Push type drop output device

A technology of output device and drop, which is applied in the field of medical equipment, can solve problems such as unsanitary, inconvenient soaking, and rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

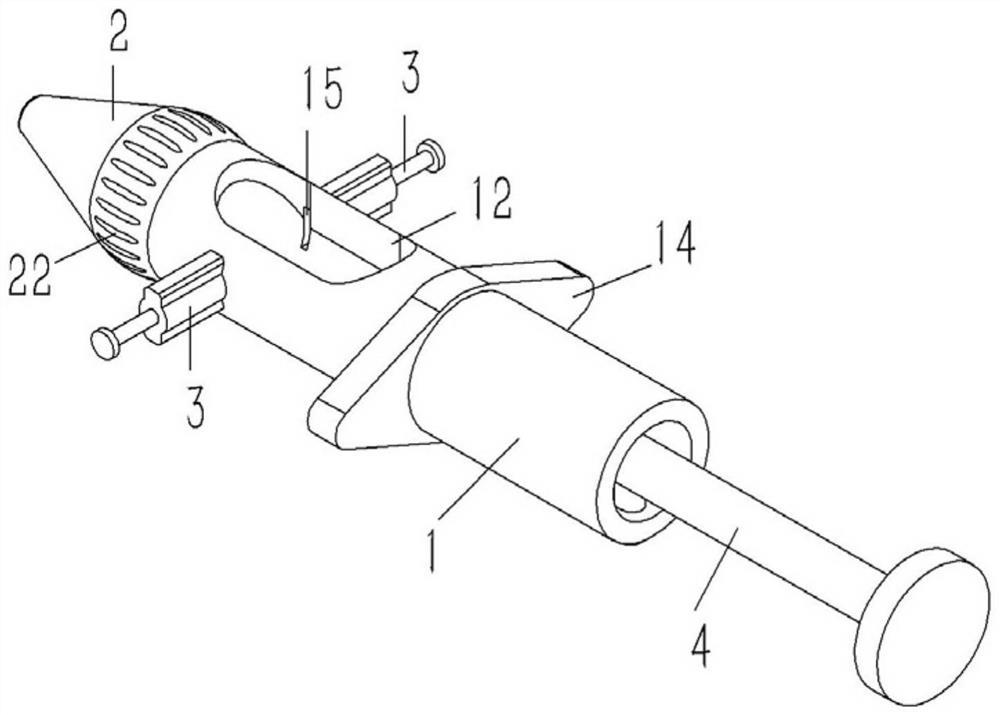

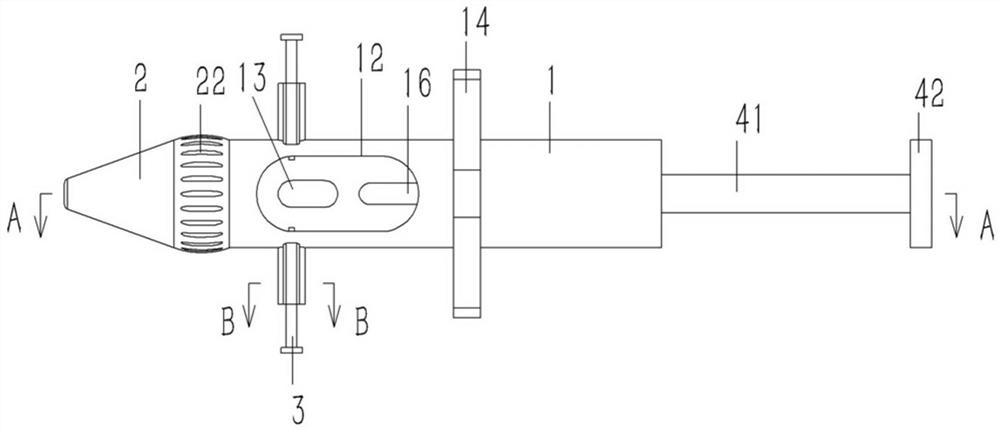

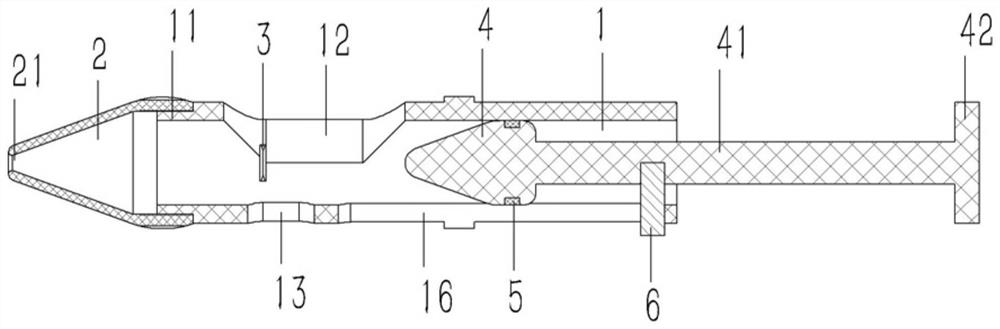

[0022] Example: see Figures 1 to 5 As shown, a push-type drop delivery device includes a tubular loading cylinder 1, an external thread sleeve 11 is formed on the front end surface of the loading cylinder 1, and a conical cap sleeve 2 is screwed on the external thread sleeve 11. The front end of the cap 2 is formed with an output hole 21; the upper outer wall of the loading tube 1 near the front end is formed with a feed groove 12 that runs through the inner wall of the loading tube 1, and the lower outer wall of the loading tube 1 at the front end of the feeding groove 12 A waste material outlet 13 is formed, and two cutting grooves 15 facing each other are formed on the loading cylinder 1 on both sides of the waste material outlet 13, and a cutting mechanism 3 opposite to the cutting groove 15 is fixed on the two side walls of the loading cylinder 1; Conical ribs 14 are formed on the two side walls of the loading cylinder 1 on the rear side of the feeding chute 12, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com