Sump packer

A packer and sand settling technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problem of affecting operation efficiency, low pressure difference level of rubber cylinder sealing, and hanging load of slip anchoring Small and other problems, to achieve the effect of reliable setting and recovery operations, high working sealing pressure, and large suspension load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

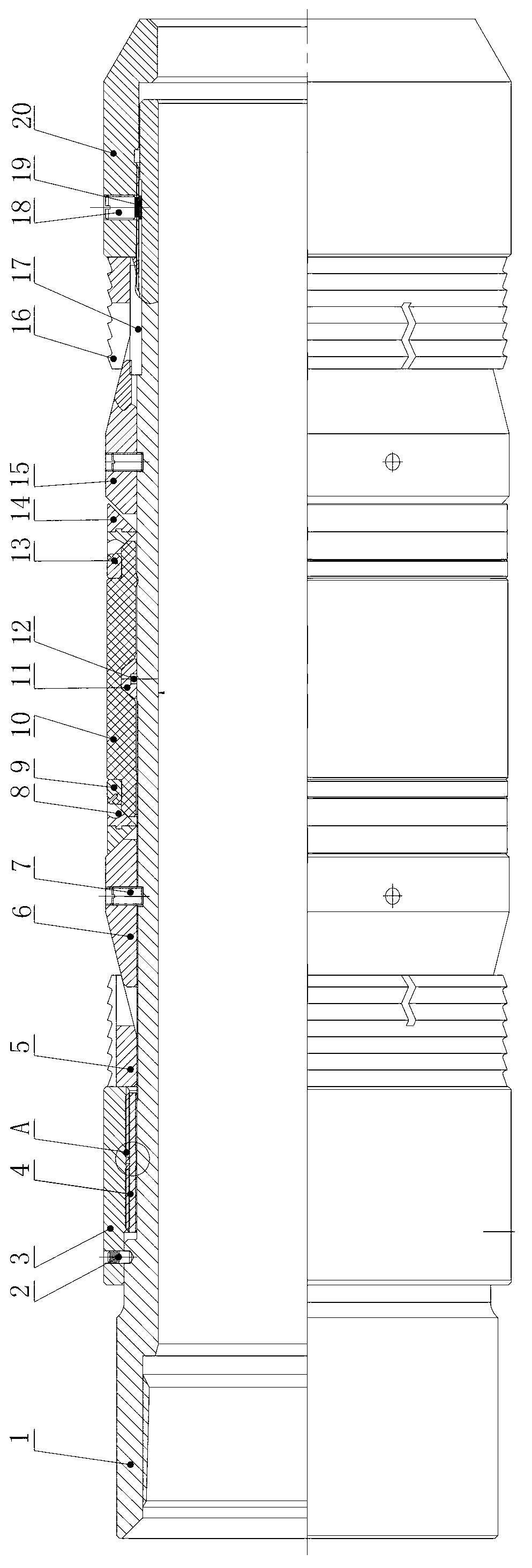

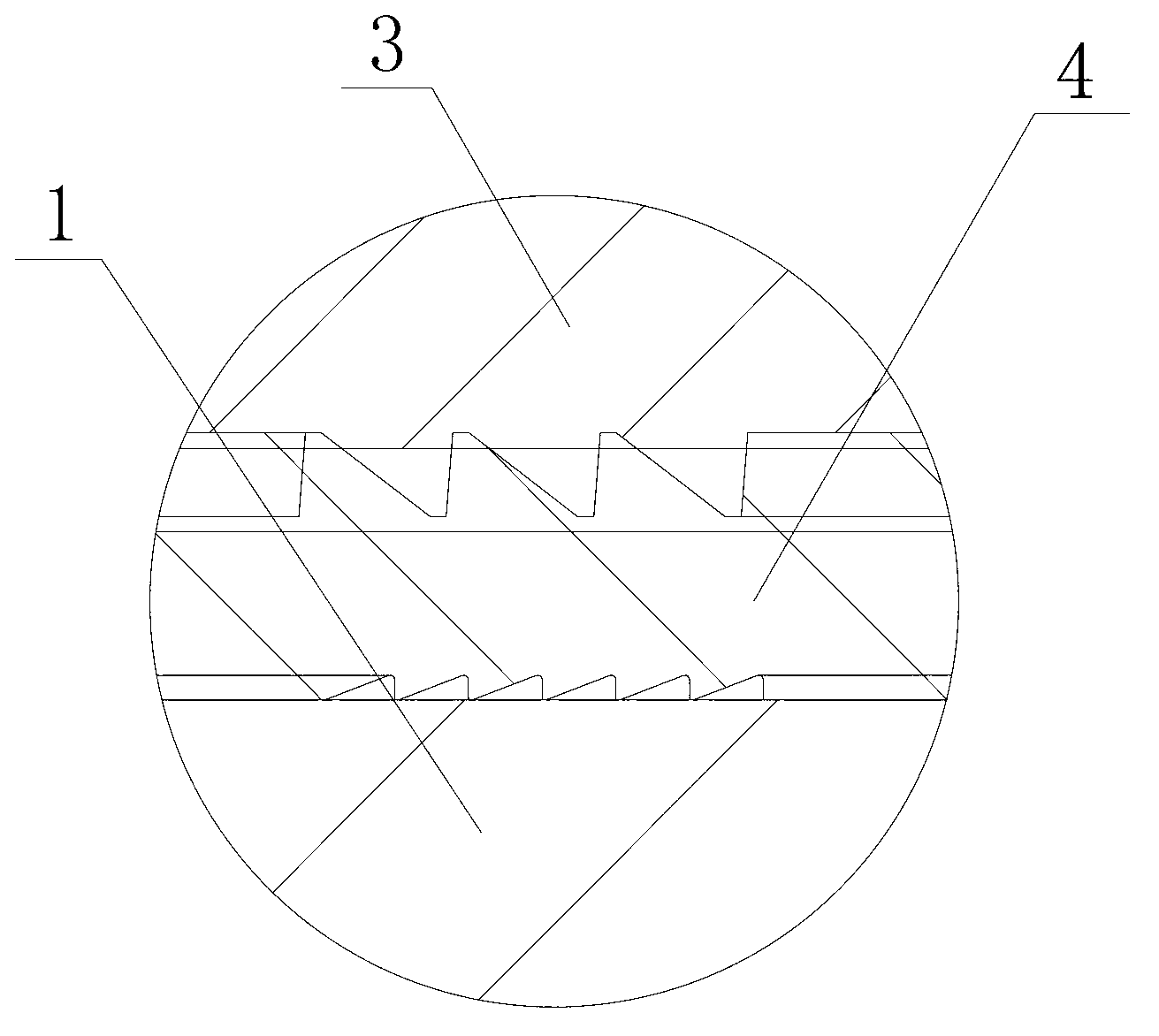

[0027] see figure 1 and figure 2 , a grit-set packer, including a center pipe 1 for internal support of the packer, and the center pipe is provided with a seated locking mechanism and a suspension sealing assembly. The seated locking mechanism includes a pressure ring 3 fixed to the center pipe by shear pins 2; the suspension sealing assembly includes an upper slip 5, an upper cone 6, a sealing rubber cartridge assembly, The lower cone 6 and the lower slips 16 are axially fixed to the center pipe through shear pins. Both the lower cone and the lower slips are circumferentially fixed to the central tube through the key 17, the purpose of which is to prevent the circumferential rotation between the lower cone and the lower slips and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com