Patents

Literature

63results about How to "Achieve melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive for smelting aluminium alloy and preparation method and application method thereof

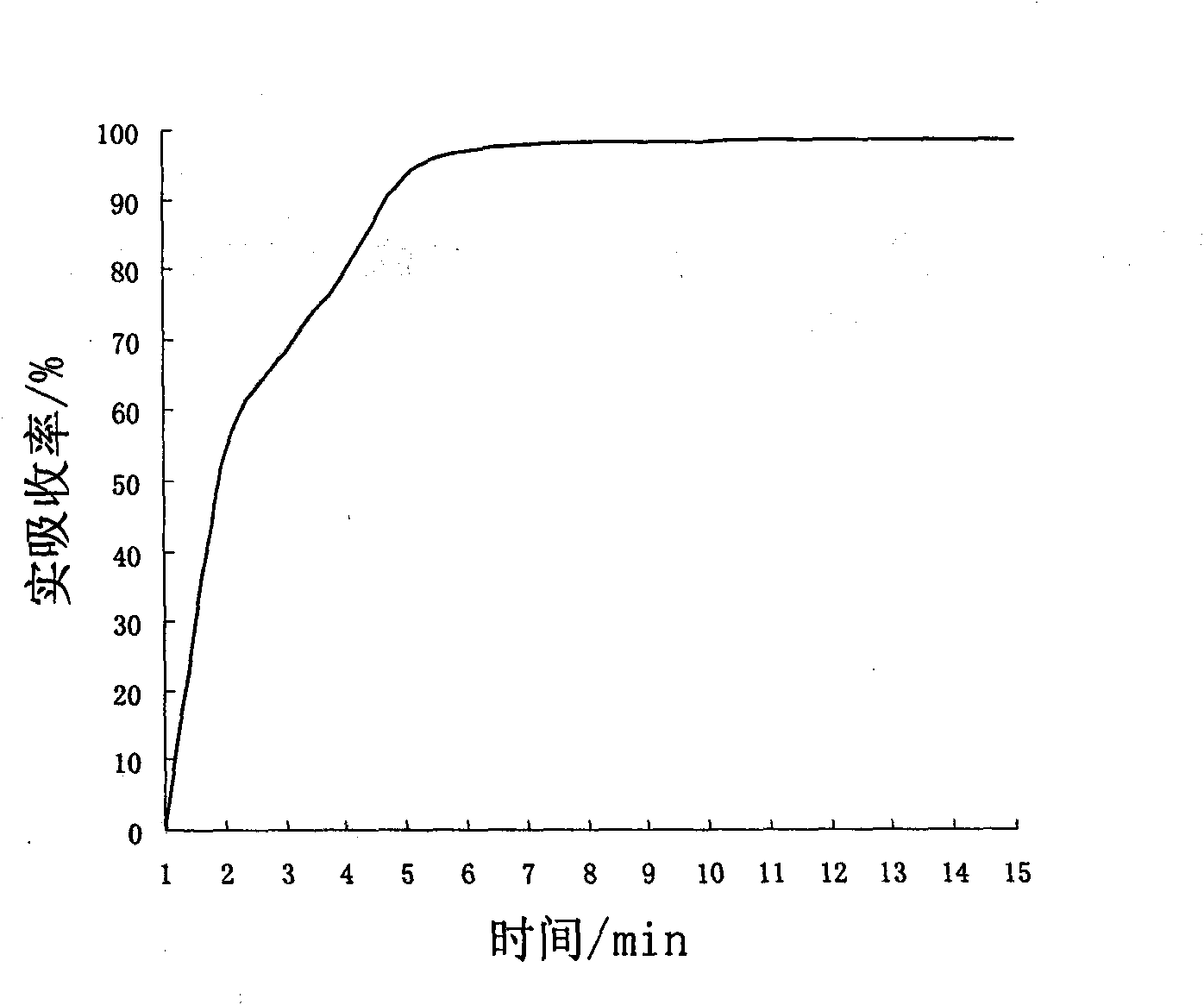

The invention relates to an additive for smelting aluminium alloy and a preparation method and an application method thereof, relating to the technical field of nonferrous alloy manufacturing with a special additive. The additive is composed of metal powder, cosolvent, heat-generating agent, detonating agent and moisture proof agent. The preparation method comprises the following steps: raw materials comprising the following by mass percentage, 70-81.5% of metal powder, 15-20% of cosolvent, 2-5% of heat-generating agent, 1-3% of detonating agent and 0.5-2% of moisture proof agent, are fully mixed evenly into compound powder with a ball mill, and the mixture is put into a mould, and is performed with cold pressing by a hydraulic pressure machine so as to obtain the additive for smelting aluminium alloy. The application method of the invention comprises the following steps: a graphite crucible filled with a pure aluminium pig is arranged in a resistance furnace to be heated until the aluminium pig is melted into aluminium liquid, and then the additive is added to react with the aluminium liquid so as to obtain aluminium alloy. Under the condition that the quality of aluminium alloy is not lowered, the additive solves the problems of high dissolving temperature, low absorptivity and unstable absorptivity of the additive.

Owner:HEBEI UNIV OF TECH

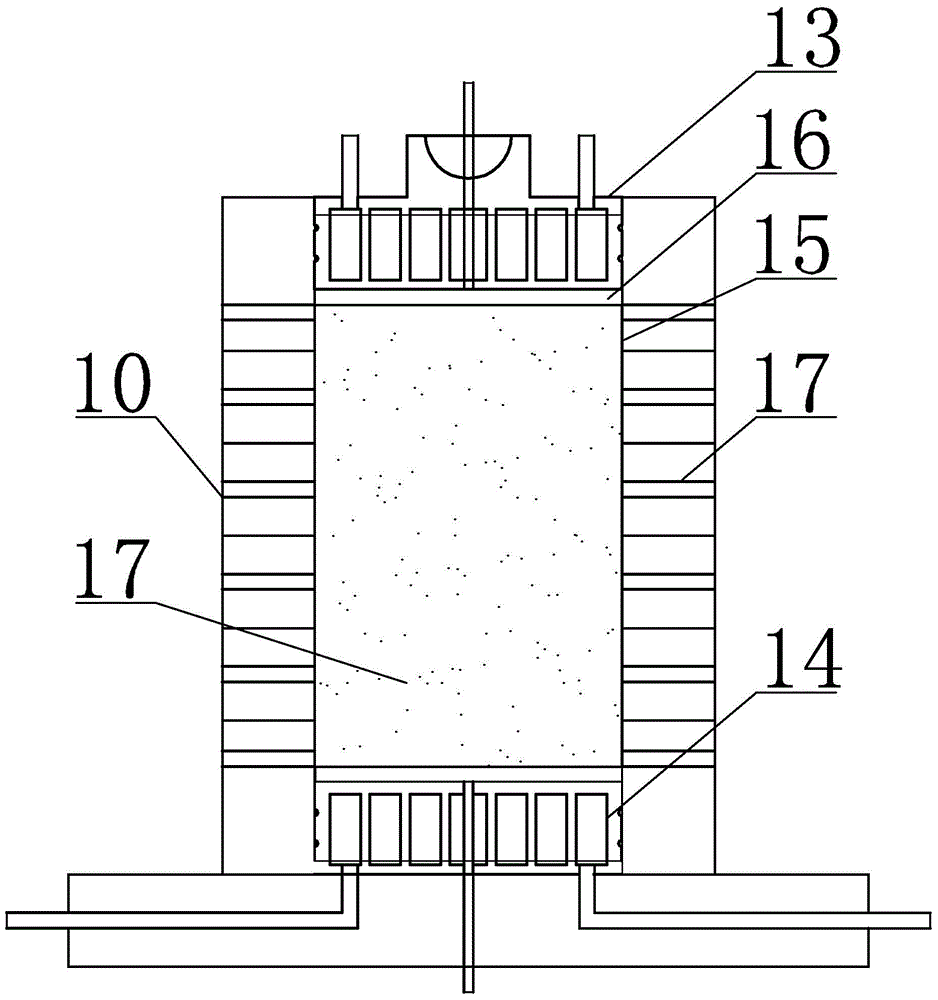

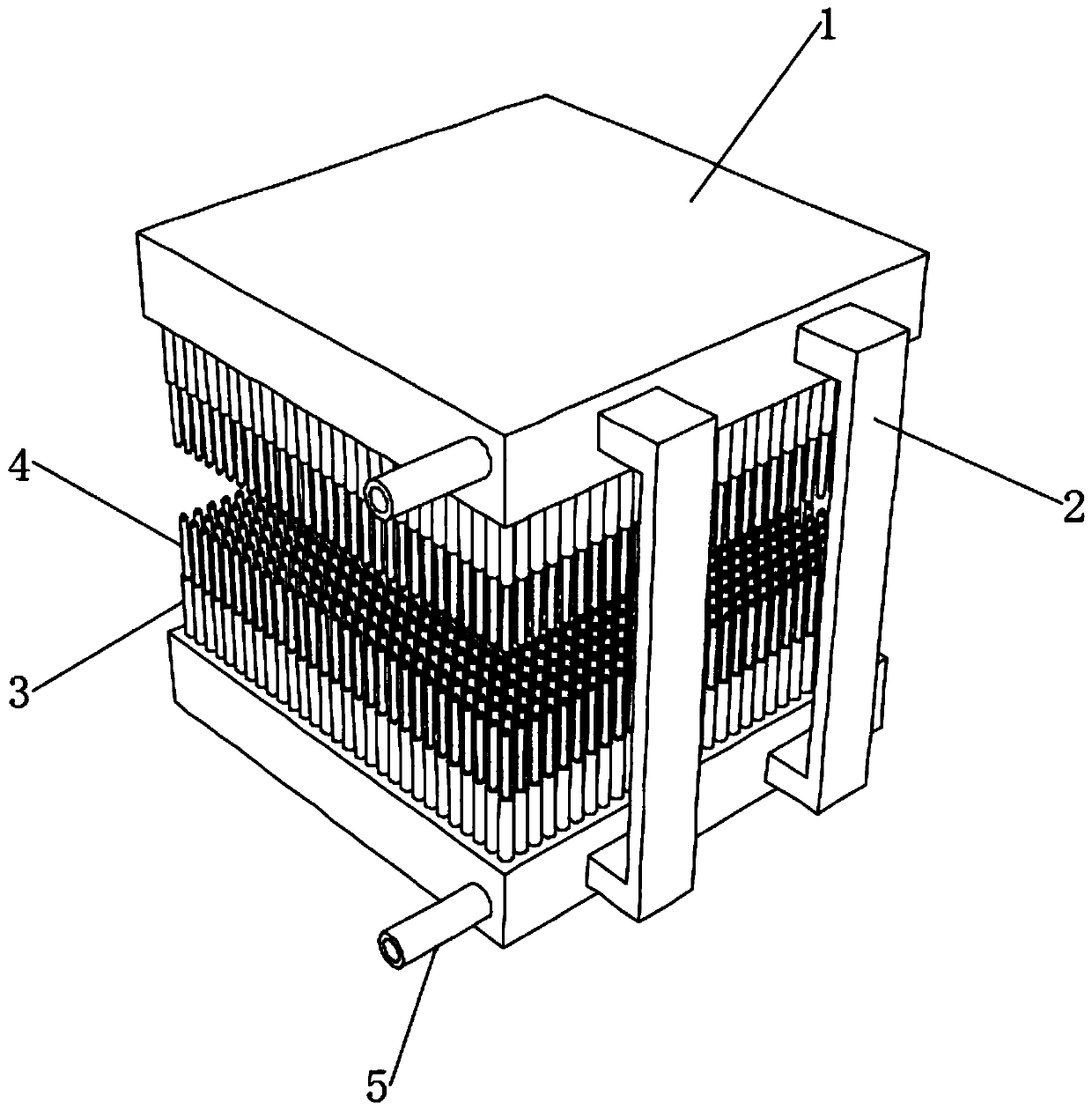

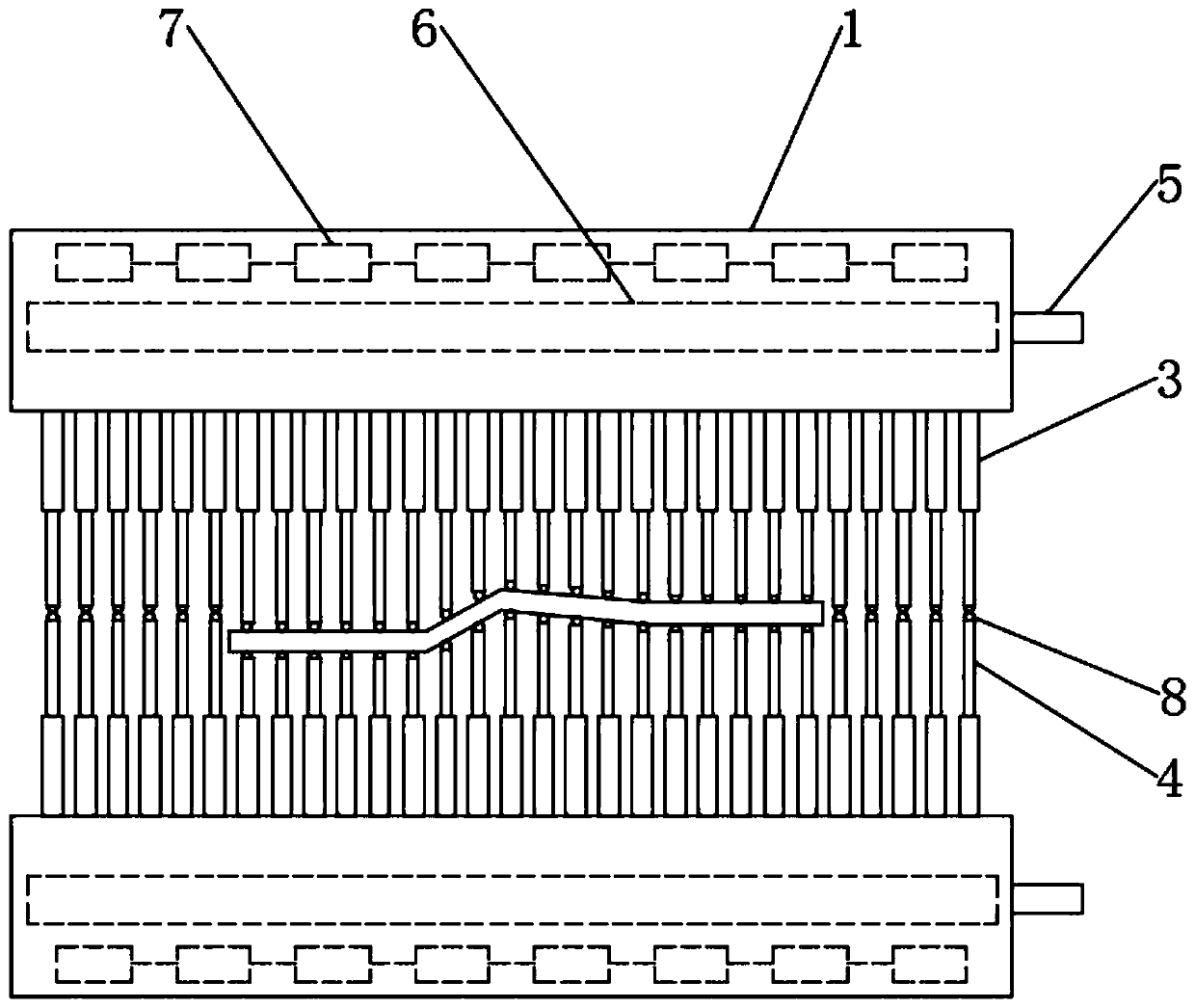

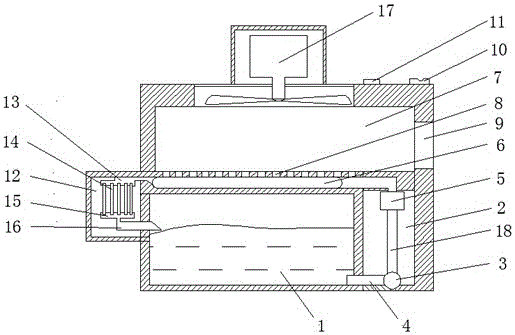

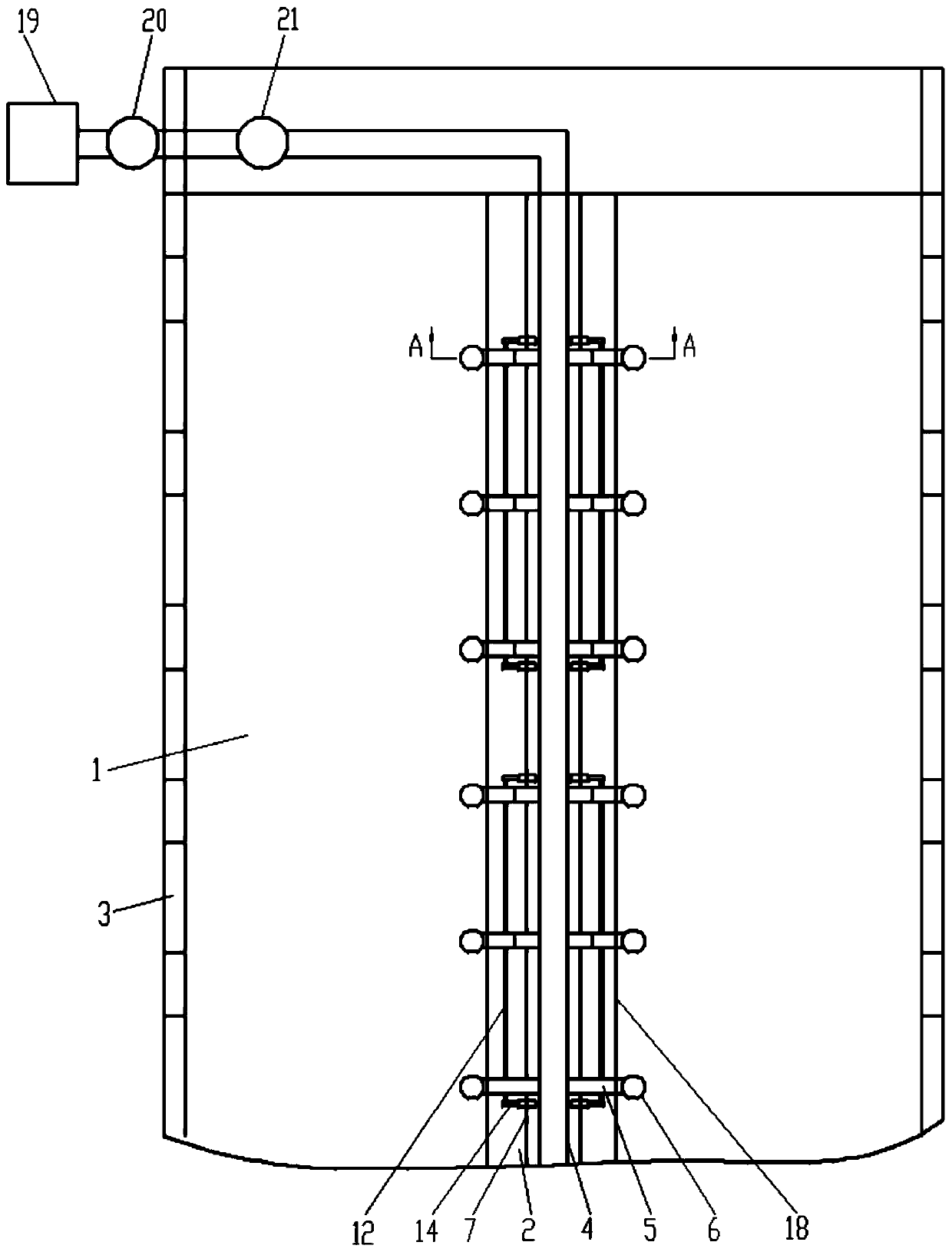

Bilateral frost-heaving test device for porous materials and testing method

ActiveCN104990947ASteady temperature loadAchieve frost heaveMaterial thermal analysisWater storageData acquisition

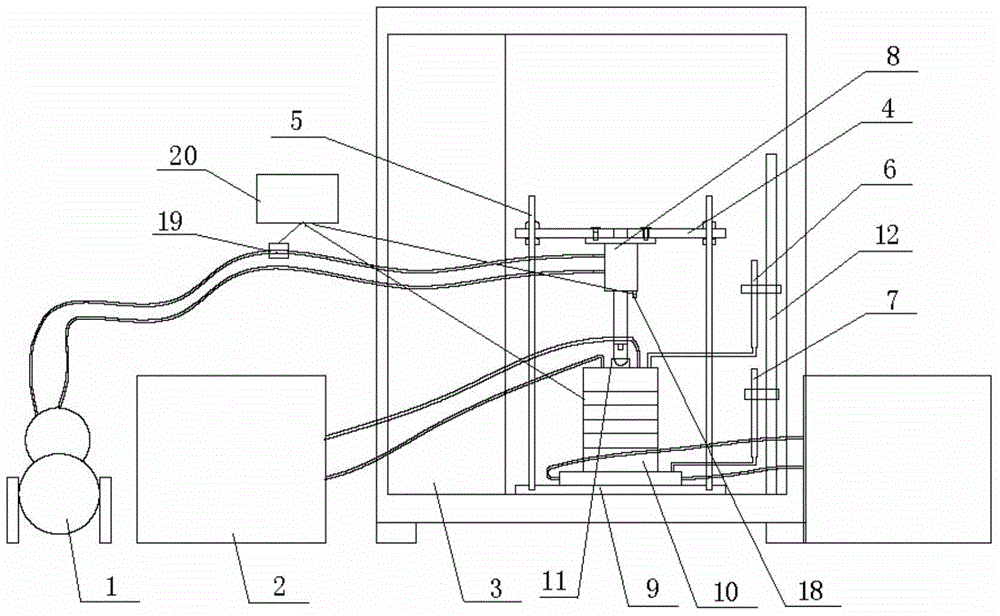

The invention relates to a bilateral frost-heaving test device for porous materials and a testing method. In the prior art, the changes of temperature field, water field, and deformation filed have not been taken into account during the freezing and thawing process of porous materials, thus the frost-heaving resistant performance of porous materials cannot be precisely evaluated, and in order to solve the problem mentioned above, the invention provides the bilateral frost-heaving test device. The test device comprises a pressure machine, a constant-temperature constant-moisture curing box, a reaction frame top tray, a reaction frame support, a first water storage tube, a second water storage tube, a cylinder, a pedestal, a frost-heaving test-piece assembly, a pressure head, a test tube rack, a LVDT displacement sensor, a pressure sensor, a data collector, and two cold-bath circulators. The LVDT displacement sensor is installed on the body of the cylinder and is close to a piston rod. The reaction frame top tray is fixedly arranged on the top end of the reaction frame support. The pedestal is fixedly arranged on the bottom end of the reaction frame support. The frost-heaving test-piece assembly is fixedly arranged on the pedestal. The provided bilateral frost-heaving test device is used to carry out porous material frost-heaving tests.

Owner:HARBIN INST OF TECH

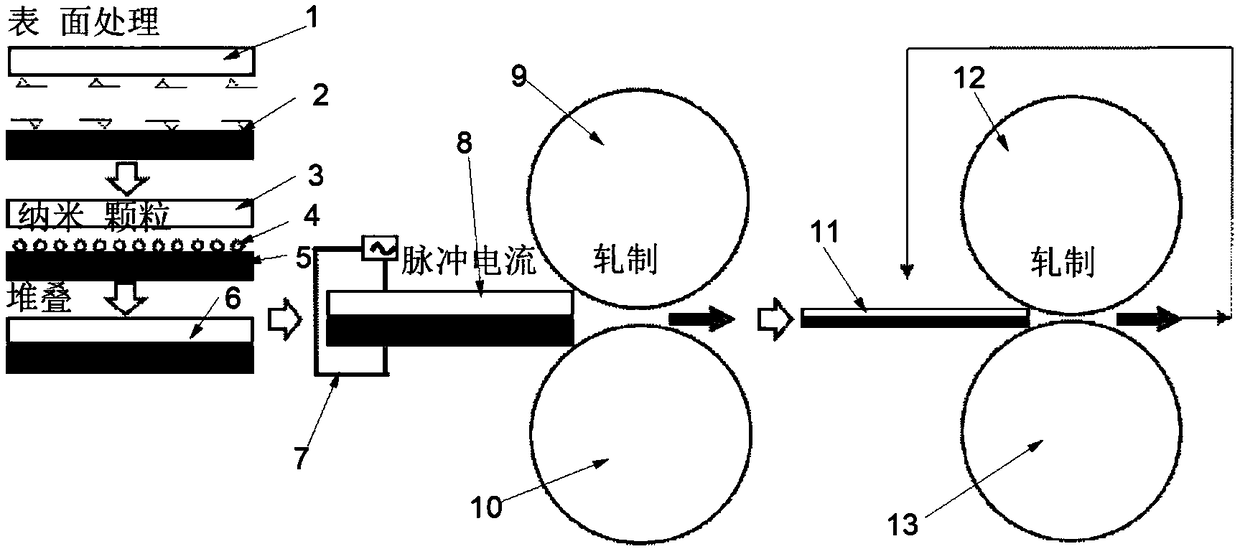

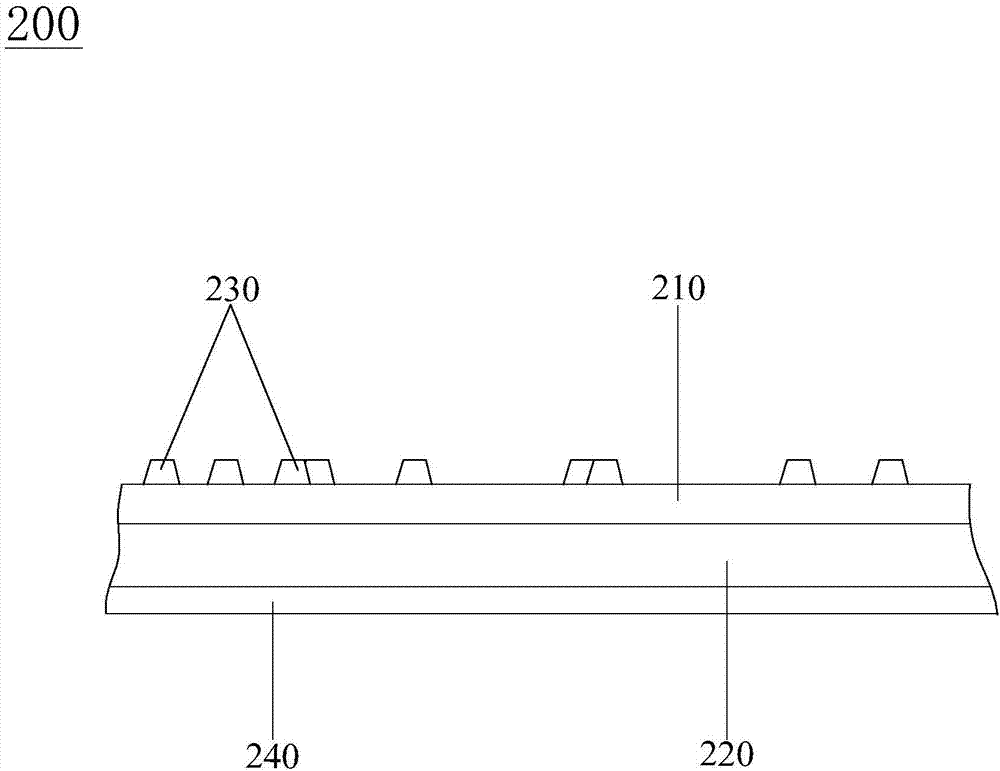

Rolling preparation method for improving interface bonding strength of lamellar aluminum-titanium composite through nano-metal powder

ActiveCN108296288AAchieve meltingAchieve metallurgical bondingMetal rolling arrangementsNoise reductionTitanium alloy

The invention provides a rolling preparation method for improving the interface bonding strength of a lamellar aluminum-titanium composite through nano-metal powder. According to the rolling preparation method, a titanium alloy strip material and an aluminum alloy strip material are machined to be at the same dimension, surface treatment is conducted so as to remove surface oxides, nanometer particles are arranged on the treated surfaces, stacking is conducted, so that a titanium / aluminum composite strip material is obtained, vacuum edge welding is conducted on the titanium / aluminum compositestrip material, a pulse current is exerted to the welded titanium / aluminum composite strip material so as to enable the nanometer particles and a local area of the surface of the composite strip material to conduct electric discharge, and surface metal is molten; then, rolling is conducted on the titanium / aluminum composite strip material, and material interface welding bonding is achieved; and finally, rolling continues until the total reduction rate of the strip material reaches 80%-95%. By the adoption of the rolling preparation method, the high-performance titanium / aluminum composite stripmaterial can be prepared. The plate material has the potential to be applied to the bulletproof protection field, the aerospace field, the sound insulation and noise reduction field, the automobile weight reduction field and the like. The rolling preparation method may be used for preparing composite strip materials composed of other nonferrous metal materials such as copper and magnesium in thefuture.

Owner:CENT SOUTH UNIV

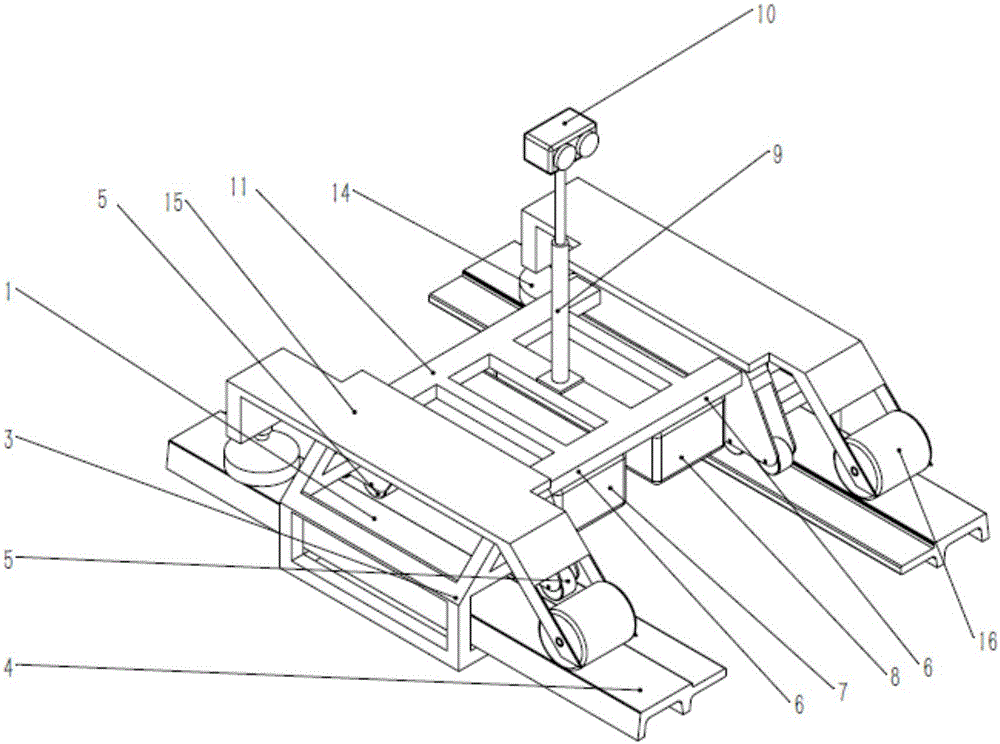

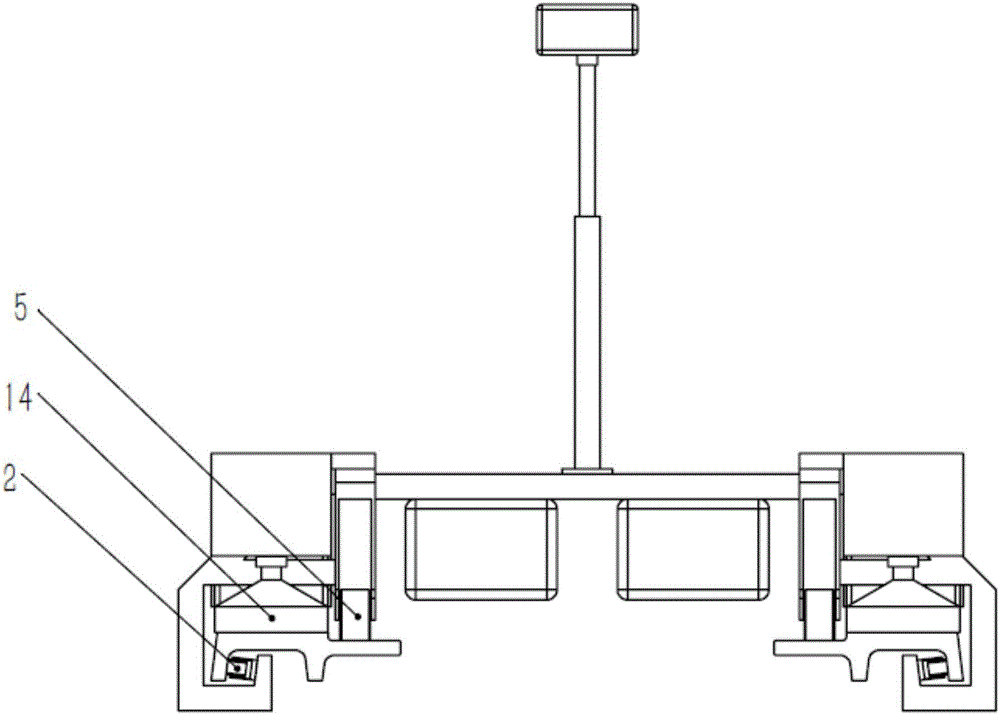

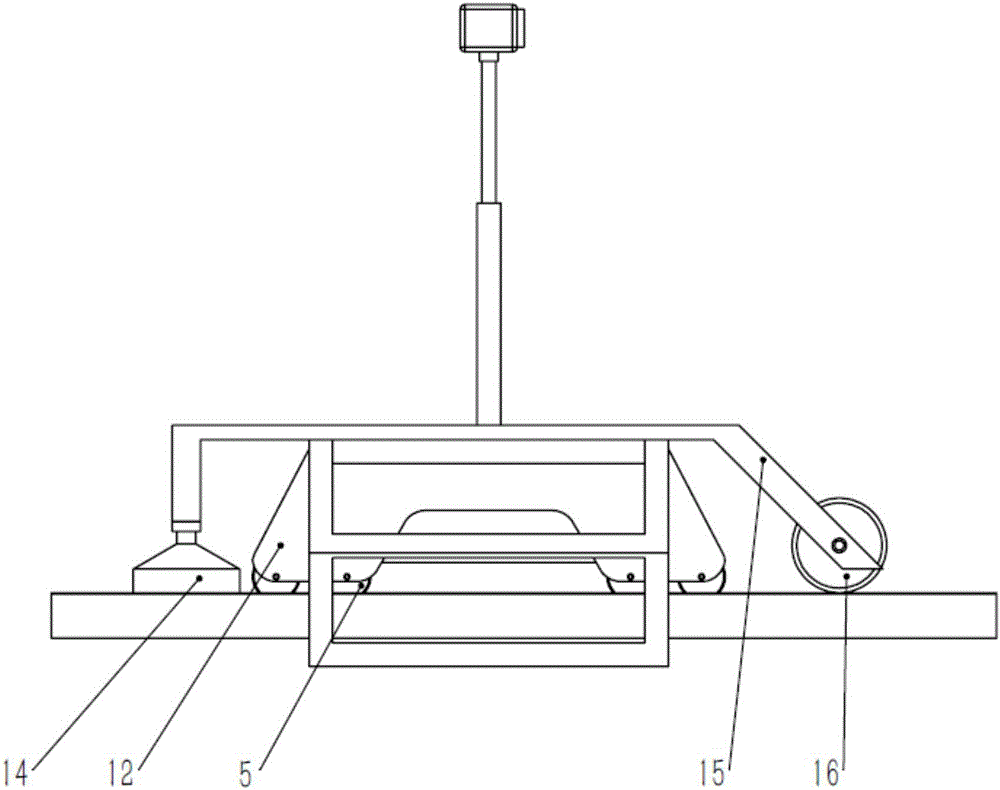

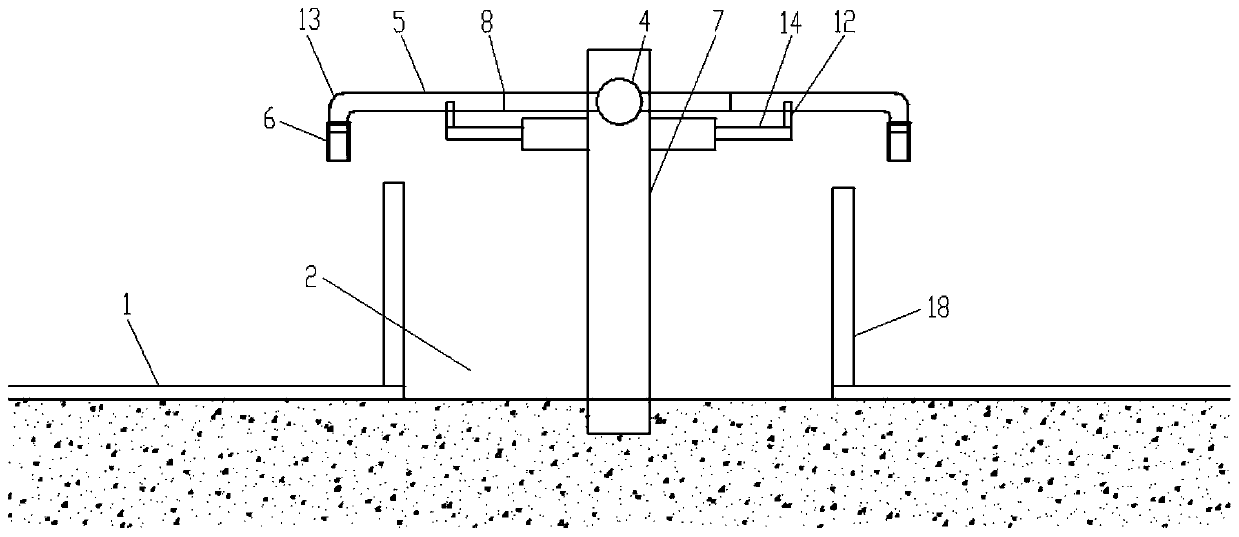

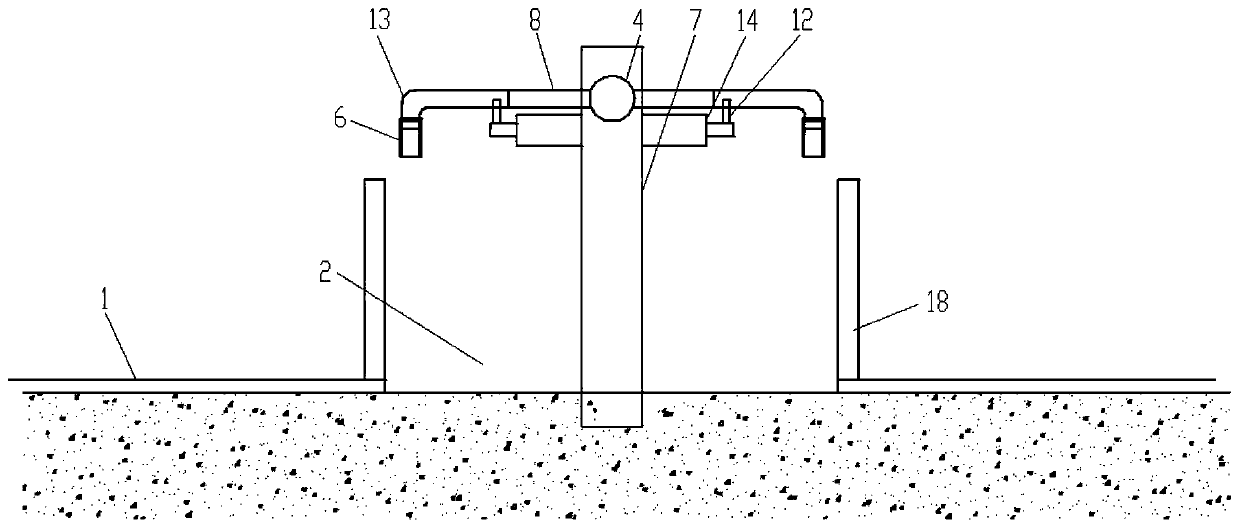

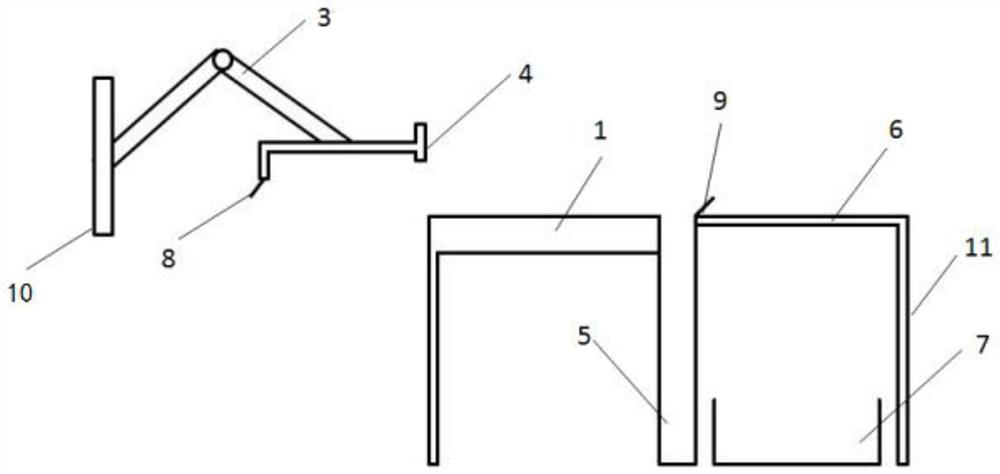

Low and medium speed magnetic levitation icebreaking and snow melting cleaning robot

ActiveCN106120636AEffective Public Works MaintenanceEffective Operational SecurityRailway cleaningFixed frameSnow melting

The invention discloses a low and medium speed magnetic levitation icebreaking and snow melting cleaning robot which comprises a machine frame, two folding bending mechanisms, an ice melting cleaning mechanism and an autonomous cruising module. The machine frame stretches over two rails F of low and medium speed magnetic levitation to be detected. The two folding bending mechanisms are arranged at the two ends of the machine frame and located above the rails F. Each folding and bending mechanism is provided with a walking wheel pair and a clamping wheel pair. The snow melting cleaning mechanism comprises a fixed frame, a rail F obstacle removal cleaning unit and an ice melting heating unit. The fixing frame is installed on the machine frame and located above the folding bending mechanisms and arranged in the extending direction of the rails F. The rail F obstacle removal cleaning unit and the ice melting heating unit are arranged at the two ends of the fixing frame. The autonomous cruising module is installed below the machine frame. Rail F ice and snow melting and cleaning can be achieved, and the low and medium speed magnetic levitation icebreaking and snow melting cleaning robot has the advantages of being simple in structure, convenient to operate and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

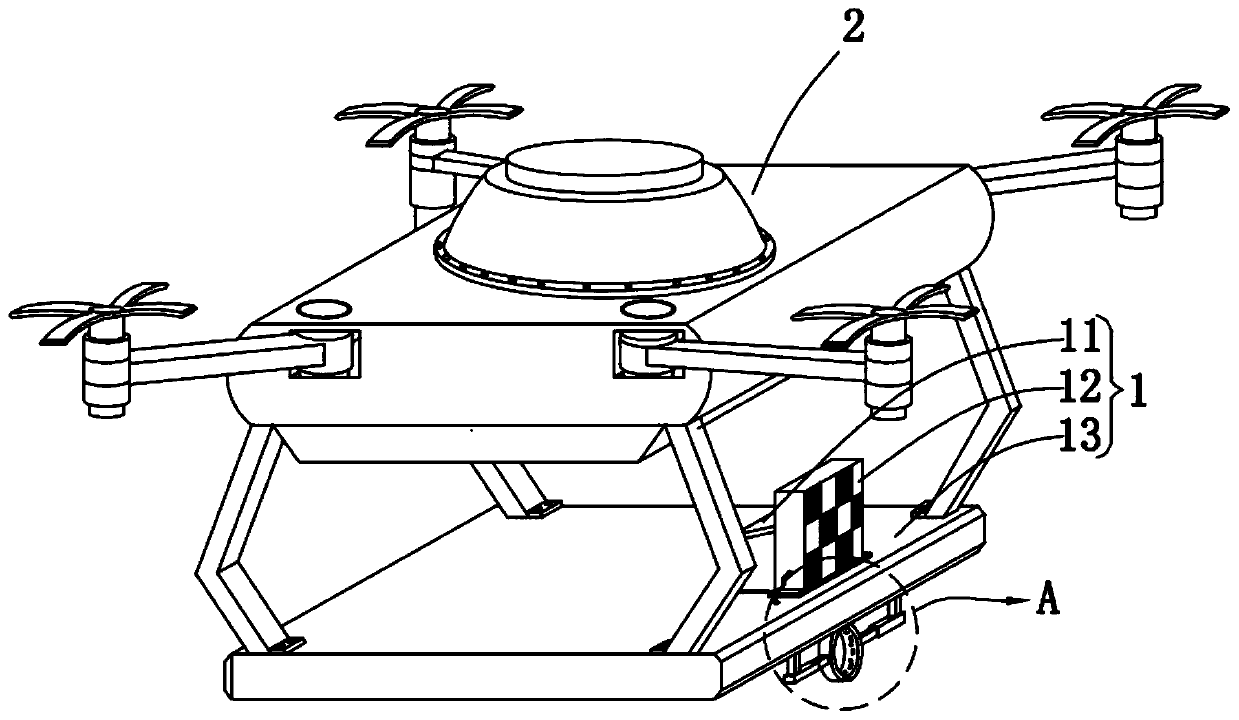

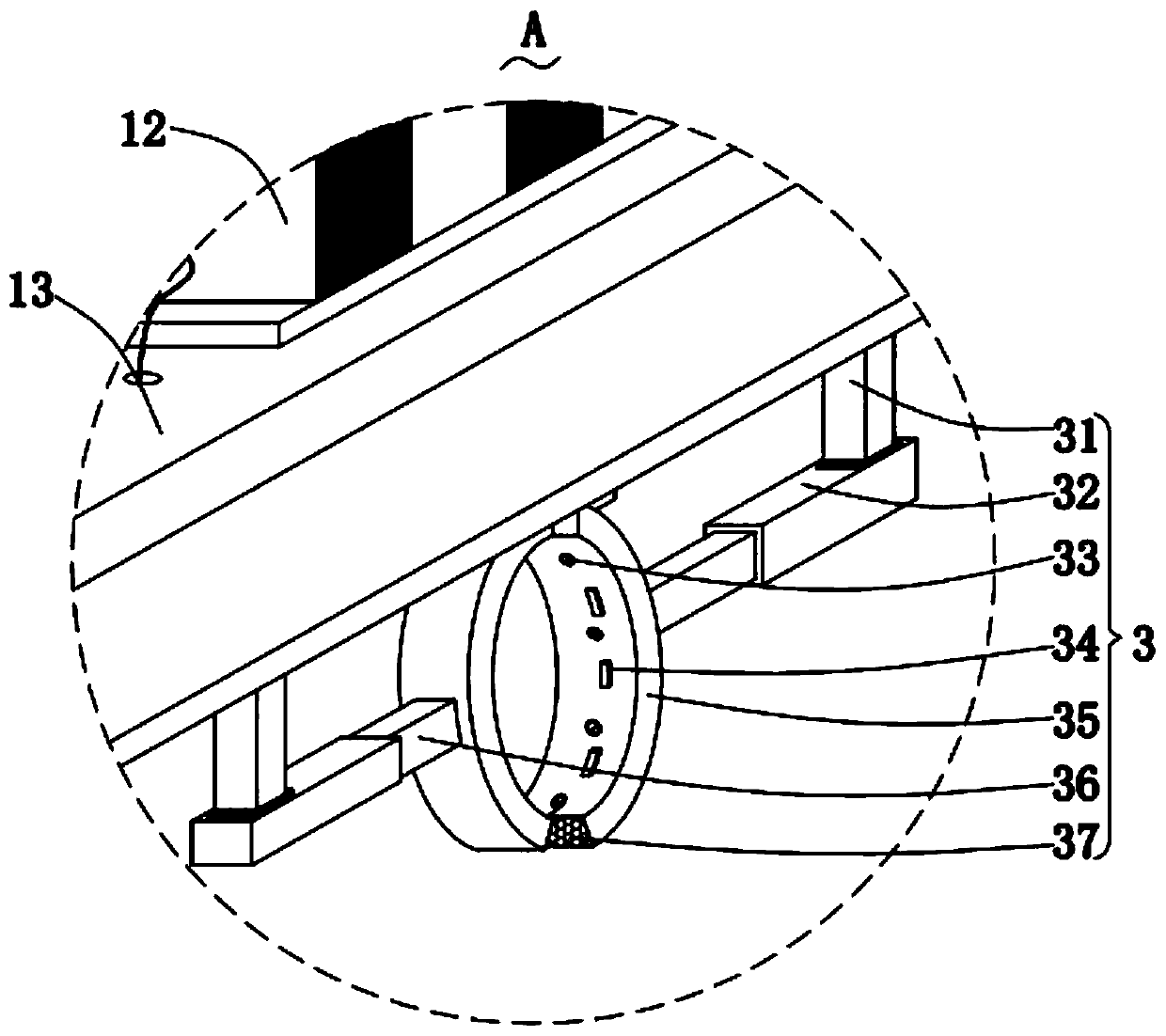

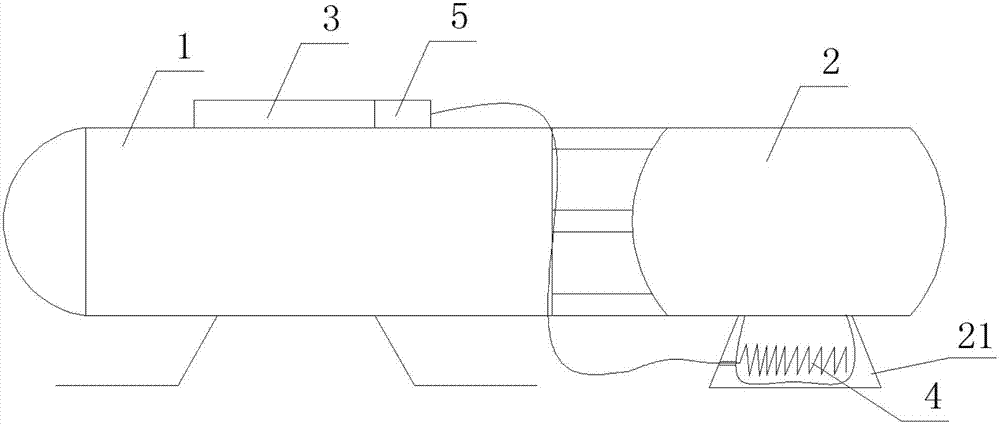

Unmanned aerial vehicle with cable wire snow removal and ice removal functions

ActiveCN109733602AAvoid getting stuckSpeed up meltingOverhead installationAircraftsEngineeringRelative motion

The invention relates to the field of cable wire ice removal, in particular to an unmanned aerial vehicle with cable wire snow removal and ice removal functions. The unmanned aerial vehicle comprisesa control mechanism, an unmanned aerial vehicle body, a cleaning mechanism and a sliding mechanism, wherein the control mechanism is matched with the cleaning mechanism to achieve the goal of enablingtwo connecting rods to do relative movement by an electric push rod; the relative movement of two cases is further realized; the abutting contact of two heat conduction plates positioned at the opposite side walls of heating plates, and ice and snow on the surface of a cable wire is further realized; the ice and snow melting is realized; springs are arranged between the two heating plates and thecase; the springs are matched with steel balls; on one hand, the guide on an integral structure is realized; on the other hand, the clamping of the integral structure on the surface of the cable wireis avoided; the melting speed of the ice and snow on the surface of the cable wire is accelerated; through the case of an arc-shaped structure and the heating sheet of an arc-shaped structure, the connection stability of the heat conduction plates, the steel balls and the cable wire is enhanced; and through the heat conduction plates fixed onto the surface of the heating plate at equal intervals,the ice and snow melting is realized.

Owner:通航教育科技有限公司

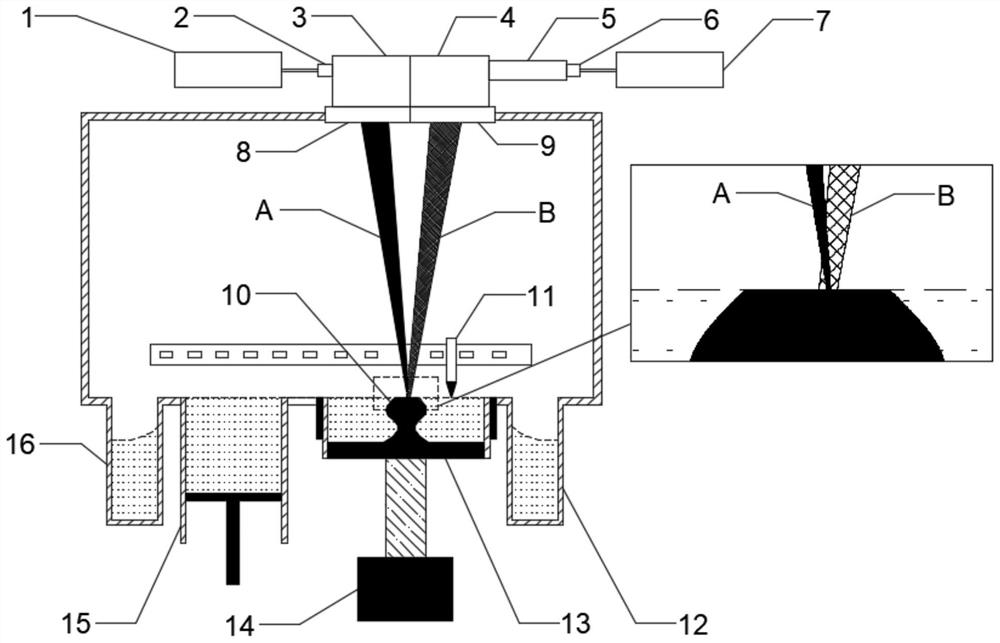

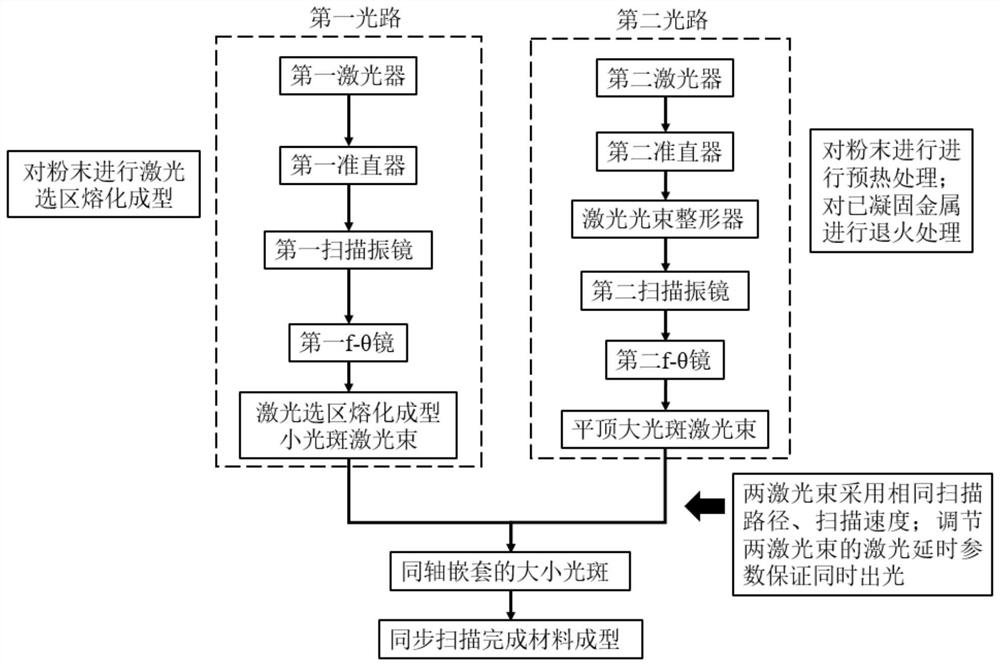

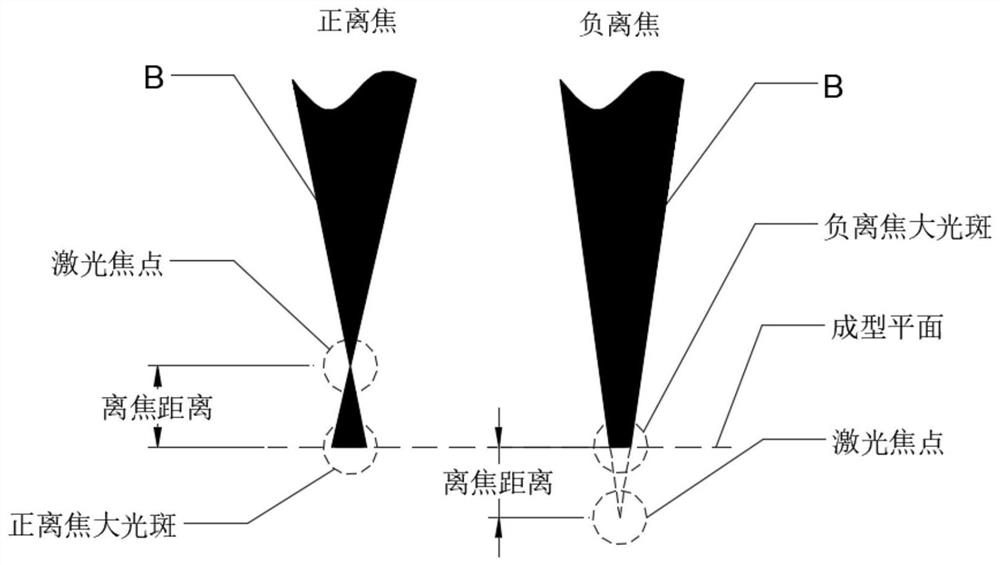

In-situ energy controlled selective laser melting device and method

PendingCN111842892AIncrease input control meansReduce defectsAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention discloses an in-situ energy controlled selective laser melting device and method. According to the in-situ energy controlled selective laser melting device and method, a path of synchronously scanned flat-topped large light spot is additionally arranged, energy below a powder melting point threshold value is provided, the powder preheating / solidification rate is regulated and controlled, formed metal is annealed, the temperature gradient is reduced, and the forming internal stress is reduced, so that behaviors such as deformation and cracking caused by stress are reduced; and meanwhile, due to the fact that energy input lower than the melting point threshold value of a material is provided, material melting can be completed only by providing low energy input for original SLMsmall light spots, and the adverse conditions of molten pool splashing, micro air hole generation and the like are improved. In addition, time and space distribution of laser energy is realized basedon an in-situ energy control mode. Therefore, according to the method, defects generated in the part forming process are effectively reduced, meanwhile, the solidification rate is controlled, the structure evolution is regulated and controlled, and the method plays an important role in stably and efficiently forming high-performance parts and promoting wide application of the additive manufacturing technology.

Owner:SOUTH CHINA UNIV OF TECH

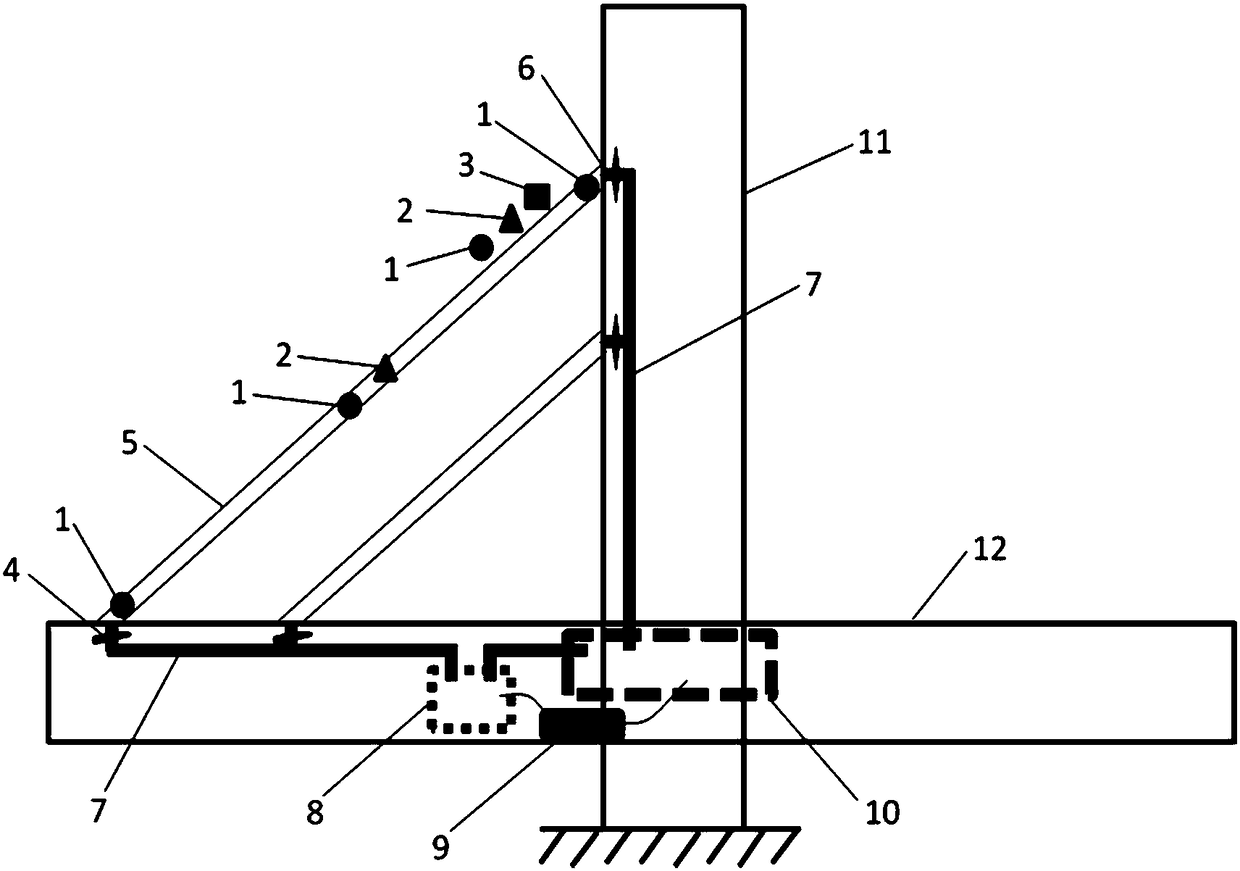

Cable-stayed bridge inhaul cable intelligent dehumidifying and deicing system and method

ActiveCN108301324AReduce manpower consumptionReduce operating powerBridge structural detailsBridge erection/assemblySurface layerCable stayed

The invention discloses a cable-stayed bridge inhaul cable intelligent dehumidifying and deicing system and method and relates to the field of bridge operation safety protection. The system comprisesan air feeding unit, a monitoring unit and a control unit. The air feeding unit comprises a high-pressure dry air production device and an air heating device. The high-pressure dry air production device is used for generating high-pressure dry air and driving the generated high-pressure dry air to pass through the air heating device, enter inhaul cables from the bottom ends of the inhaul cables and flow out from the top ends of the inhaul cables. The monitoring unit comprises humidity sensors and temperature sensors, all of which are arranged in the inhaul cables, and the monitoring unit further comprises humidity sensors, temperature sensors and icing sensors, all of which are arranged on the outer surface layers of the top ends of the inhaul cables. The control unit is electrically connected with the air feeding unit and the monitoring unit. The inhaul cables can be automatically dehumidified and deiced according to external climate changes, the inhaul cables are protected against corrosion, and meanwhile the inhaul cables are effectively prevented from being iced.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Fired mold shell manufacturing process using coating transferring method

The invention discloses a fired mold shell manufacturing process using a coating transferring method. The manufacturing process particularly comprises the process steps that a release agent is pouredon a cotton gauze, and the release agent is slightly coated to the surface of a wax pattern with the cotton gauze; after the release agent on the surface of the wax pattern forms a film, the wax pattern slowly immerses into transferred coating, slow rotation is carried out until a layer of transferred coating is evenly attached to the surface of the wax pattern, the wax pattern is taken out, and even coating is carried out with a hairbrush; quartz sand is scattered to the surface of the coated wax pattern, the quartz sand is scattered to the surface of the wax pattern after the coating does not drop downwards, and then the wax pattern is soaked into a hardening agent to be hardened; after hardening, the wax pattern is taken out to be subject to air drying, the wax pattern is placed into aboric acid solution to be boiled until the wax pattern in a sand mold shell is completely fused and discharged, the sand mold shell is obtained, then roasting is carried out, and a sand mold die is obtained. According to the fired mold shell manufacturing process, the boric acid solution is adopted for boiling and demolding the sand pattern, quick wax dissolving can be achieved, meanwhile, the dissolving capacity of the transferred coating is weak, and coating anti-falling dissolving while demolding can be achieved.

Owner:ANHUI XINHONG MACHINERY

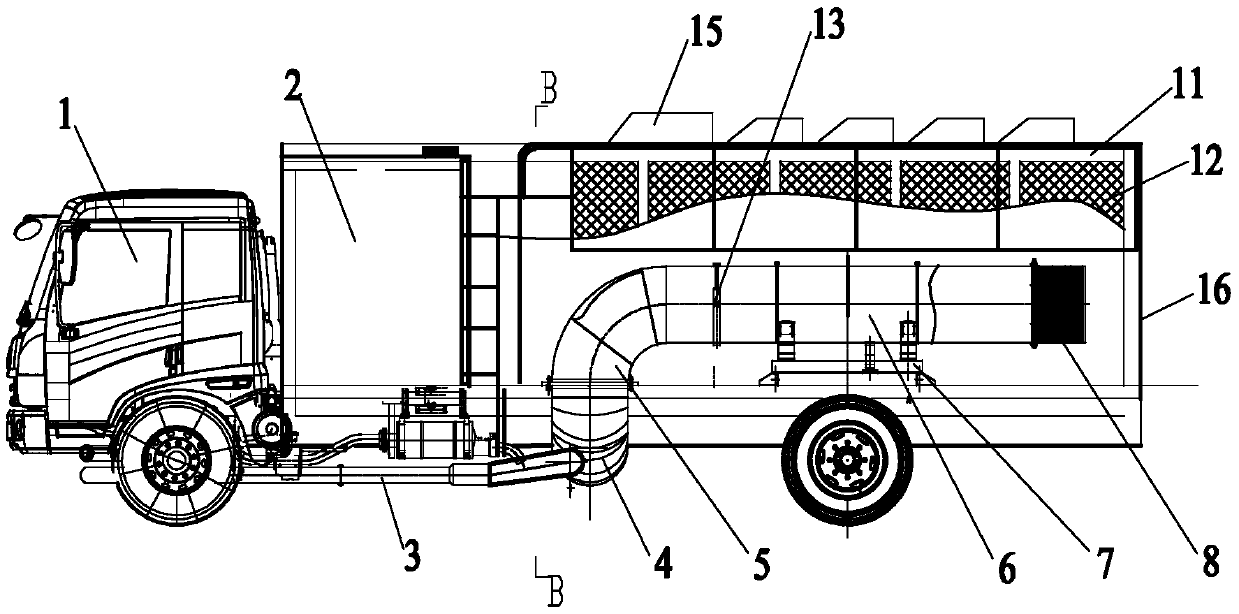

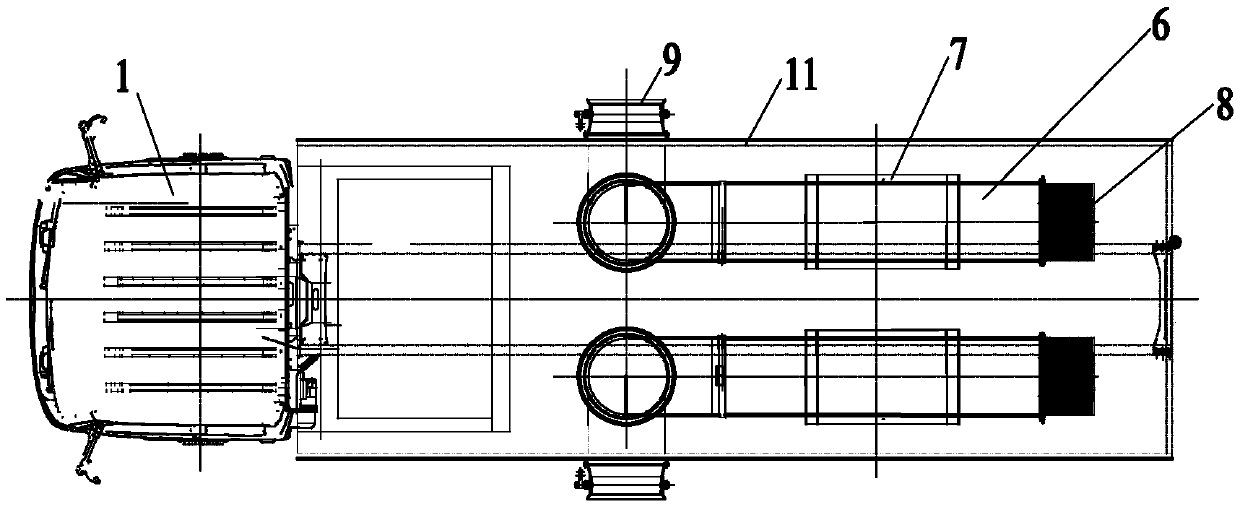

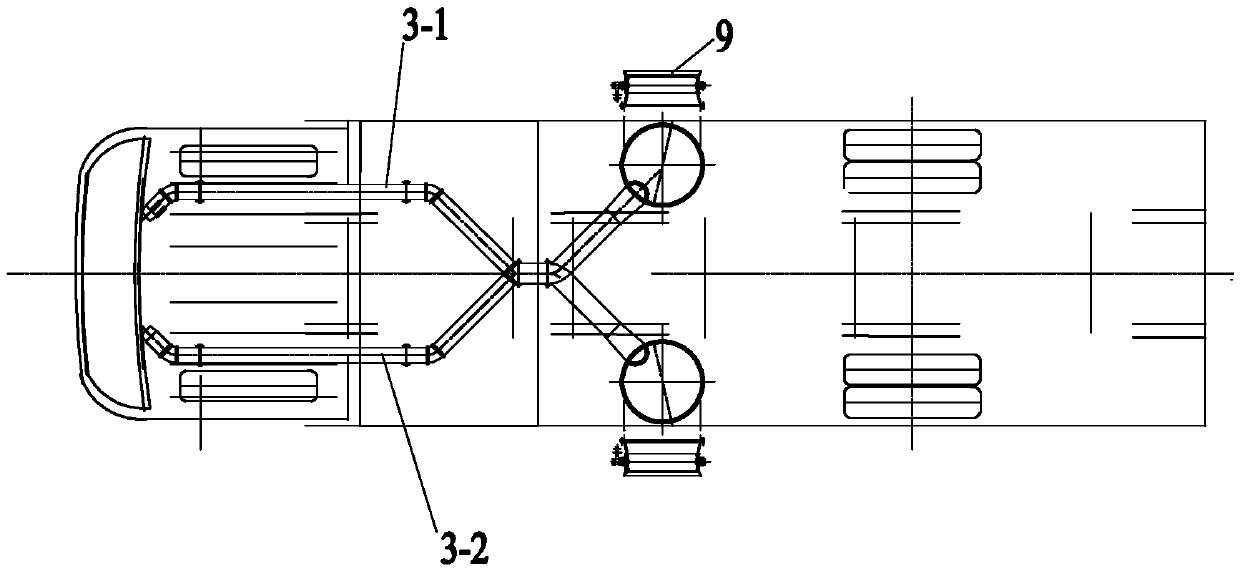

snow blower

The invention relates to snow removing devices, in particular to an air injection type snow blowing cart. The air injection type snow blowing cart comprises a second-class automobile chassis, wherein an aircraft turbojet engine, an air inlet compartment and an oil tank are installed on the second-class automobile chassis, and an aircraft turbojet engine starting power supply package and an air injection snow blowing pipeline set are installed on the bottom of the chassis. The turbojet engine is fixed into the air inlet compartment through a special shock-absorption rack, the air inlet end of the turbojet engine is covered with an air inlet filter screen, an exhaust pipe on the tail portion of the turbojet engine is connected to the high-temperature pressure-resistant snow blowing pipeline set in a sealed mode, snow blowing pipelines stretch out from one side of a cart compartment body, the directions of nozzles at the lower ends of the snow blowing pipelines can be adjusted, and snow is blown towards the left side and the right side of the air injection type snow blowing cart. Front hot air spraying pipes are connected to the walls of the snow blowing pipelines in a sealed mode and are used for blowing snow on a road on which the air injection type snow blowing cart travels forwards. The air injection type snow blowing cart has the advantages that the design is reasonable and ingenious; due to the fact that snow blowing nozzles are arranged on the side portions of a cart body and the front end of the snow removing cart, blind-angle-free snow blowing is achieved effectively, and it is guaranteed that snow accumulated on roads are effectively removed.

Owner:WUXI YOUPENG AUTOMOBILE SERVICE

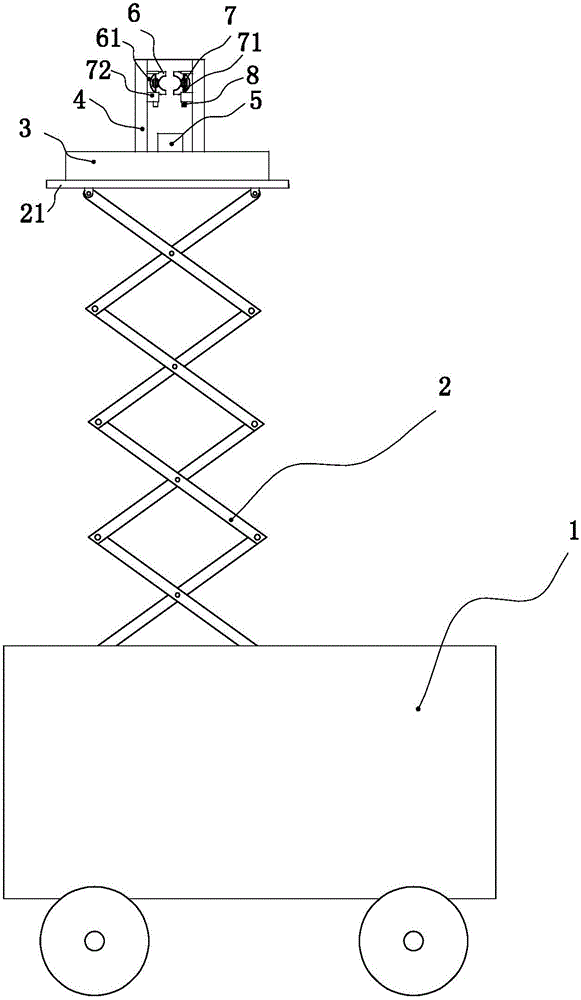

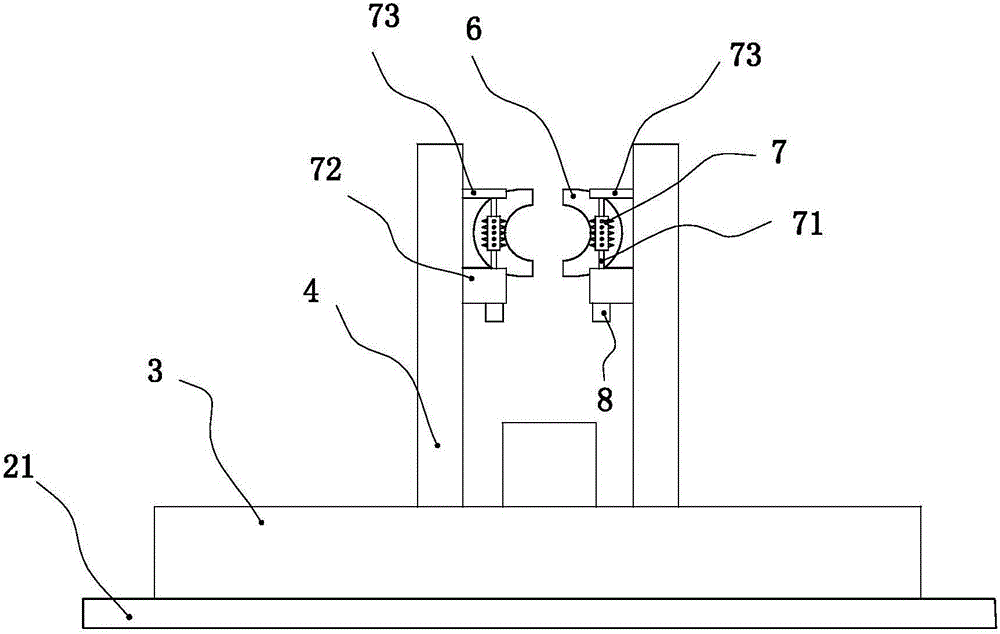

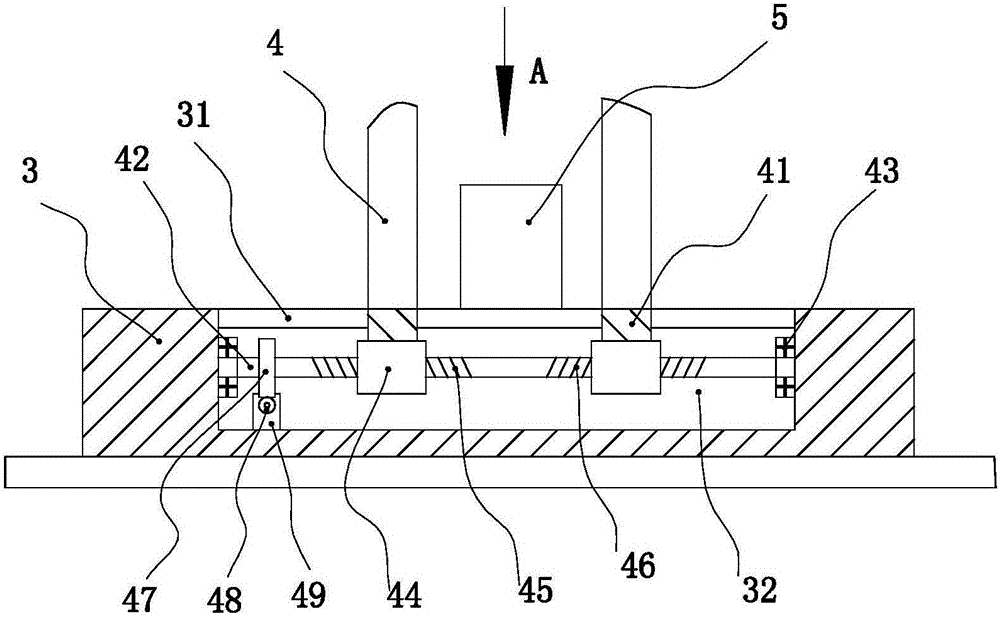

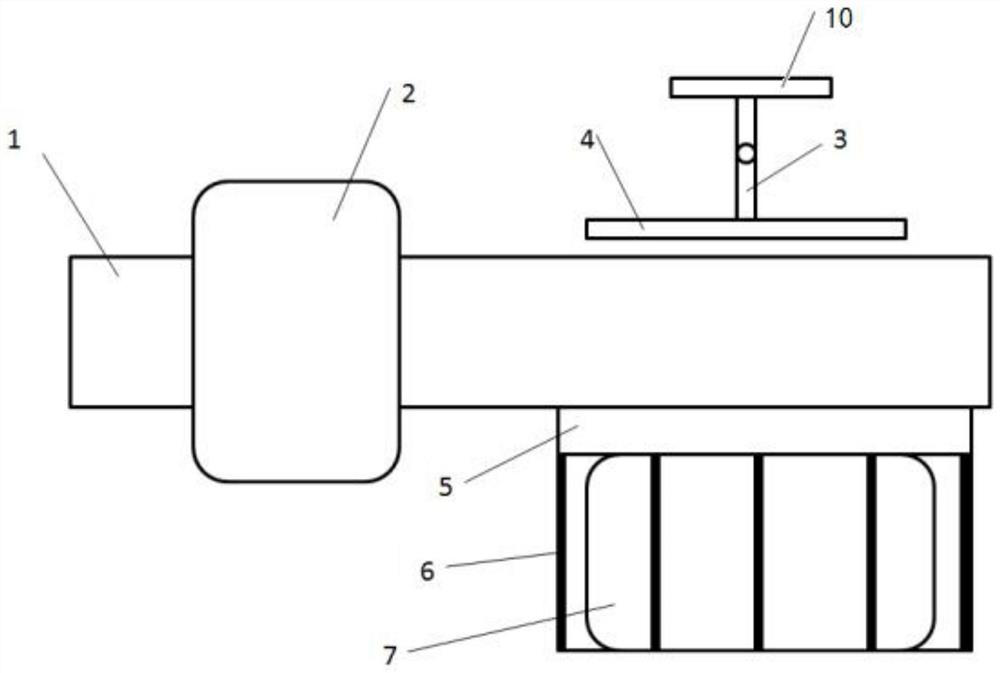

Distribution line maintenance apparatus

Provided is a distribution line maintenance apparatus for removing ice and snow on a power transmission line. An elevator is disposed on the roof of a vehicle body. A pedestal is disposed on the top of the elevator. A pair of installing frames are installed on the top of the pedestal in a sliding way. A lead screw is disposed on the pedestal and provided with two nuts with opposite moving directions. The nuts are fixedly connected with a slide block on the bottom of the installing frames. An inclined block is arranged between the two installing frames. Travel switches are disposed on both sides of the inclined block and are in signal connection with a controller. The controller is in signal connection with a cylinder solenoid valve. A heater is disposed on the top of the installing frames. A heating wire is disposed on the inner side of the heater. An upper support and a lower support are disposed on the rear side of the heater. A roller is installed rotationally between the upper and lower supports. Thorns are distributed on the outer wall of the roller. The roller is driven to rotate by a second motor on the bottom of the lower support. The distribution line maintenance apparatus may melt and break ice so as to remove the ice and is high in deicing efficiency.

Owner:PINGYIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

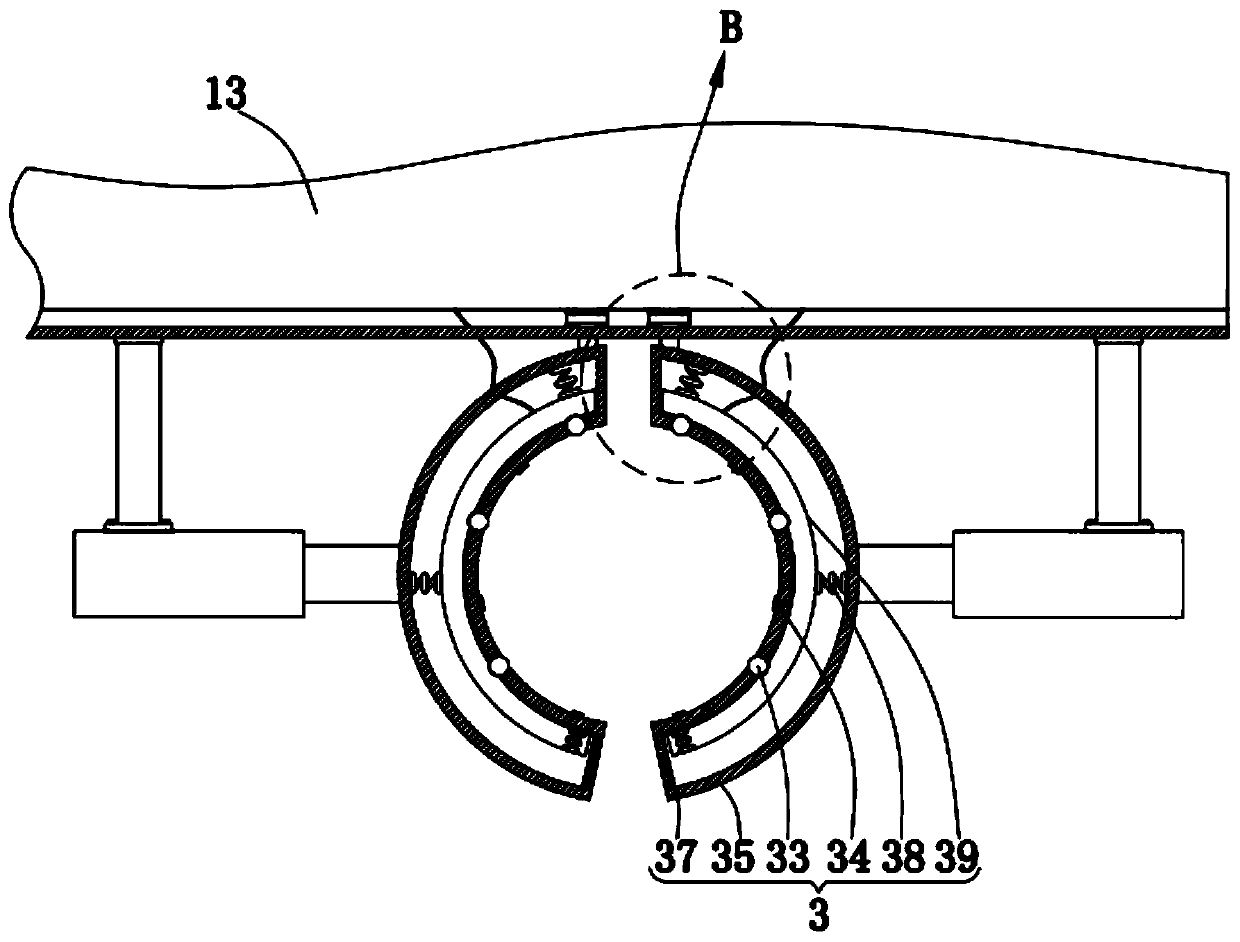

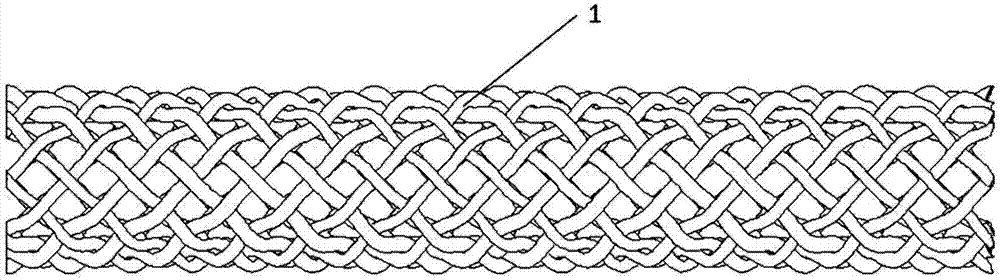

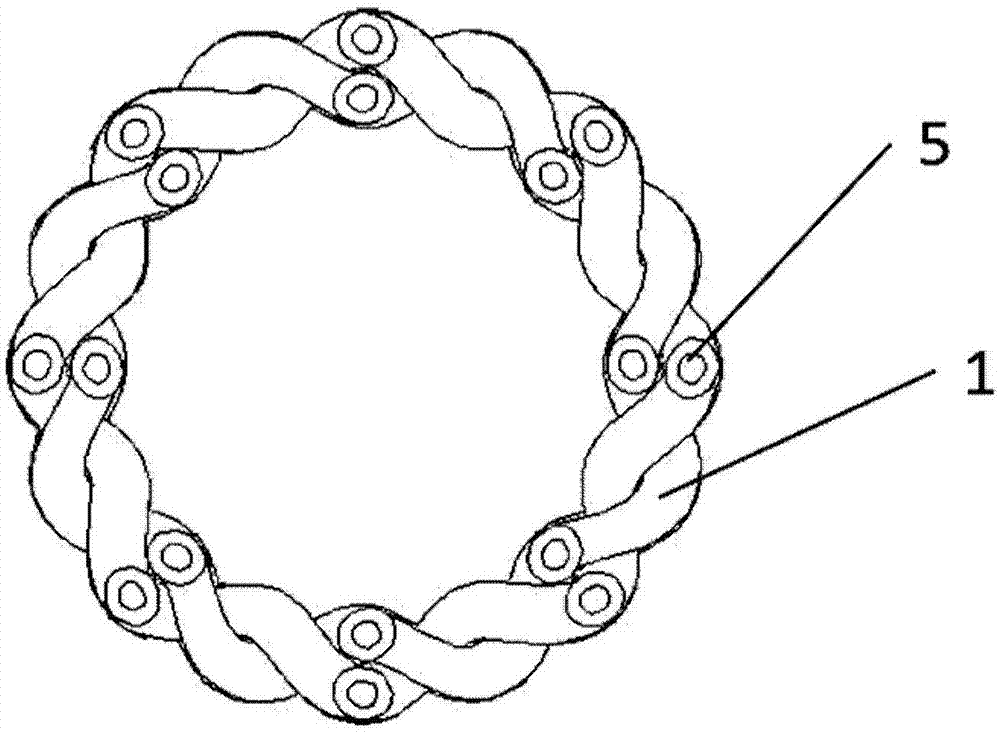

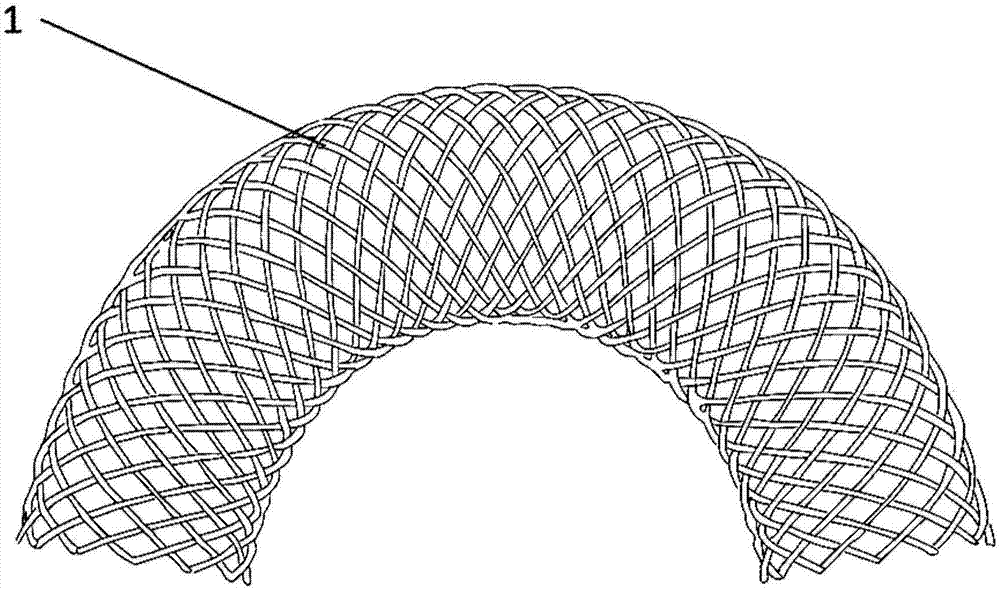

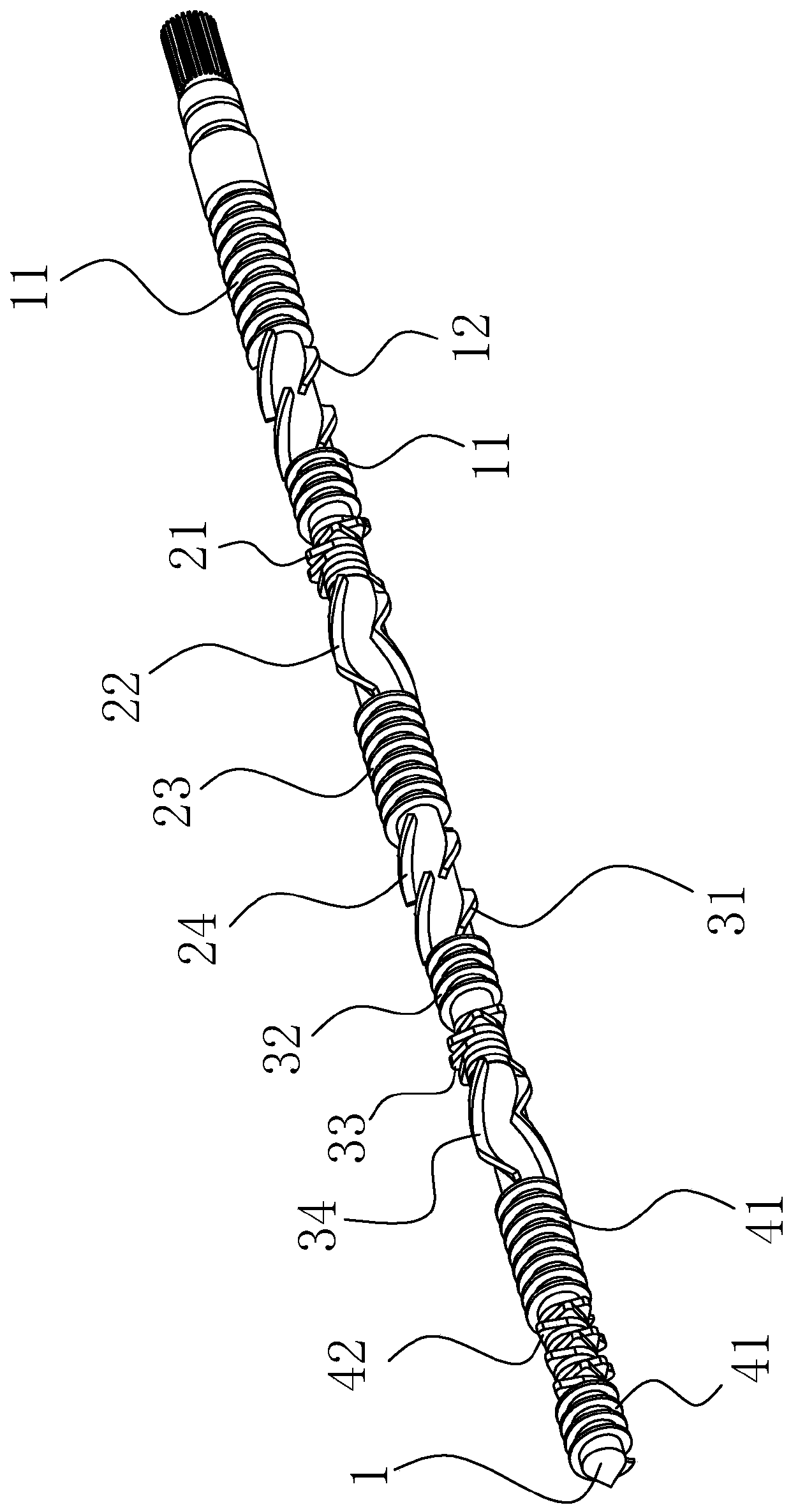

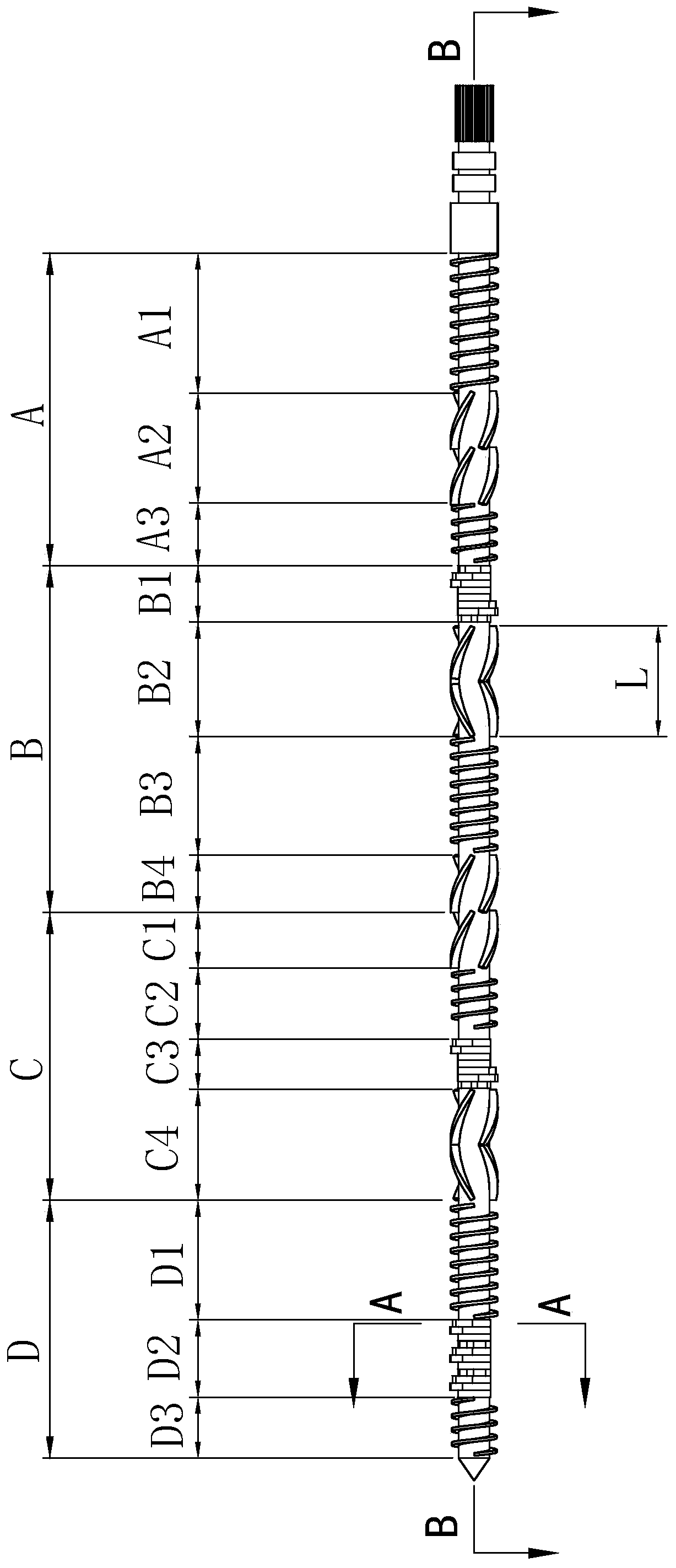

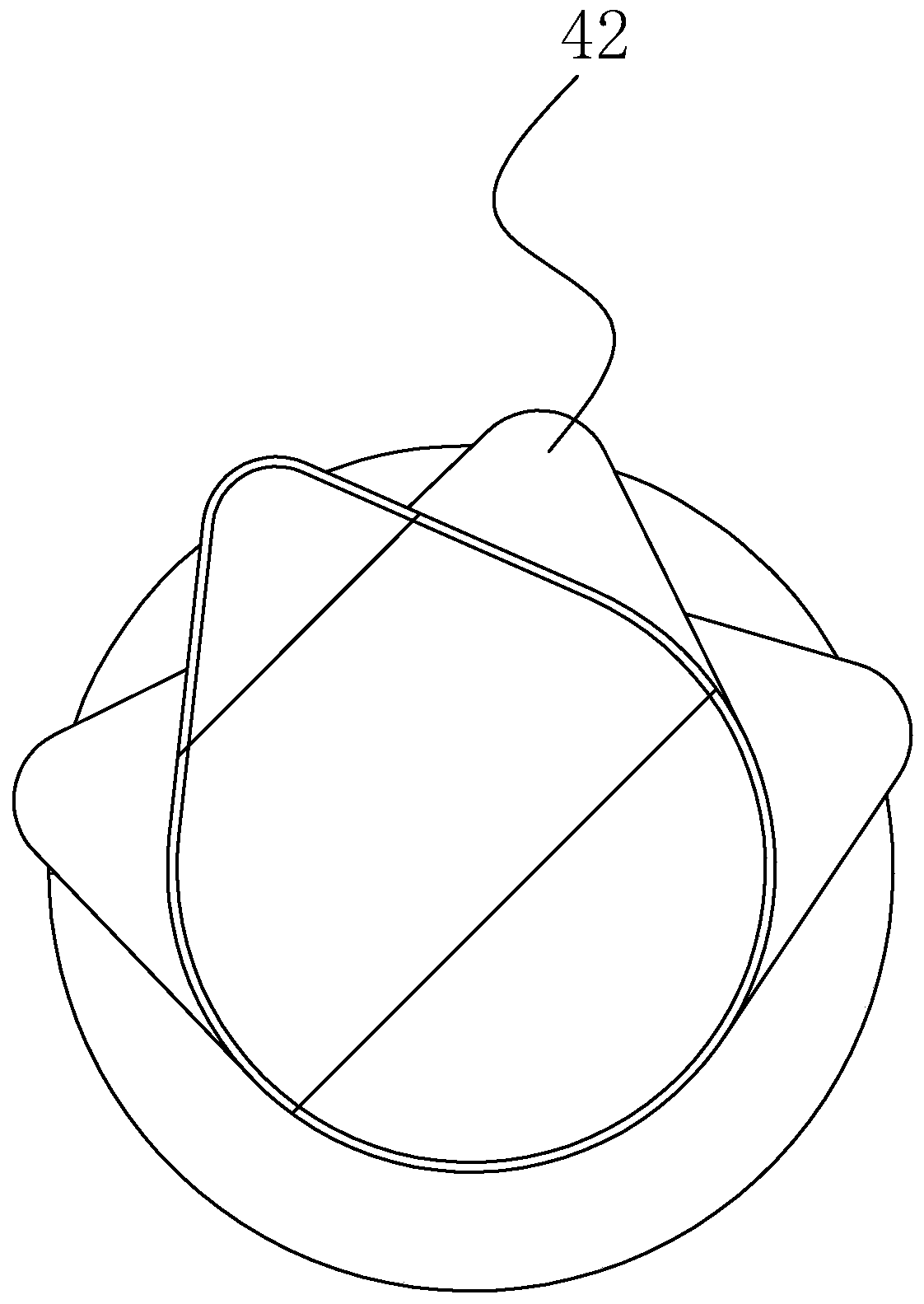

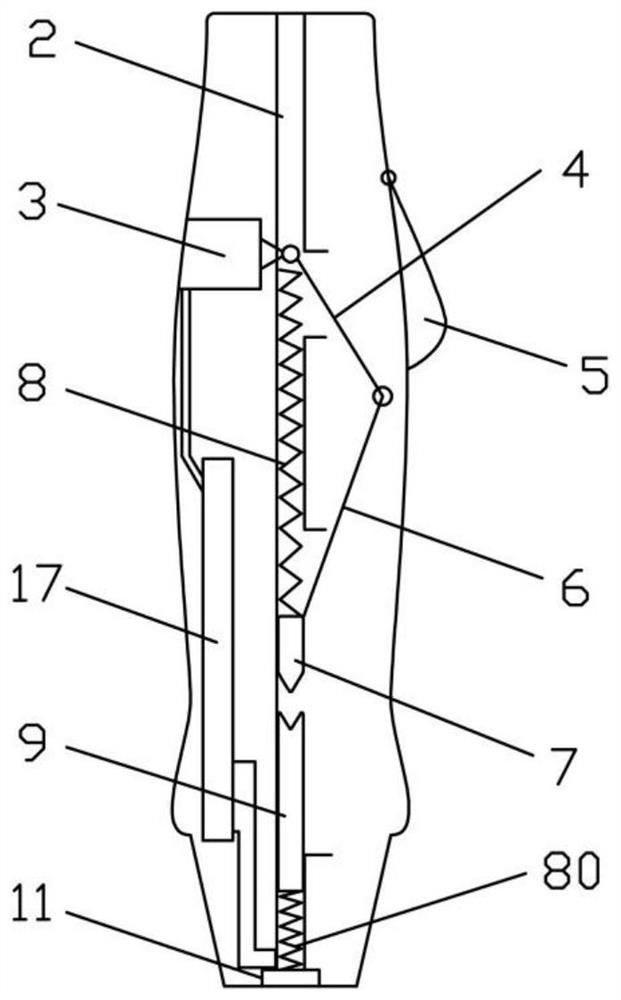

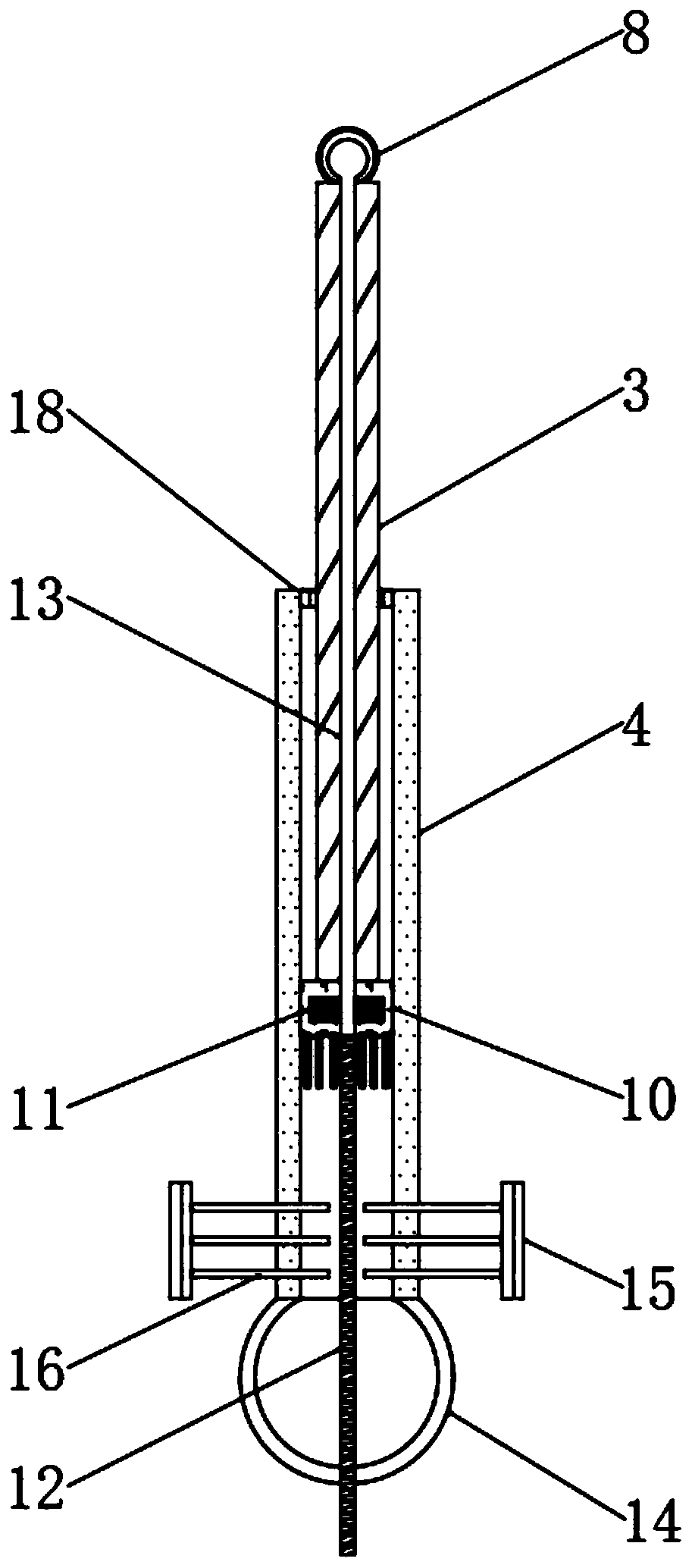

Variable-stiffness protective sheath for natural cavity operation and application method thereof

ActiveCN107280716AImprove flexibilityStrong environmental abilityDiagnosticsSurgeryVariable stiffnessAlloy

The invention discloses a variable-stiffness protective sheath for a natural cavity operation. The protective sheath comprises a braided tube, the braided tube is formed by spirally winding and intersecting multiple hoses, and the interiors of the hoses are filled with alloy with a low melting point. The invention further provides a method for applying the variable-stiffness protective sheath to the natural cavity operation. The method comprises the steps that the alloy with the low melting point in the hoses is powered on and melted, and the braided tube is in a flexible and small-diameter state; the braided tube is put into a natural cavity; the diameter of the braided tube is increased, the alloy with the low melting point is solidified at the human-body temperature, and the braided tube is in a rigid and large-diameter state; an operation tool is put into the braided tube for the operation; after the operation, the alloy with the low melting point in the hoses is powered on, and the braided tube is restored to be the flexible state and drawn out of the natural cavity. The structural stiffness of the braided tube of the variable-stiffness protective sheath is changed through the adoption of a phase transformation technology of the alloy with the low melting point, it can be ensured that the variable-stiffness protective sheath has a relatively large stiffness changing range, and the human cavities are protected from being scratched and stabbed by the operation tool.

Owner:TIANJIN UNIV

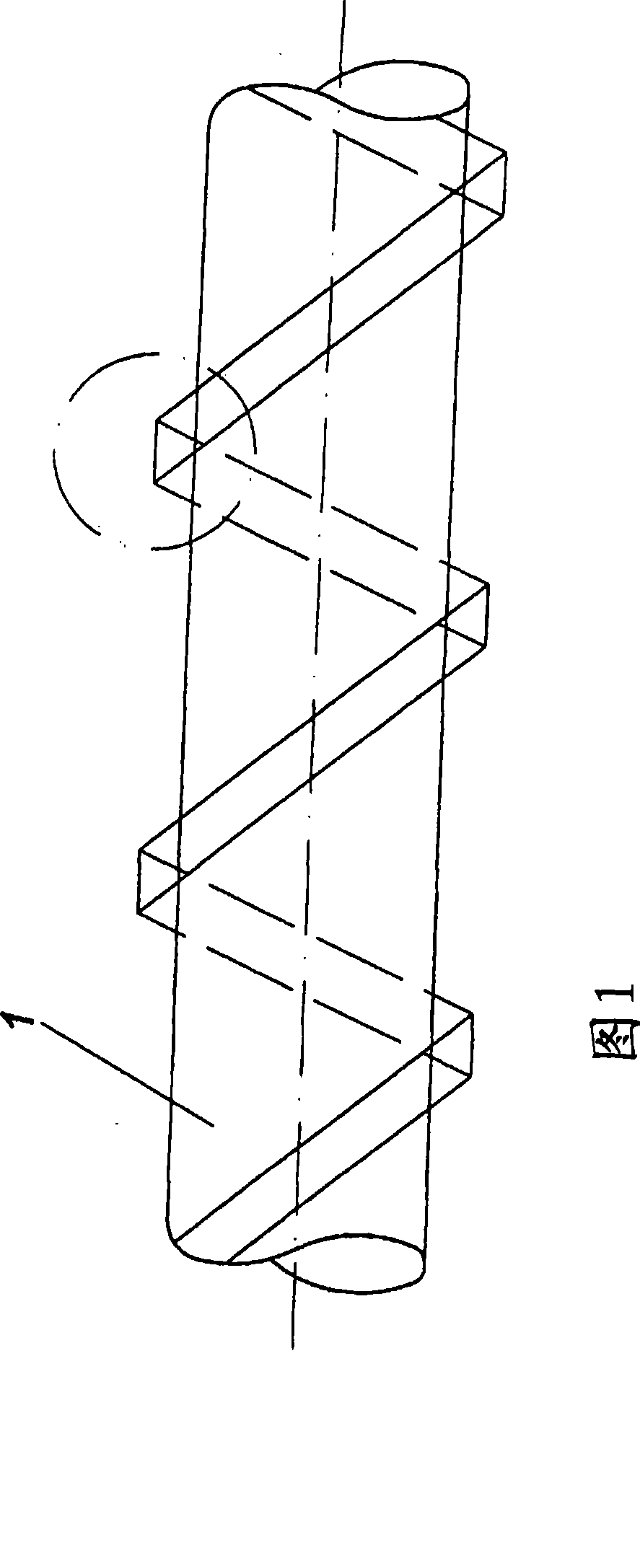

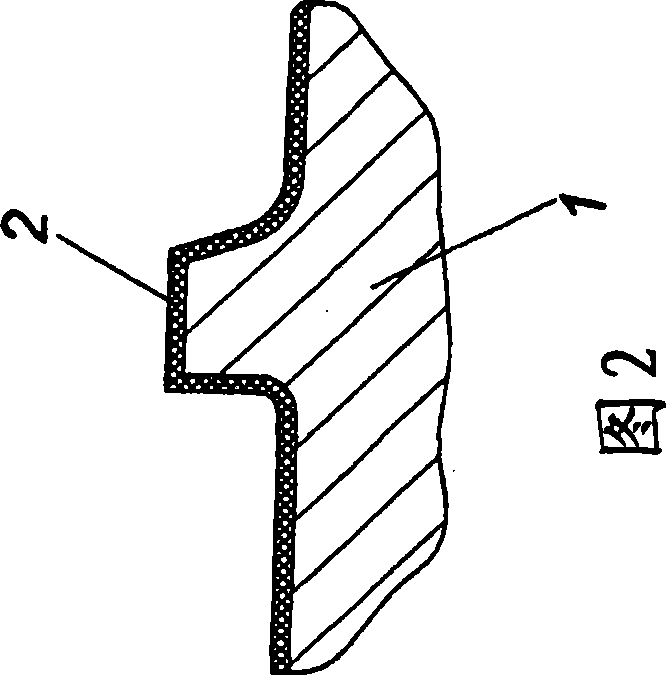

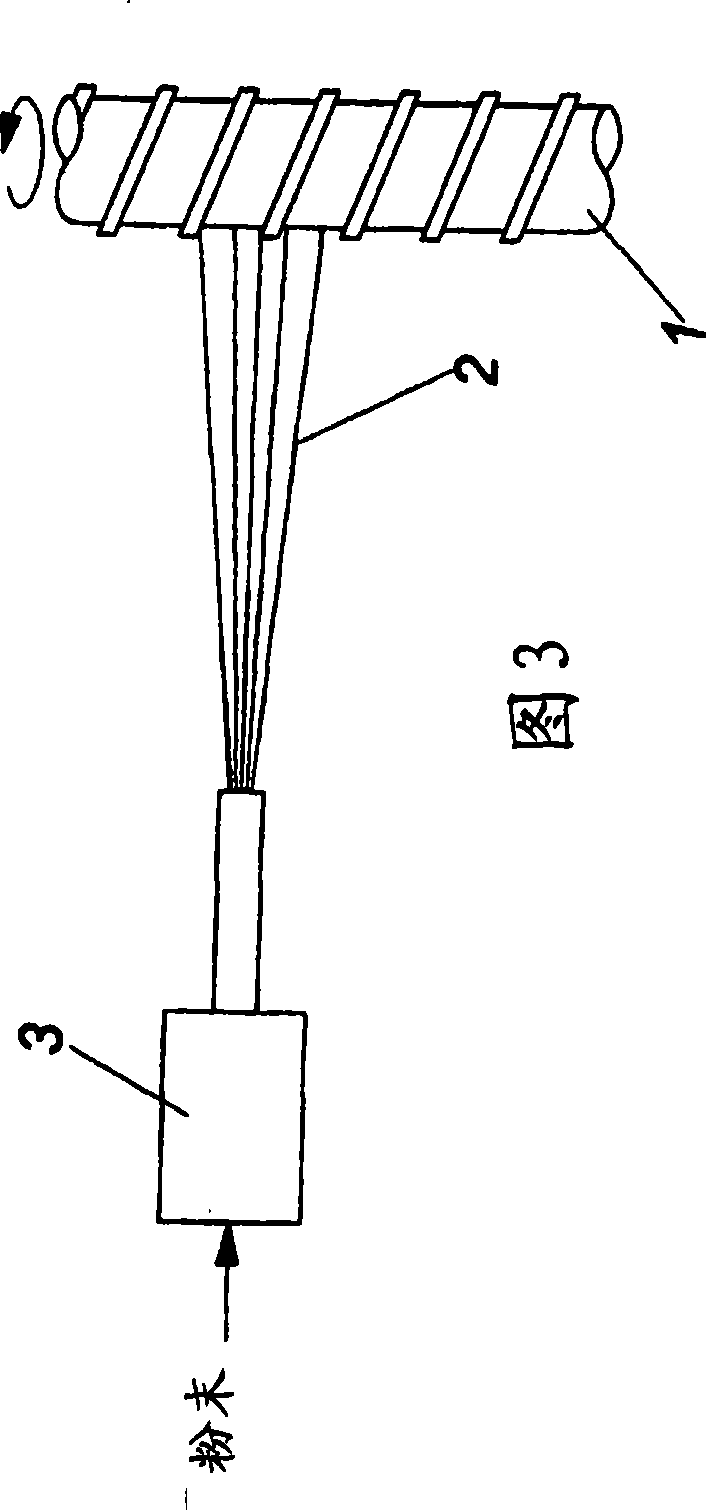

Method for producing coated plasticized screw

InactiveCN101457335AEasy to wearAvoid heat transferMolten spray coatingPressure inorganic powder coatingMetal alloyPlasticizer

The invention relates to a method for producing coated plasticizer screws for injection molding or extrusion of plastics comprises coating at least the worn-out surfaces of the plasticizer screws (1) subject to wear with a metal alloy (2); heating the coated plasticizer screws (1) for melting the metal alloy (2) and the plasticizer screws (1); cooling the coated plasticizer screws (1). All the worn-out surfaces to be coated are simultaneously heated above the melting point of the alloy (2).

Owner:ENGEL AUSTRIA

Anti-freezing water pump

InactiveCN107575418APrevent frostbitePrevent freezingPump componentsPump controlStopped workElectricity

The invention provides an anti-freezing water pump. The anti-freezing water pump comprises a motor and a pump head. The motor is fixedly matched with the pump head and drives the pump head to work. Apower box is fixedly arranged on a shell of the motor and electrically connected with an external power source. A base is arranged at the bottom of a pump case of the pump head, and a heating device is fixedly arranged in the base. The power box provides electricity for the heating device. Due to the fact that the heating device is arranged at the bottom of the pump head, after residual water in the pump head is frozen, and the pump head stops working, the heating device is energized, the purpose that ice blocks in the pump head are melted can be achieved, or the situation that the water in the pump head is not frozen is guaranteed, the anti-freezing water pump can be directly used when the anti-freezing water pump is used again, and the phenomenon that due to the fact that the residual water is frozen, the frost damage to the pump head happens, or startup of the motor is affected can be avoided.

Owner:ANHUI JINWAN PUMP TECH CO LTD

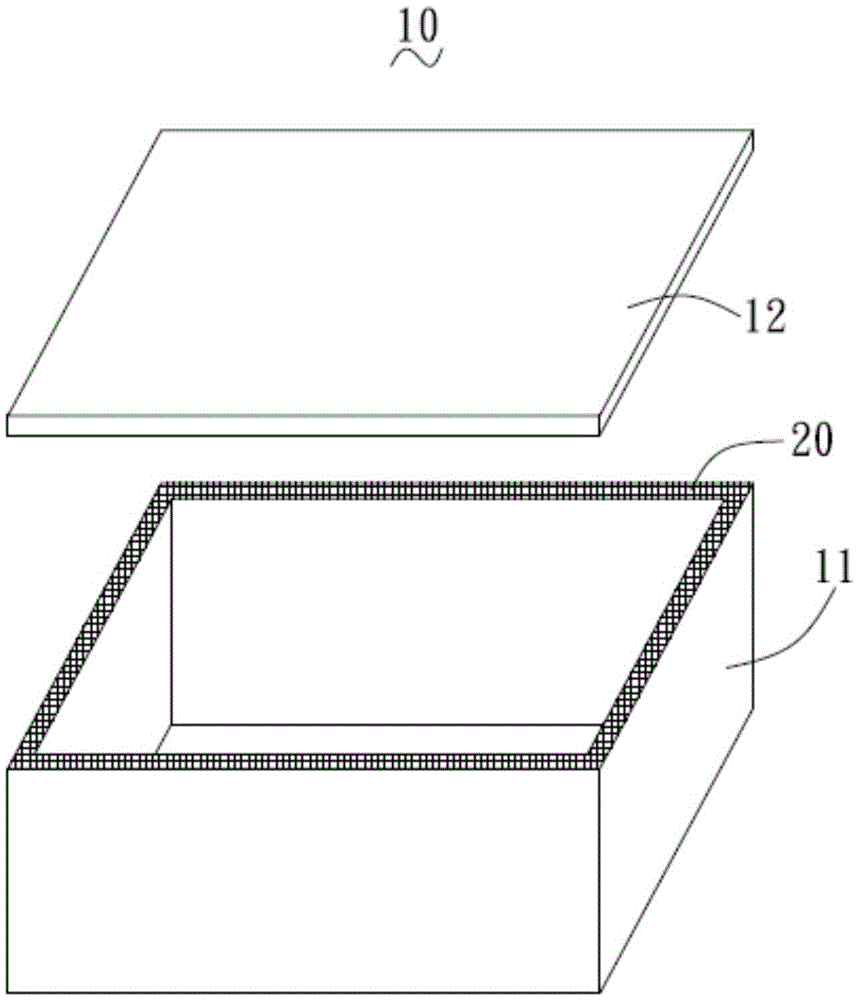

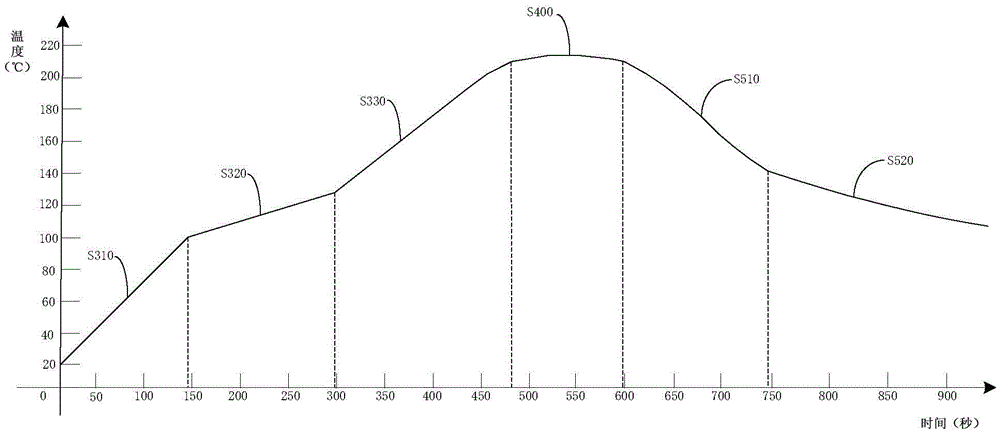

Welding process used for passive device

The invention relates to a welding process used for a passive device. The passive device comprises a box body and a waterproof cover plate encapsulated on the box body. The welding process used for the passive device comprises the following steps: printing mixed tin paste at a joint of the box body and the waterproof cover plate by use of a steel mesh; mounting the waterproof cover plate on the box body, and clamping the waterproof cover plate on the box body by use of a tool clamp; and putting the passive device into a reflux soldering furnace to sequentially carry out pre-heating, heating, heat-preserving and cooling. According to the welding process, the passive device is input into the reflux soldering furnace to sequentially carry out pre-heating, heating, heat-preserving and cooling, so that tin powder in the tin paste is molten, and soldering flux slowly volatilizes to form a welding seam which is continuous and compact, and is high in welding strength, and therefore, waterproof and gastight requirements are achieved. Meanwhile, the production cost is reduced, the thinning treatment of the wall thickness of the passive device is facilitated, and batched automatic production is easy to realize.

Owner:DONGGUAN CHAULEONG TELECOM TECH CO LTD

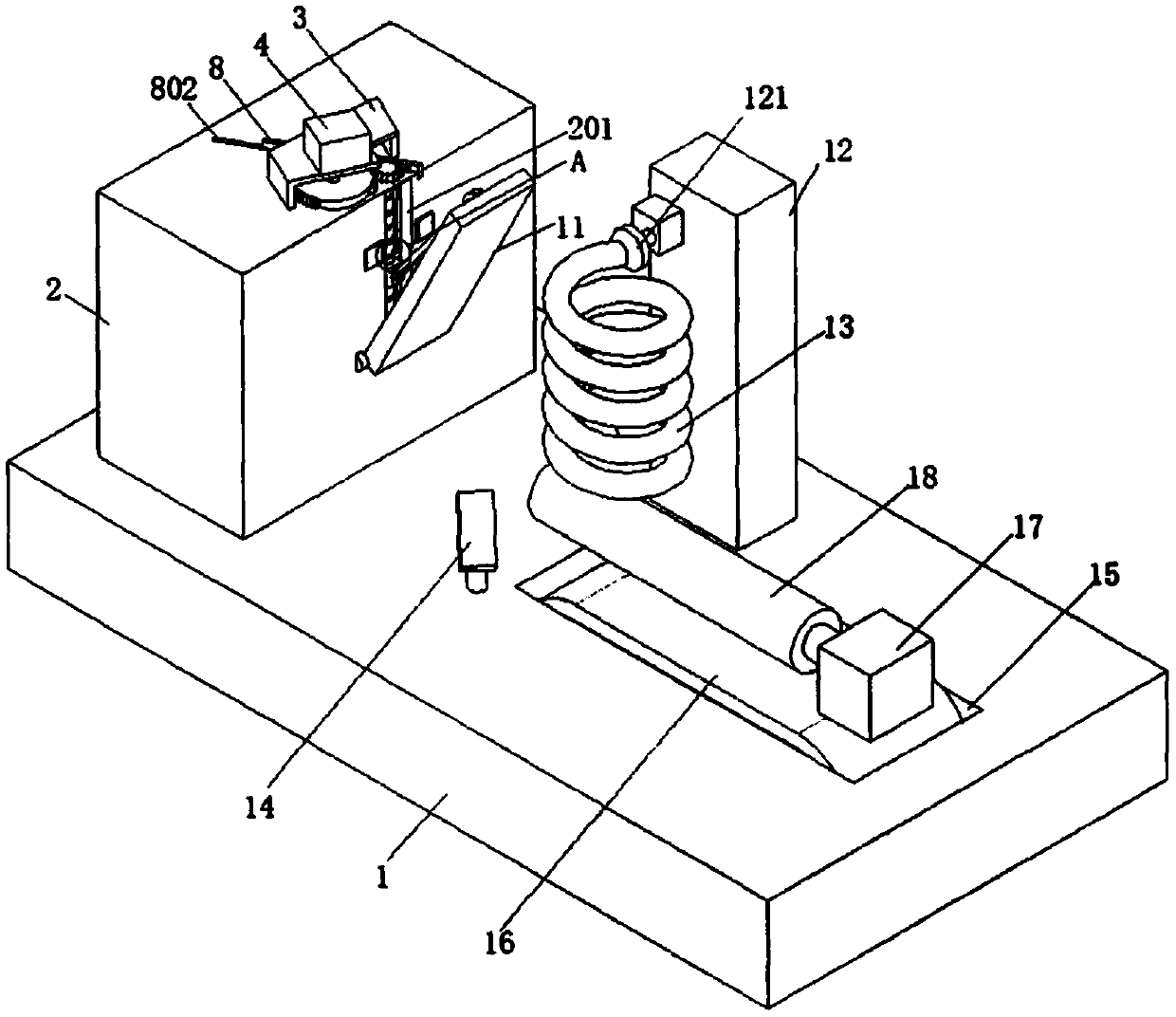

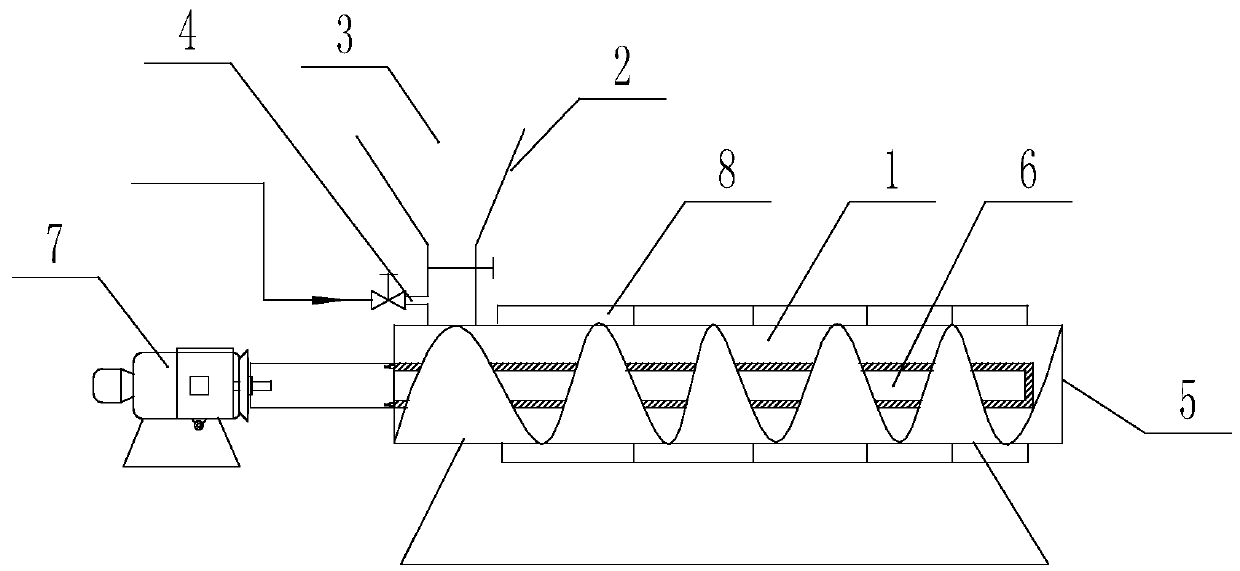

Extrusion screw for regenerating waste rubber

The invention discloses an extrusion screw for regenerating waste rubber. The extrusion screw comprises a rod body and spiral edges, wherein the spiral edges are divided into a feeding section, a melting section, a mixing section and a discharging section, the melting section comprises a first melting section, a second melting section, a third melting section and a fourth melting section, the first melting section is composed of N cams arranged in the axial direction of the rod body, the top end connecting line of the N cams is a spiral line, and the spiral direction of the spiral line is thesame as the spiral direction of the feeding section; the second melting section is screw-edge protrusions with inverted V-shaped projections, and the screw-edge protrusions are uniformly distributed on the outer circumference of the rod body corresponding to the second melting section; and the third melting section is a single-rotor spiral edge which is the same as the spiral direction of the feeding section, and the fourth melting section is four-rotor spiral edge, the four spiral edges of the four-rotor spiral edge are uniformly distributed on the outer peripheral surface of the rod body corresponding to the fourth melting section, and the four-rotating spiral edges are the same as the spiral direction of the feeding section. The extrusion screw has the advantages that the number of thescrew edges is changed, continuously variable extrusion force can be applied in the flowing process of the waste rubber, so that the melting reprocessing of the waste rubber is realized.

Owner:ZHEJIANG DONGBIN RUBBER MACHINERY SCREW

Rotary light beam ultra-high-speed laser cladding method

InactiveCN110923698AImprove stabilityPromote meltingMetallic material coating processesUltra high speedSpray nozzle

The invention discloses a rotary light beam ultra-high-speed laser cladding method, and belongs to the technical field of laser cladding. The rotary light beam ultra-high-speed laser cladding method comprises a workbench. A fixed table is connected with the top of the workbench. A mirror surface is connected with the outer wall of the fixed table through a hinge. A reciprocating movement mechanismis further connected with the outer wall of the fixed table and is connected with the mirror surface. A powder box and a laser head are connected with the top of the workbench. A spraying nozzle is connected with the top of the powder box. The outer wall of the spraying nozzle is connected with a conveying pipe. A concave hole is chiseled in the outer wall of the workbench and internally connected with a conveying belt. A second motor is fixedly connected with the outer wall of the conveying belt. The output end of the second motor is connected with a workpiece body. Large-area even irradiation can be performed on powder, it is ensured that more powder is molten in a limited space and a large melt bath is formed, the powder utilization rate and cladding efficiency are increased, the subsequent grinding machining amount and powder consumption are reduced, and cost is saved.

Owner:JINAN G WEIKE SCI & TECH

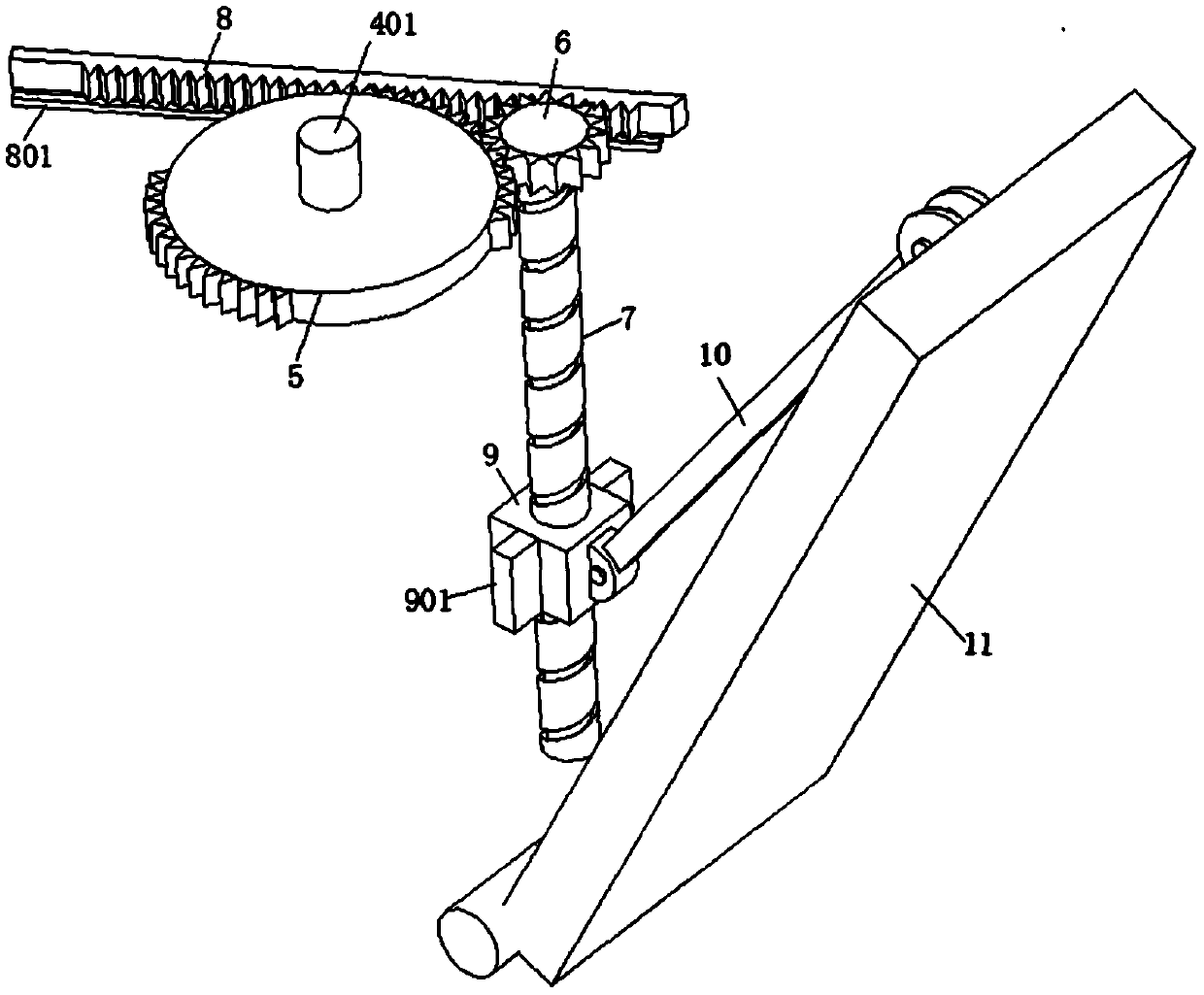

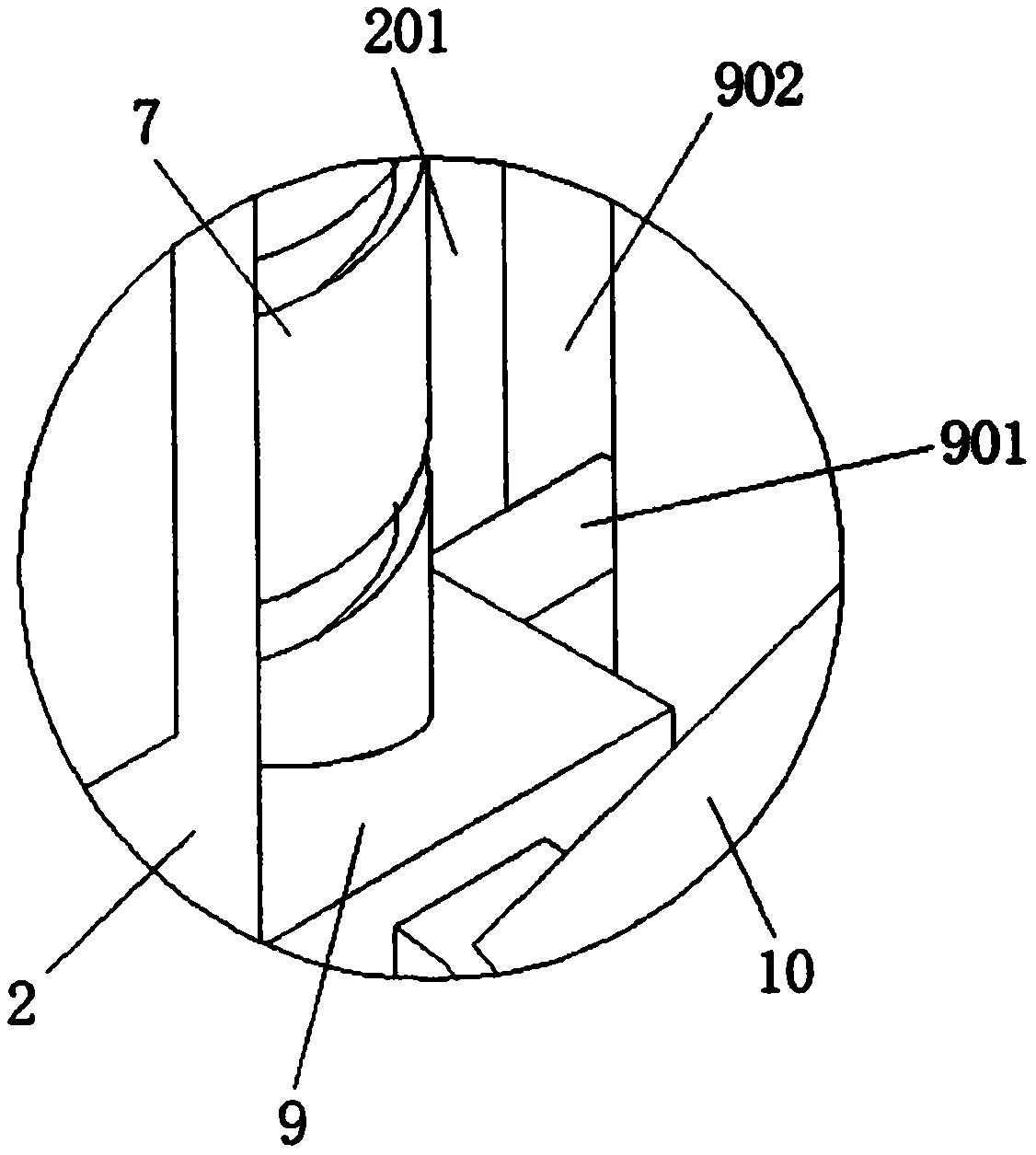

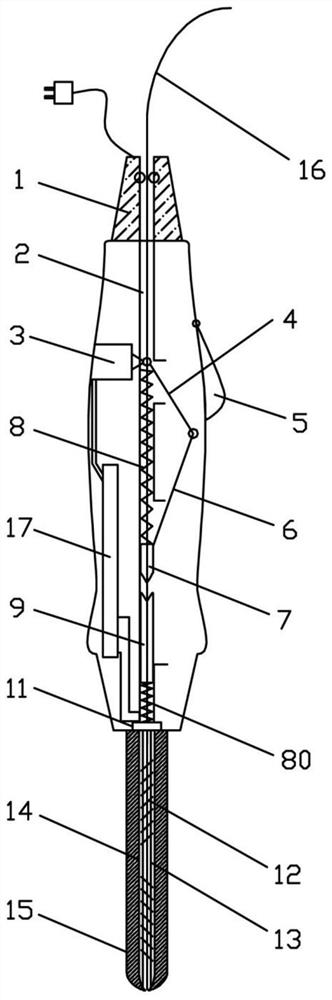

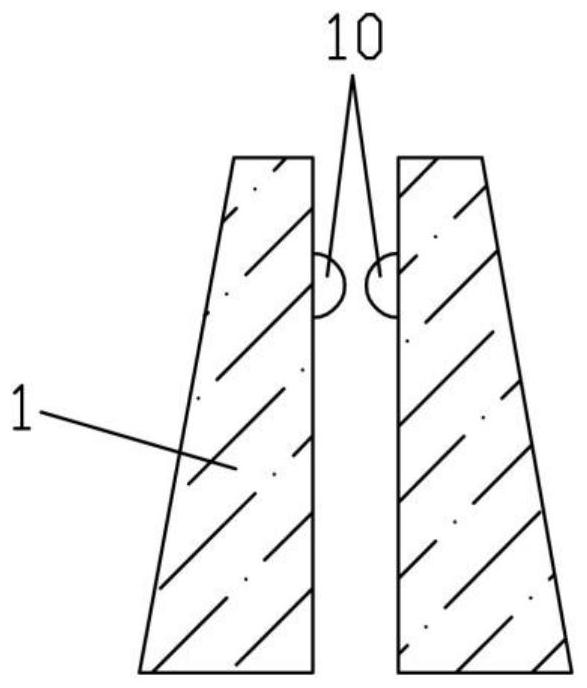

An automatic soldering iron

InactiveCN108555412BAchieve meltingEasy to operateMetal working apparatusSolder feeding devicesEngineeringMechanical engineering

Owner:HUBEI UNIV OF TECH

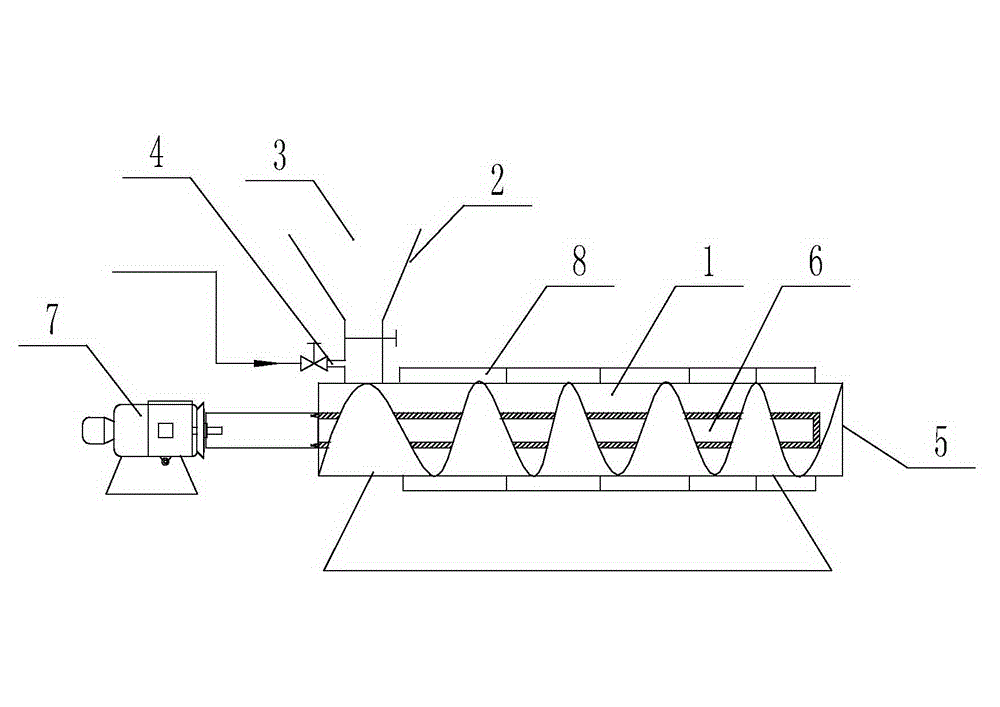

Feeding device for esterification reactor

InactiveCN103272530AShorten the time of alcoholysisAchieve meltingFeed devicesPolyethylene terephthalateEngineering

The invention relates to a feeding device for an esterification reactor. The feeding device comprises a barrel, wherein one end of the barrel is provided with a feeding hopper, the bottom of the feeding hopper is connected with the barrel, the upper part of the feeding hopper is provided with a PET (polyethylene terephthalate) bottle piece inlet, the side part of the feeding hopper is provided with an ethanol feeding pipe, and the other end of the barrel is provided with a discharging port; and a screw rod is arranged in the barrel, a screw rod driving device is arranged outside the barrel, and a heating device is arranged on the wall of the barrel. The feeding device for the esterification reactor adopts the mode of screw rod extrusion by feeding PET bottle pieces and ethanol together at the feeding port, so that the melting of PET bottle pieces as well as alcoholysis in advance is achieved in the barrel, the alcoholysis time in the esterification reactor is shortened, and the output efficiency is improved.

Owner:江苏宝田新材料股份有限公司

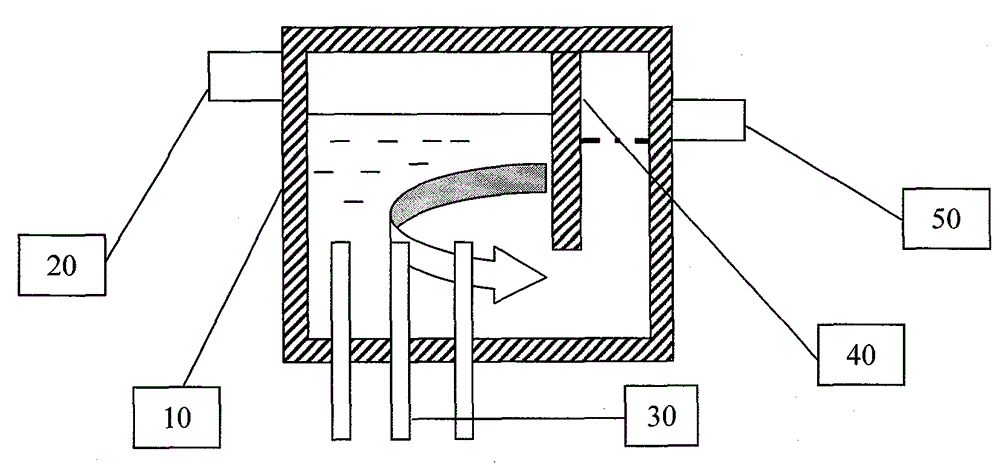

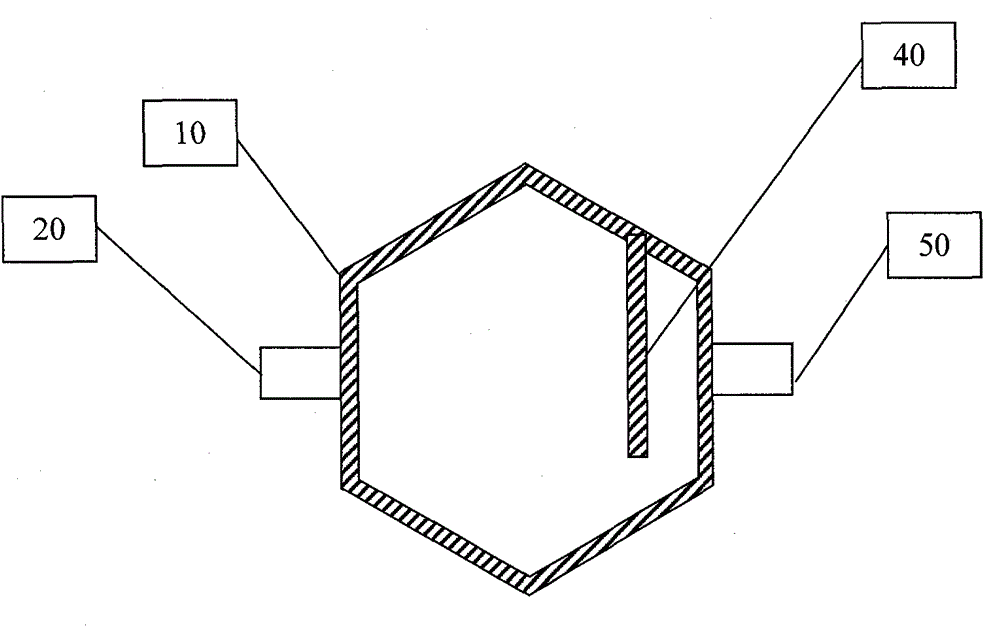

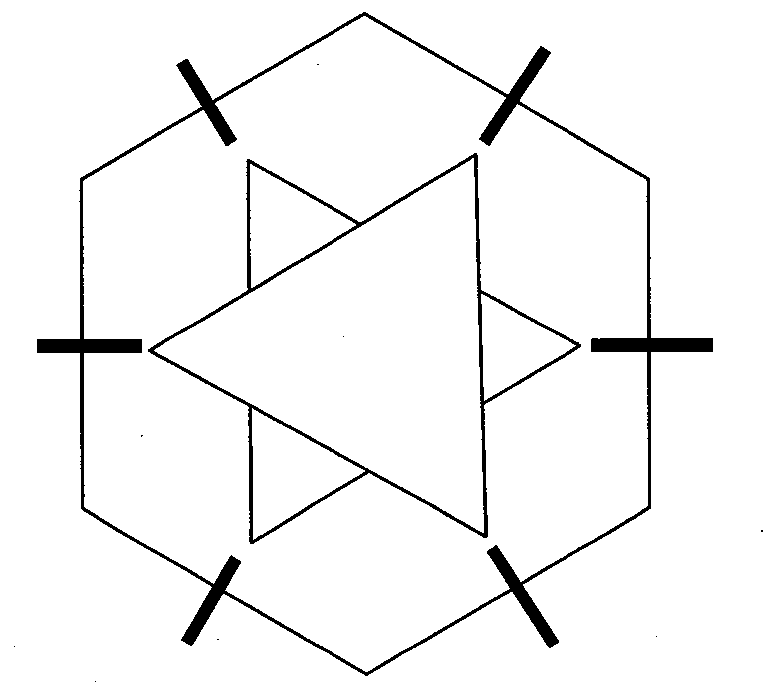

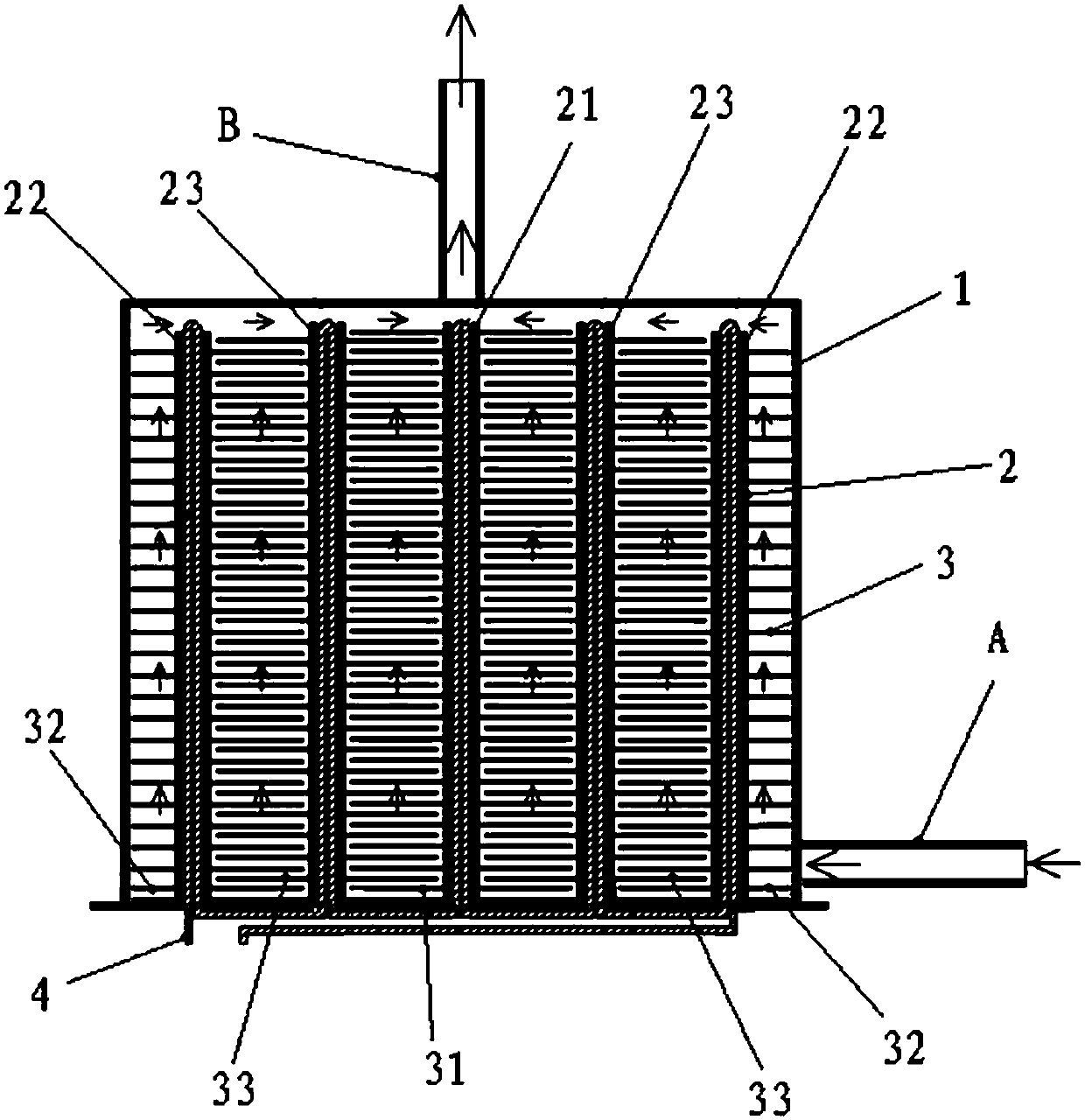

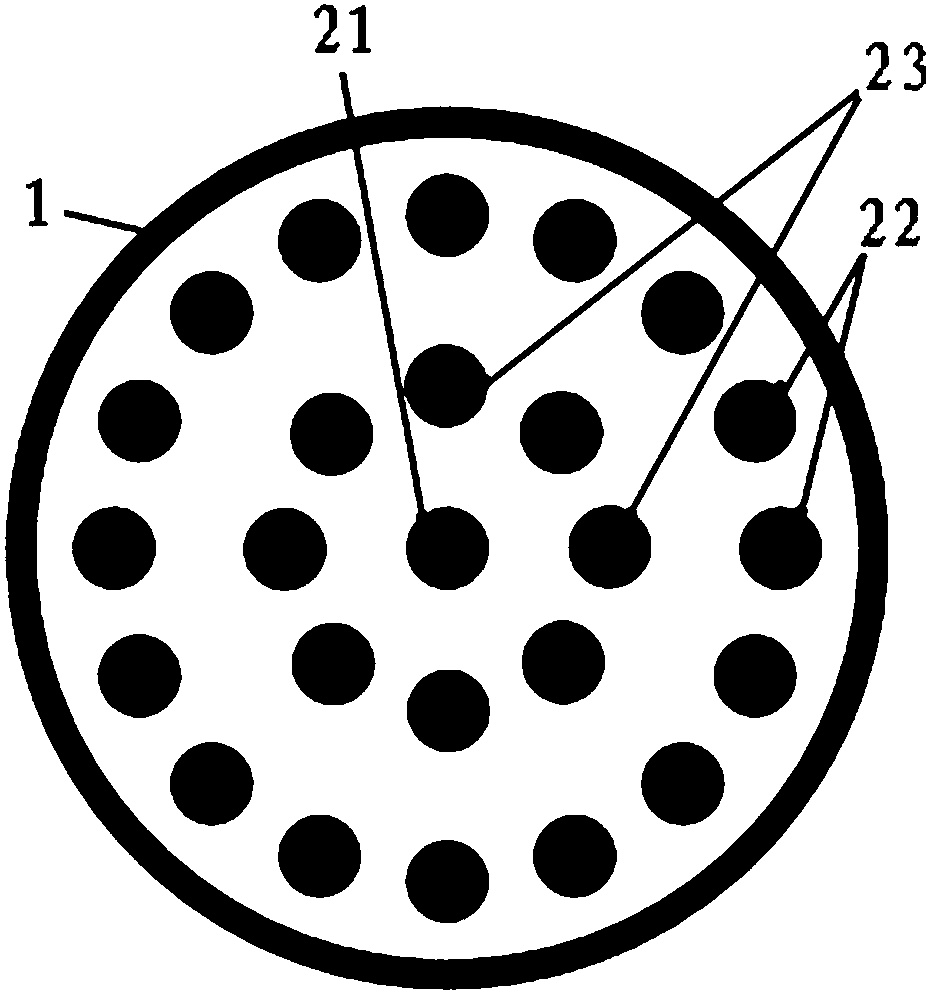

Centrifugal glass wool full-electric kiln

InactiveCN104370436AReduce heat dissipationSmall footprintElectric furnaceGlass productionGlass meltingMolten glass

The invention discloses a centrifugal glass wool full-electric kiln. The electric kiln comprises a glass wool kiln body, a feeding opening, a molybdenum electrode heating rod, a partition wall and a discharge opening. The glass wool kiln body is in a symmetrical hexagonal shape, and is very close to a circle, thus the heat dissipation of the glass wool kiln body is little, auxiliary facilities such as regenerative chamber, heat exchanger, and the like are not needed, and the space occupied by the kiln is reduced. The molybdenum electrode is inserted into the bottom of the kiln, heats the molten glass in the kiln, is capable of melting the glass in the vertical direction deeply, and solves the problem that the glass melting rate is low in common kilns. Furthermore, the electrode is crossly powered by a three-phase power supply, so the problem that the current flow direction in common kilns is single and the glass is not evenly melted is solved. The provided centrifugal glass wool full-electric kiln can be used to melt superfine glass wool raw materials.

Owner:SUZHOU V I P NEW MATERIAL

Quick workpiece cooling device for hardware processing

ActiveCN111426095ARapid coolingCool evenlyDomestic cooling apparatusMachines using electric/magnetic effectsLiquid waterLiquid state

The invention discloses a quick workpiece cooling device for hardware processing and belongs to the technical field of hardware processing. For workpieces of different shapes, comprehensive multi-point setting on the workpiece is carried out first by means of a magnetic driven telescopic structure, and meanwhile, liquid state water after hydraulic change is cooled to be frozen, so that on the onehand, the telescopic structure is locked and positioned, and a local deformation phenomenon of the workpiece in the cooling process is avoided, and on the other hand, an air flow for cooling is cooled, the cooled air flow is diffused at a contact end of the telescopic structure to blow the surface of the workpiece, cooling dead angles are not prone to happen, multi-point distributed cooling is formed, and the workpiece can be quickly cooled comprehensively and uniformly by matching with a quick heat conducting property of the contact end. The processing property is improved, internal stress ofa material is removed, the dimension of the workpiece is stabilized to prevent deformation and cracking, and the forming quality and the dimensional precision of the workpiece are improved obviously.

Owner:西安思创精密机电科技有限公司

Water circulation unfreezing equipment

InactiveCN106509055AAchieve meltingAchieve deliveryMeat/fish preservation by freezing/coolingWater circulationEngineering

The invention discloses water circulation unfreezing equipment. The water circulation unfreezing equipment comprises a first cavity, wherein a second cavity is arranged on the right side of the first cavity, a water pump is arranged at the bottom of the second cavity, and a first suction pipe communicating with the water pump is arranged at the bottom of the right side of the first cavity in a penetrating manner; a second suction pipe communicates to the upper end of the water pump, a heater communicates to the upper end of the second suction pipe, a condensation heat release pipe communicates to the upper end of the heater, and a third cavity is arranged on the upper surface of the condensation heat release pipe; heat dissipation holes are formed in the bottom of the third cavity; the left end of the condensation heat release pipe penetrates through a fourth cavity to communicate with a flow divider; and capillary pipes communicate to the lower end of the flow divider, a flow collector communicates to the lower ends of the capillary pipes, and a water inlet pipe penetrating through the first cavity communicates to the lower end of the flow collector. Through the heater and the condensation heat release pipe, the purpose of melting frozen meat is realized; and through the heat dissipation holes formed in the bottom of the third cavity in a penetrating manner, the frozen meat is prevented from being heated unevenly.

Owner:SUZHOU KANGXI MEDICAL CLEANING EQUIP

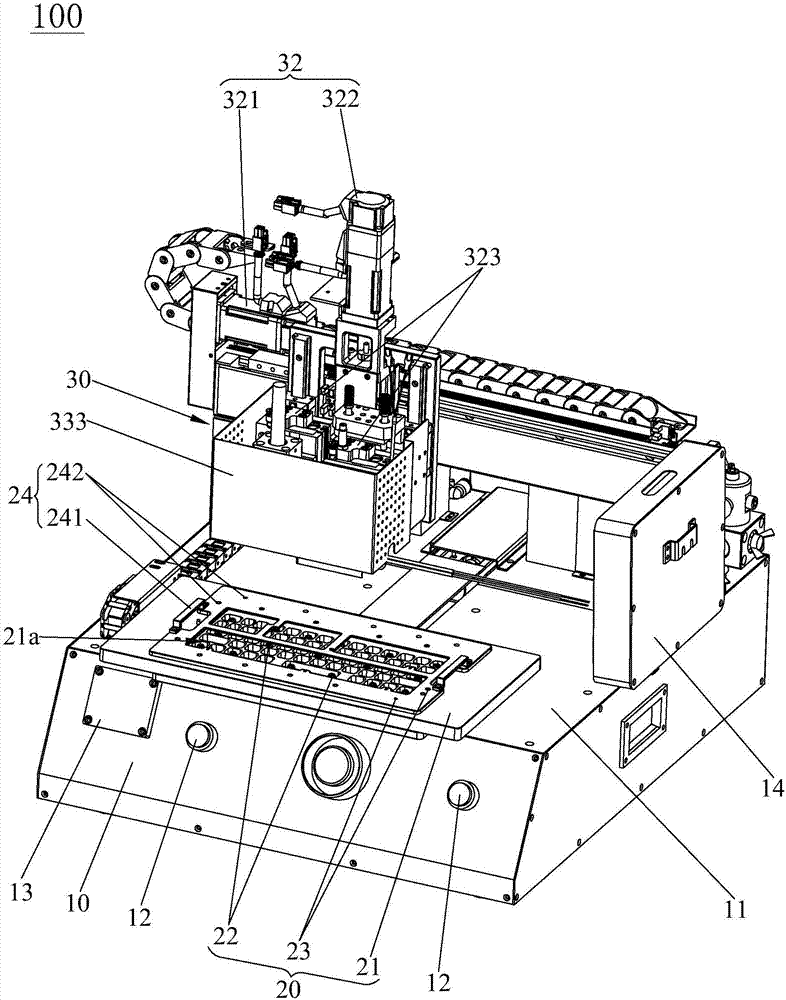

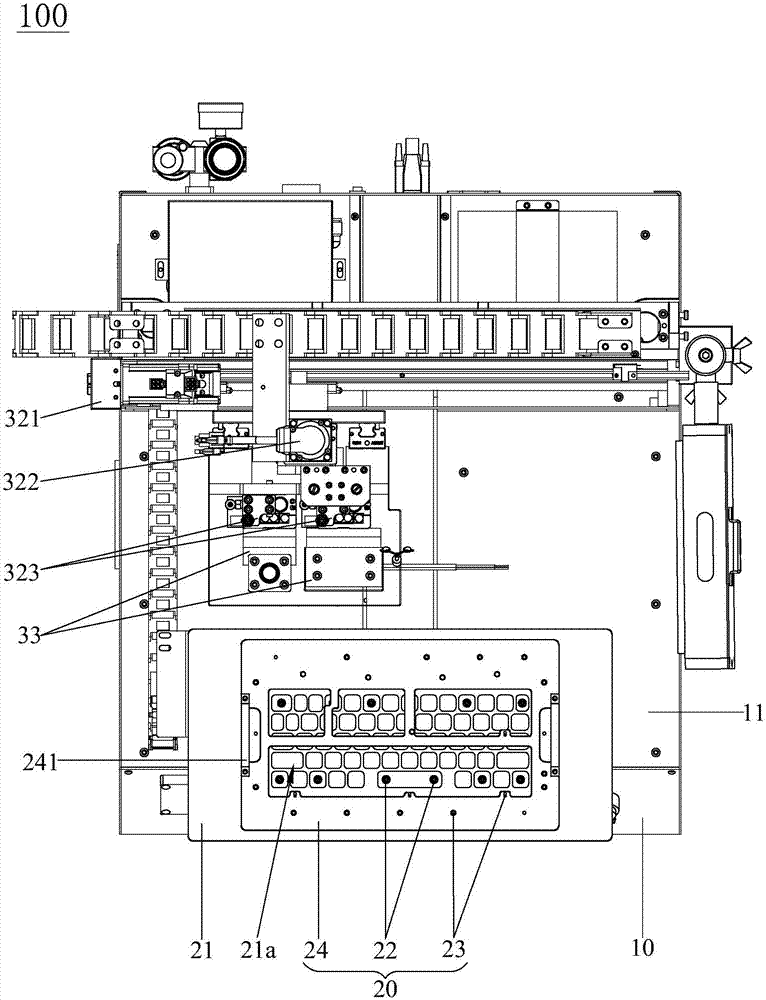

Automatic keyboard disassembling device

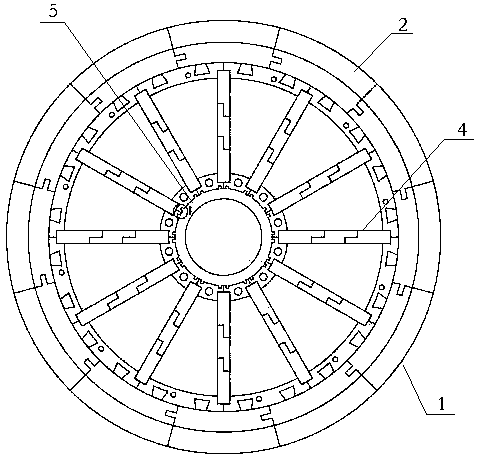

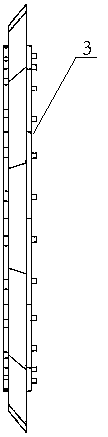

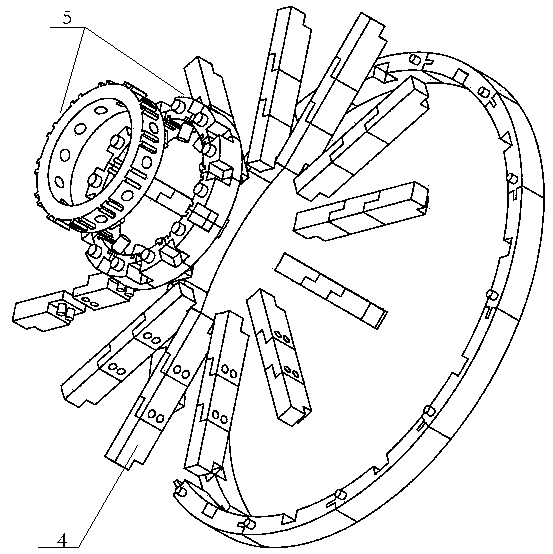

PendingCN107377596AEasy and fast separationIncrease profitSolid waste disposalElectronic waste recyclingEngineeringHot melt

The invention discloses an automatic keyboard disassembling device. The automatic keyboard disassembling device is used for melting of hot melting columns on a keyboard, and a circuit board of the keyboard is connected with an outer frame of the keyboard through the multiple irregular-distribution hot melting columns in a hot-melting mode. The automatic keyboard disassembling device comprises a case, a transferring device and a melting device, wherein the transferring device and the melting device are arranged on the case; the transferring device is used for fixing the keyboard and transferring the keyboard to the melting device, the melting device is used for hot pressing the hot melting columns on the keyboard, the hot melting columns are melted till connection between the circuit board and the outer frame is relieved. The automatic keyboard disassembling device is simple in structure, reasonable in arrangement, high in separation efficiency, good in separation effect and capable of avoiding waste of resources.

Owner:DONGGUAN WORLD PRECISION MACHINERY

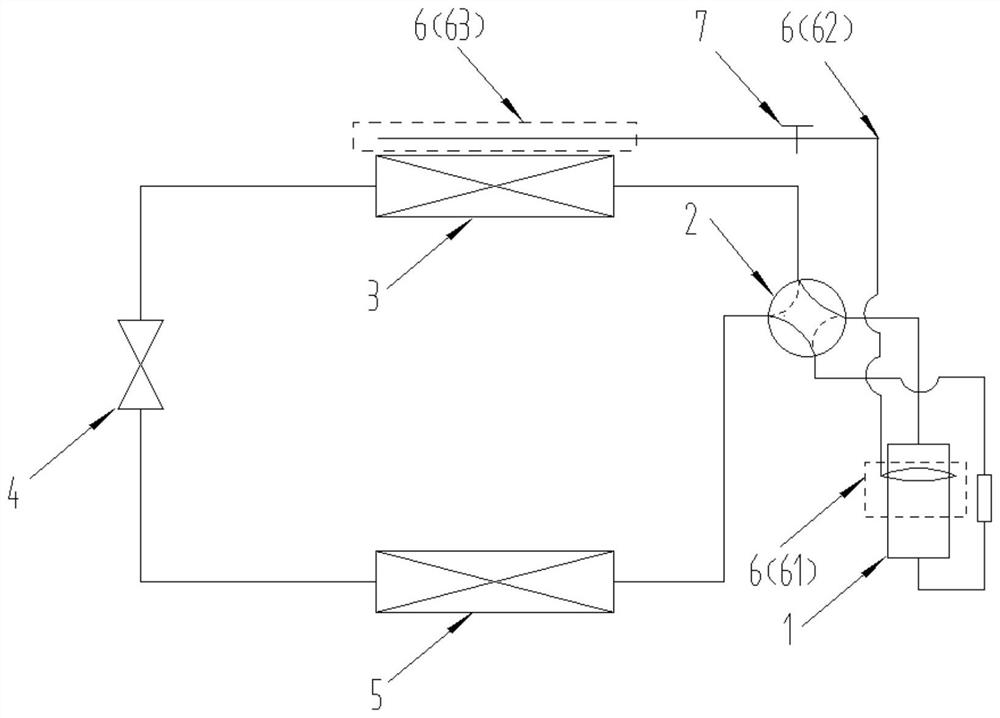

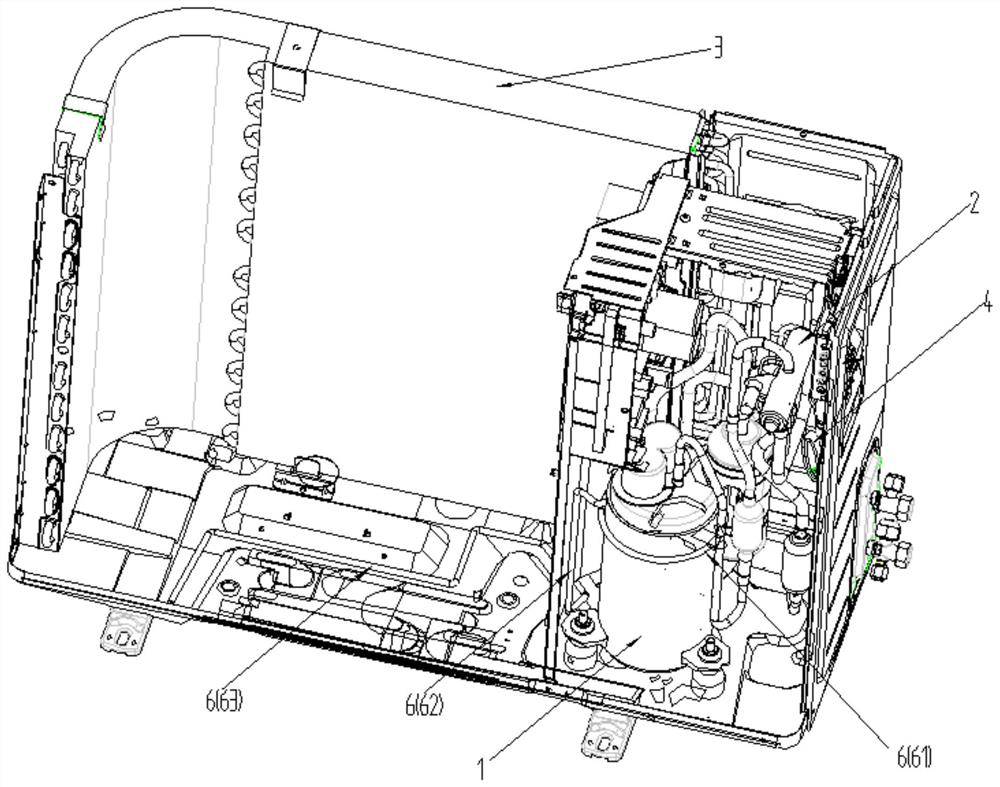

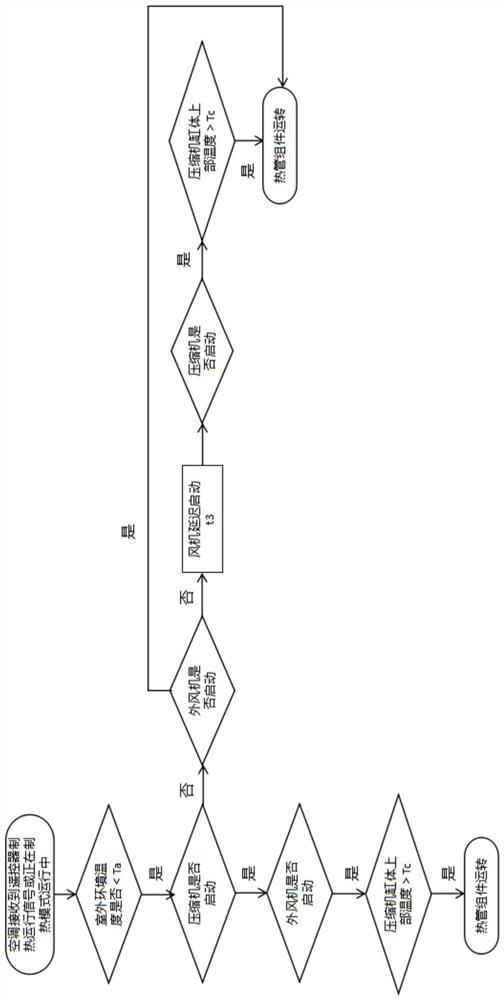

Air conditioner, heat pipe defrosting control method, computer equipment, medium and terminal

InactiveCN112682907ADefrost achievedAchieve meltingMechanical apparatusCondensate preventionExternal energyEngineering

The invention belongs to the technical field of air conditioner control, and discloses an air conditioner, a heat pipe defrosting control method, computer equipment, a medium and a terminal. A heat pipe evaporation section is used for absorbing heat from a compressor cylinder body and transmitting the heat to a chassis through a heat pipe condensation section for melting frost on the chassis of an outdoor unit. Under the condition that external energy consumption and split machine power consumption are not increased, a compressor heat source and a heat pipe device outside the split air conditioner are used for transferring heat, and in combination with the control scheme, chassis deicing and chassis defrosting can be achieved without chassis electric heating belts / pipes and other external heat sources or whole machine refrigerant deicing to increase power consumption. The energy utilization rate is high, the structural form is simple, and the cost advantage is high. Compared with an electric heating belt / pipe scheme which is widely applied at present, the air conditioner has great advantages in the aspect of saving energy, and monthly power consumption can be saved by 79.2 kilowatts or above.

Owner:GREE ELECTRIC APPLIANCES INC

Expressway dripping type snow melting device and snow melting method

PendingCN109989449ASave human and financial resourcesLow installation and laying costsWay cleaningWater supply installationWater diversionReclaimed water

The invention provides an expressway dripping type snow melting device and a snow melting method. The device comprises a main water pipeline laid in a greening isolation belt in the middle of an expressway in the longitudinal direction of the expressway. The water inlet end of the main water pipeline is connected with a reservoir for taking water through urban reclaimed water; a plurality of waterdiversion pipelines are uniformly arranged on the main water pipeline; one ends of the water diversion pipelines extend out of a middle greening belt protective fence of the greening isolation belt in the middle of the expressway and are arranged at the upper part of the expressway pavement; water dripping heads are connected to the water diversion pipelines; and water dripping openings of the water dripping heads are downward, so that a snow-melting agent passing through the main water pipeline and the water diversion pipelines is dripped on the high side of the expressway pavement and transversely flows from the expressway into a drainage channel on the low side of the expressway pavement. The expressway dripping type snow melting device saves manpower and financial resources, is low ininstallation and laying cost, cannot influence the expressway subgrade, melts ice and snow on the expressway in a dripping mode, avoids the influence of snow melting in an injection mode on running vehicles, and reduces safety accidents.

Owner:西安纳兴电子科技有限公司

Water vapor capturing device

PendingCN110613949AEfficient removalMultiple contact areasVapor condensationMolecular sieveWater vapor

The invention discloses a water vapor capturing device, which comprises a condensation cavity used for capturing water vapor. A gas inlet for inputting to-be-treated gas and a gas outlet for outputting treated gas are formed in a shell of the condensation cavity; a column-shaped condensation rod and a plurality of groups of water vapor capture sheets are arranged in the condensation cavity; the water vapor capture sheets are installed on the column-shaped condensation rod and are arranged in a multi-layer staggered mode, wherein gaps are formed between the water vapor capture pieces in each layer. Compared with an existing molecular sieve device, the condensation capture structure provides a larger water vapor contact area, and a large-volume molecular sieve device does not need to be built with a large amount of cost; and moreover, the water vapor is captured by adopting a condensation principle, so that the captured water vapor is converted into solids (such as ice crystals) througha condensation effect, the condensate can be molten only by heating operation in a regeneration process, electronic gas does not need to be consumed, and toxic by-products cannot be introduced or secondarily generated.

Owner:紫石能源有限公司

Adhering structure of non-metal sheet and adhering method thereof

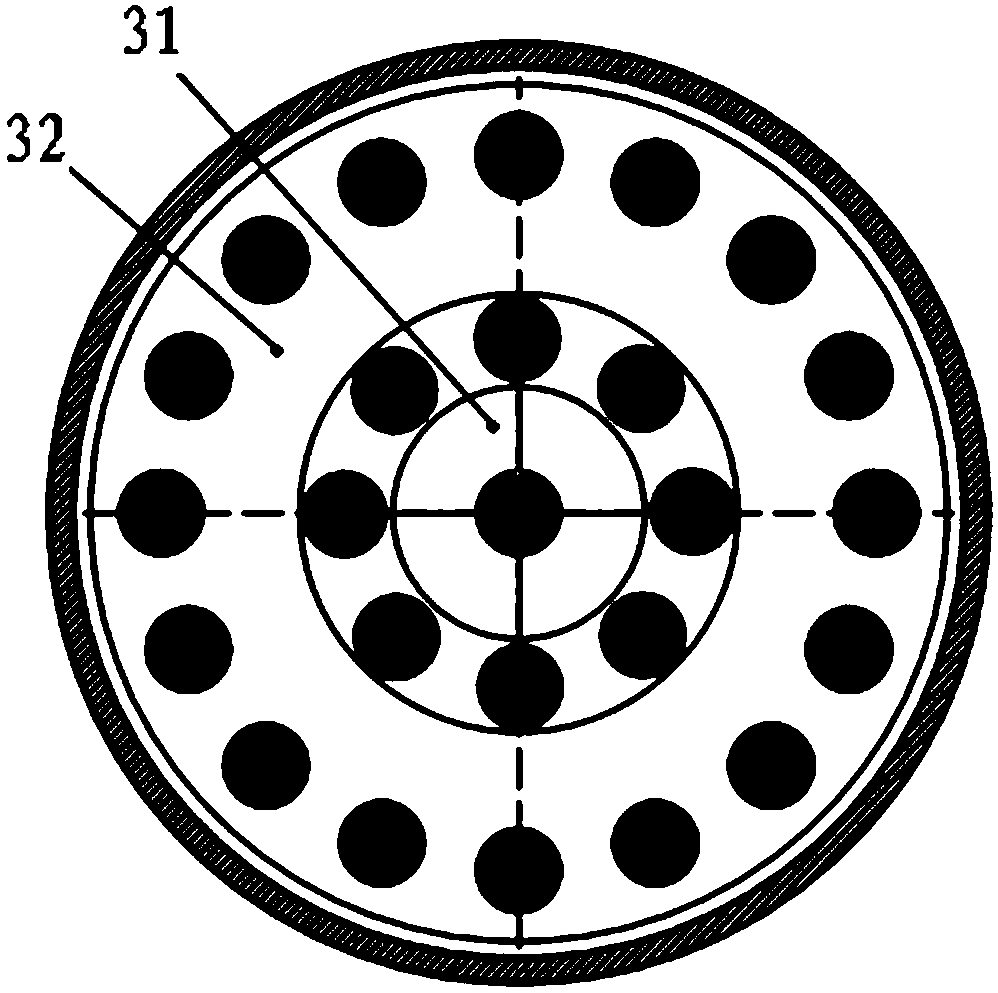

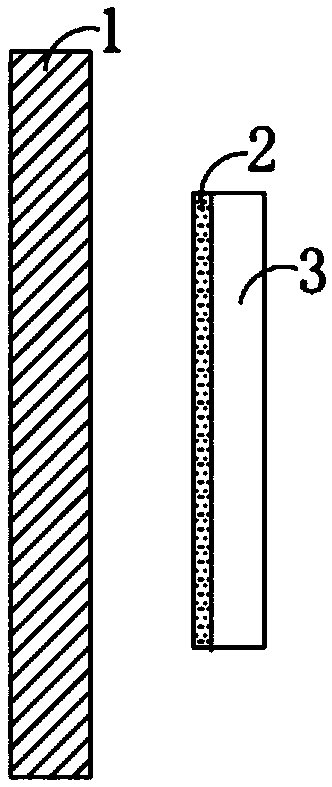

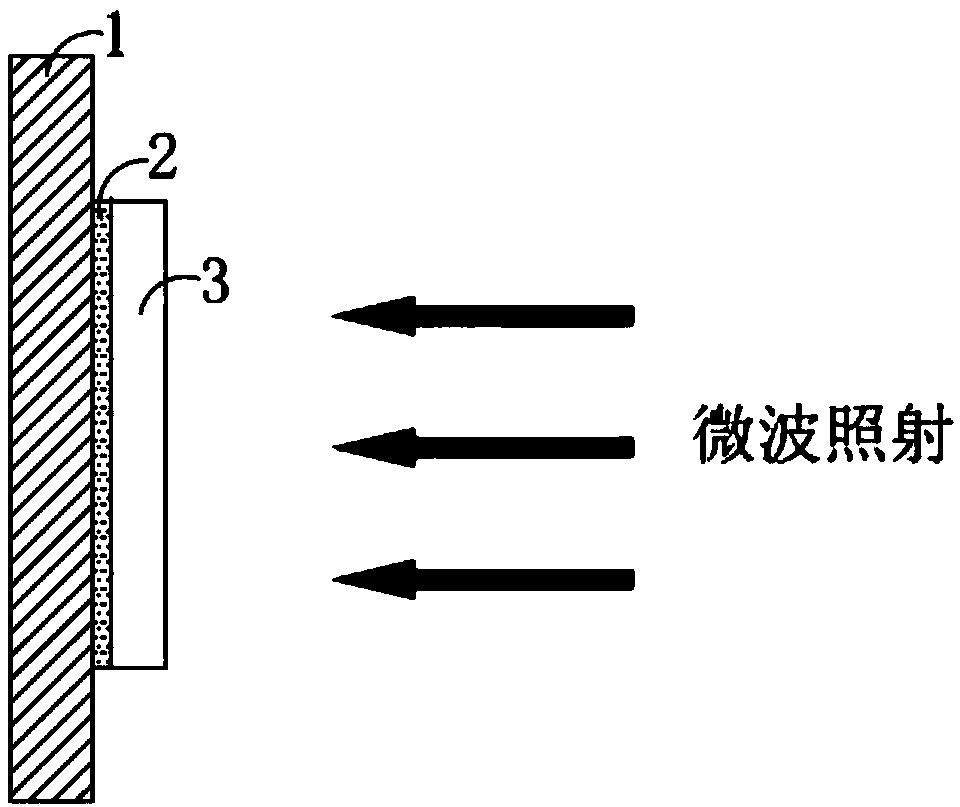

ActiveCN109252641AAchieve meltingImplementation statusBuilding constructionsEngineeringOrganic solvent

The invention relates to the technical field of architectural decoration construction, in particular to an adhering structure of a non-metal sheet and an adhering method thereof. The adhering structure comprises a to-be-bonded layer, an adhesive layer arranged on the to-be-bonded layer and the non-metal sheet arranged on the adhesive layer; the adhesive layer is melted through microwave irradiation and solidified when microwave irradiation is stopped, so that the non-metal sheet fixedly adheres to the to-be-bonded layer. The adhering structure and the adhering method have the advantages that the construction speed is high, dismantling and assembling are convenient, materials can be recovered, no dust is emitted in the construction process, no organic solvent volatilizes, and the green andenvironmentally friendly effect is achieved.

Owner:广东景龙建设集团有限公司

Petroleum pipeline plugging device

The invention provides a petroleum pipeline plugging device. The petroleum pipeline plugging device comprises a plugging part which is matched with a to-be-maintained pipeline in shape, wherein the bottom of one side, away from an opening part of the to-be-maintained pipeline, of the plugging part is sealed; flange shaped sealant is further arranged on the side surface of the plugging part; a groove is formed in the side surface of one side, close to the opening part of the to-be-maintained pipeline, of the sealant; and both the plugging part and the sealant are made of a material which can bedissolved into petroleum. The petroleum pipeline plugging device has the beneficial effects of high efficiency and high safety.

Owner:李得恩

Plane target unbinding device and method

ActiveCN111607768AUnbinding implementationAchieve meltingVacuum evaporation coatingSputtering coatingIndiumCopper wire

The invention provides a plane target unbinding device and method, and belongs to the technical field of target unbinding. The plane target unbinding device can achieve plane target unbinding. A conveying device is used for achieving conveying of plane targets in all areas, an infrared heating device is used for carrying out infrared heating on the plane targets, and melting of indium welding fluxin the plane targets is achieved. All components in an indium removing device are reasonably arranged, indium welding flux attached to a back plate and waste targets can be effectively scraped away (the back plate can be directly put into secondary use), the indium welding flux recycling rate is high (the recycling rate can reach 97% or above), automatic separation of the indium welding flux andcopper wires can be achieved, the secondary separation of the indium welding flux and the copper wires is avoided, and the treatment efficiency is improved. In addition, the plane target unbinding device can achieve automatic large-batch plane target unbinding, a large amount of manpower is saved, and the unbinding efficiency is greatly improved.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Feeding device for esterification reactor

InactiveCN103272530BShorten the time of alcoholysisAchieve meltingFeed devicesPolyethylene terephthalateEngineering

The invention relates to a feeding device for an esterification reactor. The feeding device comprises a barrel, wherein one end of the barrel is provided with a feeding hopper, the bottom of the feeding hopper is connected with the barrel, the upper part of the feeding hopper is provided with a PET (polyethylene terephthalate) bottle piece inlet, the side part of the feeding hopper is provided with an ethanol feeding pipe, and the other end of the barrel is provided with a discharging port; and a screw rod is arranged in the barrel, a screw rod driving device is arranged outside the barrel, and a heating device is arranged on the wall of the barrel. The feeding device for the esterification reactor adopts the mode of screw rod extrusion by feeding PET bottle pieces and ethanol together at the feeding port, so that the melting of PET bottle pieces as well as alcoholysis in advance is achieved in the barrel, the alcoholysis time in the esterification reactor is shortened, and the output efficiency is improved.

Owner:江苏宝田新材料股份有限公司

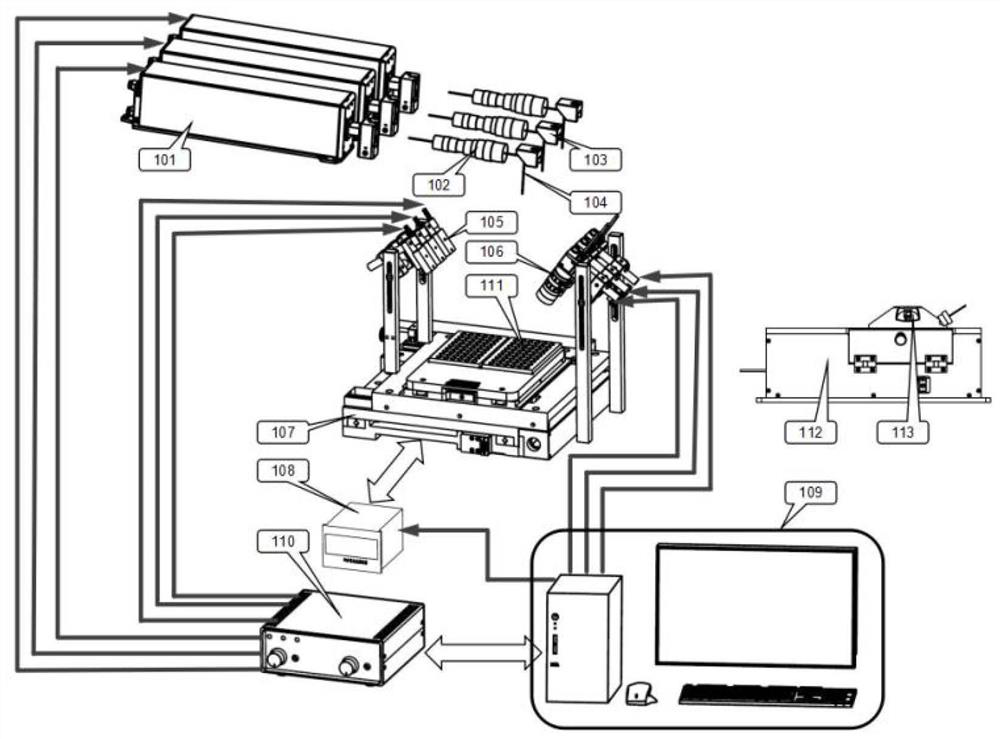

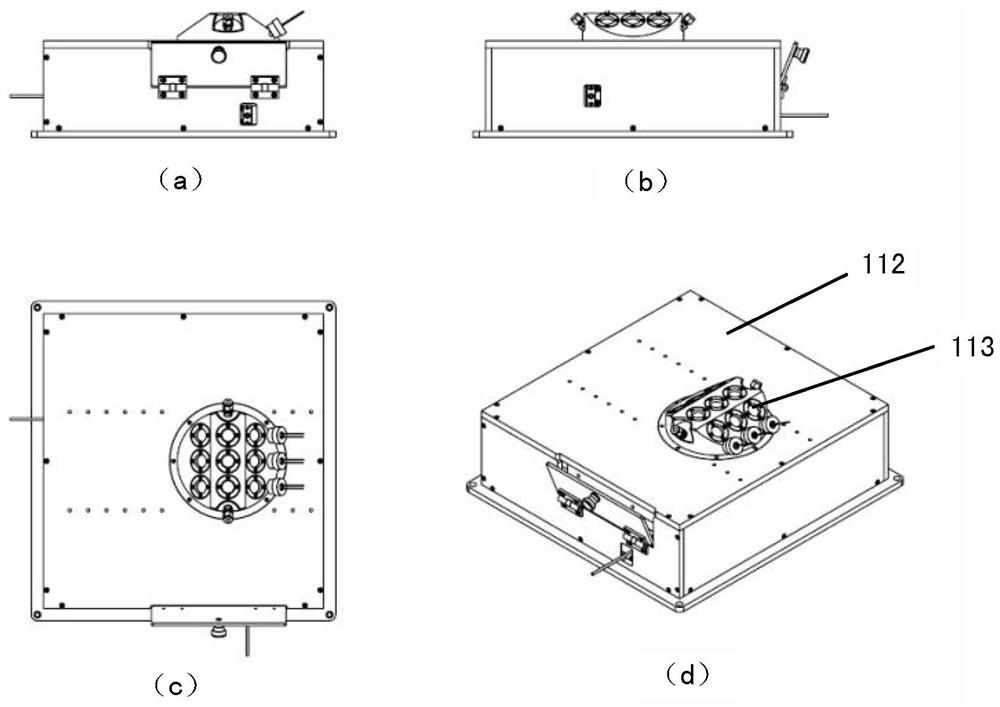

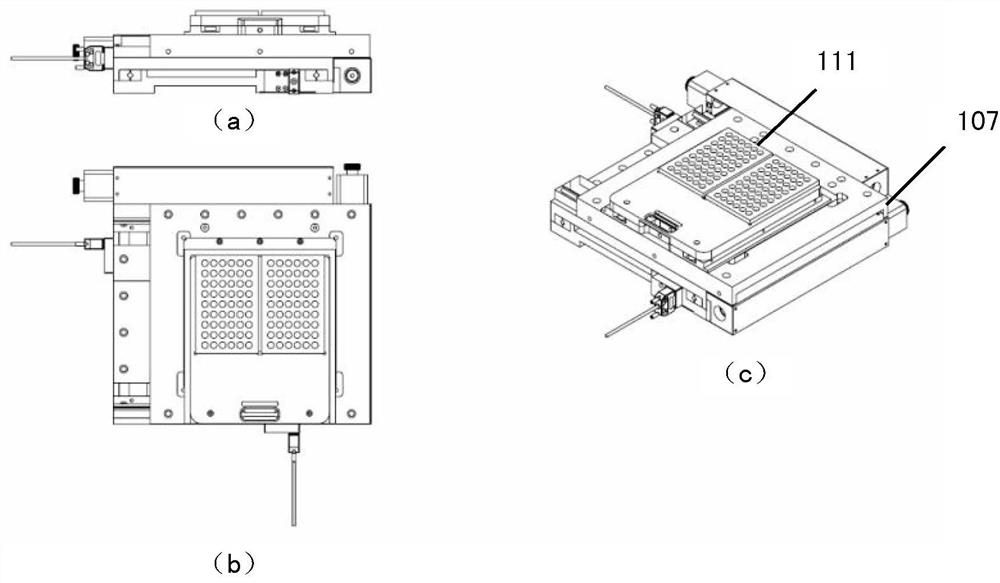

Array sample laser heating system

ActiveCN109352182BRealize in situ chemical reactionAchieve crystallizationPreparing sample for investigationLaser beam welding apparatusImage recordingLight beam

The array sample laser heating system provided by the present invention includes: a laser light source unit that outputs laser light to provide heating energy, and has a plurality of lasers arranged in parallel or in an array; a laser that is arranged downstream of the laser light source unit to change the laser spot size The beam spot adjustment unit; the sample stage for placing the array sample; the temperature measurement unit for measuring the laser heating temperature of the array sample to be heated and feeding back the heating effect; the image recording unit for recording the experimental results; and the laser light source Unit, temperature measurement unit, and image recording unit are connected to the master control unit. The invention can realize multi-beam parallel and adjustable beam spot laser heating, and is used for rapid and directional heating of material array samples required for material genetic engineering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com