Device and method of achieving digital microfluid cracking of acoustic surface waves

A technology of digital microfluidics and surface acoustic wave, applied to laboratory containers, chemical instruments and methods, laboratory utensils, etc., can solve the problems of high electrical signal power, fragmentation of lithium niobate substrates, and difficulty in popularization and application and other problems, to achieve the effect of simple structure, small size, simple design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

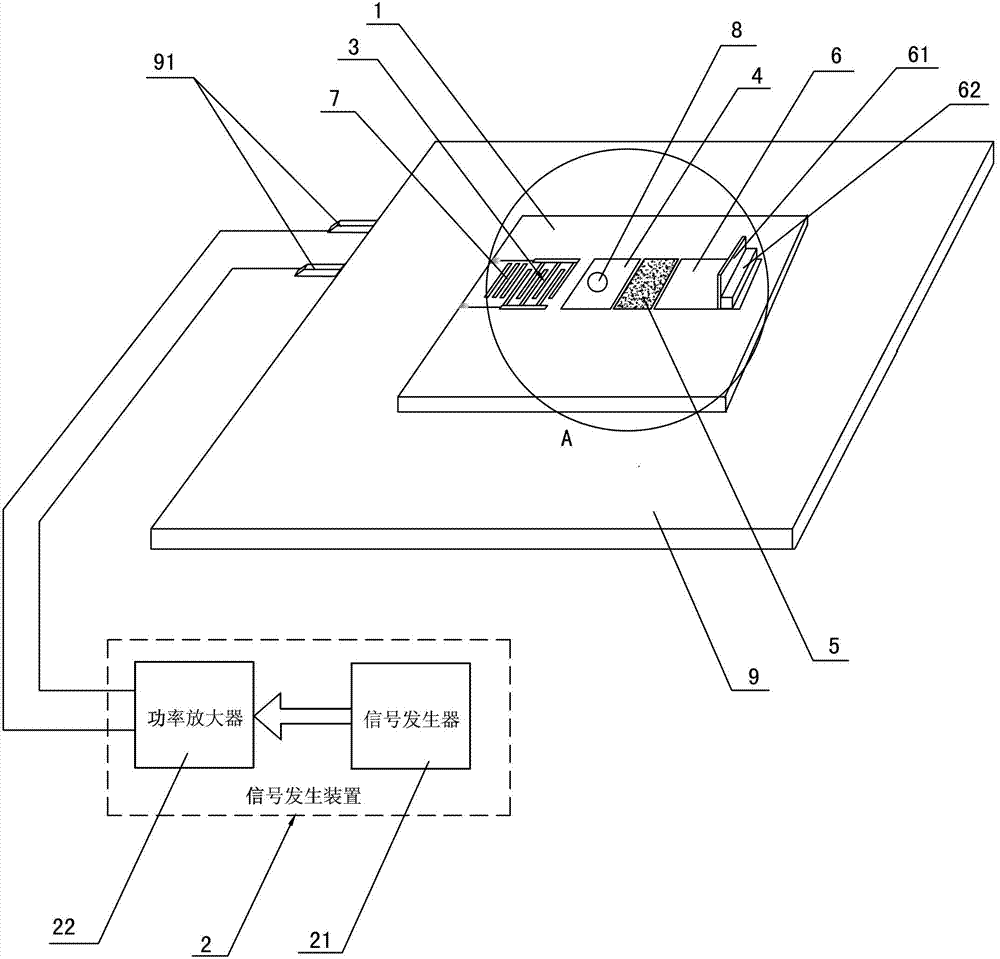

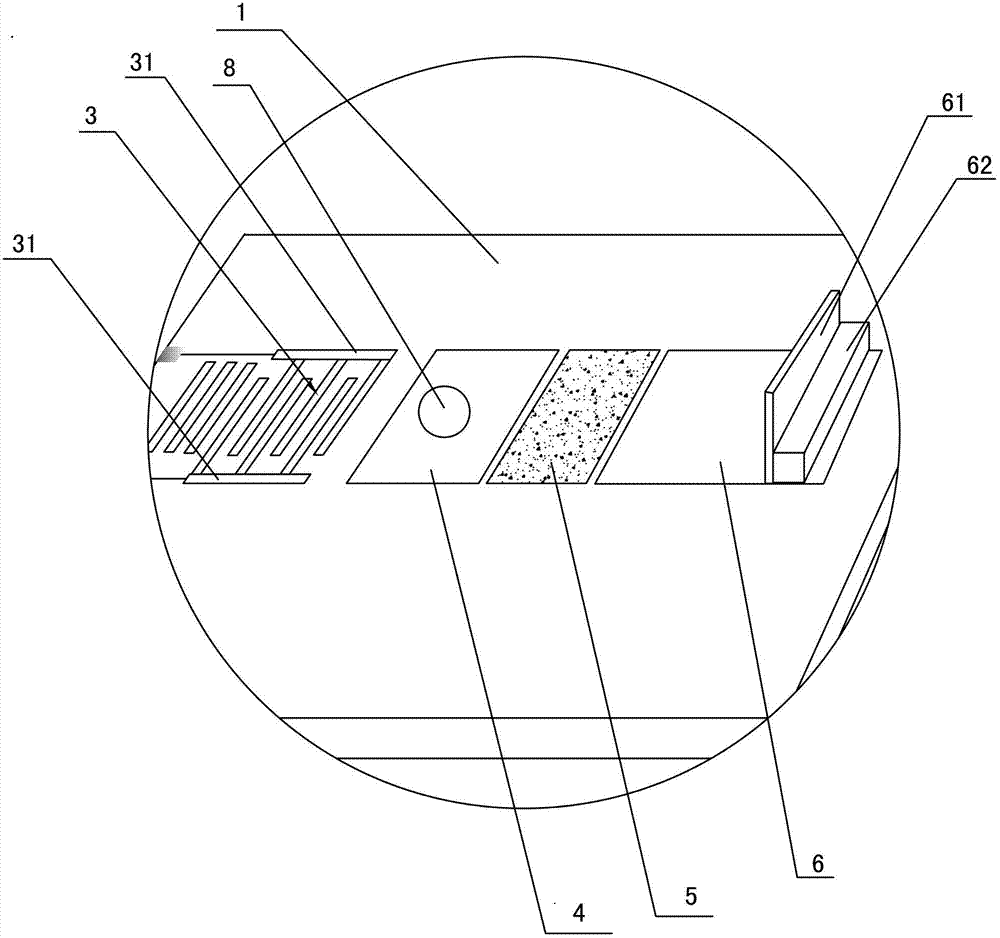

[0031] The present invention proposes a device for digital microfluid rupture by surface acoustic waves, as shown in the figure, which includes a piezoelectric substrate 1 and a signal generating device 2 for generating RF electrical signals, the upper surface of the piezoelectric substrate 1 As the working surface, the working surface of the piezoelectric substrate 1 is provided with an interdigital transducer 3 connected to the signal generating device 2 and used to excite the surface acoustic wave, and a first hydrophobic surface for placing the digital microfluidic 8 to be broken. Layer 4, the sound-absorbing coating 5 for attenuating the intensity of the surface acoustic wave excited by the interdigital transducer 3, the second hydrophobic layer 6 for receiving the ruptured digital microfluidics, and for reducing the load on the signal gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com