Patents

Literature

30results about How to "Achieve rupture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

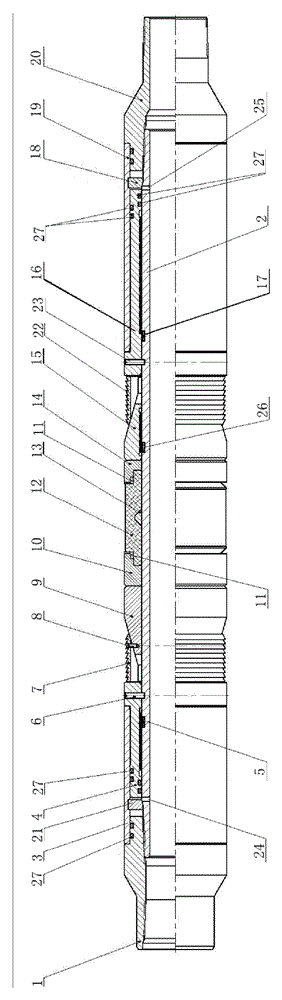

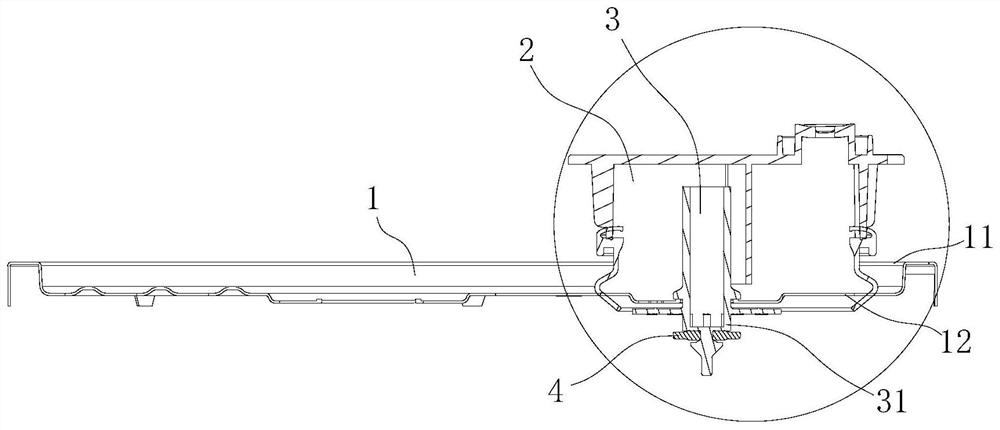

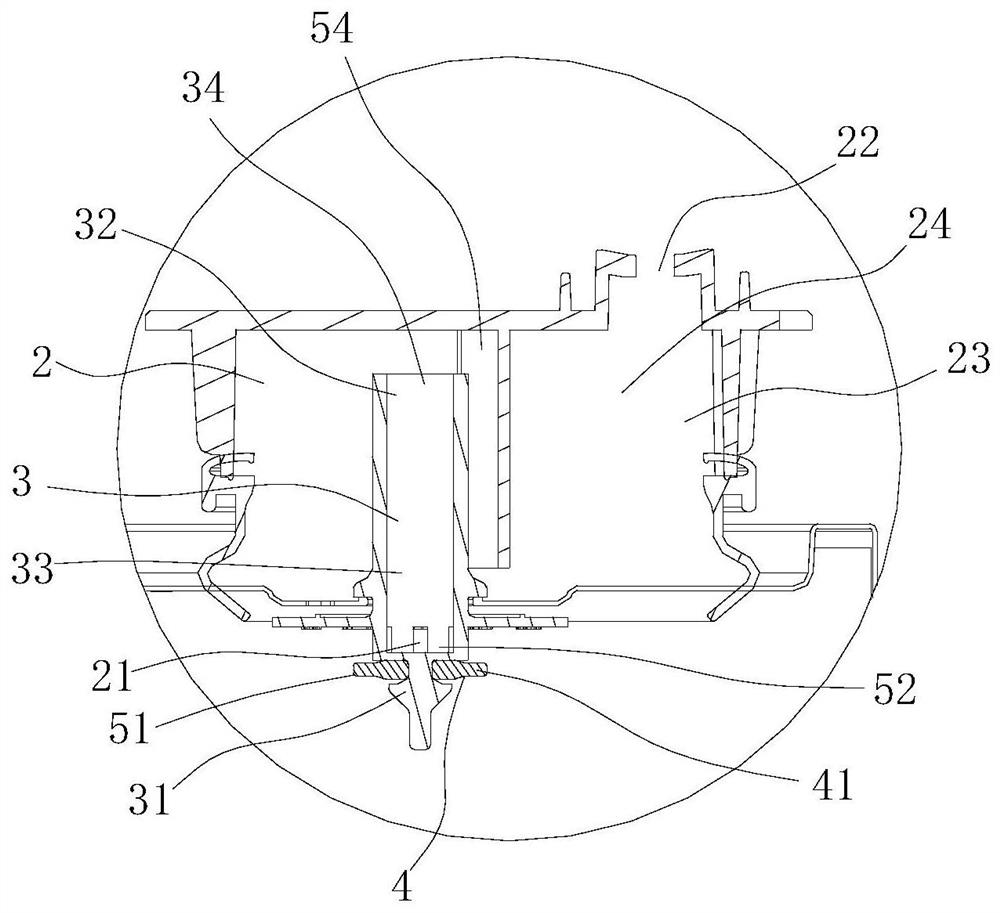

Bidirectional seat seal hook-wall packer, preparation method thereof and shaft circumferential packing method

ActiveCN103184850AImprove reliabilityImprove pressure bearing capacitySealing/packingPistonEngineering

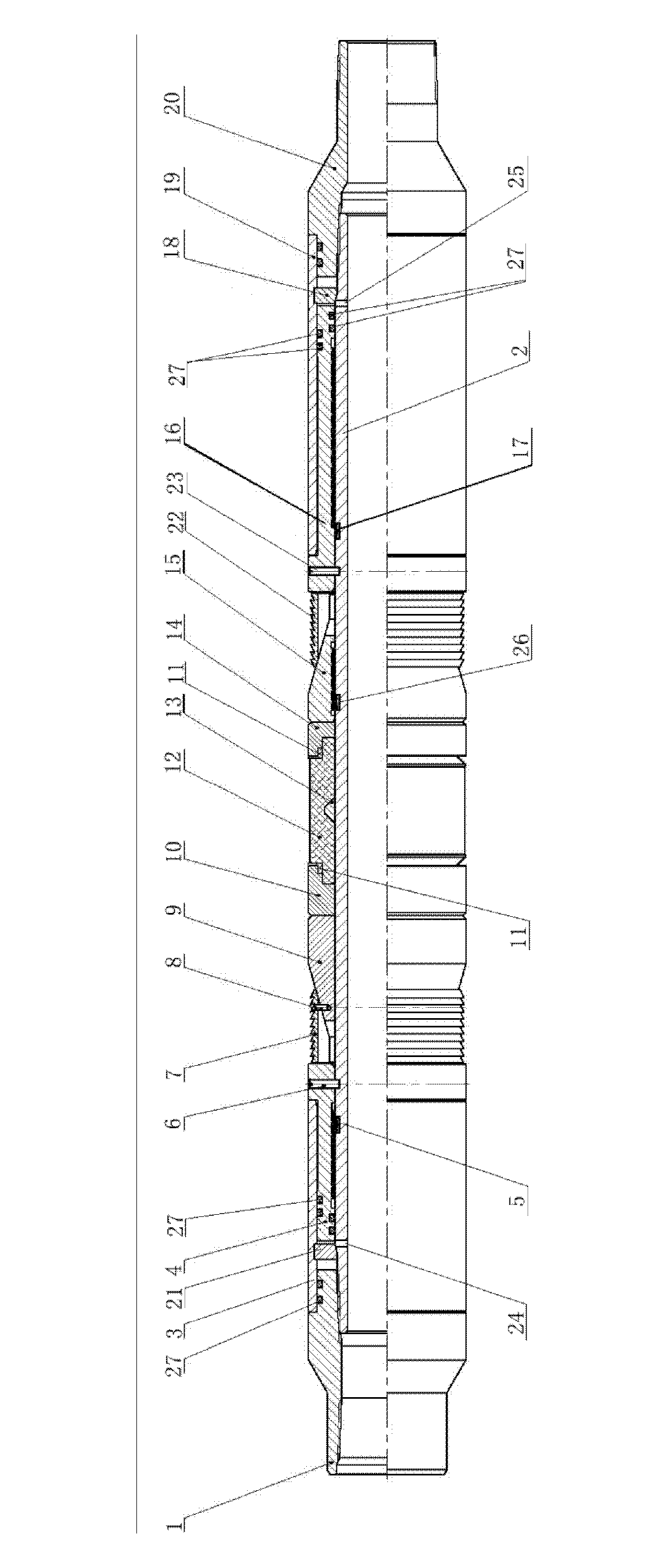

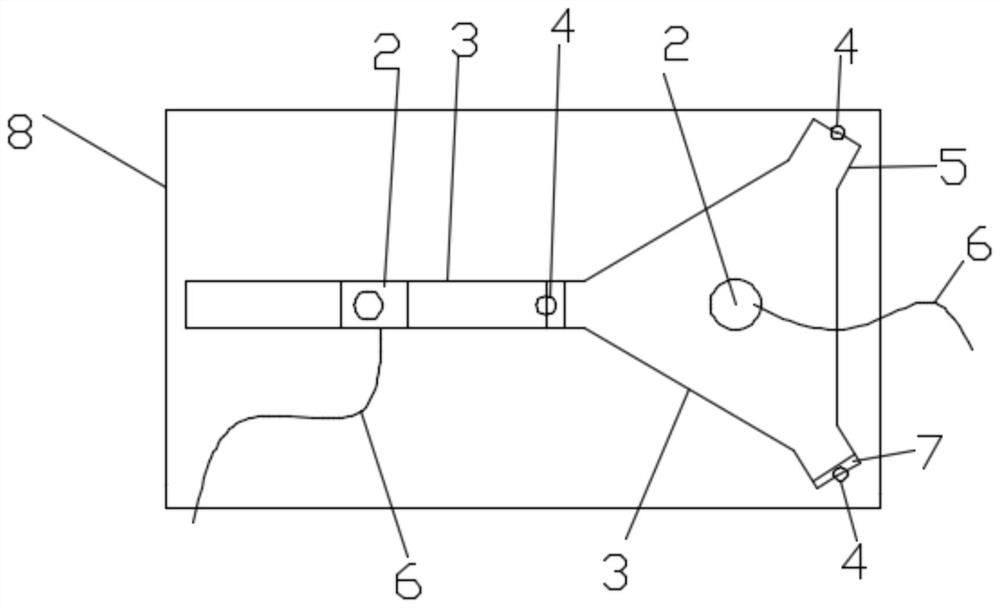

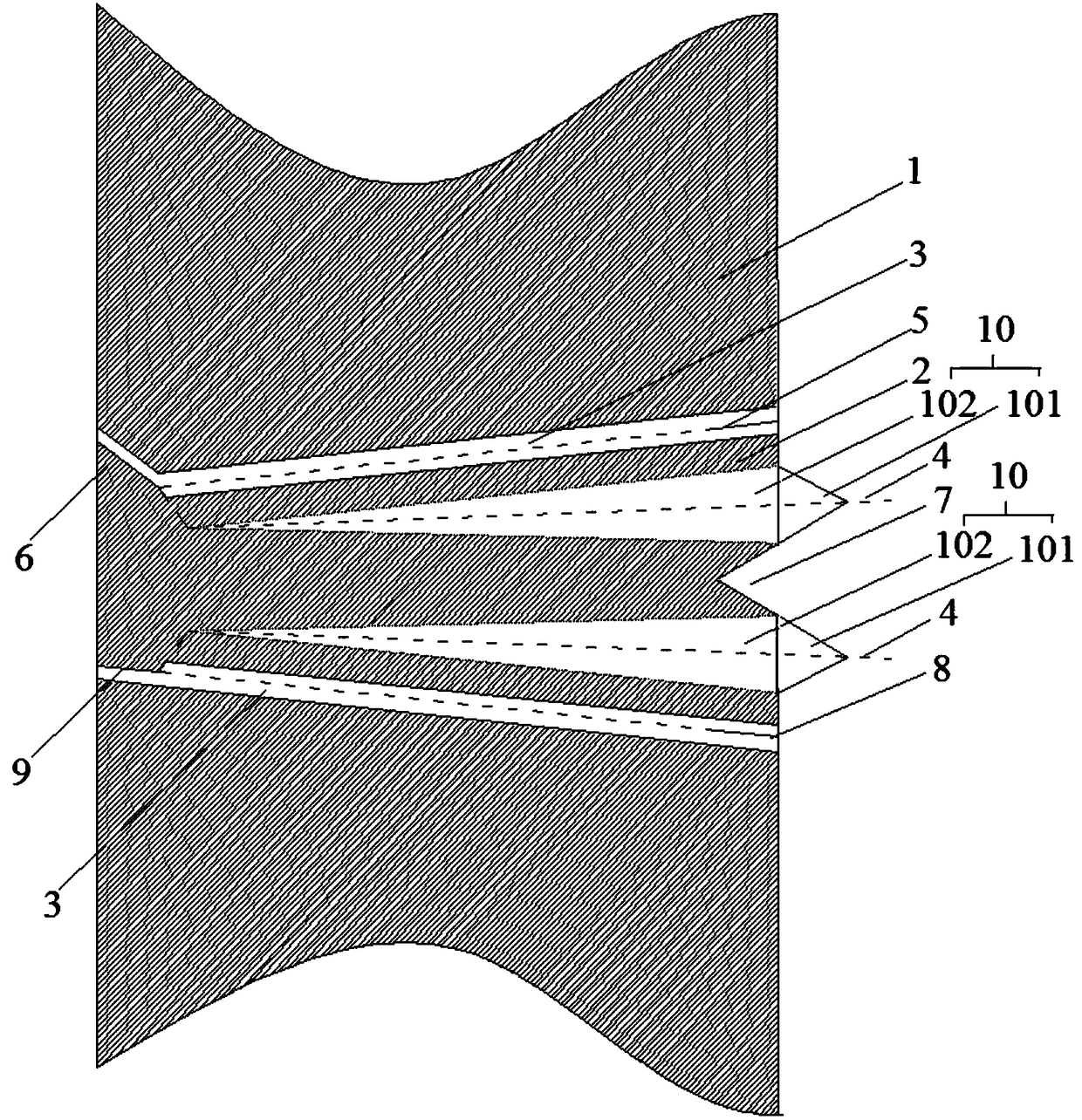

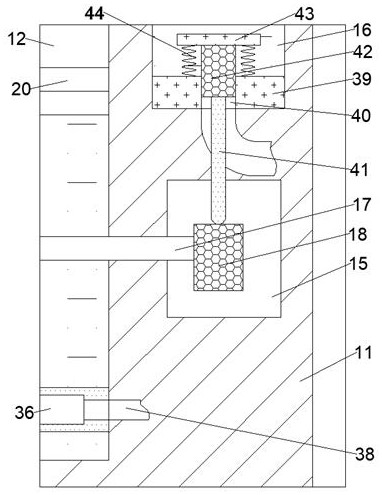

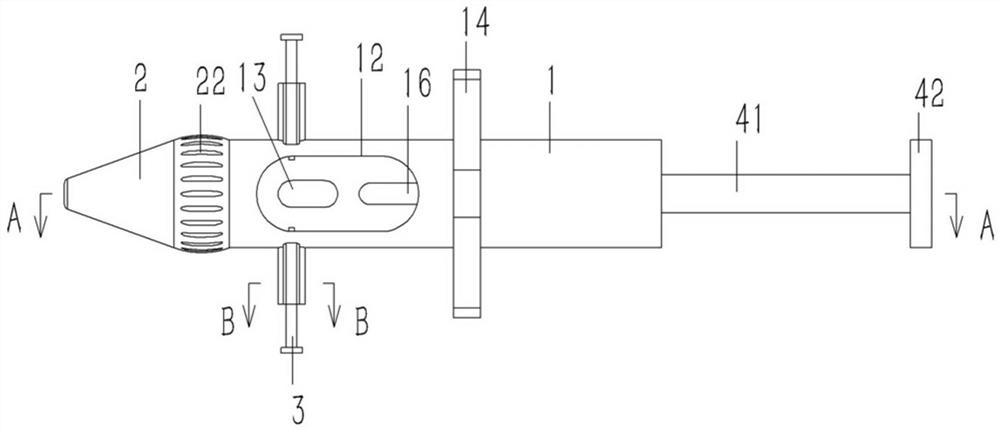

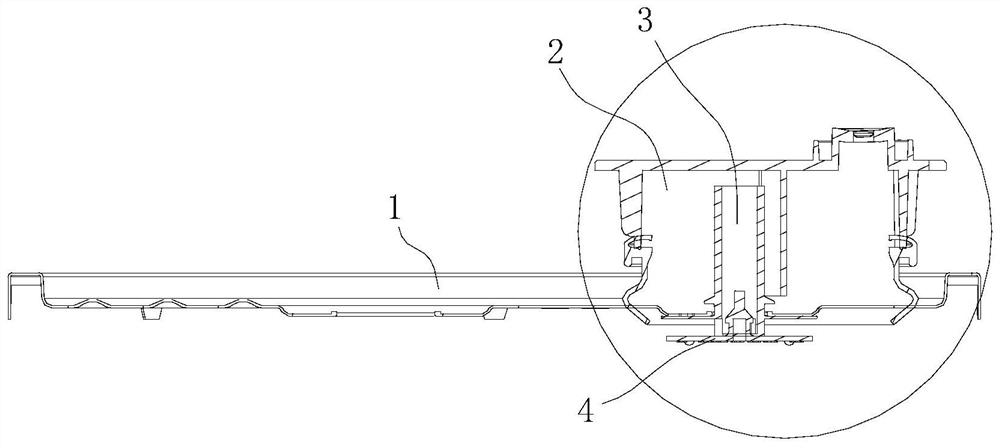

The invention discloses a bidirectional seat seal hook-wall packer, a preparation method thereof and a shaft circumferential packing method. The packer comprises a central tube. The two ends of the central tube are respectively connected with a first joint and a second joint. A first stop collar, a first piston, a first slip, a first cone, a first rubber tube compression ring, a rubber tube, a second rubber tube compression ring, a second cone, a second slip, a second piston and a second stop collar are sequentially sheathed on the central tube from the first joint. A first hydraulic cylinder which is connected with the first joint is sheathed on the external side of the first piston. A first locking slip which is used for preventing the first piston from moving towards the first joint is fixedly arranged on the central tube. A supporting ring is arranged between the central tube and the rubber tube. A second hydraulic cylinder which is connected with the second joint is sheathed on the external side of the second piston. A second locking slip which is used for preventing the second piston from moving towards the second joint is fixedly arranged on the central tube. A first pressure transmission hole and a second pressure transmission hole which respectively correspond to the first piston and the second piston are arranged on the central tube. The packer disclosed by the invention can be reliably anchored.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

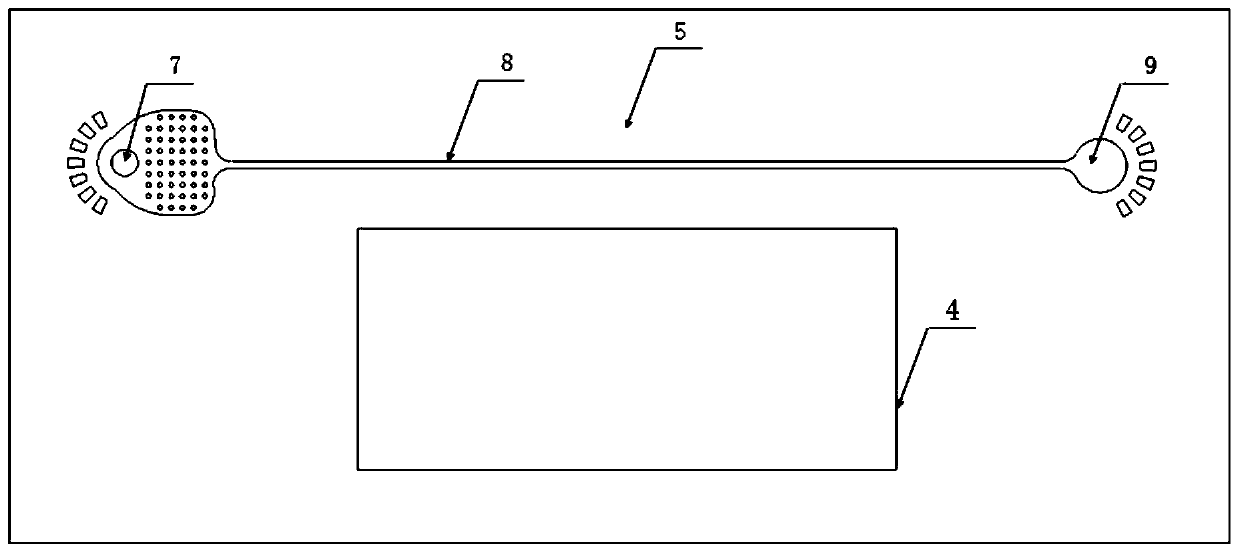

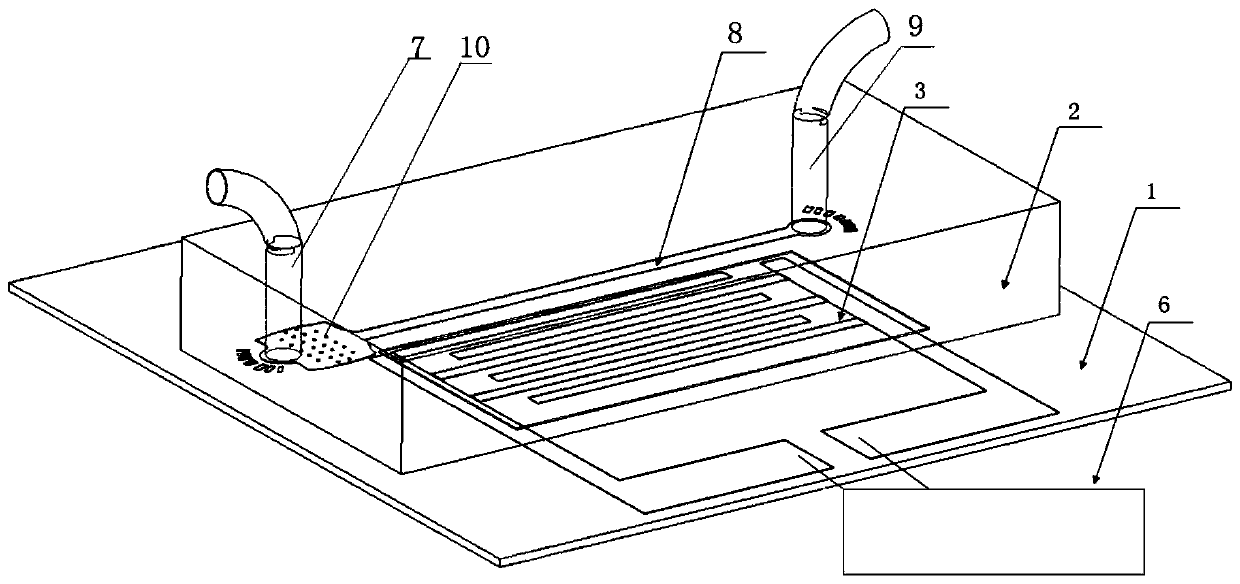

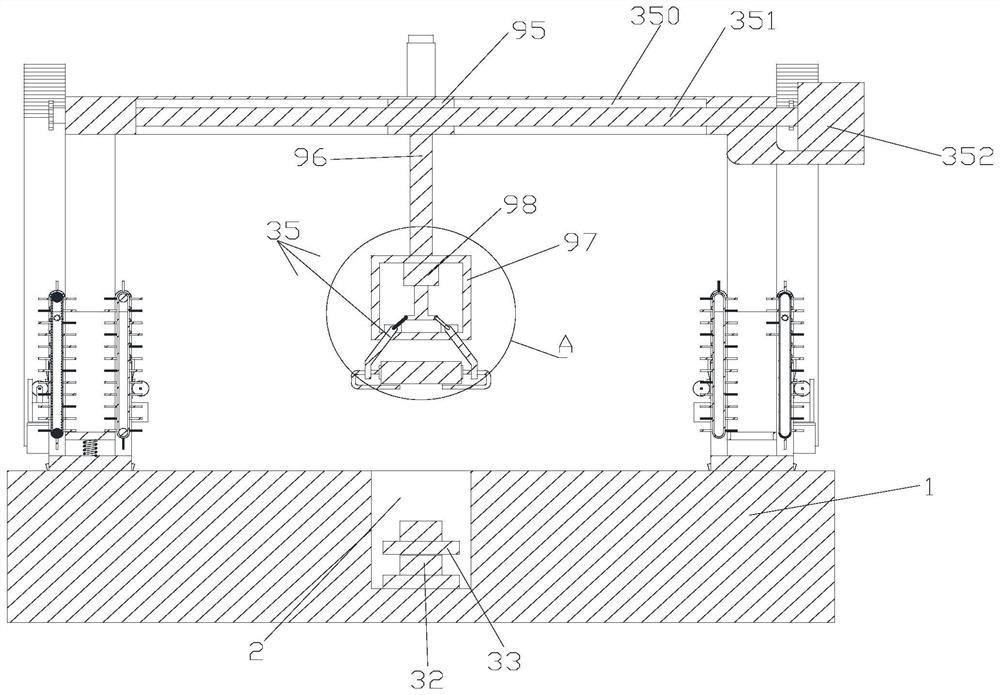

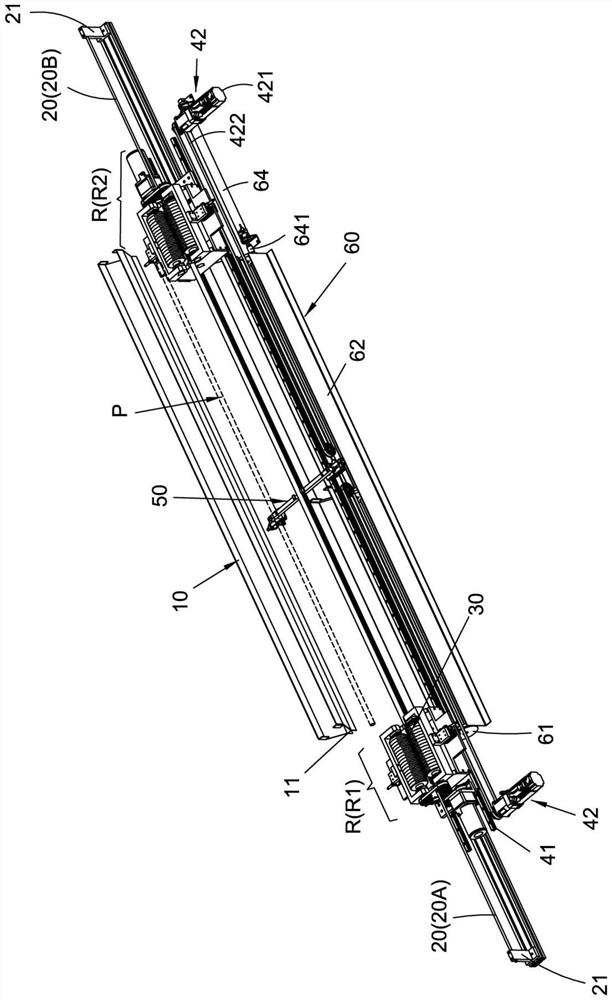

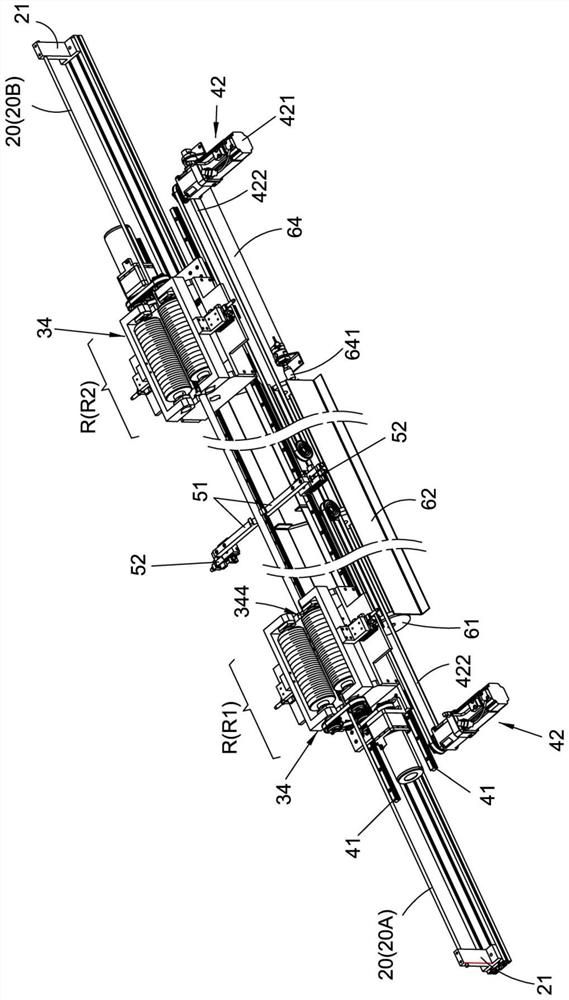

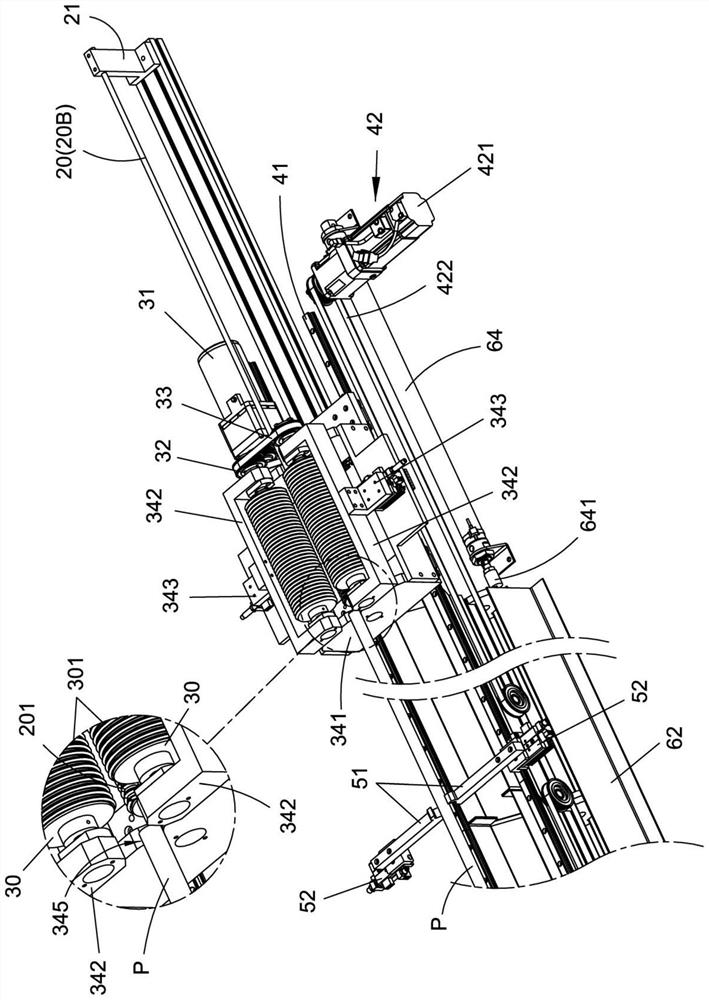

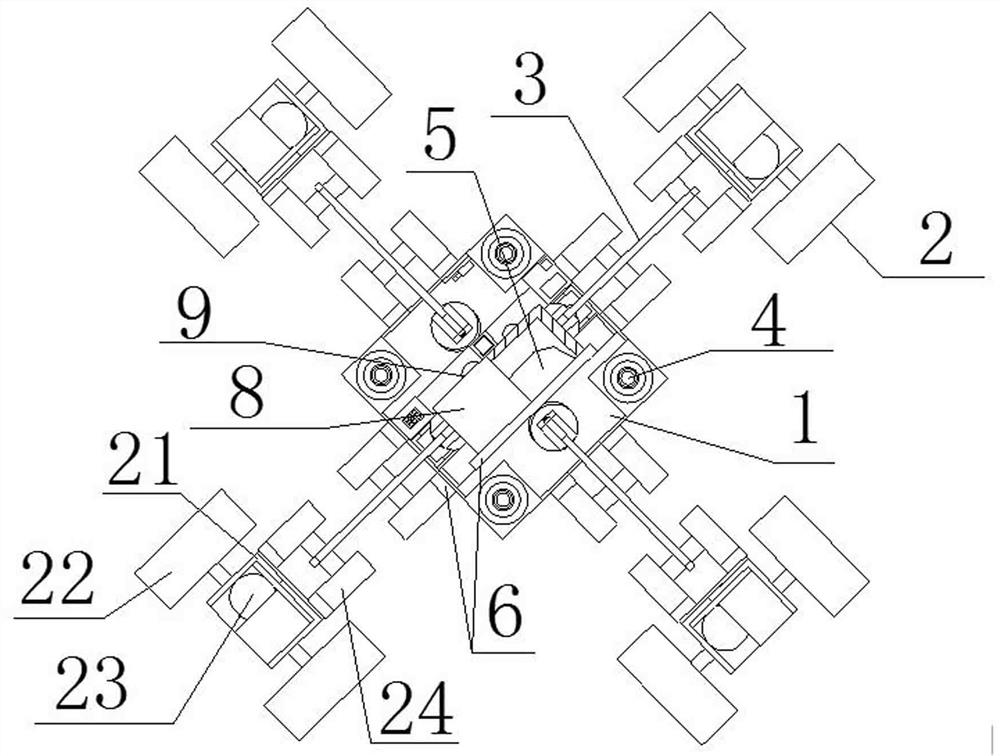

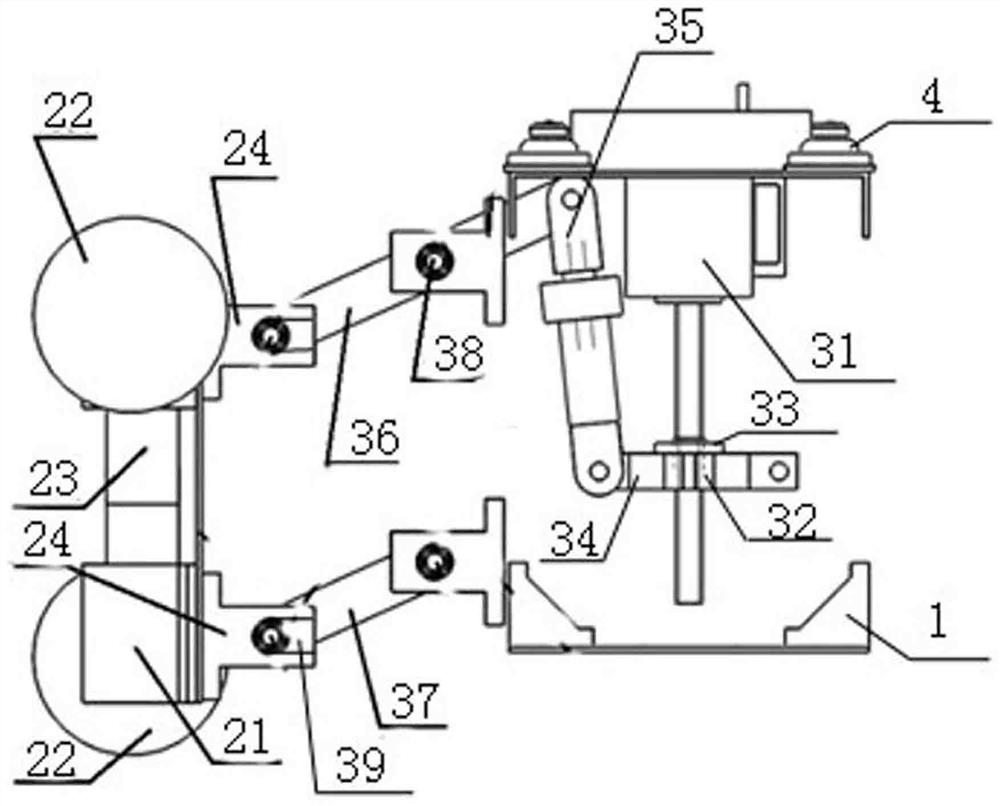

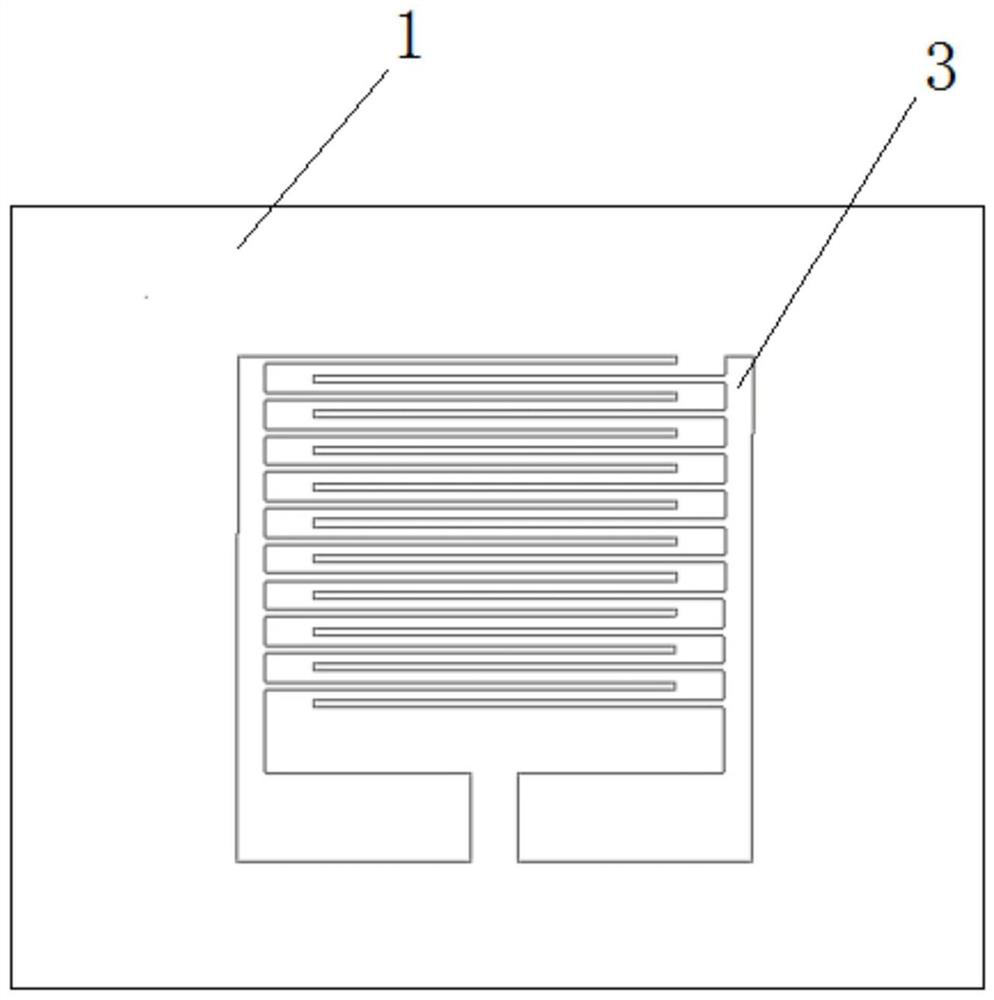

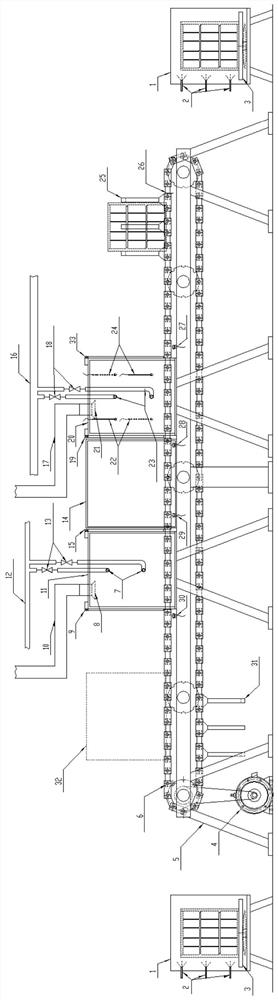

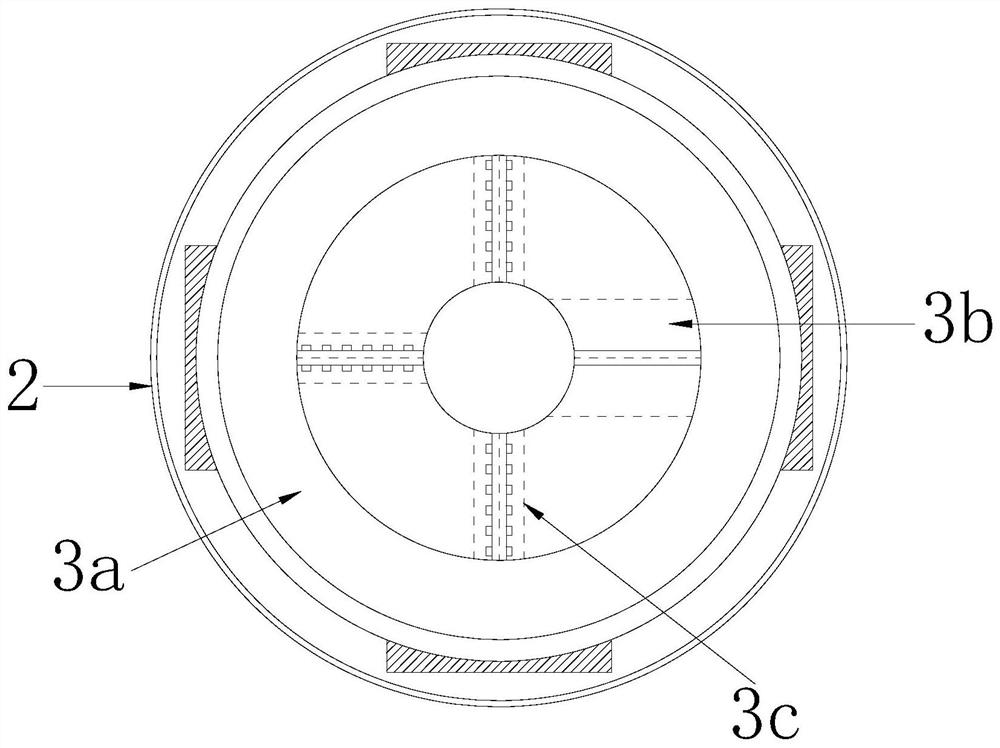

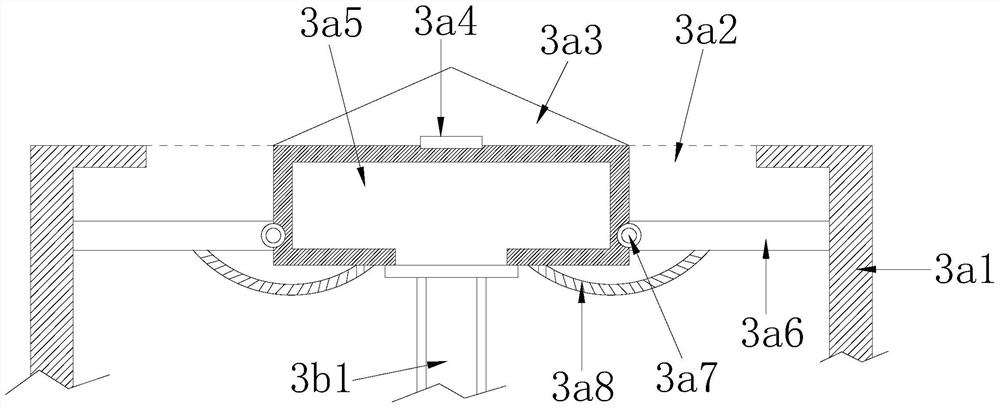

Low and medium speed magnetic levitation icebreaking and snow melting cleaning robot

ActiveCN106120636AEffective Public Works MaintenanceEffective Operational SecurityRailway cleaningFixed frameSnow melting

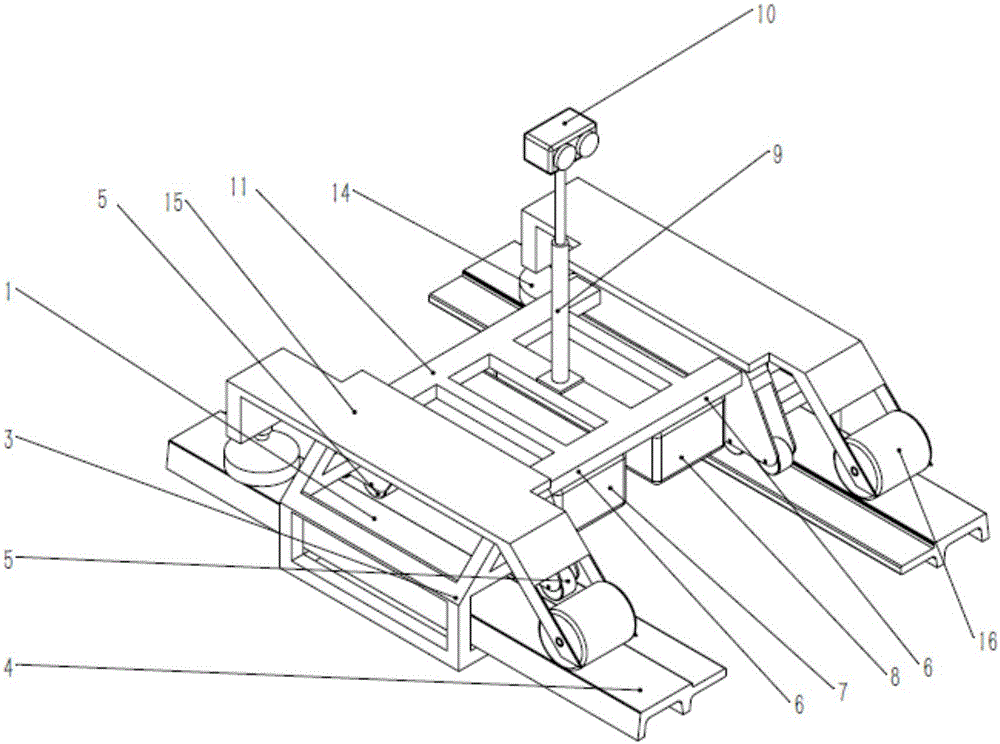

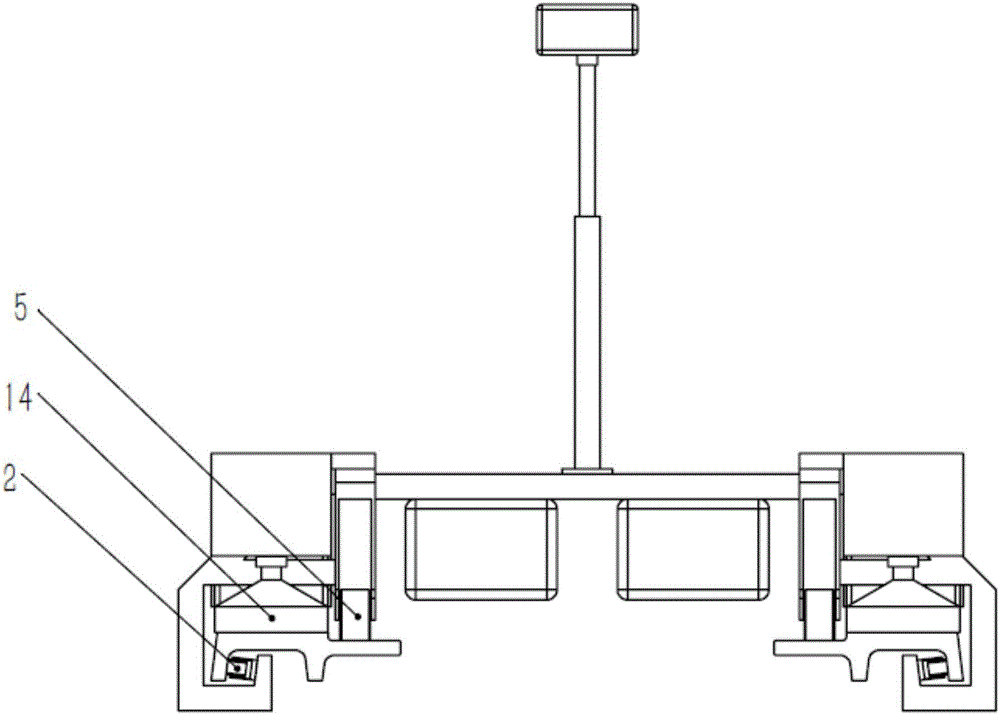

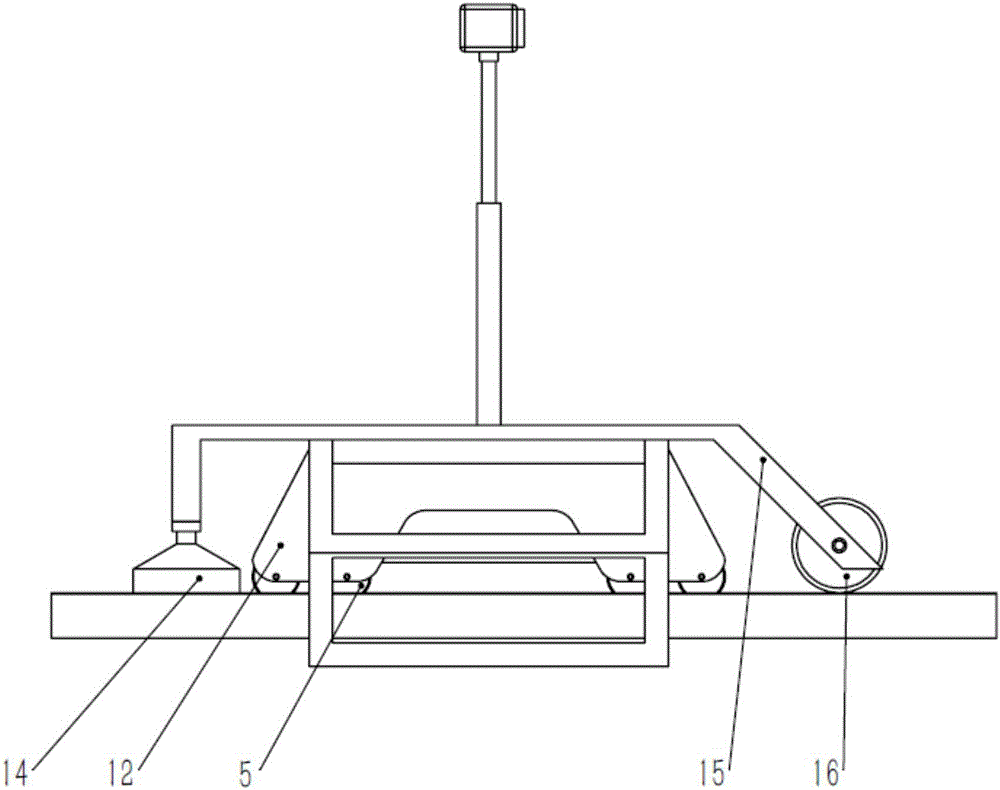

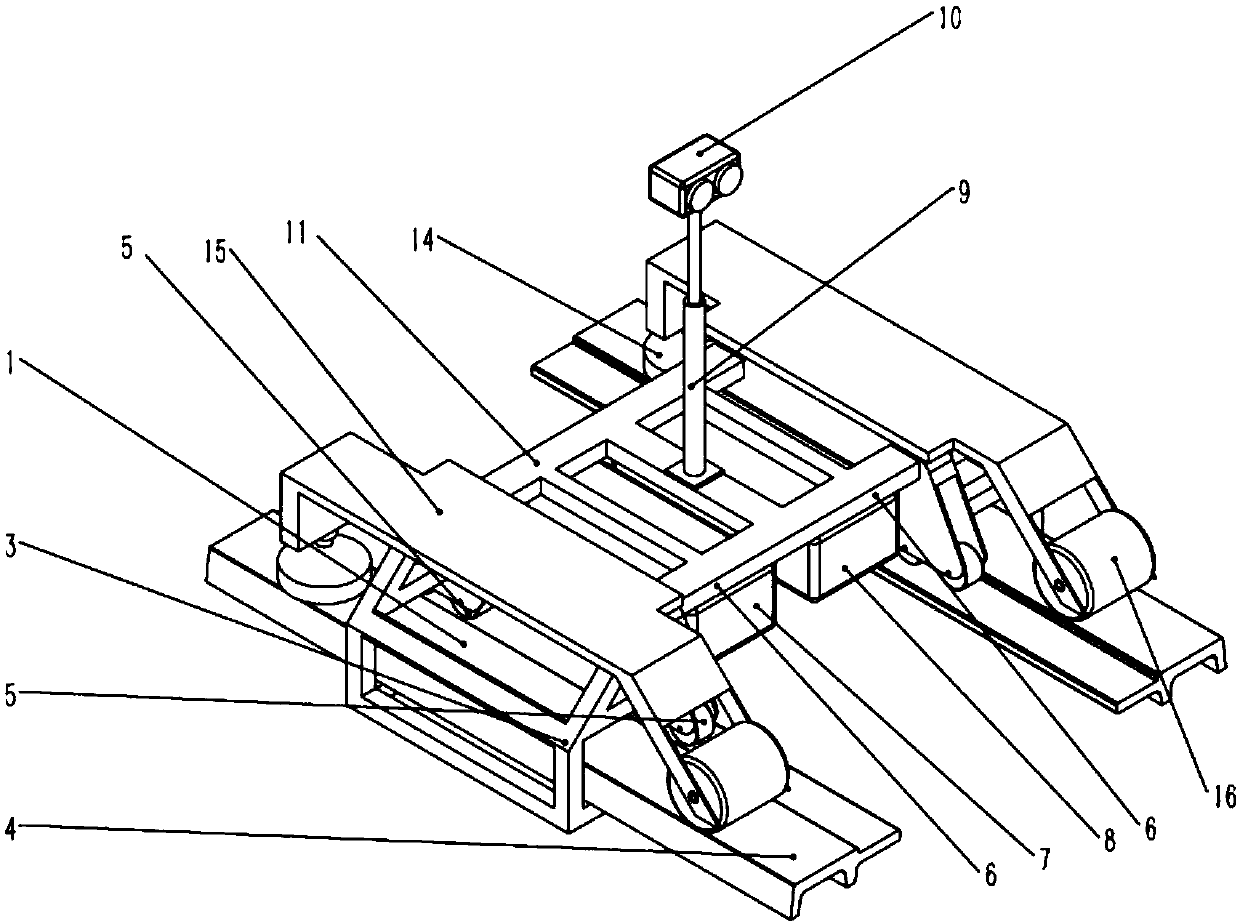

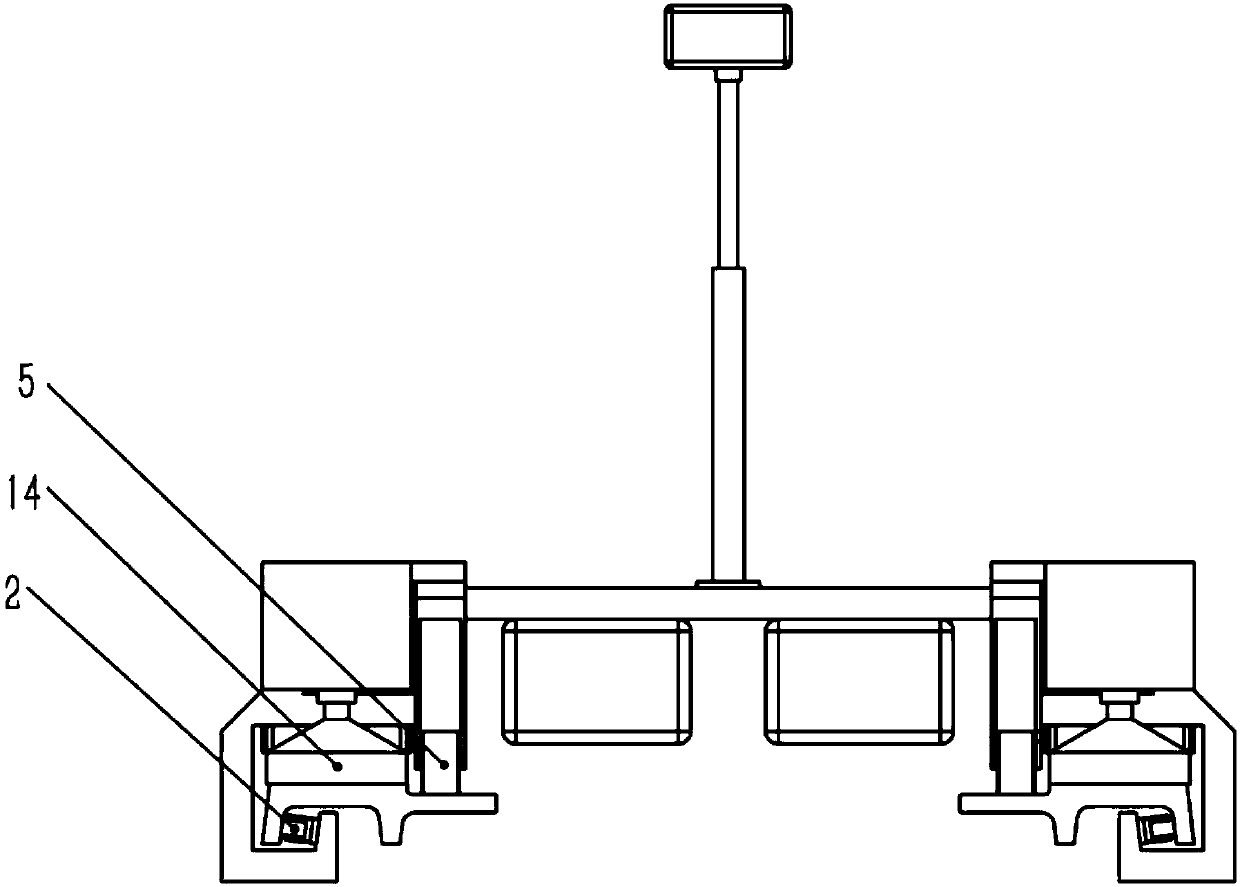

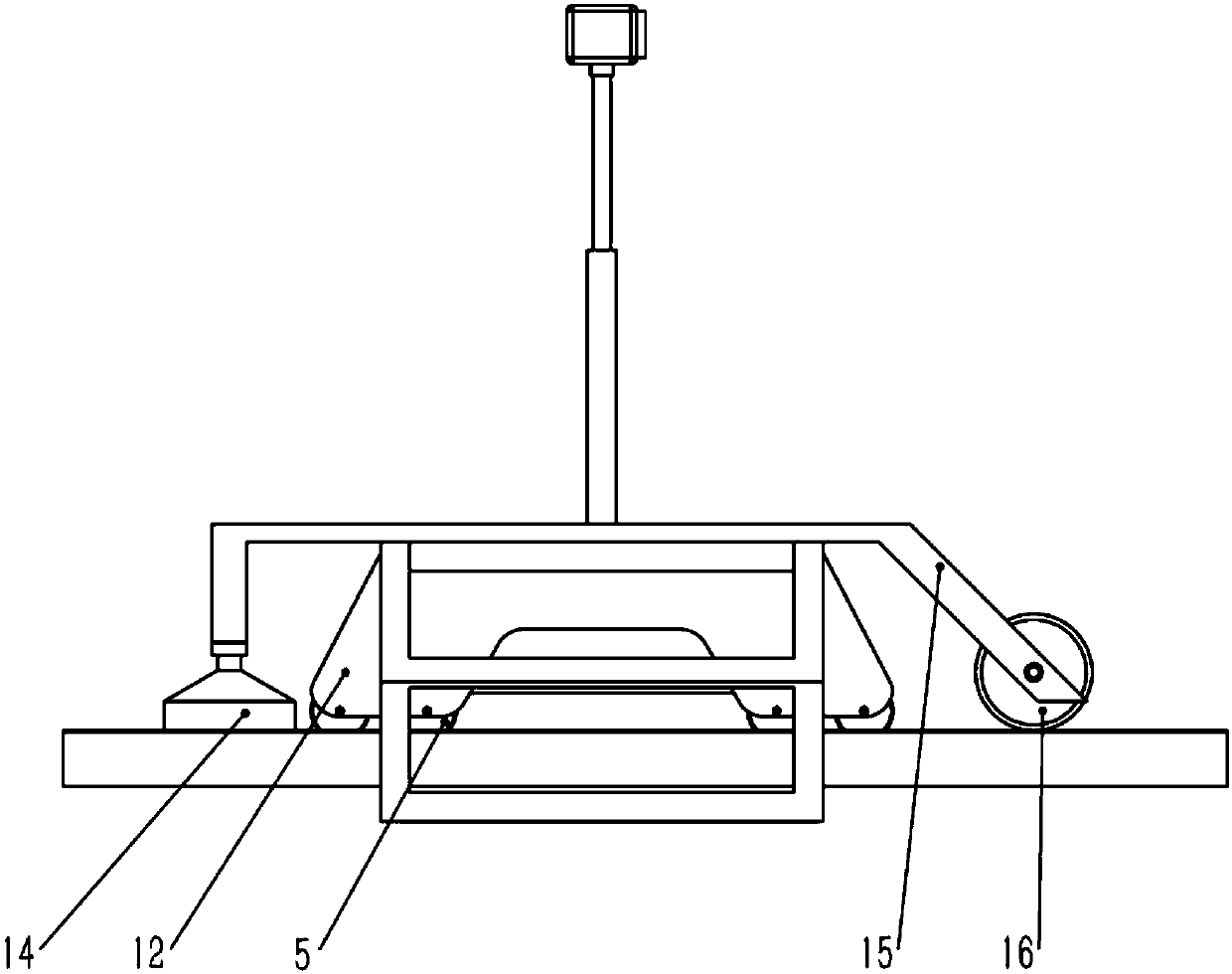

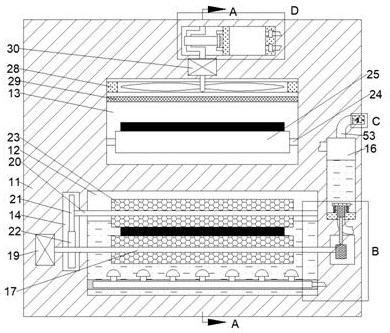

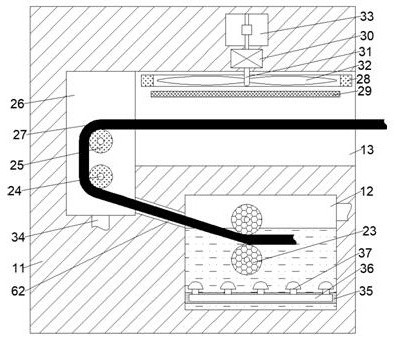

The invention discloses a low and medium speed magnetic levitation icebreaking and snow melting cleaning robot which comprises a machine frame, two folding bending mechanisms, an ice melting cleaning mechanism and an autonomous cruising module. The machine frame stretches over two rails F of low and medium speed magnetic levitation to be detected. The two folding bending mechanisms are arranged at the two ends of the machine frame and located above the rails F. Each folding and bending mechanism is provided with a walking wheel pair and a clamping wheel pair. The snow melting cleaning mechanism comprises a fixed frame, a rail F obstacle removal cleaning unit and an ice melting heating unit. The fixing frame is installed on the machine frame and located above the folding bending mechanisms and arranged in the extending direction of the rails F. The rail F obstacle removal cleaning unit and the ice melting heating unit are arranged at the two ends of the fixing frame. The autonomous cruising module is installed below the machine frame. Rail F ice and snow melting and cleaning can be achieved, and the low and medium speed magnetic levitation icebreaking and snow melting cleaning robot has the advantages of being simple in structure, convenient to operate and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

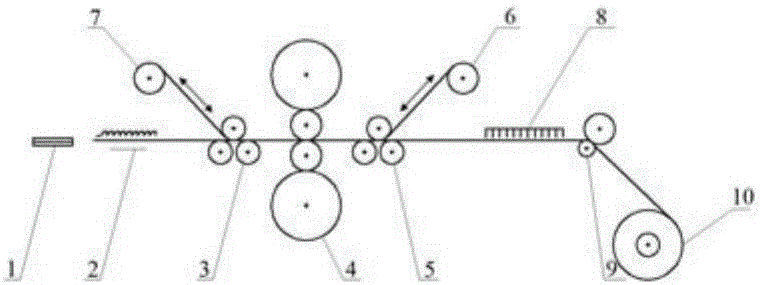

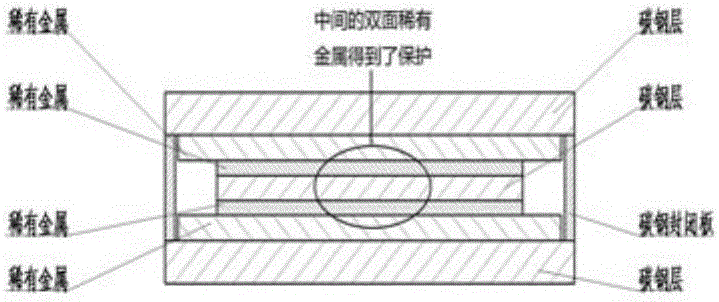

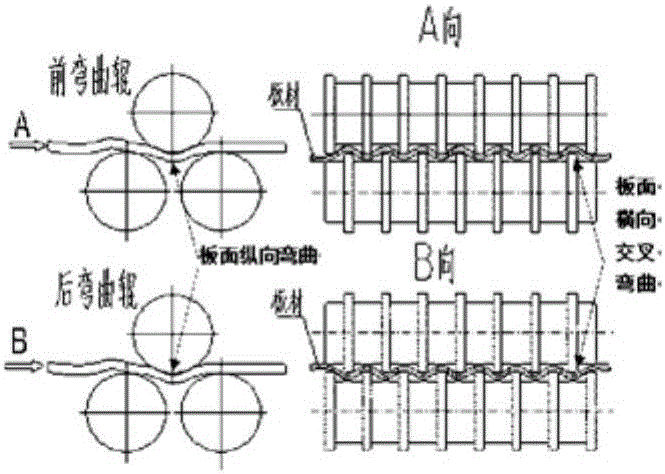

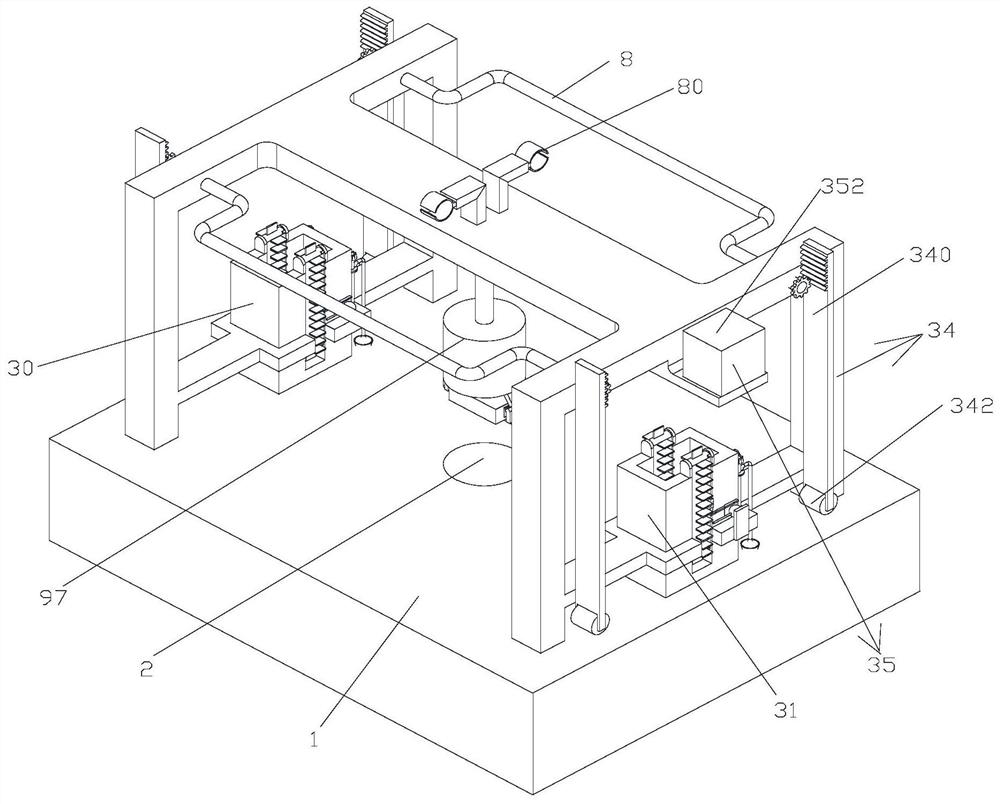

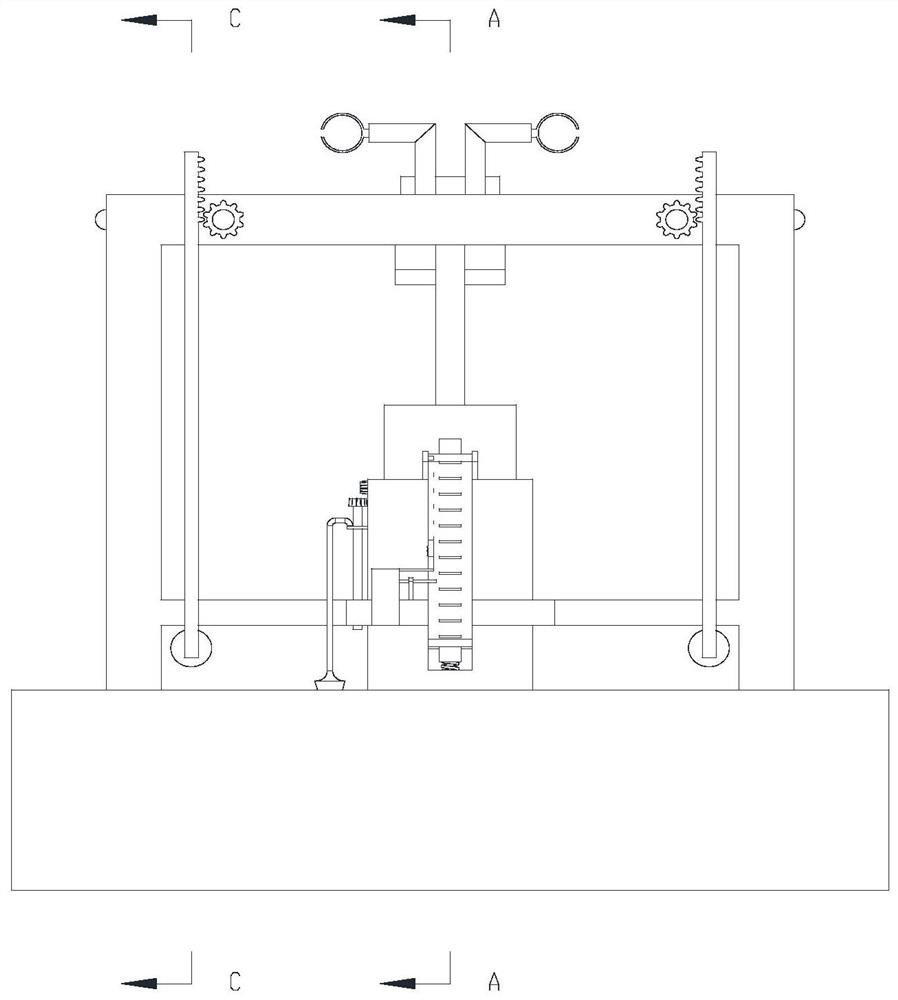

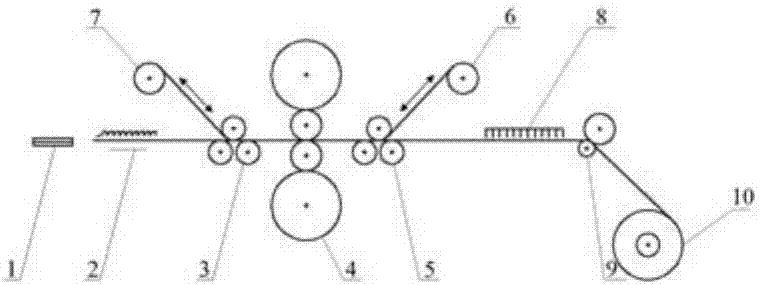

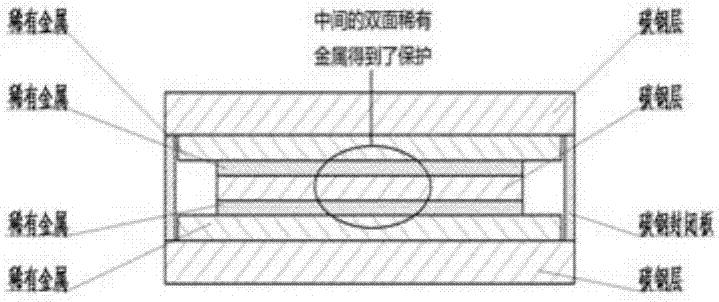

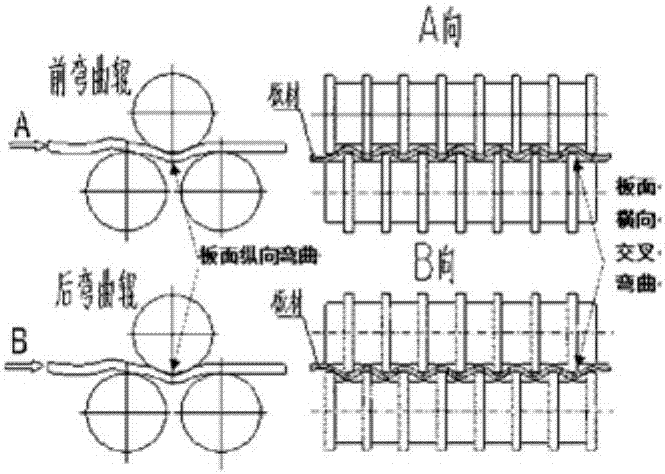

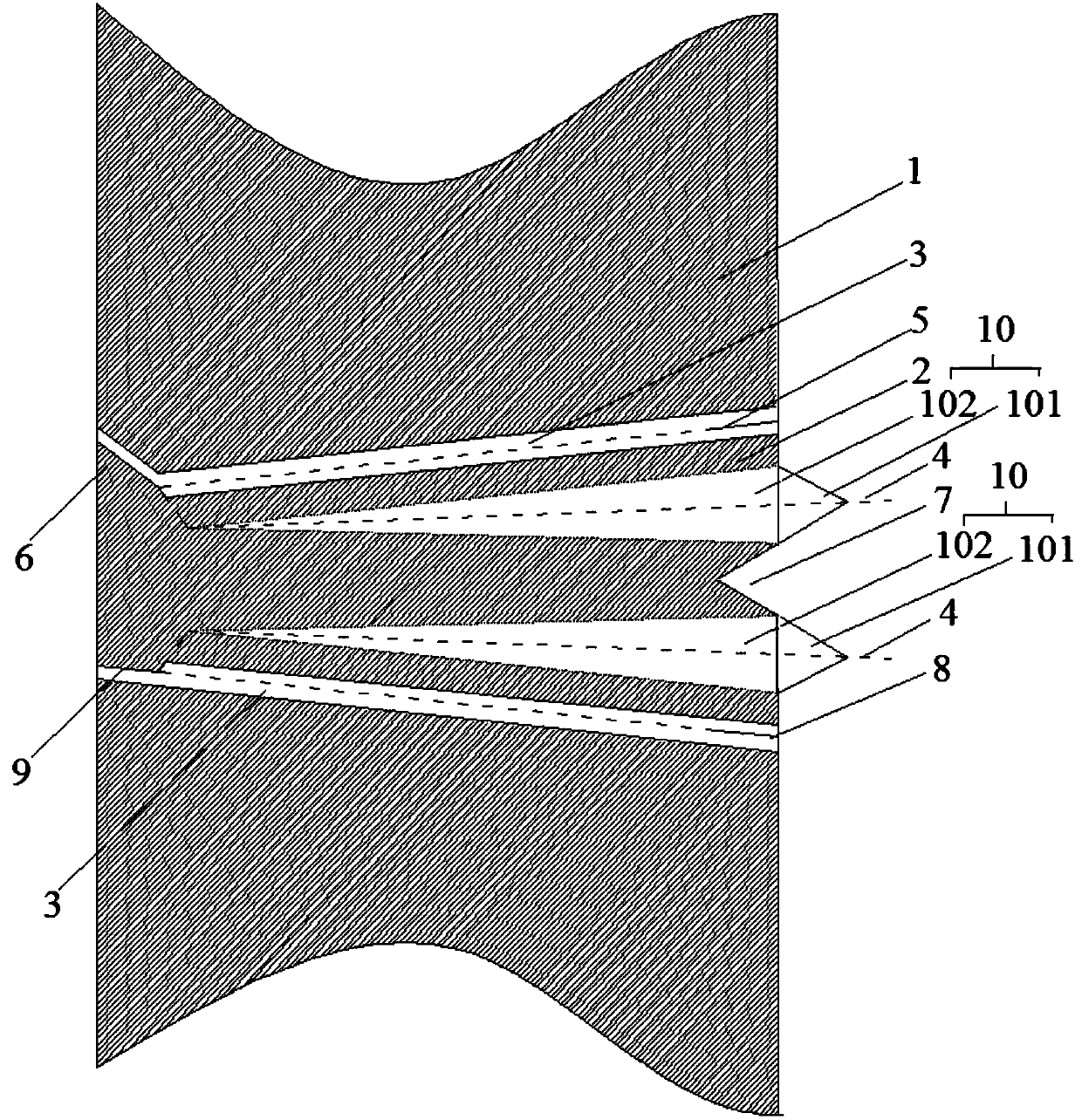

Multilayer metal coupling deformation rolling combined method and device

ActiveCN106001110AReduce the number of rolling millsLess investmentTemperature control deviceAuxillary arrangementsCombined methodHigh pressure water

The invention provides a multilayer metal coupling deformation rolling combined method and device. The device comprises a compound blank heating furnace, a high-pressure water descaling machine, a four-roller reversible rolling mill, a front reeling holding furnace, a rear reeling holding furnace, a front board criss cross bending deformation unit, a rear board criss cross bending deformation unit, a laminar cooling unit and a finished product reeling machine. According to the method, the reeling heating furnaces are equipped in front of and in rear of the single-frame four-roller reversible rolling mill, and the tension bending units are arranged between the front reeling furnace and the rear reeling furnace, the tension bending rollers are flower rollers of which the surfaces are of a convex and concave structure, three flower rollers form a reverse bending deformation unit, and a convex-concave structure of a front roller surface and a convex-concave structure of a rear roller surface are arranged in a staggered mode, so that a temperature controlling reeling coupling deformation rolling combined mechanism used for applying tension and achieving board criss cross bending deformation is formed, residual stress of a compound interface is remarkably reduced, and board shape quality is ensured; and meanwhile, the bonding strength and binding rate of the compound interfaces are greatly improved, the structure performance and comprehensive mechanical performance of composite boards are improved, and the production efficiency and yield are remarkably improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

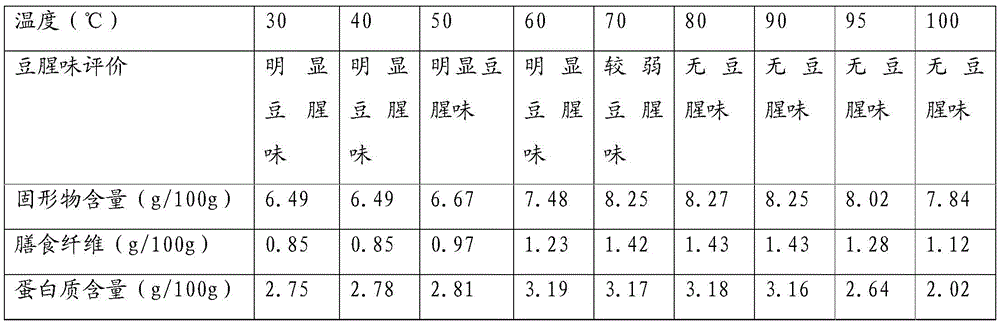

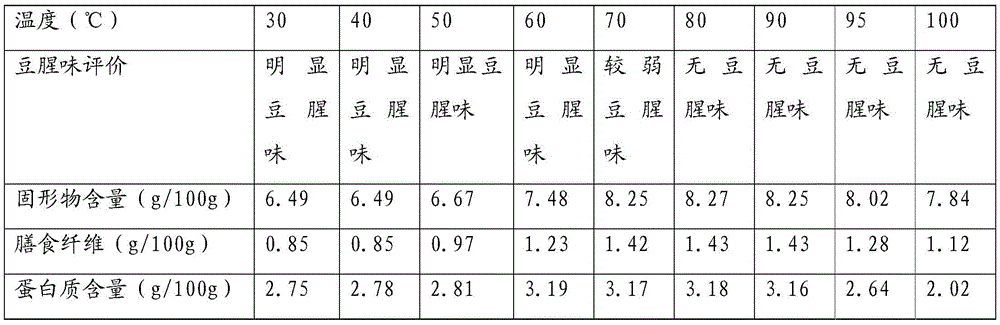

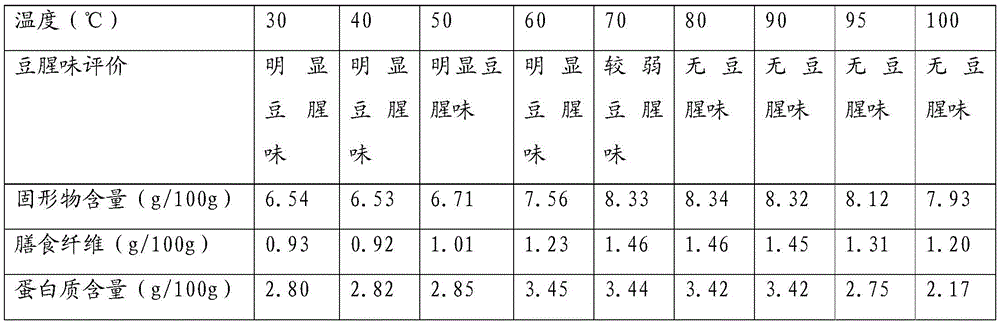

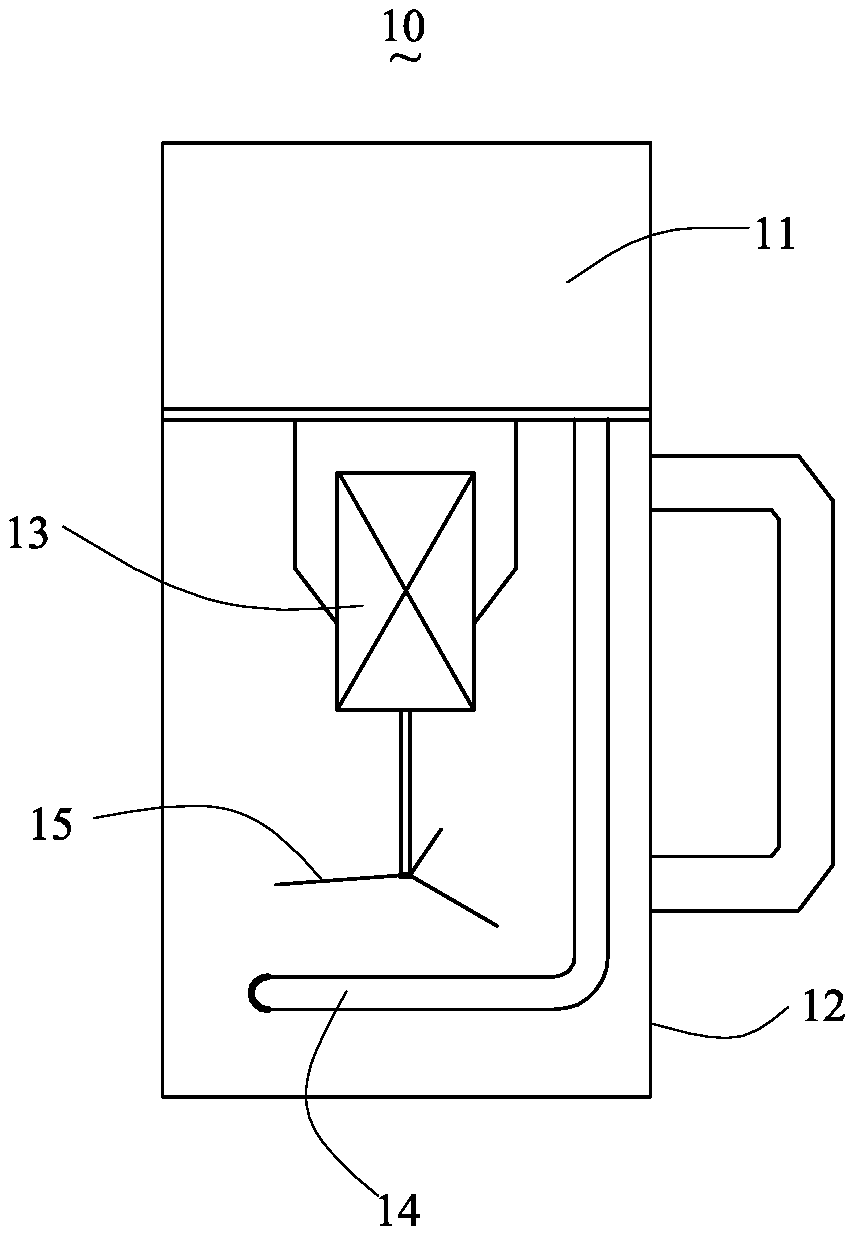

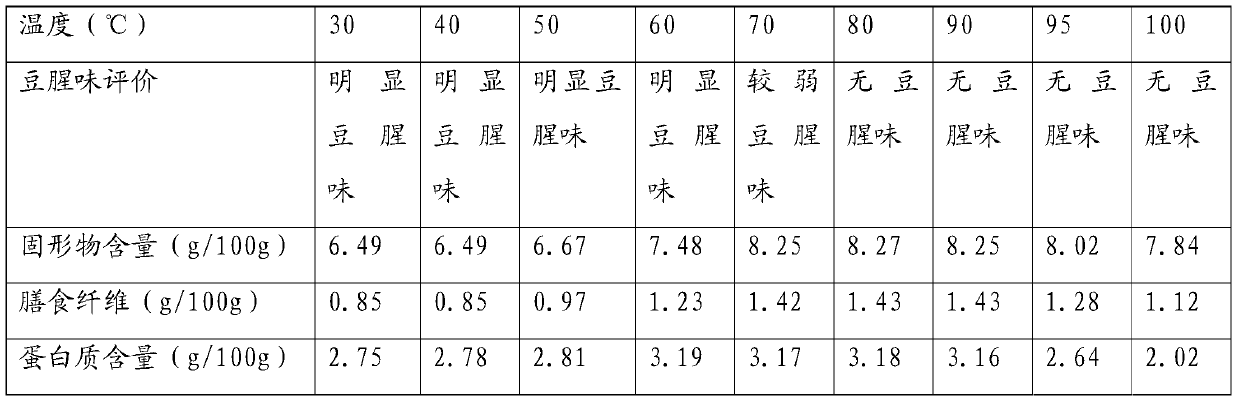

Method for preparing highly-enriched soya-bean milk by utilizing household soybean milk machine

The invention relates to a method for preparing highly-enriched soya-bean milk by utilizing household soybean milk machine. The method comprises at least following steps: a, a wall-crushing phase: a first step, keeping soybean milk material within the first temperature range of 1 to 14 minutes with the first temperature of 70 to 90 DEG C; a second step: rotating to crushing for milk by a crushing cutter at the first rotation speed of 16000 to 35000 turns / minute; b, a boiling phase: heating soybean milk till it is boiled by a heating element. Compared with the prior art, dietary fibers are highly microparticulated and dispersibility and water binding capacity of dietary fibers are greatly improved such that emulsion of soybean milk is very stabilized and soybean milk is not easily stratified after finishing preparation. Therefore, the method is adopted so that soya-bean milk is highly-enriched and not easily stratified and tastes good.

Owner:JOYOUNG CO LTD

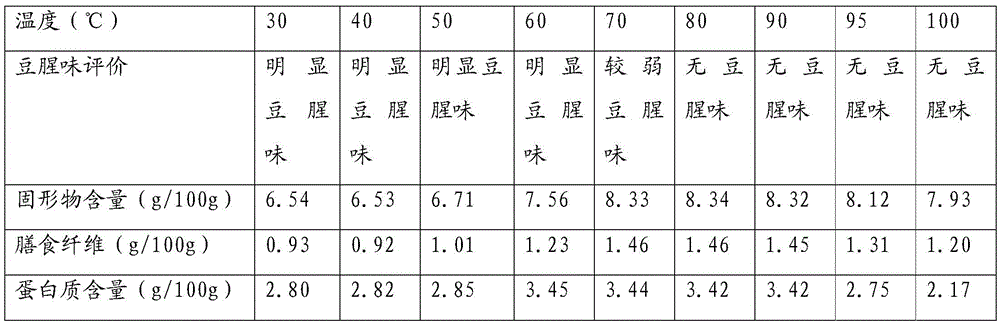

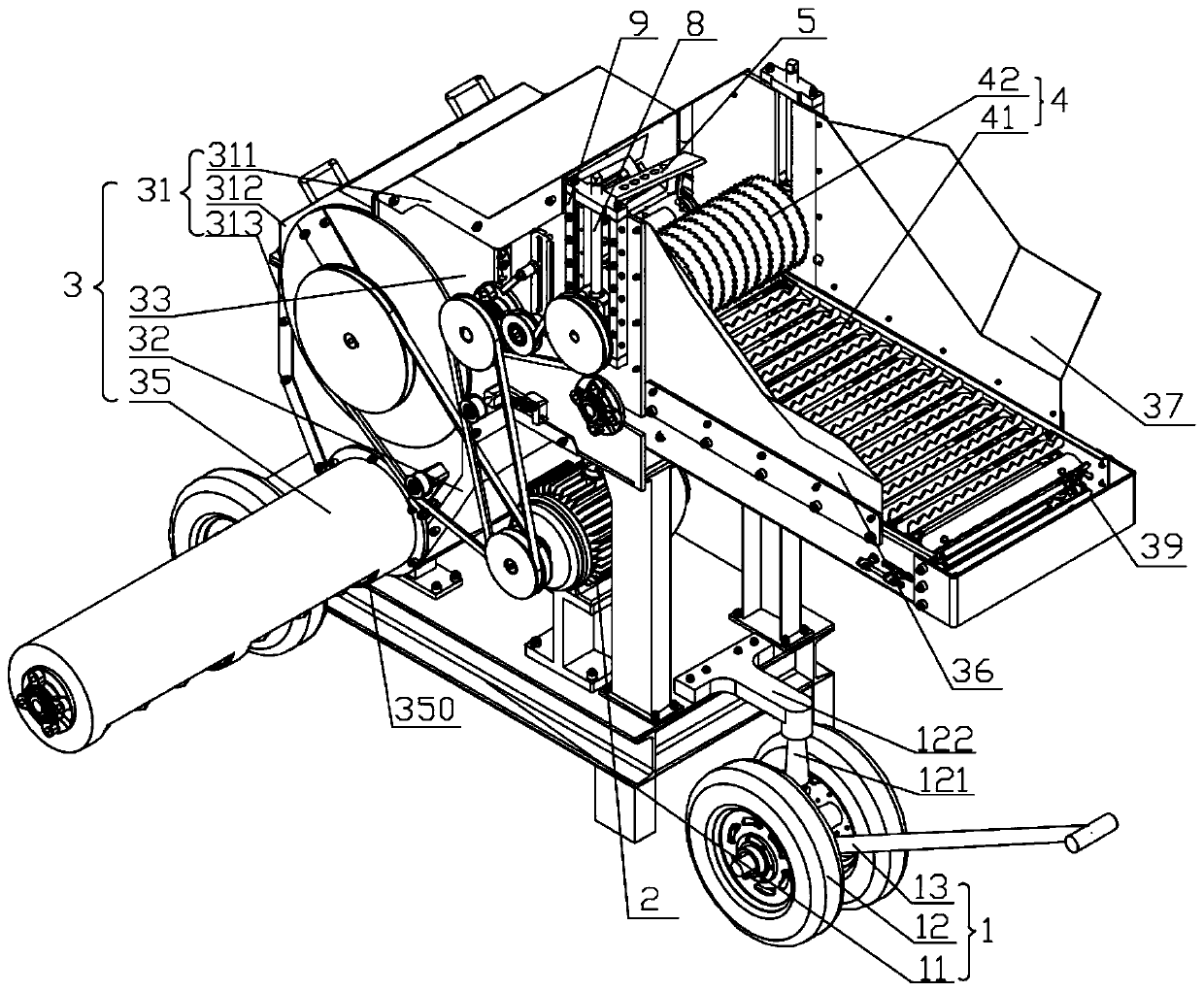

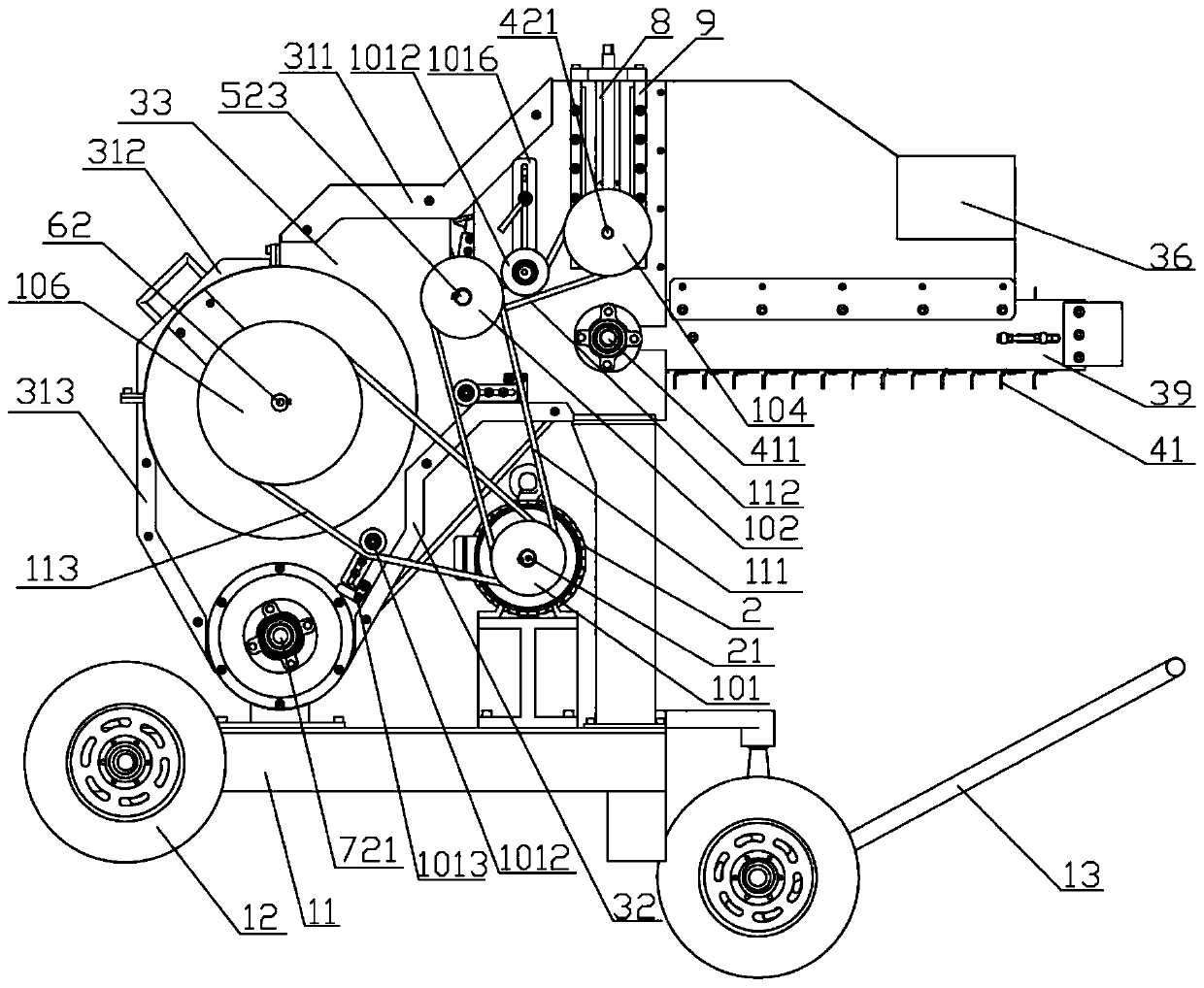

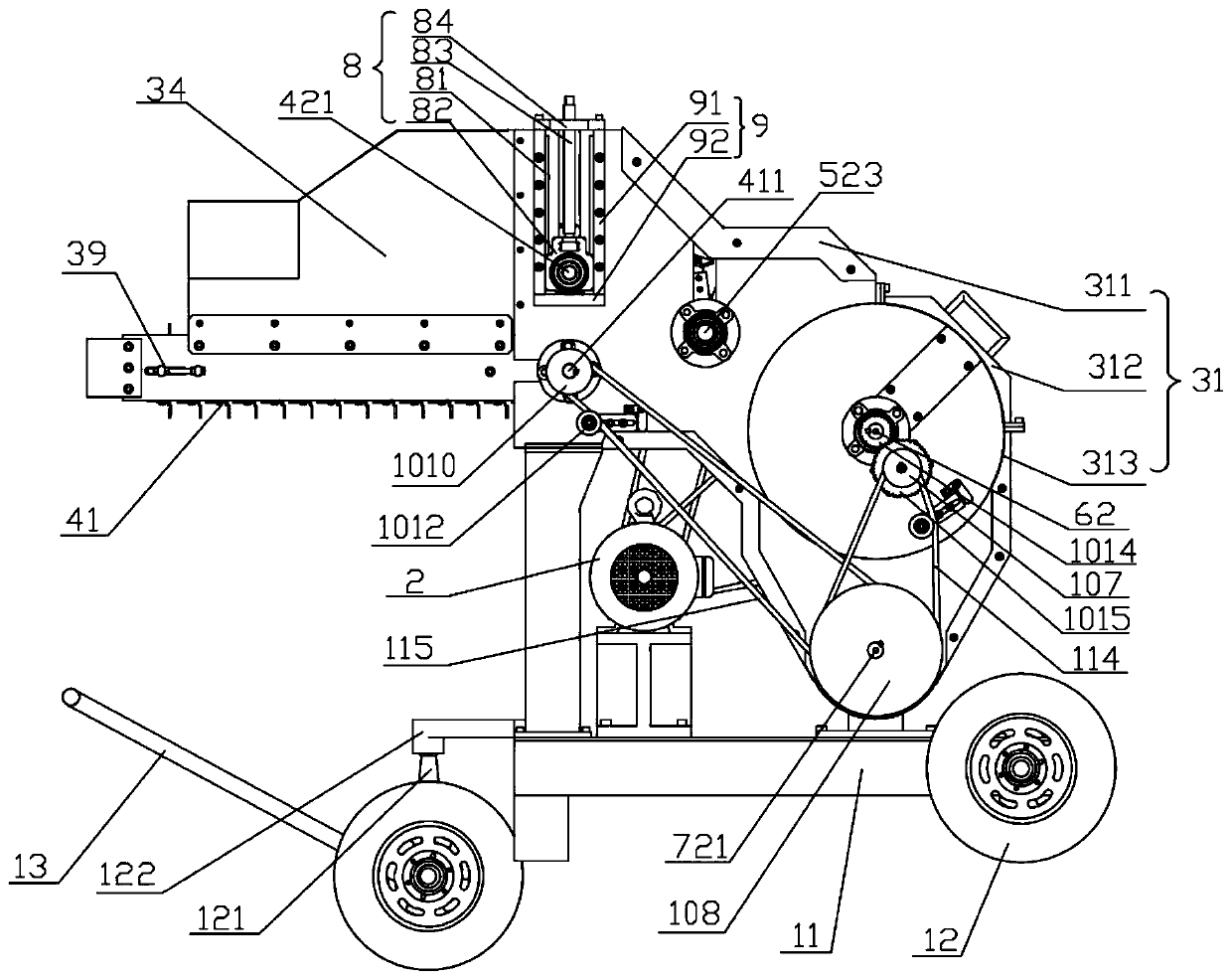

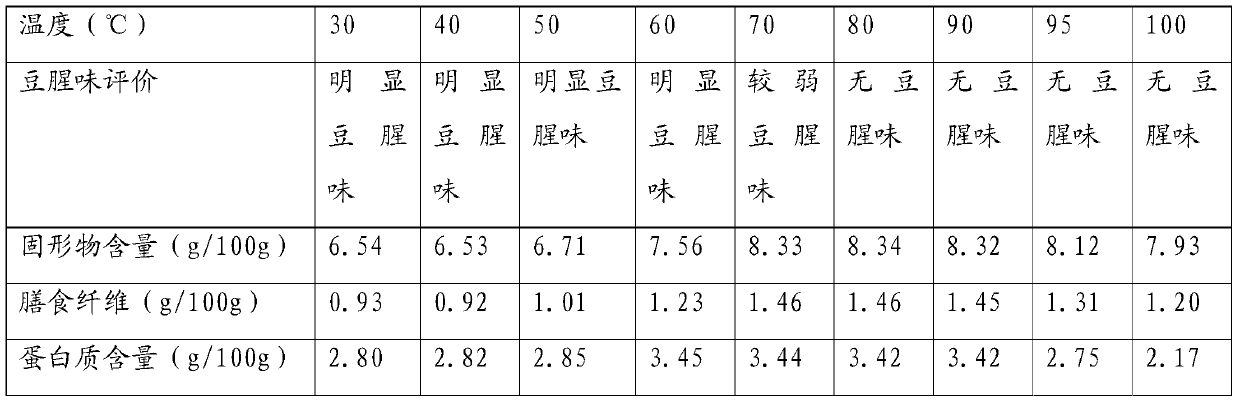

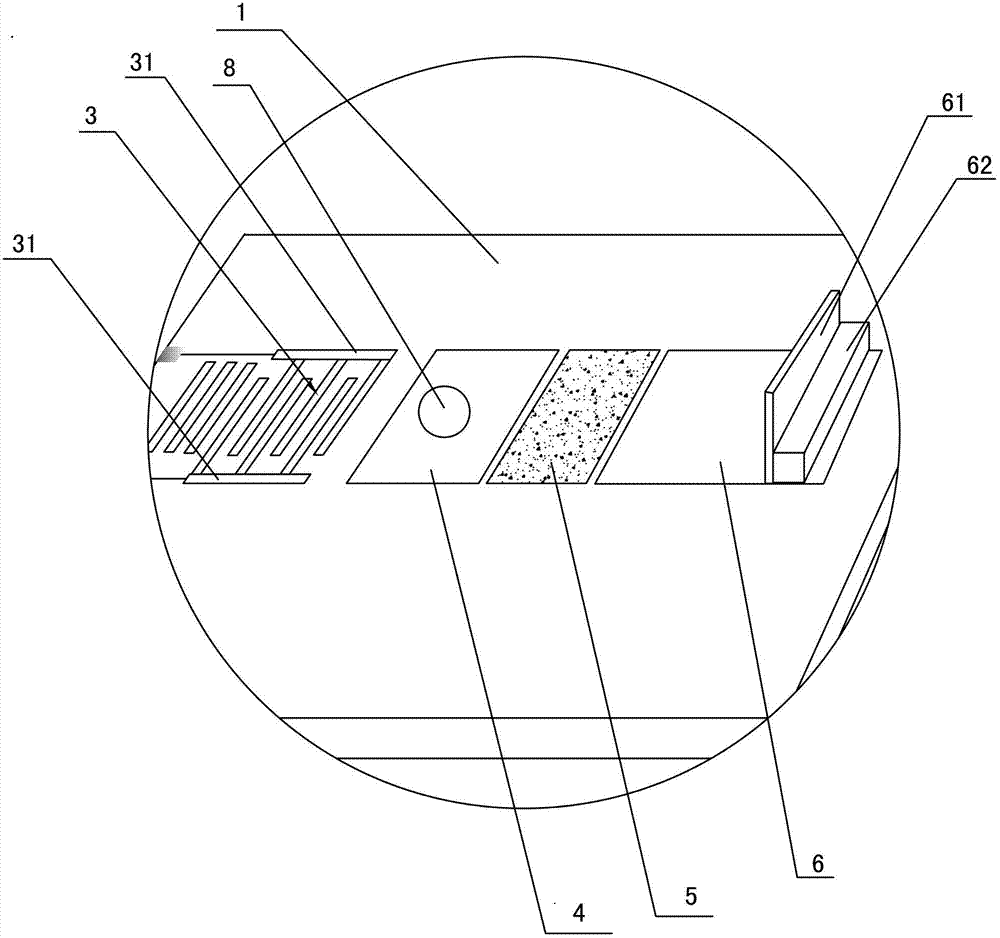

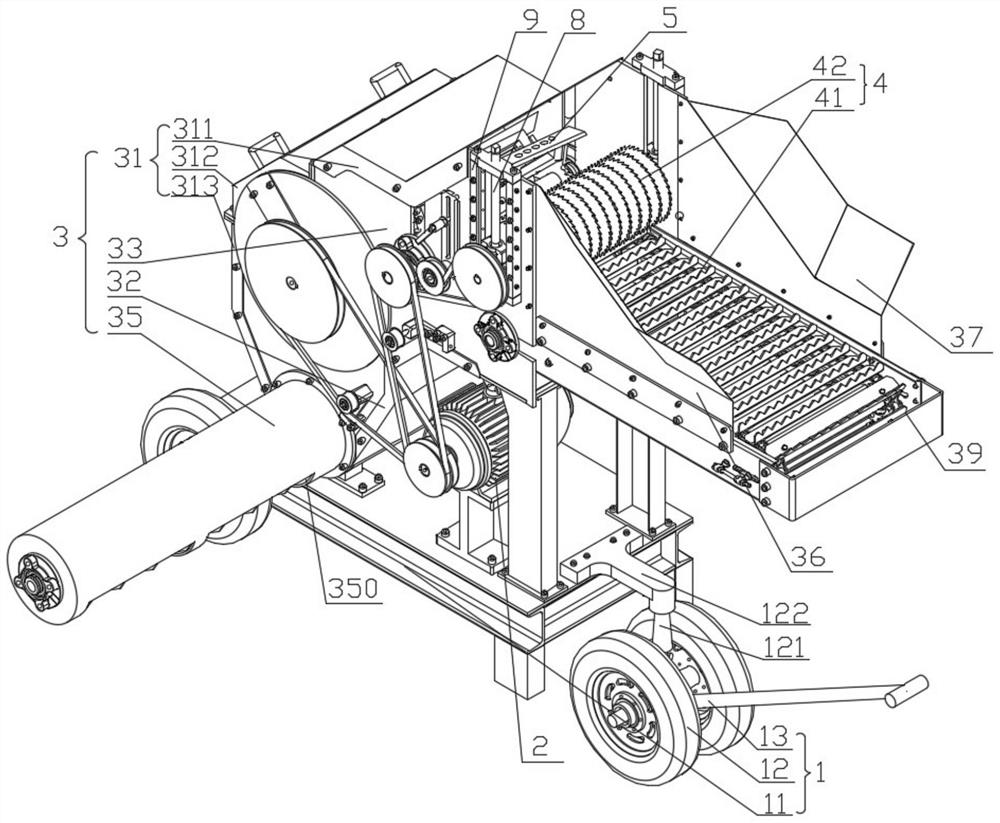

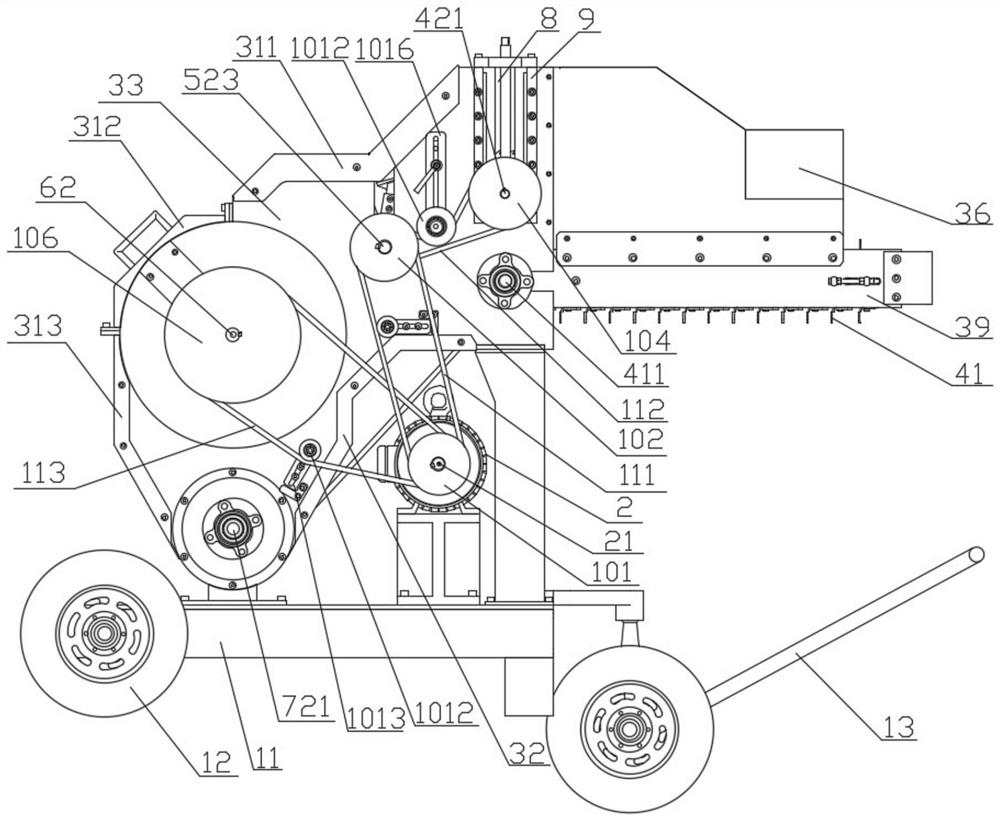

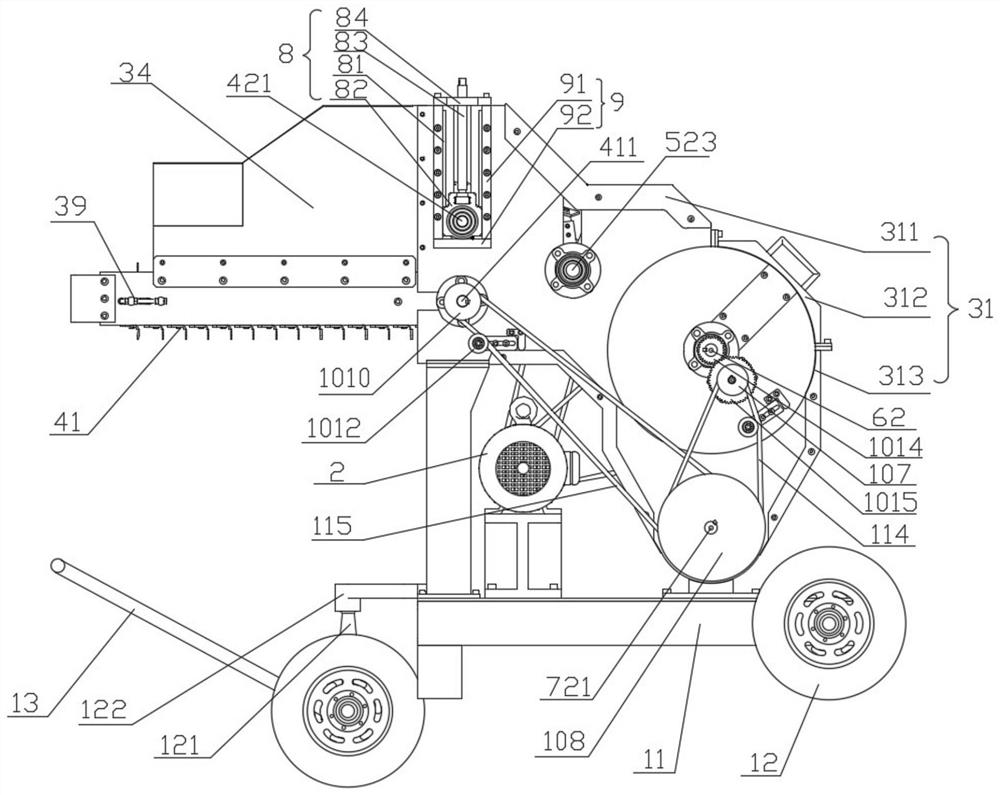

Straw filamentation machine

The invention discloses a straw filamentation machine. The straw filamentation machine comprises a supporting mechanism, a driving mechanism, a protection mechanism, a feeding mechanism, a shredding mechanism, a filament rubbing mechanism and a discharging mechanism, wherein the driving mechanism, the protection mechanism, the feeding mechanism, the shredding mechanism, the filament rubbing mechanism and the discharging mechanism are arranged on the supporting mechanism. A feeding hole, a straw moving channel and a discharging hole are formed in the protection mechanism; the feeding mechanismis located at the feeding hole and includes a conveyor belt and a saw disc knife roller; straw is conveyed to the shredding mechanism after being primarily crushed; the shredding mechanism and the filament rubbing mechanism are located in the straw moving channel; the shredding mechanism comprises a fixed cutter and a hob cutter, and the straw is shredded under the sliding cutting action of the fixed cutter and the hob cutter and is conveyed to the filament rubbing mechanism; the filament rubbing mechanism is used for filamentation of the shredded straw and for conveying straw filaments to thedischarging mechanism; after being screened through the discharging mechanism, the straw filaments are sent out of the machine through the discharging hole. According to the straw filamentation machine, filamentation of the straw is achieved through cooperation of feeding and division, cutting and crushing, hammering and rubbing, the filamentation efficiency is high, material accumulation is avoided, the structure is very simple, and the requirement of decentralized operation of agricultural production is met.

Owner:SHENYANG AGRI UNIV

Process for making bean curd by household soybean milk machine

The invention relates to a process for making bean curd by a household soybean milk machine. The process at least includes the following stages: an all-wall breaking stage: 1, maintaining the pulp materials in a first temperature range of 70 DEG to 90 DEG C for 1-10 min, and 2, crushing the materials into a slurry by using the crushing tool at a first speed of 16000-35000 RPM; a boiling stage: heating the above slurry by a heating element until a cooked state; bean curd manufacture phase: first adding a brine agent to the slurry, continuing solidifying, and finally pressing. Compared with the prior art, the soybean milk for making bean curd does not need filtering, so that the bean curd has high yield; and the bean curd has more comprehensive nutrients, and fine taste.

Owner:JOYOUNG CO LTD

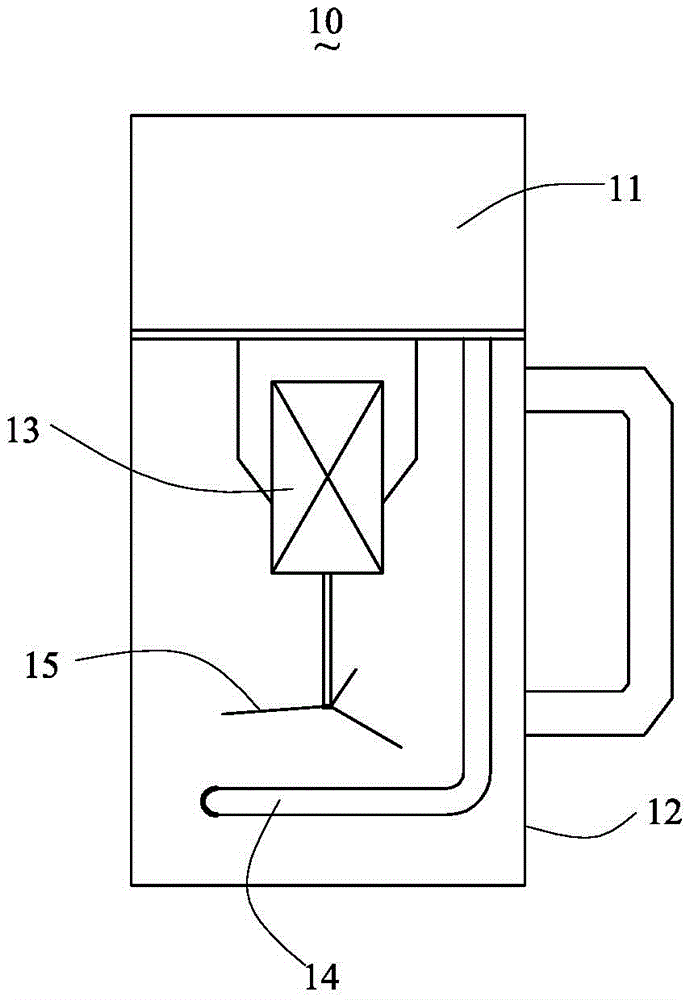

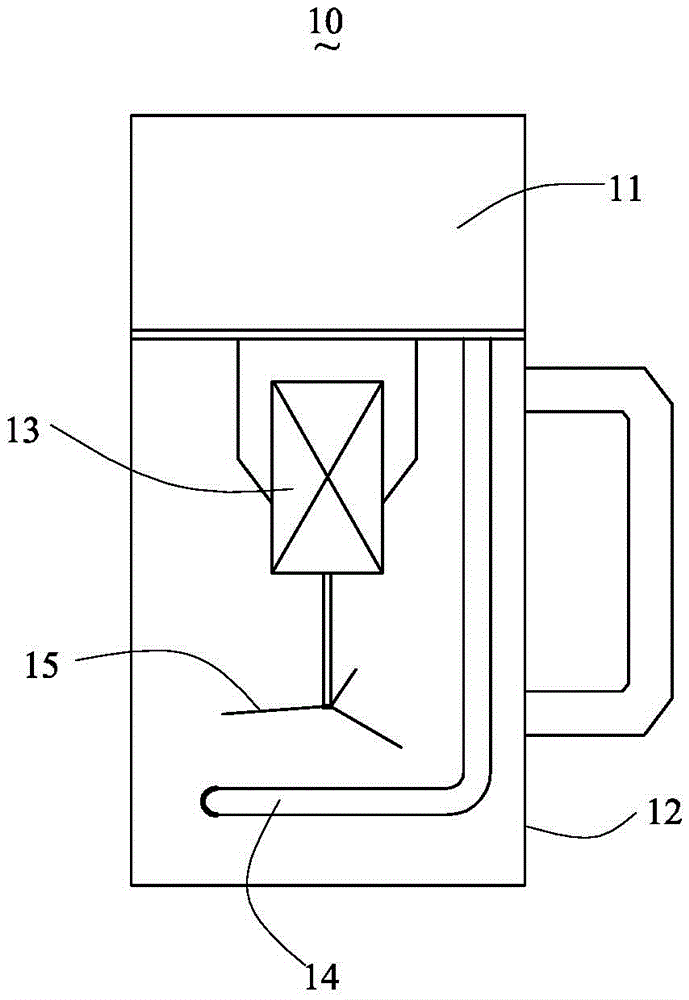

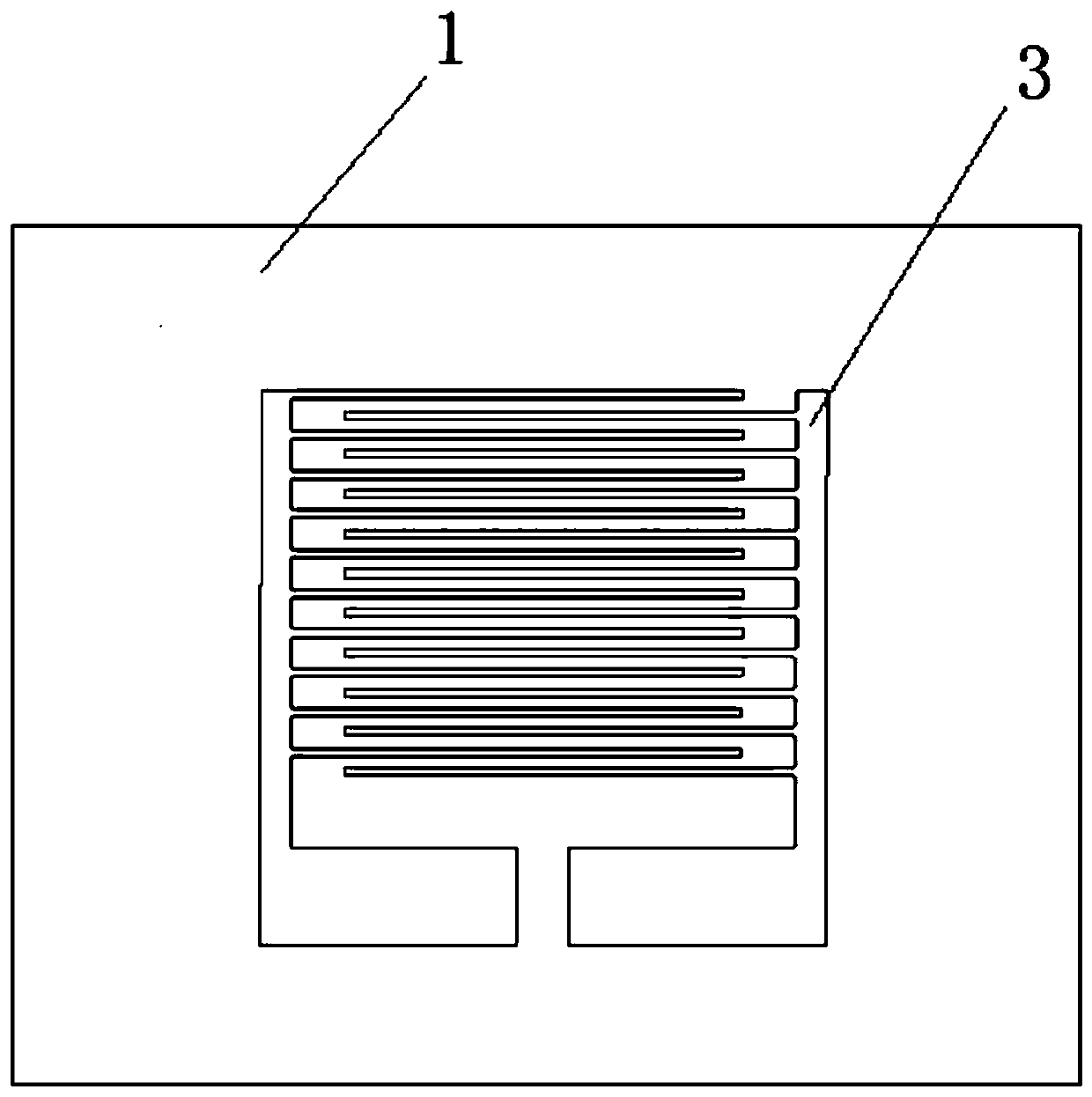

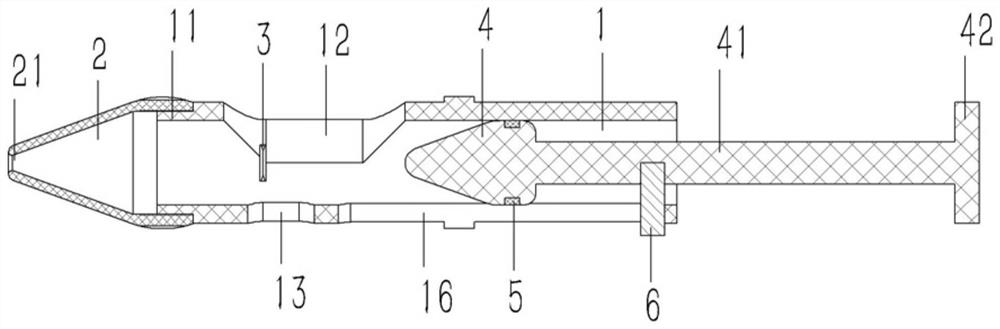

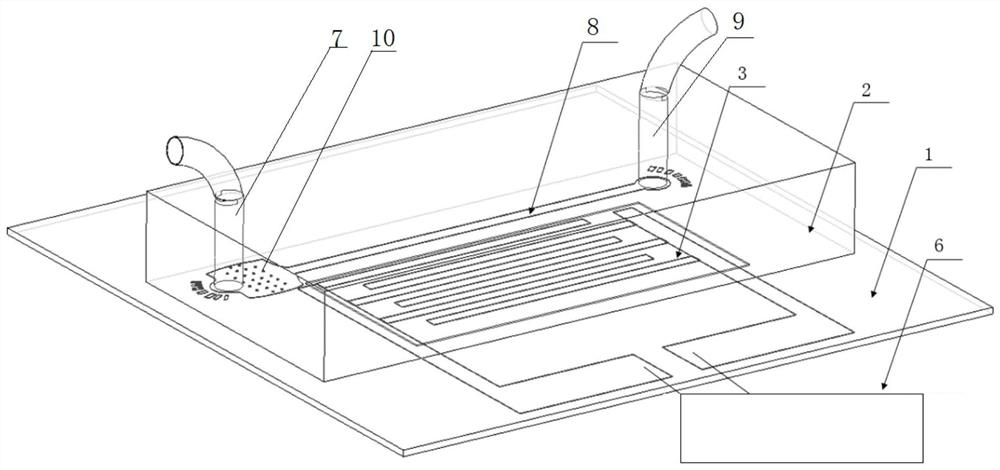

Micro bacteria cracking reactor based on surface acoustic waves and bacteria cracking method

ActiveCN109868218AAvoid cross infectionAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringControl system

The invention discloses a micro bacteria cracking reactor based on surface acoustic waves and a bacteria cracking method. The reactor comprises a lower bottom plate and an upper cover plate which arealigned and bonded together; a group of surface acoustic wave generation structures are arranged on the lower bottom plate; a groove is formed in one side of the upper cover plate, and a micro-channelstructure allowing liquid to flow through is arranged in the middle of the upper cover plate; a signal control system is used for controlling the surface acoustic wave generation structures; the micro-channel structure comprises a sample introduction hole, a reaction area and a product outflow hole. The method is suitable for cracking different types of bacteria, does not need any chemical reagent, and avoids the pollution of the chemical reagent to a cracked product.

Owner:XI AN JIAOTONG UNIV

Blasting method for foundation pit excavation

The invention discloses a blasting method for foundation pit excavation. The blasting method comprises the following steps of surveying a terrain, excavating a side slope, protecting the side slope, establishing a safety protection enclosure, drilling, charging, blocking, performing stepped blasting and removing ballast. The blasting method for foundation pit excavation is more scientific and reasonable, through the use of a mature slope protection technology and a rock stratum excavation construction technology, the establishment of a safe enclosure, strict drilling operation, a charging technology, standard operation of blasting, and the use of detection means with strict measures, the risk coefficient in the construction process can be effectively reduced, the blasting safety is greatly improved, and meanwhile, the influence of blasting on the surrounding environment can be effectively reduced, and the blasting method is high in blasting efficiency, low in cost and worthy of popularization.

Owner:北京理工北阳爆破工程技术有限责任公司

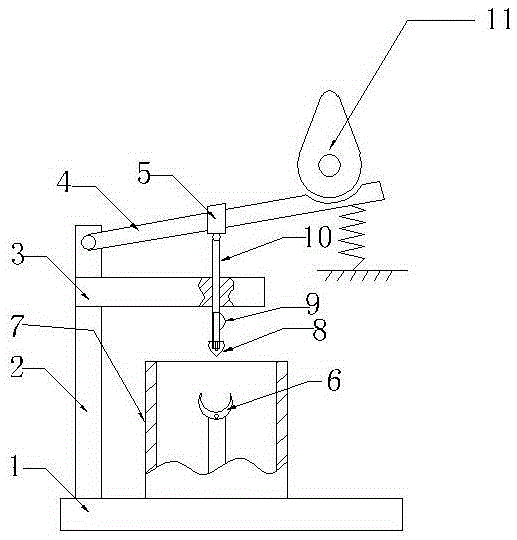

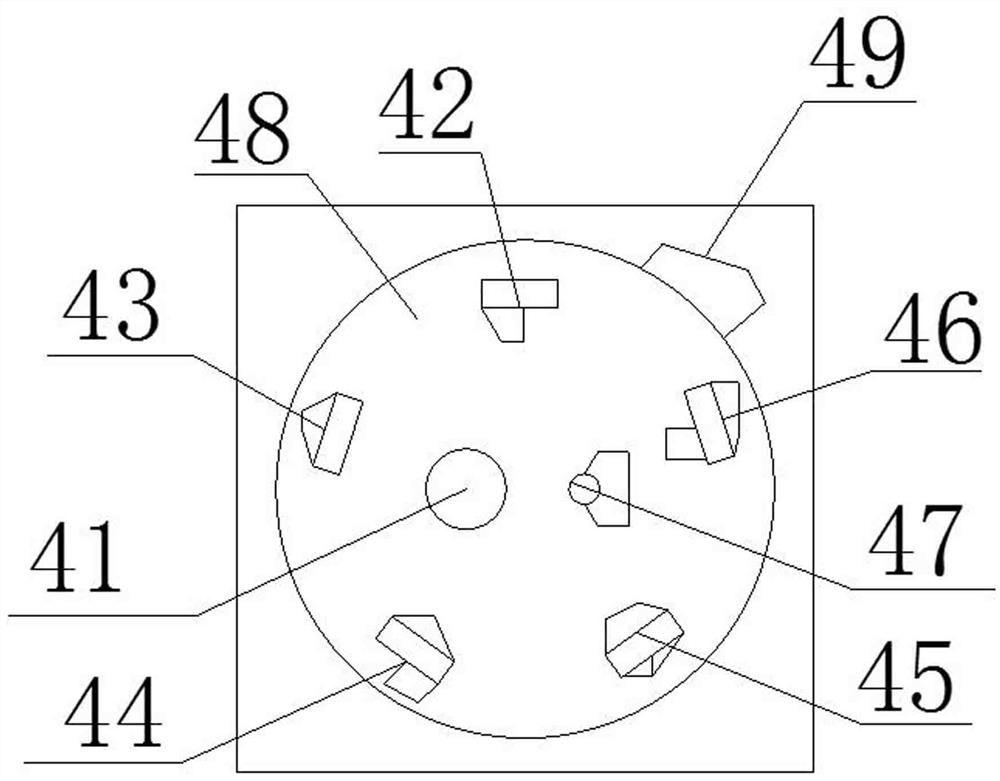

Corn cob breaking mechanism

The application of the invention relates to an apparatus for stripping corn kernels, and discloses a corn cob breaking mechanism. The mechanism comprises a rack, wherein a vertical rod and a charging bucket are fixedly connected with the rack; a compression rod and a fixed plate are separately connected with the vertical rod from top to bottom; a hole is formed at one side of the fixed plate away from the vertical bar; a cob breaking rod is slidably connected in the hole; the charging bucket is located under the cob breaking rod; a spring is arranged between the compression rod and the rack; an arc-shaped slot is opened on the upper surface of the compression rod; a cam matched with the arc-shaped slot is arranged above the compression rod; a sliding block is slidably connected with the compression rod; the sliding block is hinged with a ball at the upper end of the cob breaking rod; a petal shaped inflation body is connected with thread on the other end of the cob breaking rod; a claw is arranged in the charging bucket; and the claw is located under the petal shaped inflation body. Compared with the prior art, the corn cob breaking mechanism pushes the compression rod to move by virtue of the cam which rotates to be matched with the arc-shaped slot, so that the cam is in the rotating working state all the way, thereby ensuring the work continuity and improving the work efficiency.

Owner:CHONGQING NONGZHENG AGRI DEV CO LTD

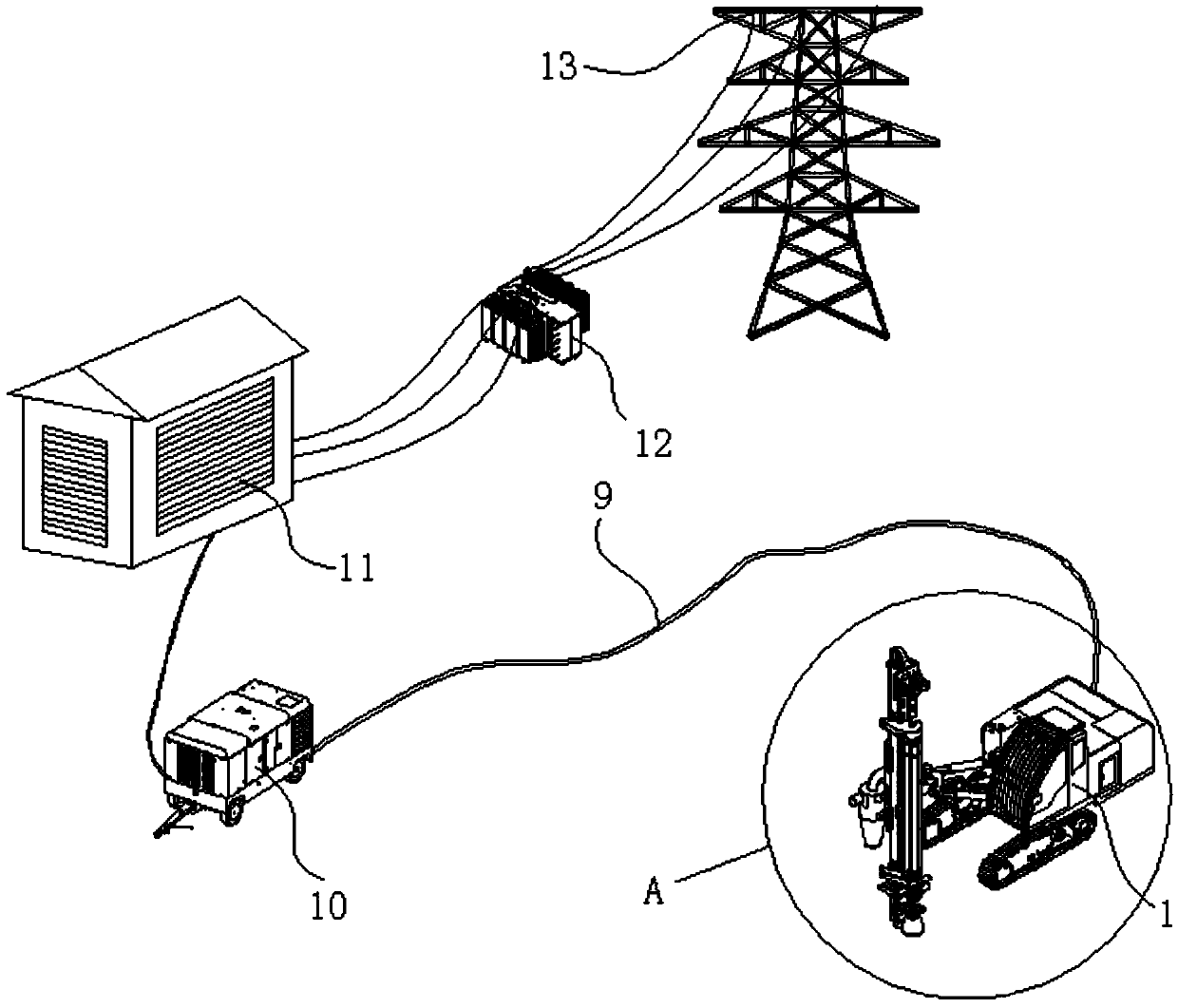

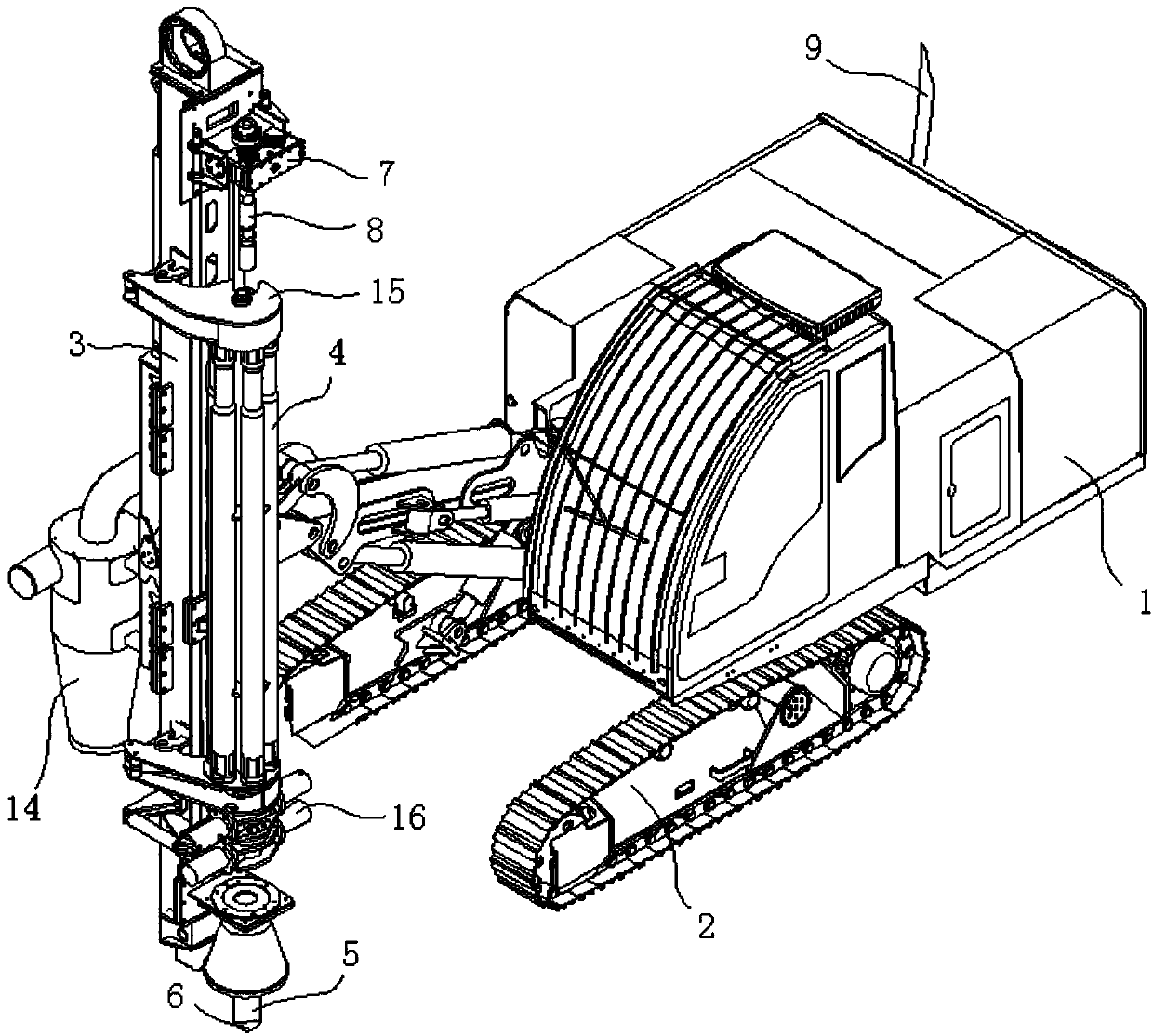

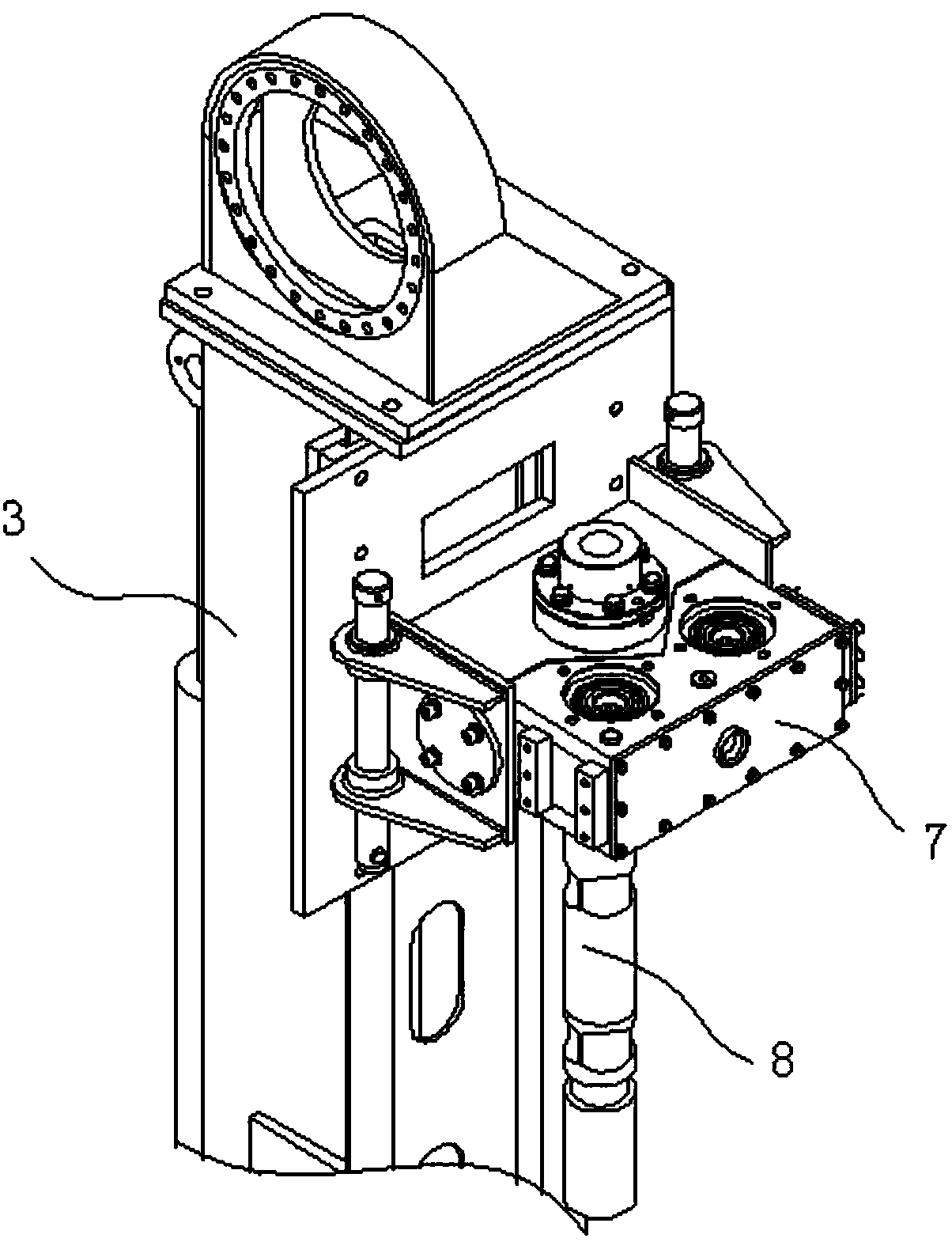

Down-the-hole drill

InactiveCN107620567ASolve the problem of not being able to drill into large-diameter blastholesAddress shockDerricks/mastsBorehole drivesAirflowDrill pipe

The invention discloses a down-the-hole drill comprising a drill body. Traveling mechanisms are arranged at the bottom of the drill body; a drilling frame is arranged on the drill body; hollow drilling rods are arranged on the drilling frame; the lower ends of the hollow drilling rods are connected with a down-the-hole impacter; the lower end of the down-the-hole impacter is connected with a drilling bit; a ventilation hole is formed in the drilling bit; the upper ends of the hollow drilling rods are connected with a power head; damping joints are arranged between the hollow drilling rods andthe power head; a high-pressure air pipe is connected to the power head; and an air compressor is connected to the high-pressure air pipe. High-pressure air flow inputting equipment is innovatively introduced on the power head, and meanwhile the damping joints are arranged between the hollow drilling rods and the power head, so that the problem of impact of high-strength reverse vibration force tothe power head during drilling of a large-hole-diameter blast cavity is effectively solved, the defect that a traditional down-the-hole drill cannot drill the large-hole-diameter blast cavity is overcome, and smooth conducting of mine development work is guaranteed.

Owner:CHANGSHA HEIJINGANG IND CO LTD

Suspension packer with two-way setting seal and its preparation method and wellbore circumferential isolation method

ActiveCN103184850BEnsure safe operationAchieve ruptureSealing/packingHydraulic cylinderPressure transmission

The invention discloses a bidirectional seat seal hook-wall packer, a preparation method thereof and a shaft circumferential packing method. The packer comprises a central tube. The two ends of the central tube are respectively connected with a first joint and a second joint. A first stop collar, a first piston, a first slip, a first cone, a first rubber tube compression ring, a rubber tube, a second rubber tube compression ring, a second cone, a second slip, a second piston and a second stop collar are sequentially sheathed on the central tube from the first joint. A first hydraulic cylinder which is connected with the first joint is sheathed on the external side of the first piston. A first locking slip which is used for preventing the first piston from moving towards the first joint is fixedly arranged on the central tube. A supporting ring is arranged between the central tube and the rubber tube. A second hydraulic cylinder which is connected with the second joint is sheathed on the external side of the second piston. A second locking slip which is used for preventing the second piston from moving towards the second joint is fixedly arranged on the central tube. A first pressure transmission hole and a second pressure transmission hole which respectively correspond to the first piston and the second piston are arranged on the central tube. The packer disclosed by the invention can be reliably anchored.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Method and device for manufacturing bendable paper hookah pipe

PendingCN114714672ARapid Automated ManufacturingAccelerate drying and hardeningPaper/cardboard articlesTobacco pipesHookah pipeStructural engineering

The invention provides a method and a device for manufacturing a bendable paper hookah tube, the device is provided with a roller and a central support shaft, the roller comprises at least one rolling wheel, the outer surface of the rolling wheel is provided with a plurality of protruding annular embossments, and the central support shaft is provided with a plurality of annular embossments which can be matched with the annular embossments. The center supporting shaft penetrates into the center of the paper spiral pipe located at the operation position, so that the pipe wall of the paper spiral pipe is located between the center supporting shaft and the rolling wheel, and the rolling device and the center supporting shaft can move to one or more preset positions in the direction parallel to the axis of the paper spiral pipe. The pipe wall of a paper spiral pipe is rolled to form a bellow pipe structure through cooperative operation of a rolling wheel and a center supporting shaft, then the paper spiral pipe which is rolled to form the bellow pipe structure is extruded in the axis direction of the paper spiral pipe, and then the bendable paper hookah pipe is formed.

Owner:许喻婷

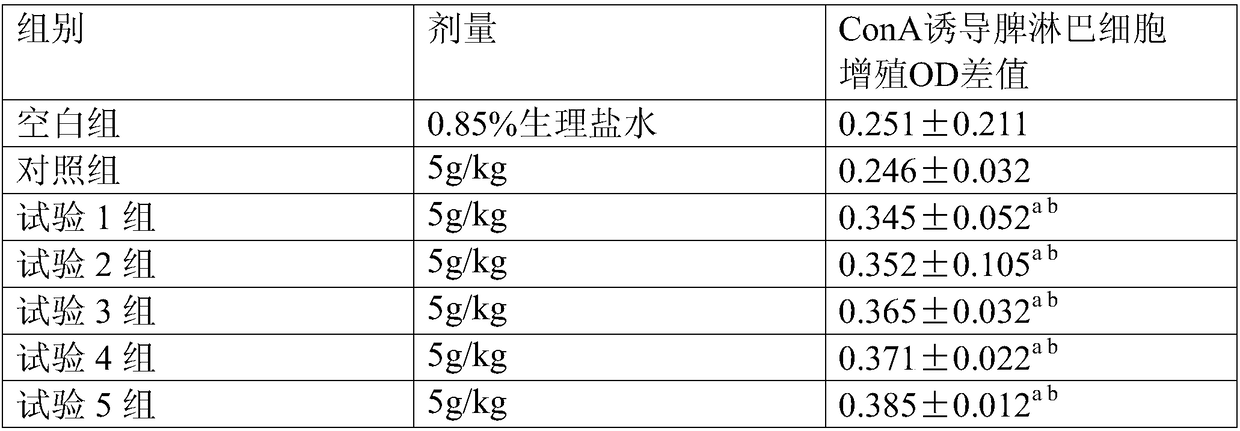

Thymic extract freeze-dried food capable of improving immunity of old people

InactiveCN108125139AEnhance the immune function of the bodyEnhance physical fitnessFood freezingFood ingredient functionsThymus extractOlder people

The invention relates to a thymic extract freeze-dried food capable of improving the immunity of old people. The thymic extract freeze-dried food is composed of 20-100 parts by weight of beta-glucan,20-100 parts by weight of starch dextrin and 2.1 to 3.5 parts by weight of thymus extract with the molecular weight of 3000 and 50000 daltons. Through use of a certain amount of calf thymus extract with the molecular weight of 3000 and 50000 daltons, the freeze-dried food with a health care function is obtained. The thymic extract freeze-dried food can significantly improve the immunity of old people and enhance the physique of old people.

Owner:长春三真实业有限公司

Line protection device

ActiveCN113161196AAchieve disconnectionAchieve ruptureHeating/cooling contact switchesThermal switch detailsRotational axisEngineering

Owner:XIEXUN ELECTRONICS JI AN

A low-to-medium-speed magnetic levitation ice-breaking and snow-melting cleaning robot

An ice-breaking and snow-melting cleaning robot for a medium and low speed maglev, comprising a rack (11), folding bending mechanisms, an ice-melting and cleaning mechanism, and an autonomous cruise module (7). The rack (11) spans between two F rails of a low and medium speed maglev to be detected. There are two groups of folding bending mechanisms, which are disposed at two ends of the rack (11) respectively and are located above the F rails. Each group of folding bending mechanisms is provided with a walking wheel pair (5) and a detent wheel pair (2). The snow-melting and cleaning mechanism comprises a fixing frame (15), an F rail obstacle-removal and cleaning unit (14), and an ice-melting heating unit (16). The fixing frame (15) is mounted on the rack (11), located above the folding bending mechanisms, and deployed along the extension direction of the F rails. The F rail obstacle-removal and cleaning unit (14) and the ice-melting heating unit (16) are disposed at two ends of the fixing frame (15) respectively. The autonomous cruise module (7) is mounted below the rack (11). The cleaning robot can melt and clean ice and snow on the F rails, and is simple in structure and convenient to operate.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

A content combined sealed package

The invention relates to a combined sealing package for contents. The combined sealing package for the contents comprises a surface bag body in which at least two inner bag bodies are arranged, wherein the inner bag bodies are arranged at intervals in the length direction of the surface bag body; a cut bag body is arranged between adjacent inner bag bodies; the surface bag body, the inner bag bodies and the cut bag body are thermally pressed to form an integrated sealing structure; pulling ropes are arranged in first propping connecting areas between the adjacent inner bag bodies and the cut bag body, and each pulling rope extends from one end of each first propping connecting area to the other end and enters the other end of the cut bag body and then passes out through one end of the cutbag body. According to the combined sealing package for the contents, the pulling ropes arranged in the first propping areas between the adjacent inner bag bodies and the cut bag body are pulled to break the bottom parts of the inner bag bodies, and then the contents in the upper inner bag body can be mixed with the contents in the lower inner bag body through the cut bag body, and thus the contents in the inner bag bodies can be mixed on the premise that the sealing performance of the outer bag body is ensured.

Owner:傅强

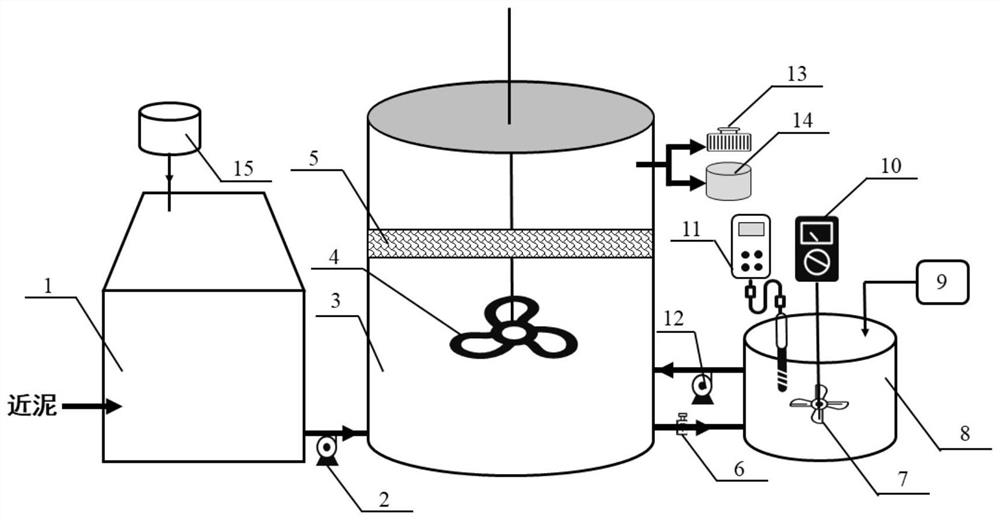

High-efficiency and low-consumption device for improving hydrolytic acidification effect of excess sludge and operation method thereof

ActiveCN114291990AEvenly distributedImproved resistance to shock loadsSludge treatment by de-watering/drying/thickeningWaste based fuelSludgeOrganic matter

The invention discloses a high-efficiency low-consumption device for improving the hydrolytic acidification effect of excess sludge and an operation method thereof.The device comprises a sludge adjusting pool, a sludge hydrolytic acidification tank and an outer circulation weak base rapid stirring tank and is further provided with a sludge inlet pump, a one-way timing valve, an alkali dosing tank, a rapid stirrer, a pH meter and an outer circulation pump; a baffle plate is arranged at the middle upper part of the sludge hydrolytic acidification tank, a soft biological carrier is arranged on the plate surface, a mechanical stirring paddle is arranged at the middle lower part of the sludge hydrolytic acidification tank, and the external circulation weak base rapid stirring tank is provided with a sludge inlet pipe and a sludge return pipe, and is also provided with an alkali dosing pipe and a rapid stirrer. Compared with the prior art, the volume of the hydrolytic acidification tank is small, the hydrolytic acidification efficiency of organic matters in the sludge is high, and stable, economical and efficient operation effects are achieved under the conditions of low energy consumption and low drug consumption.

Owner:NANJING UNIV

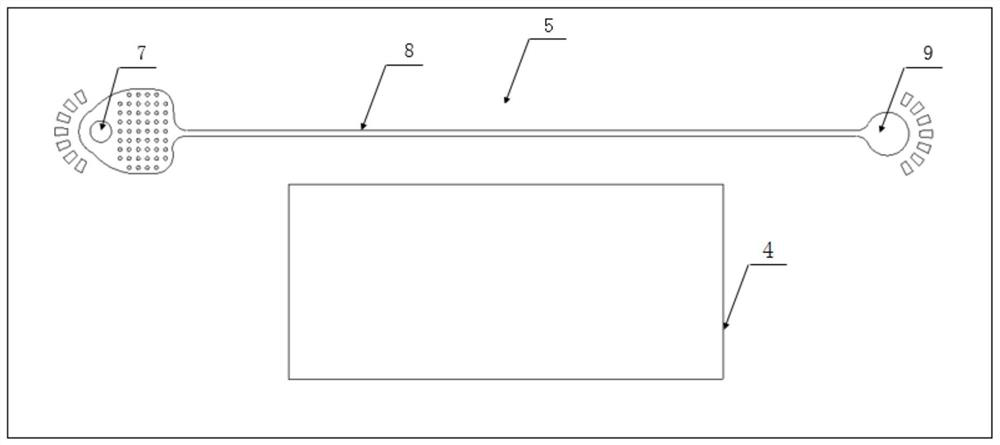

A telescopic support type multi-eye wireless pipeline detection robot

The invention relates to a telescopic support type multi-eye wireless pipeline detection robot. The telescopic support type multi-eye wireless pipeline detection robot comprises a bearing machine body, walking mechanisms, telescopic drive mechanisms, pipeline detection sets and a control system. The bearing machine body is of a cavity structure with the rectangular cross section. The totally fourwalking mechanisms are arranged, evenly distributed around the axis of the bearing machine body and are connected with the side surfaces of the bearing machine body through the telescopic drive mechanisms. At least four pipeline detection sets are arranged and evenly distributed on the upper end face and the lower end face of the bearing machine body around the axis of the bearing machine body. The control system is embedded in the bearing machine body and electrically connected with the walking mechanisms, the telescopic drive mechanisms and the pipeline detection sets. According to the telescopic support type multi-eye wireless pipeline detection robot, on one hand, the requirement for automatic detection work on the interiors of pipelines with the circular cross sections and the regularpolygons can be effectively met, detection data are comprehensive, and the data communication capability is high; and on the other hand, during detection running operation, the situation of pipelineinner wall scratching due to the too high contact face pressure is effectively prevented, and the detection work reliability is greatly improved.

Owner:HENAN POLYTECHNIC UNIV

A compound method and device for multi-layer metal coupling deformation rolling

ActiveCN106001110BProtectAvoid burnsTemperature control deviceAuxillary arrangementsCombined methodHigh pressure water

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cloth coloring agent uniform adding device

InactiveCN112458673AAvoid wrinklesRealize drying processTextile treatment containersLiquid/gas/vapor removalMechanical engineeringColoring agents

The invention discloses a cloth coloring agent uniform adding device. The uniform adding device comprises a machine body; a dyeing cavity is formed in the machine body; a dyeing agent diluent is stored in the dyeing cavity; a drying cavity extending backwards is formed in the front end face of the machine body in a communicating mode; the drying cavity is located on the upper side of the dyeing cavity; the rear side of the drying cavity is provided with a guide cavity extending downwards in a communicating mode; and an inclined cloth conveying channel is arranged between the rear wall face ofthe dyeing cavity and the front wall face of the guide cavity in a communicating mode. According to the invention, drum-type stretching and conveying are performed on cloth, so that the cloth is effectively prevented from being wrinkled in the dyeing process; a high-concentration coloring agent can be continuously added into the dyeing cavity while the cloth is dyed by the device, so that the concentration of the coloring agent in the dyeing cavity can be supplemented in time, and drying treatment of the cloth is achieved; and meanwhile, the device is provided with a high-pressure unloading apparatus, so that high-pressure unloading can be achieved in time, and the situation that the inner wall of the device is broken due to too large pressure is prevented.

Owner:天津亿华网络科技有限公司

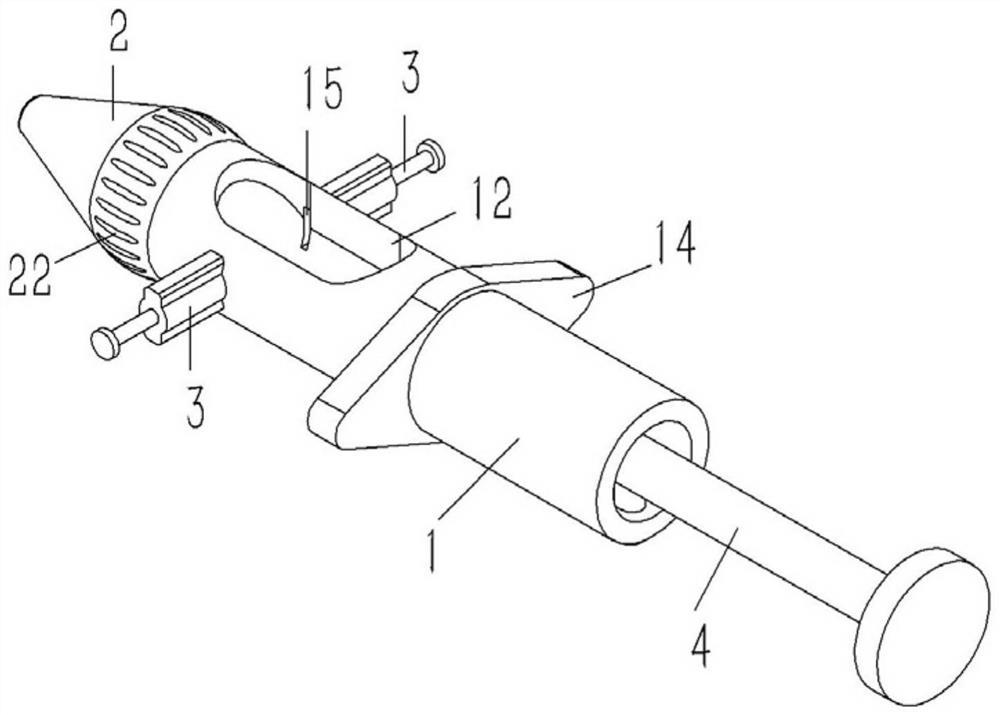

Push type drop output device

InactiveCN111743776AAchieve ruptureAchieve outputOral administration deviceWaste materialIndustrial engineering

The invention discloses a push type drop output device which comprises a tubular loading cylinder; an outer threaded sleeve is formed on the front end face of the loading cylinder, a conical cap sleeve is connected to the outer threaded sleeve in a threaded mode, and an output hole is formed in the front end of the cap sleeve. A feeding groove penetrating through the inner wall of the loading cylinder is formed in the outer wall of the upper side, close to the front end, of the loading cylinder; a waste discharging groove is formed in the outer wall of the lower side, at the front end of the feeding groove, of the loading cylinder; two opposite cutting grooves are formed in the loading cylinder on the two sides of the waste discharging groove, and cutting mechanisms opposite to the cuttinggrooves are fixed to the two side walls of the loading cylinder; conical flanges are formed on the two side walls of the loading cylinder on the rear side of the feeding groove, a conical extrusion head is inserted into the loading cylinder on the rear side of the feeding groove, a push rod is formed on the rear end face of the extrusion head, and the rear end of the push rod extends out of the loading cylinder to form a push block.

Owner:龚家良

A kind of surface acoustic wave-based miniature bacterial lysis reactor and bacterial lysis method

ActiveCN109868218BAvoid cross infectionReduce consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsSurface acoustic waveReaction zone

Owner:XI AN JIAOTONG UNIV

Method for removing sprayed plastic layer on surface of magnesium alloy

ActiveCN112405358AAchieve ruptureAchieve clearingDomestic cooling apparatusLighting and heating apparatusSand blastingHeat conservation

The invention provides a method for removing a sprayed plastic layer on the surface of a magnesium alloy. The method comprises the steps that primary sand blasting treatment is conducted on a magnesium alloy casting with the sprayed plastic layer; heat preservation treatment and cooling treatment are sequentially conducted on the magnesium alloy casting; dual sand blasting treatment is conducted on the magnesium alloy casting; and the device adopted for achieving the removing method is a magnesium alloy recycling and processing system and comprises a sand blasting device and a circulating system used for driving the magnesium alloy casting to be conveyed in sequence. Due to the adoption of the scheme, the sprayed plastic layer of the magnesium alloy casting can be broken and removed on thepremise that a base body of the magnesium alloy casting is not damaged, sprayed plastic layers on the surfaces of most magnesium alloy castings can be effectively removed, all working procedures areclosely connected, the production cost is low, and the method is suitable for large-scale industrial production.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND +1

Anti-overflow pot cover assembly for cooking device and cooking device

ActiveCN114052490APrevent spillsSimple structureBoiling over preventionCooking-vessel lids/coversEngineeringMechanical engineering

The invention discloses an anti-overflow pot cover assembly for a cooking device, the assembly comprises a cover body and a steam valve, the steam valve is provided with a steam inlet, a steam discharge outlet and a steam channel, the steam valve comprises a flow guide part, the flow guide part is provided with a steam inlet end, and the steam inlet is formed in the steam inlet end; the anti-overflow pot cover assembly further comprises an anti-overflow bubble breaking piece, the anti-overflow bubble breaking piece is arranged at the steam inlet end and comprises a first anti-overflow bubble breaking part, the first anti-overflow bubble breaking part is located below the steam inlet, and the outer diameter of at least partial area of the first anti-overflow bubble breaking part is larger than that of the steam inlet end such that a first steam corner is formed on the outer edge of the first anti-overflow bubble breaking part. The invention further discloses a cooking device which comprises a pot body and a pot cover used for opening or closing the pot body, and the pot cover is the anti-overflow pot cover assembly. The cooking device has a good anti-overflow and bubble-breaking function, and the anti-overflow and bubble-breaking piece is simple in structure, small in overall size and low in cost.

Owner:JOYOUNG CO LTD

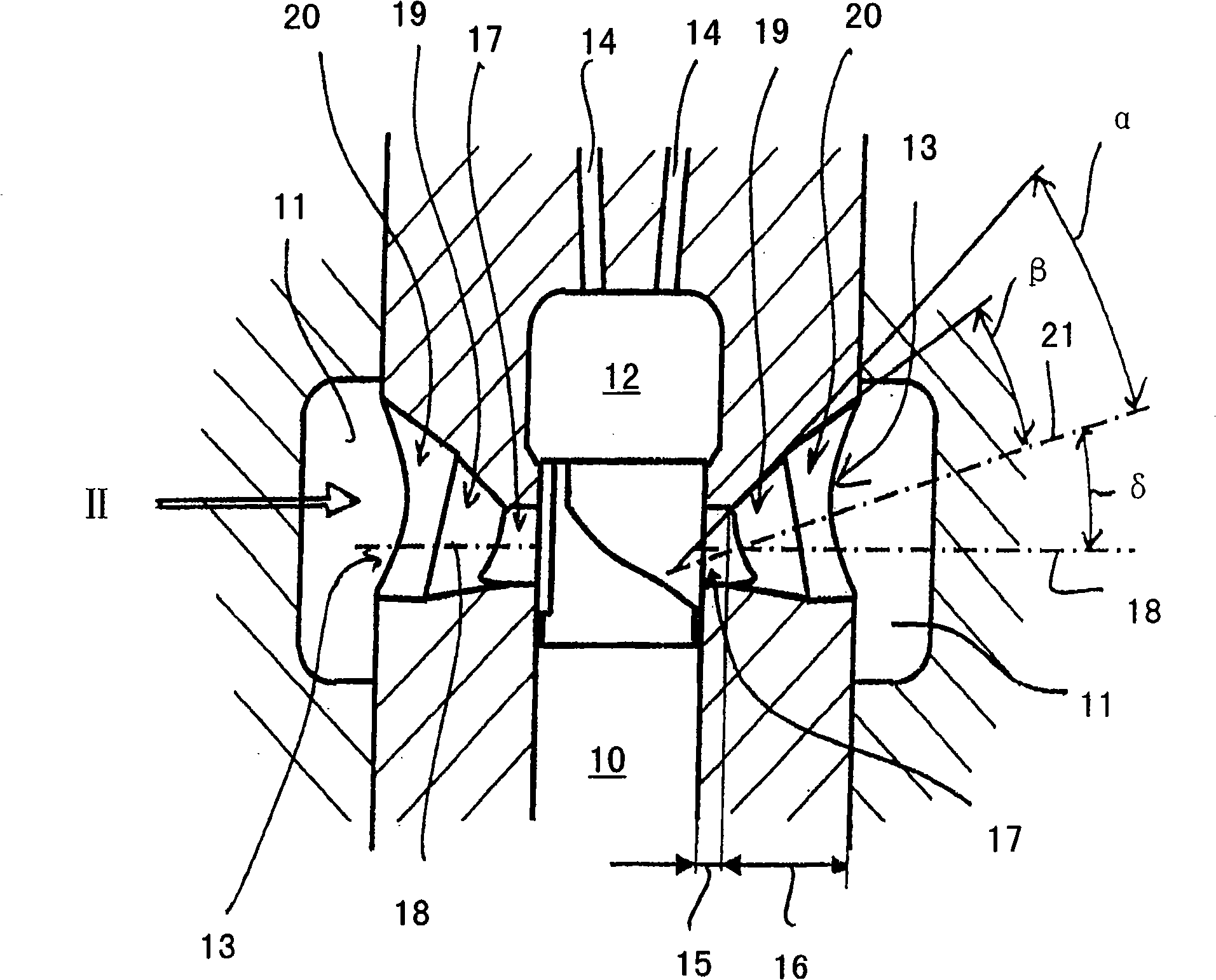

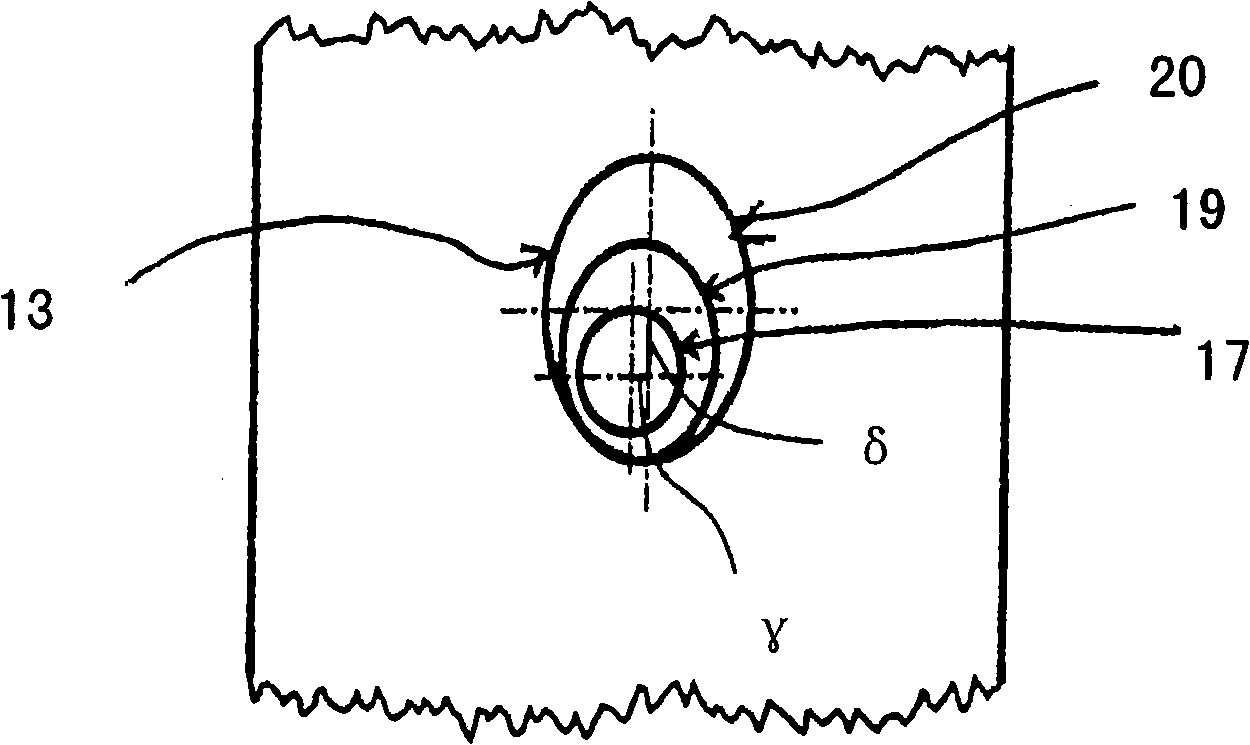

Injection pump for internal-combustion engine and internal-combustion engine

ActiveCN101135284BReduce wearExtended service lifeMachines/enginesFuel injecting pumpsEngineeringInternal combustion engine

The present invention relates to an injection pump for internal combustion engine which has at least one piston (10), wherein, a pump chamber (11) and a high pressure chamber (12) connected via two suction holes (13) work together with the piston or each piston (10) in order to make the piston or each piston (10) close the suction hole or each suction hole (13) at a first position and to restrain the fuel flow from the pump chamber (11) to the high pressure chamber (12), and the piston or each piston (10) will release the suction hole or each suction hole (13) at a second position in order to fill the high pressure chamber (12) with fuel from the pump chamber (11). The suction hole or each suction hole (13) has a cylinder type section (17) adjacent to the high pressure chamber (12), wherein, the cylinder type section (17) is connected with at least two truncated cone shape sections (19, 20), the axes (21) of which rotates or declines relative to the axes (18) of the cylinder type section (17) in horizontal direction or vertical direction.

Owner:MAN ENERGY SOLUTIONS SA

A process for preparing tofu with a household soybean milk machine

ActiveCN105935085BAchieve ruptureImprove instabilityCheese manufactureFood scienceEngineeringProcess engineering

The invention relates to a process for making tofu with a household soybean milk machine, which at least includes the following stages, the complete wall breaking stage: the first step: the pulping material is kept in the first temperature range for 1 to 10 minutes, and the first temperature is 70 °C to 90 °C; then proceed to the second step: the crushing tool is rotated and pulverized into a slurry at a first rotating speed of 16000 to 35000 rpm; the cooking stage: the heating element heats the above slurry until it is cooked; the stage of making tofu: first The brine step of adding a brine point agent to the slurry; then performing the squatting step; and finally performing the pressing step. Compared with the prior art, the soybean milk for making tofu does not need to be filtered, so that the production rate of the tofu is high, and the nutrients of the tofu are more comprehensive, and the taste of the tofu is delicate.

Owner:JOYOUNG CO LTD

Chemical feeding equipment

InactiveCN112844709AIncrease the effect of flying powderDoubling the amount of flying powderGrain treatmentsDrive motorCaking

The invention discloses chemical feeding equipment. The chemical feeding equipment structurally comprises a support, a vibrating screen drum, a raising crushing device, a feeding frame, a controller and a driving motor. The chemical feeding device has the beneficial effects that under the cooperation of a conical block and a separate feeding ring, powder which is fed downwards is dispersed and flown so as to avoid the situation that the powder flying effect is increased due to the fact that a large amount of powder is fed downwards; through the cooperation of opening and closing plates, synchronous opening and closing are conducted on downward feeding of the powder so as to prevent the situation that after downward feeding is completed, the powder flows back and rises again in cooperation with the vibration effect of a vibrating screen, and the powder flying amount is doubled; under the action of rotary motion of a stroking and pressing piece, caked materials, discharged by the vibrating screen, in the powder are subjected to centralized stroking treatment; in cooperation with a grinding and extruding mechanism, the caked materials are extruded and mixed with one another so as to be broken; and meanwhile, in cooperation with airflow blown downwards, the crushed caked materials are blown downwards, so that the materials are prevented from being raised upwards and attached to the upper part in the grinding and extruding mechanism.

Owner:陈培安

Combined sealing package for contents

The invention relates to a combined sealing package for contents. The combined sealing package for the contents comprises a surface bag body in which at least two inner bag bodies are arranged, wherein the inner bag bodies are arranged at intervals in the length direction of the surface bag body; a cut bag body is arranged between adjacent inner bag bodies; the surface bag body, the inner bag bodies and the cut bag body are thermally pressed to form an integrated sealing structure; pulling ropes are arranged in first propping connecting areas between the adjacent inner bag bodies and the cut bag body, and each pulling rope extends from one end of each first propping connecting area to the other end and enters the other end of the cut bag body and then passes out through one end of the cutbag body. According to the combined sealing package for the contents, the pulling ropes arranged in the first propping areas between the adjacent inner bag bodies and the cut bag body are pulled to break the bottom parts of the inner bag bodies, and then the contents in the upper inner bag body can be mixed with the contents in the lower inner bag body through the cut bag body, and thus the contents in the inner bag bodies can be mixed on the premise that the sealing performance of the outer bag body is ensured.

Owner:傅强

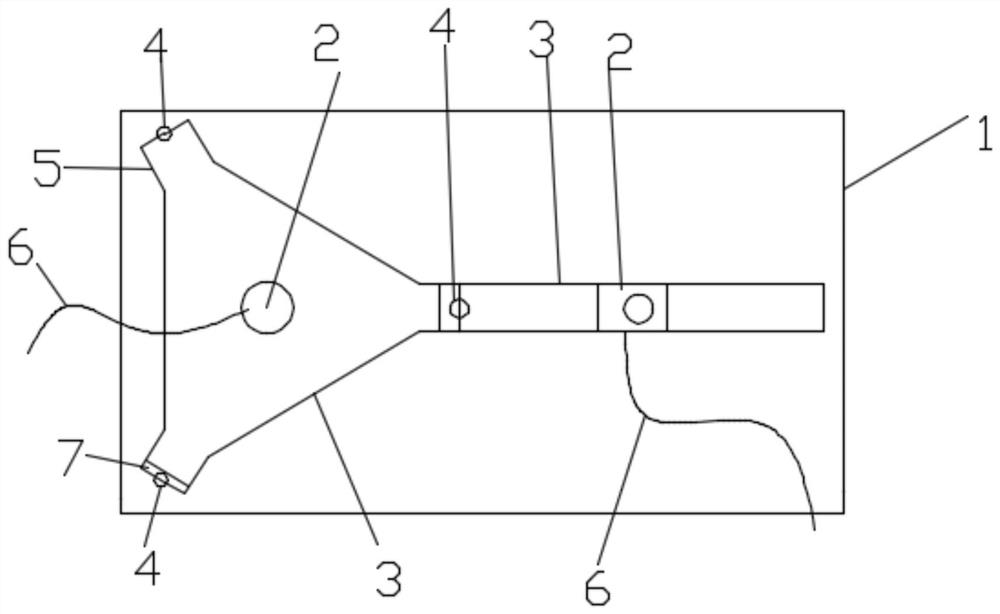

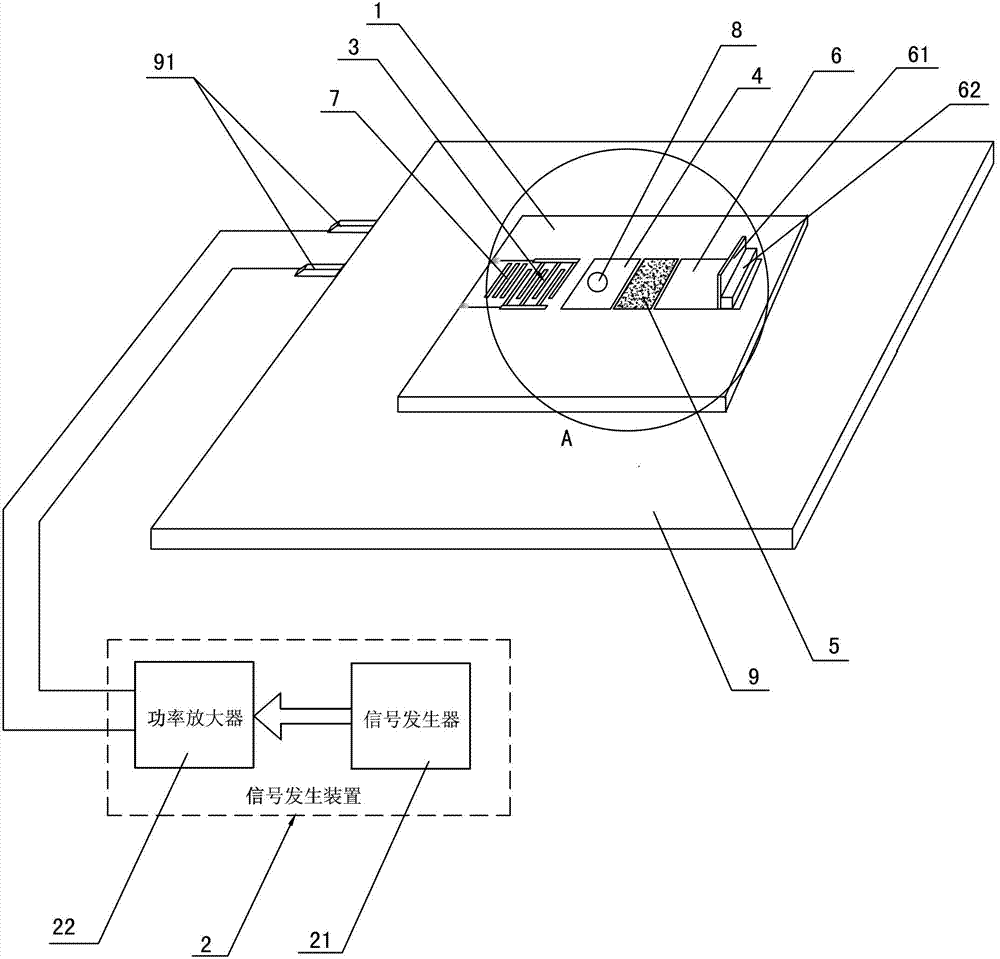

Device and method of achieving digital microfluid cracking of acoustic surface waves

The invention discloses a device and method of achieving digital microfluid cracking of acoustic surface waves. The device comprises a piezoelectric substrate and a signal generating device. An interdigital transducer used for stimulating the acoustic surface waves, a first hydrophobic layer used for placing digital microfluid to be cracked, a sound absorption coating used for attenuating the intensity of the acoustic surface waves simulated by the interdigital transducer and a second hydrophobic layer used for receiving cracked digital microfluid are arranged on the piezoelectric substrate. The first digital microfluid, the sound absorption coating and the second digital microfluid are sequentially located on sound transmission paths of the acoustic surface waves. When the power of an RF electrical signal loaded on the interdigital transducer by the signal generating device is instantaneously reduced, and is greater than or equals to 15dBm, the digital microfluid cracks, and the cracked digital microfluid flies out and drops on the second hydrophobic layer. The device has the advantages that the interdigital transducer which is not weighted is adopted, and therefore cracking of the interdigital transducer can be achieved with low power electrical signal power. In addition, the device is simple in structure and small in size and easy to be integrated.

Owner:NINGBO UNIV

straw silk machine

ActiveCN110583257BHigh silking efficiencyAvoid accumulationCuttersPulp and paper industryConveyor belt

The invention discloses a straw silk machine, which comprises a supporting mechanism and a driving mechanism arranged on the supporting mechanism, a protective mechanism, a feeding mechanism, a chopping mechanism, a kneading mechanism and a discharging mechanism; the protective mechanism forms a feeding port, and the straw moves The channel and the discharge port; the feeding mechanism is located at the feeding port, including the conveyor belt and the saw disc knife roller, after the straw is initially crushed, it is transported to the chopping mechanism; the chopping mechanism and the kneading mechanism are located in the straw movement channel, and the chopping mechanism Including the fixed knife and the hob, under the action of sliding cutting of the fixed knife and the hob, the straw is chopped and sent to the kneading mechanism; the kneading mechanism is used to shred the chopped straw and deliver the straw to the feeding mechanism; After the material mechanism screens the straw silk, it is sent out of the machine through the discharge port. The straw silking machine of the present invention adopts the cooperative operation mode of feeding and dividing, cutting and crushing, and hammering and kneading to realize the silking treatment of straws, has high silking efficiency, avoids material accumulation, has a light and simple structure, and meets the needs of decentralized operations in agricultural production.

Owner:SHENYANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com