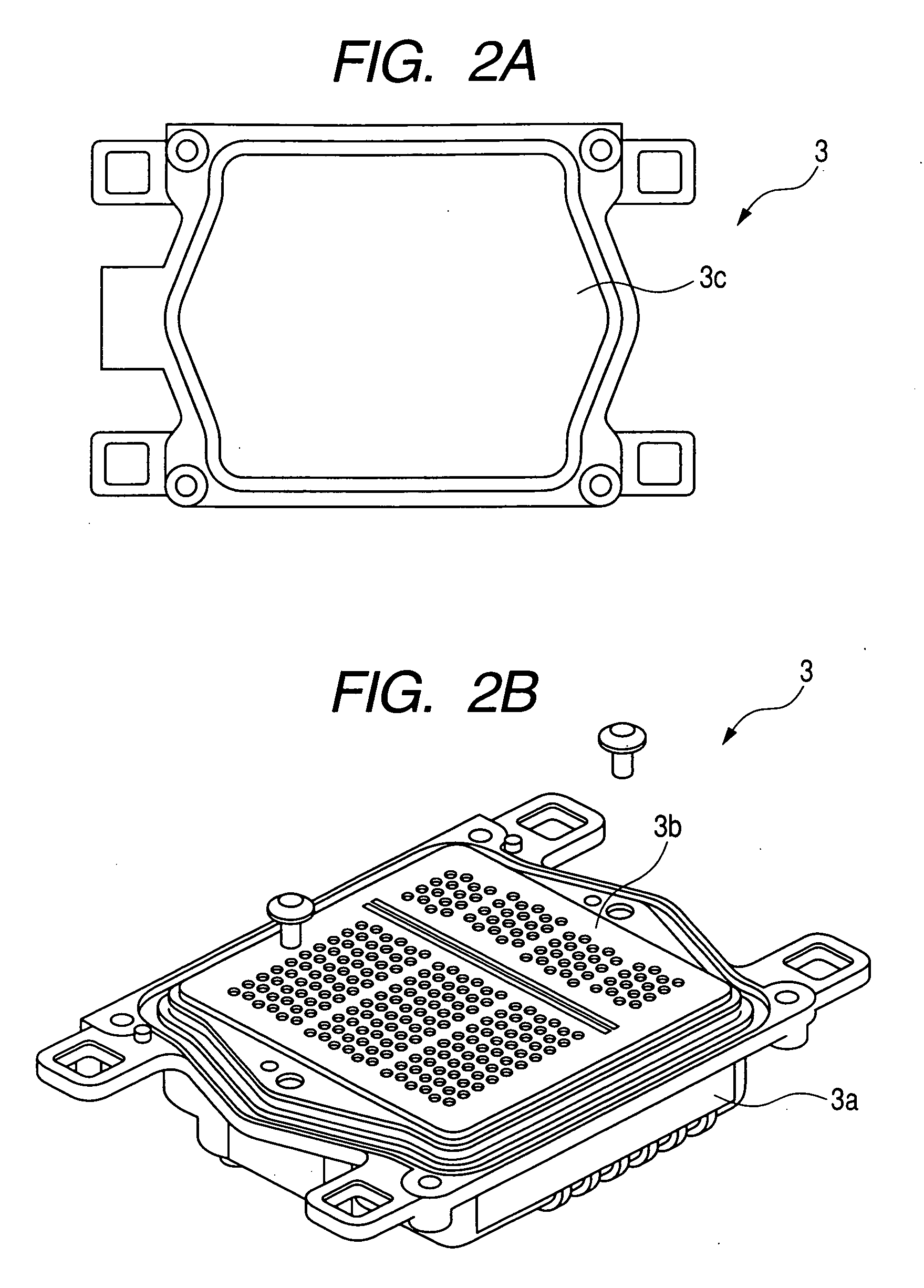

Camera module with improved leaf spring attachment

InactiveUS7705909B2Evenly loadedHigh bonding strengthTelevision system detailsColor television detailsOptical axisCamera module

Owner:MITSUMI ELECTRIC CO LTD

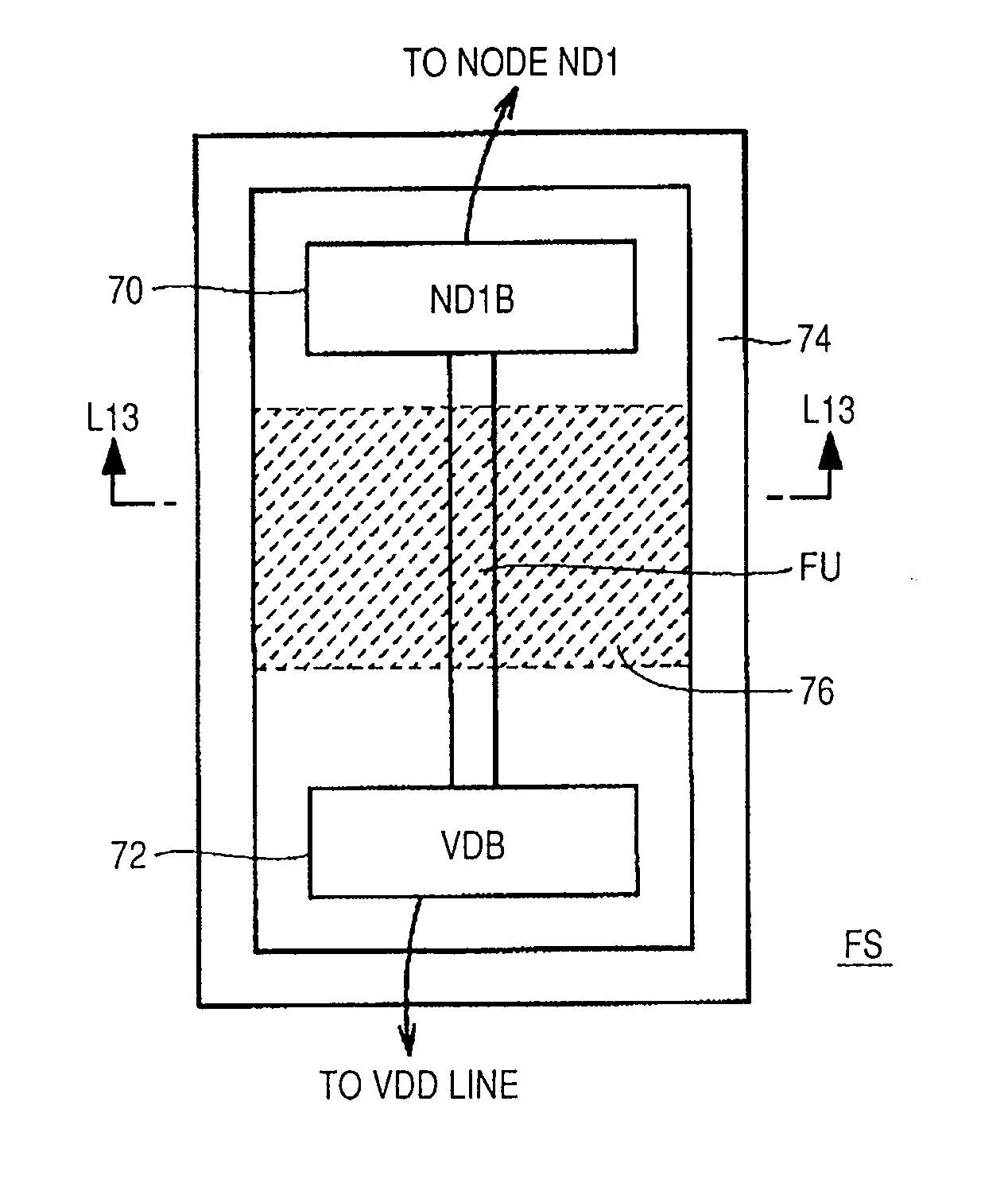

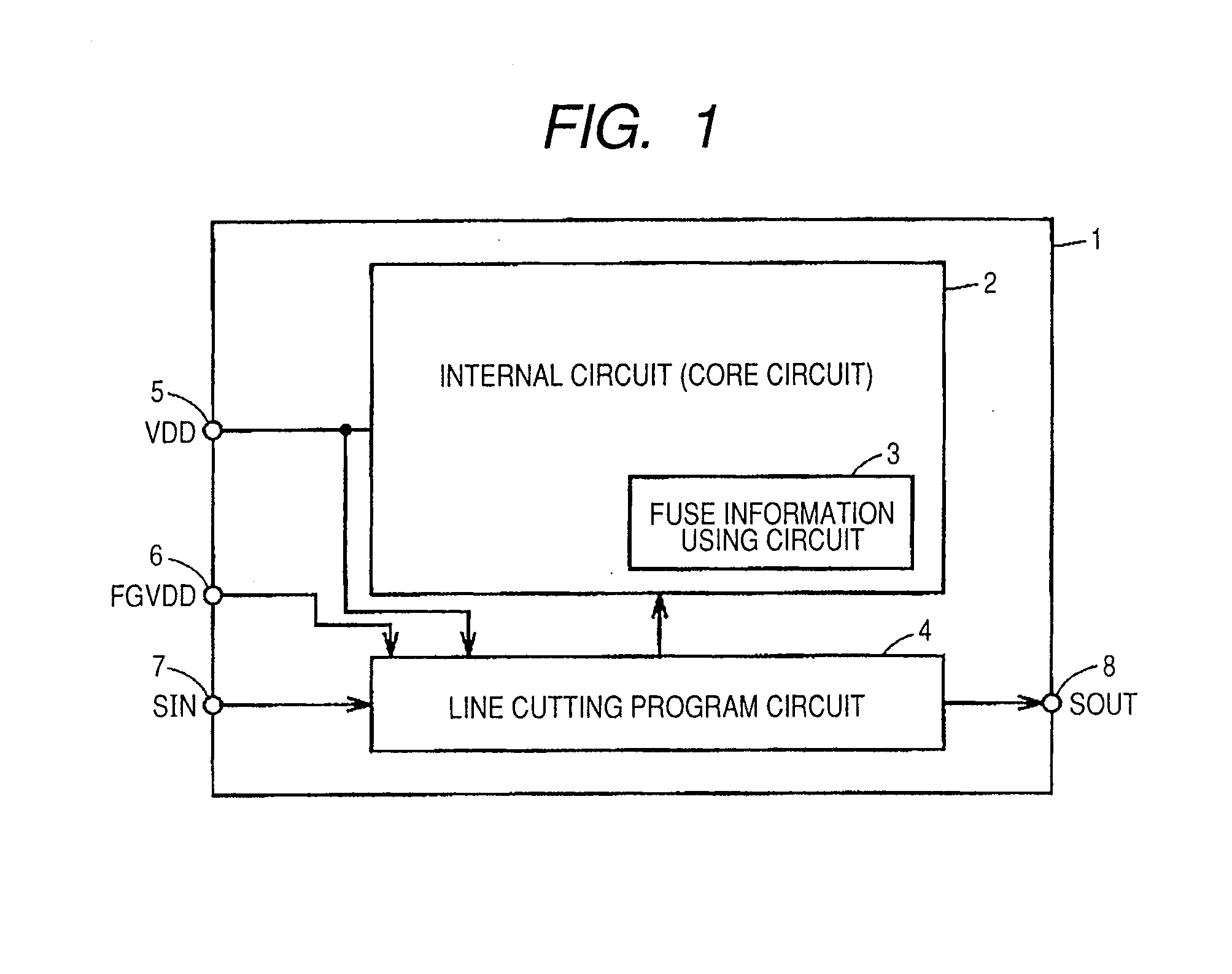

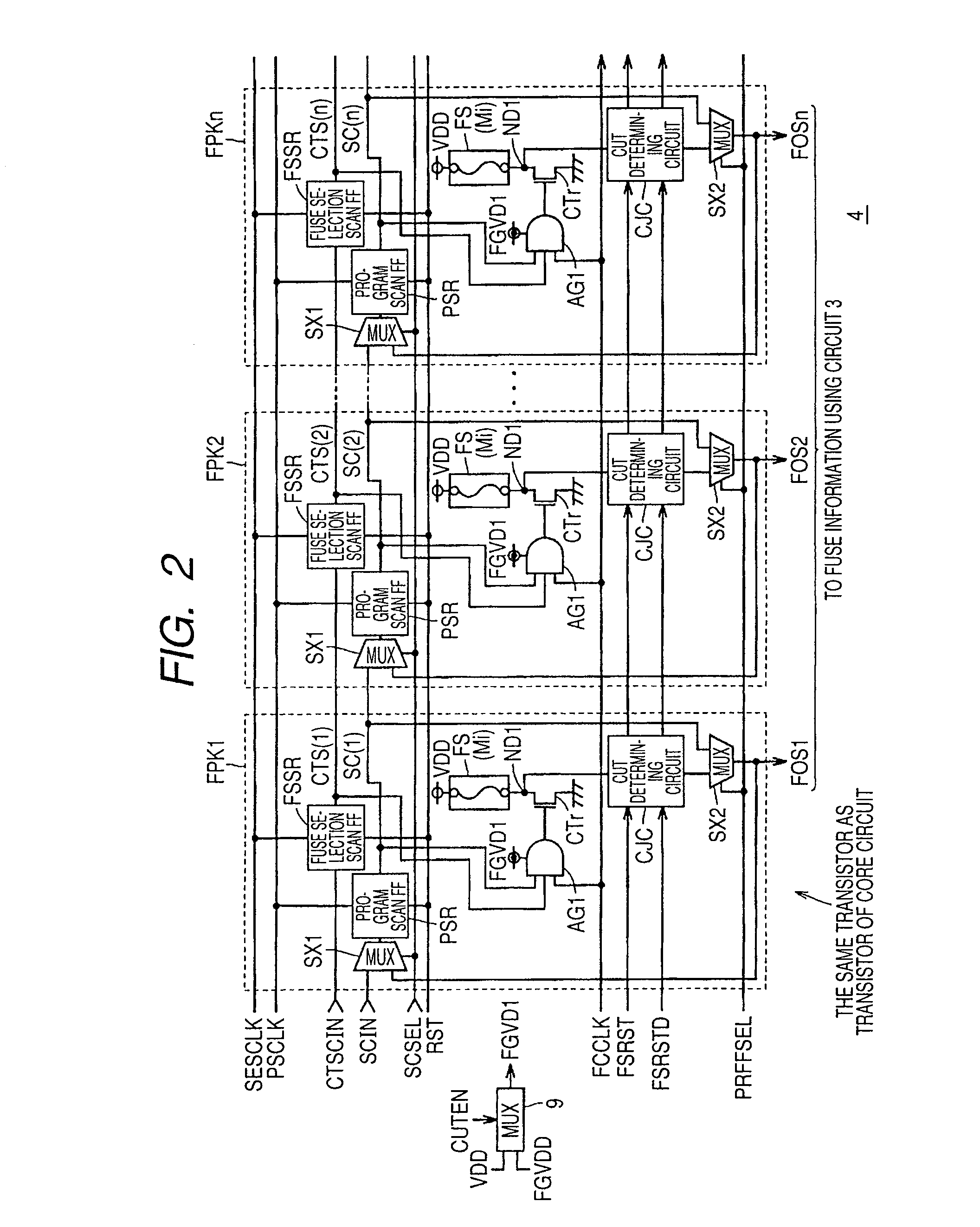

Semiconductor device

ActiveUS20100230780A1Reduce in quantityReduced footprintSemiconductor/solid-state device detailsSolid-state devicesCopper atomTransmitted power

The present invention provides a semiconductor device realizing reliable cutting of a fuse without enlarging layout area of a fuse element and the reduced number of wiring layers of a preventing wall that prevents diffusion of fuse copper atoms. A fuse is formed by using a wire in a metal wiring layer as an upper layer in a plurality of metal wiring layers. Wires are disposed just above and just below a fuse each with a gap of at least two wiring layers. In an upper layer, a power wire that transmits power supply voltage is used as a part covering a preventing wall structure just above the fuse.

Owner:RENESAS ELECTRONICS CORP

Aluminium alloy twin-wire dipulse welding method and welding power supply thereof

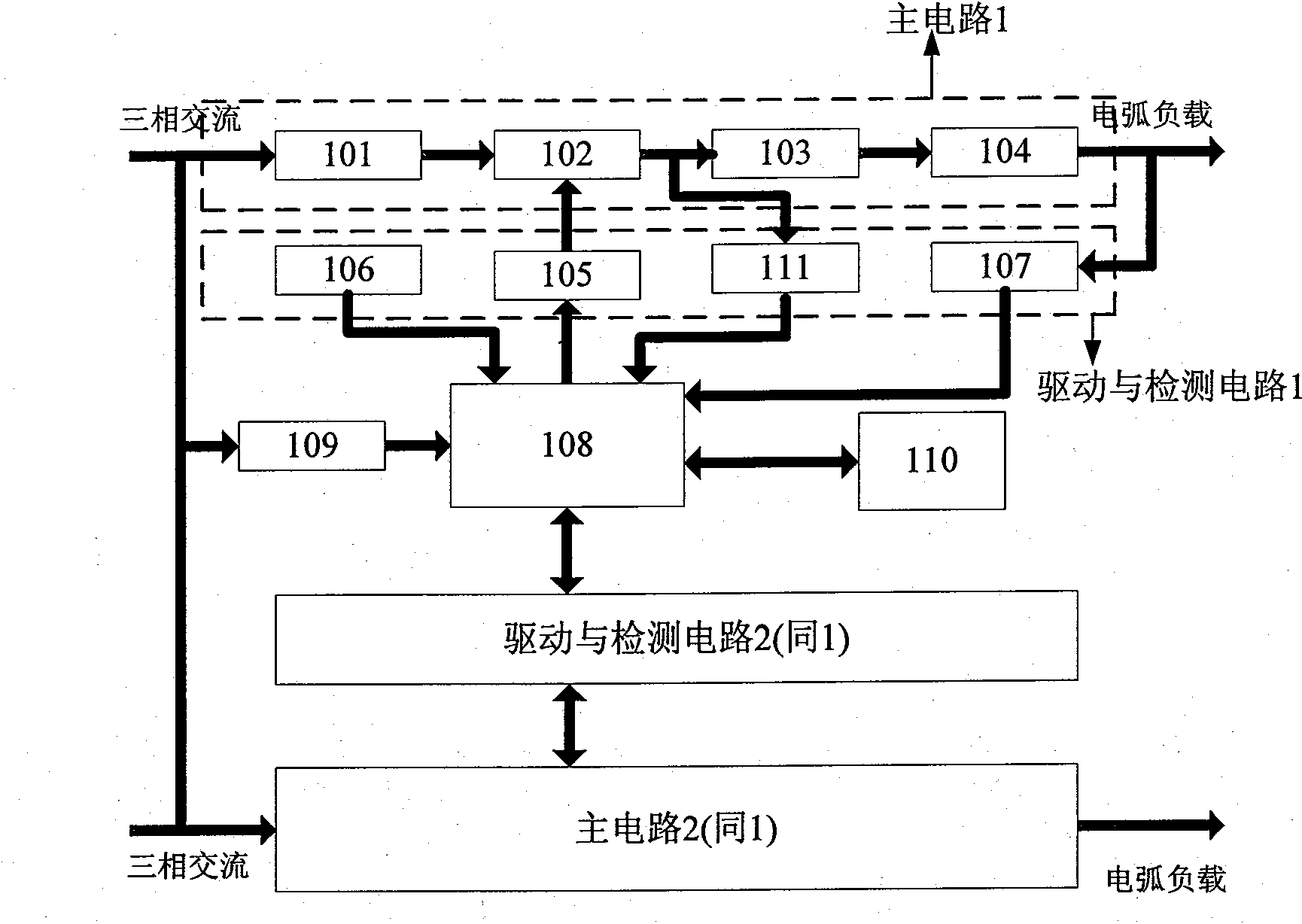

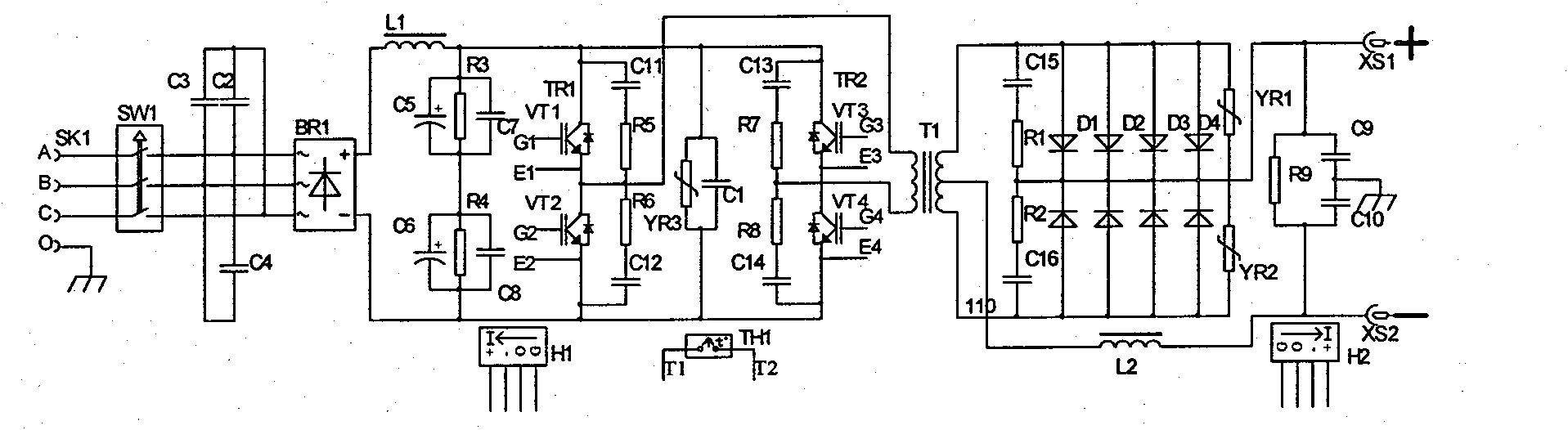

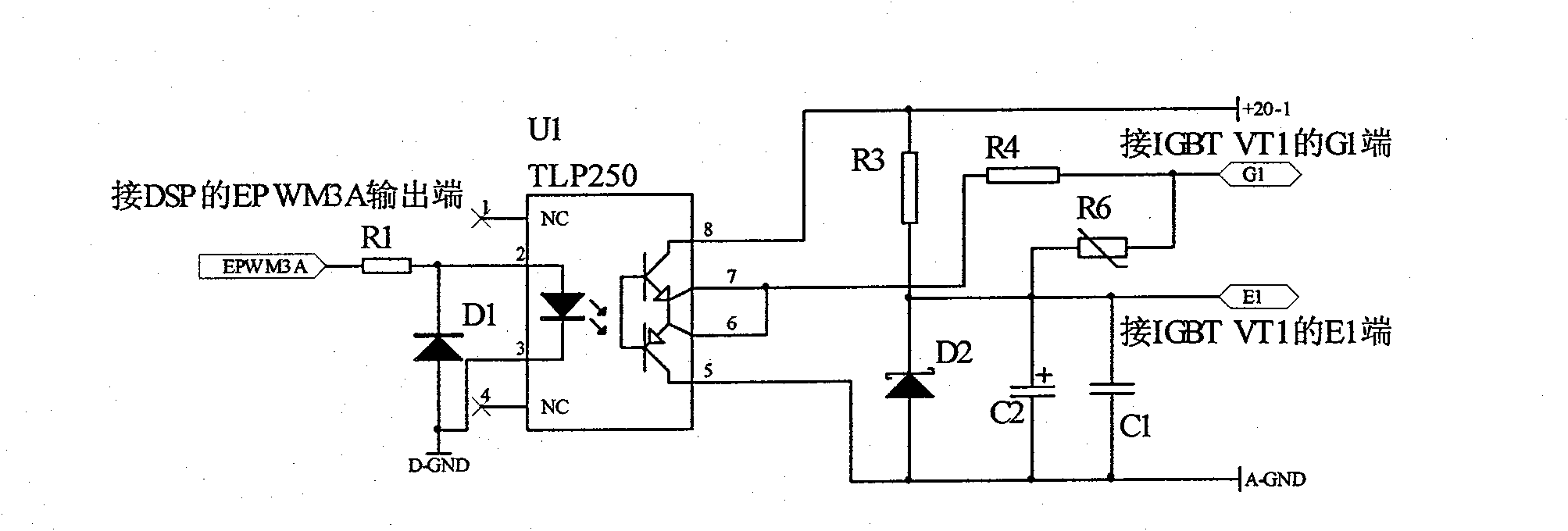

InactiveCN101791733AImprove consistencyImprove dynamic response performanceArc welding apparatusSoft switchingWelding power supply

The invention discloses an aluminium alloy twin-wire dipulse welding method and a welding power supply thereof. The specific method is as follows: carrying out low frequency modulation on pulse wave shapes on the basis of high frequency to obtain periodically varied pulse bursts; and carrying out efficient and superior welding on aluminium alloy through the active phase match of two branches of the pulse bursts. The welding power supply comprises IGBT soft switching main circuits which are integrated into a whole, a DSP control circuit and a man-machine interactive system. The invention puts forward realizing dipulse aluminum alloy welding on a twin-wire welding machine for the first time, realizes all digital control, directly generates eight branches of PWM signals by utilizing a software module, controls the two main circuits, and reduces the control problems caused by communication; and simultaneously, the two main circuits are concentrated on the same welding machine so that the overall structure is much smaller than the master-slave mode welding machine, in addition methods such as instantaneous energy control and the like are adopted to realize the fine control of dipulse.

Owner:SOUTH CHINA UNIV OF TECH

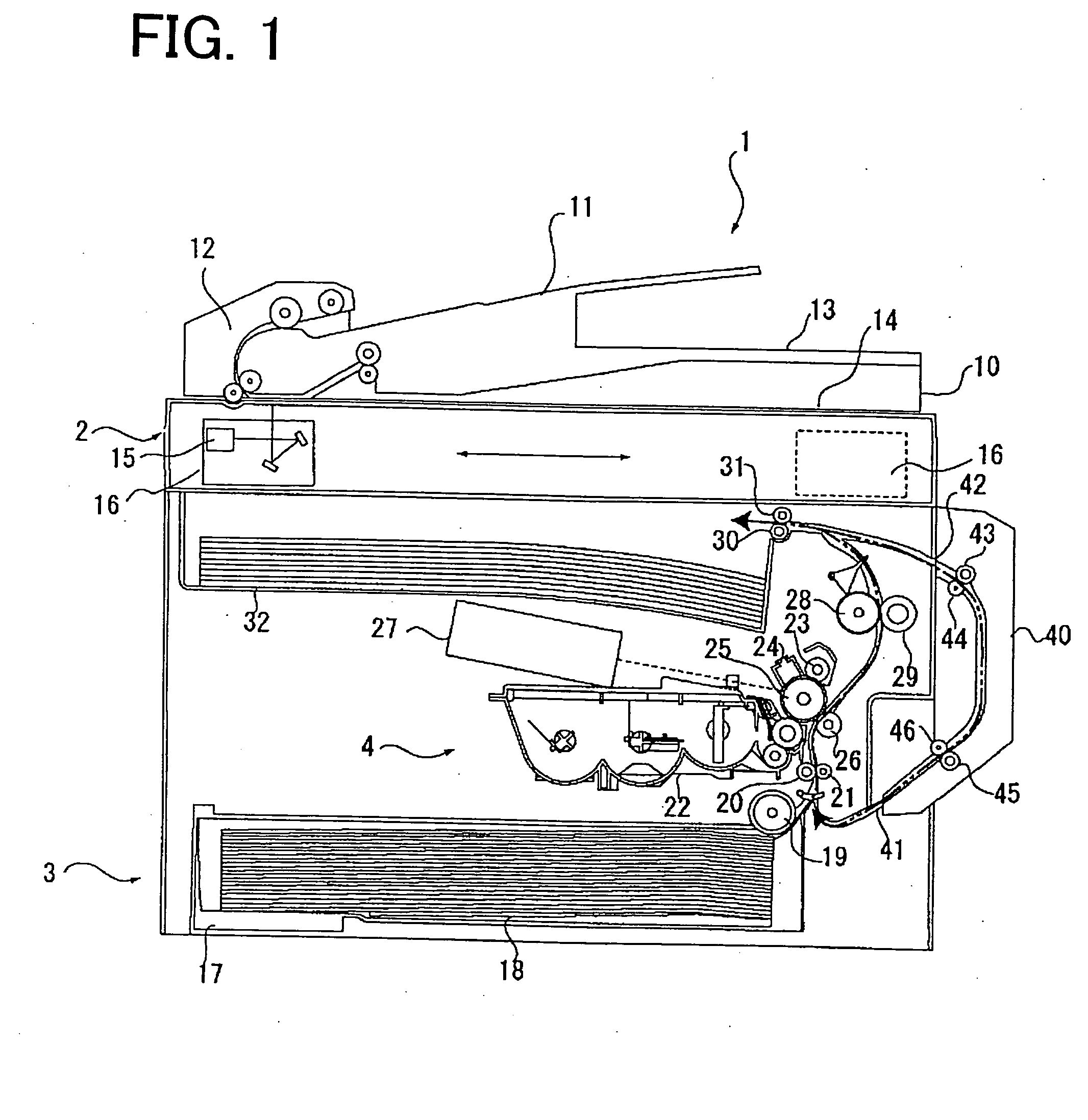

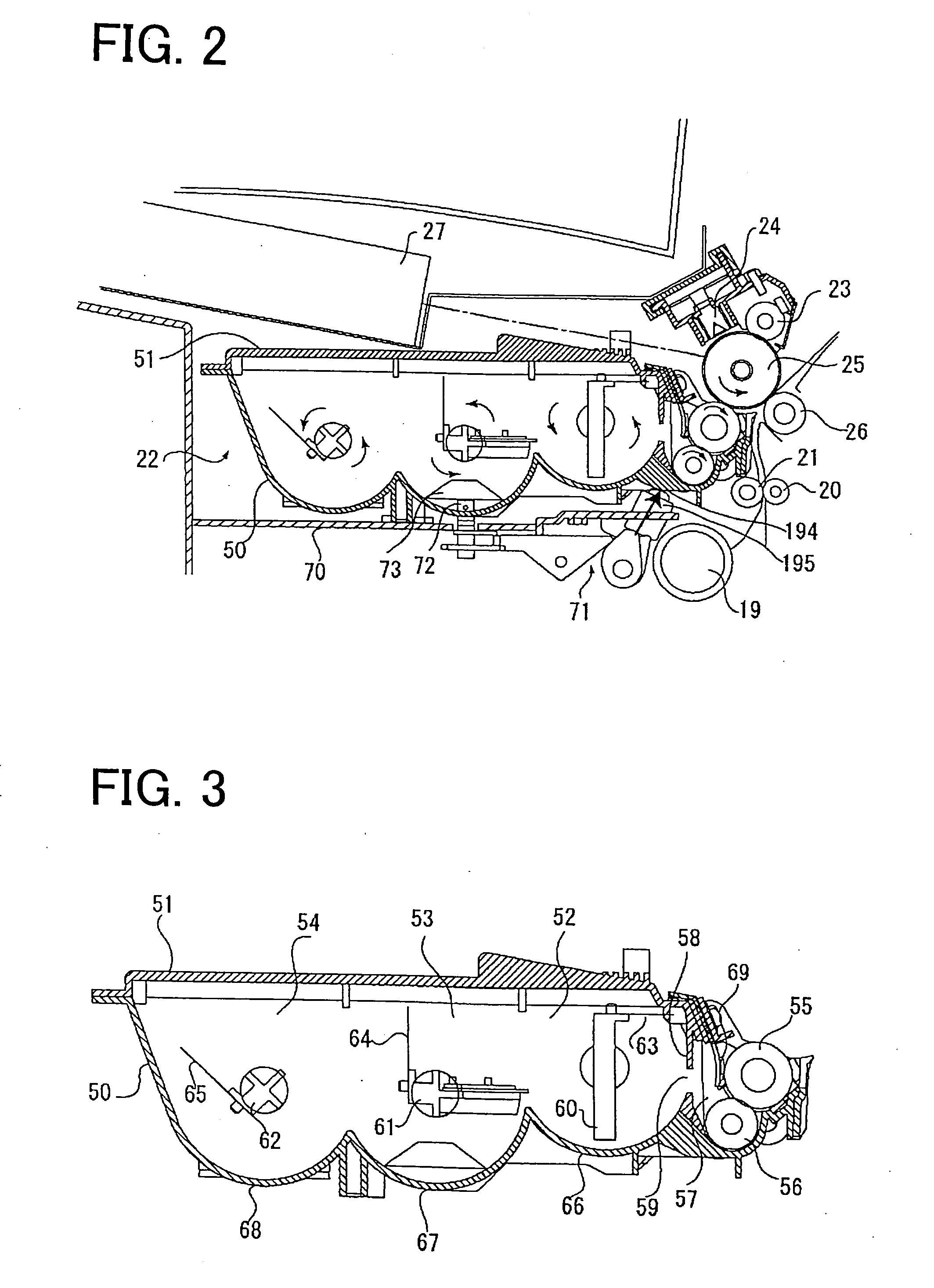

Image forming device

InactiveUS20050047825A1Made preciselyEasy to operateElectrographic process apparatusLatent imageImage formation

An image forming device includes an electrostatic latent image carrier on which an electrostatic latent image is formed, a main frame which supports the electrostatic latent image carrier, and a developing unit which is inserted removably in the main frame. The developing unit includes a developer carrier which supplies a developer to the electrostatic latent image carrier and a replenish chamber which replenishes the developer to the developer carrier. The image forming device also includes a pressing body which is provided on the main frame and is slidable in a direction along a straight line orthogonal to a rotational center shaft of the electrostatic latent image carrier and a rotational center shaft of the developer carrier, and an operating unit which operates the pressing body to press a bottom surface of the developing unit by sliding the pressing body in a direction of the straight line and to hold the pressing body so that the developer carrier is maintained under a state making contact with the electrostatic latent image carrier.

Owner:MURATA MASCH LTD

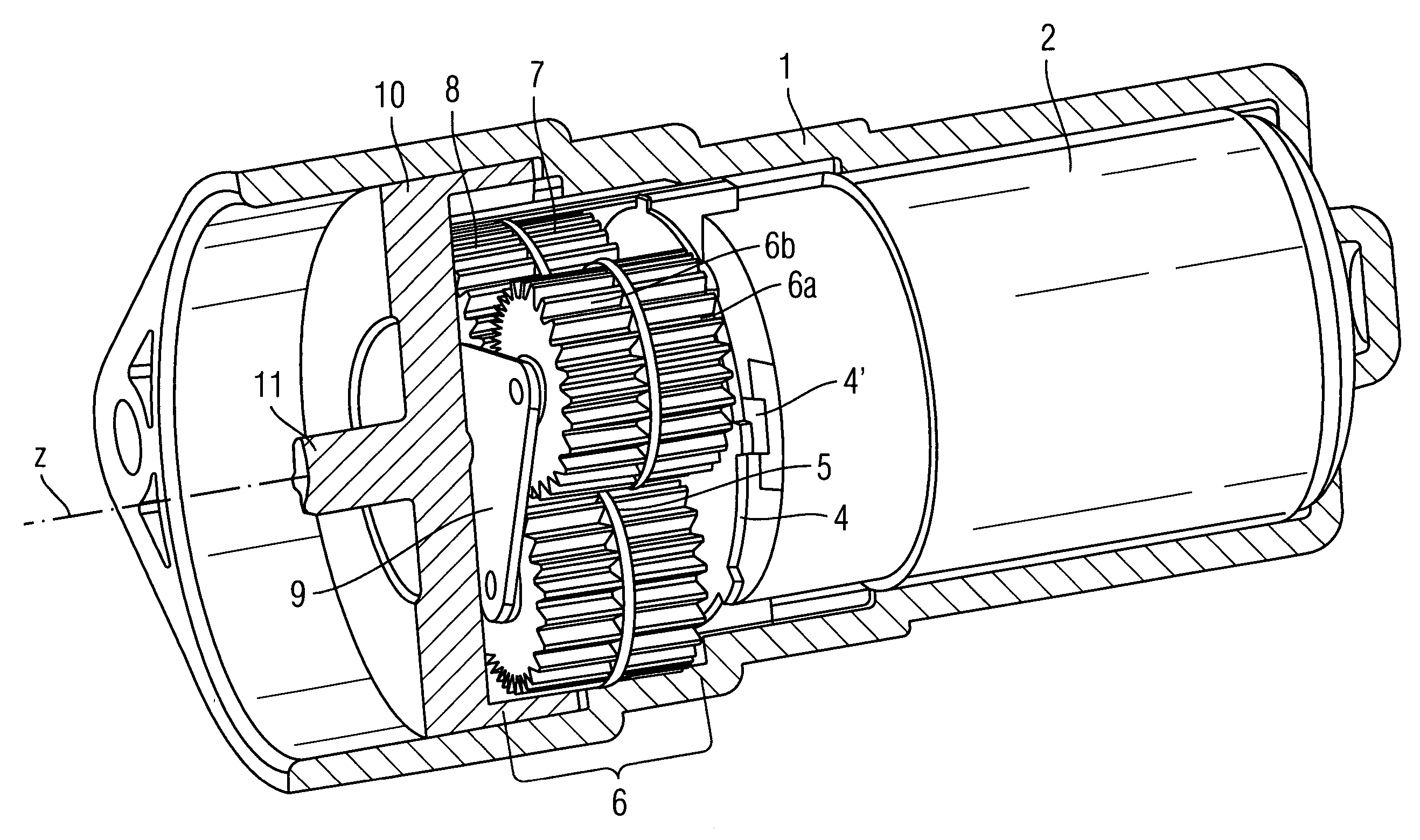

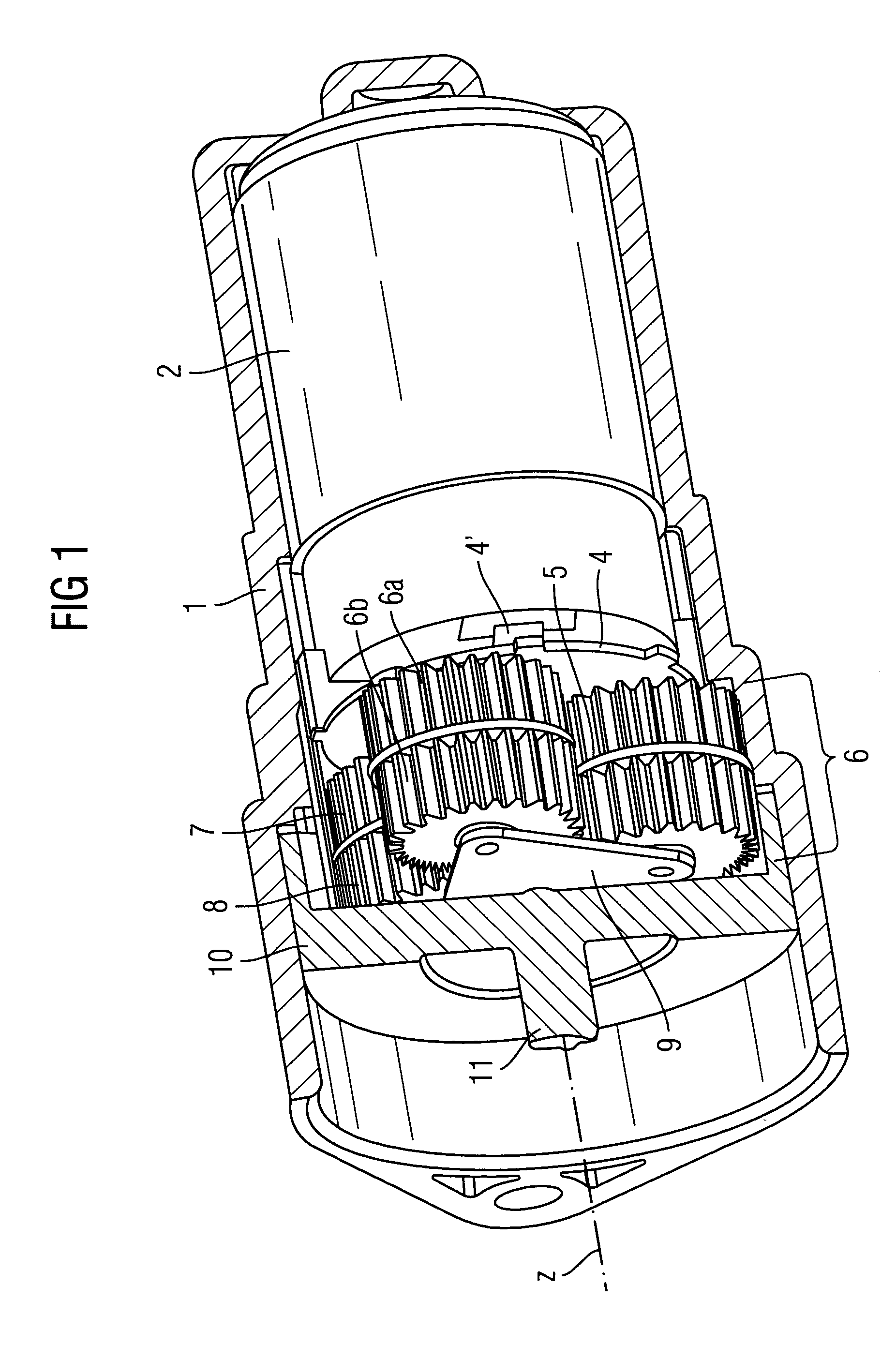

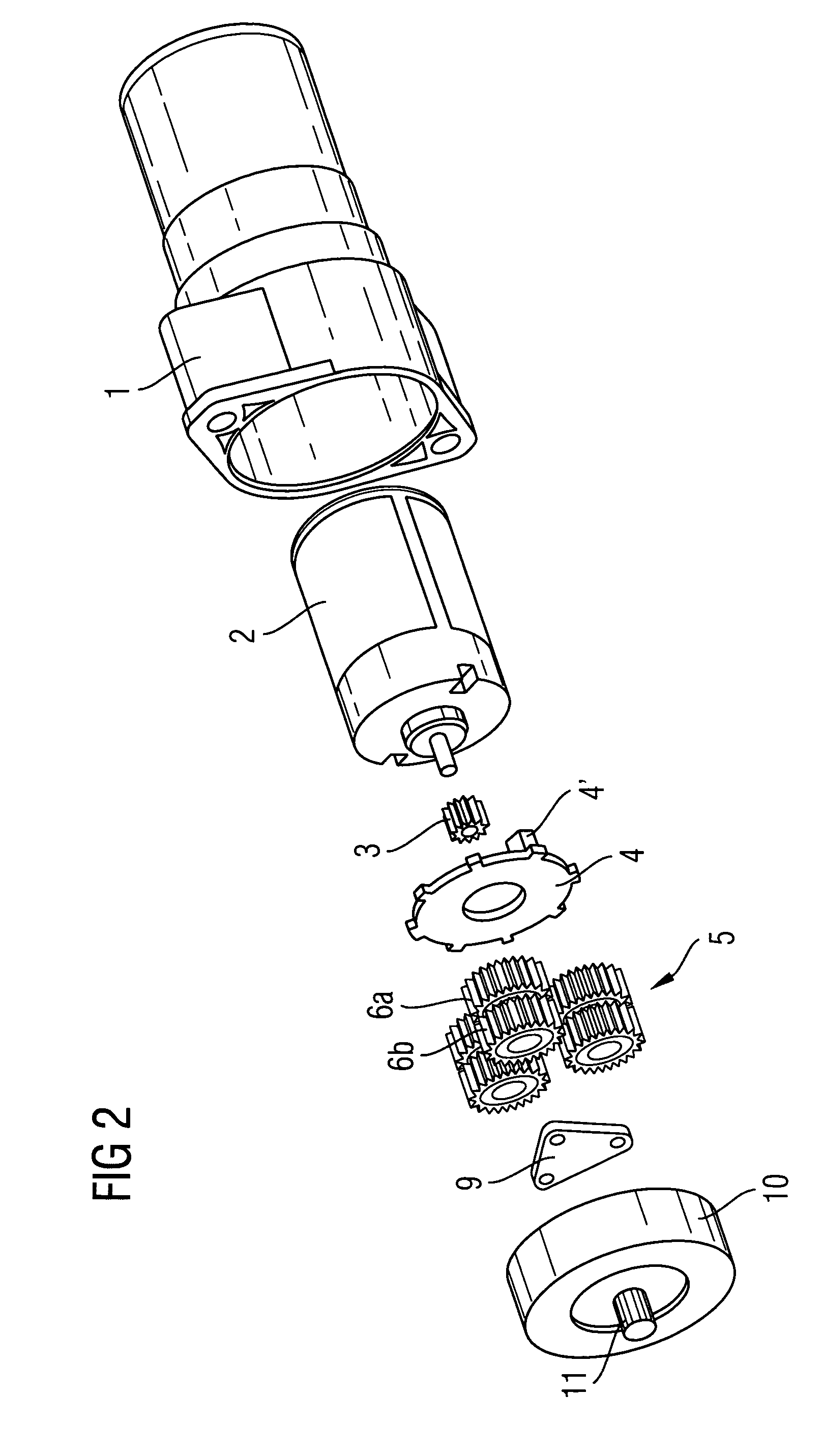

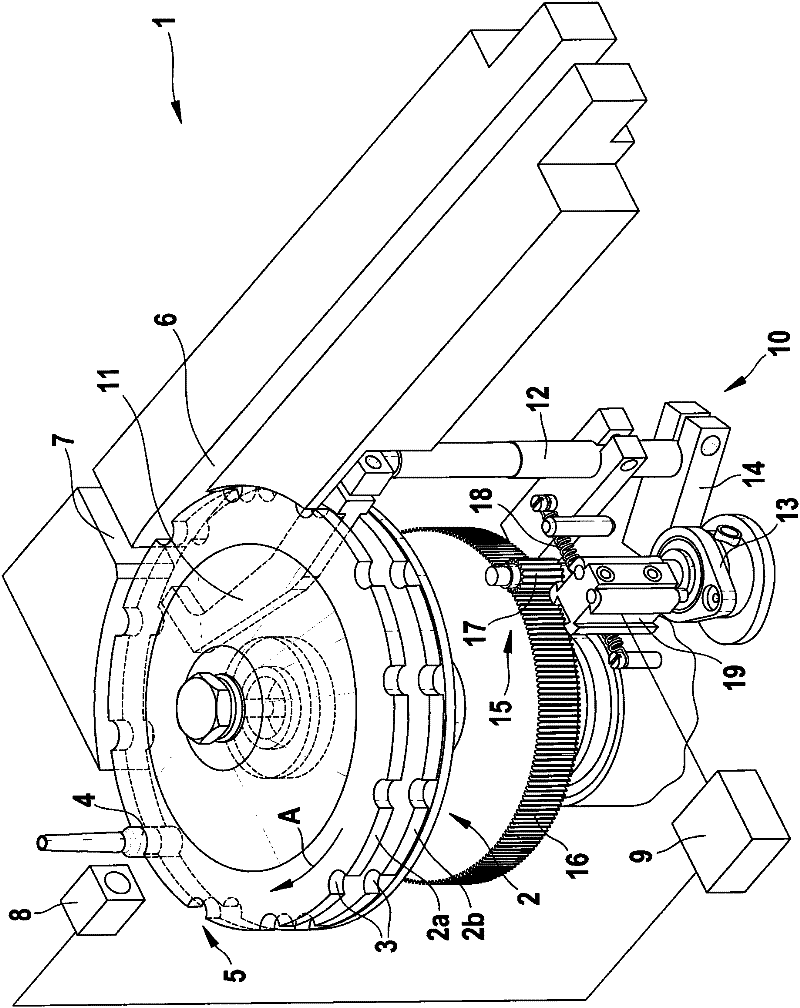

Actuator

InactiveUS20050046290A1Raise the ratioNo lateral structural spaceToothed gearingsMechanical energy handlingMobile vehicleActuator

The actuator comprises a housing which has a longitudinal axis Z and in which an electric motor having a pinion is arranged. The pinion is in engagement in each case with at least one first gearwheel of a planetary gear, the first gearwheel forming, in each case together with a second gearwheel arranged directly adjacent, a uniform double gearwheel. One or more double gearwheels are arranged here. The first gearwheels run in a first toothed ring, which is connected fixedly to the housing. The respective second gearwheels run in a rotatably mounted, second toothed ring, which is connected to the part which is to be driven, with the number of teeth of the first toothed ring not being identical to the number of teeth of the second toothed ring. The invention furthermore relates to the use of the actuator for actuating a parking brake in a motor vehicle.

Owner:SIEMENS AG

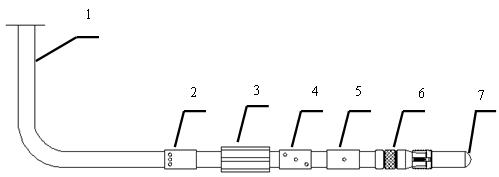

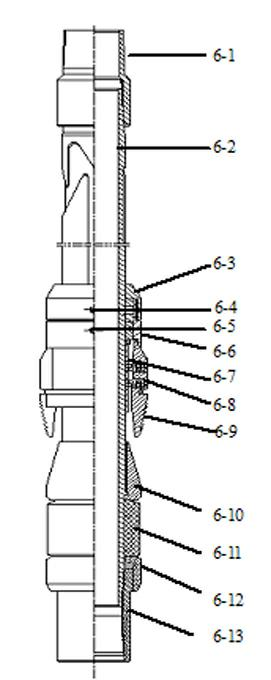

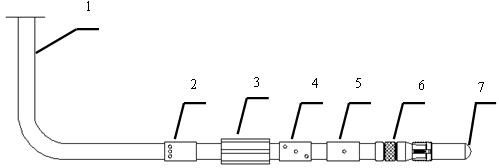

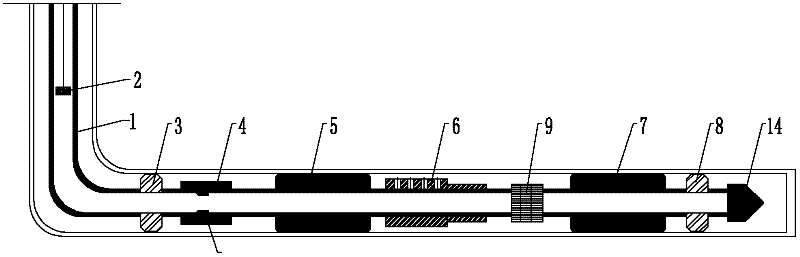

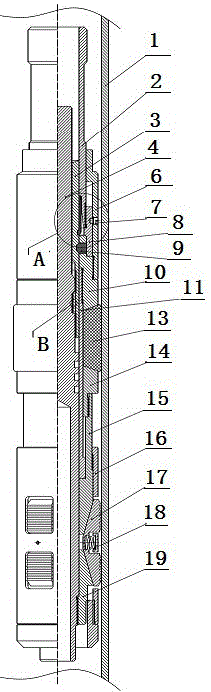

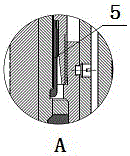

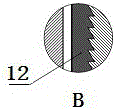

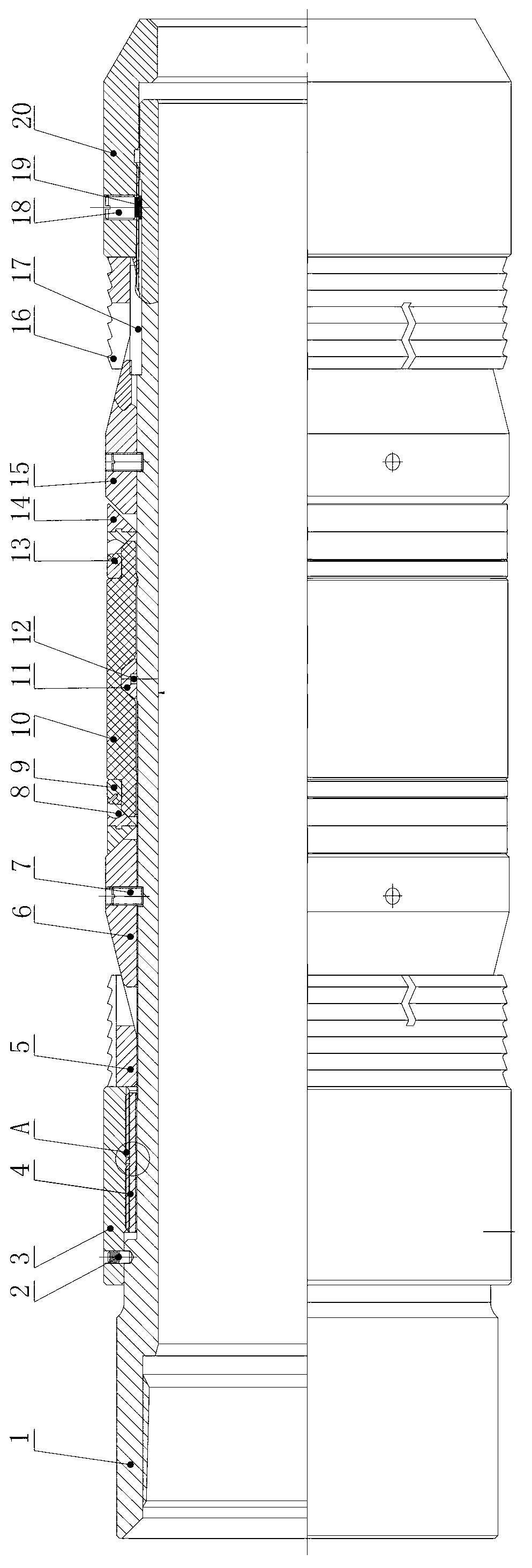

Continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and casing fracturing method

ActiveCN102691493ARemarkable effectSignificant progressDrilling rodsFluid removalSand blastingHorizontal wells

The invention discloses a continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and a casing fracturing method, which are suitable for application in vertical wells and horizontal wells in the petroleum industry, in particular for sectional fracturing of unconventional oil-gas reservoir horizontal wells such as tight sandstone wells. The fracturing pipe column comprises a safety joint, a centralizer, a hydraulic jet tool and a reverse circulation valve, which are connected to a continuous oil pipe in sequence, wherein a mechanical continuous oil pipe fracturing packer is connected below the reverse circulation valve. The sectional casing fracturing method is used for placing the fracturing pipe column provided with the mechanical continuous oil pipe fracturing packer into a casing in a well through the continuous oil pipe; and by the method, a fracturing well section closest to the bottom of the well is fractured at first, and then the fracturing well section is packed by using the mechanical continuous oil pipe fracturing packer. By the continuous oil pipe sectional sand-blasting perforation casing fracturing pipe column and the casing fracturing method, a sand stopper is not needed as an isolation section, so that the sand stopper is not needed to be subjected to back flushing, the production cost is reduced, and multi-layer section fracturing operation for a short horizontal well section or straight well section can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

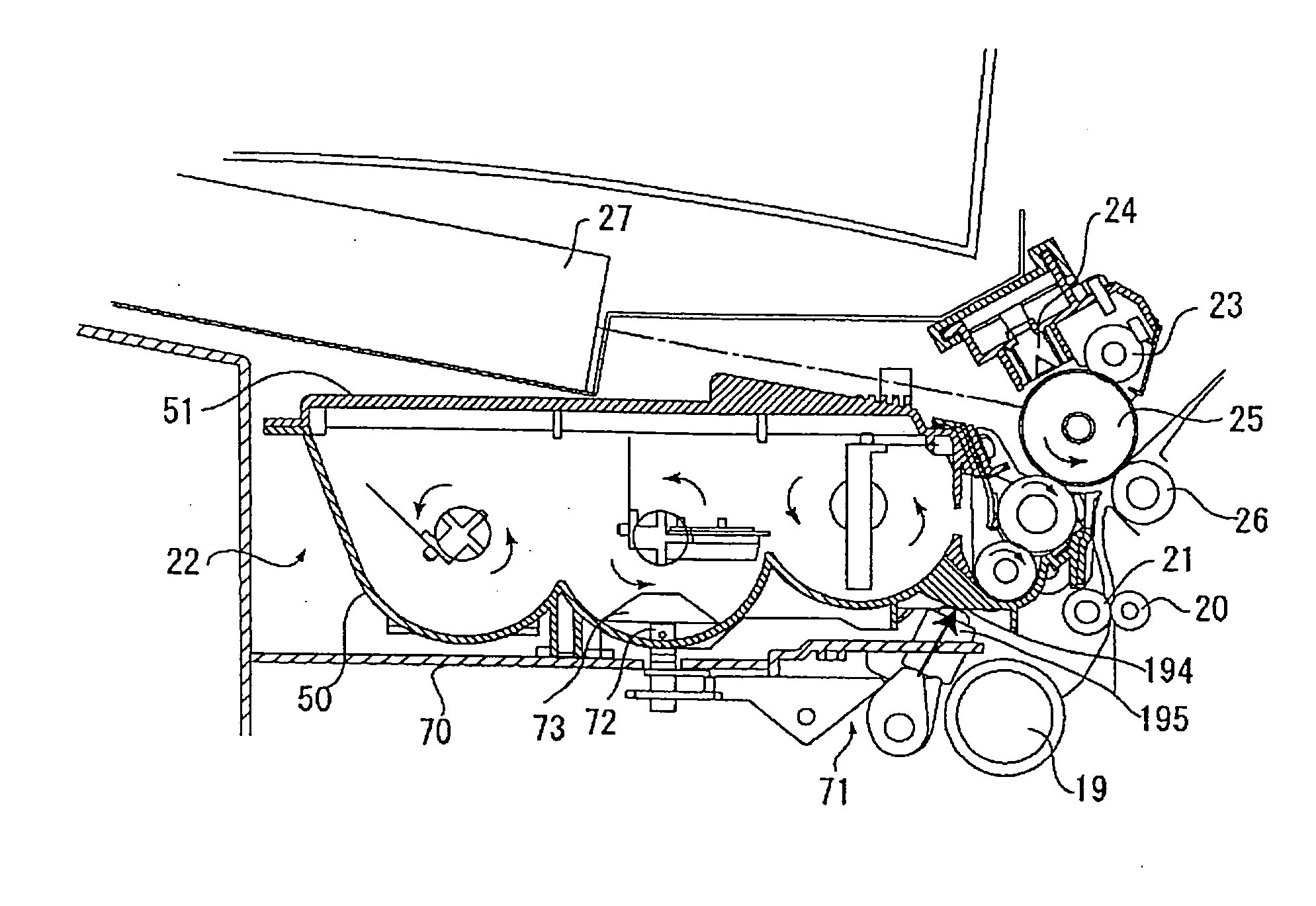

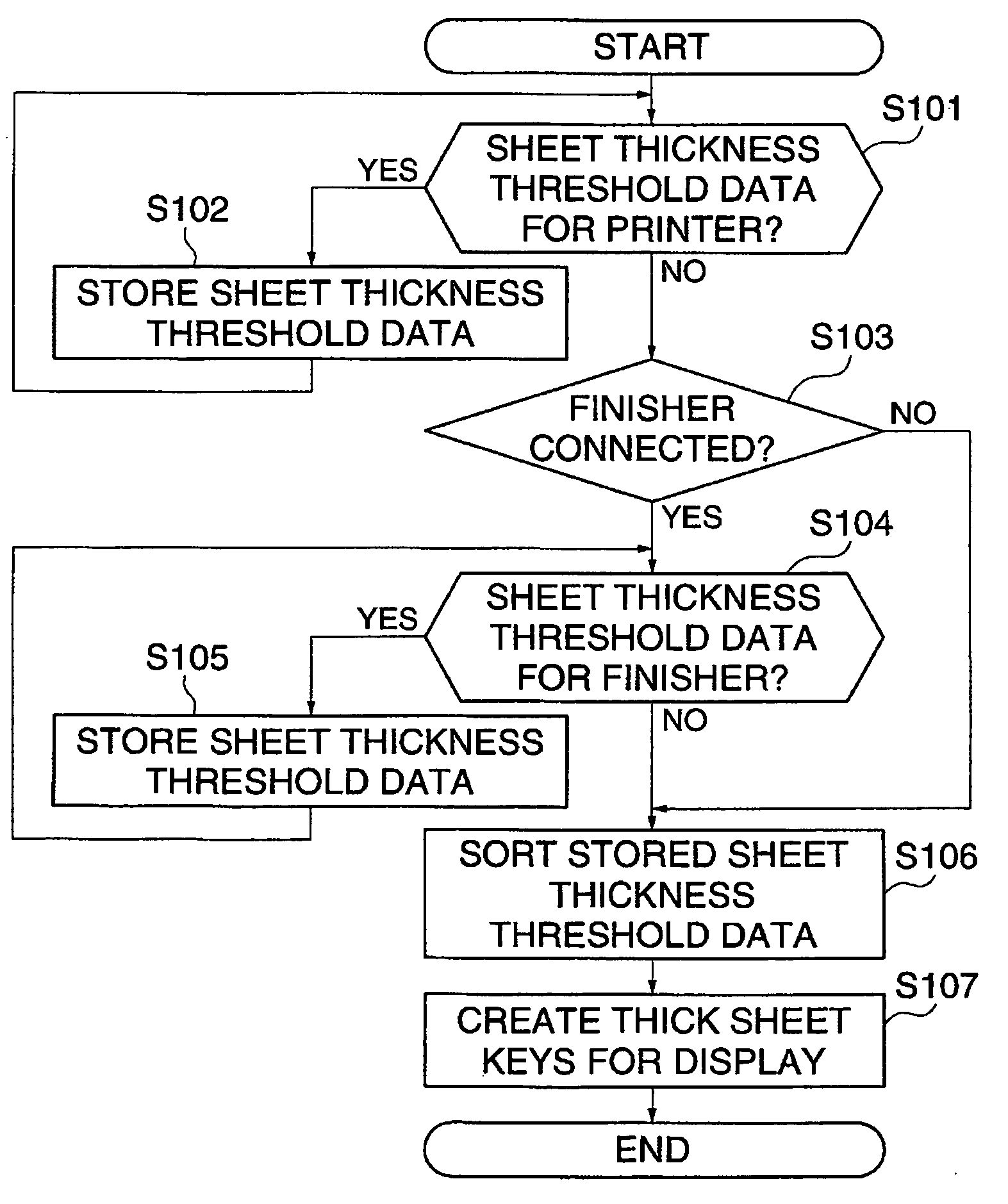

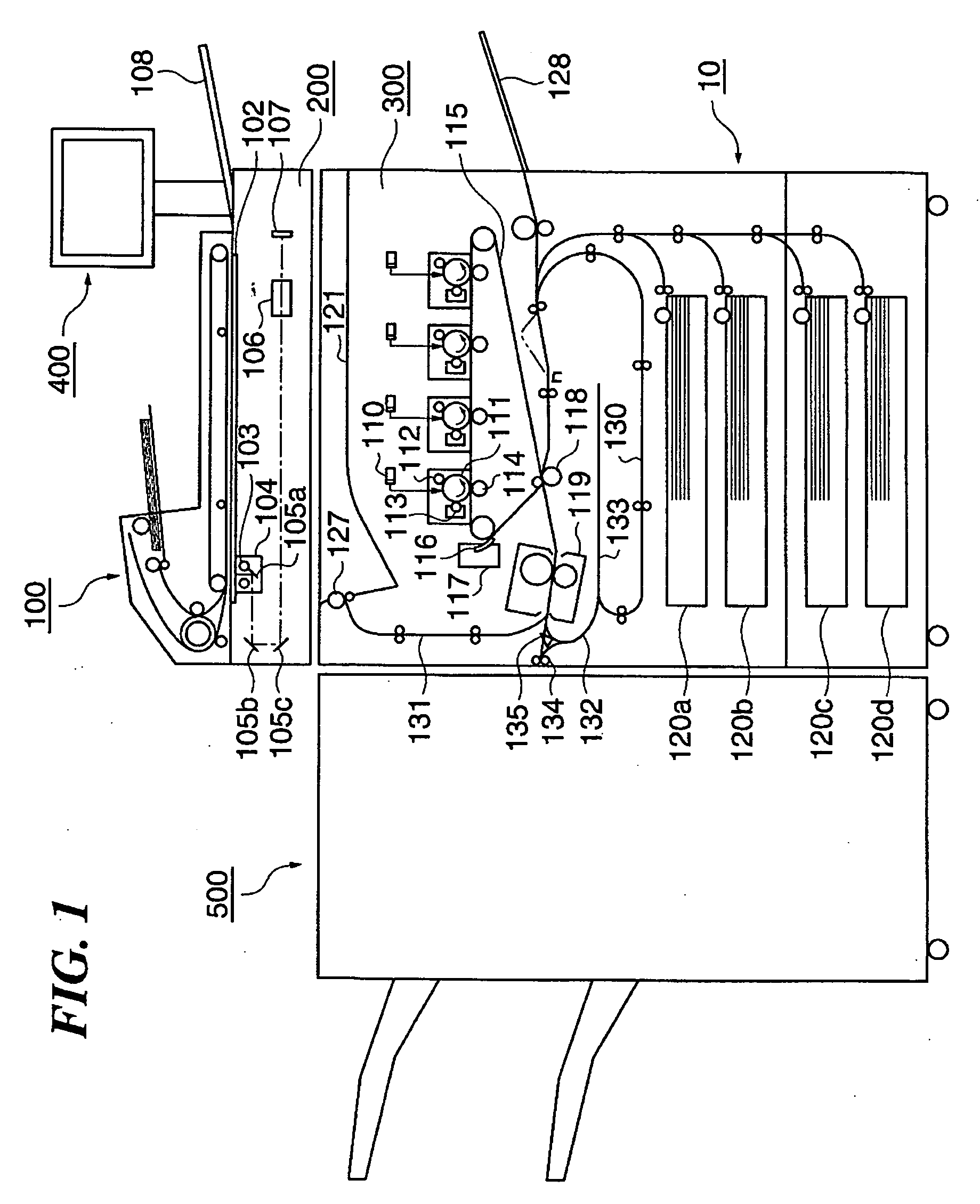

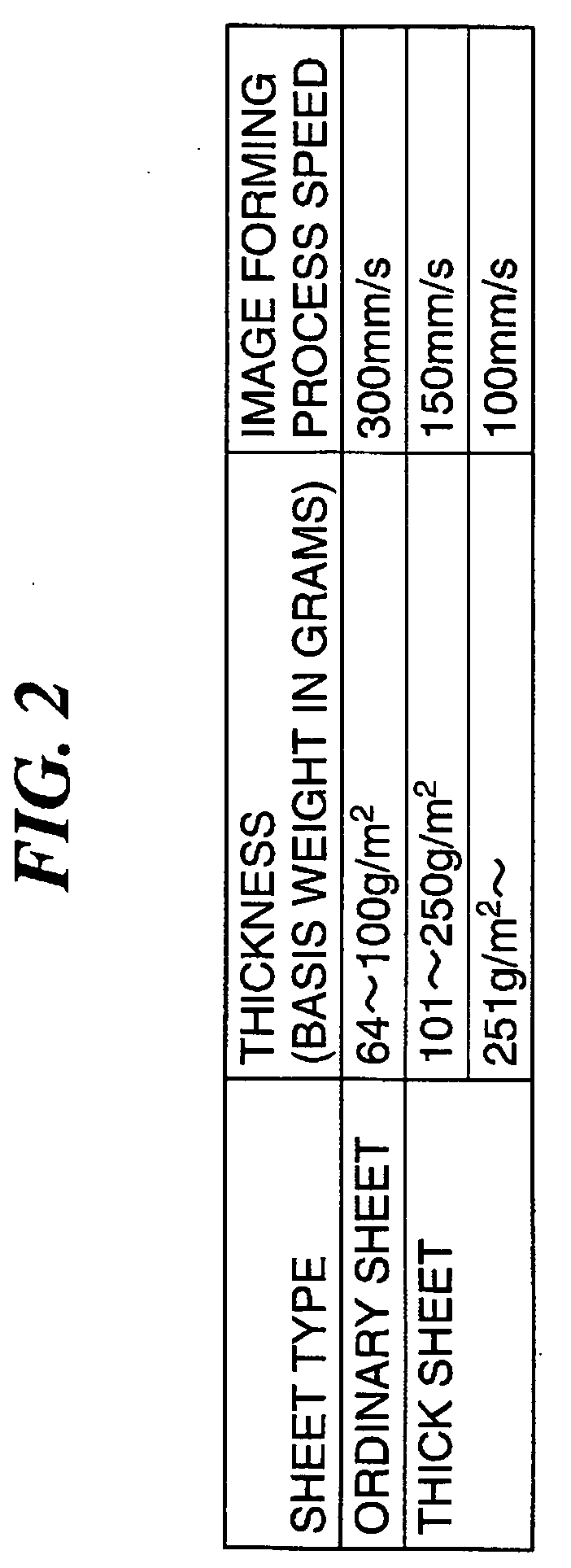

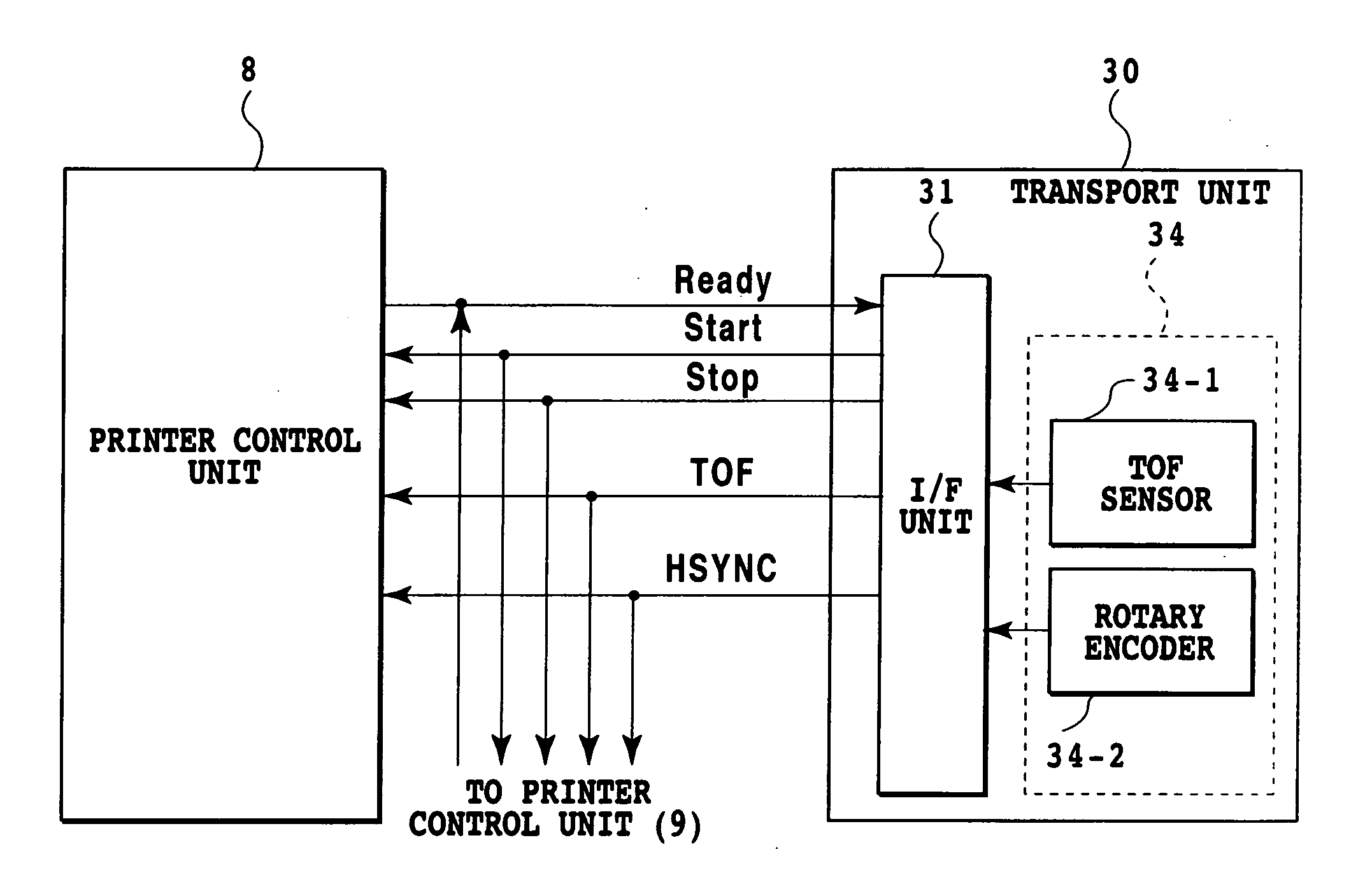

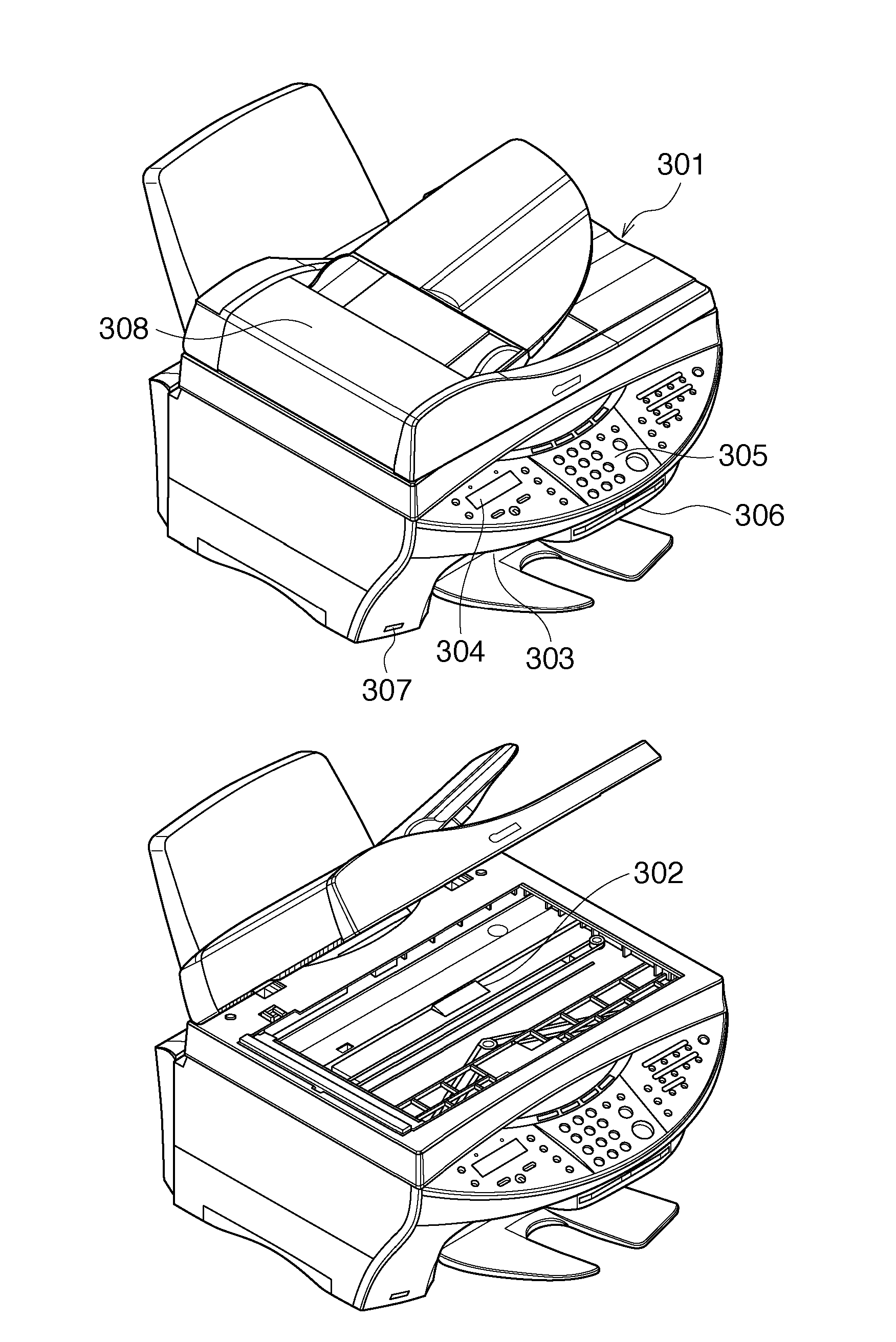

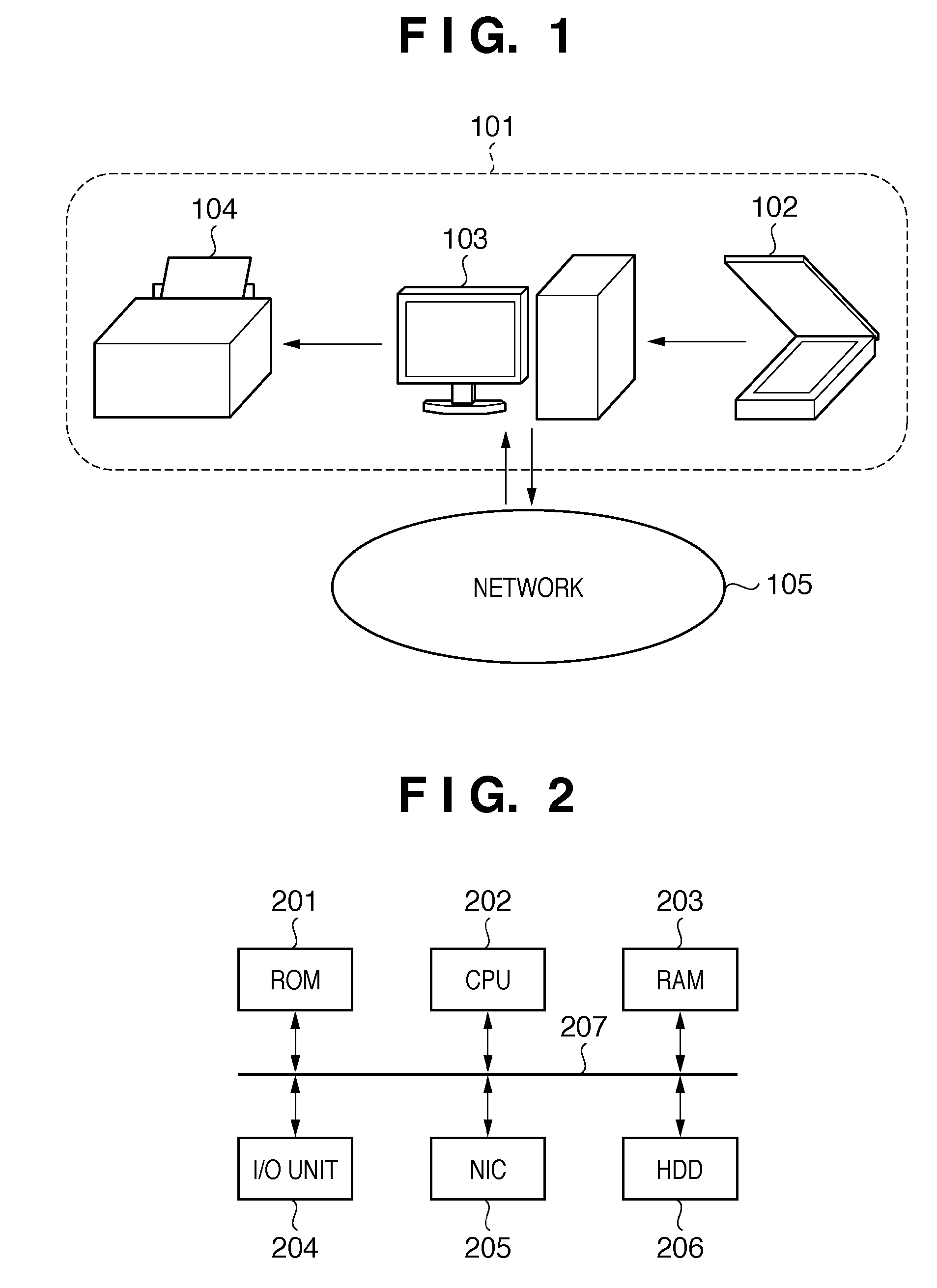

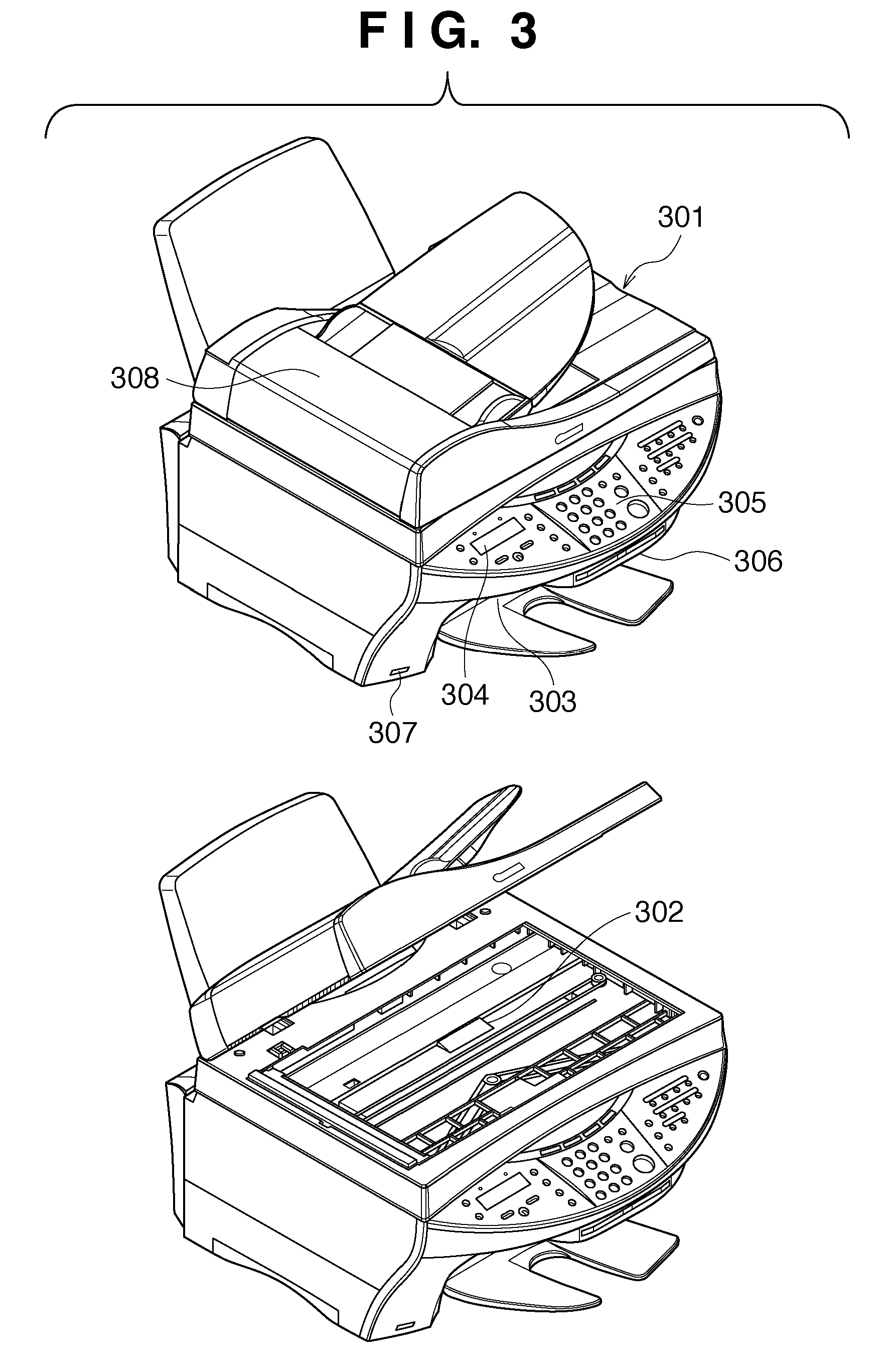

Image forming apparatus, post-processing apparatus, and image forming control method and program for implementing the method

InactiveUS20060216048A1Reliable settingsEasy to controlElectrographic process apparatusImage formationEngineering

An image forming apparatus that enables a post-processing apparatus to perform optimum control in accordance with the type (thickness) of sheet. A user sets on an image forming apparatus main unit 10 a thickness of sheet to be conveyed. A CPU circuit section 150 obtains first thickness-determination information used for the sheet conveying speed control in a finisher 500 from the finisher 500. A plurality of candidate sheet thicknesses that can be set, are determined based on the first thickness-determination information obtained by the CPU circuit section 150 and second thickness-determination information used when image-forming process speed control is performed in the image forming apparatus main unit 10 according to sheet thickness.

Owner:CANON KK

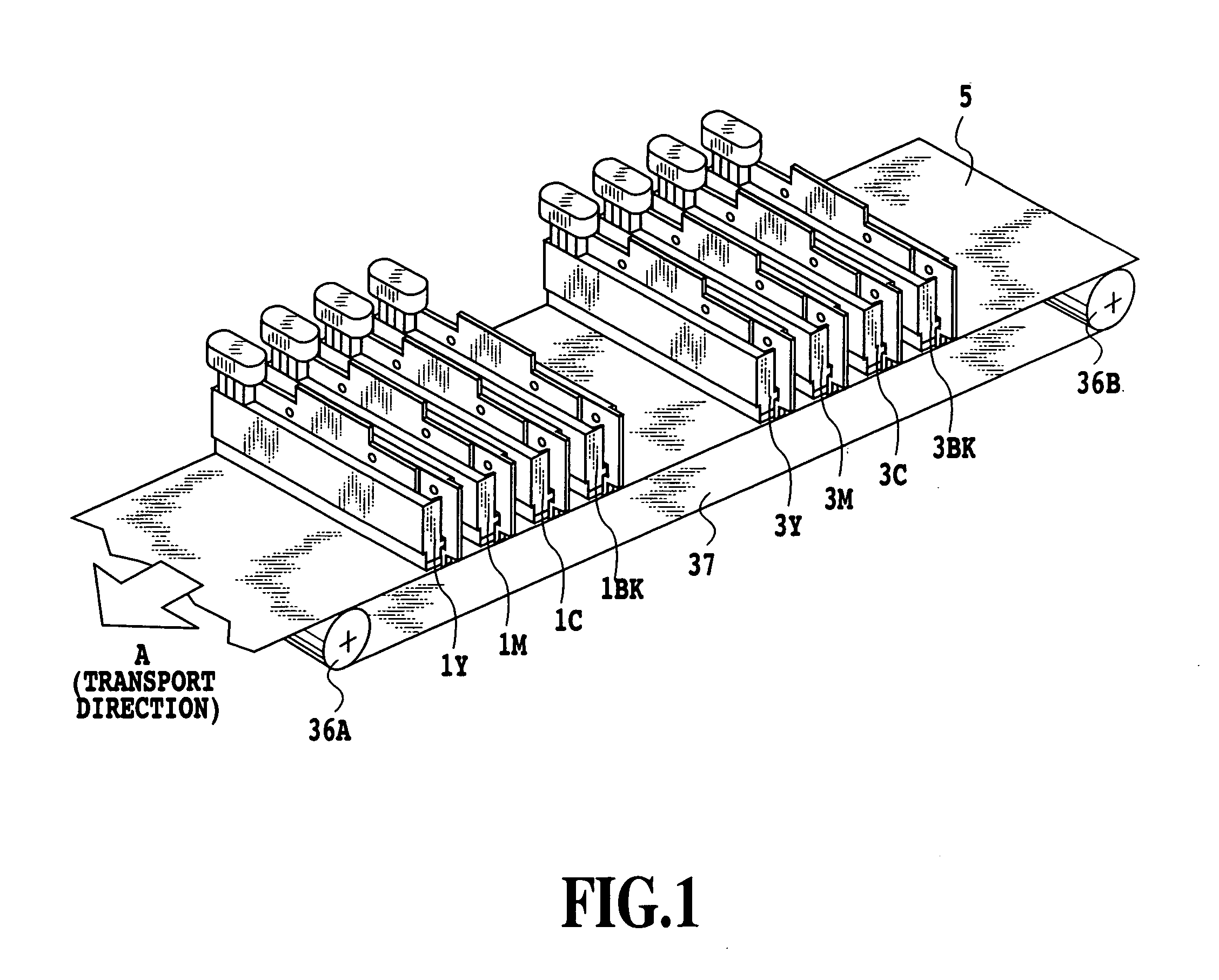

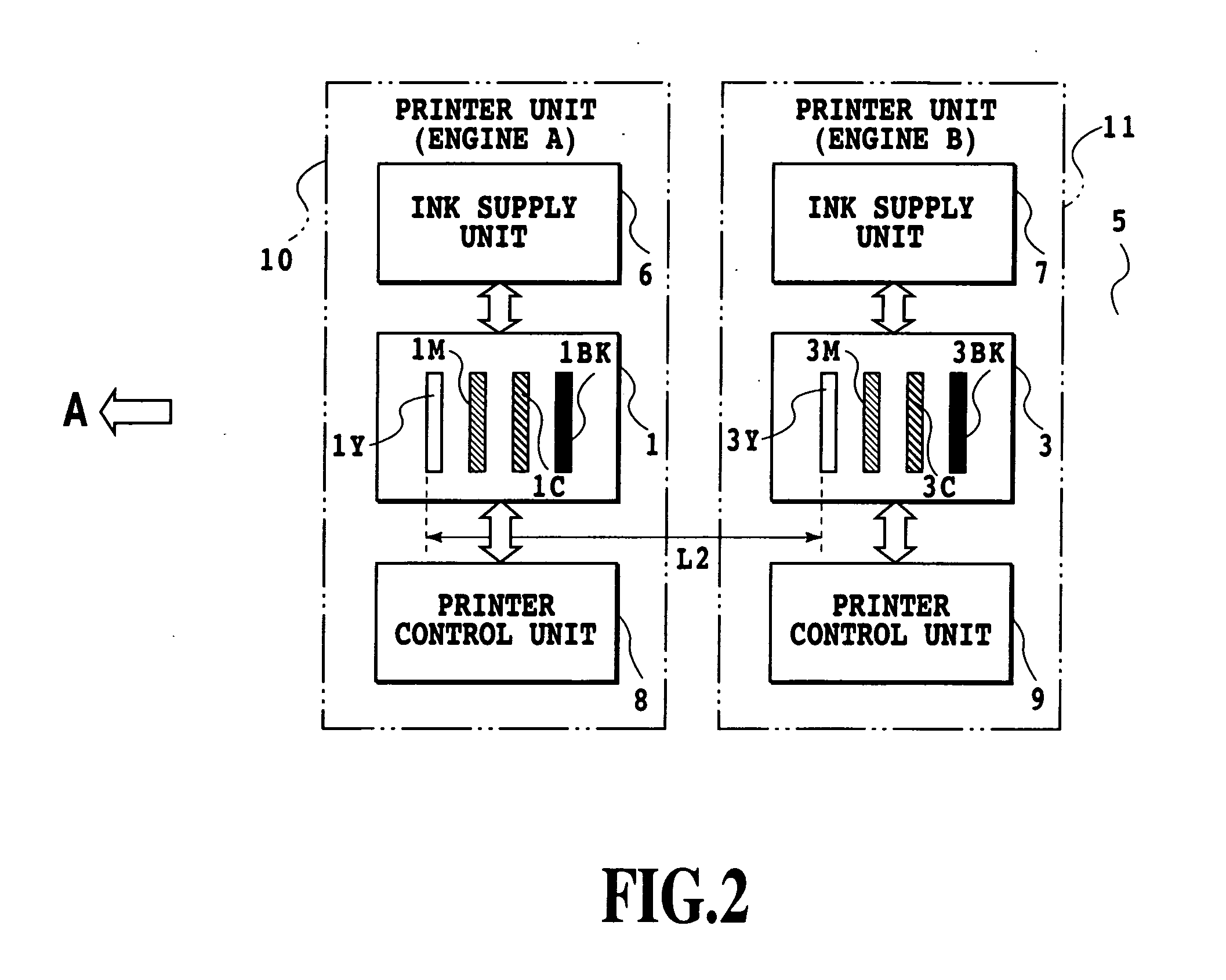

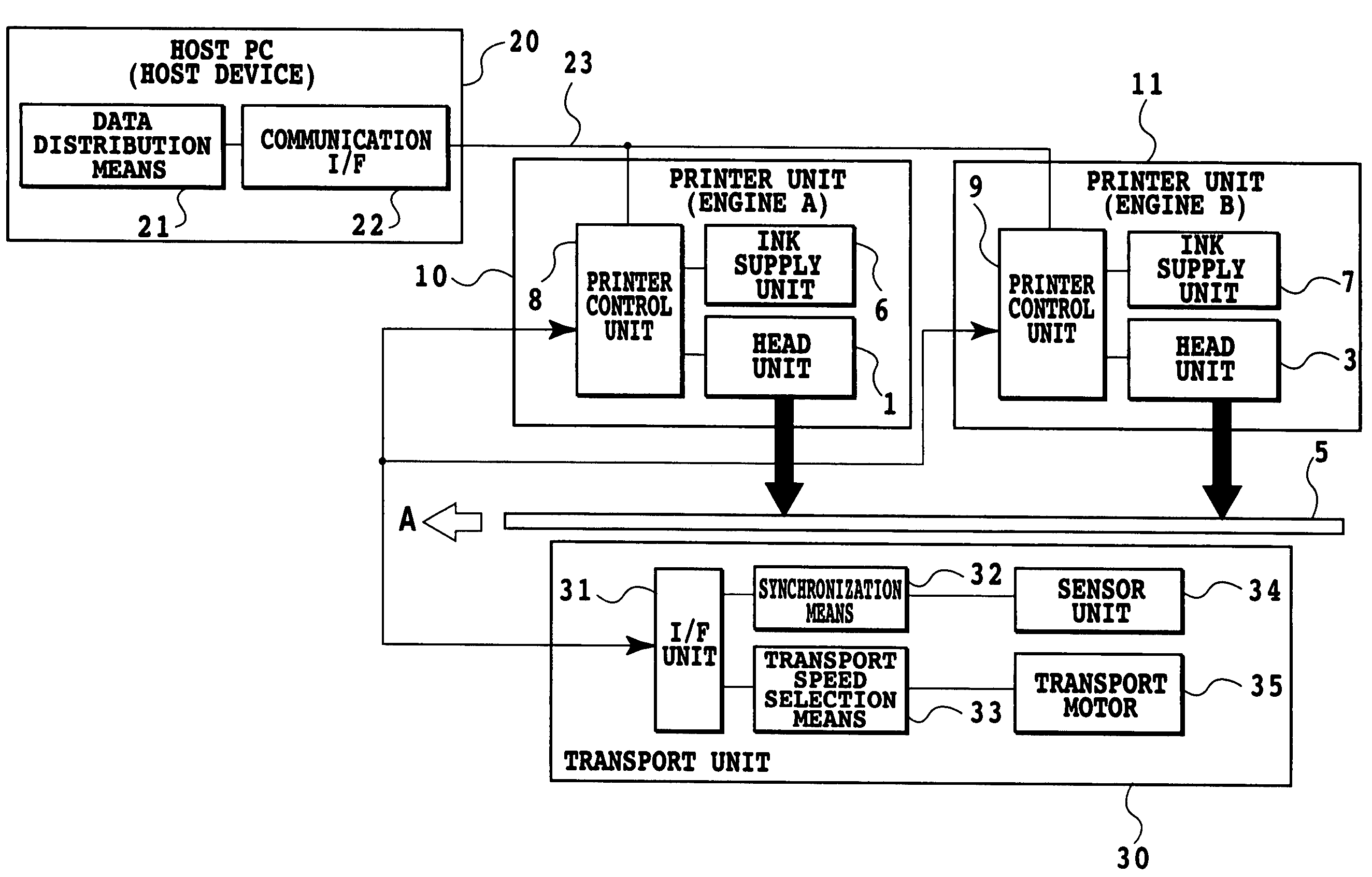

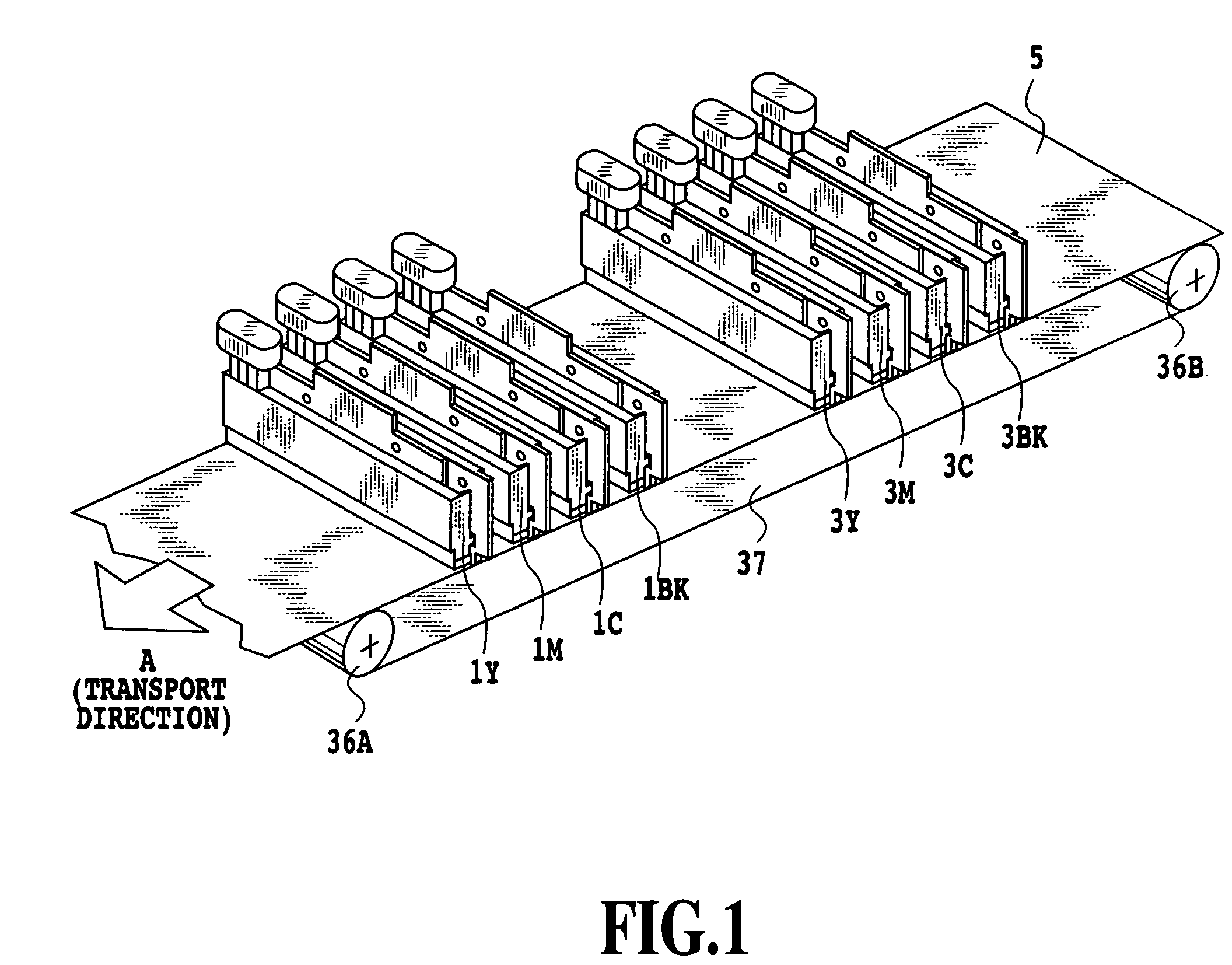

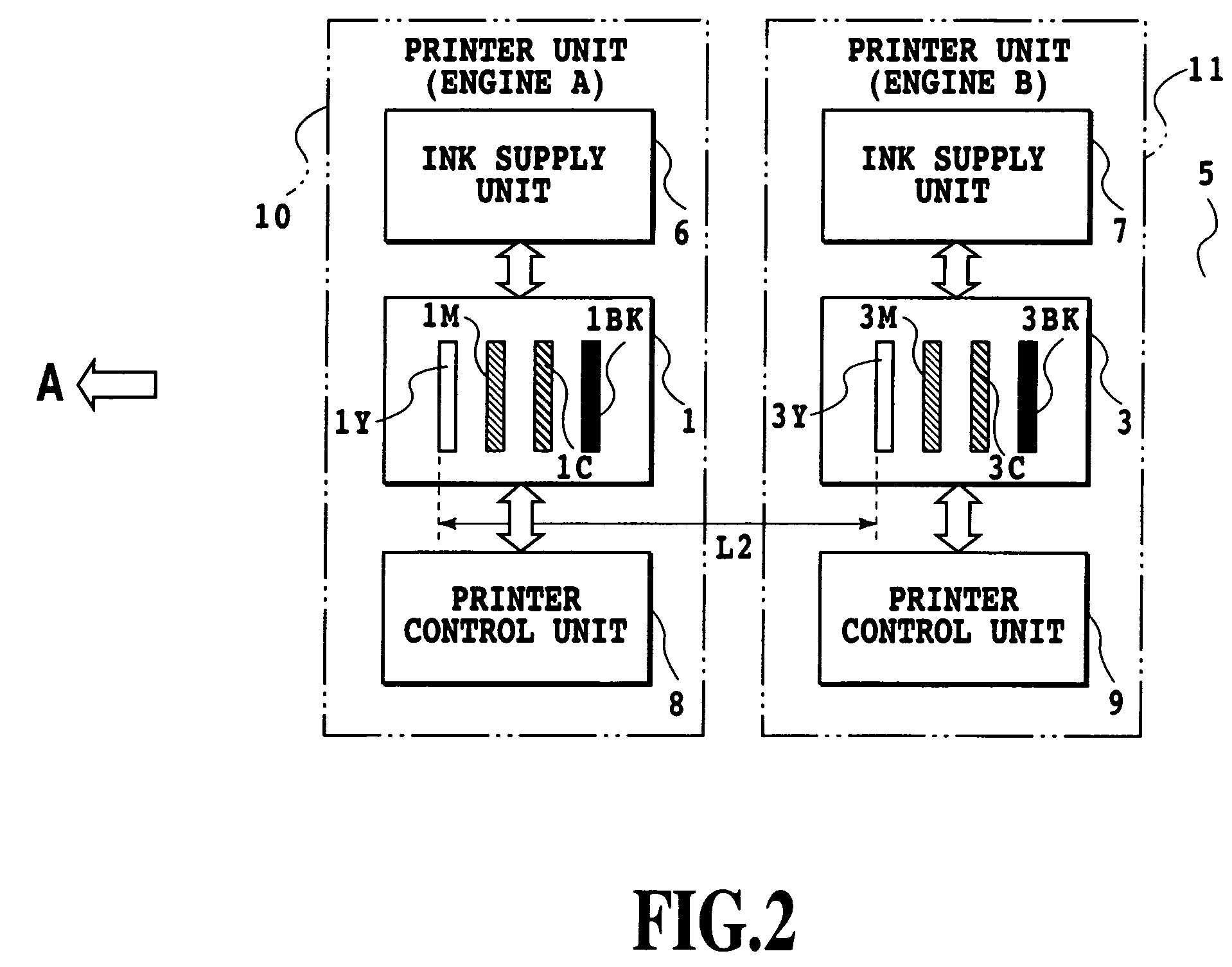

Printing apparatus, printing system, printing method, and program

InactiveUS20060033764A1Increase speedHigh speed printingOther printing apparatusHigh densityEngineering

Owner:COPYER

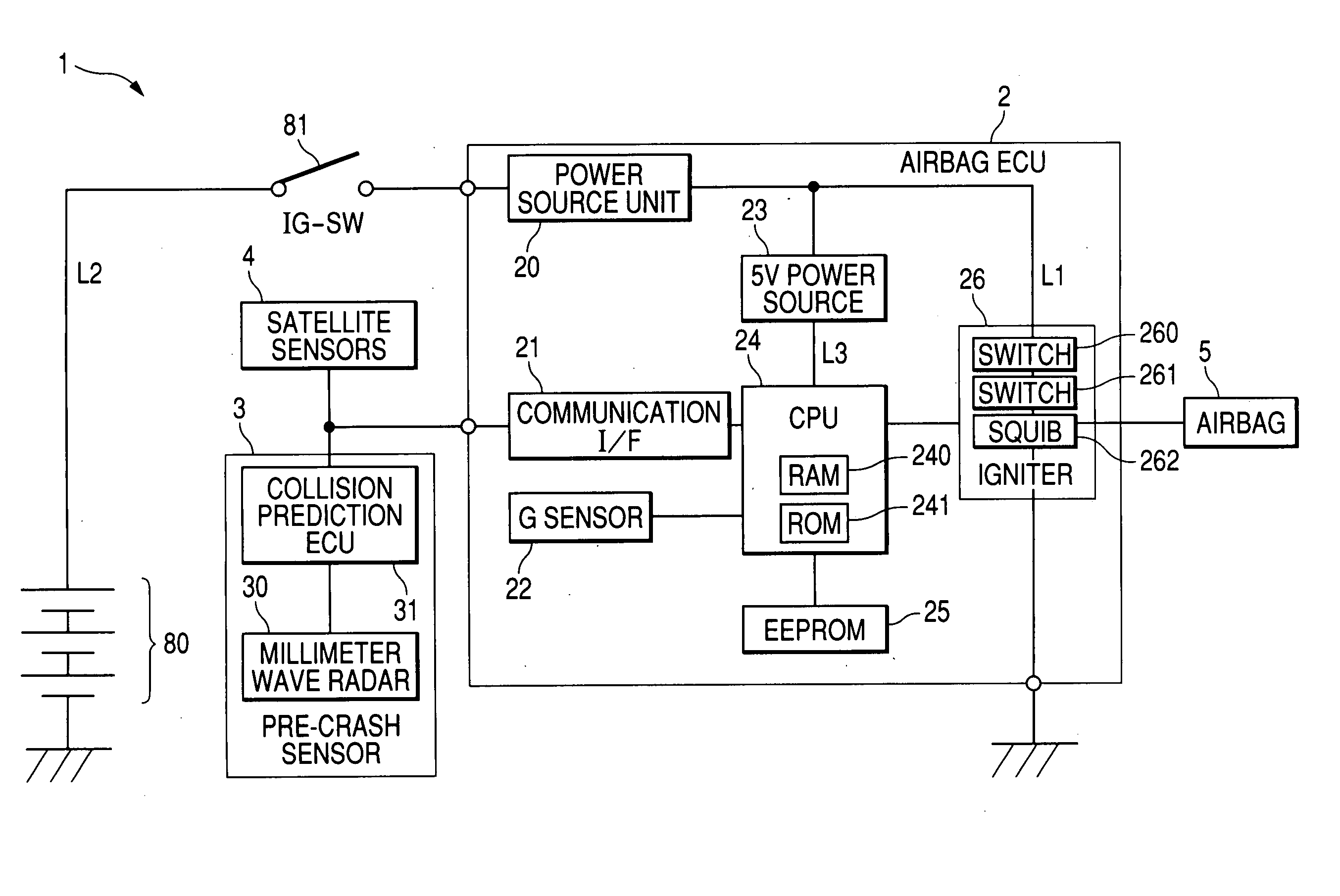

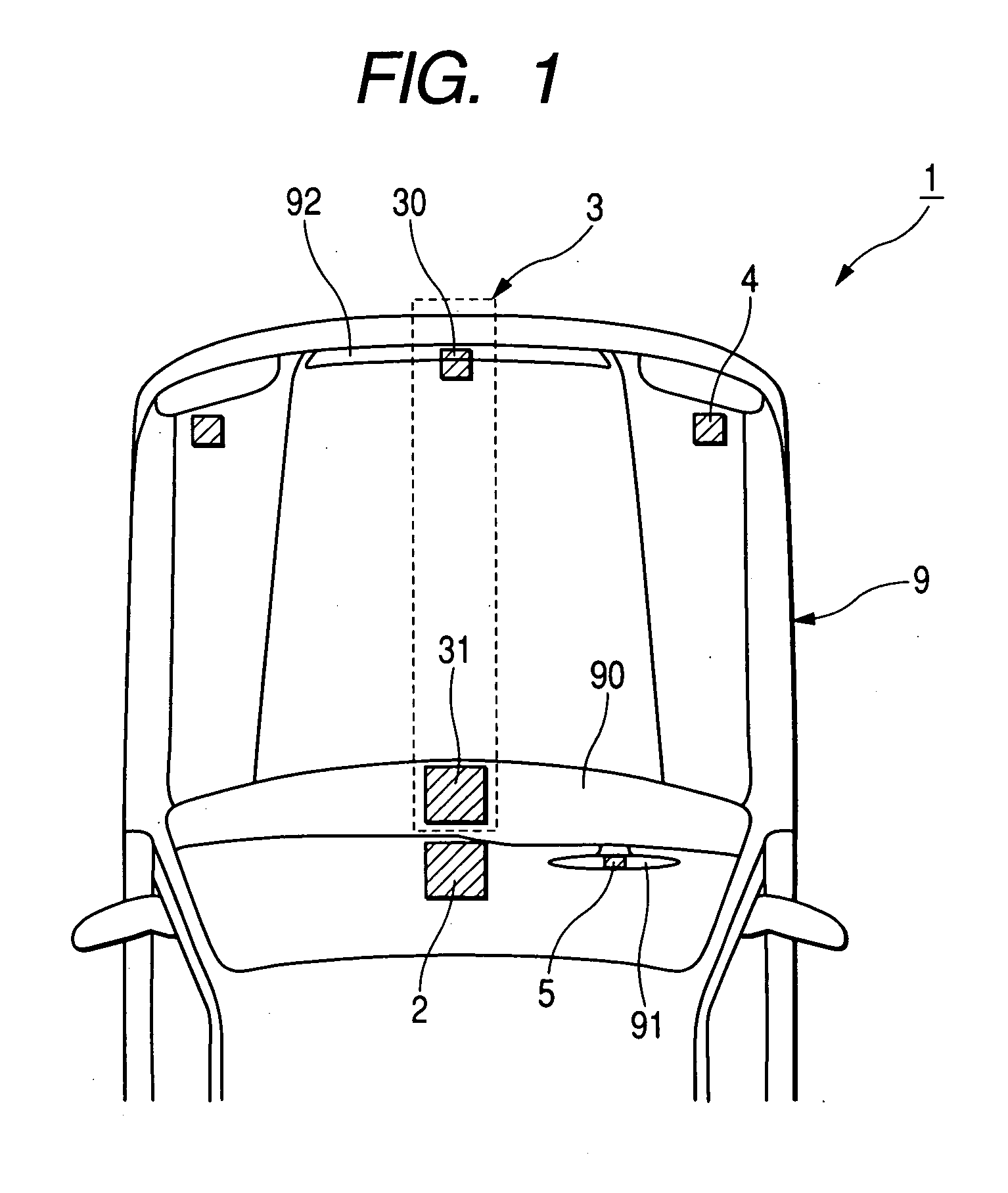

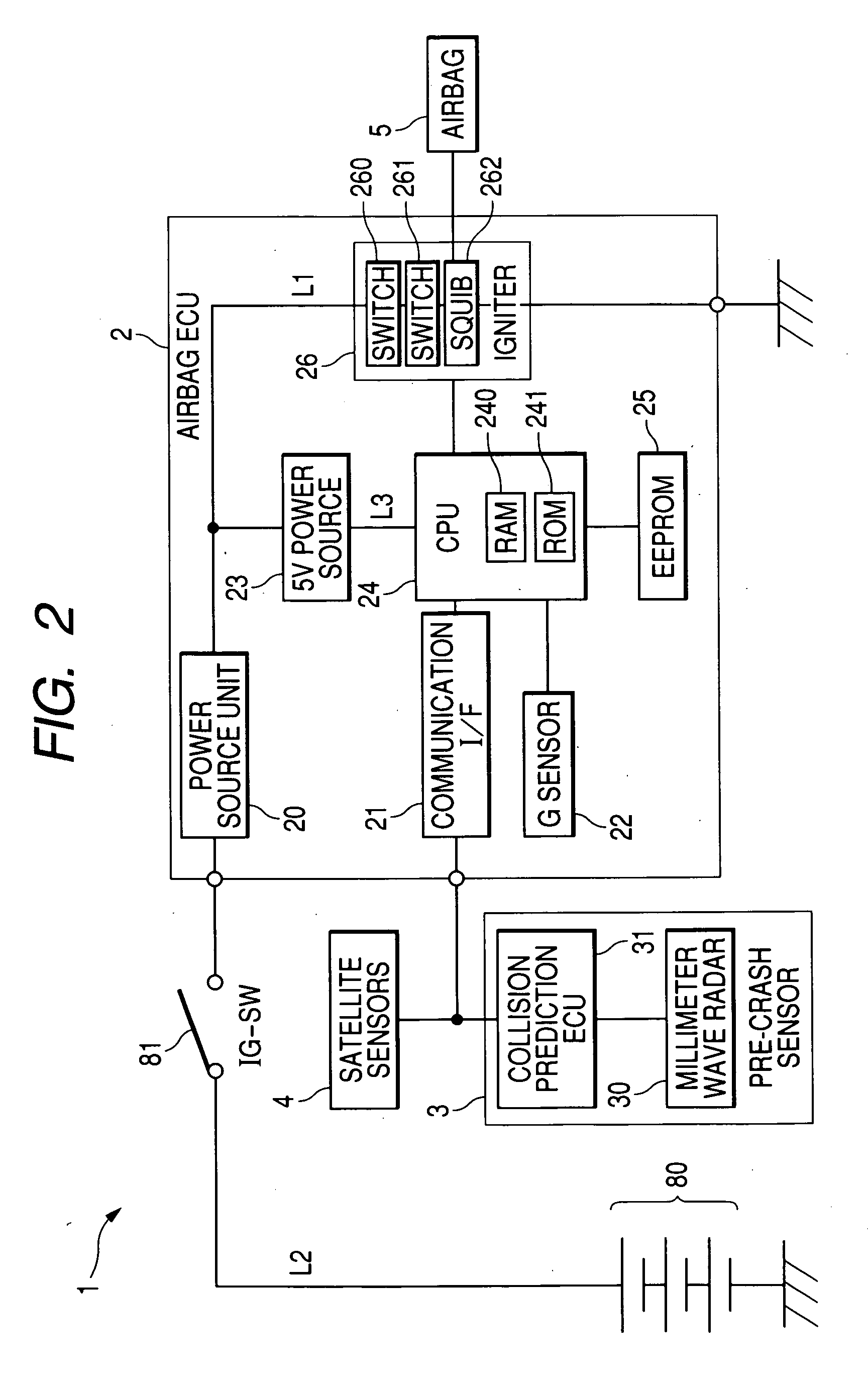

Occupant restraint system

InactiveUS20050187685A1Reliable settingsReduce loadDigital data processing detailsPedestrian/occupant safety arrangementEngineeringAirbag

An occupant restraint system of a vehicle has an airbag, a pre-crash sensor which calculates a probability of a collision of a vehicle with an object and outputs a pre-crash signal indicating a prediction of the collision when the probability is higher than a predetermined value, a satellite sensor which detects a degree of acceleration of the vehicle and starts outputting an acceleration signal indicating the detected degree of acceleration in response to the pre-crash signal, and an airbag ECU which processes the acceleration signal to obtain a processing result and deploys the airbag when the processing result indicates a collision of the vehicle with the object. Therefore, because the airbag ECU does not start processing the acceleration signal until the satellite sensor outputs the acceleration signal in response to the pre-crash signal, a load on the airbag ECU can be alleviated.

Owner:DENSO CORP

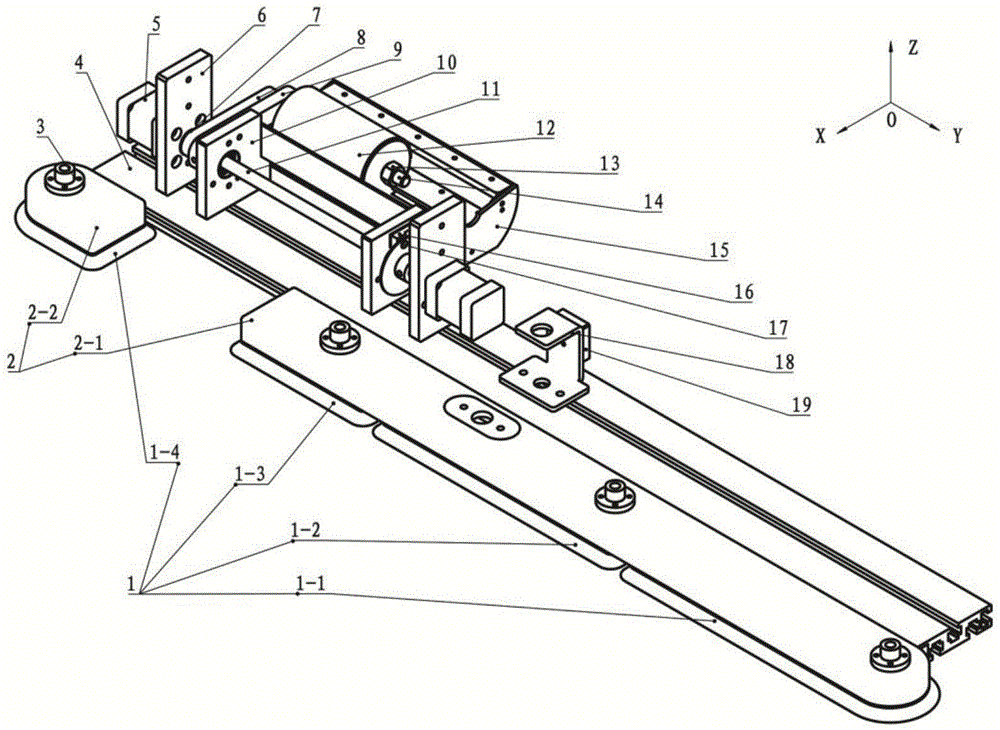

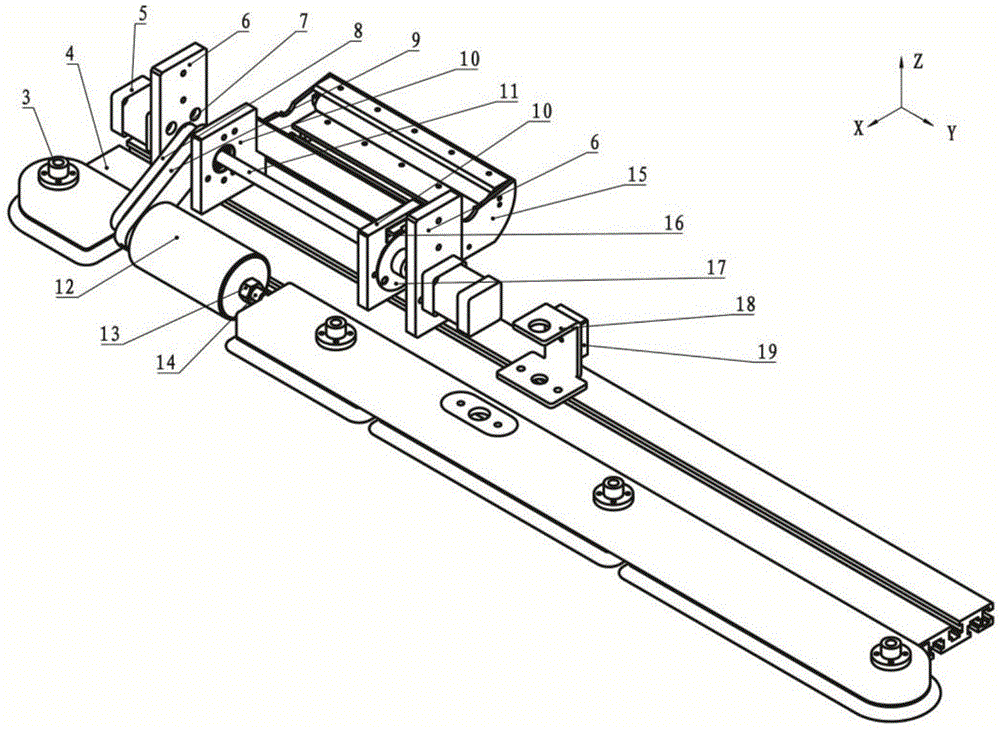

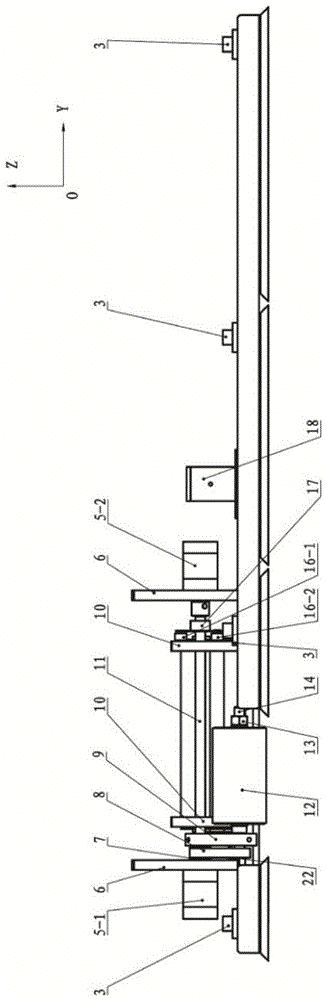

Automatic cloth single-layered separation and fetching method and mechanism of sewing machine

The invention relates to an automatic cloth single-layered separation and fetching method of a sewing machine. In a working process, a cloth sticking wheel and a cloth fetching device are pressed down together; firstly, the cloth sticking wheel is in contact with cloth; when pressure reaches a pre-set value of a pressure sensor, the cloth fetching device stops pressing down and the cloth sticking wheel is spliced with the cloth; after the cloth is stuck, the cloth fetching device ascends for a proper height; meanwhile, when the cloth sticking wheel swings upwards to be parallel to a fetching movement part, the cloth is separated in a singe layer to be fetched; the cloth sticking wheel continually ascends to be released from the cloth to be ready for secondary layering work; after each time of layering is finished, the cloth sticking wheel is driven by a sticking wheel stepping motor to roll for a certain angle to keep a new sticking surface; when the cloth sticking wheel is detected by a sensor assembly to rotate for one circle, a swinging motor drives the cloth sticking wheel to wholly swing to enter a cloth sticking wheel washing device to be washed; after the washing is finished, the cloth sticking wheel is oppositely driven by the swinging motor to wholly swing, and is detected by the sensor assembly to swing in place so as to enter a to-be-layered working state.

Owner:上海富山精密机械科技有限公司

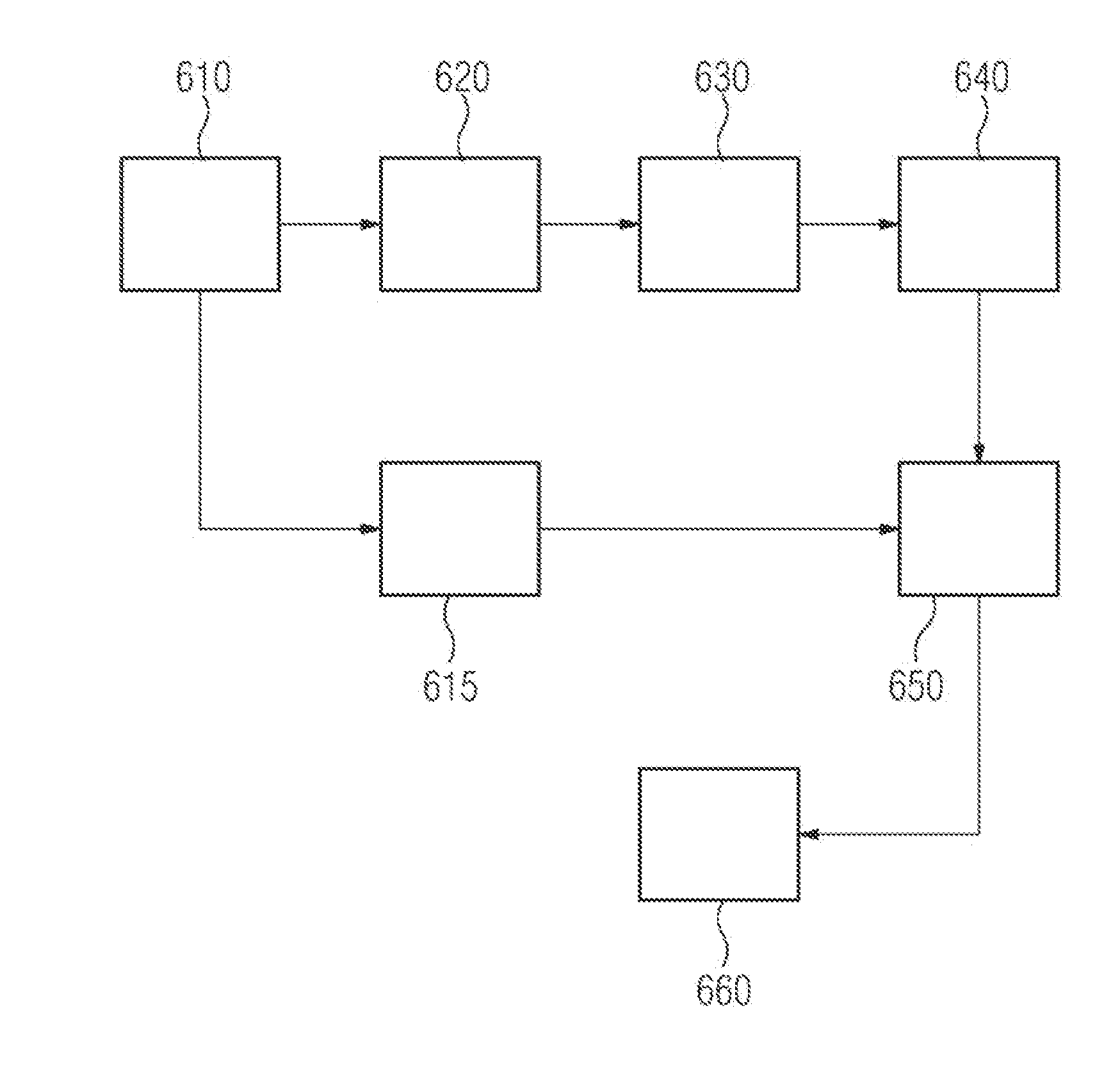

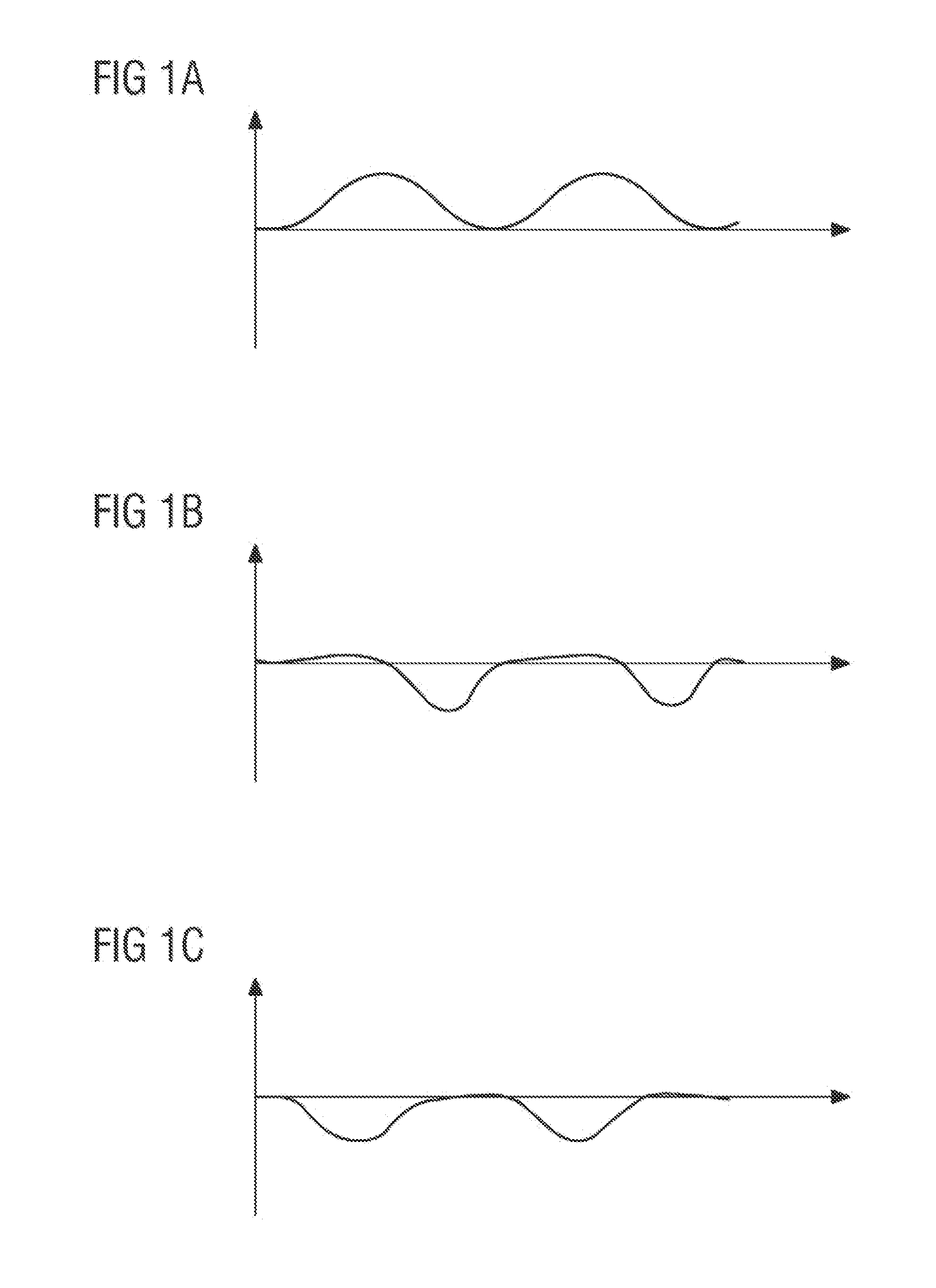

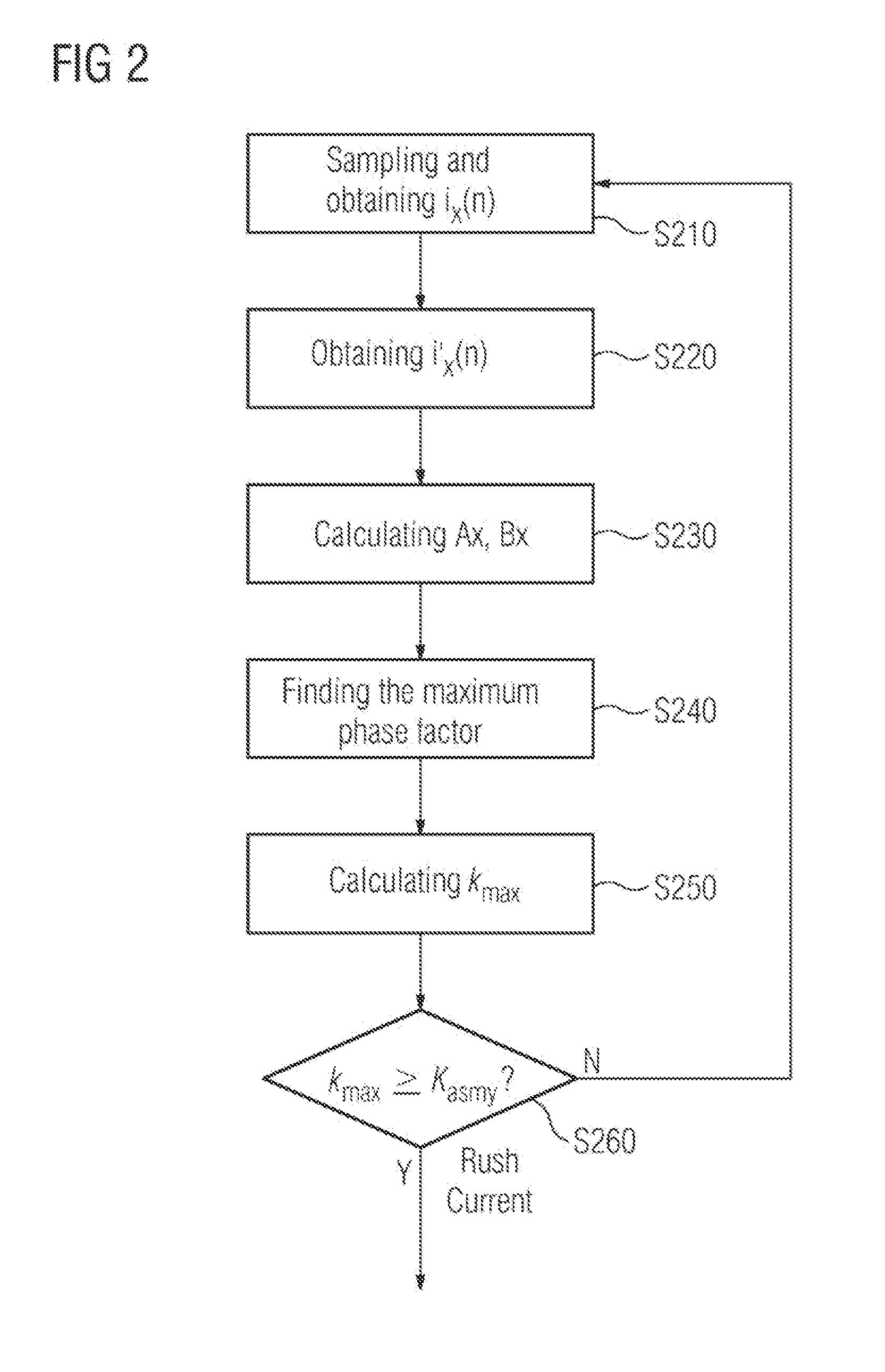

Magnetizing inrush current detection method, magnetizing inrush current restraint method and device

InactiveUS20150204918A1Accurate currentAccurate identificationCurrent/voltage measurementEmergency protective arrangement detailsPower flowRecognition algorithm

A method for detecting a magnetizing inrush current of a transformer includes the steps of obtaining a difference current for each AC phase of a transformer and calculating, for each AC phase, at least two factors for waveform symmetry recognition, on the basis of the difference currents obtained within one period. For each type of factor, one obtains the maximum value of the three factors corresponding to the three AC phases, to serve as a maximum phase factor of that factor. Based on the maximum phase factor obtained, a waveform symmetry recognition algorithm is used to calculate a corresponding waveform symmetry parameter, and if the waveform symmetry parameter meets a requirement for waveform asymmetry, then it is determined that a magnetizing inrush current has occurred. A device for protecting the transformer is further provided.

Owner:SIEMENS AG

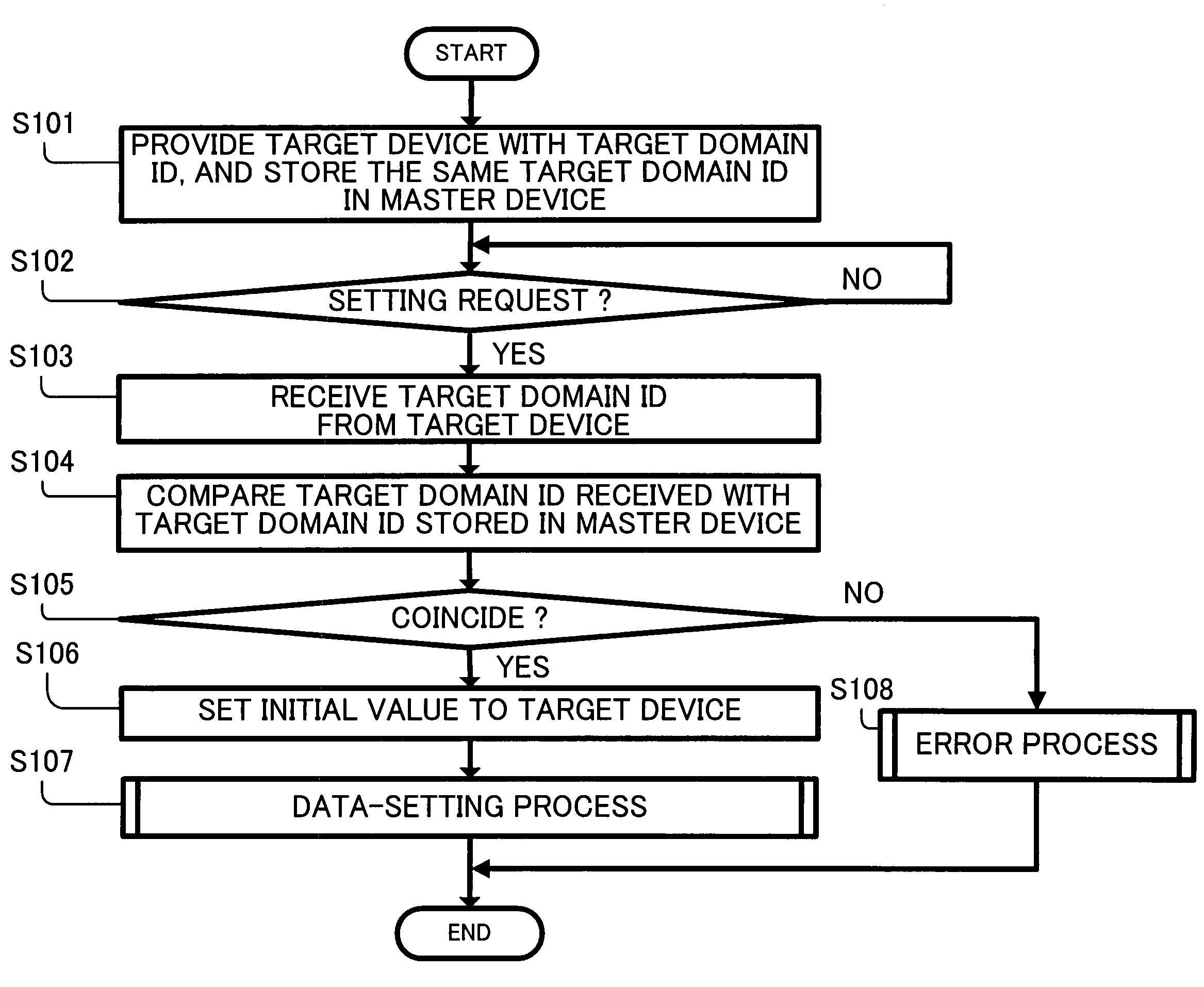

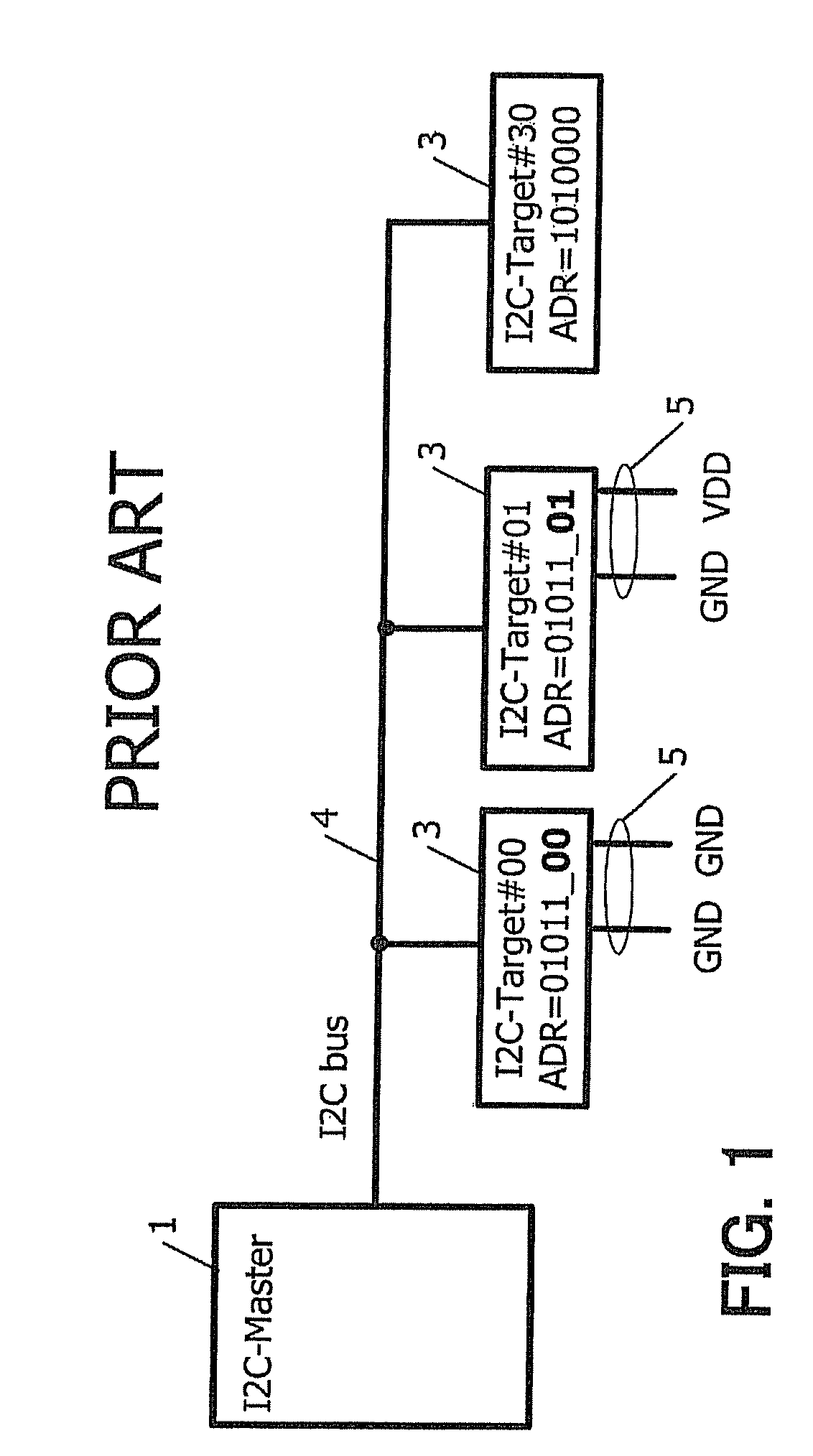

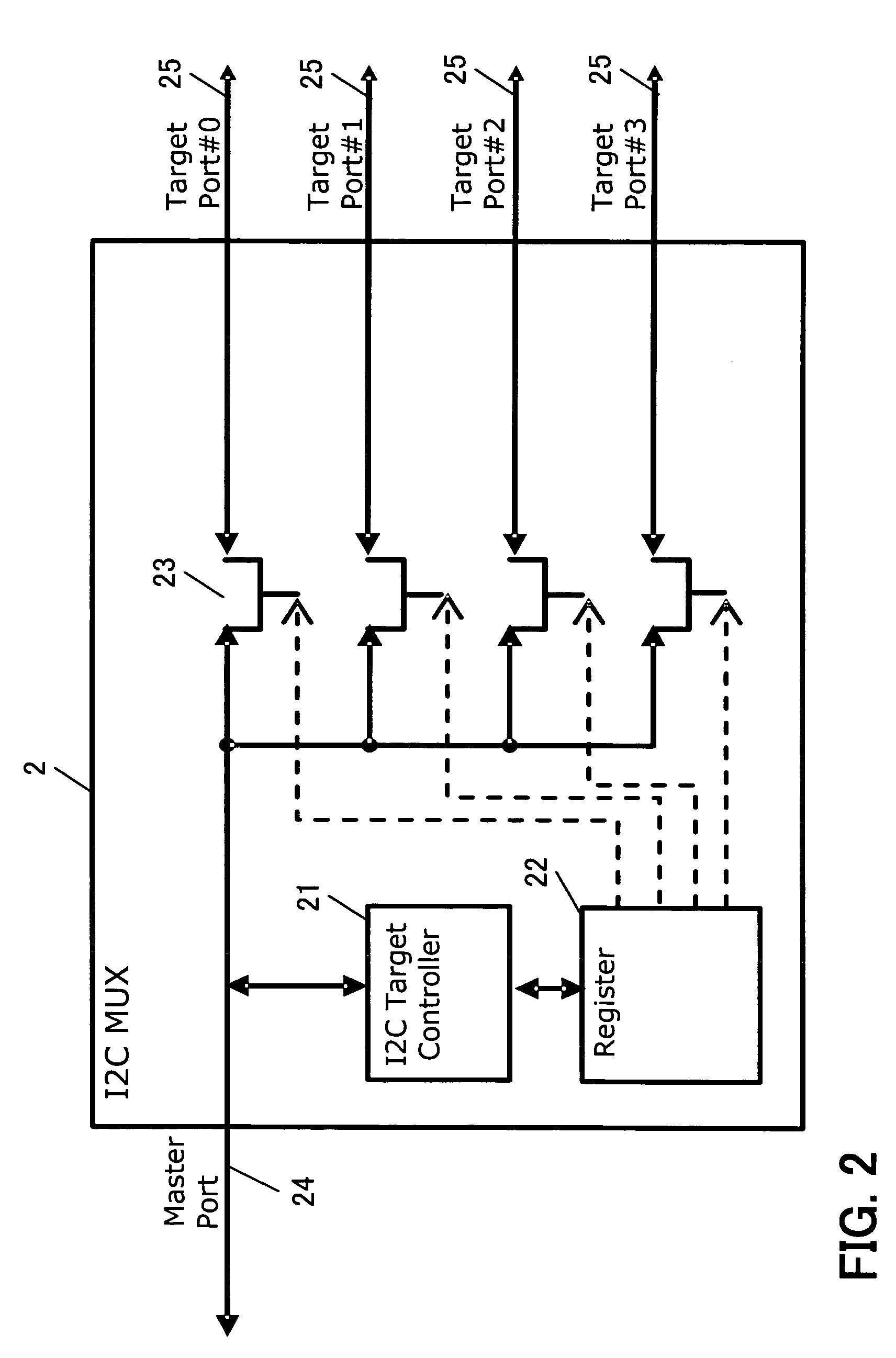

Sideband bus setting system and method thereof

InactiveUS7715450B2Reduce the numberReliable settingsError preventionTransmission systemsData setMultiplexer

A sideband bus setting system in which multiple target devices (ICs) are communicably connected to a master device through a bus so as to set data to ICs mounted on an electronic device. The target device is provided with a target domain ID identifying a target domain-which is a subgroup of multiple target devices, and the master device is provided with the same target domain ID as that provided for the target device. The master device receives the target domain ID from the target device, and performs data-setting process to the target device when the target domain ID received from the target device coincides with the target domain ID provided for the master device. According to the above feature, the failure of the bus (for example, the failure of a sideband multiplexer) can be detected in advance, thereby preventing overlooking the improper data-setting operation.

Owner:FUJITSU LTD

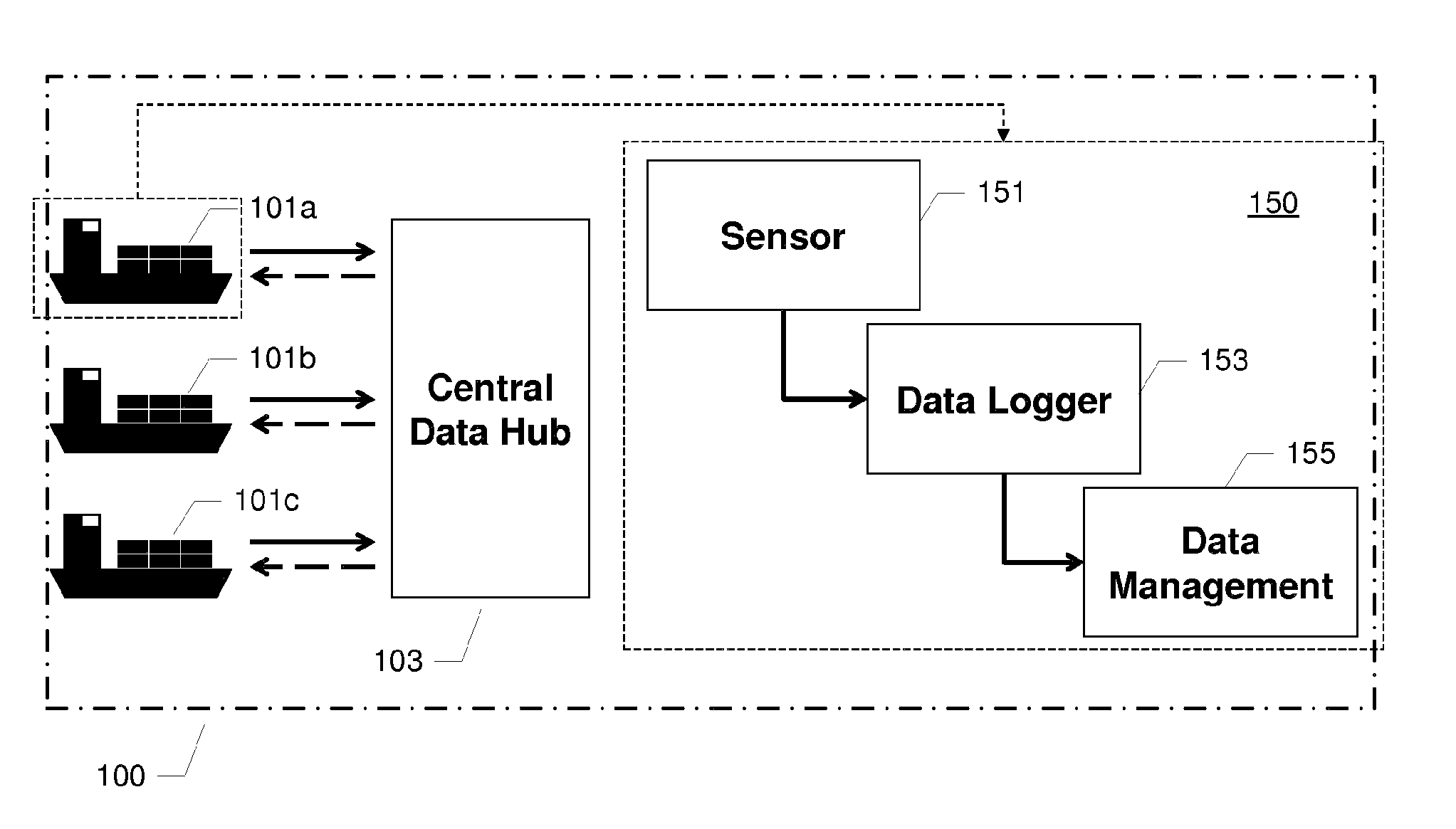

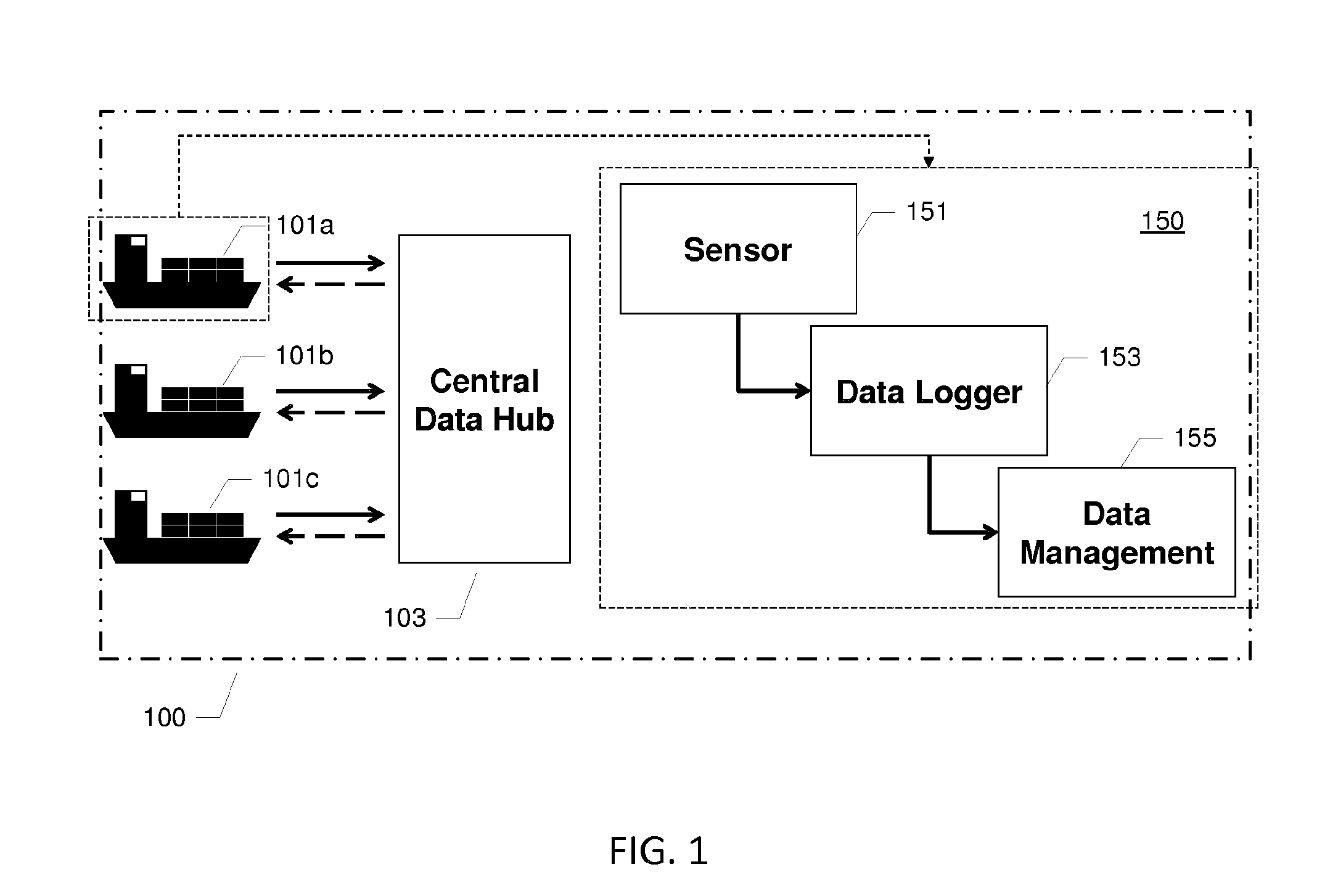

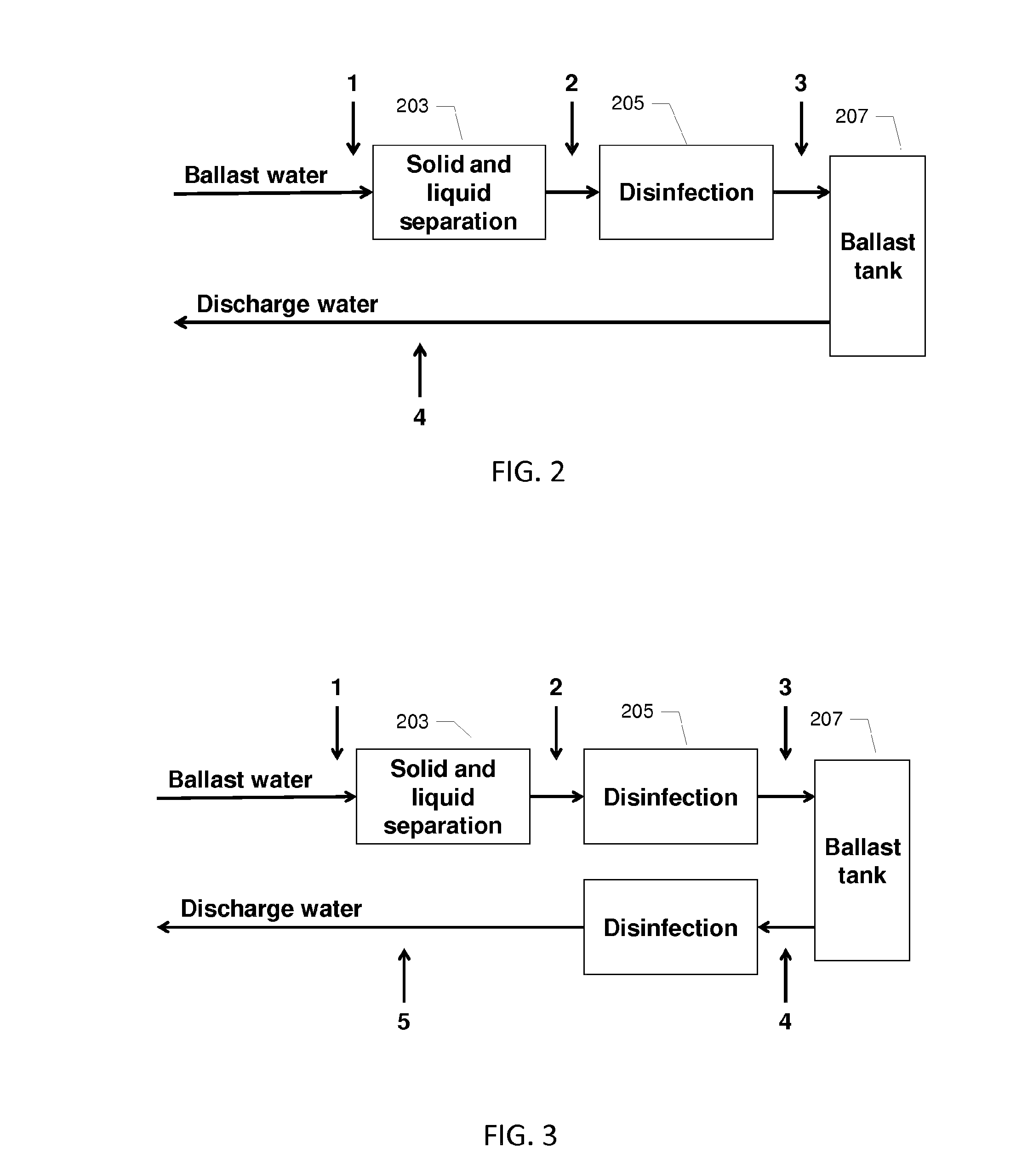

A method and system for monitoring quality of ballast water of a vessel

ActiveUS20150369787A1Faster and more flexible uploadingIncrease volumeWater treatment parameter controlAuxillariesData loggerPiping

The present invention relates to a system for monitoring quality of ballast water. The system comprises a central data hub comprising a data hub computer adapted for generating a set of acceptance criteria for ballast water quality parameters at one or more geographic positions based upon uploaded ballast water data from on-board computers of at least two vessels. The uploaded ballast water data indicates where, and possibly when, a volume of ballast water was loaded into a ballast water tank of each of the at least two vessels and the respective values of each of the ballast water quality parameters that are measured on each of the volumes of ballast water. The system for monitoring quality of ballast water further comprises at least two vessels, such as ships, each vessel comprising an on-board ballast water system comprises an on-board computer with a monitor, a data logger, a data storage for storage of a set of acceptance criteria for a number of the ballast water quality parameters corresponding to a geographical position and at least one geographical position. The on-board ballast water system further comprises detection means adapted for logging into the data logger the geographical position where the volume of ballast water is loaded into the ballast water tank and a number of ballast water quality sensors each being adapted for measuring at least one of the ballast water quality parameters of the ballast water in the ballast water piping or in ballast water tank. The on-board ballast water system is further adapted for logging ballast water data comprising a value of each of the ballast water quality parameters into the data logger and the on-board computer being further adapted for downloading the set of acceptance criteria from the central data hub and up-loading the ballast water data and the corresponding geographical position to the central data hub. The on-board computer is adapted to perform a comparison of the values of the ballast water quality parameters with corresponding acceptance criteria corresponding to said geographical position, and to display information on the monitor depending on said comparison.

Owner:LITEHAUZ APS

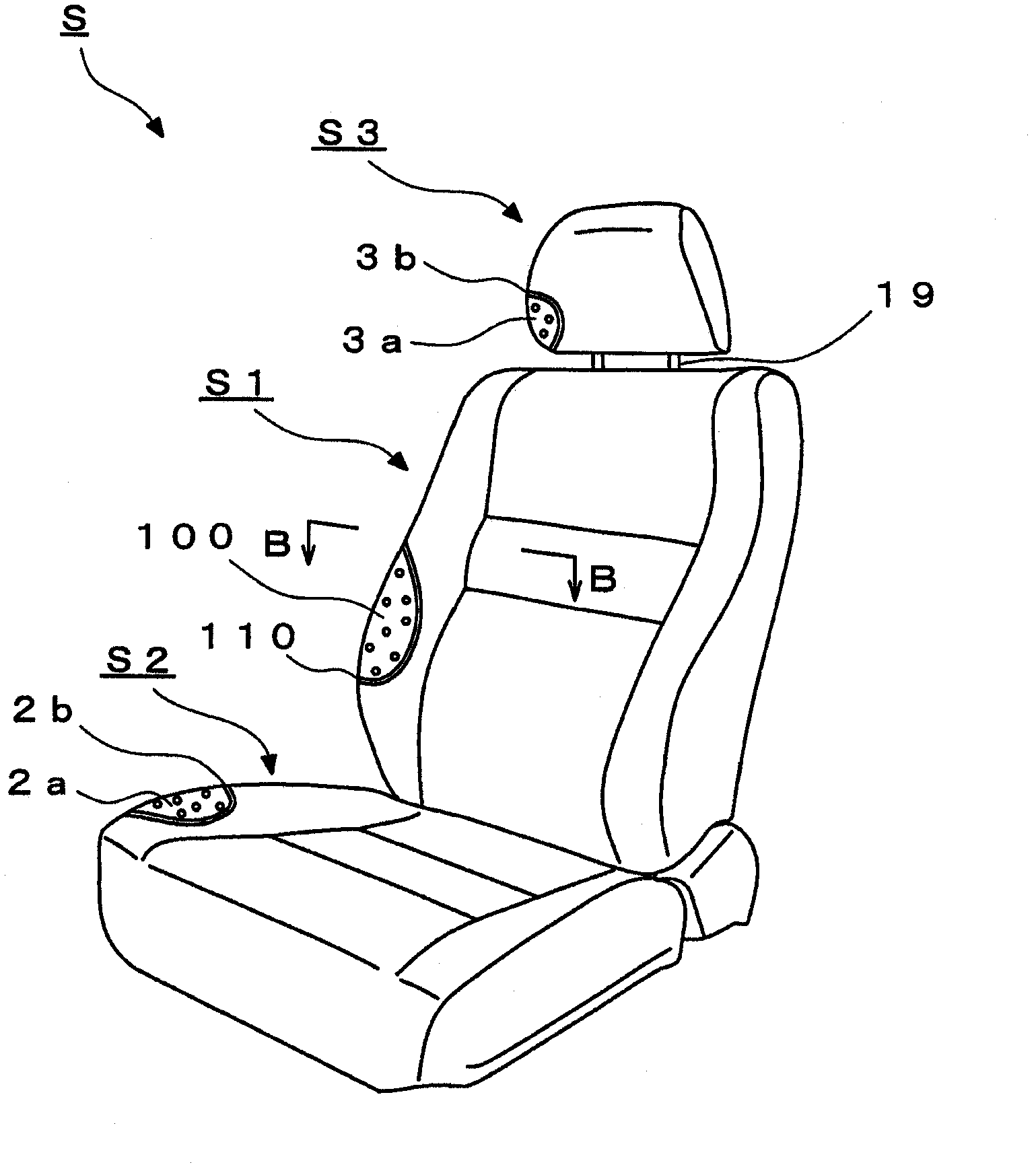

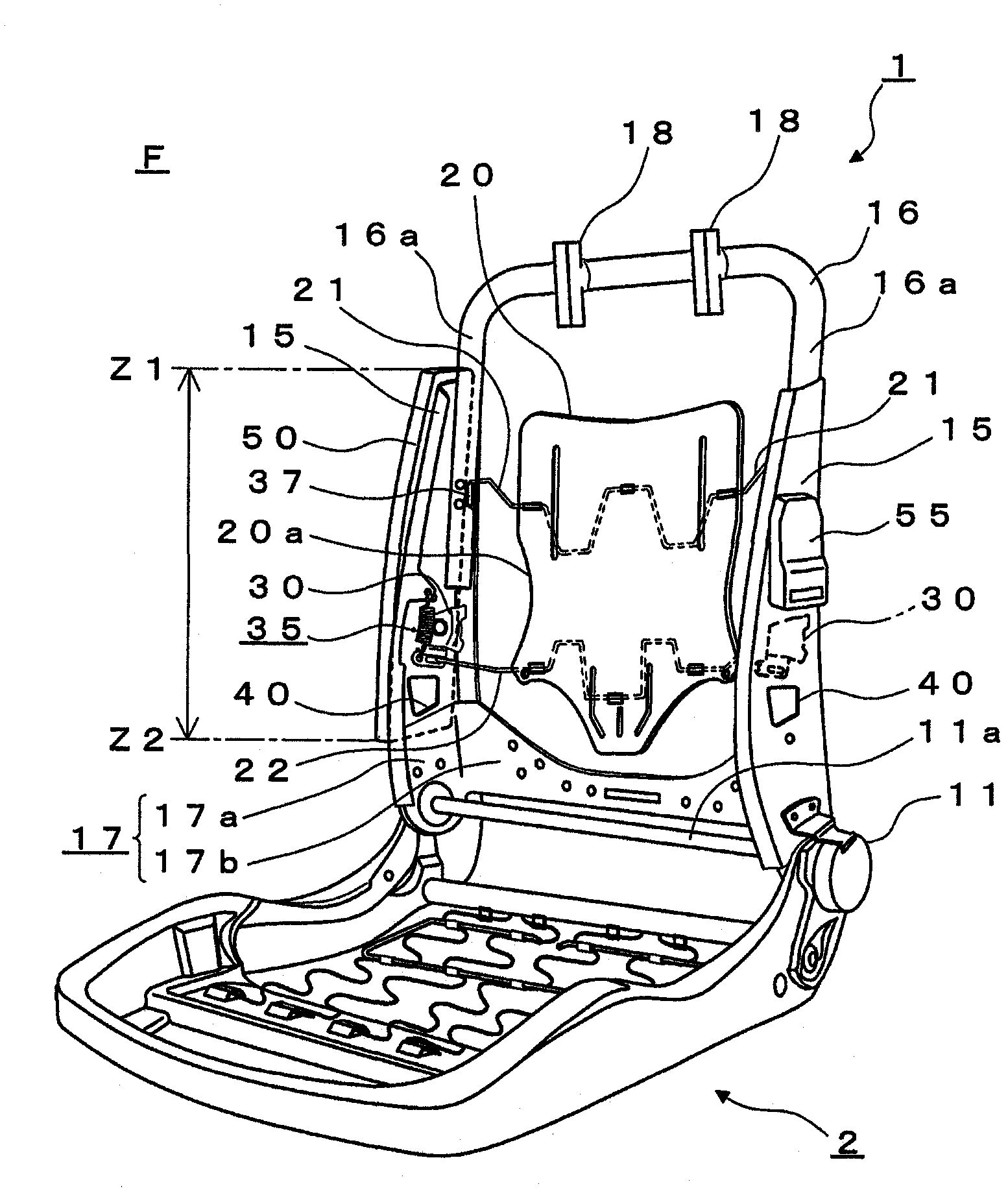

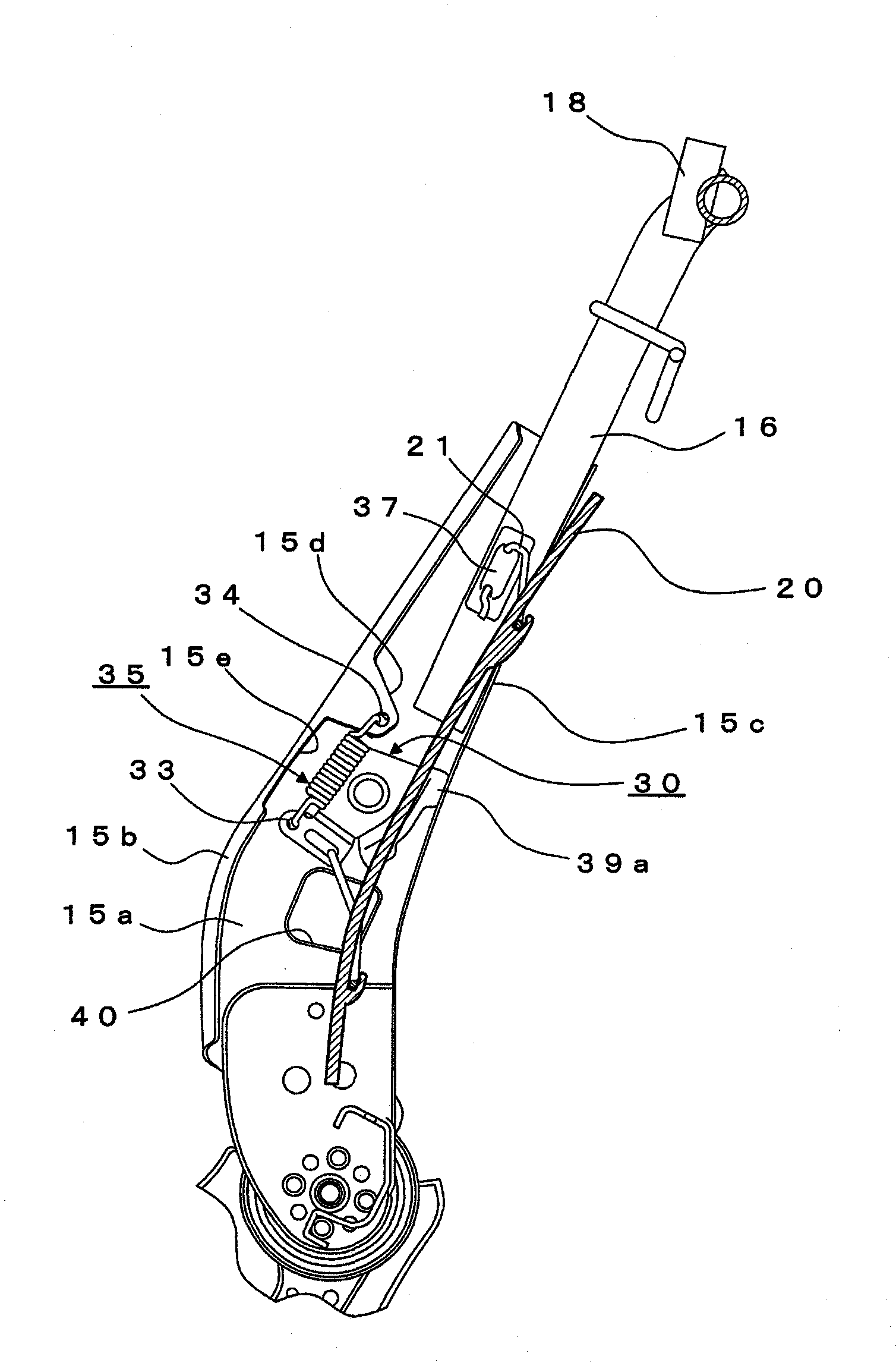

Vehicle seat

By providing a simple structure that is relatively independent from the headrest, the amount of sinking (moving) of the entire sitting body including the waist to the rear side of the passenger can be increased during a rear collision, and the force exerted on the seat during a rear collision can be effectively reduced. A passenger seat for a shock to a passenger. A seat (S) for a vehicle, including a seat back frame (1), a headrest (S3), a pressure-bearing part (20) that supports the passenger's body and moves relatively independently of the headrest (S3), and is arranged on the seat At least one side of the back frame (1) is connected to the pressure receiving member (20) at the same time, and is a rotating member (30) relatively independently movable relative to the headrest (S3) by a certain impact load. Furthermore, the entire pressure receiving member (20) moves rearward of the seated object by a certain impact load that is heavier than a general seating load.

Owner:TS TECH CO LTD

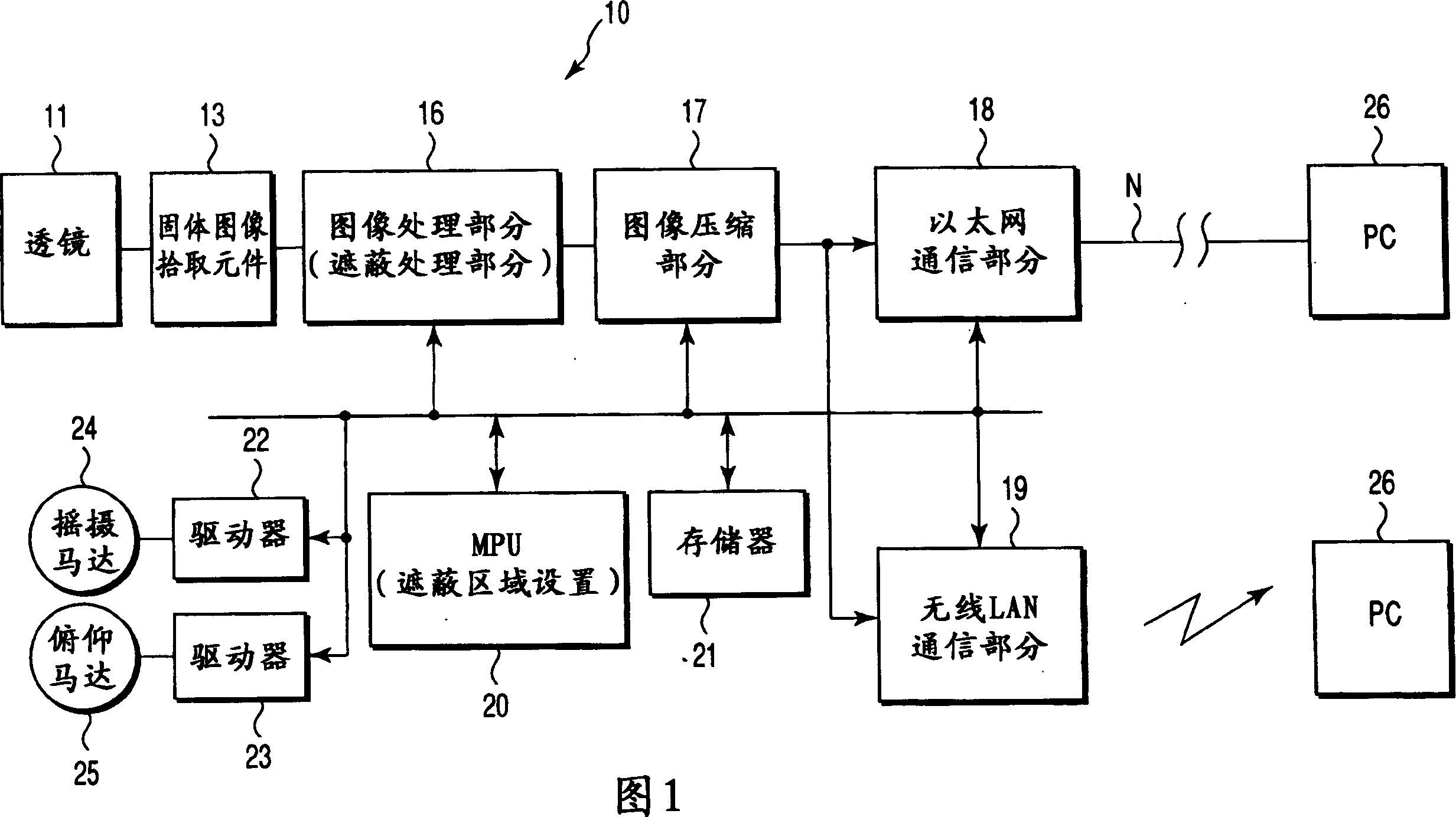

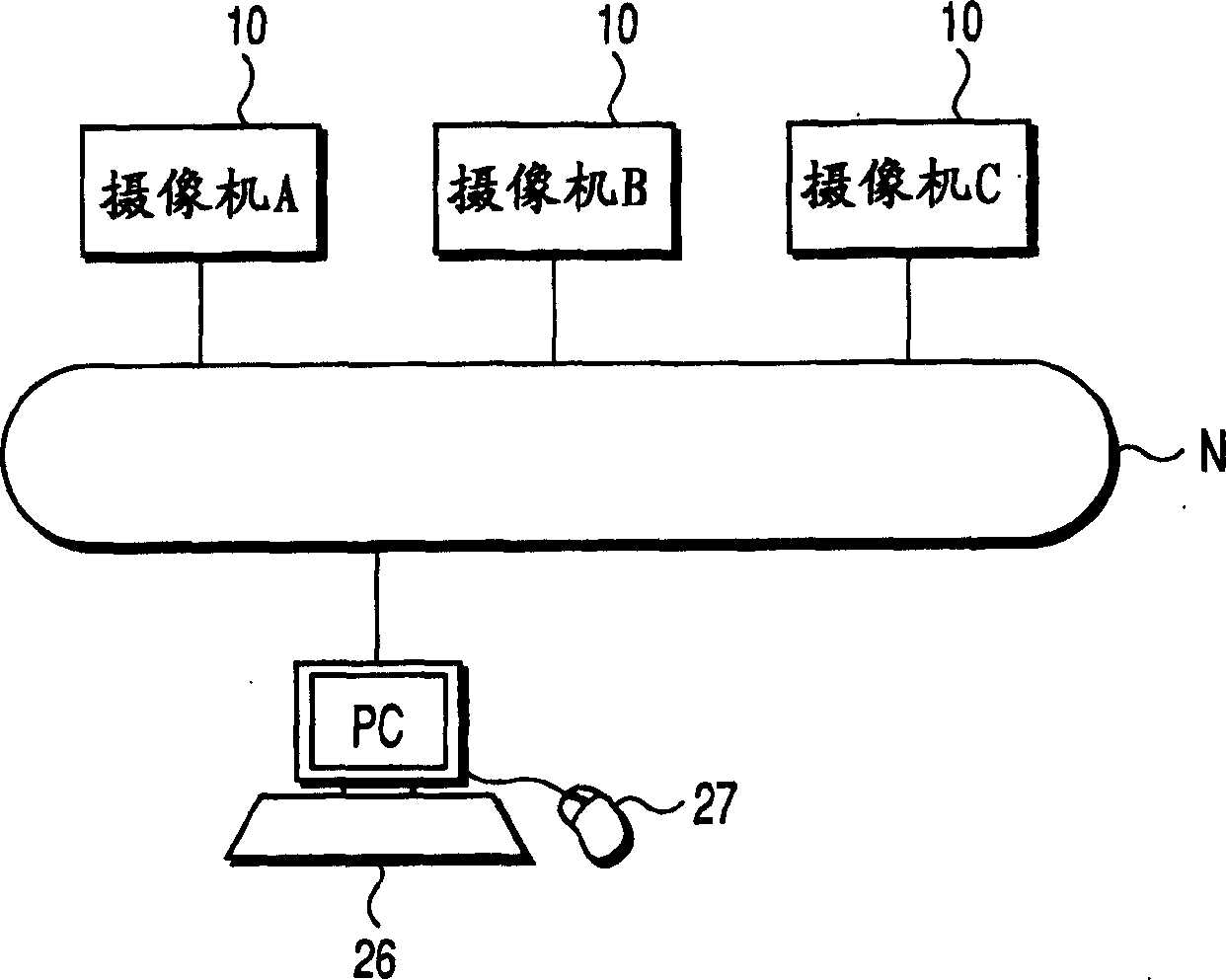

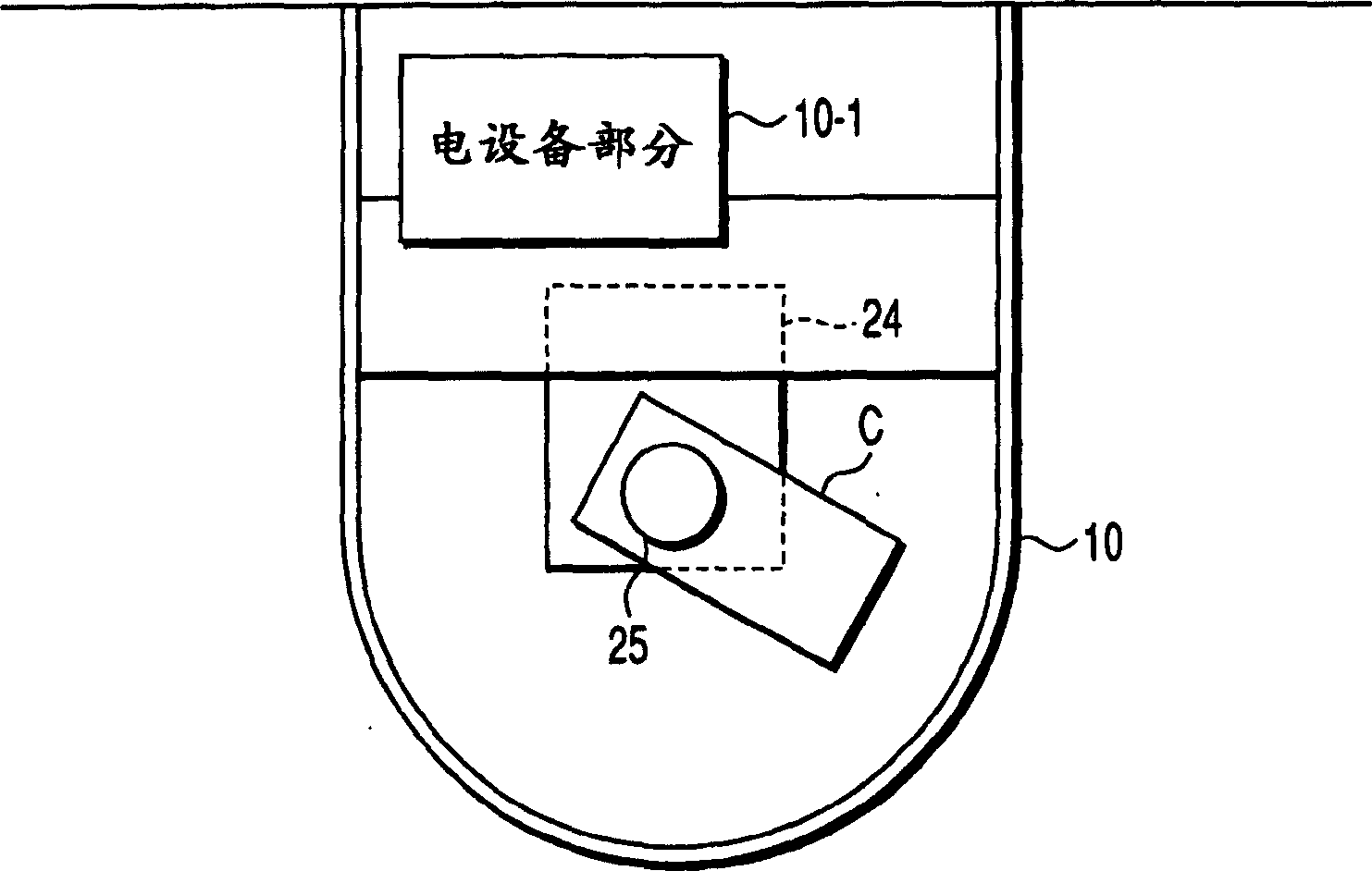

Image pickup apparatus, image pickup system, and image pickup method

InactiveCN1574891AReliable settingsEasy and reliable setupTelevision system detailsColor television detailsComputer graphics (images)

An image pickup apparatus including an image pickup section which picks up an image (11,13), a communication section (18, 19) which transmits the image to an external device, and which receives control information from the external device, and a processing section (20) which, in a state in which the image is displayed on a display screen of the external device, when a predetermined region on the display screen is designated, transmits regional information to the external device via the communication section in order to indicate the predetermined region within the image, and carries out masking processing for the image which is picked up at the image pickup section on the basis of the predetermined region, and setting of the masking processing is easily carried out on a screen of a PC 26 or the like, on a network.

Owner:KK TOSHIBA

Printing apparatus, method, and program comprising a plurality of printer units using synchronized, divided print data

InactiveUS7658460B2Reliable settingsHigh speed printingOther printing apparatusData controlHigh density

Owner:COPYER

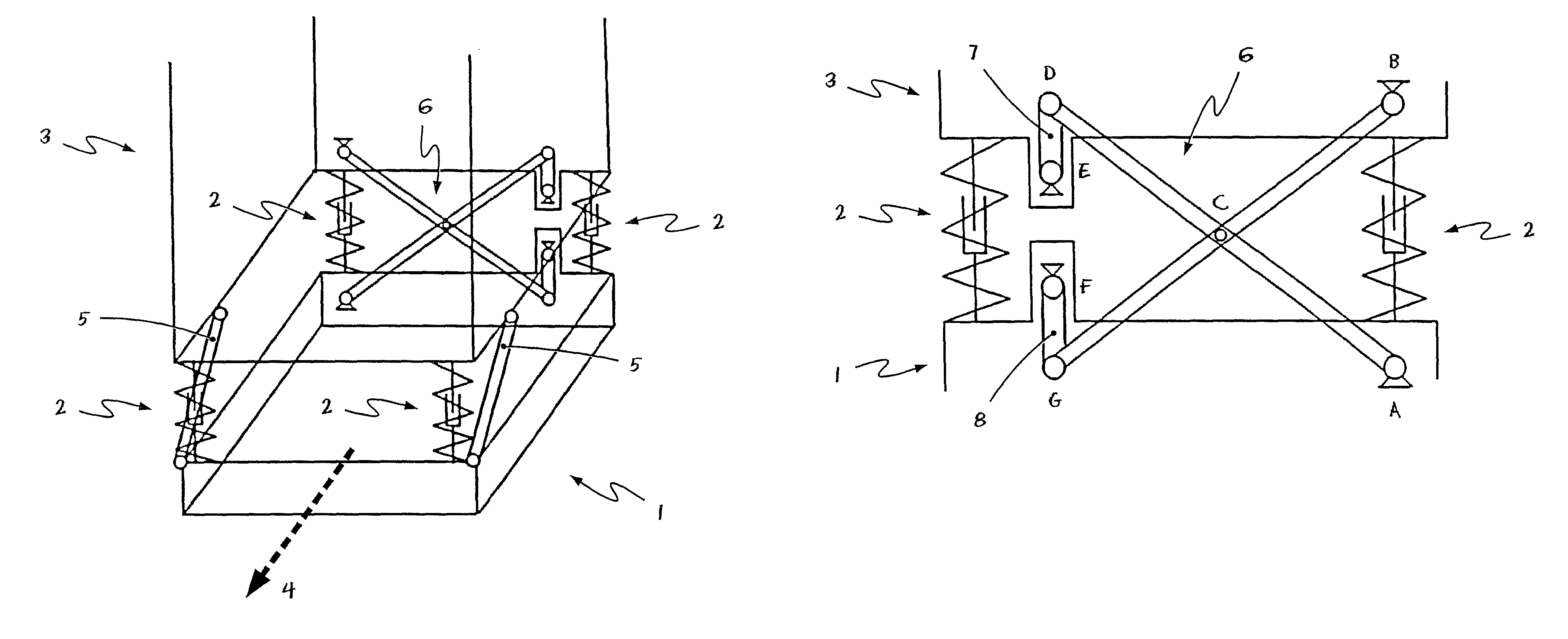

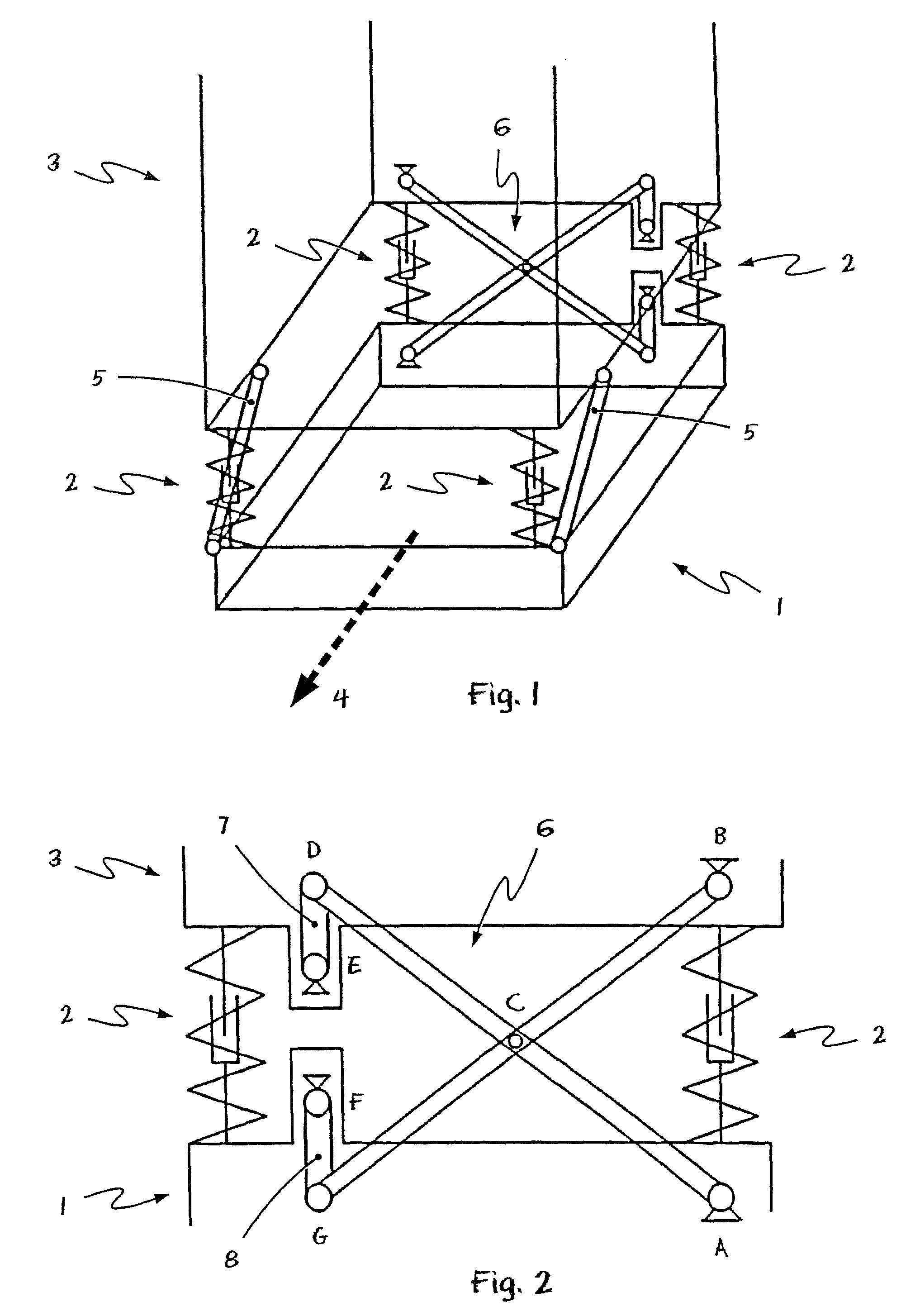

Suspension means with scissor pantograph

InactiveUS7950727B2Reliable settingsEffectively absorb and suppressVehicle seatsStands/trestlesEngineeringSpatial direction

A suspension arrangement for spring suspending a mass body (3) in relation to a substructure (1), for example, a driver's cabin (3) of a heavy goods vehicle in relation to the vehicle chassis (1) thereof. The suspension arrangement comprises a spring / damper arrangement (2) which is arranged between the mass body (3) and the substructure (1) and which is used to dampen thrusts and / or oscillations. The suspension arrangement in characterized in that it comprises at least one pantograph (6) which is used to reduce the freedom of movement of the mass body (3). The inventive suspension arrangement is constructively robust and can determine the provided freedom of movement of the mass body in a reliable manner and can dampen and / or prevent undesired movements in other spatial directions. The invention enables an economical and a reliable spring suspension, in particular, for a driver's cabin of heavy good vehicles, to be produced.

Owner:ZF FRIEDRICHSHAFEN AG

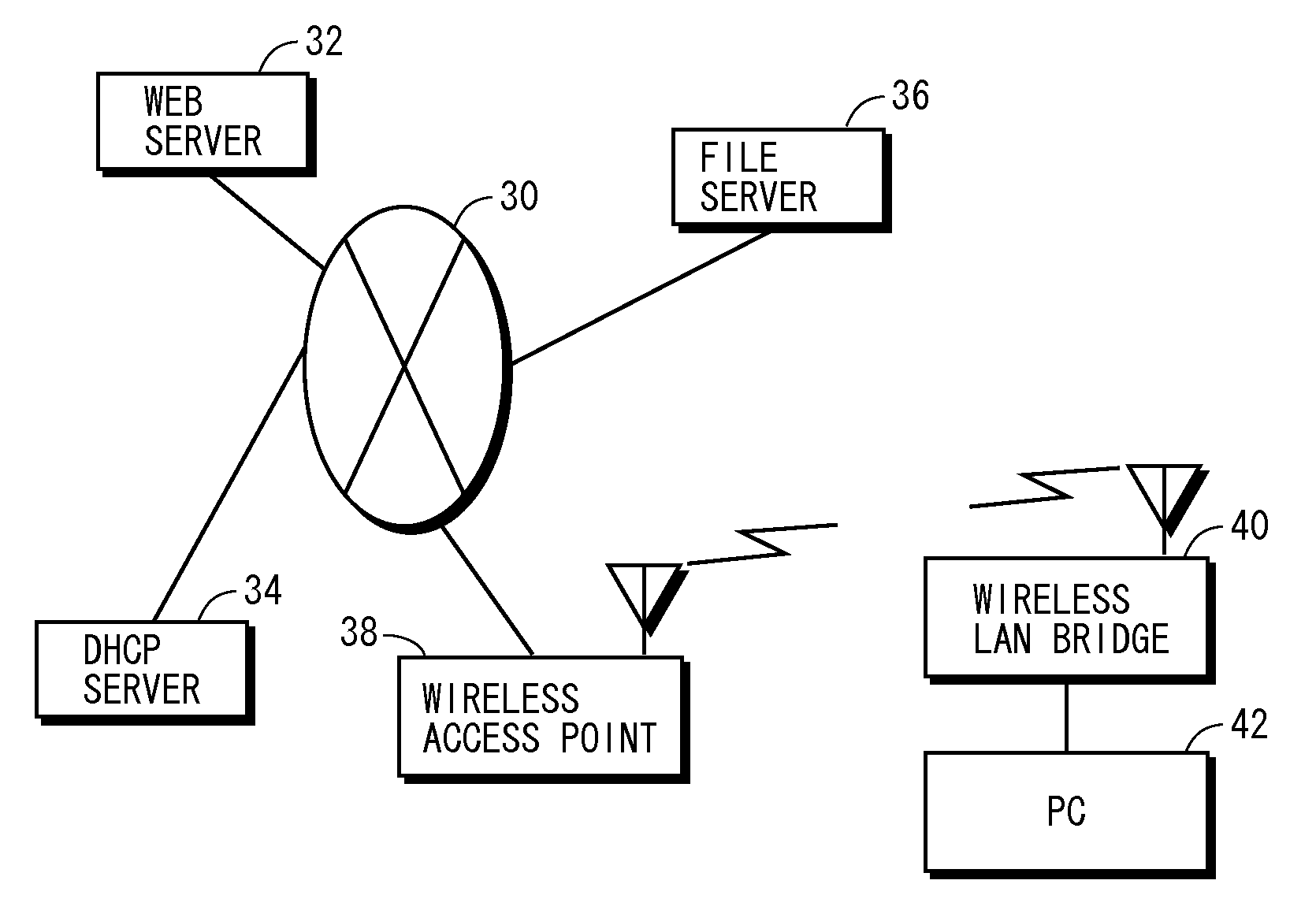

Conveyors for transporting goods

ActiveCN102300791AImprove robustnessSimple structureSortingConveyor partsEngineeringMechanical engineering

The present invention relates to a transport apparatus for conveying goods (4), comprising a rotatably mounted transport wheel (2), which has a plurality of bags (3) arranged on an outer circumference for receiving the goods (4) to be conveyed, an inlet region (5) in which the goods (4) are fed to the transport wheel (2), an outlet region (6) in which the goods (4) are led out of the transport wheel (2), an inspection device (8) which inspects the goods (4) in order to identify rejected goods, a reject outlet (7) to discharge rejected goods, a pushing device (10) having a pushing element (11) to push rejected goods into the reject outlet (7), and a control unit (9) that is connected to the inspection device (8) and the pushing device (10) in order to activate the pushing element (11) when rejectedgoods are detected and to push the rejected goods into the reject outlet (7).

Owner:SYNTEGON TECHNOLOGY GMBH

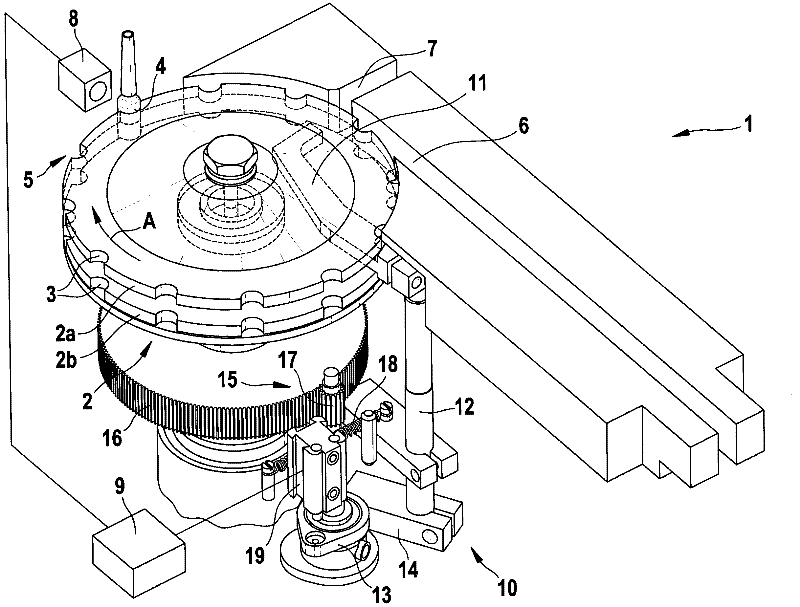

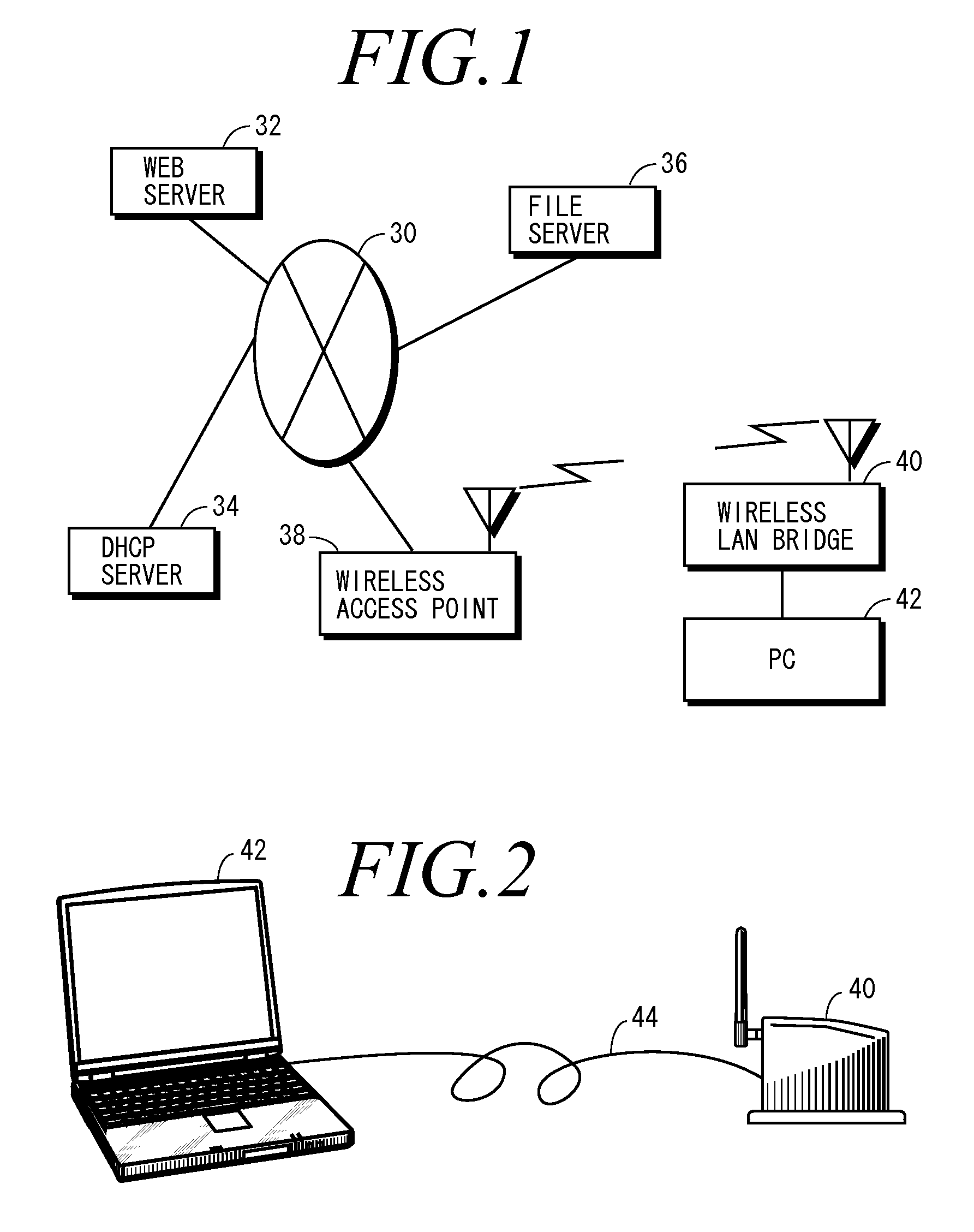

Network Device Allowing Easy Setup and Computer Program Therefor

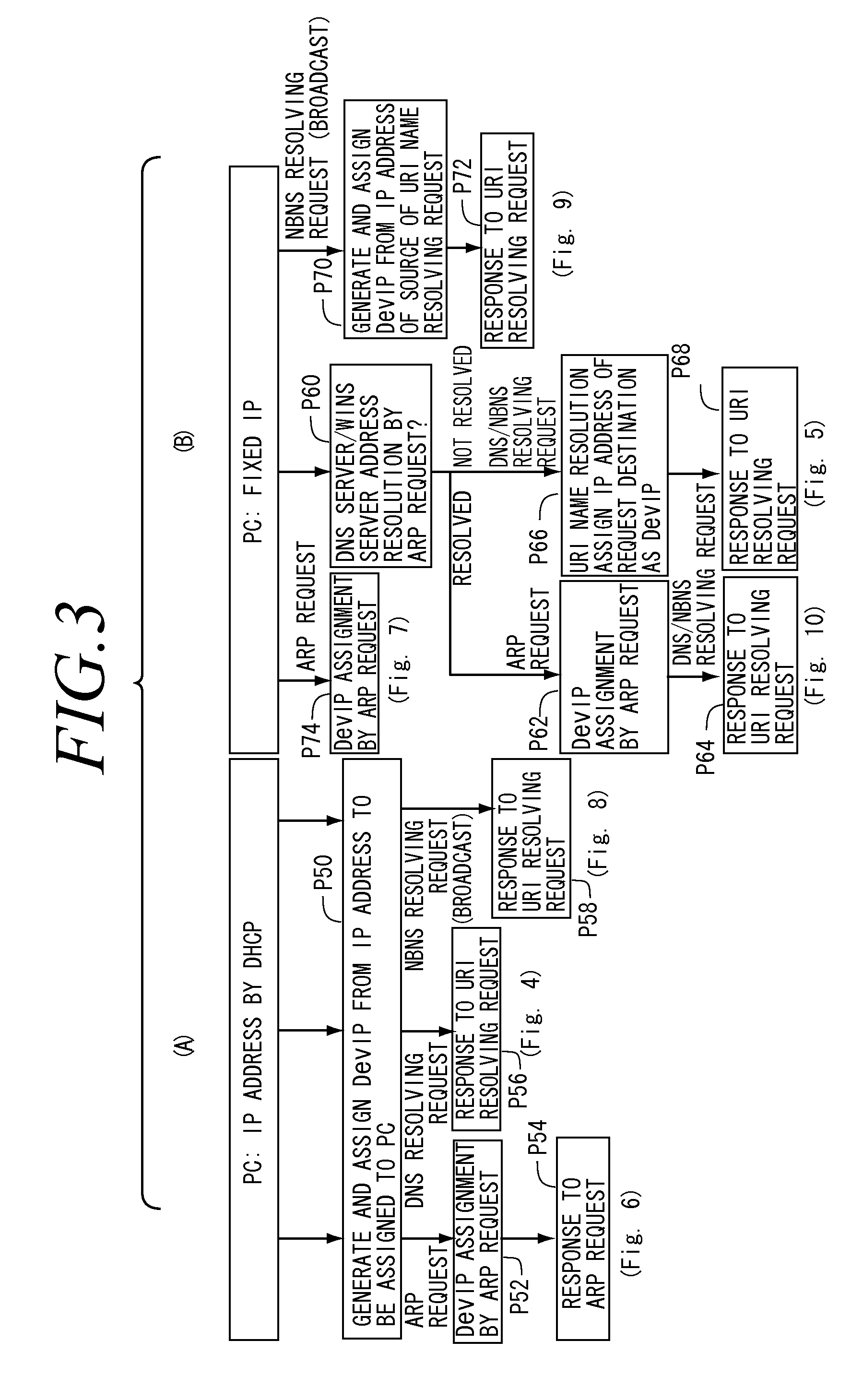

InactiveUS20080059611A1Excessive burdenReliable settingsMultiple digital computer combinationsWireless network protocolsOperation modeComputer program

A network device operating in a configuring mode and a normal operational mode includes: a configuration parameter memory; a network interface; a dynamic address generating unit that generates two logical addresses, when a DHCP request is received in the configuring mode, and returning one logical address to a transmission source of the request and assigning the other to the network device; a name resolving unit that transmits, when a name resolving request is received in the configuring mode, a logical address of the network device to the transmission source regardless of the name; and a parameter setting unit storing a parameter value transmitted, after the logical address of the network device is transmitted by the identifier resolving unit to the transmission source, using the logical address by said transmission source. In the normal operational mode, a network function is realized using parameters in the memory.

Owner:SILEX TECHNOLOGY INC

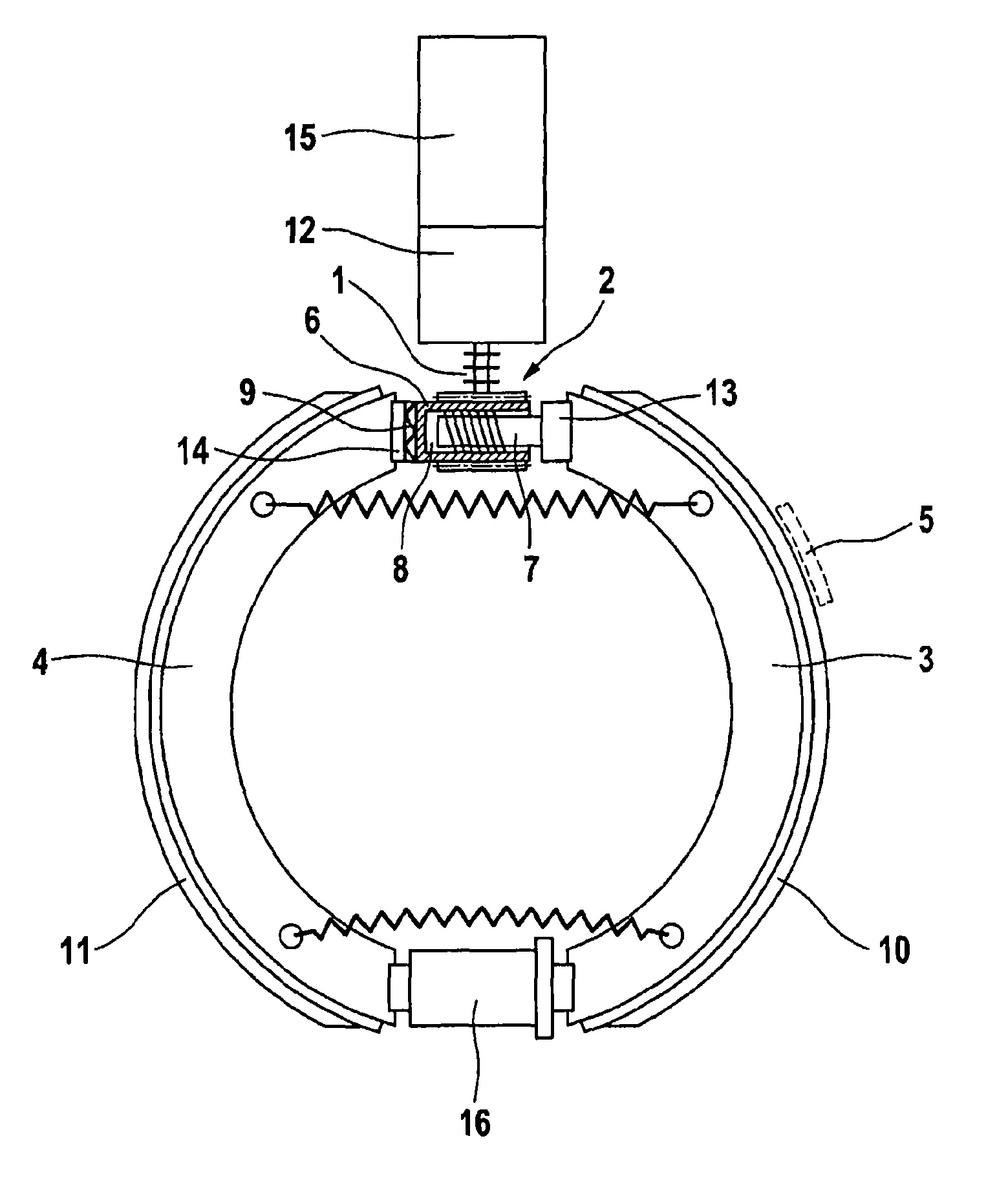

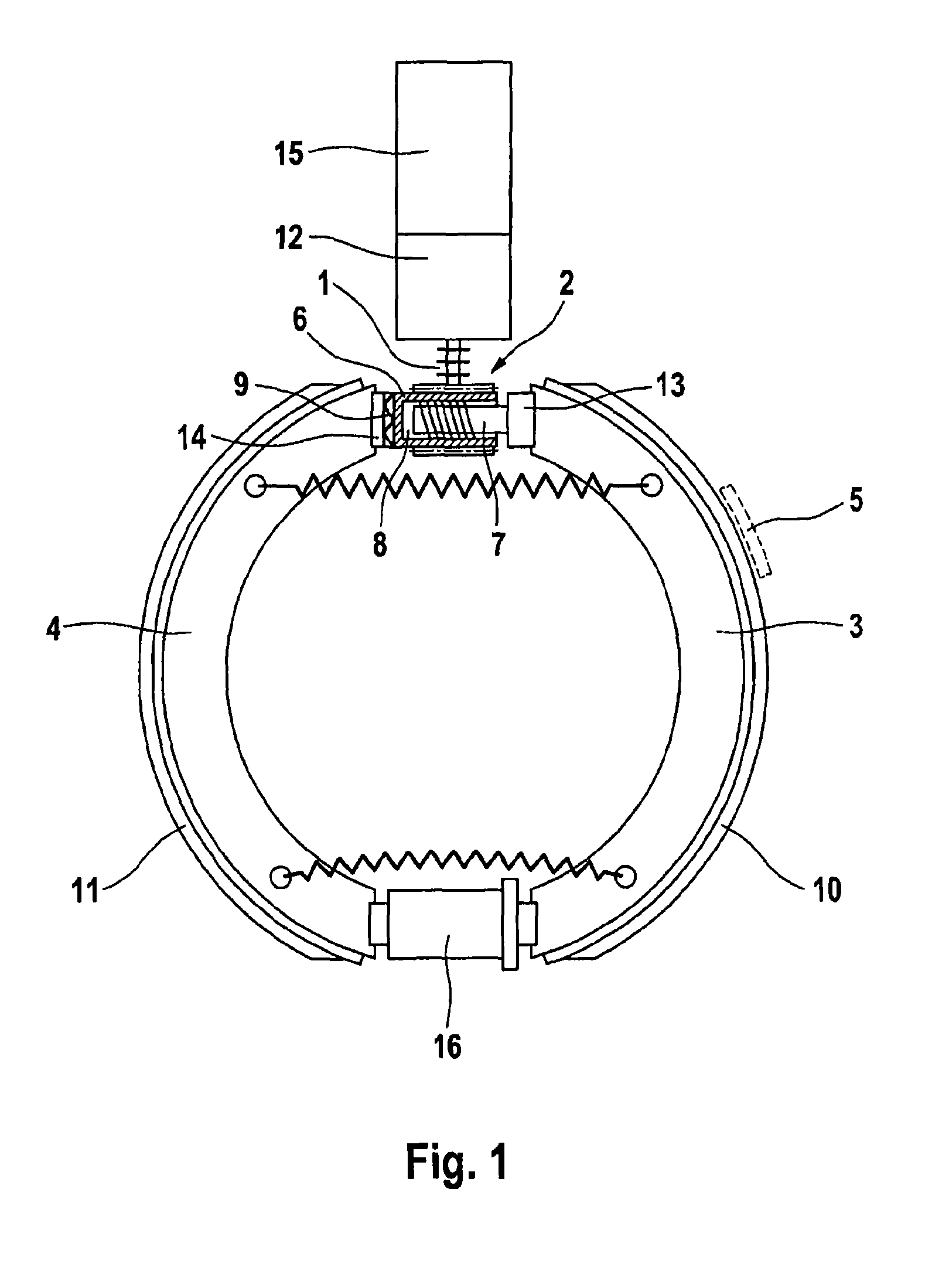

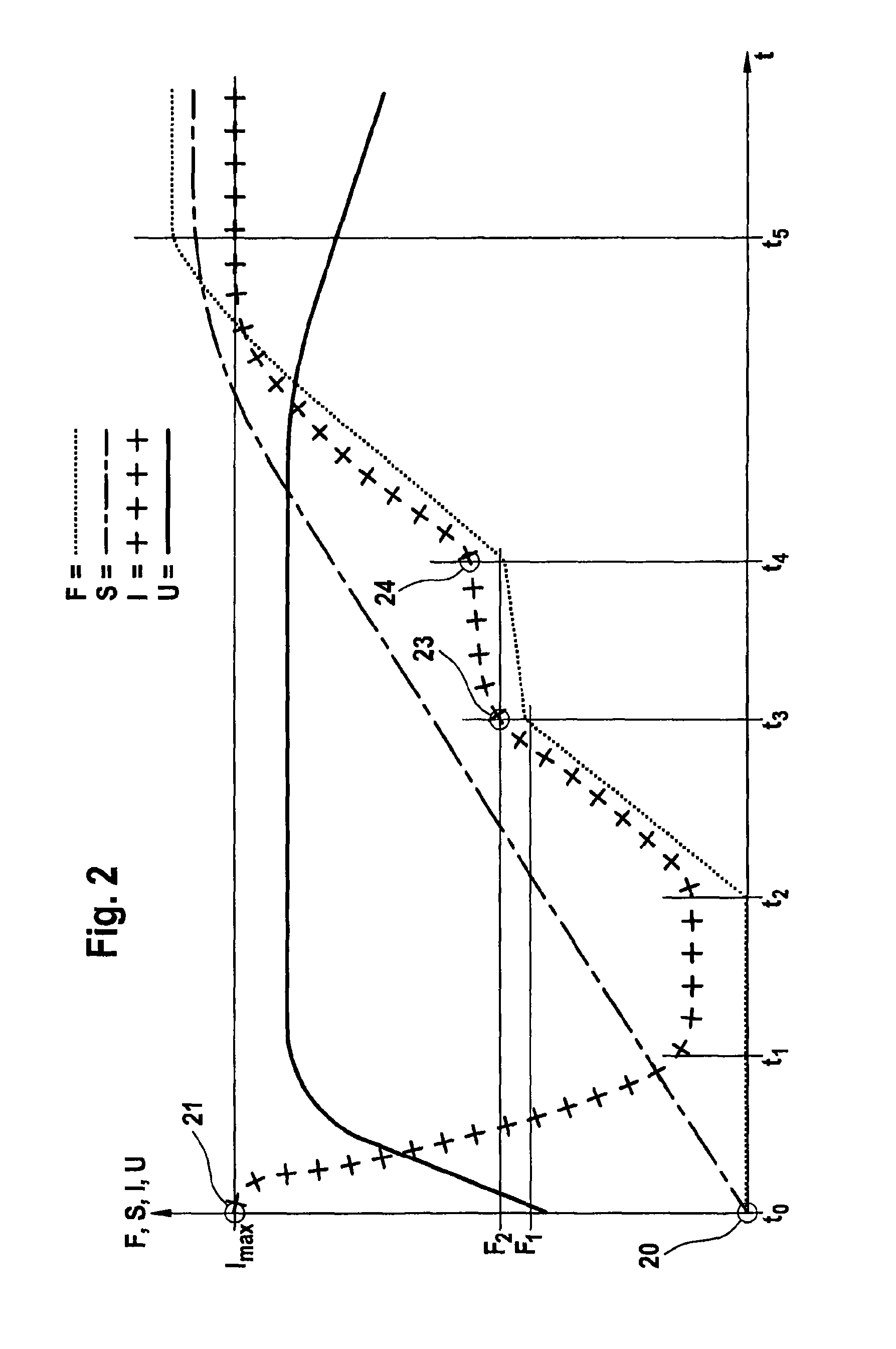

Method for the operation of an electromechanically operable parking brake

InactiveUS8185287B2Operational securityReliable settingsVehicle testingAnalogue computers for trafficPower flowCurrent consumption

An electromechanically actuable parking brake for motor vehicles is disclosed. The brake includes at least one electromechanical actuator whose rotational movement is converted into a translational movement by an actuating unit, and which moves at least one brake element in such a way that at least one brake lining which is connected to the brake element is pressed with a locking force against a rotor which is connected to a motor vehicle wheel, wherein the current consumption of electromechanical actuator when the parking brake is engaged and / or released can be acquired. Furthermore, a method for operating the electromechanically actuable parking brake is also disclosed.

Owner:CONTINENTAL TEVES AG & CO OHG

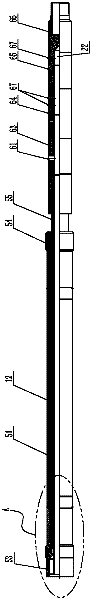

Water searching pipe column of open-hole horizontal well

The invention discloses a water searching pipe column of an open-hole horizontal well, comprising an oil pipe, wherein a suction device is arranged in the oil pipe; the water searching pipe column is characterized in that: the oil pipe extends along the axis of a shaft of the horizontal well; the lower end of the oil pipe is connected with a horizontal well centering device, a hydraulic setting tool, a long rubber cylinder water searching upper packer, a flow distributing device, a lower packet and a lower centering device which are sequentially connected from top to bottom. The long rubber cylinder water searching upper packer disclosed by the invention employs hydraulic setting and lifting unsetting; the water searching and plugging pipe column of the open-hole horizontal well can realize water searching and plugging of the open-hole horizontal well, and search water step by step on a horizontal section, and is reliable in setting and simple in unsetting.

Owner:PETROCHINA CO LTD

Sheet music creation method and image processing system

InactiveUS20090158915A1Turn easilyComplex to performMusicInput/output processes for data processingImaging processingComputer graphics (images)

Image data of sheet music formed from a plurality of pages is input, and the input image data is divided into bars. The complexity of performance of each divided bar is determined for each page. An easy-to-play portion is detected as a page feed position for each page in accordance with the determination result. The layout of the sheet music is changed based on the detected page feed position, and the layout-changed sheet music is output.

Owner:CANON KK

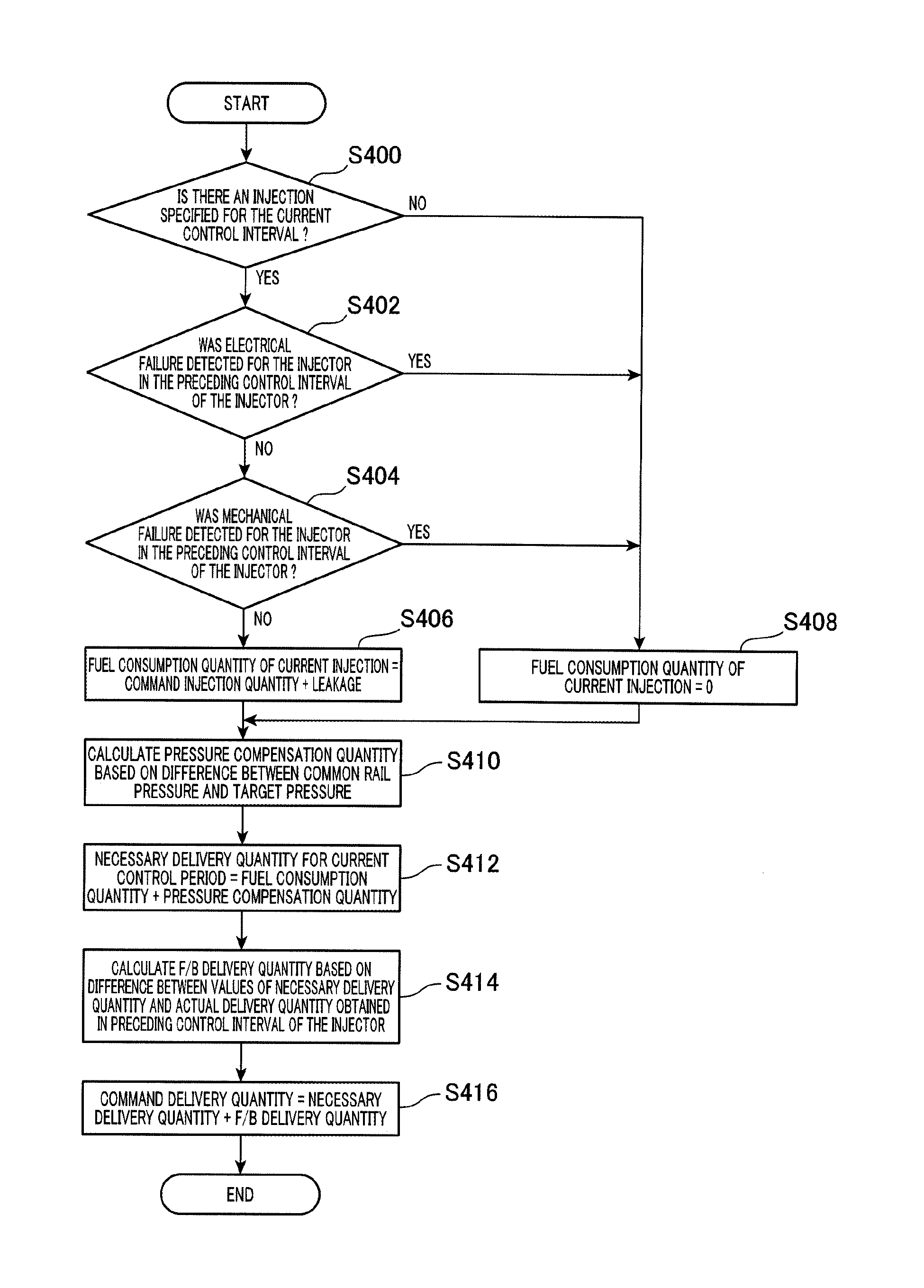

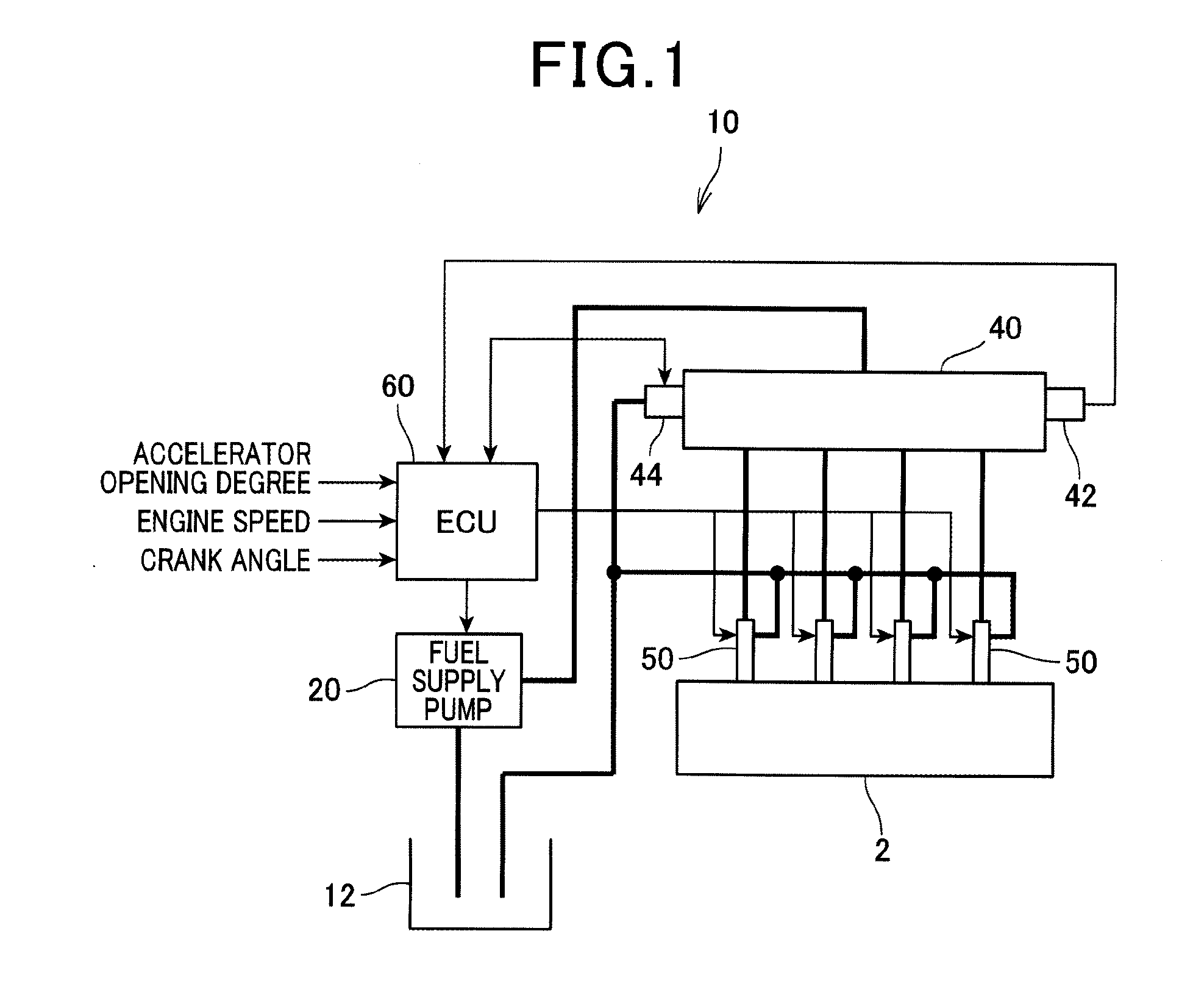

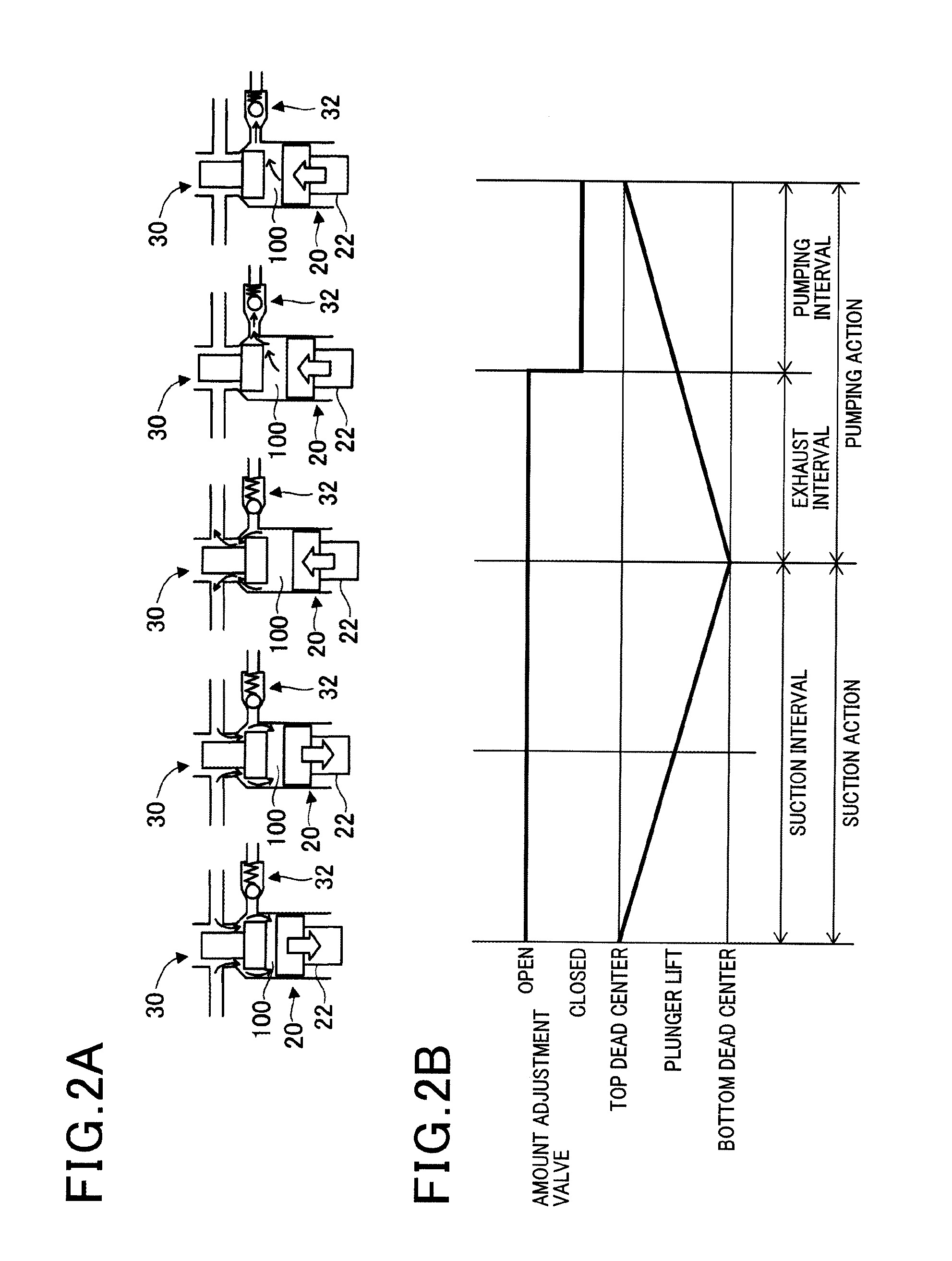

Pump control apparatus for fuel supply system of fuel-injection engine

InactiveUS20150112576A1Accurate valueReliable settingsElectrical controlDigital data processing detailsRail pressureFuel supply

An estimated fuel consumption quantity corresponding to a fuel injection timing of an engine is reduced or set to zero if failure of the corresponding injector has been detected. A pump control apparatus controls a fuel supply pump to maintain the pressure in a common rail at a target value by control of a command delivery quantity supplied from the pump to the common rail in correspondence with each injection timing. Each command delivery quantity is determined based on a necessary delivery quantity and on a feedback quantity, which is derived from a difference between previously obtained values of command delivery quantity and of a corresponding actual delivery quantity from the pump. Prior to the injection, a pressure compensation quantity is calculated, as a fuel quantity required to bring the fuel rail pressure to the target pressure value, and is added to the fuel consumption quantity to obtain the necessary delivery quantity.

Owner:DENSO CORP

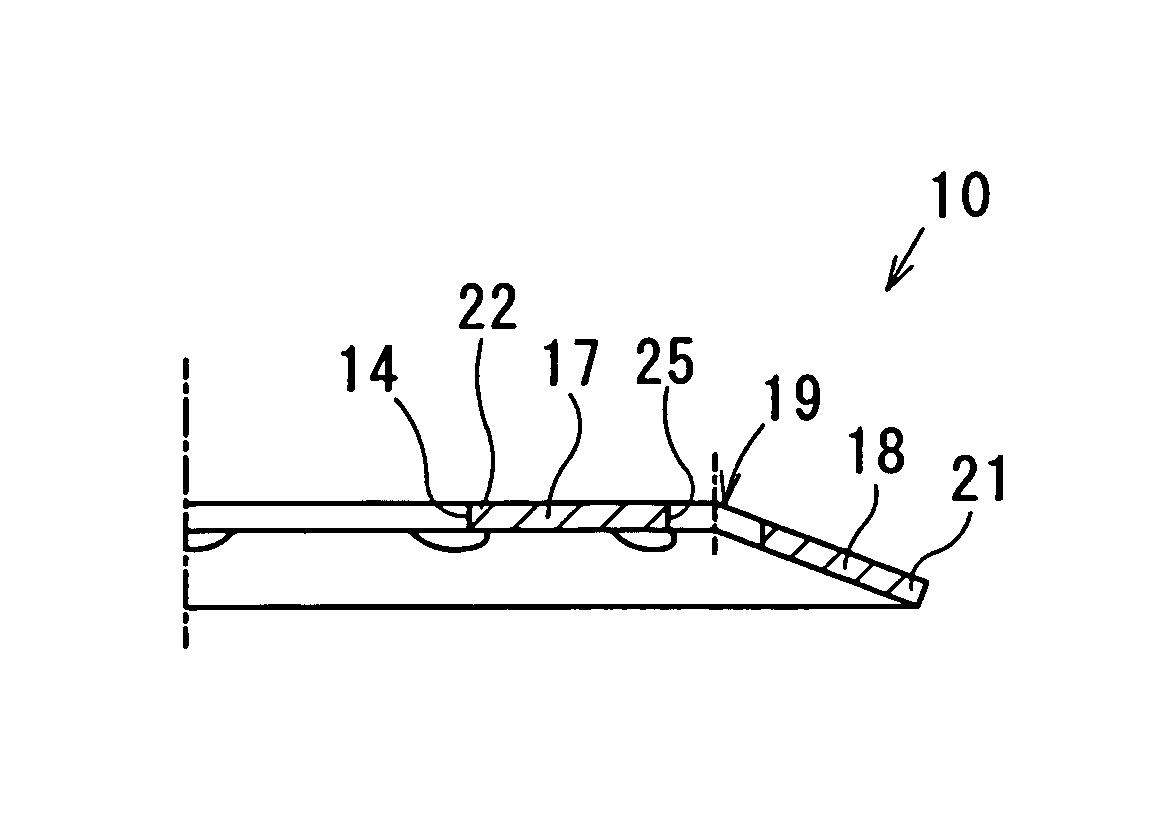

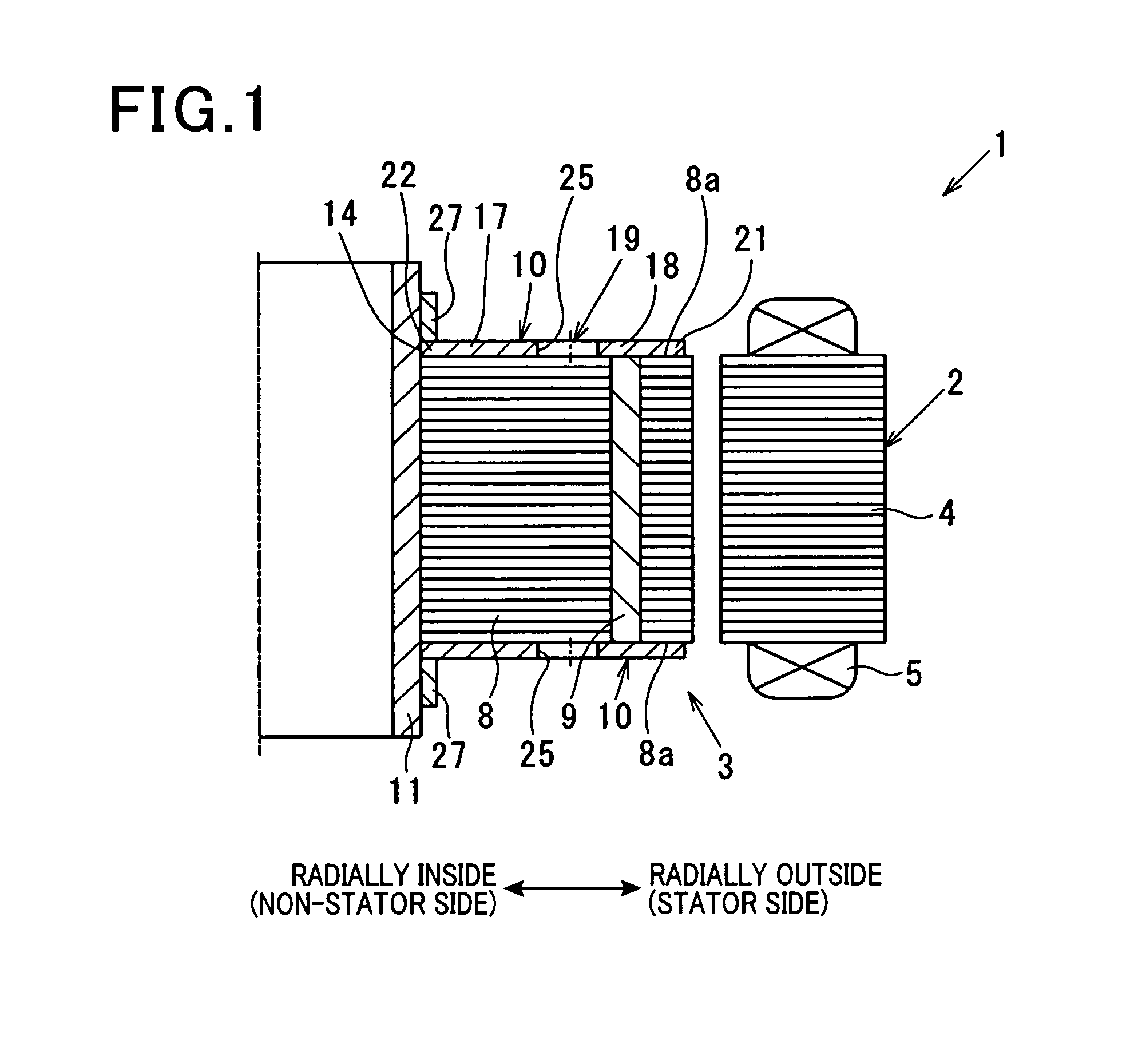

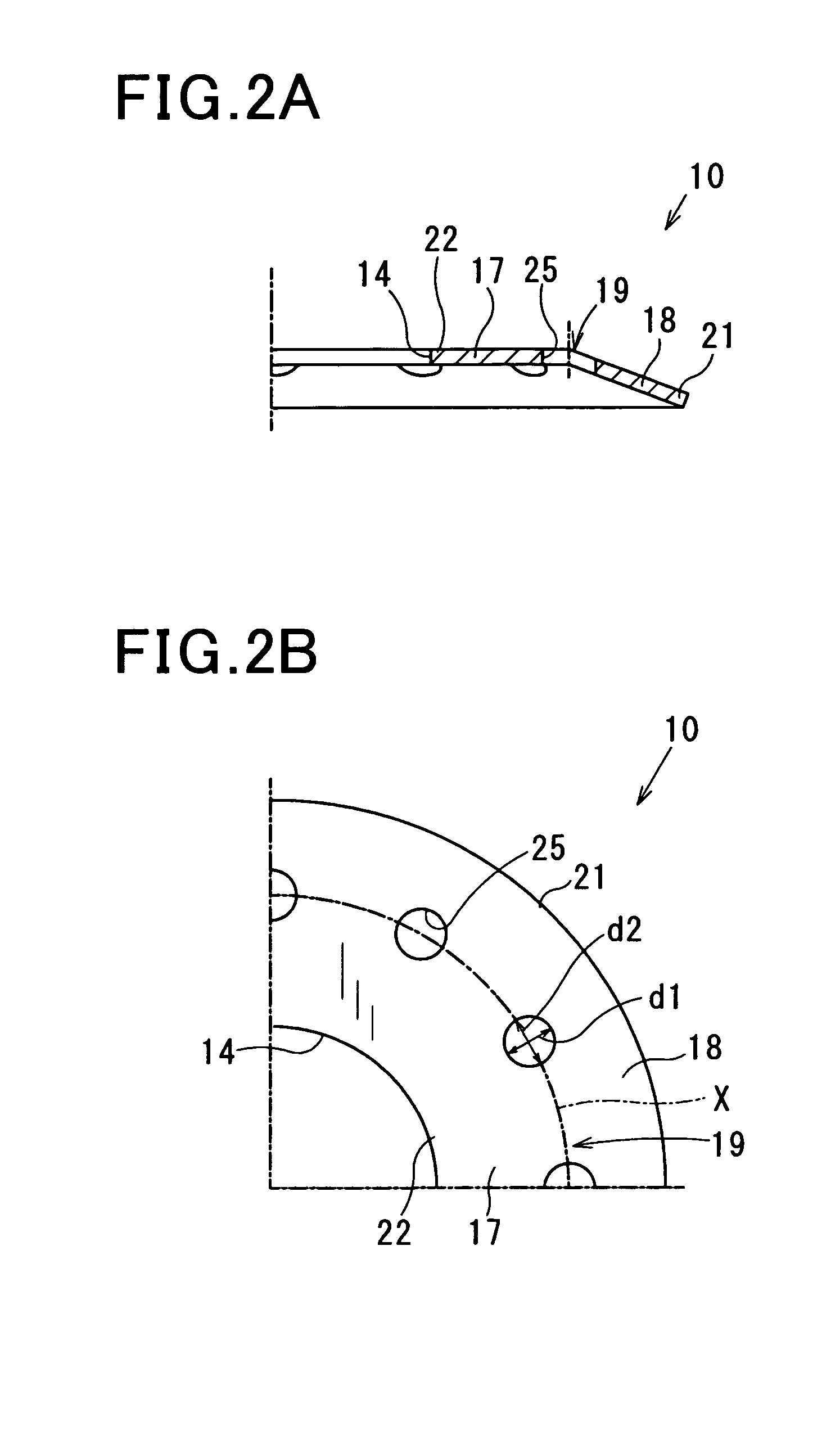

Rotor for electric rotating machine and method of manufacturing the same

ActiveUS8970085B2Improve performanceHigh strengthMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

A rotor includes a rotor core comprised of magnetic steel sheets laminated in the axial direction and a pair of end plates that are respectively provided on the axial end faces of the rotor core so as to together sandwich the rotor core in the axial direction. The rotor is rotatably disposed in an electric rotating machine with a circumferential surface of the rotor core facing a stator. At least one of the end plates is configured to have through-holes, each of which is formed so as to axially penetrate the end plate, and a pressing portion that is radially positioned on the stator side of the through-holes. The pressing portion abuts a corresponding one of the axial end faces of the rotor core and exerts an axial load on the corresponding axial end face of the rotor core by an elastic force of the end plate.

Owner:DENSO CORP

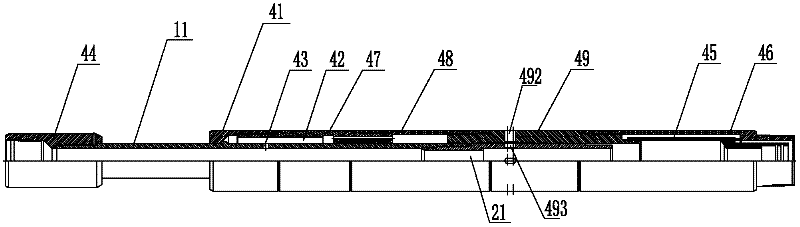

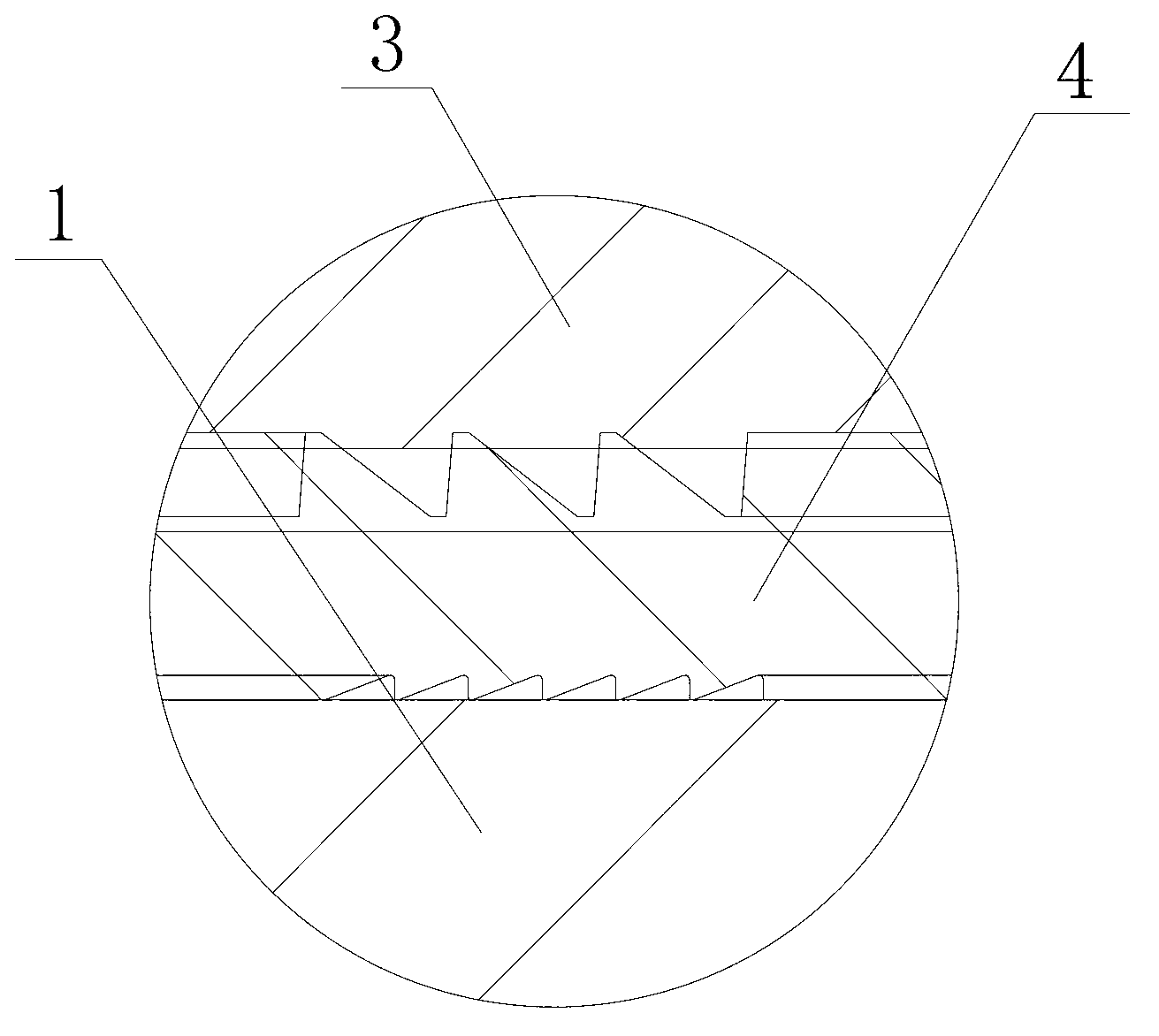

Fishable bridge plug releasing mechanism and releasing and fishing method thereof

The invention belongs to the technical field of oilfield underground construction operations and particularly relates to a fishable bridge plug releasing mechanism and a releasing and fishing method thereof. The mechanism is an important underground tool for separate layer fracturing, testing and production of oil and gas wells. According to the fishable bridge plug releasing mechanism and the releasing and fishing method thereof, with the adoption of the reasonable structure, under the condition of setting of a bridge plug, releasing of a packer and anchoring relieving of slips are completed through continuous lifting and lowering, reliable setting and releasing of the bridge plug are realized, the setting and releasing reliability of the bridge plug is improved, and problems of unreliable setting and releasing of partial bridge plugs in the prior art are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

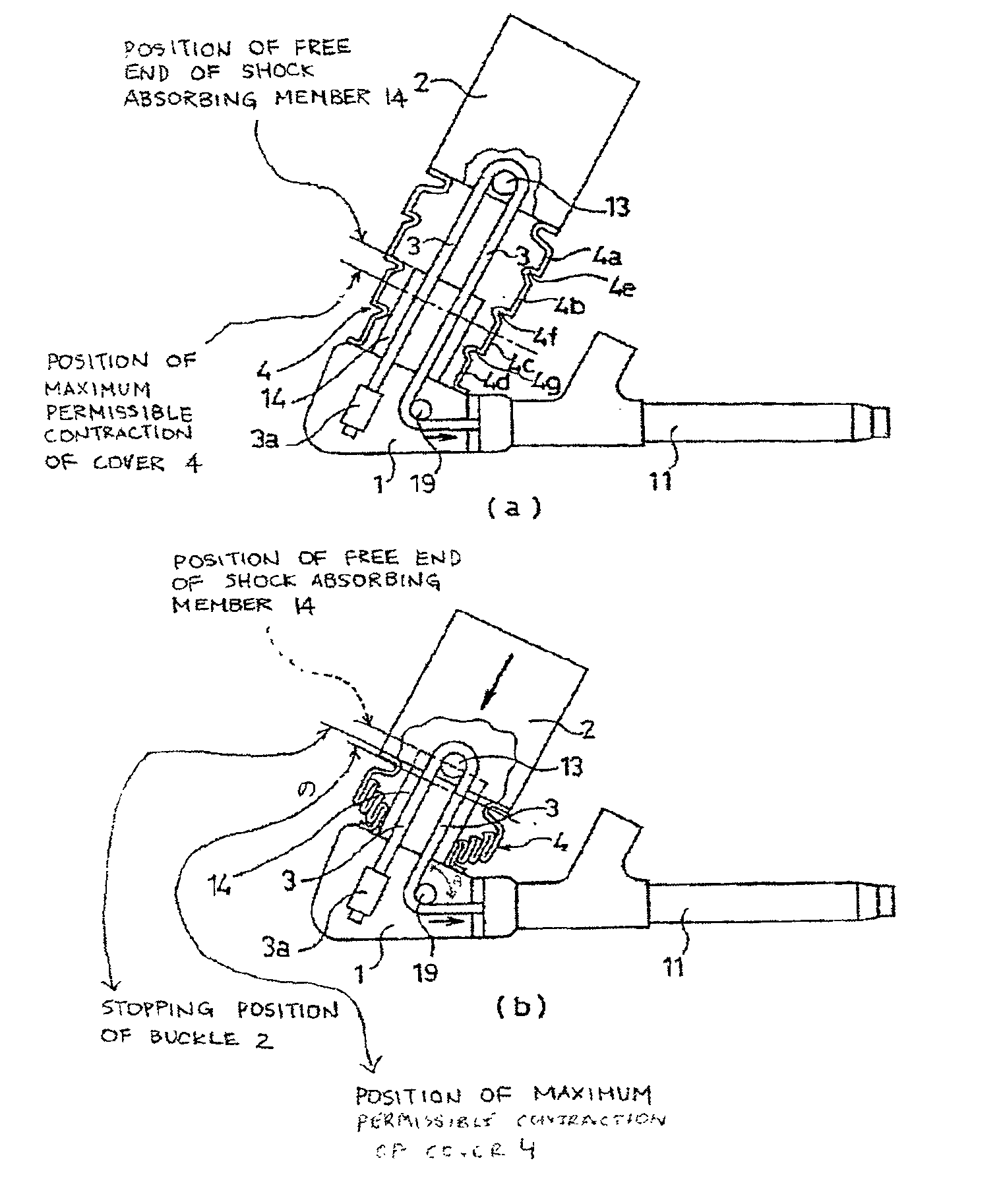

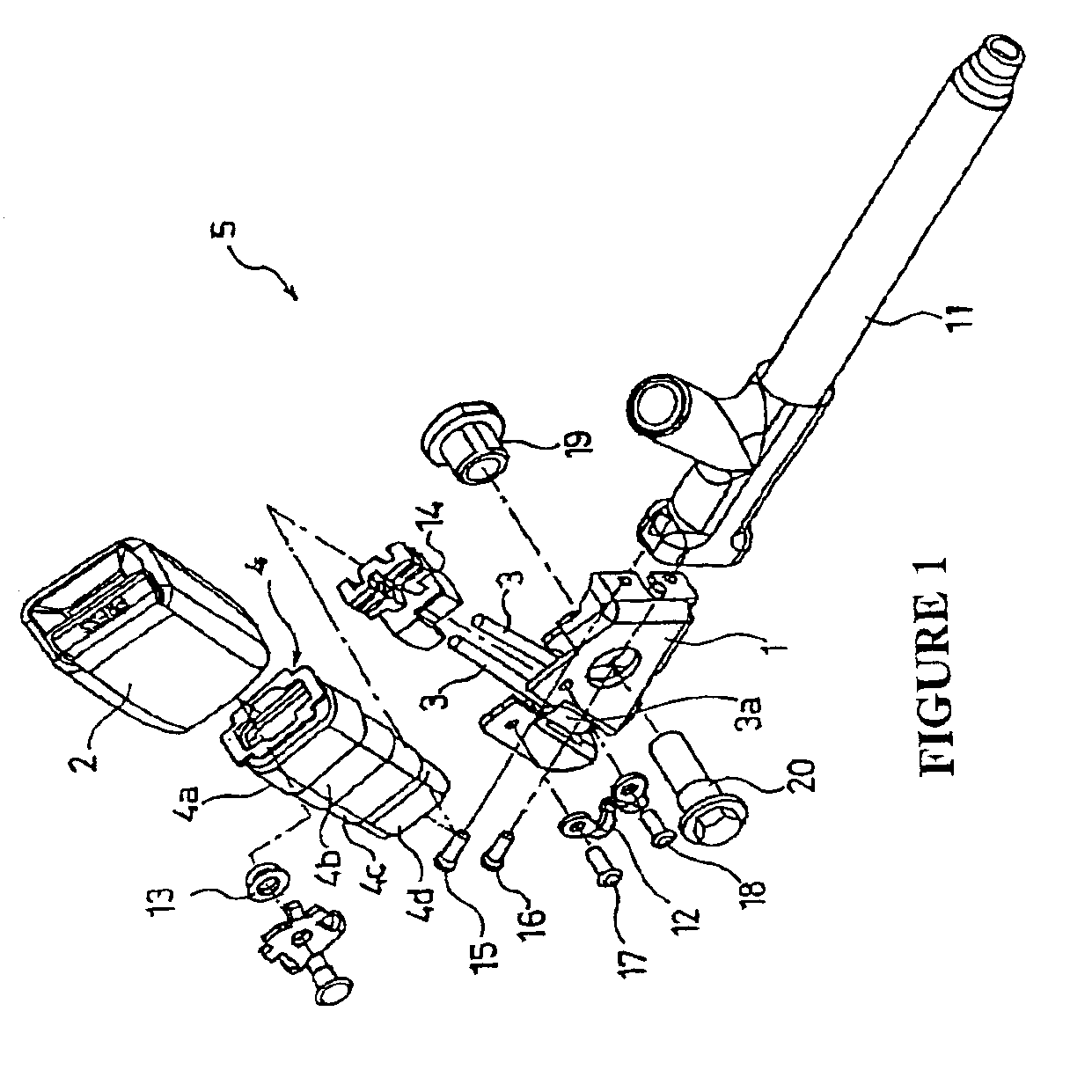

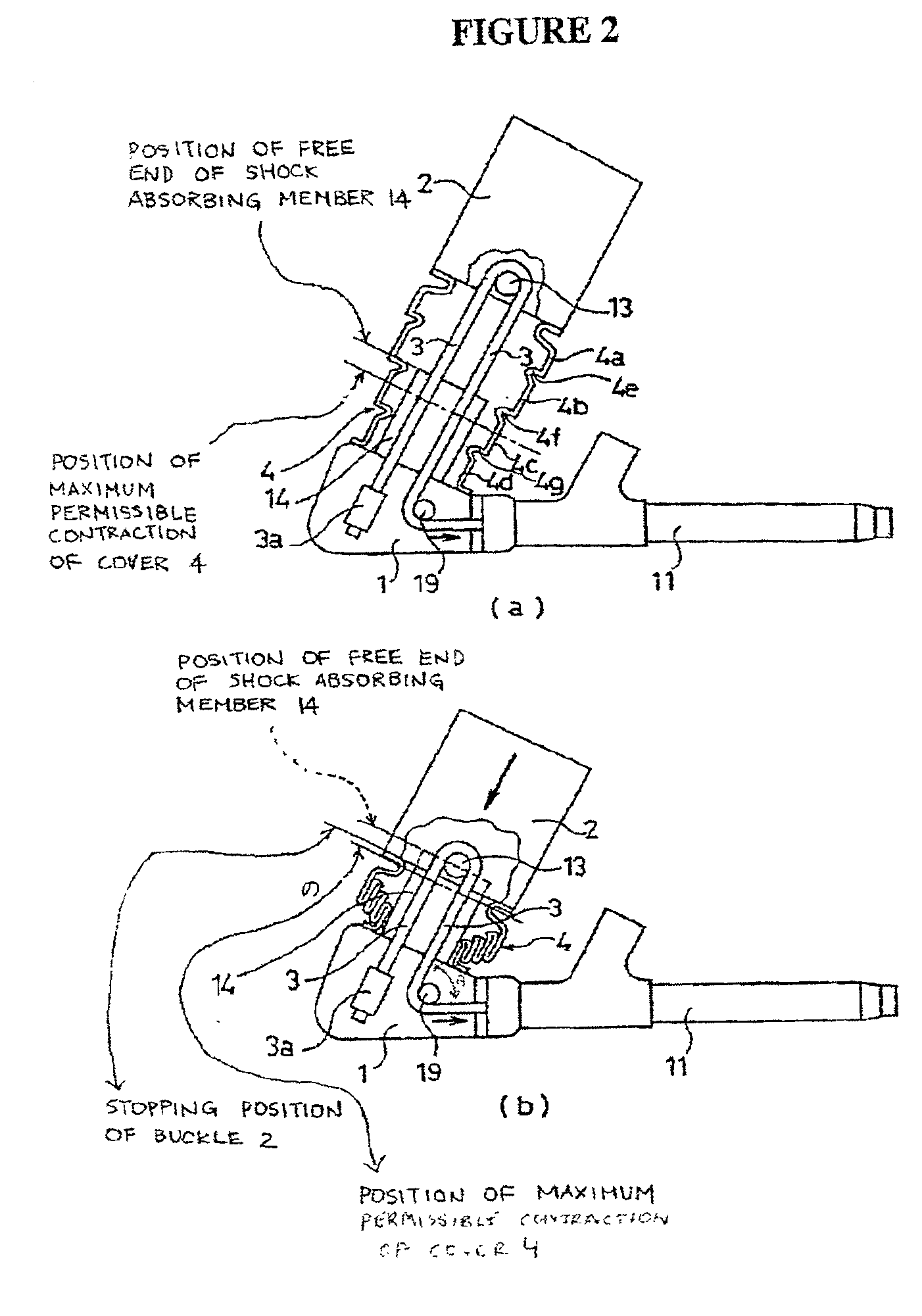

Seatbelt device

InactiveUS6874817B2Improve shock absorptionImprove impact performanceBelt retractorsBucklesSeat beltEngineering

A seat belt device including a shock absorbing mechanism to gently stop a pull-in member and to prevent a large impact force from being exerted on the pull-in member when the pull-in member is pulled in by a pre-tensioner. The device may include a wire pulled by operation of a buckle pre-tensioner at the time of an emergency, a buckle is pulled in towards a bracket while a cover contracts. Before the cover contracts to a maximum permissible contraction position, the buckle comes into contact with the free end of a shock absorbing member, and, then, is pulled in while the shock absorbing member is caused to contract. By the contraction of the shock absorbing member, the shock absorbing member absorbs impact energy of the buckle.

Owner:JOYSON SAFETY SYST JAPAN KK

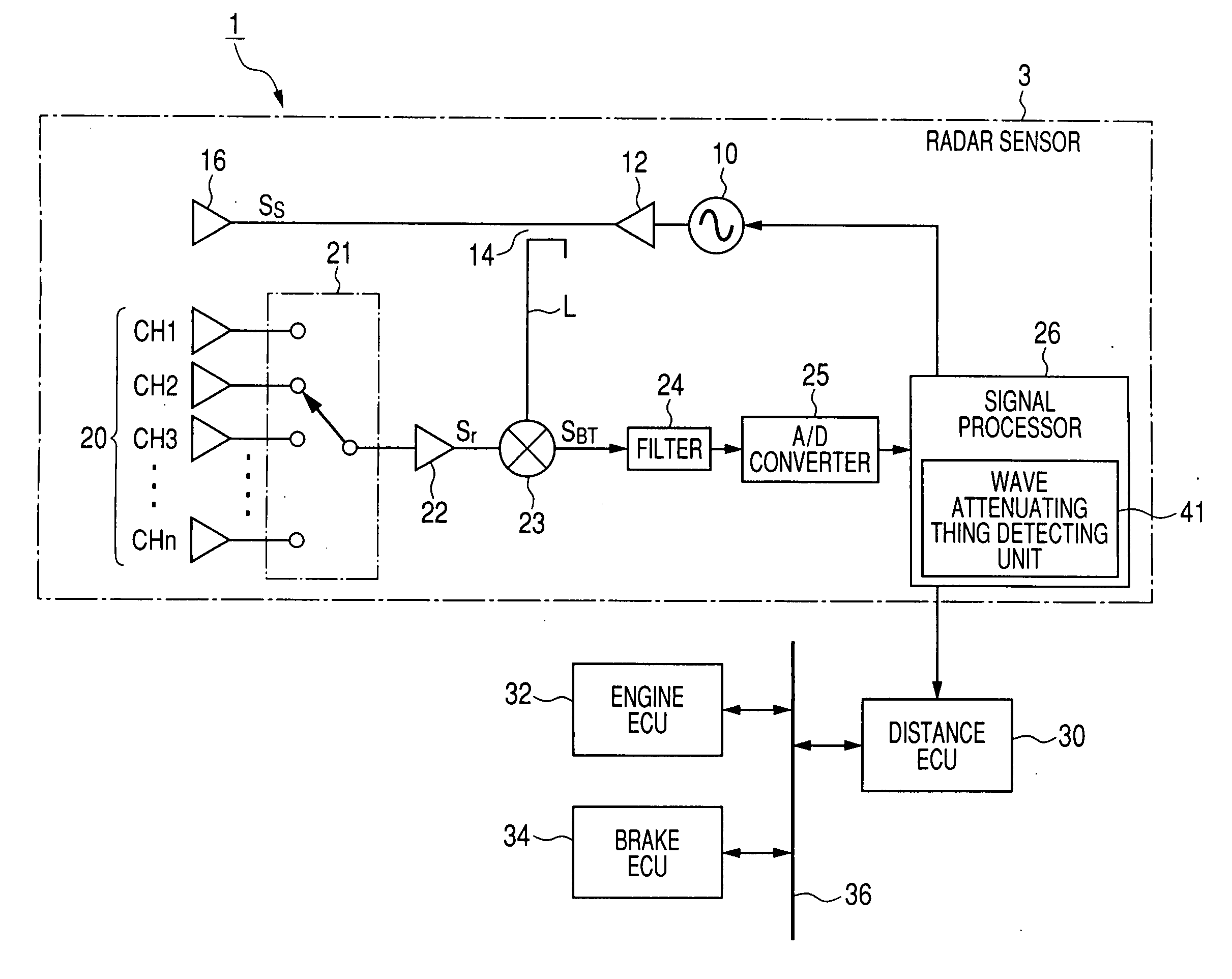

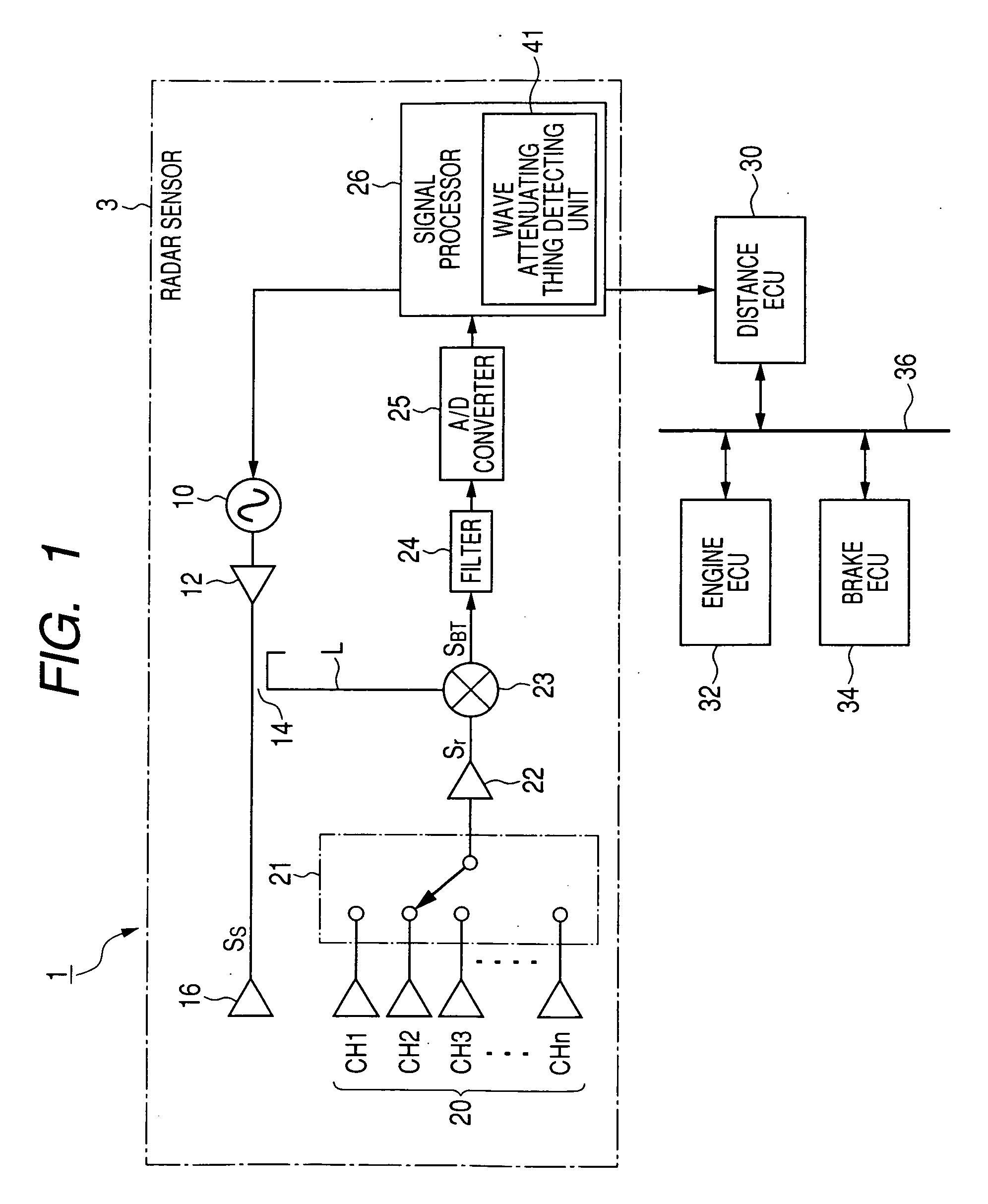

Radar sensor for receiving radar wave while judging existence of wave attenuator

ActiveUS20090207079A1Reliably detectReduce levelRadio wave direction/deviation determination systemsVehicle fittingsVIT signalsElectricity

A radar sensor receives a radar wave signal through a radome in each of antennas while judging existence of an attenuating thing in a detecting unit. This unit extracts a maximum level channel from receiving channels assigned to the antennas every modulation period, calculates a difference in signal level between the maximum level channel and each receiving channel every modulation period, sets each receiving channel corresponding to large level differences in one measuring period including plural modulation periods as a candidate channel every measuring period, increments a preliminary variable of each candidate channel every measuring period, increases a final variable each time the preliminary variable of at least one receiving channel reaches or exceeds a preliminary value in one measuring period, and judges in response to the final variable reaching a final value that the attenuating thing attenuates the radar wave directed toward the radome.

Owner:DENSO CORP +1

Sump packer

ActiveCN103233698AAvoid the risk of early settingAchieving an annulus sealSealing/packingLocking mechanismHigh pressure

The invention relates to a sump packer which comprises a center tube. The sump packer is characterized in that a setting locking mechanism and a suspension sealing assembly are arranged on the center tube, the setting locking mechanism comprises a pressing ring fixed to the center tube through a shear pin, the suspension sealing assembly comprises an upper slip, an upper cone, a sealing rubber cylinder component, a lower cone and a lower slip which are sequentially sleeved on the center tube, the sealing rubber cylinder component comprises a rubber cylinder, a female expansion ring, a male expansion ring and a shroud ring, the female expansion ring and the male expansion ring are symmetrically arranged on two sides of the rubber cylinder, and a supporting ring and a sealing ring are mounted between the rubber cylinder and the center tube. The sump packer has the advantages that the upper portion and the lower portion of the rubber cylinder of the packer can bear 5000Psi high pressure, the risk of setting the packer in advance is avoided, setting is reliable, well-completion practice can be smoothly performed, a sealing oil layer is annular, the anchored slips can bear the load of a sand prevention tubular column and axial load under the working condition in the later period, additionally, the sump packer is high in working sealing pressure, reliable in setting and recycling operation and simple and convenient to operate, and operation efficiency can be greatly improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

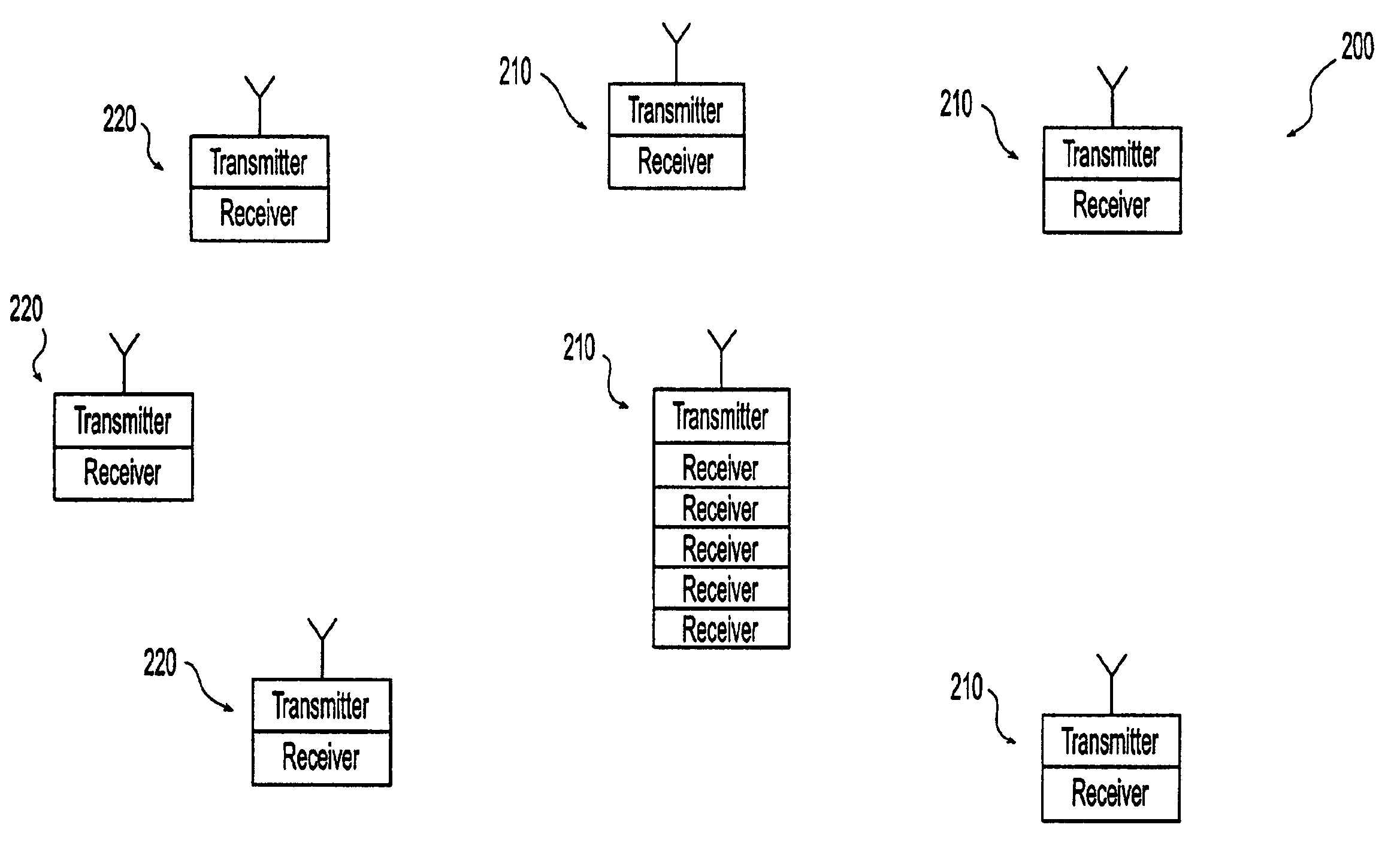

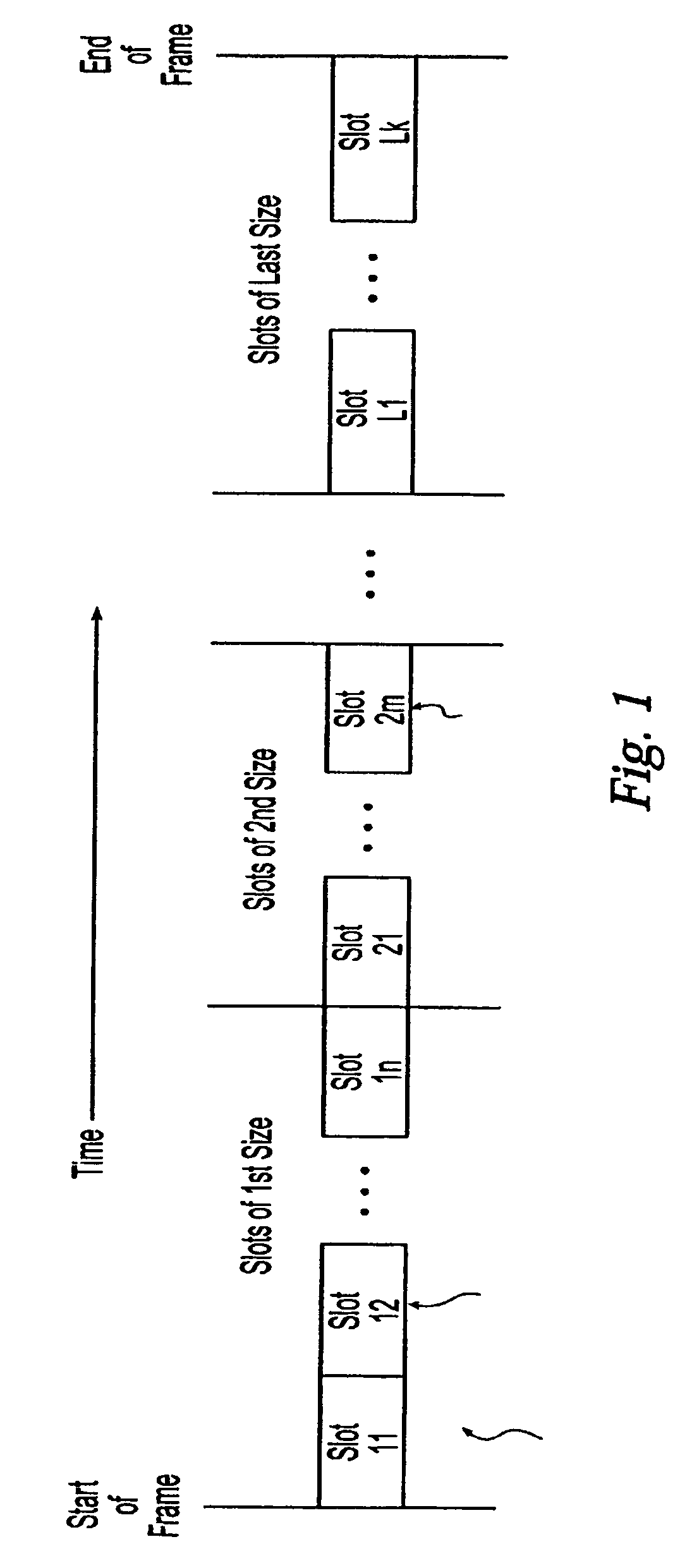

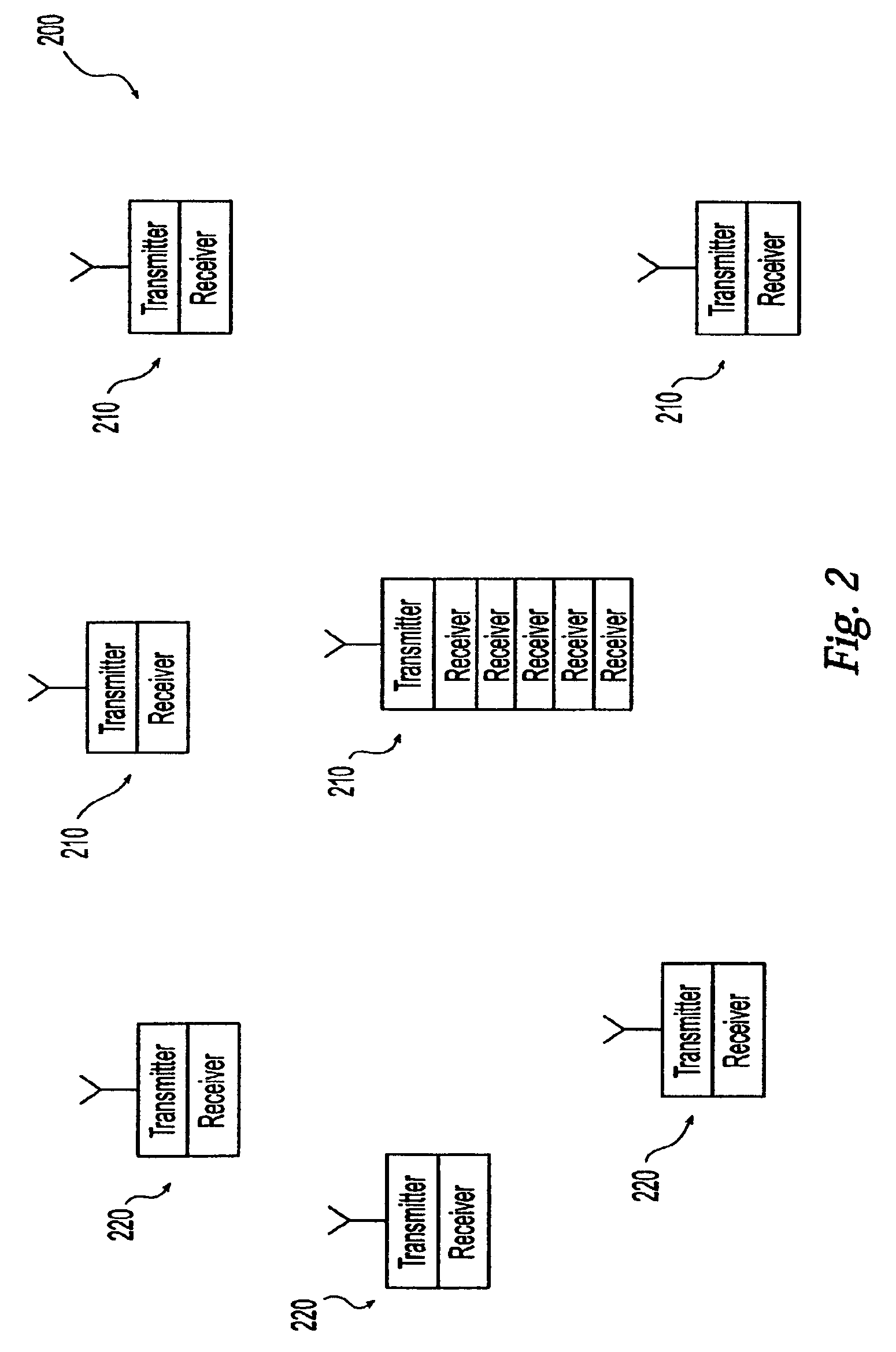

Method and system for configuring radio interface in a communication system

InactiveUS7167482B1Reliable settingsImprove matchTime-division multiplexRadio/inductive link selection arrangementsCommunications systemPacket data transmission

A method and system for configuring a radio interface between a mobile station and a base station in a time-division multiplex mobile radio system for packet data transmission, wherein time slots for signalling are allocated by the base station to the mobile stations in accordance with a sequence which can be predetermined, independent of packet data transmission. The time for configuration of the radio interface also can be reduced by a plurality of time slots for signalling being combined to form a signalling block, or the signalling to a plurality of mobile stations being carried out within one time slot. This signalling is used to define and set the timing advance.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com